Enhance Quality & Cut Costs with Auto Diecasting (2025)

Introduction: Navigating the Global Market for auto diecasting

In an increasingly competitive landscape, sourcing quality auto diecasting components can pose significant challenges for international B2B buyers. Understanding the nuances of the auto diecasting market, including different types and applications, is crucial for organizations looking to optimize their supply chains. This comprehensive guide aims to equip buyers from Africa, South America, the Middle East, and Europe, including regions like Australia and Germany, with the knowledge necessary to make informed purchasing decisions.

Throughout this guide, we will delve into essential aspects of auto diecasting, including the various types of diecasting processes such as high-pressure, low-pressure, and gravity diecasting, alongside their respective applications in industries like automotive, aerospace, and consumer goods. Additionally, we will explore effective strategies for vetting suppliers, ensuring that your partnerships are built on reliability and quality. Understanding the cost factors associated with auto diecasting, from material selection to production methods, will also be a focal point, helping you forecast budgets accurately and maximize ROI.

By addressing these critical areas, this guide empowers B2B buyers to navigate the global market confidently. Whether you’re seeking to enhance product quality, reduce lead times, or streamline procurement processes, the insights provided here will serve as a valuable resource in your journey toward successful auto diecasting sourcing.

Understanding auto diecasting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Pressure Die Casting | Utilizes high pressure to inject molten metal | Automotive components, consumer electronics | Pros: High precision, excellent surface finish. Cons: Higher initial cost, limited to non-ferrous metals. |

| Low-Pressure Die Casting | Employs lower pressure, allowing for thicker walls | Aerospace parts, machinery components | Pros: Better for thicker sections, reduced porosity. Cons: Slower production rate, less suitable for intricate designs. |

| Gravity Die Casting | Relies on gravity for metal flow, simpler setup | Heavy machinery, large automotive parts | Pros: Cost-effective, versatile for various metals. Cons: Lower precision, potential for surface imperfections. |

| Vacuum Die Casting | Uses vacuum to eliminate air pockets in the mold | High-performance automotive parts, medical devices | Pros: Superior material properties, reduced defects. Cons: More complex setup, higher costs. |

| Die Casting Alloys | Involves specific alloys designed for die casting | Electronics housings, automotive trim | Pros: Tailored properties for specific applications. Cons: Material costs can vary significantly. |

What Are the Characteristics and Suitability of High-Pressure Die Casting?

High-pressure die casting is characterized by the rapid injection of molten metal into a mold at high pressure, typically using non-ferrous metals like aluminum and zinc. This method is particularly suitable for mass production of complex parts, such as automotive engine blocks and intricate electronic housings. B2B buyers should consider the high initial investment in machinery and tooling, which can be offset by the high volume of parts produced. Quality control is crucial, as precision is paramount for parts that require tight tolerances.

How Does Low-Pressure Die Casting Differ in Applications and Benefits?

Low-pressure die casting operates at lower pressures, allowing for thicker wall sections and improved filling of larger molds. It is particularly beneficial for applications in the aerospace and heavy machinery sectors, where strength and durability are critical. B2B buyers should evaluate the slower production rates against the advantages of reduced porosity and enhanced structural integrity. This method is ideal for producing larger parts that require less intricate detail, making it a cost-effective choice for specific applications.

What Are the Key Advantages of Gravity Die Casting?

Gravity die casting is one of the simplest and most cost-effective methods, relying solely on gravity to fill the mold with molten metal. This method is well-suited for large parts in industries such as heavy machinery and automotive manufacturing. While it allows for a wide range of metals, B2B buyers should be aware that it may result in lower precision and potential surface imperfections. The setup costs are lower compared to high-pressure methods, making it an attractive option for businesses looking to minimize initial investment while still achieving reasonable production quality.

Why Choose Vacuum Die Casting for High-Performance Applications?

Vacuum die casting is a specialized technique that uses a vacuum to eliminate air pockets during the metal injection process, resulting in superior material properties and reduced defects. This method is ideal for high-performance applications, including automotive and medical device components, where reliability and precision are critical. B2B buyers should consider the complexity and higher costs associated with this method, as the benefits often justify the investment in applications where quality cannot be compromised.

What Role Do Die Casting Alloys Play in Industry Applications?

Die casting alloys are specifically formulated to enhance the performance of cast components. They are tailored for various applications, such as electronics housings and automotive trim, offering unique properties like improved strength and corrosion resistance. B2B buyers need to assess the material costs and the specific requirements of their projects, as the right alloy can significantly impact product performance and longevity. Understanding the nuances of different alloys is essential for making informed purchasing decisions in this competitive landscape.

Key Industrial Applications of auto diecasting

| Industry/Sector | Specific Application of Auto Diecasting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Components | High strength-to-weight ratio, improved fuel efficiency | Supplier reliability, adherence to automotive standards, lead times |

| Aerospace | Structural Components | Lightweight structures, enhanced safety features | Certification requirements, material specifications, global sourcing |

| Electronics | Housings for Electronic Devices | Enhanced thermal management, design flexibility | Precision manufacturing, surface finish quality, cost-effectiveness |

| Consumer Goods | Decorative and Functional Components | Aesthetic appeal, durability, and cost efficiency | Customization options, volume production capabilities, delivery timelines |

| Industrial Machinery | Gearboxes and Motor Housings | Increased operational efficiency, longevity | Material properties, compliance with industry standards, technical support |

How is Auto Diecasting Used in the Automotive Industry?

In the automotive sector, auto diecasting is primarily used to manufacture engine components such as cylinder heads and blocks. This process allows for the production of complex geometries with a high strength-to-weight ratio, contributing to improved fuel efficiency and performance. International B2B buyers, especially from regions like Europe and South America, must consider supplier reliability and adherence to strict automotive standards, ensuring that components can withstand rigorous testing and regulations.

What are the Applications of Auto Diecasting in Aerospace?

The aerospace industry leverages auto diecasting for creating lightweight structural components that are essential for aircraft safety and performance. These parts, such as brackets and housings, benefit from the precision and strength offered by diecasting, which helps reduce overall aircraft weight and improve fuel efficiency. Buyers in Africa and the Middle East should pay close attention to certification requirements and material specifications to ensure compliance with international aerospace standards.

How is Auto Diecasting Beneficial for Electronics Manufacturing?

In the electronics sector, auto diecasting is used to produce housings for various electronic devices, facilitating enhanced thermal management and design flexibility. This technique allows manufacturers to create intricate designs that accommodate modern electronic components while ensuring durability. B2B buyers from Europe and South America should prioritize precision manufacturing capabilities and surface finish quality to meet the demands of their product designs.

What Role Does Auto Diecasting Play in Consumer Goods?

Auto diecasting finds significant applications in the consumer goods industry, where it is utilized to create both decorative and functional components, such as kitchen appliances and furniture fittings. The process not only enhances aesthetic appeal but also provides durability and cost efficiency. Buyers in the Middle East and Africa should explore customization options and volume production capabilities, as these factors directly influence their market competitiveness.

How is Auto Diecasting Used in Industrial Machinery Production?

In industrial machinery, auto diecasting is crucial for manufacturing gearboxes and motor housings, contributing to increased operational efficiency and longevity of machinery. The high strength and precision of diecast parts help reduce wear and tear, leading to lower maintenance costs. B2B buyers from regions like South America and Europe should focus on material properties and compliance with industry standards when sourcing these components, as this ensures optimal performance in demanding applications.

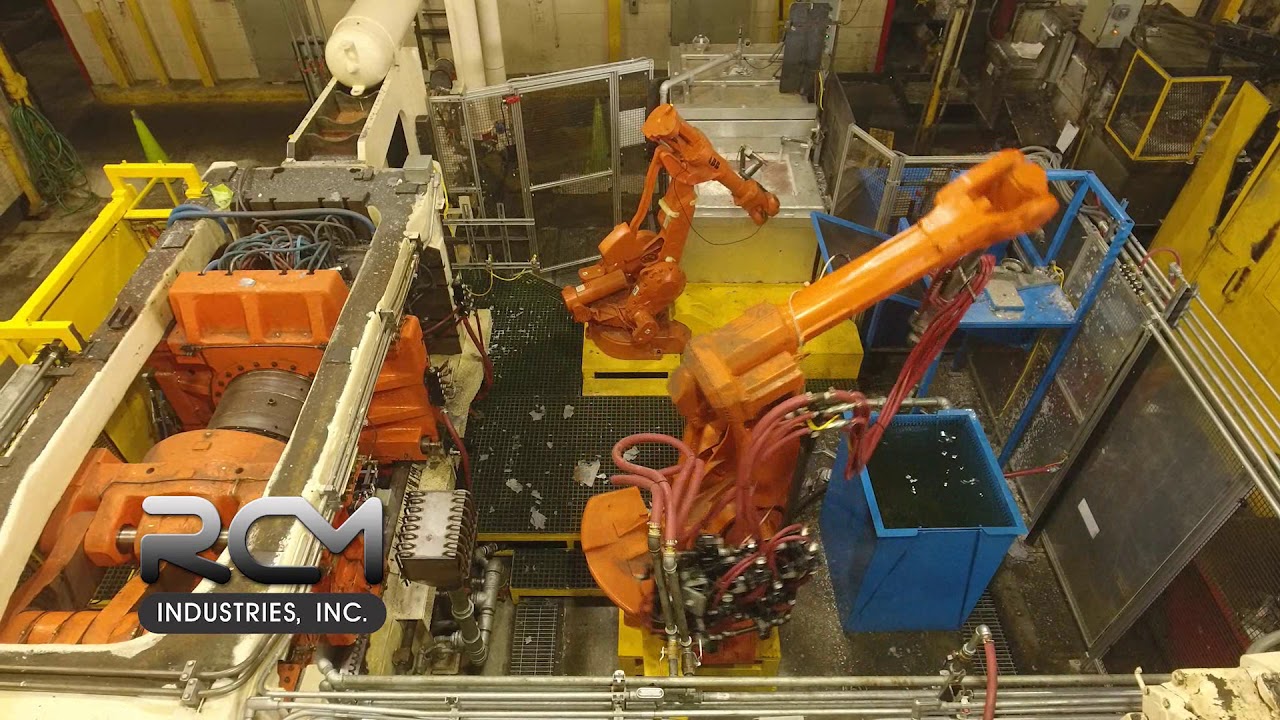

Related Video: How Pressure Die Casting is done | Die Casting process step by step | Labtech Industrial visit

3 Common User Pain Points for ‘auto diecasting’ & Their Solutions

Scenario 1: Inconsistent Quality of Diecast Components

The Problem: B2B buyers often face the challenge of inconsistent quality in diecast components, which can lead to production delays and increased costs. This inconsistency may arise from variations in raw materials, fluctuating manufacturing processes, or inadequate quality control measures at the foundry. For buyers in Africa and South America, where access to high-quality suppliers may be limited, the risk of subpar products can jeopardize the entire supply chain, impacting their reputation and profitability.

The Solution: To mitigate the risk of inconsistent quality, buyers should prioritize partnerships with certified suppliers who adhere to international quality standards, such as ISO 9001. Conducting thorough supplier audits and requiring certifications can help ensure that raw materials and production processes meet specific quality benchmarks. Implementing a robust quality assurance protocol, including regular inspections and testing of samples before full-scale production, can further safeguard against defects. Moreover, establishing clear communication channels with suppliers allows for immediate feedback and adjustments, fostering a collaborative relationship that prioritizes quality.

Scenario 2: High Production Costs Affecting Profit Margins

The Problem: Another significant pain point for B2B buyers in auto diecasting is the rising production costs that can erode profit margins. Factors such as energy costs, labor expenses, and the price of raw materials can fluctuate, particularly in regions like the Middle East and Europe, where economic conditions vary widely. Buyers may struggle to maintain competitive pricing while ensuring quality, leading to difficult decisions about sourcing and production methods.

The Solution: To combat high production costs, buyers should consider diversifying their supplier base and exploring options for nearshoring production to reduce shipping costs and lead times. Investing in automation and technology can also enhance efficiency, lowering labor costs and minimizing waste. Furthermore, negotiating long-term contracts with suppliers can lock in favorable pricing on materials and services. Buyers should also evaluate their production processes for areas where lean manufacturing principles can be applied, optimizing workflows and reducing waste to maximize profit margins.

Scenario 3: Difficulty in Customizing Diecast Parts for Diverse Applications

The Problem: Many B2B buyers encounter challenges when customizing diecast parts to meet the specific needs of different applications. This issue is particularly prevalent in industries such as automotive and aerospace, where precision and tailored designs are critical. Buyers may find that suppliers lack the capability to accommodate unique specifications, leading to delays and potential project failures.

The Solution: To address customization challenges, buyers should engage with suppliers who specialize in bespoke diecasting solutions. Communicating detailed design requirements and collaborating closely with engineers during the prototyping phase can ensure that the final product aligns with expectations. Utilizing advanced technologies such as CAD (Computer-Aided Design) and 3D printing for prototypes can facilitate rapid iterations and adjustments. Additionally, forming partnerships with design experts or consultants who understand diecasting intricacies can lead to innovative solutions tailored to specific industry needs. By proactively managing the design and manufacturing process, buyers can achieve the necessary customization without compromising on quality or timelines.

Strategic Material Selection Guide for auto diecasting

What Are the Key Properties of Aluminum in Auto Diecasting?

Aluminum is one of the most widely used materials in auto diecasting due to its excellent properties. It boasts a high strength-to-weight ratio, making it ideal for automotive applications where reducing weight is crucial for fuel efficiency. Aluminum diecastings can withstand temperatures up to 400°F (204°C) and pressures of about 10,000 psi, providing significant durability in demanding environments. Additionally, aluminum exhibits good corrosion resistance, which is vital for automotive components exposed to various weather conditions.

Pros & Cons of Aluminum in Auto Diecasting

The primary advantage of aluminum is its lightweight nature, which contributes to improved vehicle performance and fuel efficiency. It is also relatively easy to machine and can be cast into complex shapes, allowing for intricate designs. However, aluminum can be more expensive than other materials like zinc, and its lower tensile strength compared to some steels may limit its use in high-stress applications.

How Does Zinc Perform as a Material for Auto Diecasting?

Zinc is another popular material in the auto diecasting industry, particularly for smaller components. It offers excellent fluidity, making it suitable for casting intricate designs with fine details. Zinc diecastings can typically withstand temperatures up to 300°F (149°C) and pressures similar to aluminum, making them versatile for various applications.

Pros & Cons of Zinc in Auto Diecasting

Zinc’s primary advantage lies in its cost-effectiveness and ease of production. It is generally less expensive than aluminum and can be produced with a lower manufacturing complexity. However, its lower strength and higher density compared to aluminum can be a limitation for certain applications. Additionally, zinc has a lower corrosion resistance, which may necessitate additional surface treatments for components exposed to harsh environments.

What Are the Benefits of Magnesium in Auto Diecasting Applications?

Magnesium is an emerging material in the auto diecasting sector, known for its lightweight and high strength. It can withstand temperatures up to 300°F (149°C) and is particularly favored in applications where weight reduction is critical, such as in electric vehicles. Magnesium also offers good dimensional stability and is less prone to warping during the casting process.

Pros & Cons of Magnesium in Auto Diecasting

The key advantage of magnesium is its exceptional weight-to-strength ratio, making it ideal for applications where reducing weight is paramount. However, magnesium is more expensive than both aluminum and zinc, and its susceptibility to corrosion can be a significant drawback. Additionally, the manufacturing process for magnesium diecasting can be more complex, requiring specialized equipment and techniques.

What Considerations Should B2B Buyers Keep in Mind for International Standards?

When selecting materials for auto diecasting, international B2B buyers must consider compliance with various standards such as ASTM, DIN, and JIS. For instance, European buyers may prioritize materials that meet stringent environmental regulations, while buyers from Africa and South America may focus on cost-effectiveness and availability. Understanding regional preferences and standards is crucial for ensuring that the selected materials not only meet performance requirements but also align with regulatory frameworks.

Summary Table of Material Selection for Auto Diecasting

| Material | Typical Use Case for auto diecasting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, transmission housings | Lightweight with high strength-to-weight ratio | Higher cost than zinc, lower tensile strength | Medium |

| Zinc | Small intricate components, decorative parts | Cost-effective and easy to produce | Lower strength and corrosion resistance | Low |

| Magnesium | Lightweight automotive parts, electric vehicle components | Exceptional weight-to-strength ratio | More expensive, susceptible to corrosion | High |

In-depth Look: Manufacturing Processes and Quality Assurance for auto diecasting

What Are the Main Stages of the Auto Diecasting Manufacturing Process?

Auto diecasting is a sophisticated manufacturing process that involves several critical stages to produce high-quality components for the automotive industry. Understanding these stages can help international B2B buyers make informed decisions when sourcing parts.

Material Preparation: What Materials Are Used in Auto Diecasting?

The first step in the diecasting process is material preparation. Common materials used include aluminum, zinc, and magnesium alloys due to their lightweight and corrosion-resistant properties. For buyers, it is essential to verify that the chosen supplier uses high-grade materials that meet industry standards. This can be done by requesting material certifications and test reports that confirm compliance with relevant specifications.

How Is the Forming Stage Executed in Auto Diecasting?

The forming stage involves melting the metal and injecting it into a die at high pressure. This process typically uses two techniques: hot chamber diecasting and cold chamber diecasting. Hot chamber diecasting is suitable for low melting point metals, while cold chamber is preferred for high melting point alloys. Buyers should inquire about the technology used by suppliers, as it can significantly affect the quality and precision of the final product.

What Steps Are Involved in Assembly and Finishing?

After forming, components undergo assembly and finishing processes. Assembly may include machining, welding, or additional joining techniques, while finishing can involve surface treatments like anodizing or powder coating. Buyers should assess the supplier’s capabilities in these areas, as they can impact the overall aesthetics and durability of the components. Requesting samples or prototypes can be an effective way to evaluate quality before placing larger orders.

What Quality Assurance Measures Are Necessary in Auto Diecasting?

Quality assurance (QA) is paramount in the auto diecasting industry to ensure that components meet strict performance standards. International B2B buyers must understand the QA measures that suppliers implement.

Which International Standards Should B2B Buyers Look For?

Several international standards govern quality assurance in manufacturing. ISO 9001 is a widely recognized standard that focuses on quality management systems. Additionally, industry-specific certifications like CE marking for Europe and API for oil and gas components can be critical. Buyers should request copies of these certifications to ensure compliance with quality and safety regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential in the diecasting process to identify defects early. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to detect issues in real time.

- Final Quality Control (FQC): Conducting a thorough inspection of the finished product before shipping.

B2B buyers should inquire about the specific QC processes suppliers employ and request documentation of inspections and audits.

What Common Testing Methods Are Used in Auto Diecasting Quality Assurance?

Various testing methods are employed to ensure the quality of diecast components. Common tests include:

- Dimensional Inspection: Verifying that parts meet design specifications using calipers and gauges.

- Mechanical Testing: Assessing properties such as tensile strength and hardness through standardized tests.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspection help identify internal defects without damaging the part.

B2B buyers should ask suppliers about the testing methods they utilize and whether they can provide test reports as proof of quality.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing from international markets. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits help assess the supplier’s adherence to quality standards and processes. Buyers can perform these audits themselves or hire third-party firms.

-

Request Quality Reports: Suppliers should be able to provide detailed reports of their QC processes, including inspection results and certifications.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s capabilities and product quality.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers must be aware of specific nuances related to quality control and certification that can vary by region. For example:

-

Europe: Compliance with CE marking is essential for automotive components sold in the European market, indicating conformity with health, safety, and environmental protection standards.

-

Africa and South America: Buyers should consider the varying levels of certification and standards enforcement across countries. It’s advisable to conduct thorough research on local regulations and standards.

-

Middle East: The Gulf Cooperation Council (GCC) has specific standards for automotive components, and suppliers must comply with these to access the market.

-

Germany and Australia: These regions are known for stringent quality standards, so buyers should prioritize suppliers with recognized certifications and a proven track record.

Conclusion: Making Informed Decisions in Auto Diecasting Sourcing

Understanding the manufacturing processes and quality assurance measures in auto diecasting is crucial for international B2B buyers. By focusing on material quality, supplier capabilities, and adherence to international standards, buyers can mitigate risks and ensure they are sourcing high-quality components that meet their specific needs. Engaging in proactive supplier verification and maintaining clear communication throughout the sourcing process will further enhance product quality and supplier reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto diecasting’

This practical sourcing guide aims to equip international B2B buyers with a clear, actionable checklist for procuring auto diecasting services and products. As the demand for precision-engineered components continues to grow across industries, understanding the sourcing process is critical for making informed decisions that align with quality, cost, and supply chain efficiency.

Step 1: Define Your Technical Specifications

Before beginning your search for suppliers, it is essential to clearly outline your technical requirements. This includes understanding the dimensions, tolerances, and materials required for your diecasting components. Precise specifications help ensure that potential suppliers can meet your needs and reduce the risk of costly revisions later in the process.

- Considerations: What type of alloy is best suited for your application? Are there specific industry standards (e.g., ISO, ASTM) that must be adhered to?

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify potential suppliers specializing in auto diecasting. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. This step is crucial as it sets the foundation for your supplier selection process.

- Tip: Look for suppliers with a proven track record in your industry or similar applications, as this can greatly enhance reliability.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of your shortlisted suppliers to ensure they can deliver on your requirements. This involves reviewing their production processes, technologies, and capacity. A capable supplier should have advanced machinery and techniques that align with your technical specifications.

- Checklist Items:

- Do they have experience with high-volume production?

- Can they accommodate custom designs?

Step 4: ✅ Verify Supplier Certifications

Certifications are an important indicator of a supplier’s commitment to quality and compliance. Verify that potential suppliers hold relevant industry certifications, such as ISO 9001 or IATF 16949, which demonstrate adherence to quality management systems.

- Why This Matters: Certifications can assure you of consistent product quality and reliability, essential for maintaining your production standards.

Step 5: Request Samples and Prototypes

Before making a large commitment, it’s wise to request samples or prototypes of the diecast components. This allows you to evaluate the quality, finish, and precision of the products firsthand.

- Action: Assess whether the samples meet your specifications and quality expectations. This step can save you from potential issues in larger production runs.

Step 6: Negotiate Terms and Pricing

Once you have identified a preferred supplier, it’s time to discuss pricing and contract terms. Be transparent about your budget and expectations. Negotiating favorable terms can lead to better pricing, payment terms, and delivery schedules.

- Considerations: Are there bulk discounts available? What are the lead times for production?

Step 7: Establish Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your chosen supplier to discuss timelines, updates, and any potential issues.

- Best Practices: Regular check-ins can help manage expectations and ensure that both parties remain aligned throughout the project.

By following this step-by-step checklist, international B2B buyers can navigate the sourcing process for auto diecasting more effectively, ensuring they select the right suppliers to meet their production needs.

Comprehensive Cost and Pricing Analysis for auto diecasting Sourcing

What Are the Key Cost Components in Auto Diecasting?

Understanding the cost structure of auto diecasting is crucial for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The choice of alloy and its availability significantly impact pricing. Aluminum and zinc are common choices, but fluctuations in raw material prices can affect costs. Buyers should consider sourcing materials from regions with stable pricing to mitigate risks.

-

Labor: Labor costs vary widely by region. In developing countries, such as those in Africa and South America, labor may be less expensive, but the skill level can differ. Ensure that the workforce meets the necessary standards for quality assurance.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient operations can reduce overhead, making it essential to evaluate the supplier’s operational efficiency.

-

Tooling: The initial investment in tooling can be significant, especially for custom parts. Buyers should inquire about tooling costs upfront and consider whether these costs can be amortized over multiple orders to reduce the per-unit price.

-

Quality Control (QC): Implementing stringent QC processes adds to costs but is essential for maintaining product integrity. Buyers should assess a supplier’s QC certifications and practices to ensure compliance with international standards.

-

Logistics: Shipping costs, tariffs, and customs fees can add substantial amounts to the total cost. Understanding Incoterms and selecting the right shipping options can lead to significant savings.

-

Margin: Suppliers need to maintain a profit margin, which can vary by supplier and region. Understanding the competitive landscape will help buyers negotiate better terms.

How Do Price Influencers Impact Auto Diecasting Costs?

Several factors influence pricing in auto diecasting, which international buyers should consider when sourcing:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce the per-unit cost due to economies of scale. However, buyers must balance inventory costs with production needs.

-

Specifications and Customization: Custom parts require more time and resources, affecting pricing. Be clear about your specifications to avoid unexpected costs.

-

Material Choices: The choice between standard and premium materials can lead to significant price variations. Consider the trade-offs between cost and performance when selecting materials.

-

Quality and Certifications: Suppliers with ISO certifications or other quality assurances may charge higher prices. However, this can be a worthwhile investment in reliability and performance.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Engaging with multiple suppliers can provide a better understanding of market rates.

-

Incoterms: The terms of shipping and delivery can significantly impact overall costs. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will aid in budgeting accurately.

What Are the Best Negotiation Tips for International B2B Buyers?

Navigating the complexities of cost and pricing in auto diecasting can be challenging. Here are some actionable tips for international buyers:

-

Conduct Thorough Research: Understand the market rates and supplier capabilities before negotiations. This knowledge allows you to negotiate from a position of strength.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront costs but also long-term expenses, including logistics, quality assurance, and potential rework costs. A lower initial price may not always equate to better value.

-

Leverage Volume for Discounts: If possible, consolidate orders to meet or exceed MOQ thresholds. This strategy can lead to better pricing and terms.

-

Be Transparent About Your Needs: Clearly communicate your specifications, timelines, and budget constraints. This transparency can lead to more favorable terms and avoid misunderstandings.

-

Build Relationships with Suppliers: Long-term relationships can lead to better pricing and terms. Consider establishing partnerships with suppliers who demonstrate reliability and quality.

What Should International Buyers Keep in Mind Regarding Indicative Prices?

It’s essential to approach pricing with a critical eye. Prices can vary based on market conditions, currency fluctuations, and geopolitical factors. Always request updated quotes and be wary of indicative prices that may not reflect the final costs. Engaging in contracts with clear terms regarding price adjustments can safeguard against unexpected increases.

Alternatives Analysis: Comparing auto diecasting With Other Solutions

In the competitive landscape of manufacturing and metal forming, businesses often seek the most efficient and cost-effective methods to produce high-quality components. Auto diecasting is a prominent solution, but it is essential to consider alternative methods that may better fit specific operational needs. This section provides an analysis of auto diecasting in comparison to two viable alternatives: sand casting and investment casting.

Comparison Table of Auto Diecasting and Alternative Solutions

| Comparison Aspect | Auto Diecasting | Sand Casting | Investment Casting |

|---|---|---|---|

| Performance | High precision and surface finish | Moderate precision, rougher finish | Very high precision and intricate designs |

| Cost | Higher initial investment due to tooling | Lower setup costs, but higher labor costs | Moderate costs, but expensive for low volumes |

| Ease of Implementation | Requires specialized machinery | Easier setup with less specialized equipment | Complex process requiring skilled labor |

| Maintenance | Requires regular maintenance of machinery | Minimal maintenance needed | Regular maintenance of molds is essential |

| Best Use Case | High-volume production of complex parts | Low to medium volume, simpler shapes | Precision components with intricate details |

What Are the Pros and Cons of Sand Casting as an Alternative to Auto Diecasting?

Sand casting is a traditional method that involves creating a mold from sand and pouring molten metal into it. One of its primary advantages is the lower initial cost associated with setup, making it accessible for small to medium-sized businesses. Additionally, the flexibility of sand casting allows for the production of larger components compared to diecasting. However, the surface finish is generally rougher, which may necessitate additional machining processes. The method is also labor-intensive, potentially leading to higher operational costs over time.

How Does Investment Casting Compare to Auto Diecasting?

Investment casting, also known as lost-wax casting, offers exceptional precision and the ability to create complex shapes that are challenging for other methods. This technique is ideal for industries requiring highly intricate components, such as aerospace and medical devices. While the initial costs are moderate, investment casting can become expensive when producing low volumes due to the cost of molds and the labor involved. The production rate is slower compared to auto diecasting, which may be a significant disadvantage for businesses focused on high-volume outputs.

A stock image related to auto diecasting.

How Can B2B Buyers Choose the Right Solution for Their Needs?

A stock image related to auto diecasting.

When selecting the appropriate manufacturing method, B2B buyers should assess their specific requirements, including volume, complexity, and budget. Auto diecasting excels in high-volume production with intricate designs, making it suitable for industries like automotive and electronics. In contrast, sand casting may be more beneficial for projects with lower volumes or less complex shapes, while investment casting is best for precision components that require detailed engineering. Understanding these differences will enable buyers from Africa, South America, the Middle East, and Europe to make informed decisions that align with their production goals and operational capabilities.

Essential Technical Properties and Trade Terminology for auto diecasting

What Are the Key Technical Properties of Auto Diecasting?

Understanding the essential technical properties of auto diecasting is crucial for B2B buyers to ensure product quality and performance. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the specific type of alloy used in the diecasting process. Common materials include aluminum, zinc, and magnesium alloys. Each grade has unique properties such as strength, corrosion resistance, and weight, which can significantly affect the performance of the final product. For B2B buyers, selecting the right material grade is vital for meeting application requirements and ensuring durability in automotive parts.

2. Tolerance

Tolerance defines the allowable deviation from specified dimensions in the diecasting process. Precision in tolerance is essential for ensuring that parts fit and function correctly within larger assemblies. Typical tolerances in diecasting range from ±0.5 mm to ±1.5 mm, depending on the complexity and application of the part. For international buyers, understanding tolerance specifications helps in assessing quality and compatibility with existing components.

3. Surface Finish

Surface finish refers to the texture and smoothness of the diecast part after production. Common surface finishes include as-cast, shot-blasted, or anodized. A good surface finish is crucial for aesthetics and can also impact corrosion resistance and paint adhesion. For B2B buyers, specifying the desired surface finish is essential for achieving both functional and aesthetic requirements in automotive applications.

4. Weight

Weight is a critical factor in the automotive industry, where lighter components can improve fuel efficiency and reduce emissions. The choice of alloy and the design of the diecast part directly influence its weight. B2B buyers should prioritize lightweight materials without compromising strength and durability, aligning with modern automotive standards and regulations.

5. Mechanical Properties

Mechanical properties such as tensile strength, yield strength, and elongation are key indicators of how a material will perform under stress. Different alloys exhibit varying mechanical characteristics, which affect the performance and longevity of automotive parts. Understanding these properties helps B2B buyers evaluate material suitability for specific applications and operational conditions.

What Are Common Trade Terms in Auto Diecasting?

Familiarity with industry terminology is essential for effective communication and negotiation in the auto diecasting market. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles. B2B buyers often seek partnerships with OEMs to ensure quality and compatibility with existing systems. Understanding the role of OEMs is vital for sourcing reliable components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For international B2B buyers, understanding MOQ is crucial for budgeting and inventory management. Negotiating MOQ can help in optimizing supply chain efficiency and reducing costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products. This process is essential for comparing suppliers and ensuring competitive pricing. B2B buyers should prepare detailed RFQs to receive accurate and relevant quotations.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify shipping, insurance, and customs duties. For B2B buyers, understanding Incoterms is vital for managing risks and costs associated with international shipping.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the final product. It includes manufacturing and shipping times. For B2B buyers, being aware of lead times helps in planning and aligning production schedules, ensuring timely availability of components.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they select the right suppliers and materials for their auto diecasting needs.

Navigating Market Dynamics and Sourcing Trends in the auto diecasting Sector

What Are the Current Market Dynamics and Key Trends in the Auto Diecasting Sector?

The global auto diecasting market is witnessing significant growth, driven by increasing demand for lightweight automotive components and advancements in diecasting technology. Key factors propelling this market include the surge in electric vehicle (EV) production, which requires components that enhance performance while minimizing weight. Additionally, the automotive industry’s transition towards more sustainable practices is influencing sourcing strategies, particularly among international B2B buyers from Africa, South America, the Middle East, and Europe.

Emerging trends in the B2B landscape include the adoption of advanced manufacturing technologies, such as Industry 4.0 and automation, which enhance production efficiency and reduce operational costs. Buyers are increasingly leveraging digital platforms for sourcing, allowing for improved transparency and access to global suppliers. Furthermore, the integration of Artificial Intelligence (AI) in supply chain management is streamlining procurement processes, enabling real-time data analysis for better decision-making.

Another notable trend is the rise of localized sourcing as companies aim to mitigate supply chain risks exposed by recent global disruptions. This shift is particularly relevant for buyers in Africa and South America, where local suppliers are being prioritized to enhance resilience and responsiveness. Overall, understanding these dynamics is crucial for international B2B buyers to navigate the complexities of the auto diecasting market effectively.

How Is Sustainability Influencing Sourcing in the Auto Diecasting Sector?

Sustainability is rapidly becoming a critical factor in the auto diecasting sector, reflecting broader environmental concerns and consumer expectations. The environmental impact of traditional diecasting processes, which often involve high energy consumption and waste generation, has prompted a reevaluation of sourcing practices. For B2B buyers, adopting sustainable sourcing strategies not only aligns with corporate social responsibility goals but also enhances brand reputation and competitive advantage.

Ethical supply chains are gaining prominence, with buyers increasingly seeking suppliers that adhere to sustainable practices, such as reducing carbon footprints and implementing waste recycling initiatives. Certifications such as ISO 14001 for environmental management systems and the use of recycled materials are becoming essential criteria in supplier selection. Buyers from Europe, in particular, are leading the charge in demanding transparency and sustainability from their partners.

The rise of ‘green’ materials, including recyclable aluminum and other eco-friendly alloys, is reshaping the product offerings in the auto diecasting industry. By prioritizing suppliers who utilize these materials, international buyers can contribute to a circular economy and mitigate their environmental impact. In summary, integrating sustainability into sourcing strategies is not only an ethical obligation but also a strategic advantage for B2B buyers in the auto diecasting market.

A stock image related to auto diecasting.

What Is the Brief Evolution of Auto Diecasting and Its Relevance to B2B Buyers?

The evolution of auto diecasting can be traced back to the early 20th century when the process was first introduced for producing small, intricate parts. Over the decades, advancements in technology have significantly enhanced the efficiency and capabilities of diecasting, allowing for the production of complex components with high precision and minimal waste. The introduction of aluminum diecasting in the 1950s marked a turning point, as it enabled manufacturers to produce lightweight parts that are crucial for modern vehicle designs.

As the automotive industry has evolved, so too have the demands placed on diecasting processes. The shift towards electric vehicles and the need for sustainable practices are now at the forefront of the sector’s evolution. For B2B buyers, understanding this historical context is vital for making informed sourcing decisions. Recognizing the technological advancements and market shifts can help buyers identify suppliers who are not only capable of meeting current demands but are also aligned with future industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of auto diecasting

-

How do I choose the right auto diecasting supplier for my business needs?

Selecting the right auto diecasting supplier involves assessing their industry experience, technological capabilities, and quality certifications. Start by requesting samples to evaluate the quality of their castings. Check their production capacity to ensure they can meet your order volume and lead time requirements. Additionally, seek references from other clients in your region to gauge reliability and service levels. Finally, consider their ability to provide customization options to suit your specific project needs. -

What are the minimum order quantities (MOQs) for auto diecasting products?

Minimum order quantities can vary significantly based on the supplier and the complexity of the parts required. Typically, MOQs for auto diecasting range from 500 to several thousand units. It’s crucial to discuss your production needs with potential suppliers to understand their MOQ policies. If your order volume is lower than their standard MOQ, some suppliers may offer flexibility or suggest a prototype run, which can be a viable option for initial testing. -

What payment terms should I expect when sourcing auto diecasting components?

Payment terms in the auto diecasting industry can differ by supplier and region. Common arrangements include a deposit (usually 30-50%) upfront, with the balance due upon delivery or after inspection. Some suppliers may offer credit terms based on your business history and relationship with them. Always negotiate terms that are mutually beneficial and ensure they are clearly outlined in your contract to avoid disputes later. -

How can I ensure quality assurance in my auto diecasting orders?

To ensure quality assurance, begin by selecting suppliers who adhere to recognized quality standards, such as ISO 9001. Request detailed documentation of their quality control processes, including inspection reports and certifications. Consider implementing a third-party inspection service to verify product quality before shipment. Establishing clear specifications and conducting regular audits can also help maintain quality throughout the production process. -

What customization options are available in auto diecasting?

Auto diecasting offers a variety of customization options, including material selection, surface finishes, and part dimensions. Many suppliers can accommodate specific design modifications, whether for aesthetic purposes or functional enhancements. It’s important to communicate your requirements clearly and provide detailed drawings or CAD files. Collaborating with the supplier’s engineering team early in the design phase can help optimize the casting process for your unique needs. -

How do logistics and shipping impact my auto diecasting procurement?

Logistics play a critical role in the procurement process for auto diecasting products. Factors such as shipping methods, lead times, and customs clearance can affect delivery schedules and costs. When sourcing internationally, work closely with your supplier to select the most efficient shipping options. Consider using freight forwarders who specialize in handling industrial goods to streamline the process. Additionally, ensure compliance with international trade regulations to avoid delays. -

What are the common challenges faced in international auto diecasting sourcing?

Challenges in international auto diecasting sourcing may include language barriers, cultural differences, and varying quality standards. Additionally, navigating import/export regulations and tariffs can complicate procurement. To mitigate these issues, establish clear communication channels with your suppliers and consider partnering with local representatives who understand the market dynamics. Conducting thorough due diligence and maintaining flexibility in your sourcing strategy can also help address potential challenges. -

How can I stay updated on industry trends in auto diecasting?

Staying updated on industry trends involves engaging with trade associations, attending industry conferences, and subscribing to relevant publications. Networking with peers and suppliers can provide valuable insights into emerging technologies and best practices. Additionally, leveraging online resources, such as webinars and forums, can keep you informed about advancements in diecasting techniques and market shifts. Regularly reviewing case studies and success stories can also inspire innovation within your own operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for auto diecasting

In the rapidly evolving landscape of auto diecasting, strategic sourcing emerges as a critical component for B2B buyers aiming to enhance operational efficiency and competitiveness. By prioritizing relationships with reliable suppliers, businesses can ensure consistent quality and timely delivery of components essential for automotive production. Furthermore, leveraging global sourcing strategies allows companies to tap into diverse markets, potentially reducing costs while maintaining high standards.

What are the key trends shaping the future of auto diecasting? As we move forward, sustainability and technological advancements will play pivotal roles. Buyers should actively seek suppliers who are investing in eco-friendly practices and innovative diecasting technologies, such as 3D printing and automation, which can lead to significant improvements in production efficiency.

International B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to engage in strategic sourcing initiatives that align with their long-term business goals. By fostering partnerships with forward-thinking suppliers, companies can navigate market uncertainties and capitalize on emerging opportunities. Embrace the future of auto diecasting by making informed sourcing decisions today, positioning your business for success in an increasingly competitive global market.