Discover Affordable Mini Jet Boats for Sale: A Complete Guide (2025)

Introduction: Navigating the Global Market for mini jet boat for sale

In today’s competitive landscape, sourcing mini jet boats for sale can pose significant challenges for international B2B buyers. With diverse applications ranging from recreational use to commercial ventures, understanding the nuances of the global market is crucial. This guide provides a comprehensive overview of the mini jet boat sector, addressing vital aspects such as types of boats available, their specific applications, and effective supplier vetting strategies.

International buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like the UAE and Brazil—face unique hurdles in navigating logistics, compliance, and quality assurance. This guide empowers you to make informed purchasing decisions by offering insights into cost structures, shipping considerations, and negotiation tactics tailored to your region’s market dynamics.

As you delve deeper into this resource, you’ll discover actionable strategies for assessing potential suppliers, understanding the latest industry trends, and maximizing your investment in mini jet boats. Whether you are looking to enhance your fleet or enter a new market, this guide serves as your essential tool for navigating the complexities of the global mini jet boat market. Equip yourself with the knowledge to streamline your sourcing process and capitalize on emerging opportunities in this exciting industry.

Understanding mini jet boat for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Recreational Mini Jet Boat | Compact design, suitable for leisure activities | Tourism, water sports rentals | Pros: High maneuverability, fun for groups. Cons: Limited cargo capacity. |

| Commercial Mini Jet Boat | Built for durability and heavy use, larger engines | Search and rescue, fishing, eco-tourism | Pros: Robust construction, reliable performance. Cons: Higher maintenance costs. |

| Performance Mini Jet Boat | Enhanced speed and agility, specialized hull designs | Racing, performance demonstrations | Pros: Superior speed, thrilling experience. Cons: Not suitable for casual users. |

| Utility Mini Jet Boat | Versatile design, equipped for multiple functions | Transportation, logistics in shallow waters | Pros: Multi-functional, can handle various tasks. Cons: May lack specialized features. |

| Electric Mini Jet Boat | Eco-friendly, quieter operation, battery-powered | Eco-tourism, urban waterways | Pros: Low environmental impact, cost-effective in the long run. Cons: Limited range and power. |

What are the characteristics of Recreational Mini Jet Boats?

Recreational mini jet boats are designed primarily for leisure and entertainment. These boats are compact, allowing for easy maneuverability in various water conditions. They typically accommodate small groups, making them ideal for water sports rentals and tourism. When considering a purchase, B2B buyers should evaluate factors such as engine power, seating capacity, and safety features to ensure they meet customer expectations and regulatory requirements.

How do Commercial Mini Jet Boats differ from other types?

Commercial mini jet boats are built for durability and heavy use, often featuring larger engines and reinforced hulls. These boats are ideal for applications like search and rescue operations, fishing expeditions, and eco-tourism ventures. Buyers should consider the boat’s construction materials, maintenance needs, and operational efficiency, as these factors significantly influence long-term profitability and performance in demanding environments.

What makes Performance Mini Jet Boats unique?

Performance mini jet boats are engineered for speed and agility, often characterized by specialized hull designs that enhance their capabilities in competitive settings. They are frequently utilized in racing events and performance demonstrations. B2B buyers should assess the boat’s speed capabilities, handling characteristics, and safety features, as these elements are crucial for attracting clients interested in high-octane experiences.

In what scenarios are Utility Mini Jet Boats best utilized?

Utility mini jet boats are versatile and can be equipped for various functions, including transportation and logistics in shallow waters. Their adaptable design makes them suitable for a range of business applications, from commercial transport to emergency services. Buyers should focus on the boat’s load capacity, adaptability to different tasks, and ease of maintenance when making purchasing decisions.

What advantages do Electric Mini Jet Boats offer?

Electric mini jet boats are an eco-friendly option that operates quietly and efficiently, powered by batteries rather than traditional fuel sources. They are increasingly popular in eco-tourism and urban waterways where environmental impact is a concern. B2B buyers should consider the boat’s range, charging infrastructure, and overall operational costs, as these factors can affect long-term viability and customer satisfaction.

Related Video: 12′ Mini Jet Boat Walk Around 300HP

Key Industrial Applications of mini jet boat for sale

| Industry/Sector | Specific Application of mini jet boat for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Tourism and Recreation | Guided tours in rivers and coastal areas | Enhances tourist experience; increases revenue | Durability, fuel efficiency, and passenger capacity |

| Search and Rescue | Emergency response in shallow and inaccessible waters | Rapid deployment in critical situations | Performance in rough conditions, maintenance support |

| Environmental Research | Water quality monitoring and wildlife observation | Data collection for conservation efforts | Customization options, onboard technology |

| Agriculture | Irrigation and crop monitoring in remote areas | Efficient water management; cost reduction | Size, maneuverability, and adaptability to terrain |

| Defense and Security | Patrolling coastal borders and waterways | Enhanced surveillance capabilities | Speed, stealth features, and operational range |

How Are Mini Jet Boats Used in the Tourism and Recreation Sector?

In the tourism and recreation industry, mini jet boats are primarily utilized for guided tours in scenic rivers and coastal areas. These boats provide a thrilling experience for tourists while allowing operators to access remote locations that larger vessels cannot reach. By investing in mini jet boats, businesses can enhance their service offerings, leading to increased customer satisfaction and revenue. International buyers should consider the durability and fuel efficiency of these boats, as well as their capacity to accommodate various group sizes.

What Role Do Mini Jet Boats Play in Search and Rescue Operations?

Mini jet boats are invaluable in search and rescue operations, especially in shallow and challenging water conditions. Their agility and speed allow rescue teams to reach individuals in distress quickly, making them essential for emergency response units. Businesses involved in emergency services must prioritize performance in rough conditions and ensure that the boats are equipped with necessary safety features. Additionally, ongoing maintenance support is crucial to ensure operational readiness during emergencies.

How Are Mini Jet Boats Beneficial for Environmental Research?

In the field of environmental research, mini jet boats are used for water quality monitoring and wildlife observation. These boats enable researchers to access remote areas for data collection, facilitating studies on aquatic ecosystems and conservation efforts. B2B buyers in this sector should focus on customization options that allow for the integration of scientific equipment and onboard technology, ensuring that the boats meet specific research needs.

In What Ways Do Mini Jet Boats Support Agricultural Operations?

Mini jet boats find applications in agriculture, particularly for irrigation and crop monitoring in remote areas. They enable farmers to transport water efficiently and assess crop health from vantage points that may be difficult to reach by land. This can lead to significant cost reductions and improved water management practices. When sourcing mini jet boats for agricultural use, buyers should consider the size and maneuverability of the vessels, as well as their adaptability to various terrains.

How Are Mini Jet Boats Used in Defense and Security?

In the defense and security sector, mini jet boats are employed for patrolling coastal borders and waterways. Their speed and stealth capabilities enhance surveillance operations, making them ideal for monitoring sensitive areas. For international buyers in this sector, it is essential to evaluate the boats’ speed, stealth features, and operational range to ensure they meet specific security requirements. Additionally, considering the potential for customization can further enhance their effectiveness in various mission scenarios.

3 Common User Pain Points for ‘mini jet boat for sale’ & Their Solutions

Scenario 1: Complicated Import Regulations for Mini Jet Boats

The Problem:

B2B buyers, particularly those in regions like Africa and South America, often face a labyrinth of import regulations and tariffs when purchasing mini jet boats. These regulations can vary significantly by country, leading to confusion and potential delays. For example, a buyer in Brazil may discover that certain models are subject to heavy taxes or require specific certifications that are not readily available. This can result in unexpected costs and extended timelines, impacting their ability to fulfill customer demands or operate efficiently.

The Solution:

To navigate these complexities, B2B buyers should conduct thorough research on the import regulations of their specific countries. Engaging with local legal experts or customs brokers can provide invaluable insights into compliance requirements. Additionally, buyers should choose manufacturers who have experience exporting to their regions. This partnership can ensure that the boats are manufactured according to local standards and that all necessary documentation, like Certificates of Origin and compliance certifications, are provided upfront. Establishing a good relationship with the supplier can also facilitate smoother transactions and quicker responses to any regulatory changes.

Scenario 2: Insufficient Technical Support and After-Sales Service

The Problem:

Buyers often find that sourcing mini jet boats from international manufacturers can come with a lack of adequate technical support and after-sales service. This is particularly concerning for businesses in the Middle East, where operational downtime due to maintenance issues can lead to significant financial losses. Without proper support, buyers may struggle to maintain their fleet, leading to inefficiencies and reduced customer satisfaction.

The Solution:

When selecting a supplier for mini jet boats, B2B buyers should prioritize those who offer comprehensive after-sales support and service agreements. Look for manufacturers that provide a detailed warranty policy and a clear outline of the technical assistance available. Additionally, inquire about training programs for local technicians, which can empower buyers to perform routine maintenance and minor repairs in-house. Establishing a clear communication channel with the manufacturer for ongoing support can also ensure that any issues are resolved swiftly, minimizing downtime.

Scenario 3: Variability in Quality and Specifications

The Problem:

B2B buyers frequently encounter issues with variability in the quality and specifications of mini jet boats from different suppliers. For instance, a buyer in Europe may receive boats that do not match the agreed specifications, leading to operational inefficiencies or safety concerns. This inconsistency can stem from a lack of quality control in the manufacturing process, resulting in additional costs for modifications or replacements.

The Solution:

To mitigate quality concerns, buyers should implement a robust supplier evaluation process. This includes requesting detailed product specifications and sample products before making bulk purchases. Conducting factory visits or audits can also provide insights into the manufacturer’s quality control processes. Furthermore, establishing clear contracts that outline quality standards and penalties for non-compliance can protect buyers. It’s beneficial to develop long-term relationships with manufacturers who demonstrate a commitment to quality, ensuring that they consistently meet the expectations set forth in the contract. Engaging third-party quality assurance services can also add an additional layer of confidence in product quality.

Strategic Material Selection Guide for mini jet boat for sale

When considering the purchase of mini jet boats, the choice of materials plays a crucial role in determining performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the construction of mini jet boats, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum for Mini Jet Boats?

Aluminum is a popular choice for mini jet boats due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 600°F (315°C) and can withstand moderate pressure, making it suitable for various water conditions.

Pros & Cons:

The primary advantage of aluminum is its high strength-to-weight ratio, which enhances fuel efficiency and speed. However, it can be more susceptible to dents and scratches compared to other materials, impacting aesthetics and longevity. Manufacturing complexity is moderate, as aluminum can be easily shaped and welded.

Impact on Application:

Aluminum is compatible with freshwater and saltwater environments, making it versatile for different geographical applications.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM and ISO for marine-grade aluminum. In regions like the UAE and Brazil, where marine regulations may vary, confirming material certifications is essential.

How Does Fiberglass Compare for Mini Jet Boat Construction?

Fiberglass is another common material, known for its excellent strength and resistance to corrosion, UV radiation, and chemical exposure. It can withstand temperatures up to 300°F (149°C) and is generally pressure-resistant.

Pros & Cons:

Fiberglass offers exceptional durability and a smooth finish, which can enhance the boat’s aesthetic appeal. However, it is heavier than aluminum, which can affect speed and fuel efficiency. The manufacturing process is more complex, often requiring molds and specialized labor.

Impact on Application:

Fiberglass is suitable for both freshwater and saltwater use, providing flexibility for international buyers.

Considerations for International Buyers:

Buyers in Europe and the Middle East should be aware of specific regulations regarding fiberglass disposal and environmental impact. Compliance with standards like DIN and JIS is also critical.

What are the Advantages of Stainless Steel in Mini Jet Boat Construction?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it ideal for marine applications. It can handle high temperatures (up to 1,500°F or 815°C) and significant pressure.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to rust, which is crucial for boats operating in harsh environments. However, it is heavier and more expensive than aluminum and fiberglass, which may affect overall performance and cost.

Impact on Application:

Stainless steel is particularly suitable for components exposed to water, such as fittings and hardware, ensuring long-term reliability.

Considerations for International Buyers:

Buyers should verify that the stainless steel used meets international standards such as ASTM A240 for corrosion resistance. In regions like Africa, where access to high-quality materials may be limited, sourcing from reputable suppliers is vital.

Why is Polyethylene a Viable Option for Mini Jet Boats?

Polyethylene is a lightweight, high-density plastic that offers excellent impact resistance and buoyancy. It can withstand temperatures up to 200°F (93°C) and is resistant to many chemicals.

Pros & Cons:

The key advantage of polyethylene is its affordability and low maintenance requirements. However, it may not be as durable as metals, particularly in high-stress applications, and can be susceptible to UV degradation over time.

Impact on Application:

Polyethylene is best suited for recreational mini jet boats used in calm waters, making it a popular choice for leisure activities.

Considerations for International Buyers:

Buyers should ensure that the polyethylene used is UV-stabilized and compliant with local environmental regulations, especially in regions like South America where such standards may vary.

Summary Table of Material Properties for Mini Jet Boats

| Material | Typical Use Case for mini jet boat for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight hull construction | High strength-to-weight ratio | Susceptible to dents and scratches | Medium |

| Fiberglass | Hulls and decks for durability | Excellent corrosion resistance | Heavier and complex to manufacture | High |

| Stainless Steel | Hardware and fittings | Exceptional durability | Heavy and costly | High |

| Polyethylene | Recreational boats | Low cost and maintenance | Less durable in high-stress areas | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to invest in mini jet boats. Understanding the properties and implications of each material will aid in making informed purchasing decisions that align with regional standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mini jet boat for sale

What Are the Key Stages in the Manufacturing Process of Mini Jet Boats?

The manufacturing process of mini jet boats involves several critical stages that ensure the final product meets the required performance and safety standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing mini jet boats.

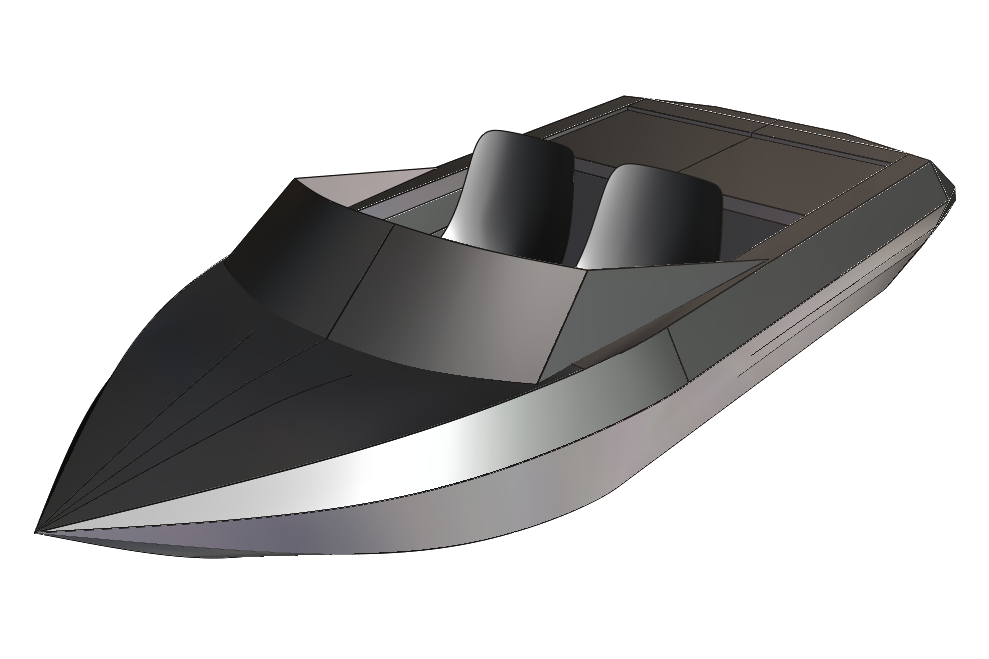

A stock image related to mini jet boat for sale.

1. Material Preparation: What Materials Are Used in Mini Jet Boat Construction?

The first step in the manufacturing process is material preparation. Mini jet boats are typically constructed from high-strength materials such as fiberglass, aluminum, and sometimes composite materials.

- Fiberglass is favored for its lightweight properties and resistance to corrosion, making it ideal for aquatic environments.

- Aluminum offers durability and strength while being relatively lightweight, which is crucial for performance.

- Composite materials can provide enhanced durability and flexibility, though they may come at a higher cost.

B2B buyers should inquire about the specific materials used by suppliers and their sourcing practices, as this can impact both the quality and longevity of the boats.

2. Forming: What Techniques Are Employed in Shaping Mini Jet Boats?

Once materials are prepared, the next phase is forming. This involves shaping the materials into the desired hull and structure of the mini jet boat.

- Molding is a common technique for fiberglass, where liquid resin is poured into a mold to create the boat’s hull. This ensures a precise shape and smooth finish.

- CNC machining is often used for aluminum components, allowing for high precision in cutting and shaping parts.

- Welding may be necessary for assembling aluminum parts, ensuring robust joints that can withstand the stresses of water navigation.

Buyers should assess the manufacturing capabilities of suppliers, particularly their technology and techniques, as these can greatly influence the quality and performance of the final product.

3. Assembly: How Are Mini Jet Boats Assembled for Optimal Performance?

The assembly stage brings together all components of the mini jet boat. This stage is crucial as it affects the boat’s overall integrity and performance.

- Modular assembly techniques allow for efficient construction, where sections of the boat are built separately and then joined together.

- Quality fasteners and adhesives are vital in ensuring that all components are securely attached and can withstand the rigors of marine use.

International buyers should seek suppliers that employ skilled labor and advanced assembly techniques, as this will ensure a higher standard of craftsmanship.

4. Finishing: What Are the Final Touches That Ensure Quality and Aesthetics?

Finishing touches are essential for both aesthetics and protection. This stage involves several processes:

- Gel coating provides a smooth, glossy surface that enhances the boat’s appearance and protects it from UV damage.

- Painting adds color and can also serve a protective function against corrosion and wear.

- Quality control measures during finishing ensure that the boat meets industry standards for both appearance and durability.

B2B buyers should verify that suppliers adhere to finishing standards that align with international expectations, particularly if the boats are destined for markets with specific aesthetic requirements.

How Is Quality Assurance Implemented in Mini Jet Boat Manufacturing?

Quality assurance (QA) is critical in the manufacturing of mini jet boats, ensuring that the end product meets both safety and performance standards.

What International Standards Should B2B Buyers Be Aware Of?

To ensure quality, manufacturers often adhere to various international standards. The most relevant include:

- ISO 9001: This standard focuses on quality management systems and is essential for maintaining high production standards.

- CE Marking: Particularly important in Europe, this certification indicates that the boat complies with EU safety, health, and environmental protection standards.

- API Standards: In regions like the Middle East, adherence to American Petroleum Institute standards may be necessary, especially for boats used in oil and gas operations.

B2B buyers should request documentation proving compliance with these standards to ensure their suppliers maintain high-quality manufacturing processes.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are crucial in the manufacturing process of mini jet boats. The main checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help catch any defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets all specifications and standards before shipment.

B2B buyers should inquire about the QC processes employed by suppliers and request access to QC reports to verify adherence to these checkpoints.

What Testing Methods Are Commonly Used in Mini Jet Boat Manufacturing?

Various testing methods are employed to ensure the quality and safety of mini jet boats:

- Hydrostatic testing checks for leaks and ensures that the hull can withstand water pressure.

- Performance testing evaluates the boat’s speed, maneuverability, and handling.

- Durability testing assesses how well the boat withstands environmental conditions, such as saltwater exposure and UV radiation.

Buyers should ask potential suppliers about their testing protocols and request evidence of testing results to ensure compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

- Conduct Audits: Regular audits of manufacturing facilities can provide insight into a supplier’s adherence to quality standards.

- Request Quality Reports: Suppliers should be able to provide documentation of quality checks and testing results.

- Engage Third-Party Inspectors: Utilizing independent inspectors can offer an unbiased evaluation of the supplier’s manufacturing and QC processes.

Understanding the nuances of quality control certification and practices is especially important for buyers in regions like Africa and South America, where standards may vary significantly from those in Europe or the Middle East.

Conclusion: Why Understanding Manufacturing and Quality Assurance Is Essential for B2B Buyers

In summary, a thorough understanding of the manufacturing processes and quality assurance measures involved in producing mini jet boats is essential for international B2B buyers. By focusing on material selection, manufacturing techniques, quality standards, and verification processes, buyers can ensure they source high-quality products that meet their specific needs. This knowledge not only aids in making informed purchasing decisions but also fosters stronger relationships with suppliers, ultimately leading to successful business outcomes in the competitive marine market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini jet boat for sale’

To successfully source a mini jet boat for sale, international B2B buyers must navigate various considerations that ensure they find the right product and supplier. This checklist serves as a comprehensive guide to streamline the procurement process, enabling buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical specifications required for the mini jet boat. Consider factors such as size, engine power, weight capacity, and intended use (e.g., recreational, commercial, or emergency services). A well-defined specification will help you communicate your needs effectively to potential suppliers and avoid any misunderstandings.

Step 2: Research the Market Landscape

Conduct thorough market research to understand current trends, pricing structures, and available models of mini jet boats. Utilize online resources, trade publications, and industry reports to gather insights. This step is crucial to ensure you are aware of competitive pricing and the latest technologies, enabling you to negotiate better deals.

Step 3: Identify and Verify Suppliers

Compile a list of potential suppliers who specialize in mini jet boats. Focus on those with a proven track record in your target regions. Request documentation to verify their legitimacy, including:

– Business licenses

– Quality certifications (e.g., ISO)

– Customer references

A credible supplier will provide transparency, which is essential for building trust.

Step 4: Evaluate Product Quality and Compliance

Assess the quality of the mini jet boats offered by your shortlisted suppliers. Inquire about the materials used, production processes, and any certifications that demonstrate compliance with international safety and environmental standards. Products that meet these standards not only ensure safety but also minimize potential legal issues in the future.

Step 5: Request Samples and Conduct Testing

Before finalizing a purchase, request samples or arrange for a demonstration of the mini jet boats. Conduct hands-on testing to evaluate performance, durability, and comfort. This step allows you to make informed decisions based on actual experience rather than just specifications and marketing claims.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment options, delivery timelines, and warranty provisions. Clear agreements on these terms can prevent misunderstandings and ensure a smoother transaction.

Step 7: Establish Logistics and After-Sales Support

Plan the logistics for transporting the mini jet boats to your location, including shipping methods and customs clearance processes. Additionally, inquire about after-sales support, such as maintenance services and parts availability. Reliable after-sales support is critical for ensuring the longevity of your investment.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing mini jet boats, ensuring they make strategic decisions that meet their operational needs while maximizing value.

Comprehensive Cost and Pricing Analysis for mini jet boat for sale Sourcing

What Are the Key Cost Components in Sourcing Mini Jet Boats?

When sourcing mini jet boats, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as fiberglass, aluminum, and marine-grade composites can raise the price but ensure durability and performance. Buyers should assess the material specifications and opt for suppliers who can provide certifications to verify quality.

-

Labor: Labor costs vary widely based on geographic location. For instance, manufacturers in Europe may have higher labor costs compared to those in South America or Africa. Consider the skill level required for the production of mini jet boats, as more specialized labor can lead to increased costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Understanding the overhead costs can help buyers gauge the pricing strategy of different suppliers.

-

Tooling: If custom designs are required, tooling costs can become significant. Buyers should clarify whether these costs are included in the initial quote or charged separately, especially for low-volume orders.

-

Quality Control: Investing in robust QC processes can lead to higher upfront costs but will mitigate risks related to product failure and warranty claims. Buyers should inquire about the QC measures implemented by the manufacturer.

-

Logistics: Shipping costs can vary based on the distance from the supplier to the buyer, as well as the chosen Incoterms. Understanding these factors can help buyers plan their logistics budget effectively.

-

Margin: Suppliers typically add a profit margin to the total cost of production. This margin can fluctuate based on market demand and competition, making it essential for buyers to compare quotes from multiple suppliers.

How Do Price Influencers Affect Mini Jet Boat Sourcing?

Several factors influence the pricing of mini jet boats, which international buyers must consider:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect unit pricing. Larger orders often lead to discounts, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom features, such as enhanced engines or unique design elements, can lead to increased costs. Buyers should determine their essential specifications upfront to avoid unexpected expenses.

-

Material Quality and Certifications: The level of certification (such as ISO or CE) can impact the price. Higher certification levels typically indicate better quality and reliability, which may justify the higher cost.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms will dictate who is responsible for shipping costs and risks. Understanding these terms can help buyers assess total costs and avoid surprises.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

To maximize cost-efficiency when sourcing mini jet boats, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you’re ordering in bulk. Many suppliers are open to negotiations, particularly when they see potential for a long-term partnership.

-

Focus on Total Cost of Ownership (TCO): Instead of just comparing initial prices, consider the total cost over the boat’s lifespan, including maintenance, fuel efficiency, and potential resale value. This holistic view can lead to better purchasing decisions.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends. Economic factors, import tariffs, and currency fluctuations can all impact the final price.

-

Request Detailed Quotes: Ensure that quotes from suppliers include a breakdown of all costs involved. This transparency will help you identify areas where savings can be made.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and insights into upcoming trends or discounts.

Disclaimer on Indicative Prices

It is essential to note that prices for mini jet boats can vary significantly based on the aforementioned factors. Buyers should conduct thorough research and obtain multiple quotes to ensure they are receiving a fair and competitive price.

Alternatives Analysis: Comparing mini jet boat for sale With Other Solutions

Understanding Alternatives to Mini Jet Boats for Sale

A stock image related to mini jet boat for sale.

When considering the purchase of a mini jet boat, it’s essential for B2B buyers to evaluate alternative solutions that can serve similar purposes. Understanding the strengths and weaknesses of different technologies or methods can help businesses make informed decisions that align with their operational needs and budget constraints. This analysis will compare mini jet boats with two viable alternatives: inflatable boats and traditional motorboats.

Comparison Table

| Comparison Aspect | Mini Jet Boat For Sale | Inflatable Boat | Traditional Motorboat |

|---|---|---|---|

| Performance | High-speed, agile | Moderate speed, less maneuverable | High-speed, stable |

| Cost | Mid to high range | Low to mid range | High range |

| Ease of Implementation | Requires specialized training | Easy to deploy and use | Requires skilled personnel |

| Maintenance | Moderate maintenance | Low maintenance | High maintenance |

| Best Use Case | River and shallow water | Recreational use, calm waters | Open water and heavy loads |

What Are the Benefits and Drawbacks of Inflatable Boats?

Inflatable boats are a popular alternative to mini jet boats, particularly for recreational use in calm waters. One of their main advantages is their affordability; they typically fall within a lower price range compared to mini jet boats, making them accessible for smaller businesses or budget-conscious buyers. Additionally, they are lightweight and easy to transport, which allows for quick deployment in various settings. However, inflatable boats generally have lower performance capabilities. They are not designed for high-speed travel or maneuverability in challenging water conditions, limiting their use cases.

How Do Traditional Motorboats Compare to Mini Jet Boats?

Traditional motorboats offer high performance and stability, making them suitable for a range of applications from fishing to transport. These vessels can handle open water and heavy loads, providing a reliable solution for businesses that operate in diverse environments. However, they come with a higher initial investment and ongoing maintenance costs, which can be a significant consideration for B2B buyers. Additionally, operating a traditional motorboat often requires skilled personnel, which may not be feasible for every organization.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right vessel for your business needs, it’s crucial to assess the specific applications and environments in which the boat will be used. Mini jet boats excel in performance and agility, making them ideal for river navigation and shallow waters. In contrast, inflatable boats provide a budget-friendly option for recreational activities, while traditional motorboats offer stability and performance in more demanding conditions. By carefully analyzing the pros and cons of each alternative, B2B buyers can align their choice with operational requirements, budget constraints, and long-term goals.

Essential Technical Properties and Trade Terminology for mini jet boat for sale

What Are the Key Technical Properties of Mini Jet Boats?

When evaluating mini jet boats for sale, understanding their technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The materials used in the construction of mini jet boats significantly affect their durability, performance, and maintenance. Common materials include aluminum, fiberglass, and high-density polyethylene (HDPE). For instance, aluminum offers a lightweight yet strong option, while fiberglass provides excellent corrosion resistance. Assessing the material grade helps buyers ensure the boat can withstand environmental conditions specific to regions like Africa or the Middle East.

2. Engine Power and Type

The engine is the heart of any jet boat. Buyers should look for specifications that include engine horsepower, type (e.g., two-stroke or four-stroke), and fuel efficiency. A powerful engine will provide better acceleration and maneuverability, which is essential for activities like water sports or rescue missions. Understanding the engine specs enables B2B buyers to match their operational needs, especially in diverse markets like South America and Europe.

3. Weight Capacity

Weight capacity is a critical specification that determines how many passengers and how much cargo a mini jet boat can safely carry. This property is particularly important for commercial buyers in sectors such as tourism or rescue operations, where the boat’s load must be optimized for performance and safety. Ensure that the weight capacity aligns with the intended use to avoid performance issues.

4. Hull Design

The hull design impacts the boat’s stability, speed, and maneuverability. Key designs include flat bottom, V-hull, and tunnel hulls. Each design has advantages depending on the water conditions typical in the buyer’s region. For instance, a V-hull may perform better in rough waters, making it suitable for buyers in coastal areas. Evaluating hull design is essential for ensuring optimal operational effectiveness.

5. Tolerance Levels

Tolerance levels refer to the allowable deviation in manufacturing specifications. This is particularly important for components like the jet drive system and hull fittings. Understanding the tolerances can help buyers gauge the quality of construction and predict maintenance needs. High tolerance levels often indicate superior craftsmanship, which is vital for longevity in harsh operating conditions.

Which Trade Terms Should B2B Buyers Know When Purchasing Mini Jet Boats?

Familiarity with industry jargon can streamline the procurement process and improve communication with suppliers. Here are some common trade terms relevant to mini jet boat purchases:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For mini jet boats, understanding whether parts are OEM can influence decisions on quality and compatibility. Buyers should inquire about OEM components to ensure reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of goods a supplier is willing to sell. This term is particularly important for B2B buyers, as it can affect budgeting and inventory management. Understanding the MOQ helps buyers plan their purchases effectively, especially if they aim for bulk procurement.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and details on specific products. For mini jet boat buyers, issuing an RFQ can facilitate comparisons across multiple vendors. This process allows buyers to obtain competitive pricing and ensure they are making informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping responsibilities, risk management, and cost allocation. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which dictate who bears costs and risks at various points in the shipping process.

5. Lead Time

Lead time is the amount of time between placing an order and receiving the goods. Understanding lead time is crucial for B2B buyers as it affects project timelines and operational readiness. Clear communication with suppliers regarding lead times can help avoid delays in business operations.

By grasping these technical properties and trade terms, international B2B buyers can make well-informed purchasing decisions regarding mini jet boats, ensuring they meet their operational needs and comply with industry standards.

Navigating Market Dynamics and Sourcing Trends in the mini jet boat for sale Sector

What Are the Current Market Dynamics and Key Trends in the Mini Jet Boat Sector?

The mini jet boat market is experiencing a significant surge, driven by a combination of recreational demand and advancements in marine technology. Globally, the rising interest in water sports, eco-tourism, and leisure activities has created a robust demand for mini jet boats. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly poised to capitalize on these trends, as urbanization and increased disposable income lead to more consumers seeking unique recreational experiences.

Emerging technologies, such as electric propulsion and enhanced safety features, are reshaping sourcing strategies. B2B buyers should focus on suppliers that offer innovative designs and sustainable solutions. Additionally, the rise of e-commerce platforms is facilitating easier access to international markets, enabling buyers to compare products and suppliers more efficiently. The adoption of digital tools for inventory management and supply chain transparency is also becoming essential, allowing buyers to streamline operations and reduce costs.

How Important Is Sustainability and Ethical Sourcing in the Mini Jet Boat Market?

As environmental concerns grow, sustainability has become a pivotal factor in the sourcing strategies of B2B buyers in the mini jet boat sector. The manufacturing process of mini jet boats can have significant environmental impacts, from resource extraction to waste generation. Buyers should prioritize suppliers that adhere to eco-friendly practices, such as using recycled materials and sustainable manufacturing processes.

Ethical sourcing is also crucial in maintaining a positive brand image and complying with international regulations. Certifications such as ISO 14001 (Environmental Management) and the use of sustainable materials can enhance a company’s credibility in the market. Buyers should look for manufacturers that provide transparency regarding their supply chains, ensuring that materials are ethically sourced and that labor practices meet international standards. This not only mitigates reputational risks but also aligns with the growing consumer preference for responsible brands.

What Is the Brief Evolution of the Mini Jet Boat Sector Relevant to B2B Buyers?

The mini jet boat industry has evolved significantly over the past few decades, transitioning from simple recreational crafts to sophisticated vessels equipped with advanced technology. Initially, these boats were primarily used for leisure activities in shallow waters. However, innovations in design and propulsion have expanded their applications to include commercial uses, such as rescue operations and tourism.

In recent years, the introduction of electric mini jet boats has marked a turning point, offering buyers sustainable options that cater to environmentally conscious consumers. This evolution not only reflects changing consumer preferences but also highlights the importance of adapting sourcing strategies to include cutting-edge technologies and sustainable practices. B2B buyers who stay informed about these developments will be better positioned to make strategic purchasing decisions that align with market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of mini jet boat for sale

-

How do I choose the right mini jet boat for my business needs?

Selecting the right mini jet boat involves assessing your operational requirements, such as the intended use (tourism, rescue, or recreation), capacity needs, and engine specifications. Consider factors like fuel efficiency, maintenance costs, and the boat’s ability to navigate local waterways. It’s also beneficial to request demonstrations and test drives from suppliers to evaluate performance. Engaging with industry peers for recommendations can provide valuable insights into reliable brands and models. -

What are the most important features to look for in a mini jet boat?

Key features to consider when sourcing a mini jet boat include the hull design for stability, engine power for performance, and storage capacity for gear. Safety features like life jackets, fire extinguishers, and GPS systems are crucial. Additionally, consider customization options that can enhance usability for specific applications, such as fishing or rescue missions. Reviewing customer testimonials and expert reviews can help gauge the reliability of these features. -

What is the typical minimum order quantity (MOQ) for mini jet boats?

The MOQ for mini jet boats can vary significantly between manufacturers. Generally, it ranges from one unit for custom orders to multiple units for bulk purchases. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ policies. Some manufacturers may offer flexibility, especially if you are a first-time buyer or if they are looking to establish a long-term relationship. -

How can I verify the credibility of a mini jet boat supplier?

To verify a supplier’s credibility, check their business licenses and certifications, such as ISO standards or regional marine regulations. Look for reviews and testimonials from previous clients, and consider visiting their manufacturing facilities if possible. Engaging with trade associations or industry networks can also provide insights into a supplier’s reputation. Additionally, request references and follow up with them to gain firsthand information about the supplier’s reliability and service quality.

A stock image related to mini jet boat for sale.

-

What payment terms are common when purchasing mini jet boats internationally?

Payment terms for international purchases of mini jet boats typically include options such as letters of credit, wire transfers, or escrow services. Some suppliers may require a deposit upfront, with the balance due upon delivery or installation. It’s essential to discuss and negotiate payment terms that provide security for both parties. Additionally, consider using a trusted payment platform that offers buyer protection to mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when importing mini jet boats?

When importing mini jet boats, it’s crucial to factor in shipping methods, customs clearance, and potential tariffs. Determine whether the boats will be shipped via container or flatbed transport, depending on their size and volume. Research the import regulations in your country, including any certifications required for marine vessels. Collaborating with a freight forwarder can streamline the logistics process and ensure compliance with all regulations. -

How can I ensure quality assurance when sourcing mini jet boats?

To ensure quality assurance, request detailed specifications and performance standards from suppliers. Conduct factory audits or third-party inspections before shipment to verify that the boats meet your requirements. Additionally, inquire about warranty terms and after-sales support, as these can provide peace of mind regarding product quality. Establishing clear communication with the supplier about quality expectations will also help mitigate potential issues. -

What customization options are available for mini jet boats?

Customization options for mini jet boats can include modifications to size, color, engine type, and onboard equipment. Some suppliers offer tailored features such as enhanced seating arrangements, specialized storage, or advanced navigation systems. Discuss your specific operational needs with potential suppliers to explore what customization services they provide. It’s beneficial to review past projects or case studies to see how other clients have successfully customized their boats to fit their requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mini jet boat for sale

In the rapidly evolving market for mini jet boats, strategic sourcing emerges as a critical component for international B2B buyers looking to optimize their procurement processes. By leveraging insights into supplier capabilities, market trends, and regional demands, companies from Africa, South America, the Middle East, and Europe can enhance their competitive edge.

Key takeaways include the importance of establishing strong relationships with manufacturers and suppliers, understanding local regulations, and conducting thorough market research to identify the most suitable products for your target audience. Buyers should prioritize sustainability and innovation, as these factors increasingly influence purchasing decisions in the marine industry.

Looking ahead, the demand for mini jet boats is expected to grow, driven by leisure activities and commercial applications. B2B buyers are encouraged to remain proactive in exploring new partnerships and technologies that can streamline sourcing processes and improve product offerings. Embracing a strategic approach to sourcing not only mitigates risks but also positions businesses for long-term success.

As you navigate this dynamic landscape, consider collaborating with industry experts and attending relevant trade shows to stay informed and seize emerging opportunities in the mini jet boat market.