Discover Holographic Cards: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for holographic cards

In today’s rapidly evolving marketplace, sourcing high-quality holographic cards can pose significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As the demand for innovative branding and marketing solutions increases, understanding the multifaceted applications of holographic cards becomes essential for businesses looking to stand out. This guide aims to provide a comprehensive overview of the holographic card market, including various types, applications, and best practices for supplier vetting.

Navigating the complexities of sourcing and purchasing holographic cards requires a keen awareness of regional market dynamics and supplier capabilities. From promotional materials to security features in identification cards, holographic cards are versatile tools that can enhance brand visibility and credibility. This guide empowers B2B buyers by offering actionable insights into cost considerations, quality assurance, and the latest trends in holographic technology.

By equipping businesses with the knowledge needed to make informed purchasing decisions, this resource serves as a crucial ally for international buyers in countries like Kenya and Colombia, helping them effectively harness the power of holographic cards to drive growth and engagement in their respective markets.

Understanding holographic cards Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1. 3D Holographic Cards | Display depth and movement; visual effects change with angle | Marketing, Packaging, Security | Pros: Eye-catching, enhances brand perception; Cons: Higher production costs, may require specialized equipment. |

| 2. Holographic Foil Cards | Metallic sheen with holographic elements; often used for branding | Business Cards, Promotional Materials | Pros: Durable, versatile design; Cons: Limited design flexibility, potential for fading over time. |

| 3. Holographic ID Cards | Embedded security features; often used for identification | Government, Corporate, Educational sectors | Pros: Enhanced security, difficult to counterfeit; Cons: Higher initial costs, complexity in production. |

| 4. Holographic Labels | Customizable labels with holographic effects; tamper-evident | Product Packaging, Anti-Counterfeiting | Pros: Increases product authenticity, customizable; Cons: May be more expensive than standard labels, adhesive issues in extreme conditions. |

| 5. Augmented Reality (AR) Cards | Integrates digital content with physical cards; interactive | Event Marketing, Customer Engagement | Pros: Engages customers, innovative experience; Cons: Requires app or device for interaction, potential tech limitations. |

What Are the Characteristics of 3D Holographic Cards?

3D holographic cards are distinguished by their ability to showcase depth and movement, creating a dynamic visual experience that changes based on the viewer’s angle. These cards are primarily used in marketing, packaging, and security applications. B2B buyers should consider the higher production costs and potential need for specialized equipment, but the eye-catching nature of these cards can significantly enhance brand perception and customer engagement.

How Do Holographic Foil Cards Stand Out?

Holographic foil cards feature a metallic sheen combined with holographic elements, making them a popular choice for business cards and promotional materials. They are durable and offer versatile design options, appealing to businesses looking to make a lasting impression. However, buyers should be aware of the limited design flexibility and the potential for fading over time, which could affect the longevity of their branding efforts.

What Are Holographic ID Cards Used For?

Holographic ID cards incorporate embedded security features, making them ideal for government, corporate, and educational sectors. Their enhanced security measures make them difficult to counterfeit, providing peace of mind for organizations that require strict identification protocols. While the initial costs may be higher and the production process more complex, the investment can be justified by the security benefits they provide.

How Are Holographic Labels Applied in B2B?

Holographic labels are customizable and often include tamper-evident features, making them effective for product packaging and anti-counterfeiting measures. These labels can increase product authenticity and enhance brand image. However, buyers should consider that they may come at a higher cost than standard labels and could face adhesive issues in extreme conditions, potentially impacting their performance.

What Are the Benefits of Augmented Reality (AR) Cards?

Augmented reality (AR) cards integrate digital content with physical cards, offering an interactive experience that can greatly enhance event marketing and customer engagement. They provide a unique way to captivate audiences and differentiate a brand in a competitive market. However, B2B buyers must consider that these cards require an app or device for interaction, which may present tech limitations and affect user accessibility.

Related Video: Holographic and reverse holographic cards explained!

Key Industrial Applications of holographic cards

| Industry/Sector | Specific Application of Holographic Cards | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security and Anti-Counterfeiting | Holographic ID and Access Cards | Enhanced security features reduce fraud and unauthorized access. | Quality of holographic technology, customization options, and compliance with local regulations. |

| Marketing and Brand Promotion | Holographic Business Cards and Promotional Materials | Unique visual appeal increases brand recognition and engagement. | Durability of materials, print quality, and design flexibility. |

| Banking and Financial Services | Holographic Credit and Debit Cards | Provides added security features that protect against card cloning. | Compliance with financial regulations, integration with existing systems, and supplier reliability. |

| Event Management and Ticketing | Holographic Event Tickets and Access Passes | Reduces ticket fraud and enhances attendee experience with visual effects. | Scalability for large events, customization capabilities, and quick turnaround times. |

| Education and Certification | Holographic Certificates and Diplomas | Increases the authenticity of credentials and enhances their perceived value. | Customization options, verification features, and security standards. |

How Are Holographic Cards Used in Security and Anti-Counterfeiting?

In the security sector, holographic cards are primarily utilized for ID and access control systems. These cards integrate advanced holographic features that make them difficult to replicate, thus significantly reducing the risk of fraud and unauthorized access. For B2B buyers in regions like Africa and the Middle East, sourcing high-quality holographic technology is crucial, as it must meet both local and international security standards. Additionally, customization options can help businesses design cards that reflect their branding while ensuring compliance with safety regulations.

What Role Do Holographic Cards Play in Marketing and Brand Promotion?

Holographic business cards and promotional materials provide a distinctive way for companies to stand out in competitive markets. The eye-catching visual effects of holography can capture potential clients’ attention, thereby enhancing brand recognition and engagement. For businesses in South America and Europe, it is essential to consider the durability and quality of the materials used, as well as the flexibility in design to align with brand identity. Suppliers should also be able to deliver high-quality prints to ensure the desired impact.

How Are Holographic Cards Enhancing Banking and Financial Services?

In the banking sector, holographic credit and debit cards serve a critical function in fraud prevention. The holographic elements add layers of security that protect against card cloning and unauthorized transactions. International B2B buyers in this sector must prioritize suppliers that comply with stringent financial regulations and can integrate seamlessly with existing banking systems. Reliability of the supplier is also vital, as financial institutions require consistent quality and performance in their card offerings.

How Are Holographic Cards Used in Event Management and Ticketing?

Holographic event tickets and access passes are increasingly being adopted to combat ticket fraud and enhance the attendee experience. These tickets often include intricate holographic designs that are challenging to forge, thereby ensuring a secure entry process. For event organizers in Africa and Europe, sourcing scalable solutions that can handle large volumes for major events is essential. Additionally, the ability to customize tickets with event branding and quick turnaround times can significantly improve overall event management.

How Do Holographic Cards Benefit Education and Certification?

Holographic certificates and diplomas are employed by educational institutions to enhance the authenticity and perceived value of credentials. The incorporation of holography makes these documents more challenging to forge, providing a layer of security that is increasingly important in a globalized job market. For B2B buyers in the education sector, customization options and verification features are critical. Suppliers must also adhere to security standards that are recognized internationally, ensuring that the credentials hold value across borders.

Related Video: HOLOGRAPHIC MARKETING

3 Common User Pain Points for ‘holographic cards’ & Their Solutions

Scenario 1: Difficulty in Ensuring Product Authenticity with Holographic Cards

The Problem: In regions such as Africa and South America, where counterfeit products are a significant issue, B2B buyers often struggle to ensure the authenticity of their products when using holographic cards. Many companies lack the proper technology or knowledge to verify these cards, leading to concerns about brand integrity and customer trust. This challenge is compounded by a lack of standardized practices in the production and distribution of holographic cards, making it even harder for businesses to confidently assess their authenticity.

The Solution: To overcome this problem, B2B buyers should partner with reputable holographic card manufacturers who provide transparency in their production processes. Buyers should inquire about the materials used, the technology employed in creating the holographic effects, and any certifications that validate the authenticity of the cards. Additionally, incorporating QR codes or NFC technology alongside holographic cards can allow end-users to verify authenticity easily via their smartphones. Investing in training for staff to understand how to identify genuine holographic cards can also enhance security measures. Finally, establishing a feedback loop with customers regarding their experiences with product authenticity can help companies fine-tune their quality control processes.

Scenario 2: High Costs Associated with Custom Holographic Card Production

The Problem: Many businesses, especially startups or SMEs in the Middle East and Europe, encounter financial strain when sourcing custom holographic cards. The costs can escalate quickly due to the complexity of design, the technology required for production, and minimum order quantities that may not align with the company’s budget or needs. This financial barrier can deter companies from utilizing holographic cards to enhance their marketing efforts or product branding.

The Solution: To mitigate these costs, B2B buyers should explore manufacturers that offer flexible order quantities and tiered pricing models. Engaging in discussions about bulk purchasing or long-term contracts can also yield discounts. Moreover, companies can collaborate with designers to create versatile holographic designs that can be used across multiple products or campaigns, thereby spreading the costs over a larger volume. Utilizing digital proofs and mock-ups before committing to production can prevent costly mistakes and ensure that the final product meets expectations. Finally, buyers should consider local suppliers to reduce shipping costs and tariffs, making the overall investment more manageable.

Scenario 3: Challenges in Integrating Holographic Cards into Existing Systems

The Problem: B2B buyers often face integration challenges when trying to incorporate holographic cards into their existing systems, whether for inventory management, promotional campaigns, or customer engagement strategies. This is particularly true for companies operating in diverse markets like Kenya or Colombia, where technological infrastructure may be inconsistent. The inability to seamlessly integrate these cards can lead to inefficiencies and missed opportunities for leveraging their full potential.

The Solution: To address integration challenges, buyers should prioritize sourcing holographic cards that are compatible with existing systems, such as point-of-sale (POS) systems or customer relationship management (CRM) software. Conducting a thorough assessment of current technological capabilities before selecting holographic card features is crucial. Buyers should also invest in training programs for their teams to ensure they are adept at utilizing new technologies associated with holographic cards. Partnering with tech-savvy vendors who can provide ongoing support and integration services can also help bridge the gap. Finally, piloting the use of holographic cards in a limited capacity can provide valuable insights and facilitate smoother integration into broader business operations.

Strategic Material Selection Guide for holographic cards

When selecting materials for holographic cards, international B2B buyers must consider various factors that influence the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in the production of holographic cards, highlighting their properties, advantages, disadvantages, and specific considerations for international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyvinyl Chloride (PVC) for Holographic Cards?

Polyvinyl Chloride (PVC) is one of the most widely used materials for holographic cards due to its excellent durability and versatility. PVC can withstand a wide range of temperatures, typically from -15°C to 60°C, making it suitable for various climates. It also exhibits good resistance to chemicals and moisture, which is crucial for maintaining the integrity of the holographic images.

Pros and Cons of PVC

The primary advantage of PVC is its cost-effectiveness, as it is relatively inexpensive to manufacture and process. However, it has a lower tensile strength compared to other materials, which can lead to tearing under extreme conditions. Additionally, PVC is less environmentally friendly, raising concerns in markets with stringent sustainability regulations.

How Does Polycarbonate Compare as a Material for Holographic Cards?

Polycarbonate is another popular choice, known for its exceptional impact resistance and clarity. It can endure higher temperatures than PVC, with a rating of up to 120°C. This makes polycarbonate suitable for applications where durability and visual quality are paramount.

Pros and Cons of Polycarbonate

While polycarbonate provides superior strength and optical clarity, it comes at a higher cost compared to PVC. The manufacturing process is also more complex, which can lead to longer lead times. For international buyers, especially in regions with varying economic conditions, the higher initial investment must be justified by the enhanced performance and longevity of the product.

What Are the Advantages of Using PET (Polyethylene Terephthalate) for Holographic Cards?

Polyethylene Terephthalate (PET) is gaining popularity due to its excellent dimensional stability and resistance to environmental stress. It can withstand temperatures from -40°C to 80°C and offers good chemical resistance, making it suitable for various applications, including those in humid environments.

Pros and Cons of PET

The key advantage of PET is its recyclability, aligning with the growing demand for sustainable materials in the global market. However, PET can be more expensive than PVC, and its production requires specific manufacturing conditions, which may not be readily available in all regions. Buyers in Africa and South America should consider local manufacturing capabilities when opting for PET.

Why Is Paperboard Still Relevant for Holographic Cards?

Paperboard, while not as durable as synthetic materials, remains relevant in specific applications, particularly for promotional items and temporary uses. It is lightweight and can be easily printed on, allowing for vibrant designs that enhance the holographic effect.

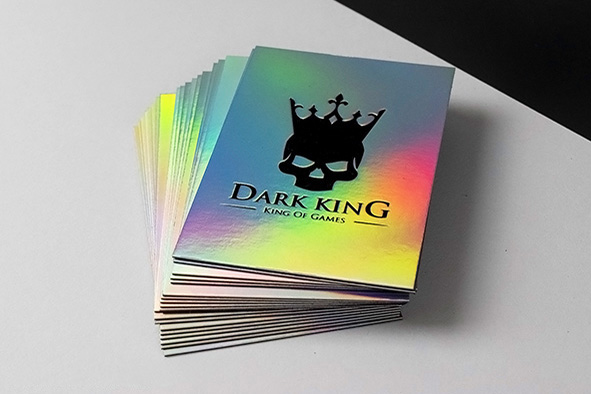

A stock image related to holographic cards.

Pros and Cons of Paperboard

The main advantage of paperboard is its low cost and ease of customization. However, it is less resistant to moisture and physical damage, which can limit its use in more demanding environments. International buyers must consider the intended use and environmental conditions when selecting paperboard for holographic cards.

Summary Table of Material Selection for Holographic Cards

| Material | Typical Use Case for holographic cards | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Loyalty cards, ID cards | Cost-effective and durable | Lower tensile strength | Low |

| Polycarbonate | High-security cards, premium products | Superior strength and clarity | Higher cost and complex manufacturing | High |

| PET | Eco-friendly cards, durable packaging | Recyclable and stable | More expensive and specific production requirements | Medium |

| Paperboard | Temporary promotional cards | Low cost and customizable | Less durable and moisture-sensitive | Low |

In conclusion, selecting the right material for holographic cards involves balancing performance, cost, and environmental considerations. International buyers should evaluate their specific needs and market conditions to make informed decisions that align with their business objectives.

In-depth Look: Manufacturing Processes and Quality Assurance for holographic cards

What Are the Key Stages in the Manufacturing Process of Holographic Cards?

Manufacturing holographic cards involves a series of meticulous stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The production of holographic cards begins with the selection of high-quality materials. Commonly used materials include:

- Polymer Films: These films serve as the base for the holographic images. They must be durable and have high optical clarity.

- Holographic Foils: These are typically produced using a special embossing process, which creates the three-dimensional patterns essential for the holographic effect.

- Adhesives and Inks: These materials are critical for bonding layers together and adding visual elements, respectively.

During this stage, suppliers must ensure that materials meet international standards for safety and performance. Buyers should verify material certifications to avoid issues in the final product.

How Are Holographic Cards Formed?

The forming stage involves several techniques to create the desired holographic patterns. The two main techniques are:

- Embossing: This process uses heat and pressure to imprint a holographic pattern onto the polymer film. The precision of this step is crucial as it directly affects the quality of the final image.

- Laser Etching: This advanced technique employs lasers to create intricate designs and patterns on the surface of the card. It offers greater flexibility in design compared to traditional embossing.

Both methods require specialized machinery and skilled operators. B2B buyers should inquire about the technology used by their suppliers, as advanced equipment often translates to higher quality products.

What Is Involved in the Assembly Stage?

The assembly stage combines various components to create the final product. This includes:

- Layering: The holographic foil is layered with other materials such as printed designs and protective coatings. Each layer must be aligned perfectly to ensure a seamless appearance.

- Cutting: After layering, the cards are cut to the desired dimensions. Precision cutting is essential to maintain consistency across large batches.

- Laminating: A protective laminate is often added to enhance durability and resistance to wear and tear.

Quality checks during assembly are vital. Buyers can request information on the assembly line processes to ensure adherence to quality standards.

What Finishing Techniques Enhance Holographic Cards?

Finishing techniques are the final touch in the manufacturing process and can significantly enhance the appeal of holographic cards. Common finishing methods include:

- Coating: Applying a special coating can improve scratch resistance and overall durability.

- Printing: Additional designs, logos, or text may be printed on the card surface, which requires precision to avoid misalignment.

- Quality Control: After finishing, a thorough quality control assessment is conducted to identify any defects.

Buyers should seek samples to evaluate the quality of finishing techniques used by suppliers.

What Quality Assurance Measures Are Essential for Holographic Cards?

Quality assurance (QA) in the manufacturing of holographic cards is crucial for ensuring consistency and reliability. Several international standards and industry-specific regulations guide this process.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 provide frameworks for quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality throughout the production process.

Additionally, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended use of the holographic cards. For example, cards used in security applications may require more stringent testing and certifications.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are vital at various stages of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage meets quality standards.

- Final Quality Control (FQC): This final inspection checks the complete product against predefined quality metrics before shipment.

B2B buyers should inquire about the specific QC processes employed by their suppliers to ensure comprehensive quality oversight.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to quality standards, B2B buyers should adopt several verification strategies:

- Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. This includes examining documentation, production methods, and equipment maintenance.

- Quality Reports: Requesting detailed quality reports can help buyers assess the supplier’s performance over time. These reports should include information on defects, returns, and compliance with standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly important for international transactions where buyers may not be able to visit facilities personally.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, there are unique considerations regarding quality control:

- Cultural Differences: Understanding the cultural context of suppliers can help in establishing effective communication about quality expectations.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should familiarize themselves with local requirements to avoid compliance issues.

- Logistics and Shipping: Quality can be affected during shipping. Buyers should ensure that their suppliers have robust packaging and shipping protocols to minimize damage.

By focusing on these areas, international B2B buyers can enhance their procurement strategies for holographic cards, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘holographic cards’

In today’s competitive market, sourcing high-quality holographic cards requires a strategic approach to ensure that your business meets its needs while maximizing value. This step-by-step checklist is designed to guide international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, through the essential steps of procuring holographic cards effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to clearly outline the technical specifications of the holographic cards you need. Consider aspects such as size, design, material, and the specific holographic effects you require.

– Why it Matters: Clearly defined specifications help prevent miscommunication and ensure that suppliers understand your requirements, reducing the risk of receiving subpar products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in holographic cards. Utilize online platforms, industry directories, and trade shows to compile a list of reputable vendors.

– What to Look For: Focus on suppliers with a proven track record in your industry and positive reviews from previous clients. Look for case studies that demonstrate their ability to meet similar needs.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers hold relevant certifications that verify their quality management systems, such as ISO certifications. This step is crucial for ensuring that the products meet international quality standards.

– Why it Matters: Certifications provide assurance of a supplier’s commitment to quality and reliability, which is vital for maintaining your business’s reputation.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the holographic cards from your top suppliers. This allows you to assess the quality of the materials and the effectiveness of the holographic effects firsthand.

– What to Assess: Pay attention to the clarity of the holographic images, the durability of the card, and overall design quality. This hands-on evaluation can significantly influence your final decision.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare not just the prices, but also the payment terms, delivery timelines, and any additional fees.

– Why it Matters: Understanding the full cost structure and terms can help you avoid unexpected expenses later on and allows you to negotiate better deals.

Step 6: Check References and Reviews

Before making a final decision, contact references provided by the suppliers and read online reviews. This can provide insights into the supplier’s reliability, customer service, and ability to meet deadlines.

– What to Ask: Inquire about the supplier’s responsiveness, their handling of issues, and whether clients received their orders on time and as promised.

Step 7: Finalize Your Order with Clear Agreements

Once you have selected a supplier, finalize your order with a clear agreement that outlines all terms, including specifications, delivery dates, payment terms, and after-sales support.

– Why it Matters: A well-documented agreement protects both parties and serves as a reference point in case of any disputes, ensuring a smoother procurement process.

A stock image related to holographic cards.

By following these steps, B2B buyers can navigate the complexities of sourcing holographic cards with confidence, ensuring they select the right supplier that meets their business needs.

Comprehensive Cost and Pricing Analysis for holographic cards Sourcing

What are the Key Cost Components in Holographic Cards Production?

When sourcing holographic cards, understanding the comprehensive cost structure is crucial for B2B buyers. The costs can be categorized into several components:

-

Materials: The quality and type of materials used significantly impact costs. Holographic films, inks, and substrates can vary widely in price based on their properties and sourcing location. Opting for high-quality materials may increase upfront costs but can enhance the card’s durability and appeal.

-

Labor: Labor costs depend on the complexity of the manufacturing process and the location of the production facility. In regions with higher labor costs, such as parts of Europe, you may find the total cost of production to be higher than in countries with lower wages.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment depreciation, and facility maintenance. Effective management of these overheads can lead to significant savings, particularly for larger orders.

-

Tooling: Initial tooling costs for molds and dies can be substantial, especially for customized designs. Buyers should consider these costs as part of their total investment when placing orders.

-

Quality Control (QC): Implementing robust QC processes ensures that the final product meets the required standards. While this may introduce additional costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the destination and the chosen Incoterms. Buyers must factor in these logistics costs, especially when importing from suppliers in other continents.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the market rates can help buyers negotiate better deals.

How Do Price Influencers Affect Holographic Card Sourcing?

Several factors influence the pricing of holographic cards, and being aware of these can empower international B2B buyers to make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Prices per unit tend to decrease with larger order volumes. Buyers should assess their needs to negotiate favorable terms and consider potential stockpiling to benefit from bulk pricing.

-

Specifications and Customization: Custom designs and specific features can add to the cost. Buyers should clearly define their requirements to avoid unexpected expenses and delays.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., ISO) may increase costs but can also enhance the product’s value proposition. Buyers should weigh the benefits against their budget constraints.

-

Supplier Factors: The supplier’s reputation, experience, and location can all affect pricing. It’s advisable to conduct thorough research and potentially visit suppliers to establish trust and negotiate better terms.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for cost management. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact total costs.

What Are the Best Practices for Negotiating Holographic Card Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing holographic cards:

-

Conduct a Total Cost of Ownership Analysis: Beyond initial prices, consider all associated costs over the product’s lifecycle, including maintenance, shipping, and potential returns.

-

Leverage Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and flexibility in negotiations.

-

Request Samples: Before placing large orders, request samples to evaluate quality and ensure that it meets your specifications. This can prevent costly mistakes later.

-

Stay Informed About Market Trends: Awareness of fluctuations in material costs, labor rates, and market demand can provide leverage in negotiations.

-

Explore Alternative Suppliers: Diversifying your supplier base can help mitigate risks and provide options for better pricing.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s important for buyers to understand that the prices quoted for holographic cards are often indicative and can fluctuate based on market conditions, material availability, and exchange rates. Always seek detailed quotes and clarify any assumptions to avoid surprises during the procurement process.

Alternatives Analysis: Comparing holographic cards With Other Solutions

Understanding Alternatives in Holographic Card Technology

In the realm of innovative solutions for security, branding, and customer engagement, holographic cards stand out due to their unique visual effects and anti-counterfeiting features. However, various alternatives can serve similar purposes, catering to the diverse needs of international B2B buyers. This analysis compares holographic cards with alternative technologies, offering insights to help businesses make informed decisions.

Comparison Table

| Comparison Aspect | Holographic Cards | NFC (Near Field Communication) | QR Codes |

|---|---|---|---|

| Performance | High visual impact and security features | Fast data transfer, interactive | Easy to scan, versatile |

| Cost | Moderate to high, depending on customization | Low to moderate, depending on technology | Very low, minimal printing costs |

| Ease of Implementation | Requires specialized printing technology | Requires NFC-enabled devices | Simple to generate and print |

| Maintenance | Durable but can be scratched or damaged | Generally low maintenance, durable | Low maintenance, dependent on print quality |

| Best Use Case | High-end branding and anti-counterfeiting | Contactless payments, access control | Marketing campaigns, product information |

Detailed Breakdown of Alternatives

What are the advantages and disadvantages of NFC technology?

NFC technology is increasingly popular for its ability to facilitate seamless transactions and interactions. Its primary advantage lies in its speed and convenience, enabling users to make contactless payments or access information simply by tapping their devices. This technology is cost-effective, especially for businesses already leveraging mobile applications. However, NFC requires specific hardware and user education, which can be a barrier for some businesses.

How do QR codes compare to holographic cards?

QR codes are an inexpensive alternative that provides significant versatility. They can be printed on various materials and scanned with any smartphone, making them highly accessible. Businesses can use QR codes for marketing campaigns, product information, and event registrations. Despite their low cost and ease of implementation, QR codes lack the visual appeal and security features of holographic cards. They can also be easily replicated, making them less effective for high-security applications.

How to Choose the Right Solution for Your Business Needs

When evaluating holographic cards against alternatives like NFC technology and QR codes, it’s essential for B2B buyers to consider their specific objectives. Holographic cards are ideal for businesses looking for high-end branding and robust security features. In contrast, NFC technology excels in environments requiring fast and convenient interactions, while QR codes offer an economical option for marketing and information dissemination.

Ultimately, the right choice will depend on factors such as budget, desired impact, and the nature of the product or service being offered. By assessing these elements, businesses can align their selection with their strategic goals, ensuring they choose the most effective solution for their needs.

Essential Technical Properties and Trade Terminology for holographic cards

What Are the Key Technical Properties of Holographic Cards?

When considering the procurement of holographic cards, it’s essential to understand their technical properties. These specifications not only affect the quality of the product but also its applicability in various industries. Here are some critical technical properties:

-

Material Grade

Holographic cards are typically made from PVC, PET, or other specialized polymers. The material grade impacts durability, flexibility, and the card’s ability to hold holographic effects. Higher-grade materials may incur higher costs but often yield better performance and longevity, which is crucial for businesses looking to maintain a professional image. -

Tolerance Levels

Tolerance refers to the allowable deviation in the card’s dimensions and properties. For instance, a tolerance of ±0.1 mm might be acceptable for thickness but could be critical for fit within card readers. Ensuring that manufacturers meet the specified tolerances can prevent operational issues in applications like identification cards or payment systems. -

Print Quality

The print quality of holographic cards is paramount, particularly for branding purposes. Key metrics include resolution (measured in DPI) and color accuracy. High-resolution prints with accurate color reproduction enhance the card’s visual appeal, which can be a decisive factor for businesses focused on customer engagement and brand recognition. -

Adhesive Strength

In cases where holographic cards are layered or include additional features (like RFID chips), the strength of the adhesive used can be crucial. Poor adhesive quality can lead to delamination or failure of the card’s functionalities. Buyers should assess adhesive properties to ensure reliability, especially in demanding environments. -

Environmental Resistance

Holographic cards should be able to withstand various environmental factors, such as UV exposure, moisture, and temperature fluctuations. Cards that fail to maintain their integrity in these conditions may lead to increased replacement costs. Understanding the environmental resistance ratings can help buyers choose products suited for specific applications.

What Are Common Trade Terms in the Holographic Card Industry?

Navigating the procurement process in the holographic card industry requires familiarity with specific trade terminology. Here are several terms that international B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of holographic cards, OEMs often provide custom solutions tailored to specific business needs, which can be a valuable option for companies seeking unique branding opportunities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory planning. Buyers from regions like Africa and South America should negotiate MOQs that align with their operational capabilities to avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. Utilizing RFQs can streamline the procurement process and ensure that buyers receive competitive pricing and clear terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help businesses avoid misunderstandings and ensure smooth transactions across borders, particularly in regions with complex trade regulations. -

Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times is vital for inventory management, especially for businesses that rely on just-in-time delivery to minimize stock levels. Buyers should inquire about lead times upfront to align their procurement with operational schedules.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their purchasing strategy for holographic cards, ensuring they choose products that meet their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the holographic cards Sector

What Are the Key Market Trends Driving the Holographic Cards Sector?

The holographic cards market is experiencing a transformative phase, driven by technological advancements, increasing demand for innovative marketing solutions, and a growing emphasis on personalization. Global drivers include the rise of digital marketing strategies that utilize holographic cards for promotional campaigns, particularly in sectors like entertainment, gaming, and security. Notably, the integration of augmented reality (AR) with holographic cards is creating immersive experiences that attract consumers and enhance brand engagement.

In regions such as Africa and South America, the adoption of holographic technology is accelerating as businesses seek to differentiate themselves in competitive markets. For instance, companies in Kenya and Colombia are leveraging holographic cards for product launches and marketing events, which have proven effective in capturing audience attention. Furthermore, the Middle East is witnessing a surge in demand for holographic cards in the luxury goods sector, where exclusivity and innovation are paramount.

Emerging trends include the rise of eco-friendly holographic materials, driven by consumer preferences for sustainable products. Additionally, the increasing availability of cost-effective production technologies is allowing small and medium enterprises (SMEs) to enter the market, enhancing competition and innovation. International B2B buyers must stay attuned to these dynamics to effectively navigate sourcing decisions and capitalize on opportunities.

How Can Sustainability and Ethical Sourcing Impact the Holographic Cards Market?

Sustainability is becoming a critical consideration for B2B buyers in the holographic cards sector, as environmental concerns gain prominence across industries. The production of traditional holographic cards can involve materials that are not environmentally friendly, leading to increased scrutiny and pressure from consumers and regulators alike. Therefore, adopting sustainable practices and sourcing eco-friendly materials is essential for companies aiming to maintain competitiveness and fulfill corporate social responsibilities.

Ethical sourcing practices are equally important, as they ensure that materials used in holographic cards are obtained without compromising human rights or environmental standards. Buyers should prioritize suppliers that provide transparency regarding their sourcing processes and adhere to recognized sustainability certifications.

Additionally, innovations in materials science have led to the development of biodegradable holographic films and inks. These advancements not only reduce environmental impact but also appeal to a growing segment of consumers who prioritize sustainability. By investing in suppliers that offer green certifications and sustainable materials, international B2B buyers can enhance their brand image and meet the increasing demand for responsible products.

What Is the Evolution of Holographic Cards and Their Relevance Today?

The evolution of holographic cards dates back to the late 20th century when holography technology was primarily used in security and authentication applications. Initially, these cards were limited to high-security environments, such as banking and government ID verification. However, as technology advanced, the use of holographic images expanded into marketing and branding, providing a unique way for businesses to stand out in crowded markets.

Today, holographic cards are not only utilized for their security features but also for their aesthetic appeal and interactive capabilities. The advent of digital printing technologies and AR has further revolutionized the sector, allowing for greater customization and engagement. This evolution has positioned holographic cards as a versatile tool for B2B marketing strategies, making them relevant across various industries, from consumer goods to high-end luxury markets.

International B2B buyers should recognize the historical context of holographic cards as they evaluate current trends and innovations, ensuring that they leverage these technologies effectively in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of holographic cards

-

How do I solve issues related to the quality of holographic cards?

To address quality concerns, initiate a thorough supplier vetting process. Request samples before placing a bulk order to evaluate the print quality, durability, and visual effects of the holographic cards. Establish clear quality assurance protocols that include regular inspections and testing during production. Collaborate closely with your supplier to ensure they meet your specific standards and requirements. Open communication channels for feedback can help resolve any issues promptly. -

What is the best way to customize holographic cards for branding?

The best approach to customizing holographic cards for branding involves collaborating with suppliers who offer flexible design options. Start by providing your logo and design elements in high-resolution formats. Discuss the specific holographic effects that align with your brand identity, such as color shifts or patterns. Ensure the supplier can accommodate your design needs within their production capabilities and timelines, allowing for iterations until the final product meets your expectations. -

What should I consider when determining the minimum order quantity (MOQ) for holographic cards?

When evaluating the MOQ for holographic cards, consider factors such as your budget, storage capacity, and projected demand. Suppliers typically set MOQs based on production costs and material usage. If you are entering a new market or testing a design, negotiate with suppliers for lower MOQs to minimize risk. Additionally, factor in the potential for future orders to establish a long-term relationship that may allow for more favorable terms over time. -

What are the payment terms I should expect when sourcing holographic cards internationally?

Payment terms for international sourcing of holographic cards can vary widely among suppliers. Common options include upfront deposits (usually 30-50%) with the balance due upon shipment or after delivery. Discuss using secure payment methods such as letters of credit or escrow services to protect your investment. Ensure you understand any additional costs related to currency exchange, taxes, and tariffs that may affect the final price. -

How can I ensure timely delivery and logistics for holographic card orders?

To ensure timely delivery, communicate your expected timelines with suppliers at the outset. Work together to establish a clear production schedule and include buffer time for any unforeseen delays. Choose logistics partners experienced in international shipping to navigate customs and regulatory requirements effectively. Regularly track shipments and maintain communication with your supplier to resolve any potential issues promptly. -

What quality assurance measures should I implement when sourcing holographic cards?

Implementing robust quality assurance measures starts with selecting reputable suppliers known for their adherence to industry standards. Establish a clear set of quality benchmarks, including material specifications and visual effects. Conduct regular audits and inspections during the production process, and ensure a final quality check before shipment. Document all findings and feedback to continuously improve future orders and maintain high-quality standards. -

How do I evaluate and vet suppliers of holographic cards?

To effectively evaluate and vet suppliers of holographic cards, start by researching their market reputation and customer reviews. Request references from past clients and assess their experience in handling international orders. Analyze their production capabilities, including technology and materials used. Schedule discussions to gauge their responsiveness and willingness to collaborate on design and quality requirements, ensuring they align with your business goals. -

What are the potential challenges in sourcing holographic cards from different regions?

Sourcing holographic cards from various regions can present challenges such as differing regulatory standards, language barriers, and variations in production quality. Additionally, shipping logistics may be complicated by customs regulations and tariffs. To mitigate these challenges, conduct thorough research on the market conditions and requirements in your target regions. Establish clear communication and set realistic expectations with suppliers to navigate cultural differences and operational hurdles effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for holographic cards

As the demand for holographic cards continues to rise across diverse markets, strategic sourcing has emerged as a critical component for B2B buyers looking to enhance their competitive edge. By leveraging a robust supply chain and fostering strong partnerships with manufacturers, businesses can ensure access to high-quality materials that meet evolving customer needs.

A stock image related to holographic cards.

How can international buyers optimize their sourcing strategies for holographic cards? Focus on establishing relationships with reputable suppliers who offer innovative solutions, transparent pricing, and sustainable practices. Additionally, consider regional market trends—whether in Africa, South America, the Middle East, or Europe—to tailor your product offerings effectively.

Looking ahead, the holographic card market is poised for growth, driven by advancements in technology and increasing applications in various industries. Now is the time for B2B buyers to take proactive steps to refine their sourcing strategies. By prioritizing collaboration and innovation, you can position your business for success in this dynamic landscape. Embrace the opportunity to lead with holographic cards that capture attention and drive engagement in your target markets.