Discover the Best Top Loader Binder: Your Ultimate Buying Guide (2025)

Introduction: Navigating the Global Market for top loader binder

In today’s global marketplace, sourcing the right top loader binder can be a daunting challenge for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With an array of options available, it is crucial to navigate through various types, applications, and quality standards to find a binder that meets specific business needs. This guide is designed to empower international buyers by providing in-depth insights into the different types of top loader binders, their applications across various industries, and essential factors to consider when vetting suppliers.

Understanding the nuances of sourcing top loader binders not only ensures compliance with regional standards but also enhances operational efficiency and brand presentation. Throughout this guide, you will discover actionable strategies for evaluating supplier credibility, negotiating costs, and optimizing your procurement process to achieve the best value for your investment.

Additionally, we will explore common challenges faced by international buyers, such as logistical hurdles, quality assurance, and cultural differences in business practices. By addressing these challenges head-on, this guide equips you with the knowledge and tools to make informed purchasing decisions that align with your business objectives. Whether you are based in Colombia, Vietnam, or any other location, understanding the global landscape of top loader binders will enable you to source effectively and enhance your competitive advantage.

Understanding top loader binder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Top Loader Binder | Clear plastic front, heavy-duty cover, 3-ring | Document storage, presentations | Pros: Cost-effective, widely available. Cons: Limited durability for heavy use. |

| Heavy-Duty Top Loader Binder | Reinforced spine, thicker cover, extra durability | Archiving, frequent handling | Pros: Long-lasting, withstands wear and tear. Cons: Higher cost compared to standard options. |

| Customizable Top Loader Binder | Personalized designs, varied sizes, branding | Marketing materials, corporate gifts | Pros: Enhances brand visibility, tailored to needs. Cons: Longer lead times for production. |

| Multi-Pocket Top Loader Binder | Multiple pockets, expandable sections | Organizing mixed media, portfolios | Pros: Versatile storage options, easy access. Cons: Can be bulkier and heavier. |

| Eco-Friendly Top Loader Binder | Made from recycled materials, sustainable design | Green initiatives, corporate responsibility | Pros: Supports sustainability goals, appealing to eco-conscious clients. Cons: May be more expensive than traditional options. |

What Are the Characteristics of Standard Top Loader Binders?

Standard top loader binders are the most common type used in various industries. They typically feature a clear plastic front cover that allows for easy visibility of inserted documents, combined with a sturdy 3-ring mechanism. These binders are ideal for general document storage and presentations. When purchasing, B2B buyers should consider the weight capacity and overall quality of the materials to ensure they meet their specific needs, especially for frequent use.

Why Choose Heavy-Duty Top Loader Binders?

Heavy-duty top loader binders are designed for businesses that require durability and frequent handling of documents. With a reinforced spine and a thicker cover, these binders provide enhanced protection for important documents. They are particularly suitable for archiving and environments where binders will be used repeatedly. Buyers should evaluate the binder’s capacity and resistance to wear when considering heavy-duty options, as they can be a more significant investment but offer long-term value.

How Do Customizable Top Loader Binders Benefit B2B Buyers?

Customizable top loader binders allow businesses to create a unique presentation for their documents. These binders can feature personalized designs, varied sizes, and branding elements that enhance corporate identity. They are particularly useful for marketing materials and corporate gifts. When considering customizable options, buyers should be aware of the potential for longer lead times and minimum order quantities, which can impact project timelines.

What Are the Advantages of Multi-Pocket Top Loader Binders?

Multi-pocket top loader binders offer versatility with multiple pockets and expandable sections, making them ideal for organizing mixed media or portfolios. They provide easy access to various documents and materials, which is beneficial for presentations or client meetings. However, buyers should keep in mind that these binders can be bulkier and heavier than standard options, which may affect portability and storage solutions.

Why Should You Consider Eco-Friendly Top Loader Binders?

Eco-friendly top loader binders are constructed from recycled materials and designed with sustainability in mind. These binders appeal to businesses that prioritize corporate responsibility and seek to align with green initiatives. While they may come at a higher price point compared to traditional binders, the investment can enhance a company’s reputation and appeal to eco-conscious clients. B2B buyers should assess the environmental certifications and materials used to ensure they meet their sustainability goals.

Related Video: Top Deck Top Loader Binder: A Way Too In-Depth Review

Key Industrial Applications of top loader binder

| Industry/Sector | Specific Application of top loader binder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Printing and Publishing | Binding printed materials like books and magazines | Enhances durability and professional appearance | Consider quality of materials and binding capacity |

| Education and Training | Organizing training manuals and educational resources | Improves accessibility and information retention | Assess compatibility with various document sizes |

| Manufacturing and Logistics | Holding assembly instructions and product manuals | Streamlines operations and reduces errors | Evaluate binding strength and resistance to environmental factors |

| Retail and E-commerce | Packaging promotional materials and catalogs | Attracts customers and enhances brand image | Look for customization options and eco-friendly materials |

| Healthcare and Pharmaceuticals | Compiling patient information and medical records | Ensures compliance and easy access to data | Verify compliance with industry regulations and data protection standards |

How is the Top Loader Binder Used in Printing and Publishing?

In the printing and publishing sector, top loader binders are crucial for binding printed materials such as books, magazines, and brochures. These binders not only enhance the durability of the printed products but also provide a professional appearance that is essential for attracting customers. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality materials that can withstand different climates is vital. Buyers should ensure that their suppliers can provide options for various page counts and binding styles to meet specific project requirements.

What Role Does the Top Loader Binder Play in Education and Training?

Top loader binders are extensively used in educational settings to organize training manuals, lesson plans, and student resources. By facilitating easy access to important information, these binders improve the learning experience and promote information retention among students. For buyers from the Middle East and Europe, it’s important to assess the compatibility of binders with various document sizes and formats, ensuring they can accommodate diverse educational materials while maintaining durability for repeated use.

How Does the Top Loader Binder Benefit Manufacturing and Logistics?

In the manufacturing and logistics industries, top loader binders are utilized to hold assembly instructions, product manuals, and safety guidelines. This application streamlines operations by providing easy access to essential documents, thereby reducing the potential for errors during production processes. International B2B buyers, particularly from regions like Africa and South America, should consider the binding strength and resistance to environmental factors, such as humidity and temperature variations, to ensure longevity and reliability in challenging conditions.

Why is the Top Loader Binder Important for Retail and E-commerce?

Retailers and e-commerce businesses leverage top loader binders to package promotional materials, catalogs, and product information sheets. This application not only attracts customers but also enhances the overall brand image by presenting information in a structured and appealing manner. For buyers in Europe and the Middle East, it is crucial to explore customization options, including branding and design, as well as the availability of eco-friendly materials to align with sustainability goals.

How Does the Top Loader Binder Contribute to Healthcare and Pharmaceuticals?

In the healthcare and pharmaceutical sectors, top loader binders are essential for compiling patient information, medical records, and compliance documents. This application ensures that critical data is easily accessible and organized, which is vital for regulatory compliance and efficient patient care. B2B buyers in these industries must verify that their suppliers comply with industry regulations and data protection standards, ensuring that the binders used do not compromise sensitive information.

3 Common User Pain Points for ‘top loader binder’ & Their Solutions

Scenario 1: Managing Document Security in Transit

The Problem: For international B2B buyers, transporting sensitive documents often poses a significant risk. In regions where theft or loss is prevalent, ensuring that important papers remain secure during transit can be challenging. Many top loader binders do not offer adequate protection, leaving documents vulnerable to environmental factors and unauthorized access. Buyers may find themselves worrying about the integrity of their materials, especially when dealing with contracts, legal documents, or sensitive client information.

The Solution: To address this concern, consider sourcing top loader binders made from durable, water-resistant materials with reinforced seams. Look for binders that feature secure closure mechanisms, such as zippers or Velcro, to prevent accidental openings. Additionally, consider binders with built-in locking systems or tamper-evident seals, which can significantly enhance security. When purchasing, request samples to test their durability and security features. Educating your team on the importance of secure handling and transport will further mitigate risks. Investing in quality binders not only protects your documents but also reinforces your commitment to professionalism and security in business transactions.

Scenario 2: Difficulty in Organizing and Accessing Documents

The Problem: B2B buyers often struggle with organizing a large volume of documents efficiently. Many find that standard top loader binders do not accommodate various sizes or types of papers, making retrieval cumbersome. This disorganization can lead to lost time and frustration, particularly in fast-paced business environments where quick access to information is essential. Buyers in sectors such as logistics, finance, or legal services may experience heightened pressure to manage extensive documentation effectively.

The Solution: To overcome this challenge, opt for customizable top loader binders that allow for flexible organization. Seek binders that come with adjustable dividers and pockets to categorize documents by type, date, or project. Consider binders with color-coded features to streamline retrieval processes. When sourcing, inquire about options that include labeling systems for easy identification of contents. Training staff on best practices for document organization and retrieval can also enhance efficiency. By investing in binders that promote organization, businesses can improve workflow and reduce time spent searching for critical documents.

Scenario 3: Environmental Impact and Sustainability Concerns

The Problem: International B2B buyers are increasingly aware of the environmental impact of their purchasing decisions. Traditional top loader binders, often made from non-recyclable plastics, contribute to waste and do not align with sustainability goals. Buyers may feel conflicted between the need for functional office supplies and the desire to make eco-friendly choices, particularly in regions where environmental regulations are becoming more stringent.

The Solution: To align with sustainability objectives, seek out top loader binders made from recycled or biodegradable materials. Many manufacturers now offer eco-friendly options that maintain functionality while reducing environmental impact. When evaluating suppliers, request information about their sustainability practices and certifications. Engage in discussions about the lifecycle of their products and consider those that offer take-back programs for used binders. Additionally, promoting the use of digital alternatives where feasible can complement your sustainability strategy. By choosing environmentally friendly products, businesses not only contribute to a healthier planet but also enhance their brand reputation among eco-conscious clients and partners.

Strategic Material Selection Guide for top loader binder

When selecting materials for top loader binders, it is essential to consider various factors, including performance properties, cost implications, and regional compliance standards. Below is an analysis of four common materials used in the manufacturing of top loader binders, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polypropylene in Top Loader Binders?

Polypropylene (PP) is a popular choice for top loader binders due to its lightweight nature and excellent chemical resistance. It can withstand temperatures ranging from -20°C to 100°C, making it suitable for various environments. Additionally, polypropylene is resistant to moisture and UV light, which helps maintain the integrity of the binder over time.

Pros & Cons: The main advantage of polypropylene is its durability and flexibility, allowing for easy handling and storage. However, it may not be as rigid as other materials, which can affect the overall structure of the binder under heavy loads. The manufacturing process is relatively simple, which keeps production costs low.

Impact on Application: Polypropylene is compatible with a wide range of media, including paper and plastic sheets, making it ideal for educational and office settings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the polypropylene used complies with local environmental regulations. Standards such as ASTM D638 for tensile properties may also be relevant.

How Does PVC Compare as a Material for Top Loader Binders?

Polyvinyl chloride (PVC) is another widely used material for top loader binders, known for its strength and rigidity. PVC can handle higher pressures and is resistant to corrosion, making it suitable for more demanding applications.

Pros & Cons: The primary advantage of PVC is its excellent durability and resistance to wear and tear. However, it can be heavier and more expensive than polypropylene, which may deter some buyers. The manufacturing process for PVC is more complex, potentially leading to higher production costs.

Impact on Application: PVC binders are particularly effective in environments where durability is crucial, such as industrial settings or for storing sensitive documents.

Considerations for International Buyers: Buyers in Europe should be aware of REACH compliance for PVC materials, while those in the Middle East may need to consider local standards for chemical safety.

What Are the Benefits of Using Paperboard for Top Loader Binders?

Paperboard is an eco-friendly alternative for top loader binders, offering a lightweight and recyclable option. It typically has a temperature resistance of up to 70°C and is biodegradable, appealing to environmentally conscious buyers.

Pros & Cons: The main advantage of paperboard is its sustainability and cost-effectiveness. However, it may not offer the same level of durability as plastic materials, making it less suitable for heavy-duty applications. The manufacturing process is straightforward, contributing to lower costs.

Impact on Application: Paperboard binders are ideal for presentations and corporate settings where aesthetics are important, but they may not withstand harsh conditions.

Considerations for International Buyers: Buyers from South America and Africa should check for compliance with local recycling regulations and standards, ensuring that their choice aligns with sustainability goals.

Why Choose Aluminum for Top Loader Binders?

Aluminum is a less common but highly durable material for top loader binders, known for its strength and lightweight properties. It can withstand extreme temperatures and is resistant to corrosion, making it suitable for various industrial applications.

Pros & Cons: The key advantage of aluminum is its longevity and resistance to environmental factors. However, it is generally more expensive and may require specialized manufacturing processes, increasing overall costs.

Impact on Application: Aluminum binders are suitable for high-stakes environments, such as laboratories or manufacturing plants, where document integrity is paramount.

Considerations for International Buyers: Buyers in Europe may need to consider the aluminum’s compliance with EU regulations regarding metal recycling, while those in Africa should assess the availability of aluminum in local markets.

Summary Table of Material Selection for Top Loader Binders

| Material | Typical Use Case for Top Loader Binder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Office and educational settings | Lightweight and flexible | Less rigid under heavy loads | Low |

| PVC | Industrial and sensitive document storage | Excellent durability | Heavier and more expensive | Medium |

| Paperboard | Presentations and corporate settings | Eco-friendly and cost-effective | Less durable in harsh conditions | Low |

| Aluminum | Laboratories and manufacturing plants | High durability and corrosion resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used for top loader binders, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for top loader binder

What Are the Key Manufacturing Processes for Top Loader Binders?

The manufacturing of top loader binders involves several critical stages that ensure both functionality and durability. Understanding these processes can aid international B2B buyers in making informed purchasing decisions.

1. Material Preparation: What Materials Are Used in Top Loader Binders?

The first step in manufacturing top loader binders is selecting the right materials. Common materials include:

- Polypropylene (PP): Known for its durability and resistance to moisture, PP is often used for the binder cover.

- Cardboard or Chipboard: This material is typically used for the binder’s spine and gives it structure.

- Metal or Plastic Rings: Depending on the design, rings can be made of either metal or durable plastic, allowing for easy page turning.

The quality of raw materials directly affects the final product’s performance. Buyers should inquire about the source and specifications of these materials to ensure they meet their needs.

2. Forming: How Are Top Loader Binders Shaped and Assembled?

Once materials are prepared, the forming stage begins. This involves several techniques:

- Cutting: Materials are cut to size using precision machinery to ensure uniformity.

- Die-Cutting: For specific designs, die-cutting techniques are employed to create unique shapes and features.

- Heat Sealing or Welding: Heat is applied to edges of the plastic cover to seal them securely, ensuring durability and preventing wear.

Buyers should evaluate the machinery and techniques used by suppliers to ensure they align with modern manufacturing standards.

3. Assembly: What Assembly Techniques Are Commonly Used?

The assembly of top loader binders typically involves the following processes:

- Ring Insertion: Depending on the design, metal or plastic rings are inserted into the spine of the binder.

- Cover Attachment: The front and back covers are attached to the spine, often using adhesives or mechanical fasteners.

- Quality Inspection: Before moving to the finishing stage, a preliminary quality check is conducted to ensure that all components fit together correctly.

International B2B buyers should request information on assembly techniques to understand the level of craftsmanship involved.

4. Finishing: What Final Touches Are Applied to Top Loader Binders?

The final stage in the manufacturing process is finishing, which includes:

- Printing and Branding: Custom designs, logos, and information can be printed on the binder’s exterior.

- Surface Treatment: Binders may undergo surface treatments for enhanced aesthetics or durability, such as lamination or UV coating.

- Final Quality Control: A thorough inspection is conducted to ensure that the final product meets quality standards before packaging.

This stage is crucial for ensuring that the product not only functions well but also meets the buyer’s branding requirements.

How Is Quality Assurance Implemented in Top Loader Binder Manufacturing?

Quality assurance is vital in the manufacturing of top loader binders, ensuring that they meet both international standards and customer expectations. Here’s how it typically works.

Relevant International Standards: What Certifications Should B2B Buyers Look For?

International standards such as ISO 9001 are essential for ensuring that manufacturers maintain consistent quality. This certification indicates that a company adheres to a quality management system that enhances customer satisfaction through effective processes.

Additionally, industry-specific certifications may be relevant:

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards.

- API Standards: If the binders are intended for specialized applications, compliance with American Petroleum Institute standards may be necessary.

Buyers from regions like Africa, South America, the Middle East, and Europe should verify these certifications as a part of their supplier vetting process.

Key Quality Control Checkpoints: What Are the Critical Stages of Quality Inspection?

Quality control in top loader binder manufacturing involves several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are performed to catch defects early.

- Final Quality Control (FQC): A comprehensive check is conducted on finished products to ensure they meet all specifications and standards.

Buyers should discuss these checkpoints with suppliers to understand their quality assurance processes better.

Common Testing Methods: How Are Top Loader Binders Tested for Quality?

Testing methods for top loader binders often include:

- Durability Testing: Assessing the binder’s ability to withstand wear and tear.

- Load Testing: Determining the maximum weight the binder can hold without compromising its integrity.

- Environmental Testing: Evaluating the binder’s performance under various conditions, such as humidity and temperature fluctuations.

Understanding these testing methods can help buyers gauge the reliability of the binders they are considering.

How Can B2B Buyers Verify Supplier Quality Assurance?

Ensuring quality assurance in your supply chain is paramount for B2B buyers. Here are actionable steps to verify supplier QC:

1. Conduct Supplier Audits: What Should You Look For?

Performing supplier audits is an effective way to assess manufacturing capabilities. Look for:

- Compliance with international standards.

- Presence of a dedicated quality control team.

- Evidence of regular training and updates to quality control processes.

2. Request Quality Assurance Reports: What Information Should These Contain?

Request comprehensive quality assurance reports that detail:

- Results of IQC, IPQC, and FQC checks.

- Any non-conformance reports and corrective actions taken.

- Certification documents and testing results from recognized laboratories.

3. Utilize Third-Party Inspections: How Can They Enhance Your Confidence?

Engaging third-party inspection services can provide an unbiased view of the manufacturing process. These services typically offer:

- Pre-shipment inspections to ensure quality before delivery.

- Random sampling of products for testing and verification.

- Detailed reports on compliance with specified standards.

Conclusion: What Should B2B Buyers Keep in Mind?

Navigating the manufacturing processes and quality assurance measures for top loader binders is essential for B2B buyers. By understanding the various stages of manufacturing and implementing thorough quality checks, buyers can ensure they are investing in reliable and high-quality products. Engaging with suppliers who adhere to international standards and maintain transparent quality assurance practices is crucial for successful procurement, particularly for buyers from diverse markets such as Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘top loader binder’

In the realm of international B2B procurement, sourcing a reliable supplier for top loader binders requires a strategic approach. This guide serves as a practical checklist to help buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing these essential office supplies.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the top loader binders you need. Consider factors such as size, material, and capacity. Detailing these requirements will not only streamline your sourcing process but also help in communicating effectively with potential suppliers.

- Material Type: Decide whether you need plastic, vinyl, or other materials based on durability and cost.

- Size Variations: Identify the sizes that best fit your documents to avoid compatibility issues.

Step 2: Conduct Market Research

Understanding the market landscape is crucial before making any commitments. Research the various suppliers and manufacturers in your target regions to gauge pricing, quality, and availability.

- Compare Prices: Collect quotes from multiple suppliers to identify competitive pricing.

- Analyze Reviews: Look for feedback from other businesses that have sourced top loader binders to understand supplier reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Supplier Background: Investigate their history and experience in manufacturing top loader binders.

- Quality Assurance: Ensure they have quality control processes in place to maintain product standards.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers comply with international standards and certifications relevant to your region. This step is essential for mitigating risks associated with product quality and safety.

- ISO Certifications: Look for suppliers with ISO certifications that indicate adherence to quality management standards.

- Sustainability Credentials: For environmentally conscious buyers, check for certifications like FSC or recycled content claims.

Step 5: Request Samples

Before finalizing your order, request samples of the top loader binders. This allows you to assess the quality, design, and functionality firsthand.

- Evaluate Quality: Check for durability, the ease of inserting documents, and overall finish.

- Test Usability: Ensure the binders meet your practical needs, such as ease of opening and closing.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, enter into negotiations regarding pricing, delivery schedules, and payment terms. Clear communication is vital to ensure a smooth transaction.

- Discuss Minimum Order Quantities (MOQ): Understand the MOQ to align with your budget and storage capabilities.

- Payment Flexibility: Explore options for payment terms that best suit your financial planning.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order with a formal purchase agreement. Keep track of the delivery process to ensure that the binders arrive on time and meet the agreed specifications.

- Set Up Tracking: Request tracking information to monitor shipment progress.

- Inspect Upon Arrival: Check the products immediately upon receipt to address any discrepancies or damages.

By following this comprehensive checklist, international B2B buyers can effectively source top loader binders that meet their organizational needs while ensuring quality and compliance.

Comprehensive Cost and Pricing Analysis for top loader binder Sourcing

What Are the Key Cost Components in Top Loader Binder Sourcing?

When sourcing top loader binders, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of materials used directly impacts the binder’s durability and appearance. Common materials include polypropylene, PVC, and paperboard, each varying in price based on quality and sourcing location.

-

Labor: Labor costs fluctuate significantly based on geographical location. For instance, manufacturing in regions with lower labor costs, such as parts of Southeast Asia, can reduce overall expenses.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, maintenance, and administrative expenses. Overhead can vary widely based on the efficiency of the production process and local economic conditions.

-

Tooling: Custom tooling may be necessary for unique binder designs or specifications. This is a one-time cost but can be substantial depending on complexity.

-

Quality Control (QC): Ensuring product quality is essential, especially for international buyers concerned with standards. QC processes add to the cost but are vital for maintaining product consistency.

-

Logistics: Shipping costs can be significant, particularly for international shipments. Factors influencing logistics costs include distance, shipping method, and any tariffs or duties applicable to the destination country.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary based on market demand, competition, and the supplier’s financial health.

How Do Price Influencers Impact Top Loader Binder Costs?

Several factors can influence the pricing of top loader binders, which international B2B buyers should consider:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Understanding the minimum order quantities (MOQs) can help negotiate better pricing.

-

Specifications and Customization: Tailoring binders to specific needs, such as size or design, can increase costs. However, customized products can also differentiate a buyer’s offerings in the market.

-

Materials: The choice of materials not only affects durability but also cost. Eco-friendly materials may be more expensive but can appeal to sustainability-focused markets.

-

Quality and Certifications: Products that meet specific quality standards or certifications may command higher prices. These certifications can be critical for compliance in certain regions.

-

Supplier Factors: The supplier’s reputation, reliability, and location can all impact pricing. Established suppliers with a track record of quality may charge more but can reduce risks associated with sourcing.

-

Incoterms: Understanding Incoterms is essential for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost of the binders.

What Are the Best Buyer Tips for Cost-Efficiency in Top Loader Binder Sourcing?

To maximize cost-efficiency when sourcing top loader binders, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if placing large orders. Leveraging multiple supplier quotes can create competitive pricing opportunities.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider shipping, handling, potential tariffs, and the longevity of the product. A higher upfront cost may lead to savings over time if the product lasts longer.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, trade tariffs, and local economic conditions that may affect pricing. Establishing long-term relationships with suppliers can also lead to better pricing agreements.

-

Research Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local manufacturers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

-

Sustainability Considerations: As global demand for sustainable products increases, sourcing from suppliers who prioritize eco-friendly practices can enhance brand reputation and market appeal.

Disclaimer on Indicative Prices

Prices for top loader binders can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and engage with multiple suppliers to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing top loader binder With Other Solutions

When considering a top loader binder for document management or presentation needs, it’s essential for B2B buyers to explore alternative solutions that may offer different benefits or drawbacks. This comparison will help international buyers, particularly those from Africa, South America, the Middle East, and Europe, make informed decisions tailored to their specific operational requirements.

Comparison Table of Document Management Solutions

| Comparison Aspect | Top Loader Binder | Ring Binder | Digital Document Management System |

|---|---|---|---|

| Performance | High durability; protects documents from wear and tear | Moderate; documents can shift or fall out | Very high; allows for easy search and retrieval |

| Cost | Generally low to moderate | Low; economical option | Higher initial investment; ongoing costs for software maintenance |

| Ease of Implementation | Simple; requires no special skills | Very simple; widely understood | Requires training for effective use |

| Maintenance | Minimal; occasional cleaning | Low; needs periodic checks | Moderate; requires updates and data management |

| Best Use Case | Ideal for physical presentations and archival storage | Suitable for everyday office use | Best for organizations with extensive digital workflows |

What Are the Advantages and Disadvantages of Using a Ring Binder?

Ring binders serve as a classic alternative to top loader binders. They are typically more cost-effective and allow for easy addition and removal of pages. However, they may not offer the same level of protection against wear and tear, and documents can shift or fall out if not handled properly. This makes them less suitable for high-stakes presentations or archival purposes, where document integrity is crucial.

How Does a Digital Document Management System Compare to a Top Loader Binder?

Digital Document Management Systems (DMS) provide a modern solution for document handling, offering robust features such as searchability, cloud storage, and collaboration tools. While they excel in performance and efficiency, the initial setup cost can be significant, and they require ongoing maintenance and user training. For organizations transitioning to digital workflows, investing in a DMS can yield long-term savings and improved productivity, but it may not be suitable for companies that still rely heavily on physical documents.

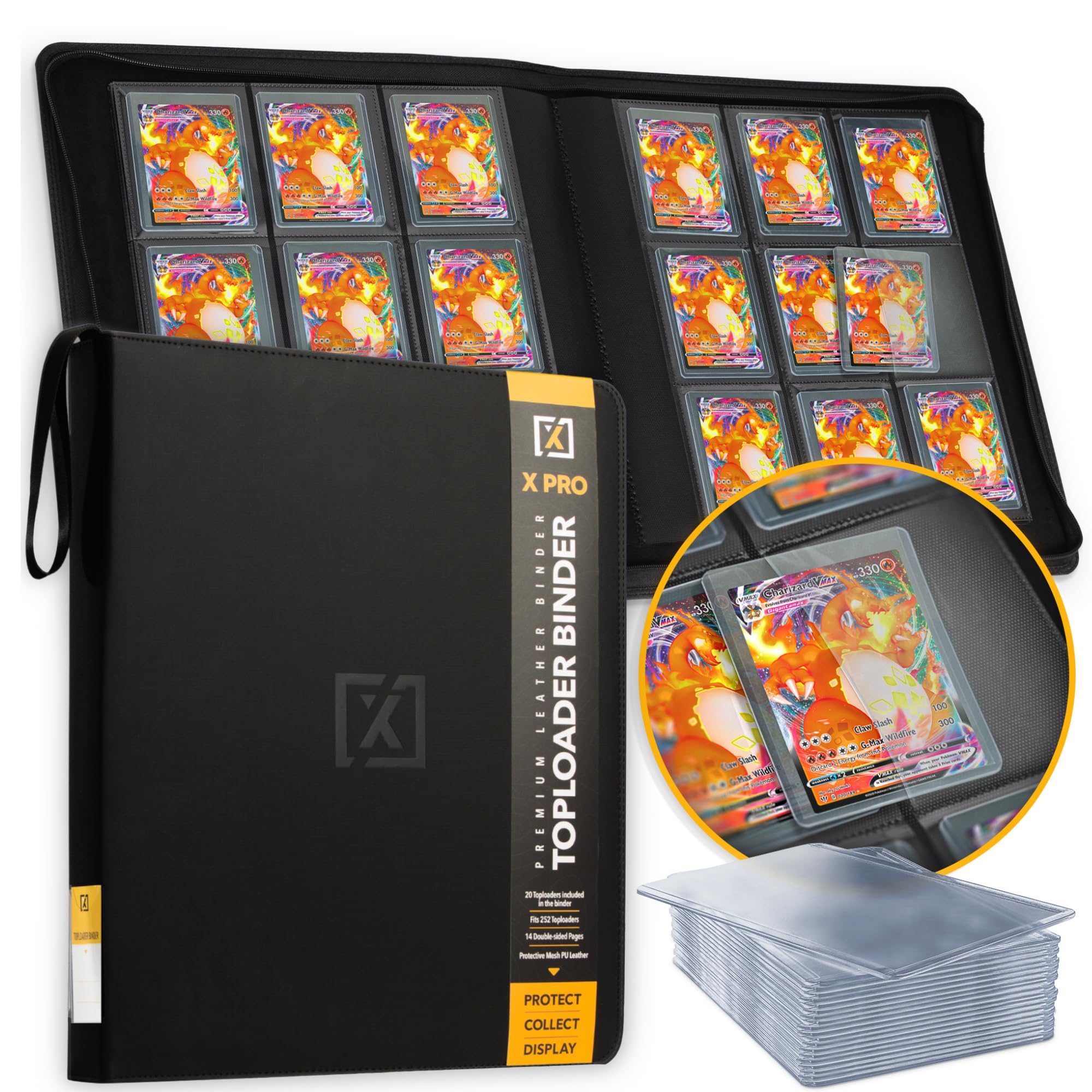

A stock image related to top loader binder.

Why Should Buyers Consider Each Alternative Based on Their Needs?

For B2B buyers, the choice between a top loader binder, ring binder, or a digital document management system should hinge on specific operational needs. If the primary focus is on physical presentations and document protection, a top loader binder may be the best option. Conversely, for businesses looking for a cost-effective, everyday solution, ring binders could suffice. However, companies aiming for efficiency and digital transformation should consider the benefits of a DMS, despite the higher initial investment.

Conclusion: How Can B2B Buyers Select the Right Document Management Solution?

In conclusion, selecting the right document management solution involves assessing the unique needs of your organization. Consider factors such as budget, the volume of documents, and the importance of digital versus physical access. By carefully weighing the pros and cons of top loader binders against alternatives like ring binders and digital systems, international B2B buyers can make decisions that enhance their operational efficiency and meet their specific requirements. Ultimately, the right choice will align with the company’s workflow and long-term goals, ensuring optimal document management practices.

Essential Technical Properties and Trade Terminology for top loader binder

What Are the Key Technical Properties of a Top Loader Binder?

Understanding the technical specifications of a top loader binder is crucial for B2B buyers seeking durable and efficient storage solutions. Here are several essential properties that should be considered:

1. Material Grade

The material used in the construction of a top loader binder often defines its durability and functionality. Common materials include polypropylene and PVC. Polypropylene offers a higher resistance to wear and tear, making it suitable for heavy usage environments. B2B buyers should assess the material grade to ensure that it aligns with their specific storage needs.

2. Capacity

Capacity refers to the number of sheets a binder can hold, typically ranging from 100 to 500 sheets. This specification is critical for businesses that require extensive documentation storage. Buyers should evaluate their document volume to select a binder that meets their capacity needs without compromising on organization.

3. Ring Mechanism

The ring mechanism is vital for the functionality of a top loader binder. Options include D-rings, O-rings, and 3-ring mechanisms, each offering different advantages in terms of sheet capacity and ease of use. D-rings, for instance, allow for a flatter storage profile and reduce the wear on sheets, which is essential for preserving important documents.

4. Tolerance

Tolerance refers to the acceptable range of variation in the binder’s dimensions. This property is crucial for ensuring that the binder fits standard sheet sizes, such as A4 or letter size, without any issues. Understanding tolerance is particularly important for international buyers who may encounter different paper sizes across regions.

5. Finish and Coating

The finish and coating of a top loader binder influence both its aesthetic appeal and functionality. Options may include matte or glossy finishes, which can enhance durability and resistance to stains. For businesses, selecting the right finish can also impact branding and presentation, especially in client-facing scenarios.

What Are Common Trade Terms Related to Top Loader Binders?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some key trade terms relevant to top loader binders:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed by another company under its own brand. In the context of top loader binders, understanding OEM relationships can help buyers source products that meet specific standards or specifications without compromising on quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers who need to manage inventory and budget constraints. Understanding the MOQ can aid in negotiating favorable terms with suppliers while ensuring that they meet their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific quantities of products. For buyers in Africa, South America, the Middle East, and Europe, issuing an RFQ for top loader binders can streamline procurement processes and facilitate competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers understand shipping responsibilities, risk management, and cost allocation, ensuring smoother cross-border transactions for top loader binders.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. It is a critical factor for B2B buyers who must plan their operations around inventory availability. Knowing the lead time for top loader binders can assist businesses in managing their supply chains effectively.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when purchasing top loader binders, ensuring they select products that best meet their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the top loader binder Sector

What Are the Current Market Dynamics and Key Trends in the Top Loader Binder Sector?

The global market for top loader binders is experiencing significant growth, driven by various factors, including increasing demand for organized documentation in both educational and corporate settings. Notably, regions like Africa, South America, the Middle East, and Europe are witnessing a surge in B2B transactions as businesses prioritize efficient document management solutions. The rise of remote work and digital collaboration tools has also heightened the need for physical documentation, enhancing the relevance of top loader binders as a reliable storage solution.

Emerging trends in sourcing indicate a shift towards digital procurement platforms, allowing buyers to streamline their purchasing processes. Platforms that facilitate direct communication with manufacturers are becoming increasingly popular, especially among international buyers. Additionally, the integration of Artificial Intelligence (AI) in supply chain management is enhancing forecasting accuracy, enabling businesses to better predict demand fluctuations and optimize their inventory.

For buyers in regions like Colombia and Vietnam, understanding local market dynamics is crucial. Factors such as currency fluctuations, trade agreements, and regional regulations can significantly impact pricing and availability. Engaging with local distributors can provide valuable insights into these dynamics and help mitigate risks associated with international sourcing.

How Are Sustainability and Ethical Sourcing Changing the Top Loader Binder Market?

Sustainability is no longer a secondary consideration but a central theme in the top loader binder sector. The environmental impact of production processes and materials is under scrutiny, pushing manufacturers to adopt more sustainable practices. Buyers are increasingly demanding products made from recycled materials and those that minimize waste during production.

Ethical sourcing is equally important, as businesses recognize the significance of transparency in their supply chains. Many manufacturers are now pursuing certifications that demonstrate their commitment to sustainable practices, such as FSC (Forest Stewardship Council) for paper products and ISO 14001 for environmental management. B2B buyers should prioritize suppliers who can provide proof of these certifications, ensuring that their sourcing aligns with corporate social responsibility goals.

Incorporating ‘green’ materials in top loader binders, such as biodegradable plastics or recycled paper, not only enhances brand reputation but also appeals to a growing segment of eco-conscious consumers. By aligning procurement strategies with sustainability goals, international buyers can foster a positive brand image while contributing to global environmental efforts.

What Is the Brief Evolution of the Top Loader Binder Market?

The top loader binder has evolved significantly since its inception, primarily as a response to changing organizational needs. Initially designed for academic use, these binders have transcended their original purpose to become essential tools in various industries, including finance, healthcare, and legal sectors.

Over the years, advancements in materials and design have enhanced the functionality and durability of top loader binders. The introduction of features such as customizable covers, enhanced protective sleeves, and eco-friendly materials reflects the industry’s adaptability to consumer demands and environmental considerations. As the market continues to evolve, staying abreast of these changes is vital for international B2B buyers looking to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of top loader binder

-

How can I ensure the quality of top loader binders from international suppliers?

To ensure quality, start by requesting samples from potential suppliers. This allows you to assess the material, durability, and overall construction of the binders. Additionally, inquire about the supplier’s quality assurance processes, certifications, and whether they adhere to international quality standards. Conducting factory audits or third-party inspections can also provide insights into their production practices. Finally, consider establishing a clear quality agreement to outline your expectations. -

What is the best material for top loader binders for long-term use?

Polypropylene and PVC are among the best materials for top loader binders, offering durability and resistance to wear and tear. Polypropylene is lightweight and flexible, making it an excellent choice for frequent handling. PVC, while heavier, provides a more rigid structure and is often more water-resistant. Assess your specific needs, such as climate conditions and usage frequency, to choose the most suitable material for your binders. -

What are the typical minimum order quantities (MOQs) for top loader binders?

Minimum order quantities for top loader binders vary by supplier and can range from 100 to several thousand units. Factors influencing MOQs include production capacity, material availability, and customization options. When sourcing, it’s essential to communicate your needs clearly and negotiate MOQs that align with your purchasing strategy. Some suppliers may offer flexibility, especially for repeat orders or long-term partnerships. -

How can I negotiate favorable payment terms with international suppliers?

To negotiate favorable payment terms, start by establishing a strong relationship with your supplier. Research industry standards for payment terms and be prepared to offer upfront payments or deposits if required. Consider using secure payment methods, like letters of credit or escrow services, to build trust. Flexibility in payment schedules can also be beneficial; for example, proposing partial payments upon shipment or delivery can ease cash flow concerns. -

What should I consider when customizing top loader binders for my brand?

When customizing top loader binders, consider design elements such as color, size, and branding options like logos or graphics. Ensure that your specifications align with the supplier’s capabilities and confirm any additional costs associated with customization. It’s also crucial to request prototypes or digital mock-ups before mass production to avoid costly mistakes. Finally, factor in lead times for custom orders, as they may differ from standard products.

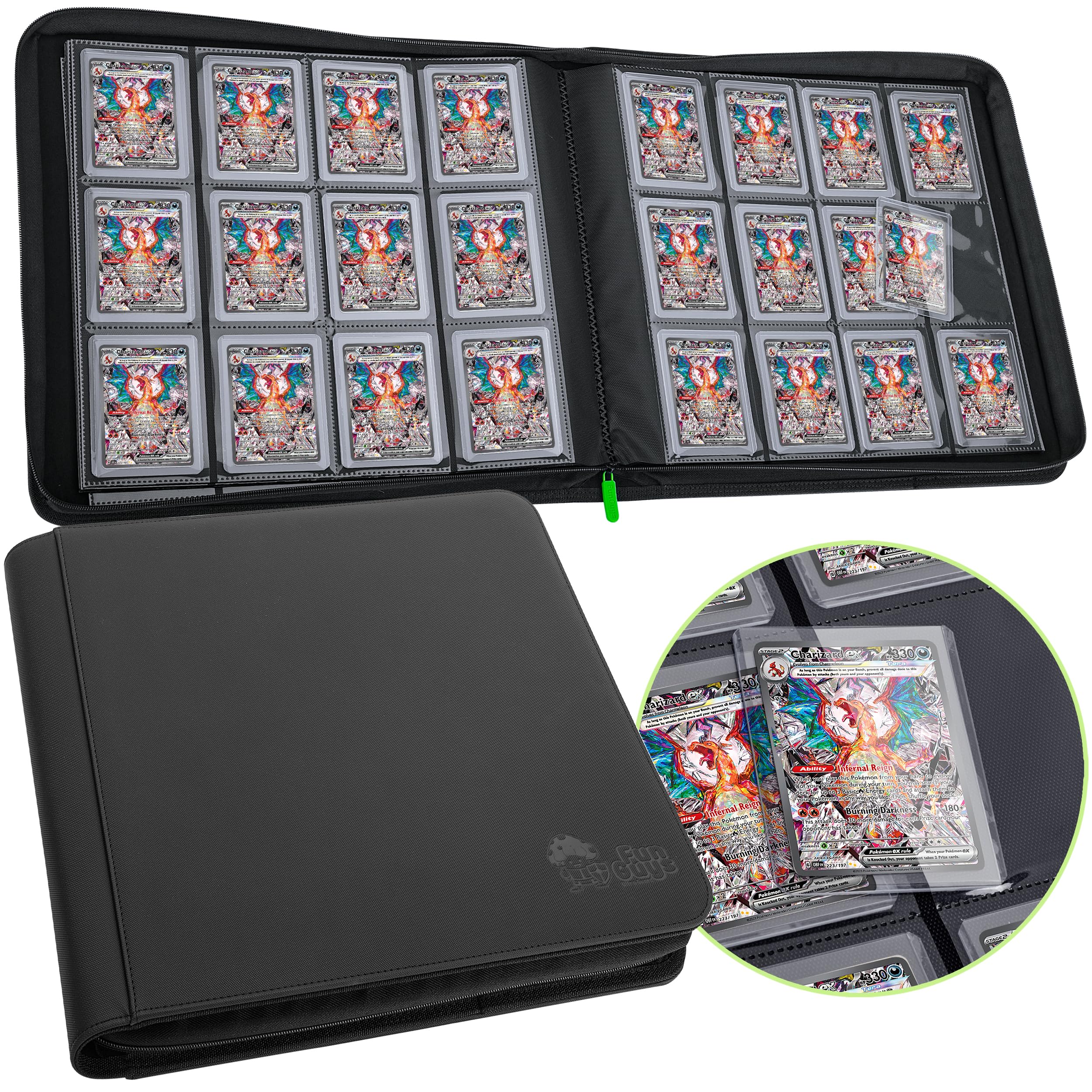

A stock image related to top loader binder.

- How do I vet potential suppliers for top loader binders?

Start by researching suppliers through platforms like Alibaba, Global Sources, or industry-specific trade shows. Check their credentials, including business licenses and certifications. Look for reviews and testimonials from previous clients, and request references to gauge reliability. Additionally, visiting the supplier’s facility can provide firsthand insight into their operations and quality control processes, ensuring they meet your standards.

A stock image related to top loader binder.

-

What logistics considerations should I keep in mind when sourcing top loader binders?

Logistics considerations include shipping methods, lead times, and import/export regulations specific to your country. Determine whether air freight or sea freight is more cost-effective for your order size and urgency. Familiarize yourself with customs requirements and tariffs that may apply when importing binders to your region. Working with a logistics provider experienced in international trade can help streamline the process and mitigate potential delays. -

How can I handle potential disputes with international suppliers?

To effectively handle disputes, start by maintaining clear and open communication with your supplier. Document all agreements, communications, and transactions to establish a clear record. If a dispute arises, attempt to resolve it amicably through negotiation. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Establishing a good rapport with suppliers can often prevent disputes from escalating.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for top loader binder

In conclusion, strategic sourcing for top loader binders presents a unique opportunity for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The key takeaway is the importance of aligning supplier capabilities with organizational needs to ensure both quality and cost-effectiveness. As you evaluate suppliers, consider factors such as material sustainability, customization options, and delivery reliability, which can significantly influence your procurement decisions.

How can buyers enhance their sourcing strategies for top loader binders? By fostering long-term partnerships with suppliers who demonstrate transparency and innovation, you can not only secure better pricing but also gain insights into market trends and new product developments. Furthermore, leveraging technology and data analytics can streamline the sourcing process, making it more efficient and responsive to changing demands.

Looking ahead, the global market for top loader binders is expected to grow as more businesses recognize their value in organizing and presenting documents effectively. As an international B2B buyer, now is the time to reassess your sourcing strategies and engage with suppliers who can help you stay ahead of the competition. Embrace this opportunity to optimize your procurement process and drive value for your organization.