Cut Costs with LKQ Engines: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for lkq engines

Navigating the global market for LKQ engines presents a unique challenge for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. As demand for high-quality, reliable engine solutions rises, sourcing the right components can be daunting. This comprehensive guide aims to demystify the complexities of acquiring LKQ engines, exploring various types, applications, and the nuances of supplier vetting.

From recycled to reconditioned and aftermarket options, understanding the spectrum of LKQ engines available is crucial for making informed purchasing decisions. This guide will also provide insights into cost considerations, warranty offerings, and maintenance implications, empowering buyers to evaluate their options critically.

By leveraging the information contained herein, B2B buyers will be better equipped to navigate the global supply chain, ensuring that they select the best products to meet their operational needs. Whether you are in Nairobi, São Paulo, Riyadh, or Berlin, this resource is tailored to help you streamline your procurement process, enhance your supply chain efficiency, and ultimately, support your business’s growth in an increasingly competitive landscape.

Understanding lkq engines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Recycled Engines | Made from salvaged parts, environmentally friendly | Cost-effective repairs for older vehicles | Pros: Lower cost, eco-friendly; Cons: Variable quality, may require additional work. |

| Reconditioned Engines | Refurbished to meet OEM standards, often with warranties | Heavy-duty applications, fleet maintenance | Pros: Reliable performance, warranty support; Cons: Higher cost than recycled. |

| Rebuilt Engines | Disassembled and rebuilt using new or refurbished parts | Custom builds, performance enhancements | Pros: Enhanced performance, tailored solutions; Cons: More expensive, longer lead times. |

| Aftermarket Engines | New engines produced by third-party manufacturers | Upgrades and replacements for various models | Pros: Wide variety, often better performance; Cons: Compatibility issues, lack of OEM support. |

| OEM Engines | Original equipment manufacturer engines | Replacement for specific vehicle models | Pros: Guaranteed fit and performance; Cons: Higher cost, limited availability. |

What Are Recycled Engines and Their B2B Suitability?

Recycled engines are derived from salvaged vehicles, making them a sustainable choice for businesses looking to minimize costs. They are particularly suitable for older vehicles that require budget-friendly repairs. When purchasing recycled engines, B2B buyers should consider the quality of the salvage process, warranty options, and the potential need for further refurbishment to ensure longevity and performance.

How Do Reconditioned Engines Serve Business Needs?

Reconditioned engines undergo extensive refurbishment to meet OEM specifications, making them a reliable option for businesses that prioritize quality. They are ideal for heavy-duty applications and fleet maintenance, where downtime can significantly impact operations. Buyers should focus on the warranty terms and the reputation of the supplier, ensuring that the reconditioning process adheres to industry standards.

What Are the Advantages of Rebuilt Engines for Custom Applications?

Rebuilt engines are completely disassembled and reassembled using a mix of new and refurbished components. This type of engine is advantageous for businesses looking for enhanced performance or custom specifications. However, buyers must weigh the higher costs and potential longer lead times against the benefits of tailored solutions that meet specific operational needs.

Why Choose Aftermarket Engines Over Other Options?

Aftermarket engines offer a wide range of options produced by third-party manufacturers, making them an appealing choice for businesses seeking performance upgrades or replacements. While they often provide better performance than OEM options, B2B buyers should be cautious about compatibility issues and ensure that the aftermarket engine is suitable for their specific vehicle models.

What Are the Benefits of OEM Engines for Replacement Needs?

OEM engines are the gold standard for replacement parts, providing guaranteed fit and performance for specific vehicle models. Businesses that prioritize reliability and quality often choose OEM engines, especially for critical applications. However, the higher cost and sometimes limited availability can be a drawback for budget-conscious buyers, making it essential to assess the total cost of ownership when considering this option.

Related Video: LKQ Engines – Professional Cleaning and Inspection Process

Key Industrial Applications of lkq engines

| Industry/Sector | Specific Application of lkq engines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation and Logistics | Replacement engines for heavy-duty trucks | Improved operational efficiency and reduced downtime | Ensure compatibility with existing fleet and warranty options |

| Construction | Powering construction machinery such as excavators and cranes | Enhanced productivity and reliability of heavy equipment | Evaluate engine specifications and performance under load |

| Agriculture | Engines for agricultural vehicles like tractors | Increased yield through reliable and powerful machinery | Consider fuel efficiency and availability of parts for maintenance |

| Mining | Engines for mining equipment such as haul trucks | Maximized uptime and productivity in harsh environments | Assess engine durability and support for extreme conditions |

| Marine | Engines for commercial vessels and fishing boats | Enhanced performance and lower operational costs | Verify compliance with maritime regulations and fuel type |

How are lkq engines utilized in the Transportation and Logistics Sector?

In the transportation and logistics sector, lkq engines are crucial for replacing worn-out or damaged engines in heavy-duty trucks. These engines ensure that fleets remain operational, reducing downtime and maintenance costs. International buyers, particularly from Africa and South America, should consider the compatibility of lkq engines with their existing fleet, as well as the warranty options available to secure their investments.

What role do lkq engines play in Construction?

In construction, lkq engines power essential machinery such as excavators and cranes. The reliability and efficiency of these engines directly contribute to enhanced productivity on job sites. Buyers in regions like the Middle East should focus on engine specifications that meet local regulatory standards and operational demands, ensuring that machinery performs optimally under various load conditions.

How are lkq engines beneficial for Agriculture?

Agricultural vehicles, including tractors, rely on lkq engines for their performance. These engines enable farmers to operate machinery effectively, leading to increased crop yields and efficient fieldwork. Buyers from Europe and Africa should prioritize fuel efficiency and the availability of replacement parts, as these factors significantly impact long-term operational costs and maintenance schedules.

Why are lkq engines important in the Mining Industry?

In the mining sector, lkq engines are utilized in heavy equipment like haul trucks, which are essential for transporting materials. These engines are designed to withstand harsh conditions, maximizing uptime and productivity. Buyers from South America and Africa should evaluate the durability of the engines and their performance under extreme conditions to ensure they meet the rigorous demands of mining operations.

How do lkq engines enhance performance in the Marine Industry?

In the marine industry, lkq engines are used in commercial vessels and fishing boats, providing the necessary power for various applications. These engines improve vessel performance and can lead to lower operational costs through better fuel efficiency. Buyers need to verify that the engines comply with maritime regulations and are suitable for the specific fuel types used in their region, ensuring smooth operations at sea.

Related Video: The Steam Engine: Powering the Industrial Revolution 🚂⚙️

3 Common User Pain Points for ‘lkq engines’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable LKQ Engines for Diverse Applications

The Problem:

International B2B buyers often struggle to find reliable sources for LKQ engines that meet their specific operational requirements. This is particularly challenging for businesses in regions like Africa and South America, where the availability of high-quality recycled or reconditioned engines can be limited. Buyers frequently face issues such as inconsistent quality, lack of warranties, and insufficient documentation regarding engine specifications, leading to costly downtime and repairs.

The Solution:

To effectively source LKQ engines, B2B buyers should establish relationships with reputable suppliers that specialize in heavy-duty truck parts. It’s essential to request detailed specifications and history of the engine, including any reconditioning processes it underwent. Additionally, buyers should prioritize suppliers that offer robust warranties, as this indicates confidence in their products’ quality. Utilizing platforms that aggregate multiple suppliers can also facilitate comparison shopping, allowing buyers to find the best options tailored to their needs. Engaging in direct communication with suppliers to clarify any doubts can further enhance the purchasing experience and ensure that the selected engine aligns with operational demands.

Scenario 2: Navigating Complex Import Regulations for LKQ Engines

The Problem:

B2B buyers importing LKQ engines into countries like Kenya or Brazil often encounter complex regulatory frameworks that can delay shipments and increase costs. The requirement for specific certifications, customs duties, and local compliance can be overwhelming, particularly for businesses that lack experience in international trade. This confusion can lead to unexpected expenses and project delays, significantly impacting operations.

The Solution:

To navigate these challenges effectively, buyers should conduct thorough research on the import regulations specific to their country. Partnering with a logistics provider that specializes in automotive parts can simplify the process. These providers often have insights into the necessary documentation and compliance requirements, ensuring that all aspects of the importation are handled correctly. Additionally, buyers should consult with local customs brokers who can provide tailored advice and assistance in preparing the required paperwork. Establishing a clear timeline for the import process will also help manage expectations and prevent operational disruptions.

Scenario 3: Ensuring Compatibility of LKQ Engines with Existing Fleet

The Problem:

Another common pain point for B2B buyers is ensuring that the LKQ engines they purchase are compatible with their existing fleet. This issue can arise due to differences in specifications, mounting arrangements, or performance characteristics, particularly when dealing with older or less common truck models. Incompatibility can result in additional costs for modifications, increased labor time, and potential downtime.

The Solution:

To mitigate compatibility issues, buyers should perform a thorough assessment of their current fleet’s engine specifications before making a purchase. This includes reviewing the vehicle’s make, model, and year, as well as the specific engine type required. Engaging with suppliers who have extensive databases or catalogues can provide valuable insights into compatibility. It’s advisable to ask for samples or detailed technical drawings from suppliers to verify that the LKQ engine will fit without extensive modifications. Additionally, maintaining open communication with both the supplier and a trusted mechanic can help ensure that the selected engine meets all operational requirements, minimizing the risk of costly compatibility issues.

Strategic Material Selection Guide for lkq engines

What Are the Common Materials Used in LKQ Engines?

When selecting materials for LKQ engines, understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers. This section delves into the most common materials used in LKQ engines, analyzing their performance characteristics, suitability for different applications, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Aluminum: The Lightweight Champion

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, making it a popular choice in engine manufacturing. It has good corrosion resistance and can withstand temperatures up to 400°F (204°C) without significant degradation.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which contributes to improved fuel efficiency. However, it can be more expensive than steel and may require specialized manufacturing processes, which can increase production costs.

Impact on Application: Aluminum is compatible with various media, including oil and coolant, making it suitable for engine components like cylinder heads and blocks. Its lightweight nature helps in reducing overall vehicle weight, enhancing performance.

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum recycling and disposal. Compliance with standards such as ASTM B221 (for aluminum extrusions) is essential, especially in regions like Europe, where environmental regulations are stringent.

Cast Iron: The Traditional Workhorse

Key Properties: Cast iron is known for its high wear resistance and excellent thermal stability. It can handle high temperatures and pressures, making it ideal for heavy-duty applications.

Pros & Cons: The durability of cast iron is a significant advantage, as it can last longer than many other materials. However, it is heavier than aluminum, which can negatively impact fuel efficiency. Additionally, cast iron can be more challenging to machine, leading to higher manufacturing costs.

Impact on Application: Cast iron is often used for engine blocks and crankshafts due to its ability to withstand high stress and thermal cycling. Its compatibility with various lubricants makes it suitable for heavy-duty engines.

Considerations for International Buyers: Buyers should consider the availability of cast iron in their local markets and the associated shipping costs. Compliance with standards such as ASTM A48 (for gray iron castings) is crucial, particularly for buyers in Africa and South America, where local standards may vary.

Steel: The Versatile Option

Key Properties: Steel offers high tensile strength and excellent ductility, making it suitable for various engine components. It can withstand high temperatures and pressures, withstanding conditions up to 1,500°F (815°C) depending on the alloy.

Pros & Cons: The versatility of steel allows for a wide range of applications, from crankshafts to connecting rods. However, it is generally heavier than aluminum and may require additional corrosion protection, increasing overall costs.

Impact on Application: Steel is compatible with various media, including oil and fuel, making it a reliable choice for engine components that require strength and durability.

Considerations for International Buyers: Buyers should be aware of the different grades of steel available and their specific applications. Compliance with standards such as ASTM A36 (for structural steel) is essential, especially in regions like the Middle East, where specific grades may be preferred.

Composite Materials: The Future of Engine Design?

Key Properties: Composite materials, such as carbon fiber reinforced polymers, offer high strength-to-weight ratios and excellent corrosion resistance. They can withstand temperatures up to 300°F (149°C) but are generally less effective under high pressure compared to metals.

Pros & Cons: The primary advantage of composites is their lightweight nature, which can significantly enhance fuel efficiency. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composites are increasingly being used in engine covers and other non-structural components due to their lightweight and corrosion-resistant properties.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their regions and the associated costs. Compliance with international standards for composites, such as ASTM D3039 (for tensile properties), is important, especially in Europe, where innovation in materials is rapidly advancing.

Summary Table of Material Selection for LKQ Engines

| Material | Typical Use Case for LKQ Engines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Cylinder heads and blocks | Lightweight, improves fuel efficiency | Higher cost, requires specialized mfg | High |

| Cast Iron | Engine blocks and crankshafts | High durability and thermal stability | Heavier, difficult to machine | Medium |

| Steel | Crankshafts and connecting rods | Versatile, high tensile strength | Heavier, needs corrosion protection | Medium |

| Composite Materials | Engine covers | Lightweight, excellent corrosion resistance | Higher production costs, less pressure resistance | High |

This guide provides a comprehensive overview of material selection for LKQ engines, helping international B2B buyers make informed decisions that align with their operational needs and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for lkq engines

What Are the Main Stages of Manufacturing LKQ Engines?

The manufacturing process for LKQ engines involves several critical stages that ensure each engine meets the high standards expected in the automotive industry. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, such as aluminum and steel, essential for engine components. Materials are rigorously inspected for defects and compliance with international standards. Suppliers often provide certification documents to confirm material quality, which is crucial for B2B buyers in ensuring that they receive durable and reliable components.

-

Forming: In this stage, raw materials are shaped into engine components through techniques such as casting, forging, and machining. Advanced technologies like Computer Numerical Control (CNC) machining are commonly employed for precision. This ensures that parts are produced to exact specifications, which is vital for the performance and longevity of the engine.

-

Assembly: Once the components are formed, they move to the assembly line. Here, skilled technicians assemble the various parts, including the engine block, crankshaft, and cylinder heads. The assembly process often incorporates automated systems to enhance efficiency and accuracy. Each assembly line typically follows a standardized procedure to ensure consistency across all produced engines.

-

Finishing: The final stage of manufacturing involves finishing processes such as cleaning, painting, and surface treatment. These steps not only enhance the engine’s aesthetic appeal but also protect it from corrosion and wear. Quality checks during this stage ensure that the engines meet the necessary performance and safety standards before they are shipped to buyers.

How Is Quality Assurance Managed in LKQ Engine Manufacturing?

Quality assurance (QA) in the manufacturing of LKQ engines is a multi-faceted approach that aligns with both international and industry-specific standards. Understanding these processes can help B2B buyers ensure that they are sourcing high-quality products.

-

International Standards Compliance: LKQ adheres to ISO 9001 standards, which emphasize a quality management system that enhances customer satisfaction through effective process management. Compliance with ISO standards assures buyers that the engines are produced with a focus on quality, reliability, and continuous improvement.

-

Industry-Specific Certifications: In addition to ISO 9001, LKQ engines may also meet other certifications such as CE marking for compliance with European safety standards and API (American Petroleum Institute) standards for engine oils. These certifications provide additional layers of assurance regarding the quality and performance of the engines.

What Are the Key Quality Control Checkpoints in Engine Manufacturing?

Quality control (QC) is integral to ensuring the performance and reliability of LKQ engines. Several critical checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC): Before materials are used in production, they undergo rigorous inspections to verify their quality and compliance with specifications. This stage is crucial for preventing defects from entering the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted at various stages, including during forming and assembly. This ensures that any deviations from quality standards are caught early, reducing waste and rework.

-

Final Quality Control (FQC): Once the engines are fully assembled, they undergo final inspections and testing. This stage includes performance testing, where engines may be run under simulated conditions to evaluate their performance and reliability.

What Testing Methods Are Commonly Used for LKQ Engines?

Testing methods play a vital role in the quality assurance of LKQ engines. Common testing methods include:

-

Functional Testing: Engines are tested for functionality to ensure they meet performance specifications. This includes testing for power output, fuel efficiency, and emissions compliance.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are utilized to detect internal and surface defects without damaging the components.

-

Durability Testing: Engines may undergo rigorous endurance tests to simulate real-world conditions, ensuring they can withstand the rigors of daily use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure quality:

-

Supplier Audits: Conducting regular audits of the manufacturing facilities can provide insights into the supplier’s quality management practices. This includes reviewing their adherence to ISO standards and industry certifications.

-

Requesting Quality Reports: B2B buyers should request detailed quality reports that outline the QC measures in place, including results from IQC, IPQC, and FQC. These reports can provide transparency regarding the supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These inspectors can provide unbiased evaluations of the manufacturing process and product quality.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from diverse regions must consider specific nuances when it comes to quality control:

-

Understanding Local Regulations: Buyers should familiarize themselves with local regulations regarding automotive parts and engine quality standards. Compliance with both international and local regulations is crucial for smooth operations.

-

Cultural Differences in Quality Expectations: Different regions may have varying expectations regarding quality. Buyers should communicate their specific requirements clearly to avoid misunderstandings and ensure that the products meet their standards.

-

Long-Term Supplier Relationships: Building long-term relationships with suppliers can enhance quality assurance. Regular communication and collaboration can help ensure that both parties are aligned on quality expectations and improvements.

By understanding the manufacturing processes and quality assurance measures associated with LKQ engines, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lkq engines’

To assist B2B buyers in effectively sourcing LKQ engines, this step-by-step guide outlines essential actions to ensure a smooth and informed procurement process. Each step is designed to help you evaluate suppliers, understand technical specifications, and secure the best deals.

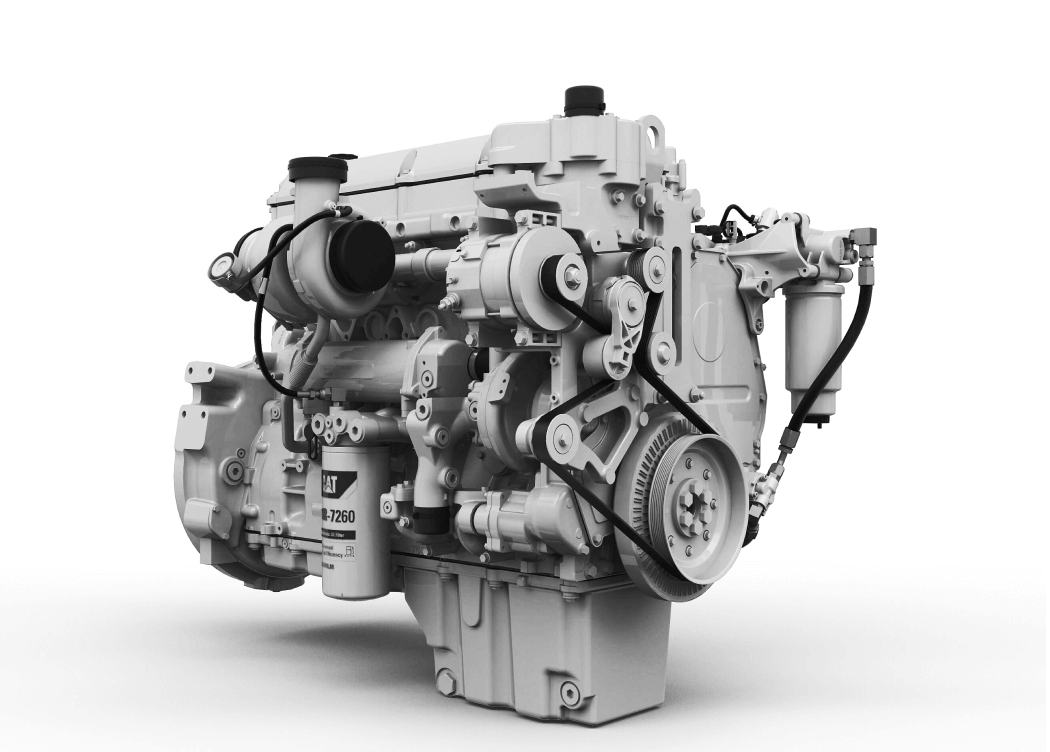

A stock image related to lkq engines.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the engines you need. This includes identifying engine types, power ratings, compatibility with existing machinery, and any specific features such as emissions compliance or fuel efficiency.

– Why it matters: Precise specifications will help avoid costly mistakes and ensure that the engines meet your operational needs.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of LKQ engines. Use industry directories, trade shows, and online platforms to compile a list of reputable vendors.

– What to look for: Focus on suppliers with a strong track record in your region, particularly those with positive customer reviews and a solid reputation in the market.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Important checks: Ensure the suppliers have relevant certifications, such as ISO or compliance with local regulations. Look for testimonials or case studies that demonstrate their reliability and service quality.

Step 4: Verify Quality Assurance Processes

Inquire about the quality assurance measures that suppliers have in place for their engines. This includes testing procedures, warranties, and return policies.

– Key aspects to confirm: Look for suppliers that offer warranties on their engines, as this reflects confidence in their product quality. Additionally, confirm that they have robust processes for inspecting and testing engines before sale.

Step 5: Negotiate Pricing and Terms

Once you’ve shortlisted suppliers, engage in negotiations to secure favorable pricing and payment terms. Be clear about your budget constraints and what you expect in terms of service.

– Negotiation tips: Don’t hesitate to ask for bulk purchase discounts or extended payment terms, especially if you’re buying multiple engines. Understand the total cost of ownership, including shipping and any potential import duties.

Step 6: Request Samples or Demonstrations

If possible, request samples or demonstrations of the engines you are considering. This hands-on approach will allow you to assess the quality and performance of the product firsthand.

– What to assess: Look for operational efficiency, ease of installation, and compatibility with your existing equipment. This step can provide valuable insights that specifications alone may not reveal.

Step 7: Finalize Your Purchase and Confirm Logistics

After selecting a supplier and finalizing terms, ensure that you confirm logistics details, including delivery timelines and installation support.

– Logistics considerations: Clearly communicate your timeline and any specific delivery requirements. Establish a point of contact for any post-purchase support or inquiries.

By following this checklist, B2B buyers can navigate the sourcing process for LKQ engines with confidence, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for lkq engines Sourcing

What Are the Key Cost Components in LKQ Engines Sourcing?

When sourcing LKQ engines, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The cost of raw materials significantly impacts overall pricing. High-quality components typically lead to higher prices but can enhance durability and performance.

-

Labor: Skilled labor is required for assembly and quality control, contributing to labor costs. Regions with higher labor costs can affect the final price of the engines.

-

Manufacturing Overhead: This encompasses utilities, depreciation, and other indirect costs associated with production facilities. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: Investments in specialized tools and machinery for engine production are factored into the pricing. Custom tooling may be necessary for specific engine models, increasing initial costs.

-

Quality Control (QC): Rigorous QC processes ensure that engines meet industry standards, adding to overall costs but providing assurance of quality to buyers.

-

Logistics: Transportation and handling costs are crucial, especially for international buyers. These costs can vary significantly based on the shipping method and distance.

-

Margin: Suppliers will add a profit margin to cover their operational costs and ensure profitability. Understanding typical margins in the industry can aid in negotiation.

How Do Price Influencers Impact LKQ Engines Costs?

Several factors influence the pricing of LKQ engines, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Understanding a supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom-built engines or those with specific specifications can incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can impact pricing. Higher-quality materials often lead to longer-lasting products, justifying a higher initial investment.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The shipping terms defined by Incoterms can influence total costs. Buyers should be aware of who bears the cost and risk at various stages of shipping.

What Are Effective Buyer Tips for Cost-Efficiency in LKQ Engines Sourcing?

To achieve cost efficiency when sourcing LKQ engines, international B2B buyers should consider the following strategies:

-

Negotiate Effectively: Building a good relationship with suppliers can lead to better pricing. Utilize volume purchases and long-term contracts as leverage during negotiations.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, warranty, and potential downtime costs. A slightly higher upfront price might result in lower TCO if the engine is more reliable.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local economic conditions that affect pricing. Currency fluctuations and import tariffs can impact the final cost.

-

Research and Compare Suppliers: Take the time to research various suppliers and compare their offerings. Look beyond price to include quality, service, and delivery times in your evaluation.

-

Request Detailed Quotations: When seeking quotes, ask for a breakdown of costs. This transparency allows for better comparison and negotiation.

Disclaimer on Indicative Prices

Prices for LKQ engines can vary widely based on numerous factors, including market demand, regional variations, and specific buyer requirements. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure they secure the best deal suited to their needs.

Alternatives Analysis: Comparing lkq engines With Other Solutions

Understanding Alternative Solutions to LKQ Engines

When considering engine solutions for heavy trucks, international B2B buyers must evaluate various options available in the market. LKQ engines are known for their quality and reliability, but there are alternative solutions that might better meet specific operational needs. This section delves into a comparative analysis of LKQ engines against other viable alternatives, helping buyers make informed decisions tailored to their unique requirements.

Comparison Table of LKQ Engines and Alternatives

| Comparison Aspect | LKQ Engines | Rebuilt Engines | Aftermarket Engines |

|---|---|---|---|

| Performance | High-quality OEM recycled parts | Varies based on rebuild quality | Generally good, but can vary |

| Cost | Competitive pricing | Moderate to high | Often lower than OEM |

| Ease of Implementation | Straightforward installation | Depends on builder’s expertise | Typically easy to install |

| Maintenance | Low maintenance with warranty | Maintenance can be higher | May require more frequent repairs |

| Best Use Case | Reliable for long-term use | Suitable for specific applications | Cost-effective for budget projects |

What Are the Pros and Cons of Rebuilt Engines?

Rebuilt engines can serve as a viable alternative to LKQ engines, particularly for businesses looking to save on costs while maintaining decent performance. The major advantage is that they can be tailored to specific needs, allowing for enhancements during the rebuild process. However, the quality can vary significantly depending on the shop performing the rebuild, which may lead to inconsistent performance and increased maintenance needs. Buyers should ensure they choose reputable rebuilders to mitigate risks.

How Do Aftermarket Engines Compare?

Aftermarket engines are typically the most cost-effective option, making them appealing for budget-conscious buyers. They can provide good performance, especially for less demanding applications. However, the downside is that their quality can be inconsistent, and they may not offer the same reliability as OEM solutions. Additionally, aftermarket engines may not come with the same level of warranty or support, which could lead to higher long-term costs due to maintenance or replacement needs.

Conclusion: How Should B2B Buyers Choose the Right Engine Solution?

Choosing the right engine solution involves weighing the specific needs of your business against the strengths and weaknesses of each option. LKQ engines offer a balance of performance and reliability, making them ideal for long-term operations. However, if budget constraints are a significant factor, rebuilt or aftermarket engines could be more suitable. Buyers should consider factors such as performance requirements, cost constraints, and maintenance capabilities before making a decision. Ultimately, the best choice will depend on aligning the engine solution with your operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for lkq engines

What Are the Essential Technical Properties of LKQ Engines?

When sourcing LKQ engines, understanding specific technical properties is crucial for ensuring compatibility, performance, and longevity. Here are several key specifications that international B2B buyers should prioritize:

-

Material Grade

The material grade of an engine refers to the type of metals and alloys used in its construction. For instance, high-grade steel is commonly used for engine blocks due to its strength and durability. Selecting engines with superior material grades can significantly reduce maintenance costs and enhance the lifespan of the engine, which is vital for businesses in sectors such as transportation and logistics. -

Tolerance Levels

Tolerance levels indicate the permissible limits of variation in the engine’s dimensions. For example, tighter tolerances in the manufacturing process ensure better fit and performance. This is particularly important for heavy-duty applications where precision can affect fuel efficiency and overall operational effectiveness. Buyers should inquire about tolerance specifications to avoid costly repairs or replacements. -

Horsepower and Torque Ratings

Horsepower and torque ratings define the engine’s performance capabilities. Horsepower measures the engine’s ability to perform work over time, while torque reflects its rotational force. For B2B buyers, understanding these ratings helps in selecting engines that meet the specific power requirements of their vehicles, ensuring optimal performance under varying load conditions. -

Engine Type (Reconditioned vs. Rebuilt)

Knowing whether an engine is reconditioned or rebuilt can influence purchasing decisions. Reconditioned engines have undergone repairs to restore their original specifications, while rebuilt engines have had significant components replaced or upgraded. Each option has implications for cost, warranty, and expected lifespan, making it essential for buyers to evaluate which type suits their operational needs best. -

Warranty Terms

The warranty offered on LKQ engines can serve as a critical indicator of quality. A robust warranty not only reflects the manufacturer’s confidence in their product but also provides peace of mind for buyers. Understanding the terms, including coverage duration and exclusions, helps businesses mitigate risks associated with engine failure.

What Are Common Trade Terms Relevant to LKQ Engines?

Familiarizing yourself with industry terminology is equally important for effective negotiation and procurement. Here are several essential trade terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. For engines, using OEM parts often ensures compatibility and reliability. Buyers should consider OEM components for critical repairs to maintain vehicle performance and warranty coverage. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of products a supplier is willing to sell. Understanding MOQs is crucial for buyers to plan inventory and manage cash flow effectively. It can influence purchasing strategies, especially for businesses looking to scale operations in regions like Africa or South America. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specified products. B2B buyers should utilize RFQs to gather competitive offers and ensure they secure the best possible deal on LKQ engines, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping costs, risks, and delivery timelines. Familiarity with Incoterms helps buyers negotiate better shipping agreements and understand their obligations, which is particularly useful when sourcing engines from diverse regions. -

Core Charge

A core charge is an additional fee applied when purchasing an engine, which is refundable upon returning the old unit. This practice encourages recycling and helps manage environmental impacts. Buyers should factor core charges into their overall cost assessments when evaluating LKQ engines.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and budget constraints, ensuring a successful procurement process for LKQ engines.

Navigating Market Dynamics and Sourcing Trends in the lkq engines Sector

What are the Key Market Dynamics and Trends in the LKQ Engines Sector?

The LKQ engines sector is experiencing notable growth driven by several global factors. Increased demand for cost-effective and sustainable engine solutions has led to a surge in the popularity of recycled and aftermarket parts. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly sourcing these parts to enhance their supply chain efficiencies and reduce operational costs. Emerging technologies such as digital marketplaces are transforming sourcing processes, enabling buyers to access a wider range of products quickly and efficiently. Additionally, advances in logistics and supply chain management are facilitating faster delivery times, which is crucial for businesses that rely on timely repairs and maintenance.

Moreover, market dynamics are influenced by regulatory changes aimed at reducing emissions and promoting sustainability. For instance, stricter emissions regulations in Europe and increasing awareness of environmental issues in Africa and South America are pushing companies to seek engines that comply with these standards. This trend is also reflected in the growing preference for engines made from recycled materials, which not only meet performance standards but also contribute to lower environmental footprints.

How Can B2B Buyers Embrace Sustainability and Ethical Sourcing in the LKQ Engines Sector?

Sustainability has become a pivotal consideration for B2B buyers in the LKQ engines sector. The environmental impact of sourcing practices is under scrutiny, and companies are increasingly held accountable for their supply chain decisions. Ethical sourcing involves ensuring that materials are procured responsibly, promoting fair labor practices, and minimizing ecological harm. As a result, buyers are encouraged to partner with suppliers who provide ‘green’ certifications, indicating compliance with environmental standards.

For example, engines manufactured using recycled components can significantly reduce waste and energy consumption compared to traditional manufacturing methods. Buyers should prioritize suppliers that are transparent about their sourcing practices and can demonstrate a commitment to sustainability. This not only enhances brand reputation but also aligns with the growing consumer demand for environmentally friendly products. Additionally, investing in sustainable engine solutions can lead to long-term cost savings, as these products often offer better fuel efficiency and lower maintenance costs.

What is the Historical Context of the LKQ Engines Sector?

A stock image related to lkq engines.

The LKQ engines sector has evolved significantly over the past few decades, paralleling advancements in automotive technology and recycling practices. Founded in the early 2000s, LKQ Corporation set out to create a robust market for recycled automotive parts, focusing on sustainability and cost-effectiveness. Initially, the sector faced skepticism regarding the reliability of recycled engines. However, advancements in quality control and technology have transformed the perception of these products.

As the industry matured, the demand for high-quality recycled and aftermarket engines surged, driven by economic factors and environmental awareness. Today, LKQ engines are synonymous with reliability and performance, catering to a diverse range of international markets. This evolution underscores the importance of sustainability and innovation in shaping modern B2B sourcing strategies, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe, who are increasingly looking for effective and responsible sourcing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of lkq engines

-

How do I ensure the quality of LKQ engines before purchasing?

To ensure the quality of LKQ engines, it is essential to review the supplier’s certifications and quality assurance processes. Look for warranties offered on the engines, as these indicate the supplier’s confidence in their products. Additionally, request detailed specifications and inspection reports to understand the condition and performance of the engines. Engaging with suppliers who have a proven track record and positive reviews can also provide peace of mind regarding quality. -

What is the best way to source LKQ engines for heavy-duty trucks?

The best way to source LKQ engines for heavy-duty trucks is to work with reputable suppliers who specialize in heavy-duty parts. Research suppliers with a strong presence in your region, such as those in Europe, Africa, or South America, and check their inventory for the specific engine models you need. Utilize platforms that connect buyers with suppliers, and consider attending industry trade shows to meet suppliers in person and establish relationships. -

What are the typical minimum order quantities (MOQ) for LKQ engines?

Minimum order quantities (MOQ) for LKQ engines can vary significantly depending on the supplier and the specific engine type. Generally, larger suppliers may have higher MOQs, while smaller or regional suppliers may offer flexibility. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that fit your purchasing strategy, especially if you are a new buyer or require engines for a specific project. -

What payment terms should I expect when purchasing LKQ engines internationally?

Payment terms for international purchases of LKQ engines often include options such as advance payment, letters of credit, or installment payments based on delivery milestones. It is crucial to clarify these terms with your supplier before finalizing the deal. Understand the currency exchange implications and any additional fees that may arise during cross-border transactions. Negotiating favorable payment terms can help mitigate financial risks. -

How can I vet suppliers of LKQ engines to ensure reliability?

Vetting suppliers of LKQ engines involves several steps: checking their business credentials, reviewing customer testimonials, and assessing their operational history. Request references from previous clients and verify their experience in the industry. Conducting a site visit, if feasible, can also provide insights into their operations. Utilize online platforms for supplier ratings and certifications to ensure you are partnering with a reliable source. -

What logistics considerations should I keep in mind when importing LKQ engines?

When importing LKQ engines, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose a logistics partner familiar with automotive parts to ensure compliance with local regulations. Also, factor in potential tariffs and taxes that may apply to your imports. Establishing clear communication with your supplier about logistics can help avoid delays and ensure timely delivery of your engines. -

Can LKQ engines be customized to fit specific vehicle models?

Yes, many suppliers offer customization options for LKQ engines to fit specific vehicle models. This may include modifications to engine specifications, such as size, power output, and compatibility with different truck systems. Communicate your requirements clearly with the supplier and inquire about their capability to deliver customized solutions. Customization can enhance performance and ensure that the engine meets your operational needs. -

What quality assurance processes should LKQ engines undergo before shipping?

Before shipping, LKQ engines should undergo rigorous quality assurance processes, including inspection for mechanical integrity, performance testing, and compliance with industry standards. Suppliers should provide documentation verifying that the engines have passed these quality checks. Ensure that your supplier has a clear QA protocol, which may involve third-party inspections, to guarantee that you receive high-quality and reliable products.

A stock image related to lkq engines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lkq engines

What Are the Key Takeaways for Strategic Sourcing of LKQ Engines?

In conclusion, strategic sourcing of LKQ engines offers a multitude of benefits for international B2B buyers. The emphasis on quality, reliability, and cost-effectiveness makes LKQ an attractive partner for businesses in regions such as Africa, South America, the Middle East, and Europe. By leveraging LKQ’s extensive network and best-in-industry warranties, buyers can ensure they are investing in durable, recycled, and reconditioned engines that meet their operational needs.

How Can B2B Buyers Benefit from a Strategic Sourcing Approach?

Implementing a strategic sourcing approach not only reduces procurement costs but also enhances supply chain efficiency. Buyers are encouraged to analyze their specific needs and align them with LKQ’s diverse offerings, ensuring a perfect fit for their machinery requirements. The proactive management of supplier relationships can lead to improved negotiations and better service levels.

What Does the Future Hold for B2B Buyers in Engine Procurement?

Looking ahead, the demand for sustainable and cost-effective engine solutions is set to rise. International buyers should seize this opportunity to partner with LKQ, tapping into their commitment to innovation and sustainability. Engaging with LKQ can provide access to cutting-edge technologies and practices that will drive efficiency and growth in their operations. Take action today to secure a competitive edge in the evolving landscape of heavy truck parts procurement.