Discover the Benefits of Drop in Auto Sear (2025)

Introduction: Navigating the Global Market for drop in auto sear

In today’s rapidly evolving global marketplace, sourcing a reliable drop in auto sear can pose significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying regulations, quality standards, and supplier capabilities, making informed purchasing decisions is essential for success. This guide aims to demystify the complexities surrounding drop in auto sears by exploring their types, applications, and the critical factors to consider when vetting suppliers.

The comprehensive nature of this guide will equip you with the knowledge needed to navigate the market effectively. We will delve into the various types of drop in auto sears, their specific applications across different industries, and key considerations for evaluating suppliers to ensure compliance with local regulations and quality expectations. Additionally, we will provide insights into pricing structures and potential cost-saving strategies, allowing you to optimize your procurement process.

By empowering B2B buyers with actionable insights and practical advice, this guide serves as a valuable resource for those looking to make strategic purchasing decisions. Whether you’re in Vietnam or Spain, understanding the nuances of drop in auto sears will enhance your ability to source high-quality products that meet your operational needs and drive business growth.

Understanding drop in auto sear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Drop-In Sear | Basic design, compatible with common firearm platforms. | Retail sales, law enforcement, military. | Pros: Easy installation, cost-effective. Cons: Limited customization options. |

| Adjustable Drop-In Sear | Features adjustable settings for rate of fire. | Tactical operations, competitive shooting. | Pros: Enhanced versatility, tailored performance. Cons: Higher cost, complexity in installation. |

| Modular Drop-In Sear | Interchangeable components for various firearms. | Custom firearm manufacturing, gunsmithing. | Pros: Customizable, long-term investment. Cons: Requires expertise for optimal use. |

| High-Reliability Drop-In Sear | Designed for extreme conditions and durability. | Military applications, extreme environments. | Pros: Enhanced reliability, robust performance. Cons: Typically more expensive. |

| Compact Drop-In Sear | Smaller size for use in compact firearms. | Concealed carry, personal defense. | Pros: Space-saving design, lightweight. Cons: May sacrifice some performance features. |

What Are the Characteristics of Standard Drop-In Sear?

The Standard Drop-In Sear is the most common type found in the market, designed for easy compatibility with various firearm platforms. It typically features a straightforward installation process, which is ideal for users looking for a quick upgrade or replacement. This type is widely used in retail sales and by law enforcement agencies due to its cost-effectiveness and reliability. However, buyers should consider that the lack of customization options might not meet the specific needs of advanced users.

How Does an Adjustable Drop-In Sear Enhance Performance?

An Adjustable Drop-In Sear offers users the ability to modify the rate of fire, making it a preferred choice for tactical operations and competitive shooting. This type allows for fine-tuning, catering to various shooting styles and preferences. While the enhanced versatility is a significant advantage, potential buyers should weigh the higher cost and the complexity involved in installation, which may require professional assistance.

What Makes Modular Drop-In Sear Suitable for Customization?

The Modular Drop-In Sear stands out due to its interchangeable components, allowing for extensive customization across different firearm types. This flexibility is particularly appealing to gunsmiths and custom firearm manufacturers who seek to tailor products to specific customer requirements. While this type can be a long-term investment, it necessitates a certain level of expertise for optimal assembly and use, which might deter less experienced buyers.

Why Choose a High-Reliability Drop-In Sear for Extreme Conditions?

Designed to withstand harsh environments, the High-Reliability Drop-In Sear is built for military applications and other extreme conditions. Its robust construction ensures consistent performance even under stress, making it invaluable for users who operate in challenging scenarios. However, the enhanced durability comes at a higher price point, which may be a consideration for budget-conscious buyers.

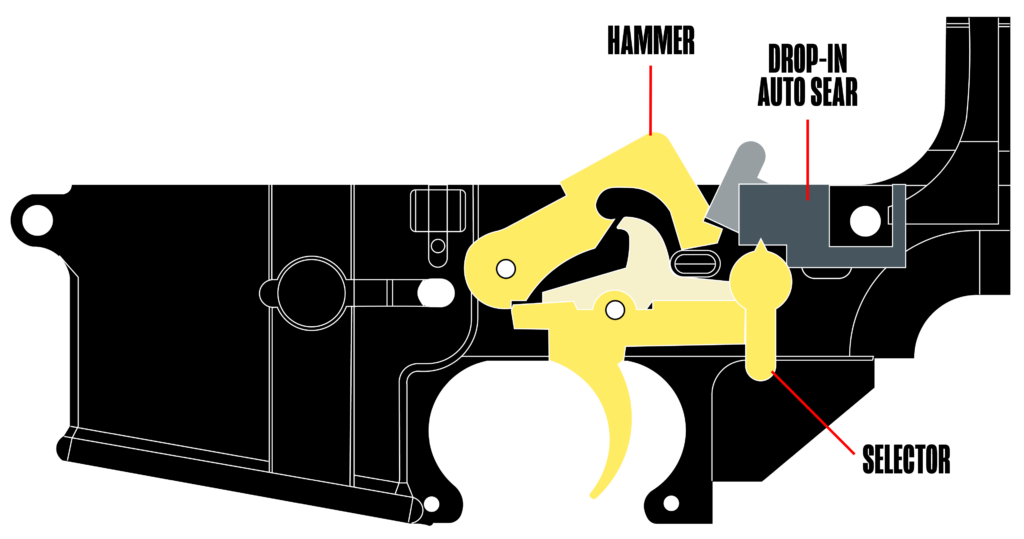

A stock image related to drop in auto sear.

What Are the Benefits of Compact Drop-In Sear for Concealed Carry?

The Compact Drop-In Sear is specifically designed for smaller firearms, making it an excellent option for concealed carry and personal defense. Its lightweight and space-saving design allow for easier handling and portability. Despite its advantages, buyers should be aware that opting for a compact model may mean sacrificing some performance features, which could affect overall shooting experience.

Related Video: Armament AK47 drop in auto sear MK3

Key Industrial Applications of drop in auto sear

| Industry/Sector | Specific Application of drop in auto sear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense and Military | Integration in firearms for rapid-fire capabilities | Enhances operational efficiency and firepower | Compliance with local and international regulations; reliability of suppliers |

| Security Services | Use in security personnel firearms for enhanced response | Improves response time in critical situations | Quality assurance; training for personnel on usage and maintenance |

| Law Enforcement | Adoption in police firearms for tactical operations | Increases effectiveness in high-stakes scenarios | Compatibility with existing equipment; sourcing from trusted manufacturers |

| Recreational Shooting | Installation in competitive shooting firearms | Enhances performance in competitions | Availability of technical support; adherence to safety standards |

| Manufacturing | Use in automated assembly lines for precision tasks | Boosts productivity and precision in manufacturing processes | Supplier reliability; ease of integration with existing machinery |

What are the Key Industrial Applications of Drop In Auto Sear?

How is drop in auto sear used in the Defense and Military sector?

In the defense and military sector, drop in auto sears are critical components that allow firearms to achieve rapid-fire capabilities. This modification enables soldiers to engage multiple targets quickly, enhancing combat effectiveness. International buyers must ensure that suppliers comply with stringent military regulations and standards, particularly in regions with strict arms control laws. The reliability of the sear is paramount, as any failure could jeopardize operational success.

What role does drop in auto sear play in Security Services?

Security services utilize drop in auto sears to modify firearms, providing personnel with enhanced response capabilities during emergencies. These modifications allow for quicker engagement of threats, which is vital in high-pressure situations. For international buyers, sourcing considerations should include the quality of the sear and the training provided for proper usage and maintenance, ensuring that all personnel can operate the modified firearms safely and effectively.

How does Law Enforcement benefit from drop in auto sear applications?

Law enforcement agencies adopt drop in auto sears to upgrade their firearms for tactical operations, allowing for rapid fire in critical incidents. This capability is essential for officers responding to violent situations, as it can provide a decisive advantage. Buyers from different regions should focus on compatibility with existing firearms and the reputation of manufacturers, as the reliability of these components directly impacts officer safety and operational success.

In what ways is drop in auto sear advantageous for Recreational Shooting?

In recreational shooting, particularly in competitive environments, drop in auto sears enhance the performance of firearms, allowing for faster follow-up shots and improved accuracy. Competitors benefit from the edge that these modifications provide, making them a popular choice in shooting sports. Buyers should consider the availability of technical support and ensure that the modifications adhere to safety standards to protect participants during events.

How does Manufacturing leverage drop in auto sear technology?

Manufacturers incorporate drop in auto sears in automated assembly lines to enhance precision in tasks that require rapid, repetitive actions. This technology boosts productivity by allowing machines to operate at higher speeds without sacrificing accuracy. For international buyers, reliability in sourcing and the ease of integration with existing machinery are crucial factors to consider, as these will influence overall production efficiency and quality.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘drop in auto sear’ & Their Solutions

Scenario 1: Sourcing Quality ‘Drop in Auto Sear’ Components

The Problem:

B2B buyers, particularly those in the firearms manufacturing sector, often face challenges in sourcing high-quality ‘drop in auto sear’ components. With numerous suppliers in the market, distinguishing between reputable manufacturers and subpar ones can be daunting. This is particularly true for buyers in regions like Africa and South America, where regulatory standards and product quality assurance may vary significantly. Inadequate sourcing can lead to costly production delays, compliance issues, and ultimately, a negative impact on brand reputation.

The Solution:

To overcome sourcing challenges, buyers should conduct thorough due diligence on potential suppliers. Start by verifying their certifications and adherence to industry standards. Engage in direct communication with suppliers to assess their understanding of quality control processes. Additionally, request samples for testing to evaluate the product’s performance and reliability. Establishing relationships with suppliers who have a proven track record in the industry can also help mitigate risks. Finally, consider attending international trade shows and industry conferences to connect with trusted manufacturers and gain insights into the latest advancements in ‘drop in auto sear’ technology.

Scenario 2: Navigating Regulatory Compliance for ‘Drop in Auto Sear’

The Problem:

International buyers frequently encounter regulatory hurdles when importing ‘drop in auto sear’ components, especially in regions with stringent firearm regulations like Europe and the Middle East. Understanding the legal implications of purchasing and using these components can be a complex process. Buyers may inadvertently violate import laws or fail to meet local safety standards, leading to severe legal repercussions and financial losses.

The Solution:

To navigate regulatory compliance effectively, B2B buyers should invest time in understanding the specific laws and regulations governing the use of ‘drop in auto sear’ in their target markets. Collaborating with legal experts or consultants who specialize in firearm legislation can provide valuable insights. Furthermore, buyers should ensure that their suppliers are compliant with relevant international standards and can provide documentation that verifies this compliance. Regular training sessions for procurement teams on regulatory updates can also keep the organization informed and prepared to adapt to any changes in legislation.

Scenario 3: Ensuring Compatibility with Existing Firearm Systems

The Problem:

One of the critical pain points for B2B buyers is ensuring that ‘drop in auto sear’ components are compatible with existing firearm systems. Discrepancies in specifications can lead to malfunctions, which not only pose safety risks but also result in costly product recalls and damage to the company’s reputation. Buyers often struggle to find reliable resources that provide detailed compatibility information for various firearm models.

The Solution:

To ensure compatibility, buyers should engage in thorough research before making a purchase. This includes consulting detailed technical specifications from both firearm manufacturers and ‘drop in auto sear’ suppliers. Developing a compatibility checklist that includes firearm models, sear specifications, and potential modifications can streamline the selection process. Additionally, buyers should leverage online forums and communities where industry professionals share their experiences and insights regarding compatibility issues. Collaborating with engineers or technical advisors during the product selection phase can also help in making informed decisions that prioritize safety and performance.

Strategic Material Selection Guide for drop in auto sear

When selecting materials for a drop-in auto sear, it’s crucial to consider the specific properties and applications of each material. Below, we analyze four common materials used in the manufacturing of drop-in auto sears, focusing on their key properties, advantages, disadvantages, and the implications for international B2B buyers.

What Are the Key Properties of Steel for Drop-in Auto Sear?

Steel is one of the most widely used materials in the production of drop-in auto sears. Its key properties include high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures. Steel can also be treated or alloyed to enhance its corrosion resistance.

Pros & Cons: The primary advantage of steel is its durability and strength, making it suitable for high-stress applications. However, it can be heavier than other materials and may require additional processing to improve corrosion resistance, which can increase manufacturing complexity and cost.

Impact on Application: Steel is compatible with various media and can perform well in both dry and lubricated environments. However, its susceptibility to rust may limit its use in humid or corrosive environments unless treated.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local environmental conditions that may affect steel performance. Compliance with standards such as ASTM A36 or DIN 17100 is also essential for ensuring quality.

How Does Aluminum Compare for Drop-in Auto Sear Applications?

Aluminum is another popular choice due to its lightweight nature and excellent corrosion resistance. It has a lower density compared to steel, which can be advantageous in applications where weight is a concern.

Pros & Cons: The main advantage of aluminum is its resistance to corrosion, which makes it suitable for outdoor applications. However, it has lower tensile strength than steel, which may limit its use in high-stress environments. Additionally, aluminum can be more expensive than steel, impacting overall production costs.

Impact on Application: Aluminum’s lightweight nature allows for easier handling and installation, but its lower strength may not be ideal for all applications, particularly those requiring high durability.

Considerations for International Buyers: Buyers in Europe, particularly in countries like Spain, should be aware of the common standards for aluminum alloys, such as EN AW-6061. Compliance with these standards ensures that the aluminum used meets performance expectations.

What Are the Benefits of Using Polymer Materials in Drop-in Auto Sear?

Polymers, such as nylon or polycarbonate, are increasingly used in the manufacturing of drop-in auto sears due to their excellent resistance to wear and corrosion. They are lightweight and can be molded into complex shapes, which can simplify manufacturing processes.

Pros & Cons: The primary advantage of polymers is their lightweight and corrosion-resistant properties. However, they may not withstand high temperatures as well as metals, potentially limiting their use in high-heat applications. Additionally, polymers can be less durable than metals, leading to a shorter lifespan.

Impact on Application: Polymers are suitable for applications where weight and corrosion resistance are more critical than high strength. They can perform well in various environments but may not be ideal for high-stress situations.

Considerations for International Buyers: Buyers should consider the specific polymer grades and their compliance with standards such as ASTM D638 for tensile properties. This ensures that the material meets the necessary performance criteria.

Why Is Stainless Steel a Preferred Material for Drop-in Auto Sear?

Stainless Steel offers excellent corrosion resistance and strength, making it a preferred choice for many applications, including drop-in auto sears. Its ability to withstand harsh environments while maintaining structural integrity is a significant advantage.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it suitable for outdoor and high-humidity environments. However, it can be more expensive than regular steel and may require specialized machining processes, increasing manufacturing complexity.

Impact on Application: Stainless steel performs well in a variety of conditions, including exposure to moisture and chemicals. Its strength ensures reliability in high-stress applications, making it a versatile choice.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades. This is particularly relevant for buyers in the Middle East, where environmental conditions can be challenging.

Summary Table of Material Selection for Drop-in Auto Sear

| Material | Typical Use Case for Drop-in Auto Sear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-stress applications | High durability and strength | Heavier, potential rust issues | Medium |

| Aluminum | Lightweight applications | Excellent corrosion resistance | Lower strength, higher cost | High |

| Polymer | Low-stress environments | Lightweight and corrosion-resistant | Lower durability, heat sensitivity | Low |

| Stainless Steel | Harsh environments | Excellent corrosion resistance | Higher cost, complex machining | High |

This guide provides a comprehensive overview of material options for drop-in auto sears, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for drop in auto sear

What Are the Key Stages in the Manufacturing Process of a Drop-In Auto Sear?

The manufacturing process of a drop-in auto sear involves several critical stages, each essential for ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Drop-In Auto Sear Production?

Material preparation is the first step, where high-quality raw materials, typically steel or aluminum alloys, are sourced. These materials are selected for their durability and ability to withstand high-stress conditions. Suppliers should provide certifications to verify that materials meet international standards, such as ASTM specifications.

In this stage, materials are cut to size and undergo processes such as annealing to relieve internal stresses. B2B buyers should ensure that their suppliers implement stringent material testing protocols, including mechanical property testing and chemical composition analysis, to confirm that the materials used will perform reliably.

What Forming Techniques Are Used in Drop-In Auto Sear Manufacturing?

The forming stage involves shaping the prepared materials into the required components of the auto sear. Common techniques include:

-

CNC Machining: Precision machining using Computer Numerical Control (CNC) ensures that components are manufactured to exact specifications, reducing variations that could affect performance.

-

Stamping: This method involves pressing the material into shape using dies, allowing for high-volume production with consistent quality.

-

Casting: Some components may be produced through casting, particularly when complex shapes are required.

Quality assurance during forming includes monitoring tolerances and surface finishes, which are critical for the assembly stage.

What Assembling Processes Are Involved in Creating a Drop-In Auto Sear?

Once individual components are formed, they are assembled into the complete auto sear. This stage may involve:

-

Precision Alignment: Ensuring that all parts fit together correctly is essential for functionality. Misalignment can lead to operational failures.

-

Welding or Fastening: Depending on design specifications, components may be welded or fastened together using screws or pins.

-

Functional Testing: After assembly, it’s crucial to conduct initial functional tests to ensure that the sear operates correctly and safely.

B2B buyers should verify that suppliers document assembly processes and retain records of any adjustments made during assembly to ensure traceability.

How Does Finishing Impact the Quality of Drop-In Auto Sear?

Finishing processes enhance the durability and aesthetic quality of the drop-in auto sear. Common finishing techniques include:

-

Surface Treatment: Processes such as anodizing or parkerizing are used to improve corrosion resistance.

-

Polishing: This step ensures that surfaces are smooth, which can reduce wear and improve the overall lifespan of the product.

-

Coating: Additional coatings may be applied to enhance performance characteristics, such as reducing friction or providing additional protection against wear.

Finishing quality checks should include visual inspections and testing for surface hardness and corrosion resistance.

What Quality Assurance Standards Are Relevant for Drop-In Auto Sear Manufacturing?

Quality assurance is crucial in the manufacturing of drop-in auto sears, especially for B2B buyers concerned about reliability and safety. Several international standards are relevant:

-

ISO 9001: This standard outlines the requirements for a quality management system. Suppliers certified under ISO 9001 demonstrate their commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with safety and environmental protection standards.

-

API Standards: In some contexts, particularly in the oil and gas industry, adherence to API standards can be critical for components used in high-stress environments.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should ensure that their suppliers possess the necessary certifications and comply with these international standards.

How Can Buyers Verify Supplier Quality Control Processes?

To ensure the quality of drop-in auto sears, B2B buyers should implement a rigorous verification process for suppliers. This can include:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and quality control measures employed by the supplier.

-

Reviewing Quality Control Reports: Regular reports should be provided by suppliers detailing quality control measures, including inspection results and any deviations from standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product reliability.

What Common Testing Methods Are Used in Quality Control for Drop-In Auto Sear?

Quality control for drop-in auto sears involves a range of testing methods to ensure performance and safety. Common methods include:

-

Dimensional Inspection: Verifying the dimensions of the components against design specifications to ensure proper fit and function.

-

Functional Testing: Simulating operational conditions to ensure the auto sear performs as intended under various scenarios.

-

Destructive and Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray can be used to detect internal flaws without damaging the product.

Buyers should inquire about the testing methods used by suppliers and request detailed testing reports to ensure compliance with quality standards.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control and certification when sourcing drop-in auto sears. Differences in regulatory requirements across regions can impact product compliance and marketability.

For instance, while CE marking is essential for European markets, other regions may have different certifications that are equally important. Buyers should conduct thorough research on regional requirements and ensure that their suppliers can meet these diverse standards.

Furthermore, language barriers and cultural differences may affect communication regarding quality assurance expectations. Establishing clear communication channels and agreements regarding quality expectations can mitigate misunderstandings and ensure a smooth procurement process.

A stock image related to drop in auto sear.

In summary, understanding the manufacturing processes and quality assurance practices for drop-in auto sears is vital for international B2B buyers. By focusing on material quality, manufacturing techniques, and thorough quality control measures, buyers can ensure they source reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drop in auto sear’

A stock image related to drop in auto sear.

Introduction

Sourcing a “drop in auto sear” requires careful consideration and a structured approach to ensure compliance with regulations and quality standards. This guide outlines a step-by-step checklist tailored for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and make informed decisions.

1. Define Your Technical Specifications

Clearly outline the specifications for the drop in auto sear you require. This includes dimensions, material composition, and functionality. Having precise technical requirements helps suppliers understand your needs and reduces the likelihood of receiving incompatible products.

- Considerations: What is the intended application? Are there specific regulatory requirements that must be met?

2. Research Market Trends and Pricing

Conduct thorough market research to understand current trends and average pricing for drop in auto sears. This will help you establish a budget and identify fair pricing ranges.

- Action Points: Use online marketplaces, industry reports, and trade publications to gather data. Compare prices from multiple sources to identify potential cost savings.

3. Evaluate Potential Suppliers

Before committing, vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions.

- Key Actions: Look for suppliers with experience in manufacturing drop in auto sears. Check their reputation in the market through reviews and testimonials.

4. ✅ Verify Supplier Certifications

Ensure that suppliers possess the necessary certifications and licenses relevant to manufacturing and exporting drop in auto sears. This includes compliance with local and international regulations.

- What to Check: Look for ISO certifications, quality control processes, and any industry-specific standards that may apply.

5. Request Samples for Evaluation

Before making a bulk purchase, request samples of the drop in auto sear. This allows you to assess quality, compatibility, and performance.

- Why It Matters: Testing samples can prevent costly mistakes and ensure the product meets your specifications. Evaluate the materials and construction quality during this phase.

6. Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms, including pricing, payment methods, and delivery timelines. Clear agreements help prevent misunderstandings later in the process.

- Considerations: Are there volume discounts available? What are the supplier’s policies regarding returns and warranties?

7. Plan for Logistics and Delivery

Finally, consider the logistics involved in shipping and delivery. Collaborate with your supplier to confirm shipping methods and timelines, ensuring that your procurement aligns with your operational needs.

- Key Actions: Assess customs regulations and potential duties that may apply when importing drop in auto sears into your country. Confirm tracking and communication processes for shipments.

By following this comprehensive checklist, B2B buyers can effectively navigate the sourcing process for drop in auto sears, ensuring that they select the right products and suppliers while maintaining compliance with regulations.

Comprehensive Cost and Pricing Analysis for drop in auto sear Sourcing

What Are the Key Cost Components in Sourcing Drop In Auto Sear?

When evaluating the costs associated with sourcing drop in auto sears, several key components need to be considered:

-

Materials: The choice of materials directly impacts the overall cost. High-quality metals and polymers that meet safety standards are essential, influencing not only the price but also the product’s durability and performance.

-

Labor: Labor costs vary significantly depending on the region. In low-wage countries, labor costs may be lower, but this can affect the quality of craftsmanship. It’s vital to assess the skill level of the workforce involved in production.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, making the supplier more competitive.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs. This cost should be amortized over the production volume to understand its impact on pricing.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspections incurs additional costs. However, robust QC can prevent costly defects and returns, ultimately saving money in the long run.

-

Logistics: Shipping and handling costs are often overlooked but can significantly affect the total cost. Factors such as shipping distance, mode of transport, and customs duties should be factored into the overall pricing.

-

Margin: Suppliers typically add a profit margin to cover their operational risks and investments. Understanding the average market margin can help in negotiating better prices.

How Do Price Influencers Affect Sourcing Decisions for Drop In Auto Sear?

Several factors influence the pricing of drop in auto sears, which international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms and lower per-unit costs.

-

Specifications and Customization: Custom features or specific tolerances can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses later in the process.

-

Materials: The choice of materials not only affects cost but also impacts performance. Buyers should balance the need for high-quality materials with budget constraints.

-

Quality Certifications: Products with certifications (like ISO or CE) may come at a premium but provide assurance of quality and compliance with international standards, which is crucial for many markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact total costs. Buyers should carefully consider who is responsible for shipping, insurance, and tariffs to avoid hidden costs.

What Tips Can Help International B2B Buyers Optimize Costs When Sourcing Drop In Auto Sear?

For buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, optimizing costs requires strategic approaches:

-

Negotiate Effectively: Establishing a good relationship with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on volume discounts or payment terms.

-

Focus on Total Cost of Ownership (TCO): Rather than looking solely at the purchase price, consider the TCO, which includes maintenance, logistics, and potential downtime costs. This broader perspective can lead to more informed purchasing decisions.

-

Understand Pricing Nuances: Be aware of local market conditions and currency fluctuations, which can affect pricing. Engaging local experts or sourcing agents can provide insights into the best practices for your specific region.

-

Conduct Market Research: Staying informed about industry trends and competitor pricing can empower buyers during negotiations. Regularly reviewing market conditions can help in identifying potential cost-saving opportunities.

Disclaimer on Pricing

Prices for drop in auto sears can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing. This analysis is indicative and should be used as a guideline rather than a definitive pricing structure.

Alternatives Analysis: Comparing drop in auto sear With Other Solutions

Understanding Alternatives to Drop In Auto Sear

When considering firearm modifications, specifically the drop in auto sear, it is essential to evaluate alternative solutions that can achieve similar outcomes. Each option presents unique advantages and potential drawbacks, which can significantly influence decision-making for B2B buyers in diverse markets, including Africa, South America, the Middle East, and Europe. This analysis compares the drop in auto sear with two notable alternatives: the trigger pack and the binary trigger system.

Comparison of Drop In Auto Sear and Alternatives

| Comparison Aspect | Drop In Auto Sear | Trigger Pack | Binary Trigger System |

|---|---|---|---|

| Performance | High rate of fire, seamless operation | Moderate rate of fire, customizable | Variable, rapid fire with trigger pull |

| Cost | Moderate to high (depends on brand) | Low to moderate | High initial investment |

| Ease of Implementation | Simple installation, minimal gunsmithing | Requires some gunsmithing skills | Moderate complexity, some training needed |

| Maintenance | Low maintenance, reliable | Moderate; parts may need replacement | Low, but requires training for optimal use |

| Best Use Case | Tactical situations, competitions | Recreational shooting, custom builds | Competitive shooting, tactical scenarios |

Detailed Breakdown of Alternatives

What is a Trigger Pack and How Does it Compare?

A trigger pack is a modular assembly that replaces the standard trigger mechanism in firearms. It allows for customization of trigger pull weight and travel distance, which can enhance shooting accuracy and comfort. While the trigger pack is generally less expensive than a drop in auto sear, it typically provides a moderate rate of fire. For B2B buyers looking for cost-effective solutions, this option is appealing, especially for recreational shooting environments. However, it may require a certain level of gunsmithing skills for installation, which could be a barrier for some users.

How Does a Binary Trigger System Function?

The binary trigger system is designed to fire one round with the pull of the trigger and another round upon release. This dual-firing capability can increase the rate of fire significantly, making it a suitable choice for competitive shooting and tactical scenarios. While the initial investment for a binary trigger system can be high, its unique firing mechanism can offer advantages in specific applications. However, it requires a learning curve to master its operation effectively. Buyers should consider whether their intended use justifies the additional cost and training requirements.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate solution among a drop in auto sear, a trigger pack, or a binary trigger system depends largely on the specific needs of the buyer. Factors such as performance requirements, budget constraints, and installation capabilities must be carefully weighed. For organizations focused on tactical applications and high rates of fire, a drop in auto sear may be the most effective choice. Conversely, those seeking customization and cost-effectiveness might find a trigger pack more suitable. Finally, the binary trigger system offers an innovative approach for competitive shooters willing to invest in training and equipment. By aligning the solution with operational goals, B2B buyers can make informed decisions that enhance their shooting capabilities.

Essential Technical Properties and Trade Terminology for drop in auto sear

What Are the Key Technical Properties of a Drop-In Auto Sear?

When sourcing drop-in auto sears for your business needs, understanding the critical technical specifications is vital. These specifications not only impact product performance but also compliance with international standards. Here are several essential properties to consider:

-

Material Grade

The material used in the construction of a drop-in auto sear significantly affects its durability and performance. Common materials include high-grade steel or aluminum alloys, which provide strength and resistance to wear. For international buyers, selecting the right material grade ensures the sear can withstand varying environmental conditions, particularly in regions with extreme climates such as Africa and the Middle East. -

Tolerance Levels

Tolerance refers to the allowable deviation from a specified dimension. Precise tolerances are crucial in the manufacturing of drop-in auto sears to ensure proper fit and function within the firearm assembly. High tolerance levels minimize the risk of malfunctions and improve overall safety. For B2B buyers, understanding tolerance specifications helps in assessing the reliability of the product and its compatibility with existing systems. -

Finish Type

The finish applied to a drop-in auto sear can enhance corrosion resistance and improve aesthetics. Common finishes include phosphate, nitride, or anodizing. Each type of finish has its benefits, such as reducing friction or providing a non-reflective surface. Buyers should consider the intended application and environmental factors when selecting the finish type to ensure longevity and performance. -

Weight

The weight of the drop-in auto sear can affect the overall weight of the firearm. A lighter sear can contribute to a more manageable weapon, which is particularly important for military and law enforcement applications. Buyers should balance weight with the need for durability and performance, especially when sourcing for tactical or competitive shooting environments. -

Compatibility

Compatibility with various firearm models is crucial for drop-in auto sears. Manufacturers often provide lists of compatible models, and understanding this can prevent costly errors and returns. B2B buyers should ensure that the sear meets the specific needs of their customer base, especially when serving diverse markets across regions like Europe and South America.

What Are Common Trade Terms in the Drop-In Auto Sear Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common trade terms that are relevant to drop-in auto sears:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can help buyers gauge product quality and reliability. OEM components typically meet stringent standards and specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ can help in planning purchases, especially for international transactions where shipping costs may escalate with smaller orders. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It outlines the specifications and requirements for the product, including quantity, quality, and delivery expectations. For buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is crucial for international B2B transactions to avoid misunderstandings regarding shipping, insurance, and liability. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It encompasses production time, shipping, and handling. For B2B buyers, understanding lead times is essential for inventory planning and ensuring timely delivery to customers.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing drop-in auto sears, enhancing their competitive advantage in diverse markets.

Navigating Market Dynamics and Sourcing Trends in the drop in auto sear Sector

What Are the Key Market Dynamics and Trends in the Drop In Auto Sear Sector?

The drop in auto sear sector has seen significant transformation driven by technological advancements and evolving market demands. Globally, the rise in firearm enthusiasts and the increasing acceptance of firearm modifications have fueled growth. In regions such as Africa and South America, where regulatory frameworks are still developing, the demand for customizable firearm components, including drop in auto sears, is on the rise. In Europe and the Middle East, however, stricter regulations and a focus on safety have led to increased scrutiny on sourcing and compliance.

Emerging B2B technology trends include the adoption of e-commerce platforms for firearm accessories, which facilitate cross-border transactions and enhance buyer accessibility. Digital supply chain management systems are also becoming prevalent, allowing buyers to track their orders efficiently and ensure timely deliveries. Moreover, the shift towards data-driven decision-making is enabling buyers to analyze market trends and optimize their sourcing strategies effectively.

How Are Sustainability and Ethical Sourcing Influencing the Drop In Auto Sear Market?

Sustainability and ethical sourcing are increasingly becoming focal points for international B2B buyers in the drop in auto sear sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. This includes the use of recycled materials and the implementation of cleaner production techniques to minimize waste.

Ethical supply chains are equally critical. Buyers are prioritizing suppliers who adhere to fair labor practices and contribute positively to their communities. Certifications such as ISO 14001 for environmental management and SA8000 for social accountability are gaining importance, as they assure buyers of a supplier’s commitment to sustainability and ethical practices. By choosing suppliers with these credentials, buyers can enhance their corporate social responsibility (CSR) profile while meeting consumer demand for ethically produced goods.

What Is the Historical Context of the Drop In Auto Sear Market?

The history of the drop in auto sear market is intertwined with the evolution of firearm technology and regulatory changes. Initially developed as a response to military needs, auto sears have transitioned into the civilian market, appealing to gun enthusiasts seeking enhanced functionality. Over the decades, advancements in materials and manufacturing processes have improved the reliability and safety of these components.

Regulatory shifts, particularly in the United States, have also shaped the market. The Gun Control Act of 1968 and subsequent legislation have influenced the manufacturing and distribution of auto sears, making compliance a critical factor for international buyers. Understanding this historical context is vital for B2B buyers to navigate the complexities of sourcing drop in auto sears while adhering to regional regulations and market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of drop in auto sear

-

How do I ensure compliance when sourcing drop-in auto sears internationally?

To ensure compliance when sourcing drop-in auto sears, familiarize yourself with both your country’s regulations and the exporting country’s laws. Key aspects to consider include import permits, export licenses, and adherence to international trade agreements. It’s also crucial to verify that the product meets safety and quality standards, such as ISO certifications. Engage with legal experts or compliance consultants who specialize in firearms and ammunition regulations to navigate the complexities of international trade effectively. -

What are the best practices for vetting suppliers of drop-in auto sears?

Vetting suppliers involves a thorough due diligence process. Start by researching potential suppliers’ reputations through online reviews, industry forums, and trade associations. Request references and verify their operational history. Additionally, assess their manufacturing capabilities, quality control processes, and compliance with local and international regulations. A site visit, if feasible, can provide deeper insights into their operations. Consider using third-party auditing services to evaluate their practices objectively. -

What customization options are available for drop-in auto sears?

Customization options for drop-in auto sears often include variations in materials, finishes, and performance specifications. Suppliers may offer tailored designs to meet specific operational needs, such as enhanced durability or improved firing rates. Discuss your requirements with potential suppliers to understand their capabilities. It’s advisable to request prototypes or samples to evaluate the customization quality before placing a larger order, ensuring that the product meets your specifications. -

What is the minimum order quantity (MOQ) for drop-in auto sears from suppliers?

The minimum order quantity (MOQ) for drop-in auto sears can vary significantly among suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include the supplier’s production capacity, the complexity of the product, and the materials used. When negotiating terms, inquire about flexibility in MOQ, especially if you are a new buyer. Some suppliers may allow lower MOQs for first-time orders or offer tiered pricing structures based on order volume. -

What payment terms should I expect when sourcing drop-in auto sears?

Payment terms can vary widely depending on the supplier and the nature of your business relationship. Common practices include 30% upfront payment with the balance due upon delivery, or net 30 to 60 days after receipt of goods. It’s advisable to negotiate terms that align with your cash flow needs and establish a clear payment schedule. Consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

How can I ensure quality assurance (QA) for drop-in auto sears?

To ensure quality assurance, establish a comprehensive QA process that includes pre-production samples, in-line inspections, and final product testing. Collaborate with suppliers to define quality standards and testing protocols upfront. Utilize third-party inspection services to conduct audits and quality checks at various production stages. Documenting quality metrics and establishing clear communication channels can help address any issues proactively and ensure that the final products meet your expectations. -

What logistics considerations should I be aware of when importing drop-in auto sears?

When importing drop-in auto sears, consider logistics factors such as shipping methods, customs clearance, and lead times. Choose a reliable freight forwarder with experience in handling firearms components. Ensure you have all necessary documentation, including commercial invoices and packing lists, for smooth customs processing. Factor in potential delays due to regulations and customs inspections, and plan your inventory management accordingly to avoid stockouts. -

What are the key risks associated with sourcing drop-in auto sears, and how can I mitigate them?

Key risks include regulatory non-compliance, supplier reliability, and product quality issues. To mitigate these risks, conduct thorough research and due diligence on potential suppliers, and maintain open communication throughout the sourcing process. Establish clear contracts that outline quality expectations and delivery timelines. Regularly review supplier performance and be prepared to pivot to alternative suppliers if necessary. Consider insurance options to protect against losses during shipping or delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drop in auto sear

What Are the Key Takeaways for B2B Buyers of Drop in Auto Sear?

In the dynamic landscape of the firearms industry, strategic sourcing of drop in auto sears remains crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The ability to streamline supply chains, mitigate risks, and ensure compliance with local regulations cannot be overstated. Buyers should prioritize suppliers who demonstrate not only product quality but also transparency in their sourcing practices.

How Can Strategic Sourcing Enhance Your Procurement Process?

Adopting a strategic sourcing approach allows businesses to make informed decisions that enhance efficiency and reduce costs. This involves evaluating potential suppliers based on their reliability, quality assurance practices, and ability to meet specific demands. By leveraging data analytics and market insights, companies can identify trends and forecast future needs, ensuring they remain competitive.

What Does the Future Hold for Drop in Auto Sear Sourcing?

Looking ahead, the demand for drop in auto sears is expected to grow as more markets open up and regulations evolve. Buyers are encouraged to stay ahead of industry trends and foster relationships with reliable manufacturers. By doing so, they can secure favorable terms and ensure a consistent supply of high-quality products. Engage with your sourcing network today to explore opportunities that could enhance your operational capabilities and market positioning.