Unlock Cost Savings: The Complete Anhydrous Milk Fat Guide (2025)

Introduction: Navigating the Global Market for anhydrous milk fat

As international B2B buyers delve into the complexities of sourcing anhydrous milk fat (AMF), they often encounter significant challenges that can impact their supply chains and product quality. Understanding the nuances of AMF—from its diverse applications in food processing to its pivotal role in dairy product formulation—is essential for making informed purchasing decisions. This comprehensive guide aims to equip buyers with crucial insights into the various types of anhydrous milk fat, their applications across multiple industries, and best practices for vetting suppliers effectively.

In the global market, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Colombia and Nigeria—the need for reliable sourcing options is paramount. This guide will explore critical factors influencing cost, quality, and regulatory compliance, enabling you to navigate the complexities of international trade with confidence.

By addressing key questions such as “What types of anhydrous milk fat are available?” and “How can I evaluate potential suppliers?”, this resource empowers businesses to make strategic decisions that align with their operational needs and market demands. With a focus on actionable insights, this guide is designed to help you optimize your sourcing strategy and achieve sustainable growth in a competitive landscape.

Understanding anhydrous milk fat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Anhydrous Milk Fat | Contains 99.8% fat content, derived from cream. | Confectionery, bakery, and dairy products | Pros: High fat content enhances flavor and texture. Cons: Limited shelf life without proper storage. |

| Organic Anhydrous Milk Fat | Sourced from organic-certified dairy farms, free from additives. | Premium food products and health-conscious brands | Pros: Appeals to health-conscious consumers. Cons: Higher cost compared to standard variants. |

| Butter Oil | Typically contains around 99% fat, with a butter flavor profile. | Chocolate coating, margarine production | Pros: Rich flavor enhances product taste. Cons: May not be suitable for all applications due to flavor. |

| Fractionated Anhydrous Milk Fat | Separates fatty acids for tailored functionality. | Specialty applications, such as spreads | Pros: Customizable properties for specific uses. Cons: More complex supply chain management. |

| Milk Fat Powder | Dehydrated form, can be reconstituted with water. | Dairy alternatives, nutritional supplements | Pros: Versatile and easy to store. Cons: Requires reconstitution, which may affect application efficiency. |

What are the characteristics of Standard Anhydrous Milk Fat?

Standard anhydrous milk fat is a concentrated dairy fat product with a fat content of approximately 99.8%. It is derived from the cream of milk through a process of evaporation, which removes moisture and non-fat solids. This type is widely used in the confectionery and bakery industries due to its ability to enhance flavor and texture in products like chocolates and pastries. When purchasing, buyers should consider storage conditions, as its shelf life can be limited without refrigeration.

How does Organic Anhydrous Milk Fat differ from Standard Variants?

Organic anhydrous milk fat is sourced from dairy farms that adhere to organic farming practices, ensuring that the milk is free from synthetic additives and pesticides. This variant caters to a growing market of health-conscious consumers and premium food brands. While its higher price point reflects its organic certification, buyers should evaluate their target market’s preferences, as the demand for organic products continues to rise, particularly in regions like Europe and North America.

What makes Butter Oil a preferred choice in certain applications?

Butter oil is another form of anhydrous milk fat that retains a distinct butter flavor, making it ideal for applications where a rich, buttery taste is desired, such as in chocolate coatings and margarine production. With a fat content of around 99%, it provides a creamy mouthfeel and enhances the overall sensory experience of food products. B2B buyers should consider the flavor profile of their end products when opting for butter oil, as its taste may not suit all formulations.

Why choose Fractionated Anhydrous Milk Fat for specialty applications?

Fractionated anhydrous milk fat is processed to separate its fatty acids, allowing for customization of its melting point and functional properties. This makes it suitable for specialty applications, such as spreads and high-performance food products. While its versatility can be a significant advantage, buyers must navigate a more complex supply chain to ensure consistent quality and functionality in their products.

What are the advantages of Milk Fat Powder in B2B applications?

Milk fat powder is a dehydrated form of anhydrous milk fat that can be easily reconstituted with water, making it a versatile ingredient in various applications, including dairy alternatives and nutritional supplements. Its long shelf life and ease of storage are key advantages for manufacturers. However, buyers should be aware that the reconstitution process may affect the efficiency of application, requiring careful consideration of the intended use in product development.

Related Video: Best and Worst Dairy (Milk Products) – Dr.Berg on Dairy Products

Key Industrial Applications of anhydrous milk fat

| Industry/Sector | Specific Application of Anhydrous Milk Fat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dairy Products Manufacturing | Cream cheese and butter production | Enhances creaminess and flavor, extending shelf life | Quality standards, supply chain reliability, cost |

| Confectionery | Chocolate and candy production | Improves texture and stability, reduces fat bloom | Consistency in quality, temperature control during transport |

| Bakery and Pastry | Cakes and pastries | Adds richness and moisture, improving product quality | Sourcing from certified suppliers, storage conditions |

| Food Service | Sauces and dressings | Provides a creamy texture, enhances mouthfeel | Compliance with food safety standards, bulk purchasing options |

| Nutraceuticals and Supplements | Health supplements and infant formulas | Offers a concentrated source of fat, beneficial for energy | Regulatory compliance, sourcing organic options, traceability |

How is Anhydrous Milk Fat Used in Dairy Products Manufacturing?

In the dairy sector, anhydrous milk fat (AMF) is primarily used in the production of cream cheese and butter. Its high-fat content contributes to the creaminess and flavor profile of these products, while also extending their shelf life by reducing moisture content. For international buyers, especially from regions like Africa and South America, it is crucial to ensure that the AMF sourced meets stringent quality standards and aligns with local dairy regulations to avoid disruptions in production.

What Role Does Anhydrous Milk Fat Play in Confectionery?

In confectionery, anhydrous milk fat is utilized to enhance the texture and stability of chocolates and candies. It helps reduce fat bloom, which is a common issue where fat separates and creates a dull appearance. Buyers in Europe and the Middle East should prioritize consistency in quality and ensure that their suppliers can maintain temperature control during transport, as AMF can be sensitive to temperature fluctuations.

How Does Anhydrous Milk Fat Benefit Bakery and Pastry Applications?

For bakery and pastry applications, anhydrous milk fat is valued for its ability to add richness and moisture to cakes and pastries. This contributes to a better mouthfeel and overall product quality, appealing to consumers seeking indulgent treats. Buyers, particularly in regions like Nigeria and Colombia, should focus on sourcing from certified suppliers who understand the importance of maintaining proper storage conditions to preserve product integrity.

In What Ways is Anhydrous Milk Fat Used in Food Service?

In the food service industry, anhydrous milk fat is commonly incorporated into sauces and dressings to provide a creamy texture that enhances the overall dining experience. This application is particularly relevant in high-end restaurants and catering services where quality is paramount. International buyers need to ensure compliance with food safety standards and consider bulk purchasing options to optimize costs and supply chain efficiency.

How is Anhydrous Milk Fat Important in Nutraceuticals and Supplements?

Anhydrous milk fat is increasingly used in the nutraceutical sector, particularly in health supplements and infant formulas, as it serves as a concentrated source of fat that is beneficial for energy. The sourcing of AMF for these applications requires adherence to regulatory compliance and a focus on traceability, particularly for buyers in Europe who may be subject to stringent health regulations. Additionally, sourcing organic options can enhance product appeal in health-conscious markets.

Related Video: The basic steps of milk production

3 Common User Pain Points for ‘anhydrous milk fat’ & Their Solutions

Scenario 1: Sourcing Quality Anhydrous Milk Fat in Emerging Markets

The Problem: International B2B buyers often face difficulties in sourcing high-quality anhydrous milk fat (AMF) due to inconsistent supply chains, especially in emerging markets like Nigeria and Colombia. This inconsistency can lead to fluctuations in product quality, impacting the end products they manufacture, such as confectionery or dairy products. Buyers may find themselves dealing with suppliers who do not meet the required standards, resulting in wasted resources and customer dissatisfaction.

The Solution: To ensure a reliable supply of quality AMF, buyers should conduct thorough market research before selecting suppliers. Look for suppliers with international certifications, such as ISO or HACCP, that demonstrate compliance with global food safety standards. Building a strong relationship with suppliers is crucial; consider establishing long-term contracts to secure stable pricing and consistent quality. Engage in regular quality audits and establish clear specifications for the AMF to be sourced, including parameters such as fat content and moisture levels. This proactive approach can help mitigate risks associated with sourcing.

Scenario 2: Understanding Regulatory Compliance for Anhydrous Milk Fat

The Problem: Navigating the regulatory landscape for food products can be daunting for B2B buyers, particularly when it comes to importing anhydrous milk fat across borders. Different regions, such as the Middle East and Europe, have varying regulations regarding food safety and labeling, which can complicate the importation process. Buyers may face delays, fines, or even product recalls if they do not comply with these regulations.

The Solution: To effectively manage regulatory compliance, it is advisable for buyers to familiarize themselves with the specific requirements of the target market. This includes understanding labeling regulations, permissible fat content, and any necessary certifications. Collaborating with a local food safety consultant or legal expert can provide invaluable insights into navigating these regulations. Additionally, maintaining an open line of communication with suppliers regarding compliance can prevent misunderstandings. Keeping abreast of changes in regulations through industry associations can also ensure ongoing compliance and avoid potential pitfalls.

Scenario 3: Managing Storage and Shelf Life of Anhydrous Milk Fat

The Problem: Anhydrous milk fat has a limited shelf life and requires specific storage conditions to maintain its quality. B2B buyers often struggle with managing inventory effectively, leading to spoilage or deterioration of the AMF. In regions with fluctuating temperatures, such as some parts of Africa and South America, ensuring the integrity of the product during storage and transport becomes a critical challenge.

The Solution: Implementing a robust inventory management system can significantly reduce waste and ensure optimal storage conditions for AMF. This includes utilizing temperature-controlled storage solutions that maintain the product within the recommended temperature range. Regular monitoring of inventory levels and expiration dates can help in planning purchases and minimizing overstock. Consider employing a first-in, first-out (FIFO) system to ensure older stock is used first. Additionally, educating staff on proper handling and storage practices can further enhance the longevity and quality of the anhydrous milk fat, ultimately contributing to better product consistency and customer satisfaction.

Strategic Material Selection Guide for anhydrous milk fat

When selecting materials for applications involving anhydrous milk fat (AMF), international B2B buyers must consider several factors, including properties, performance, and compliance with industry standards. Below is an analysis of common materials used in the production and handling of AMF, focusing on their key properties, advantages and disadvantages, and specific considerations for buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Anhydrous Milk Fat Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It is particularly suitable for food processing applications due to its non-reactive nature.

Pros & Cons: The durability of stainless steel makes it a preferred choice for long-term use, although it can be more expensive than other materials. Manufacturing complexity is moderate, as stainless steel requires specialized welding techniques. For AMF applications, stainless steel is highly suitable due to its ability to maintain product integrity without imparting flavors.

Impact on Application: Stainless steel is compatible with various media, including fats and oils, making it ideal for AMF processing and storage. However, buyers should consider the potential for pitting corrosion in chloride-rich environments.

Specific Considerations for International Buyers: Compliance with food safety standards like FDA or EU regulations is crucial. Buyers from regions like Nigeria and Colombia should ensure that the stainless steel used meets ASTM or DIN specifications.

How Does Aluminum Compare as a Material for Anhydrous Milk Fat?

Key Properties: Aluminum is lightweight and has good thermal conductivity, which can be beneficial in applications requiring efficient heat transfer.

Pros & Cons: While aluminum is generally less expensive than stainless steel, it is more susceptible to corrosion, especially in acidic environments. Its manufacturing process is simpler, allowing for cost-effective production. However, the lower durability compared to stainless steel may limit its use in certain applications.

Impact on Application: Aluminum’s compatibility with AMF is generally good, but its susceptibility to oxidation can affect product quality over time. This makes it less suitable for long-term storage.

Specific Considerations for International Buyers: Buyers in regions with high humidity, such as parts of South America, should be cautious of aluminum’s corrosion potential. Compliance with local food safety standards is also essential.

What Role Does Glass Play in Anhydrous Milk Fat Packaging?

Key Properties: Glass is inert, non-porous, and impermeable, making it an excellent choice for packaging food products.

Pros & Cons: Glass offers superior protection against contamination and is recyclable, aligning with sustainability goals. However, it is heavier and more fragile than other materials, which can lead to higher shipping costs and breakage during handling.

Impact on Application: Glass containers are ideal for short-term storage of AMF, preserving flavor and quality. However, they are not suitable for bulk transport due to weight and fragility.

Specific Considerations for International Buyers: Buyers in Europe may prefer glass for its sustainability benefits, while those in Africa may need to consider the cost implications of shipping heavier materials.

Why Is Polyethylene a Common Choice for Anhydrous Milk Fat?

Key Properties: Polyethylene is a versatile plastic known for its chemical resistance and lightweight nature.

Pros & Cons: It is cost-effective and easy to manufacture, making it a popular choice for packaging. However, polyethylene may not provide the same level of barrier protection as glass or metal, potentially affecting product shelf life.

Impact on Application: Polyethylene is suitable for short-term packaging of AMF but may not be ideal for long-term storage due to potential permeability issues.

Specific Considerations for International Buyers: Buyers should ensure that the polyethylene used complies with local food safety regulations. In regions like the Middle East, where temperatures can be high, the material’s heat resistance should also be considered.

Summary Table of Material Selection for Anhydrous Milk Fat

| Material | Typical Use Case for anhydrous milk fat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Processing equipment and storage tanks | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Heat exchangers and containers | Lightweight and cost-effective | Susceptible to corrosion | Medium |

| Glass | Packaging for retail distribution | Inert and recyclable | Heavy and fragile | High |

| Polyethylene | Short-term packaging | Cost-effective and lightweight | Limited barrier protection | Low |

This strategic material selection guide provides actionable insights for international B2B buyers in the anhydrous milk fat sector, ensuring they make informed decisions based on material properties, application impacts, and regional compliance considerations.

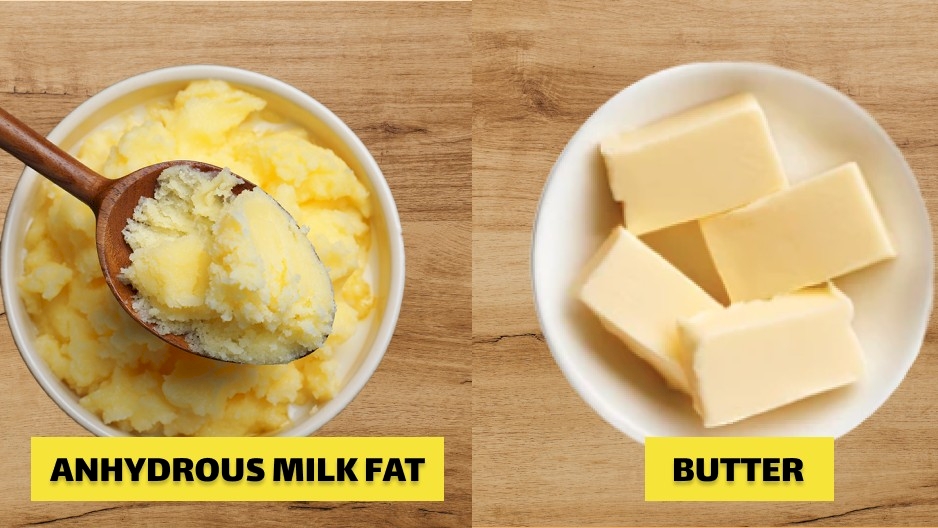

A stock image related to anhydrous milk fat.

In-depth Look: Manufacturing Processes and Quality Assurance for anhydrous milk fat

What Are the Main Stages in the Manufacturing Process of Anhydrous Milk Fat?

The manufacturing process for anhydrous milk fat (AMF) is a meticulous sequence of operations designed to ensure high-quality output. The main stages include:

-

Material Preparation: This initial stage involves sourcing high-quality milk, typically from dairy farms. The milk undergoes standardization to achieve desired fat content levels. This step is crucial as the quality of milk directly influences the final product’s flavor and texture.

-

Separation and Concentration: The standardized milk is subjected to centrifugal separation, which removes water and non-fat solids. This process can be performed at various temperatures and pressures to optimize the fat extraction. The resulting cream is then concentrated to increase the fat content.

-

Pasteurization: Following separation, the cream is pasteurized to eliminate pathogens and spoilage microorganisms. This step is vital for ensuring food safety and extending shelf life.

-

Churning: The concentrated cream is churned to facilitate the formation of butter granules. This process helps in the separation of buttermilk, leaving behind a high-fat content.

-

Dehydration: The next step involves the removal of residual moisture to achieve the desired anhydrous state. This can be accomplished through various methods, including vacuum drying or spray drying, where the cream is sprayed into a hot chamber to evaporate moisture rapidly.

-

Finishing and Packaging: Finally, the AMF is cooled and packaged in hygienic conditions to preserve its quality. Proper packaging is essential to prevent oxidation and contamination.

Which Key Techniques Are Used in the Production of Anhydrous Milk Fat?

The production of AMF employs several key techniques to ensure efficiency and quality:

-

Centrifugation: This technique is vital for separating fat from water and solids. Advanced centrifuges can optimize fat yield and purity.

-

Heat Treatment: Controlled heat treatment during pasteurization and dehydration is crucial for maintaining the functional properties of the fat while ensuring safety.

-

Homogenization: This process helps achieve a uniform fat globule size, enhancing the creaminess and mouthfeel of the final product.

-

Cold Storage: Maintaining a cold chain during storage and transportation is critical to preserving the quality of AMF, preventing rancidity, and extending shelf life.

What Are the Quality Assurance Practices for Anhydrous Milk Fat?

Quality assurance (QA) in the production of AMF is critical to meet international standards and ensure customer satisfaction. Key practices include:

-

Compliance with International Standards: Adhering to ISO 9001 standards is essential for ensuring a quality management system that consistently meets customer and regulatory requirements. Additionally, certifications such as CE mark and API standards may apply depending on the intended market.

-

Quality Control Checkpoints: Implementing a structured QA process involves several checkpoints:

- Incoming Quality Control (IQC): Assessing raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify deviations.

- Final Quality Control (FQC): Comprehensive testing of the final product before packaging to ensure it meets all quality standards.

What Testing Methods Are Commonly Used for Quality Assurance in Anhydrous Milk Fat?

Various testing methods are employed to ensure the quality and safety of AMF, including:

-

Chemical Analysis: Tests for fat content, moisture levels, and the presence of contaminants. Techniques like gas chromatography may be used for fatty acid profiling.

-

Microbiological Testing: Ensures that the product is free from harmful bacteria and pathogens, using methods such as plate counts and PCR (Polymerase Chain Reaction) testing.

-

Sensory Evaluation: Conducting taste tests to assess flavor, aroma, and texture, ensuring the product meets consumer expectations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities helps ensure compliance with quality standards and operational practices. This can include reviewing their QA processes and equipment.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including test results and certifications, to verify compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances in quality control when sourcing AMF:

-

Regulatory Compliance: Each region may have specific regulatory requirements for dairy products. Buyers should be familiar with local regulations to ensure compliance and avoid potential legal issues.

-

Cultural Preferences: Understanding regional preferences for flavor and texture can influence quality standards. For instance, preferences in taste may vary significantly between European and African markets.

-

Supply Chain Transparency: Establishing clear communication with suppliers about sourcing, manufacturing processes, and quality assurance practices can enhance trust and ensure product quality.

By focusing on these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing anhydrous milk fat, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘anhydrous milk fat’

Introduction

Navigating the procurement of anhydrous milk fat (AMF) can be complex, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. This guide aims to provide a clear, actionable checklist to streamline your sourcing process, ensuring you make informed decisions that meet your business needs.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is crucial for sourcing anhydrous milk fat. Consider aspects such as fat content, flavor profile, and intended applications (e.g., bakery products, confectionery, or dairy). This clarity helps in communicating your requirements effectively to potential suppliers, ensuring that the products meet your quality standards.

- Fat Content: Typical AMF contains around 99.8% fat. Specify any variations needed for your application.

- Flavor and Aroma: Depending on your product, you may require AMF with a specific flavor profile.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers of anhydrous milk fat. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. Focus on suppliers with a strong reputation in your target markets.

- Industry Networks: Join relevant industry groups on platforms like LinkedIn to gather insights and recommendations.

- Geographical Focus: Consider suppliers that are strategically located to minimize shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, a comprehensive evaluation is essential. Request detailed company profiles, including their production capabilities, certifications, and past client references. This step minimizes the risk of quality issues down the line.

- Certifications: Ensure suppliers have relevant certifications (e.g., ISO, HACCP) that guarantee product safety and quality.

- Client References: Ask for case studies or testimonials from clients in similar industries to gauge supplier reliability.

Step 4: Request Samples for Quality Assessment

Before finalizing any agreements, request samples of anhydrous milk fat from shortlisted suppliers. This allows you to assess the product quality firsthand, ensuring it meets your specifications and standards.

- Testing Procedures: Conduct sensory evaluations (taste, smell) and laboratory testing (fat content, microbiological safety) to validate quality.

- Comparison: Use samples from multiple suppliers to compare quality and performance in your specific applications.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to establish favorable terms. This includes pricing, delivery schedules, payment terms, and any guarantees related to product quality.

- Volume Discounts: Inquire about pricing structures based on order volumes to optimize costs.

- Delivery Terms: Ensure clarity on lead times and logistics to avoid disruptions in your supply chain.

Step 6: Establish a Robust Quality Assurance Process

Implement a quality assurance (QA) process post-purchase to monitor the quality of anhydrous milk fat received. This is vital for maintaining consistency in your final products and ensuring compliance with food safety regulations.

- Regular Audits: Schedule periodic audits of supplier practices and product quality.

- Feedback Loop: Maintain open communication with suppliers to address any quality issues promptly.

Step 7: Stay Informed on Market Trends

Finally, keep abreast of market trends affecting anhydrous milk fat, such as changes in regulations, pricing fluctuations, and innovations in production techniques. This knowledge can inform your future sourcing strategies and help you adapt to shifts in demand.

- Industry Reports: Subscribe to relevant industry publications and reports to stay updated.

- Networking: Attend industry conferences and webinars to connect with experts and gain insights into market dynamics.

By following this structured checklist, you can enhance your sourcing strategy for anhydrous milk fat, ensuring that you meet your quality requirements while optimizing costs and supplier relationships.

Comprehensive Cost and Pricing Analysis for anhydrous milk fat Sourcing

What Are the Key Cost Components of Anhydrous Milk Fat Sourcing?

When sourcing anhydrous milk fat (AMF), understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw milk, which is the primary ingredient for AMF, can vary significantly based on local dairy farming conditions, global milk prices, and seasonality. Buyers should closely monitor these fluctuations, especially in regions like Africa and South America where dairy farming may be influenced by climatic conditions.

-

Labor: This includes wages for workers involved in processing and production. In countries with lower labor costs, like Nigeria or Colombia, this component may be less significant compared to European suppliers, where labor costs can be higher.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to assess supplier capabilities in optimizing production.

-

Tooling: Investment in specialized equipment for processing AMF can impact pricing. Buyers should inquire about the supplier’s tooling capabilities and whether they can accommodate custom requirements.

-

Quality Control (QC): Ensuring product quality through rigorous testing and certifications adds to the cost. Buyers should prioritize suppliers that adhere to international quality standards, which may incur additional costs but result in higher quality products.

-

Logistics: Transportation costs can fluctuate based on distance, mode of transport, and fuel prices. For international shipments, factors like customs clearance and insurance also contribute to the overall logistics cost.

-

Margin: Suppliers typically build a profit margin into the final price. Understanding market dynamics and average margins within the AMF industry can aid buyers in negotiating better prices.

How Do Price Influencers Affect Anhydrous Milk Fat Pricing?

Several factors can influence the pricing of AMF, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on order volume. Bulk purchases can lead to significant cost savings, making it beneficial for buyers to strategize their procurement.

-

Specifications and Customization: Tailoring products to meet specific requirements can increase costs. Buyers should assess their needs and balance customization with budget constraints.

-

Materials and Quality Certifications: The source and quality of raw materials impact the price. Suppliers with higher-quality certifications may charge a premium, but this can lead to better product performance and reliability.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may command higher prices due to their proven track record, while new entrants may offer competitive rates to gain market share.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost of AMF. Buyers should understand terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to accurately calculate the total cost of ownership.

What Are the Best Buyer Tips for Sourcing Anhydrous Milk Fat?

To optimize sourcing strategies for anhydrous milk fat, international B2B buyers should consider the following tips:

-

Negotiation Strategies: Buyers should leverage their purchasing volume during negotiations to secure better pricing. Building long-term relationships with suppliers can also result in favorable terms.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership rather than just the purchase price. This includes considering logistics, potential wastage, and product longevity in applications.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, AMF sourced from Europe may be priced differently than that from Africa or South America due to varying labor and production costs.

-

Request Transparency: Ask suppliers for a detailed breakdown of costs. This transparency can help identify areas for negotiation and ensure that there are no hidden fees.

-

Stay Informed: Keep abreast of market trends and fluctuations in dairy prices. This knowledge can empower buyers to time their purchases effectively and negotiate better deals.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost and pricing structure for anhydrous milk fat, prices can vary widely based on market conditions, supplier capabilities, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and engage with multiple suppliers to obtain accurate pricing information tailored to their needs.

Alternatives Analysis: Comparing anhydrous milk fat With Other Solutions

Understanding Alternatives to Anhydrous Milk Fat

A stock image related to anhydrous milk fat.

In the food industry, particularly among international B2B buyers, understanding the alternatives to anhydrous milk fat (AMF) is crucial for making informed purchasing decisions. AMF is prized for its high fat content and versatility in various applications, but there are other viable solutions that can provide similar benefits depending on specific needs, regional preferences, and budget constraints. This section compares AMF with two notable alternatives: vegetable oils and margarine.

Comparison Table of Anhydrous Milk Fat and Alternatives

| Comparison Aspect | Anhydrous Milk Fat | Vegetable Oils | Margarine |

|---|---|---|---|

| Performance | High flavor, rich texture | Moderate flavor, variable quality | Balanced flavor, creamy texture |

| Cost | Higher cost | Generally lower cost | Moderate cost |

| Ease of Implementation | Requires specialized handling | Readily available, easy to incorporate | Easy to use, common in recipes |

| Maintenance | Requires careful storage | Minimal maintenance | Refrigeration needed |

| Best Use Case | Premium dairy products | Vegan products, frying | Spreads, baking, cooking |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Vegetable Oils?

Vegetable oils, such as palm, canola, or soybean oil, serve as a popular alternative to AMF. They are generally more affordable and widely available, making them an attractive option for manufacturers looking to cut costs. However, the flavor profile of vegetable oils can vary significantly based on the type of oil used, which may not always meet the specific taste requirements of certain applications. Additionally, the health implications of some vegetable oils, particularly those high in saturated fats, may deter health-conscious consumers.

How Does Margarine Compare to Anhydrous Milk Fat?

Margarine is another common substitute for AMF, especially in baking and cooking. It offers a creamy texture and a balanced flavor profile, making it suitable for a variety of culinary applications. Margarine is also typically less expensive than AMF, which can appeal to budget-conscious buyers. However, margarine often contains additives and preservatives that some consumers may wish to avoid. Additionally, its performance in certain high-end dairy applications may not match that of AMF, particularly when a rich, buttery flavor is desired.

Choosing the Right Solution for Your Business Needs

When selecting between anhydrous milk fat and its alternatives, B2B buyers must consider several factors, including performance requirements, budget limitations, and the specific needs of their target market. For applications demanding premium quality and flavor, AMF remains the top choice. However, if cost-efficiency is a priority or if catering to a vegan clientele, vegetable oils or margarine may be more appropriate. Ultimately, understanding these alternatives will empower international buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, to make informed decisions that align with their product goals and consumer expectations.

Essential Technical Properties and Trade Terminology for anhydrous milk fat

What Are the Key Technical Properties of Anhydrous Milk Fat?

Understanding the technical properties of anhydrous milk fat (AMF) is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some essential specifications:

-

Material Grade

– Definition: Material grade refers to the classification of AMF based on its quality, which is determined by its composition, purity, and processing methods.

– Importance: Higher-grade AMF typically exhibits superior flavor, aroma, and functional properties, making it more suitable for premium products. Buyers must ensure they are sourcing the correct grade to meet their product standards. -

Fat Content

– Definition: This indicates the percentage of fat present in the AMF, usually around 99% or higher.

– Importance: The fat content directly influences the texture, mouthfeel, and overall sensory attributes of food products. Understanding the required fat content is essential for product formulation, especially in dairy and bakery sectors. -

Melting Point

– Definition: The temperature at which AMF transitions from solid to liquid, typically ranging from 32°C to 35°C.

– Importance: The melting point affects how AMF behaves during processing and in finished products. Buyers need to consider this property to ensure compatibility with other ingredients and to achieve desired product characteristics. -

Moisture Content

– Definition: The amount of water present in AMF, which should ideally be less than 0.1%.

– Importance: High moisture content can lead to spoilage and affect the shelf life of AMF. Buyers must verify moisture levels to ensure product longevity and stability during storage and transport. -

Free Fatty Acids (FFA)

– Definition: The level of free fatty acids in AMF, which should generally be less than 0.5%.

– Importance: Elevated FFA levels can indicate poor quality or spoilage. Monitoring FFA is vital for maintaining product integrity and meeting regulatory standards.

What Are Common Trade Terms Used in Anhydrous Milk Fat Transactions?

Familiarity with trade terminology can enhance communication and negotiations in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: In the dairy industry, buyers may source AMF from OEMs that supply products tailored to their specifications, ensuring quality and compliance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding the MOQ is crucial for budget planning and inventory management, especially for international buyers looking to minimize costs while ensuring supply. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Relevance: Issuing an RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, which is essential for international transactions involving AMF. -

Shelf Life

– Definition: The length of time that AMF can be stored without becoming unsuitable for use.

– Relevance: Knowledge of shelf life helps buyers make informed decisions about storage, inventory turnover, and product freshness, which is vital for maintaining quality in the supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure high-quality anhydrous milk fat that meets their specific needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the anhydrous milk fat Sector

What Are the Key Market Dynamics and Sourcing Trends in the Anhydrous Milk Fat Sector?

The global anhydrous milk fat (AMF) market is witnessing significant growth driven by increasing demand for dairy products in emerging markets, particularly in Africa, South America, and the Middle East. With the rise of processed food consumption and the expansion of the bakery and confectionery sectors, AMF has become a key ingredient due to its rich flavor and functional properties. Notably, European countries are major exporters of AMF, leveraging advanced dairy processing technologies and stringent quality standards.

Emerging B2B technology trends are reshaping sourcing strategies. Digital platforms are facilitating direct connections between buyers and suppliers, allowing for better price transparency and enhanced negotiation capabilities. Additionally, automation in production processes is leading to improved efficiency and reduced lead times. Buyers are increasingly adopting data analytics to forecast demand accurately, helping them to maintain optimal inventory levels and reduce wastage.

International B2B buyers should be aware of fluctuating prices due to global supply chain disruptions and climatic impacts on dairy farming. Navigating these market dynamics requires continuous monitoring of market trends and flexibility in sourcing strategies, enabling buyers to adapt quickly to changing conditions.

How Does Sustainability Influence Ethical Sourcing in the Anhydrous Milk Fat Sector?

Sustainability is becoming a crucial factor for B2B buyers in the anhydrous milk fat sector. The environmental impact of dairy farming—ranging from greenhouse gas emissions to water usage—is prompting buyers to seek suppliers who prioritize sustainable practices. Ethical sourcing is not merely a regulatory requirement; it has transformed into a market differentiator that can enhance brand reputation and customer loyalty.

Buyers are encouraged to look for suppliers who have obtained ‘green’ certifications, such as the Rainforest Alliance or Organic certifications, which guarantee adherence to sustainable farming practices. These certifications often indicate that suppliers are committed to reducing their environmental footprint and promoting animal welfare.

Furthermore, the demand for transparency in supply chains is increasing, with buyers wanting to trace the origins of AMF to ensure it meets ethical standards. Collaborating with suppliers who engage in sustainable practices can also open up new market opportunities, as consumers increasingly favor brands that demonstrate corporate social responsibility.

What Is the Historical Context of Anhydrous Milk Fat in the B2B Marketplace?

The production of anhydrous milk fat has evolved significantly over the past century. Initially, AMF was primarily used for military purposes during World War II, as its extended shelf life made it an ideal food supply for troops. Post-war, the food industry began to recognize its versatility in various applications, leading to a surge in demand for AMF in the 1960s and 1970s.

By the late 20th century, advancements in dairy processing technologies allowed for the mass production of AMF, making it more accessible to food manufacturers. Today, AMF is a staple ingredient in the bakery, confectionery, and dairy industries, reflecting its transformation from a niche product into a key component of global food supply chains. Understanding this historical context is essential for B2B buyers to appreciate the evolving nature of the AMF market and its implications for sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of anhydrous milk fat

-

How can I ensure the quality of anhydrous milk fat from suppliers?

To guarantee the quality of anhydrous milk fat (AMF), it is crucial to conduct thorough supplier vetting. Request Certificates of Analysis (CoA) that confirm compliance with international standards and specifications. Additionally, consider third-party audits or quality certifications like ISO or HACCP. Establishing a trial order can also help assess product quality before committing to larger purchases. Regular communication with the supplier about quality control measures is essential to maintain standards. -

What are the typical payment terms for purchasing anhydrous milk fat internationally?

Payment terms can vary significantly depending on the supplier and the buyer’s negotiation power. Common options include letters of credit (LC), advance payment, or open account terms. It’s advisable to discuss payment terms upfront and ensure they are documented in the purchase agreement. For international transactions, using secure payment methods that offer buyer protection, such as PayPal or escrow services, can mitigate risks associated with foreign trade. -

What is the minimum order quantity (MOQ) for anhydrous milk fat?

Minimum order quantities for anhydrous milk fat can differ based on the supplier, production capacity, and shipping logistics. Generally, MOQs can range from 500 kg to several tons. It’s beneficial to discuss your needs directly with potential suppliers to negotiate MOQs that suit your purchasing strategy. Larger orders may also lead to better pricing, so consider your inventory needs and storage capabilities when placing orders. -

How do I find reputable suppliers of anhydrous milk fat?

Finding reputable suppliers involves several strategies. Start by attending industry trade shows and exhibitions, which can facilitate direct interactions with potential suppliers. Utilize online platforms like Alibaba or specialized B2B marketplaces. Conduct online research to read reviews and testimonials from other buyers. Networking with industry professionals and joining relevant associations can also provide valuable recommendations. -

What factors should I consider when customizing anhydrous milk fat for my business?

Customization of anhydrous milk fat can include variations in fat content, flavor profile, or packaging. When considering customization, assess your end product requirements and target market preferences. Collaborate closely with suppliers to discuss available options and any potential impacts on pricing and lead times. It’s also important to validate the customized product through quality testing to ensure it meets your specifications.

A stock image related to anhydrous milk fat.

-

How can I manage logistics when importing anhydrous milk fat?

Effective logistics management for importing anhydrous milk fat involves coordinating shipping, customs clearance, and storage. Work with a freight forwarder experienced in dairy products to navigate international shipping regulations. Ensure you have all necessary documentation, such as phytosanitary certificates and import permits. Planning for temperature-controlled storage is critical, as AMF needs to be kept at specific temperatures during transit to maintain quality. -

What are the common uses of anhydrous milk fat in various industries?

Anhydrous milk fat is widely used in the food industry, particularly in bakery products, confectionery, and dairy products. It serves as a flavor enhancer and provides a creamy texture. In the cosmetics and pharmaceuticals sectors, AMF is utilized for its emollient properties. Understanding the applications of AMF can help B2B buyers target specific markets and enhance product offerings. -

How can I evaluate the sustainability practices of my anhydrous milk fat supplier?

To evaluate the sustainability practices of suppliers, request information on their sourcing methods, environmental policies, and certifications related to sustainability. Look for suppliers who practice responsible dairy farming, waste management, and energy-efficient production processes. Engaging in direct conversations about their sustainability initiatives can provide insights into their commitment to environmentally friendly practices, which can be essential for aligning with your company’s values and objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for anhydrous milk fat

What are the Key Takeaways for Strategic Sourcing of Anhydrous Milk Fat?

As we conclude this guide on anhydrous milk fat, it is essential to emphasize the significance of strategic sourcing in enhancing supply chain efficiency and product quality. B2B buyers in regions such as Africa, South America, the Middle East, and Europe should prioritize establishing strong relationships with reliable suppliers who can provide consistent quality and competitive pricing. Understanding market dynamics, regulatory requirements, and logistical challenges is crucial for making informed purchasing decisions.

How Can B2B Buyers Prepare for Future Market Trends?

Looking ahead, the demand for anhydrous milk fat is expected to rise due to its applications in various food products and increasing consumer preferences for high-quality dairy alternatives. Buyers should remain agile and adaptable to market changes, leveraging data analytics to forecast trends and optimize procurement strategies. Engaging in collaborative partnerships and exploring innovative sourcing options will be vital to staying ahead in this competitive landscape.

What Steps Should You Take Next?

In summary, strategic sourcing is not just about cost savings but also about fostering quality and reliability in your supply chain. International B2B buyers are encouraged to take proactive steps in their sourcing strategies, ensuring they are well-prepared to meet the evolving demands of the market. Embrace these insights and elevate your sourcing practices to capitalize on the growing opportunities within the anhydrous milk fat sector.