26 Inch Rims Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for 26 inch rims

In the ever-evolving automotive market, sourcing high-quality 26 inch rims poses a significant challenge for international B2B buyers. With the diverse preferences and specifications across regions—particularly in Africa, South America, the Middle East, and Europe—navigating the complexities of rim selection can be daunting. This guide aims to demystify the landscape of 26 inch rims, offering insights into various types, applications, and finishes. Whether you are looking for stylish chrome rims for luxury SUVs or rugged off-road wheels for lifted trucks, understanding the nuances of these products will empower you to make informed purchasing decisions.

The comprehensive scope of this guide includes supplier vetting strategies, cost considerations, and performance criteria essential for meeting the demands of your target market. By equipping B2B buyers with actionable insights and practical resources, this guide facilitates a streamlined purchasing process. You will discover how to identify reputable suppliers, evaluate product specifications, and negotiate favorable terms that align with your business goals.

As the global demand for 26 inch rims continues to grow, leveraging this guide will position you ahead of competitors, ensuring that your offerings meet the evolving needs of consumers. Join us as we explore the intricacies of the 26 inch rim market and unlock the potential for your business to thrive in this dynamic industry.

Understanding 26 inch rims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Rims | Unique designs, finishes, and bolt patterns | Automotive customization shops, luxury vehicle dealers | Pros: Stand out aesthetics, tailored fit. Cons: Higher cost, longer lead times. |

| Off-Road Rims | Reinforced construction, aggressive tread patterns | Off-road vehicle retailers, adventure vehicle suppliers | Pros: Durability, enhanced traction. Cons: Heavier, may affect fuel efficiency. |

| Performance Rims | Lightweight materials, aerodynamic designs | Racing teams, high-performance vehicle distributors | Pros: Improved speed and handling. Cons: May sacrifice comfort for performance. |

| Staggered Rims | Varied widths for front and rear wheels | Custom vehicle builders, tuning shops | Pros: Enhanced handling, aggressive stance. Cons: Complex fitment, potential for uneven tire wear. |

| Luxury Rims | High-end finishes, often chrome or polished | Luxury car dealerships, upscale vehicle markets | Pros: Premium aesthetics, brand appeal. Cons: Higher maintenance, can be prone to scratches. |

What Are the Key Characteristics of Custom Rims?

Custom rims are tailored to meet specific aesthetic and performance needs. They feature unique designs, finishes, and bolt patterns, allowing businesses to offer personalized options to clients. B2B buyers should consider the customization capabilities of their suppliers, as well as the potential for longer lead times and higher costs associated with bespoke manufacturing. These rims are particularly suitable for automotive customization shops and luxury vehicle dealers looking to differentiate their offerings.

How Do Off-Road Rims Differ from Other Types?

Off-road rims are designed for durability and enhanced traction, often featuring reinforced construction to withstand rugged terrains. They typically come with aggressive tread patterns and are heavier than standard rims, making them ideal for off-road vehicle retailers and adventure vehicle suppliers. B2B buyers should evaluate the weight and load ratings to ensure compatibility with their vehicle models. While off-road rims provide superior performance in challenging conditions, their added weight may affect overall fuel efficiency.

What Advantages Do Performance Rims Offer?

Performance rims are crafted from lightweight materials and designed with aerodynamics in mind, making them a popular choice among racing teams and high-performance vehicle distributors. These rims improve speed and handling, which can significantly enhance driving experiences. B2B buyers should weigh the benefits of improved performance against potential comfort trade-offs, as these rims may not provide the same level of ride comfort as standard options. They are best suited for businesses focused on competitive automotive markets.

Why Choose Staggered Rims for Your Business?

Staggered rims feature varied widths for front and rear wheels, enhancing handling and providing an aggressive vehicle stance. They are often sought after by custom vehicle builders and tuning shops that aim to create unique builds. When purchasing staggered rims, B2B buyers should be mindful of the fitment complexities and the potential for uneven tire wear. While they offer aesthetic and performance advantages, proper alignment and tire selection are crucial for optimal performance.

What Makes Luxury Rims a Popular Choice?

Luxury rims are characterized by high-end finishes, such as chrome or polished surfaces, appealing to upscale vehicle markets and luxury car dealerships. They provide a premium aesthetic that enhances the overall appearance of high-end vehicles. B2B buyers should consider the maintenance requirements associated with luxury rims, as they can be prone to scratches and may require more frequent upkeep. Despite the higher costs, their brand appeal and visual impact make them a valuable investment for businesses targeting affluent customers.

Key Industrial Applications of 26 inch rims

| Industry/Sector | Specific Application of 26 inch rims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Customization | High-end SUV and truck modifications | Enhances vehicle aesthetics and performance | Ensure compatibility with vehicle specifications; consider local regulations for modifications. |

| Off-Road Vehicles | Off-road racing and adventure vehicles | Improved handling and stability on rugged terrain | Look for durable materials; assess load ratings for safety. |

| Transportation & Logistics | Fleet upgrades for luxury transport services | Boosts brand image and passenger comfort | Evaluate maintenance support and availability of parts; consider financing options for bulk purchases. |

| Agriculture | Customization of utility vehicles | Increases efficiency and adaptability in the field | Assess load capacity and terrain compatibility; ensure timely delivery options to remote areas. |

| Construction | Heavy equipment modifications | Enhances mobility and functionality on-site | Focus on durability and resistance to wear; check for warranties and service agreements. |

How Are 26 Inch Rims Used in Automotive Customization?

In the automotive customization sector, 26 inch rims are primarily utilized for enhancing the aesthetics and performance of high-end SUVs and trucks. These rims not only provide a striking visual appeal but also improve handling and stability. For international buyers, particularly from regions like Africa and South America, it’s crucial to ensure that the rims are compatible with local vehicle models and comply with any regulations regarding vehicle modifications. Sourcing from suppliers that offer a variety of finishes and styles can help businesses cater to diverse customer preferences.

What Role Do 26 Inch Rims Play in Off-Road Vehicle Applications?

In the off-road vehicle market, 26 inch rims are essential for racing and adventure vehicles. They enhance the vehicle’s ability to navigate rugged terrains by providing better traction and stability. Buyers in regions with challenging landscapes, such as the Middle East, should prioritize sourcing rims that are made from durable materials with high load ratings to ensure safety and performance. Additionally, understanding the specific requirements for off-road applications, including rim width and offset, is vital for optimal performance.

How Can Transportation Companies Benefit from 26 Inch Rims?

Transportation and logistics companies often upgrade their fleets with 26 inch rims to improve the comfort and image of luxury transport services. These rims can significantly enhance the driving experience for passengers, making them an attractive option for businesses looking to differentiate themselves in competitive markets. When sourcing these rims, companies should consider the availability of maintenance support and parts, especially in regions with limited access to automotive services, ensuring long-term operational efficiency.

What Advantages Do 26 Inch Rims Offer in Agricultural Applications?

In the agricultural sector, 26 inch rims are used to customize utility vehicles for improved efficiency and adaptability in various farming tasks. These rims can enhance the vehicle’s capability to handle heavy loads and navigate uneven terrain, crucial for agricultural operations. Buyers should focus on assessing the load capacity and terrain compatibility of the rims, especially in areas where access to quality automotive parts may be limited. Timely delivery options are also a key consideration, as agricultural operations often require quick modifications.

How Are 26 Inch Rims Utilized in the Construction Industry?

In construction, 26 inch rims can be applied to heavy equipment to enhance mobility and functionality on job sites. These rims support the demands of construction environments, where durability and performance are critical. When sourcing for this application, businesses should prioritize rims that offer high resistance to wear and tear, as well as robust warranties and service agreements. This is particularly important for construction firms operating in remote areas, where equipment reliability can significantly impact project timelines and costs.

3 Common User Pain Points for ’26 inch rims’ & Their Solutions

Scenario 1: Sourcing Quality 26-Inch Rims for Diverse Markets

The Problem: B2B buyers, especially those catering to markets in Africa, South America, and the Middle East, often struggle to find high-quality 26-inch rims that meet local standards. These buyers face challenges such as inconsistent product quality, lack of trusted suppliers, and variations in manufacturing practices that can lead to compatibility issues with different vehicle models. Furthermore, the risk of receiving subpar products can significantly impact their reputation and sales.

The Solution: To effectively source quality rims, buyers should establish strong relationships with reputable manufacturers and suppliers who specialize in 26-inch rims. Conduct thorough research to identify suppliers with positive reviews and a proven track record. It’s advisable to request product samples and certifications to ensure the rims meet international quality standards. Additionally, leveraging platforms like Alibaba or trade shows can facilitate connections with verified suppliers. Creating a checklist of specifications—such as bolt patterns, load ratings, and finishes—can also help streamline the selection process, ensuring the rims will fit the intended vehicles without compatibility issues.

Scenario 2: Understanding the Technical Specifications of 26-Inch Rims

The Problem: Many B2B buyers are not fully versed in the technical specifications required for 26-inch rims, which can lead to poor purchasing decisions. Misunderstanding key factors like offset, width, and bolt patterns can result in ordering rims that do not fit the vehicles in question, leading to costly returns and delays in delivery. This lack of technical knowledge can be particularly detrimental in competitive markets where timely service is critical.

The Solution: To overcome this knowledge gap, buyers should invest time in understanding the technical aspects of 26-inch rims. This can be done by attending workshops or webinars focused on automotive parts and specifications. Additionally, creating partnerships with technical experts or consulting with manufacturers can provide invaluable insights. Utilizing online resources that offer detailed explanations of specifications—such as load ratings, offsets, and fitment guides—can also empower buyers to make informed decisions. Implementing a system to cross-reference vehicle specifications with rim details before placing orders can further minimize the risk of errors.

Scenario 3: Managing Inventory and Supply Chain for 26-Inch Rims

The Problem: Efficient inventory management is a critical challenge for B2B buyers in the automotive sector, particularly those dealing with niche products like 26-inch rims. Fluctuations in demand and supply chain disruptions can lead to overstocking or stockouts, both of which have financial implications. Buyers often find themselves grappling with balancing sufficient inventory to meet demand without tying up too much capital in unsold products.

The Solution: To effectively manage inventory, buyers should implement a just-in-time (JIT) inventory system that aligns closely with market demand. This involves analyzing historical sales data to predict future trends and adjusting orders accordingly. Establishing strong communication channels with suppliers will allow for more flexible order quantities and faster response times to changes in demand. Additionally, utilizing inventory management software can help track stock levels, automate reordering processes, and provide real-time insights into sales trends. Collaborating with logistics partners who specialize in automotive parts can also ensure timely deliveries, reducing the risk of stockouts and enhancing customer satisfaction.

Strategic Material Selection Guide for 26 inch rims

What Are the Common Materials Used in 26 Inch Rims?

When selecting materials for 26-inch rims, understanding the properties, advantages, and limitations of each option is crucial for international B2B buyers. Here, we analyze four common materials: aluminum, steel, magnesium, and carbon fiber.

How Does Aluminum Perform in 26 Inch Rims?

Aluminum is one of the most popular materials for 26-inch rims due to its favorable strength-to-weight ratio. It typically has a temperature rating up to 300°C and exhibits good corrosion resistance, making it suitable for various environments. Aluminum rims are generally lightweight, enhancing vehicle performance and fuel efficiency.

Pros: Aluminum rims are durable, resistant to rust, and offer a wide range of finishes, appealing to aesthetic preferences. They are also relatively easy to manufacture, making them a cost-effective choice for many applications.

Cons: While aluminum is strong, it may not withstand extreme impacts as well as steel, leading to potential deformation. The cost can be higher than steel, which may be a consideration for budget-conscious buyers.

Impact on Application: Aluminum rims are compatible with a variety of vehicles and driving conditions, but they may require protective coatings in harsh environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or JIS, particularly regarding safety and performance specifications.

What Are the Benefits of Steel for 26 Inch Rims?

Steel rims are known for their exceptional durability and strength, making them ideal for heavy-duty applications. They can withstand high pressure and temperature fluctuations, withstanding conditions up to 400°C.

Pros: Steel rims are robust and less likely to bend or crack under stress, making them suitable for off-road and rugged use. They are also generally more affordable than aluminum.

Cons: The primary drawback is weight; steel rims are heavier, which can negatively impact vehicle performance and fuel efficiency. Additionally, they are prone to rust if not properly coated.

Impact on Application: Steel rims are particularly effective in harsh environments, but their weight may limit their use in performance-oriented vehicles.

Considerations for International Buyers: Buyers in regions with high humidity or saline conditions, such as coastal areas in the Middle East, should prioritize corrosion-resistant coatings to enhance longevity.

How Does Magnesium Compare for 26 Inch Rims?

Magnesium rims are known for their lightweight properties and high strength, making them an attractive option for performance vehicles. They have a temperature rating of approximately 350°C and are resistant to corrosion.

Pros: Magnesium rims offer significant weight savings, which can improve acceleration and handling. They also have excellent thermal conductivity, which can help with brake cooling.

Cons: The manufacturing process for magnesium rims can be complex and costly, limiting their availability. Additionally, they may be more susceptible to damage from impacts compared to aluminum.

Impact on Application: Magnesium is ideal for racing and high-performance applications but may not be suitable for everyday use in rugged conditions.

Considerations for International Buyers: Compliance with international safety standards is critical, especially in markets like Europe, where stringent regulations exist.

What Are the Advantages of Carbon Fiber for 26 Inch Rims?

Carbon fiber is increasingly being used in high-end 26-inch rims due to its exceptional strength and light weight. It can handle temperatures up to 200°C and offers excellent resistance to corrosion.

Pros: Carbon fiber rims provide the best weight savings and can significantly enhance vehicle performance. They also have a unique aesthetic appeal, often sought after by luxury vehicle manufacturers.

Cons: The primary disadvantage is the high cost and complexity of manufacturing, making them less accessible for budget-conscious buyers. They are also more fragile than metal options, which may limit their application in off-road environments.

Impact on Application: Carbon fiber rims are best suited for luxury and performance vehicles but may not be ideal for heavy-duty or off-road applications.

Considerations for International Buyers: Buyers should ensure that carbon fiber rims meet local safety standards and understand the implications of their higher cost in overall vehicle budgets.

Summary Table of Material Selection for 26 Inch Rims

| Material | Typical Use Case for 26 inch rims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | SUVs, performance vehicles | Lightweight and corrosion-resistant | Less impact resistance than steel | Medium |

| Steel | Heavy-duty vehicles, off-road applications | Exceptional durability | Heavier, prone to rust | Low |

| Magnesium | Racing, high-performance vehicles | Significant weight savings | Complex manufacturing, susceptible to damage | High |

| Carbon Fiber | Luxury and performance vehicles | Best weight savings and aesthetics | High cost, fragile | High |

This guide provides valuable insights for B2B buyers in diverse international markets, ensuring informed decisions when selecting materials for 26-inch rims.

In-depth Look: Manufacturing Processes and Quality Assurance for 26 inch rims

What Are the Main Stages in the Manufacturing Process of 26 Inch Rims?

The manufacturing process of 26 inch rims consists of several critical stages that ensure quality and durability. Understanding these stages can help B2B buyers make informed decisions about their suppliers.

Material Preparation

The first stage involves the selection and preparation of raw materials, typically aluminum or steel alloys. These materials are chosen for their lightweight properties and strength. The materials undergo thorough inspections to ensure they meet specified standards. This includes checking for impurities and verifying the alloy composition, which is essential for achieving the desired performance characteristics in the finished product.

Forming Techniques Used in Rim Production

After material preparation, the next step is forming. The most common techniques include casting, forging, and rolling.

-

Casting: This method involves pouring molten metal into a mold to create the rim shape. It is widely used for producing intricate designs and allows for mass production.

-

Forging: This process involves shaping the material under high pressure, resulting in a denser and stronger rim. Forged rims are often preferred for performance applications due to their superior strength-to-weight ratio.

-

Rolling: In this technique, metal sheets are passed through rollers to achieve the desired thickness and shape. This method is typically used for steel rims and allows for efficient mass production.

Each technique has its advantages and is selected based on the rim’s intended application, whether for luxury vehicles, off-road use, or standard automobiles.

How Are Rims Assembled for Optimal Performance?

The assembly stage is where various components, such as the rim, bead seat, and other structural elements, are brought together. This is often done using automated machinery to ensure precision and consistency.

During assembly, manufacturers may incorporate additional features such as valve stems and rim protectors, which enhance the rim’s performance and longevity.

What Quality Assurance Measures Are Essential in Rim Manufacturing?

Quality assurance (QA) is critical in the manufacturing of 26 inch rims to ensure safety, performance, and compliance with international standards.

What Are the Relevant International Standards for Rim Manufacturing?

B2B buyers should be aware of the various international standards applicable to rim manufacturing. The most notable include:

-

ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

-

CE Marking: Required for products sold within the European Economic Area, it indicates conformity with health, safety, and environmental protection standards.

-

API Standards: While primarily for the oil and gas industry, certain API standards may apply to rims used in specialized vehicles.

Understanding these standards helps buyers assess the legitimacy and quality of potential suppliers.

What Are the Key Quality Control Checkpoints in Rim Production?

Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival. Any subpar materials are rejected before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are taken to ensure that each stage meets quality specifications. This might involve testing dimensions, surface finishes, and mechanical properties.

-

Final Quality Control (FQC): Once the rims are completed, they undergo a final inspection to check for defects, ensure proper finish, and verify compliance with technical specifications. This may include visual inspections and functional tests.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must perform due diligence to ensure that their suppliers adhere to high-quality standards. Here are actionable steps to verify supplier QC:

What Should Buyers Look for in Supplier Audits and Reports?

-

Supplier Audits: Conducting or requesting regular audits is essential. These audits should focus on the manufacturing processes, quality control systems, and compliance with international standards.

-

Quality Reports: Suppliers should provide detailed quality reports that outline the results of inspections, testing methodologies, and any corrective actions taken for defects. This transparency builds trust and ensures accountability.

Why Are Third-Party Inspections Important for Quality Assurance?

Engaging a third-party inspection service can provide an unbiased assessment of the manufacturing processes and product quality. These inspections often include:

-

Random Sampling: Inspectors take random samples from production batches to evaluate compliance with specifications.

-

Testing Methods: Common testing methods include tensile strength tests, fatigue tests, and visual inspections for surface defects.

By leveraging third-party inspections, B2B buyers can further ensure that the products meet their quality expectations.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with suppliers from different regions, such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific QC nuances:

-

Cultural Differences: Different regions may have varying approaches to quality control. Understanding these differences can help buyers communicate more effectively with suppliers.

-

Regulatory Compliance: Each region has its own regulatory requirements that must be adhered to. Buyers should ensure that their suppliers are compliant with local and international regulations to avoid potential legal issues.

-

Logistical Challenges: International shipping can introduce risks such as damage during transit. Buyers should ensure that their suppliers have robust packaging and handling protocols in place.

By focusing on these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions that enhance their supply chain’s reliability and efficiency when sourcing 26 inch rims.

Practical Sourcing Guide: A Step-by-Step Checklist for ’26 inch rims’

In the competitive landscape of B2B sourcing, ensuring the right procurement of 26-inch rims is essential for optimizing vehicle performance and aesthetics. This guide provides a structured checklist to help international buyers make informed decisions when sourcing these products.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for the 26-inch rims. This includes the bolt pattern, width, offset, and finish. Knowing these details ensures compatibility with your vehicles and helps you avoid costly returns or modifications.

- Bolt Patterns: Identify whether you need 5-lug, 6-lug, or 8-lug patterns based on your vehicle models.

- Width and Offset: Determine the desired width (e.g., 9, 10, or 12 inches) and offset values to ensure optimal fitment and performance.

Step 2: Research Market Trends

Understanding current market trends can provide insights into popular styles and finishes, which can influence your purchasing decisions. This knowledge can help you align your inventory with consumer preferences, especially in regions like Africa, South America, and Europe.

- Popular Finishes: Consider trends in glossy, matte, or chrome finishes, which may appeal to different market segments.

- Vehicle Compatibility: Research which vehicles commonly use 26-inch rims in your target market to tailor your offerings.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request company profiles, customer testimonials, and references from buyers in similar industries or regions.

- Certifications: Verify that suppliers hold necessary quality certifications, such as ISO or other relevant industry standards.

- Product Samples: If possible, request samples to assess the quality and craftsmanship of the rims.

Step 4: Assess Pricing and Payment Options

Price comparison is vital for maintaining profitability. Gather quotes from multiple suppliers and inquire about bulk pricing, discounts, and financing options.

- Transparent Pricing: Ensure that the pricing structure is clear, including any additional costs for shipping or customs duties.

- Flexible Payment Terms: Explore financing options that cater to various credit profiles to facilitate easier purchasing.

Step 5: Check Shipping and Logistics

Efficient shipping and logistics can significantly affect your procurement timeline. Confirm shipping policies, lead times, and return policies with your chosen supplier.

- Shipping Costs: Evaluate shipping costs and methods to find the most economical options that still meet your timeline.

- Return Policy: Understand the return policy in case the rims do not meet your expectations upon arrival.

Step 6: Finalize Contracts and Agreements

Once you have chosen a supplier, formalize your agreement with a detailed contract. This should include all agreed-upon terms, conditions, and specifications to protect both parties.

- Legal Review: Have legal counsel review contracts to ensure all terms are enforceable and protect your interests.

- Payment Schedule: Clearly outline the payment schedule and any milestones for delivery to maintain accountability.

Step 7: Monitor Supplier Performance

After procurement, continuously monitor supplier performance to ensure they meet quality and delivery expectations. This ongoing assessment will help you maintain strong supplier relationships and make adjustments as necessary.

- Feedback Loop: Establish a feedback mechanism to address any issues promptly and maintain open communication.

- Performance Metrics: Track metrics such as delivery times and product quality to inform future sourcing decisions.

By following this practical sourcing checklist, B2B buyers can navigate the complexities of procuring 26-inch rims, ensuring a strategic and efficient purchasing process.

Comprehensive Cost and Pricing Analysis for 26 inch rims Sourcing

What Are the Key Cost Components in Sourcing 26 Inch Rims?

When evaluating the cost structure of 26 inch rims, several components contribute to the overall pricing. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for 26 inch rims include aluminum and alloy, which provide a balance of strength and weight. Premium finishes, such as chrome or custom paint, can also elevate costs.

-

Labor: Manufacturing labor costs vary by region and are influenced by local wage standards. Skilled labor is necessary for tasks such as wheel design, machining, and finishing, which can add to the overall expense.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and factory operations. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or specific bolt patterns. This upfront investment is crucial for ensuring precision and quality in the manufacturing process.

-

Quality Control (QC): Rigorous QC processes are essential to meet international standards and certifications. This might include testing for load ratings and durability, which can add to the cost but ensures product reliability.

-

Logistics: Shipping costs can vary based on the destination, size of the order, and chosen Incoterms. International shipping may also involve customs duties and tariffs, further influencing final costs.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. This margin can vary depending on the supplier’s market position and the demand for specific styles or finishes.

How Do Price Influencers Affect the Cost of 26 Inch Rims?

Several factors can influence the pricing of 26 inch rims:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted pricing. Suppliers may offer better rates for bulk purchases, which is advantageous for B2B buyers looking to stock inventory.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Rims made from higher-grade materials or those with quality certifications (like ISO) typically command higher prices. Buyers should assess whether the additional cost aligns with their performance requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record and customer service.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can significantly affect total costs. Understanding these terms is crucial for calculating the landed cost of products.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing 26 Inch Rims?

-

Negotiation Strategies: Buyers should leverage their purchasing power to negotiate better terms. Discussing payment terms, bulk discounts, and shipping arrangements can lead to significant savings.

-

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as maintenance, durability, and warranty. A higher upfront cost may result in lower long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe must be aware of currency fluctuations and local taxes. Engaging with suppliers who offer stable pricing or fixed quotes can mitigate risks associated with currency volatility.

-

Supplier Relationship Management: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to new product lines. Regular communication fosters trust and can yield benefits over time.

-

Research and Compare: Conduct thorough research to compare prices and offerings from multiple suppliers. This not only provides insights into market rates but also helps identify potential partners who align with your quality and pricing expectations.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on current market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and confirm terms directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing 26 inch rims With Other Solutions

In the automotive industry, particularly when it comes to customizing vehicles, the choice of rims can significantly influence both performance and aesthetic appeal. While 26-inch rims are a popular choice for many vehicles, especially SUVs and lifted trucks, there are alternative solutions that buyers may consider. This analysis compares 26-inch rims with two viable alternatives: 24-inch rims and off-road wheels designed specifically for rugged terrains.

| Comparison Aspect | 26 Inch Rims | 24 Inch Rims | Off-Road Wheels |

|---|---|---|---|

| Performance | Enhanced stability and handling; suitable for both on-road and off-road use | Good balance of comfort and performance; slightly less stability than 26-inch | Superior traction and durability; designed for extreme conditions |

| Cost | Generally higher price point due to size and design options | More affordable; can be a cost-effective alternative | Variable pricing based on material and design; often premium prices for specialized features |

| Ease of Implementation | Requires specific vehicle compatibility; may need adjustments | Easier to install; compatible with a wider range of vehicles | May require additional modifications for optimal fit and performance |

| Maintenance | Regular checks needed for alignment and wear | Lower maintenance due to smaller size | High maintenance; can be damaged by rough terrains and require frequent inspections |

| Best Use Case | Ideal for urban and suburban driving, as well as off-road adventures | Suitable for everyday driving and light off-roading | Best for off-road enthusiasts and vehicles designed for rugged environments |

What are the Benefits and Drawbacks of 24-Inch Rims as an Alternative to 26-Inch Rims?

24-inch rims offer a balance between performance and cost. They provide reasonable stability and handling while being more affordable than their 26-inch counterparts. Their lighter weight can enhance fuel efficiency, making them suitable for everyday driving. However, they may not deliver the same level of aesthetic appeal or road presence as larger rims, which can be a critical factor for B2B buyers focused on branding and image.

How Do Off-Road Wheels Compare to 26-Inch Rims for Rugged Use?

Off-road wheels are engineered specifically for challenging terrains, offering superior traction and durability. They are often made from stronger materials that can withstand extreme conditions, making them an excellent choice for businesses that operate in harsh environments. However, they typically come at a higher price point and may require modifications to the vehicle for proper fitment. Additionally, maintenance can be more intensive due to the wear and tear from rugged use.

How Should B2B Buyers Choose Between 26-Inch Rims and Their Alternatives?

When selecting the appropriate rim size and type, B2B buyers should consider the specific needs of their operations. If aesthetics and urban performance are priorities, 26-inch rims may be the best choice. Conversely, for cost-conscious buyers looking for a balance between performance and price, 24-inch rims may suffice. For businesses engaged in off-road activities, investing in specialized off-road wheels can enhance vehicle capability and safety. Ultimately, understanding the use case and application will guide buyers to make informed, strategic decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 26 inch rims

What are the Key Technical Properties of 26 Inch Rims?

When considering 26-inch rims for vehicles, several technical specifications are critical for ensuring compatibility, performance, and durability. Understanding these properties can significantly impact purchasing decisions, especially for international B2B buyers.

-

Material Composition

– Definition: Most 26-inch rims are made from aluminum or alloy materials. Aluminum is lightweight, enhancing fuel efficiency and handling, while alloy rims provide a balance of weight and strength.

– B2B Importance: The choice of material affects the overall performance, aesthetic appeal, and cost. Buyers should consider the intended use—off-road, performance, or aesthetic upgrades—when selecting the material. -

Bolt Pattern

– Definition: The bolt pattern indicates how many bolts are used to secure the rim to the vehicle and their spacing. Common patterns for 26-inch rims include 5-lug, 6-lug, and 8-lug configurations.

– B2B Importance: Ensuring the correct bolt pattern is crucial for compatibility with specific vehicles. Incorrect patterns can lead to installation issues and safety hazards, making it essential for buyers to verify this specification. -

Offset

– Definition: Offset refers to the distance from the wheel’s mounting surface to its centerline, which can be positive, negative, or zero. It influences the vehicle’s handling characteristics and wheel alignment.

– B2B Importance: Buyers must select the appropriate offset to ensure that the rims fit correctly within the wheel wells and maintain optimal vehicle dynamics. An incorrect offset can lead to tire wear and handling problems. -

Load Rating

– Definition: Load rating indicates the maximum weight a rim can support safely. For 26-inch rims, this rating is crucial for vehicles that carry heavy loads or are used in off-road conditions.

– B2B Importance: Understanding load ratings helps buyers ensure that the rims can safely support the vehicle’s weight, especially in commercial applications where durability and safety are paramount. -

Width

– Definition: The width of a rim affects tire selection and vehicle handling. Common widths for 26-inch rims range from 9 to 14 inches.

– B2B Importance: Wider rims can accommodate larger tires, which may be necessary for off-road performance or aesthetic preferences. Buyers should match rim width with tire specifications for optimal performance.

What Trade Terminology Should B2B Buyers Know When Purchasing 26 Inch Rims?

Familiarity with industry terminology can enhance communication and decision-making for B2B buyers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to parts made by the vehicle’s original manufacturer. OEM rims are designed to meet specific quality and performance standards.

– Importance: Buyers often prefer OEM parts for their reliability and compatibility, especially in commercial fleets where performance is critical. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell in a single order.

– Importance: Understanding MOQ helps buyers plan their purchases and manage inventory effectively. It can also affect pricing and shipping costs. -

RFQ (Request for Quotation)

– Definition: A formal request to suppliers for pricing and terms for specific products.

– Importance: Submitting an RFQ allows buyers to compare offers from different suppliers, ensuring they get the best price and terms for their needs. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce, used in international trade contracts.

– Importance: Knowledge of Incoterms helps buyers understand shipping responsibilities, costs, and risks involved in international transactions. -

Fitment Guarantee

– Definition: A promise from the seller that the rims will fit the specified vehicle without modification.

– Importance: This assurance is crucial for buyers, as it minimizes the risk of purchasing incompatible parts, saving time and costs associated with returns or adjustments.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands, ensuring successful procurement of 26-inch rims.

Navigating Market Dynamics and Sourcing Trends in the 26 inch rims Sector

What Are the Current Market Dynamics and Key Trends in the 26 Inch Rims Sector?

The global market for 26-inch rims has experienced significant growth, driven by the rising popularity of SUVs and lifted trucks, especially in regions such as Africa, South America, the Middle East, and Europe. With consumers increasingly seeking customized and performance-enhanced vehicles, there is a growing demand for diverse rim styles and finishes, including chrome, matte, and machined options. International B2B buyers are particularly interested in sourcing high-quality rims that cater to local preferences and vehicle specifications.

Emerging technologies in the B2B sourcing landscape, such as e-commerce platforms and advanced supply chain management systems, have transformed the purchasing process. Buyers can now easily compare prices, styles, and specifications from various manufacturers, making informed decisions more accessible. Additionally, the rise of financing options and flexible payment plans has made it easier for businesses to invest in premium products without significant upfront costs.

Market dynamics are also influenced by regional economic conditions and trade policies. For instance, buyers in Africa and South America may face different import tariffs and regulations compared to their European counterparts. Staying informed about these factors is crucial for B2B buyers to navigate potential challenges effectively.

How Is Sustainability and Ethical Sourcing Impacting the 26 Inch Rims Market?

Sustainability is becoming an increasingly important consideration for B2B buyers in the 26-inch rims sector. Environmental concerns surrounding the manufacturing processes and materials used in rims have prompted a shift towards more sustainable practices. Buyers are now more inclined to partner with suppliers who prioritize ethical sourcing and production methods, as these factors can significantly impact brand reputation and consumer loyalty.

The use of recycled materials and eco-friendly production processes is gaining traction. Manufacturers are exploring options like aluminum recycling, which not only reduces waste but also lowers the carbon footprint associated with producing new rims. Furthermore, certifications such as ISO 14001 for environmental management systems are becoming valuable indicators of a supplier’s commitment to sustainability.

B2B buyers should actively seek out suppliers who can provide transparency in their supply chains and demonstrate a commitment to sustainable practices. By prioritizing ethical sourcing, businesses can contribute to a more sustainable industry while enhancing their own brand image.

What Is the Evolution of the 26 Inch Rims Industry and Its Relevance to B2B Buyers?

The evolution of the 26-inch rims industry has been marked by technological advancements and shifting consumer preferences. Initially, rims were primarily utilitarian, focusing on functionality and durability. However, as automotive customization became a trend, the focus shifted towards aesthetics and performance.

In recent decades, the introduction of advanced manufacturing techniques, such as CNC machining and casting, has allowed for greater design flexibility and precision. This has led to a broader range of styles, finishes, and sizes, catering to the diverse needs of international markets. For B2B buyers, understanding this evolution is vital, as it highlights the importance of innovation and adaptability in sourcing decisions.

As the market continues to evolve, staying ahead of design trends and consumer demands will be crucial for businesses looking to remain competitive in the dynamic 26-inch rims sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 26 inch rims

-

How do I choose the right 26 inch rims for my vehicle?

Selecting the appropriate 26-inch rims involves understanding your vehicle’s specifications, such as bolt pattern, offset, and load rating. It’s essential to match these details with the rims to ensure compatibility. Additionally, consider the intended use—whether for street performance or off-road driving—as this influences the design and finish of the rims. Consulting with suppliers who offer a fitment guarantee can also simplify the selection process and enhance your purchasing confidence. -

What are the benefits of customizing 26 inch rims for my clients?

Customizing 26-inch rims allows you to cater specifically to your clients’ aesthetic preferences and vehicle requirements. Options such as finishes, colors, and patterns can differentiate your offerings in a competitive market. Custom rims can also command higher prices, improving your margins. Moreover, personalization enhances customer satisfaction, fostering loyalty and repeat business, especially in regions where vehicle aesthetics are paramount. -

What is the minimum order quantity (MOQ) for 26 inch rims from suppliers?

The MOQ for 26-inch rims varies by supplier and can depend on factors such as rim type, customization options, and production capabilities. Typically, MOQs can range from a few sets to several dozen. When negotiating with suppliers, inquire about flexibility on MOQs, especially if you are a new buyer or looking to test market demand. Some suppliers might offer sample sets to help you gauge quality before committing to larger orders. -

How can I ensure the quality of 26 inch rims before purchasing?

To ensure quality, request samples or detailed specifications from potential suppliers. Look for certifications that demonstrate adherence to international standards, such as ISO or TUV. Additionally, consider conducting a factory audit or hiring a third-party quality assurance service to inspect production processes. Reviews and testimonials from other buyers can also provide insights into a supplier’s reliability and product quality. -

What payment terms should I expect when ordering 26 inch rims internationally?

Payment terms for international orders can vary widely, but common practices include upfront payments, deposits, or net payment terms (e.g., 30, 60, or 90 days after delivery). It’s advisable to negotiate terms that align with your cash flow and risk management strategies. Be wary of suppliers requesting full payment upfront, especially if they are not well-established. Using secure payment methods like letters of credit can further protect your transaction. -

How do I navigate logistics when importing 26 inch rims?

When importing 26-inch rims, consider working with a freight forwarder who can manage shipping, customs clearance, and delivery to your location. Ensure you understand the associated costs, including tariffs, taxes, and handling fees. Familiarize yourself with local regulations regarding vehicle modifications, as some regions may have specific compliance requirements. Planning logistics ahead of time can prevent delays and additional expenses. -

What are the common finishes available for 26 inch rims?

26-inch rims come in various finishes, including glossy, matte, chrome, and custom powder coatings. Each finish can influence the aesthetic appeal and durability of the rims. For example, chrome finishes offer a luxurious look but may require more maintenance, while matte finishes can provide a modern, understated style. When sourcing rims, consider offering a range of finishes to meet diverse customer preferences and market trends. -

How can I vet suppliers for 26 inch rims effectively?

To vet suppliers, begin by checking their business credentials, including years of operation and market reputation. Request references from previous clients and evaluate their responsiveness and communication style. Online reviews and industry forums can provide additional insights into reliability and product quality. If possible, visit their facilities or attend trade shows to assess their production capabilities and product offerings firsthand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 26 Inch Rims Manufacturers & Suppliers List

1. BB Wheels – 26-Inch Custom & Off-Road Wheels

Domain: bbwheelsonline.com

Registered: 2012 (13 years)

Introduction: 26-Inch Wheels & Rims – Custom, Off-Road & Performance | Free Shipping to Lower 48 States | Financing available for all credit types | Contact: 320-333-2155 (Call), 507-432-2127 (Text)

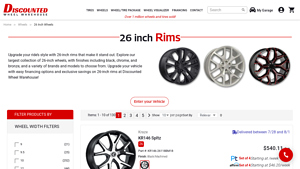

2. Discounted Wheel Warehouse – 26 Inch Rims

Domain: discountedwheelwarehouse.com

Registered: 2002 (23 years)

Introduction: 26 Inch Rims | 26 Inch Wheels | Discounted Wheel Warehouse offers a large collection of 26-inch wheels with various finishes including black, chrome, and bronze. The site features over 1 million wheels and tires sold, easy financing options, and exclusive savings on 26-inch rims. Customers can filter products by wheel width, color, brand, model, and finish.

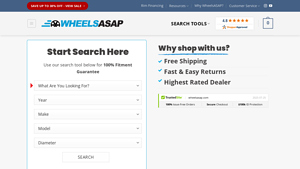

3. WheelsASAP – Key Product Details for 26 Inch Rims

Domain: wheelsasap.com

Registered: 2017 (8 years)

Introduction: Key Product Details for 26 Inch Rims:

– **Diameter**: 26 inches

– **Width Options**: 9, 10, 12, 14 inches

– **Bolt Patterns**: 5×115, 5×127, 6×135, 6×139.7, 8×165.1, 8×170, 8×180

– **Offsets**: -76, -75, -44, 15, 18, 20, 24, 25, 28, 30, 31, 35

– **Finishes Available**: Glossy Black, Matte Black, Black Machined, Candy Red, Milled Chrome, Chrome Plated, Gloss Black Machined Face, Gloss Black Milled…

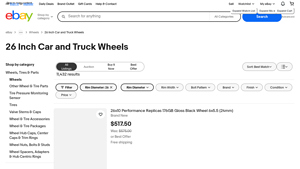

4. eBay – 26 Inch Car and Truck Wheels

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 26 Inch Car and Truck Wheels for sale on eBay. Available rim widths: 9.5, 10, 12, 14. Related searches include 26 in Truck Rims, 26 in Rims and Tires, 26 in Rims Set of 4, and 26 in Mag Wheels. Categories include Wheel & Tire Parts, Tire Pressure Monitoring Sensors, Wheel Hub Caps, and Wheel Nuts. Example products: 26×10 Silver Wheel Replica Tech RT7 6×5.5 for $376.60 with free shipping, 26×10 Chr…

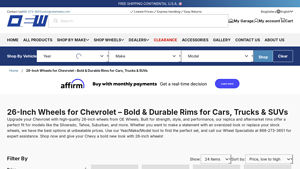

5. OE Wheels – 26 Inch Chevy Rims

Domain: oewheelsllc.com

Registered: 2008 (17 years)

Introduction: 26 Inch Chevy Rims | Aftermarket Chevy 26 Inch Wheels | Fits models like Silverado, Tahoe, Suburban | Built for strength, style, and performance | Perfect fit for various Chevrolet models | Unbeatable prices | Free shipping in the continental U.S.A. | Contact: 866-273-3651 | Year/Make/Model tool available for fitment assistance.

6. WheelSetGo – Custom 26-Inch Rims

Domain: wheelsetgo.com

Registered: 2021 (4 years)

Introduction: Custom 26-Inch Rims for Sale Online | WheelSetGo. Free Shipping to Lower 48 States. Financing All Credit Types. Available bolt patterns: 5×100, 5×105, 5×108, 5×110, 5×112, 5×114.3, 5×115, 5×120, 5×120.65, 5×127, 5×130, 5×135, 5×139.7, 5×150, 6×114.3, 6×115, 6×120, 6×127, 6×130, 6×132, 6×135, 6×139.7, 7×150, 8X165.1, 8×170, 8×180, 8×200, 8×210, 10×225, Blank Custom Drilled. Customization options in…

Strategic Sourcing Conclusion and Outlook for 26 inch rims

In the competitive landscape of the 26-inch rims market, strategic sourcing is crucial for international B2B buyers aiming to optimize their purchasing processes. By understanding the diverse options available—including various finishes, bolt patterns, and load ratings—buyers can make informed decisions that align with their specific vehicle requirements. Moreover, sourcing from reliable suppliers not only ensures product quality but also facilitates better pricing and terms, which are essential for maintaining competitive advantages in emerging markets.

As the demand for customization and performance wheels continues to grow across regions such as Africa, South America, the Middle East, and Europe, buyers are encouraged to leverage comprehensive supplier networks. This approach not only enhances sourcing efficiency but also opens doors to innovative products that meet evolving consumer preferences.

Looking ahead, the 26-inch rims market presents significant opportunities for growth. B2B buyers should actively engage with manufacturers and distributors, exploring financing options and flexible purchasing agreements that can enhance their operational capabilities. Embrace this momentum to secure your position in the market and drive your business forward.