The Ultimate Guide to Integrated Solutions Console (2025)

Introduction: Navigating the Global Market for integrated solutions console

In the fast-evolving landscape of global commerce, sourcing integrated solutions consoles presents a significant challenge for B2B buyers across continents, particularly in Africa, South America, the Middle East, and Europe. These consoles, which combine various functionalities to enhance operational efficiency, require a keen understanding of diverse supplier capabilities and market dynamics. As businesses increasingly seek to streamline their processes and enhance productivity, making informed purchasing decisions becomes paramount.

This comprehensive guide delves into the intricacies of integrated solutions consoles, covering essential aspects such as types, applications, and supplier vetting processes. It also addresses cost considerations, enabling international buyers to navigate the complexities of procurement with confidence. By offering actionable insights and strategic recommendations, this guide equips B2B buyers with the knowledge to identify the most suitable solutions for their unique operational needs.

Whether you are a buyer from Germany looking to enhance your manufacturing capabilities or a South American enterprise aiming to digitize your operations, understanding the global market for integrated solutions consoles is crucial. This guide serves as a valuable resource, empowering decision-makers to make informed choices that drive their businesses forward, ensuring they remain competitive in an increasingly integrated world.

Understanding integrated solutions console Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cloud-Based Integrated Console | Accessible via the internet, flexible scaling | Remote work, global collaborations | Pros: Cost-effective, easy updates. Cons: Dependent on internet connectivity. |

| On-Premises Integrated Console | Installed on company servers, high control | Manufacturing, sensitive data handling | Pros: Enhanced security, control over data. Cons: Higher upfront costs, maintenance required. |

| Hybrid Integrated Console | Combines cloud and on-premises features | Large enterprises, diverse operations | Pros: Flexibility, tailored solutions. Cons: Complexity in management and integration. |

| Mobile Integrated Console | Optimized for mobile devices, real-time access | Field operations, remote monitoring | Pros: Convenience, instant data access. Cons: Limited functionality compared to desktop versions. |

| Industry-Specific Integrated Console | Tailored to specific sectors (e.g., healthcare) | Niche markets, specialized applications | Pros: Customized features, better compliance. Cons: Potentially higher costs and vendor lock-in. |

What Are the Characteristics of Cloud-Based Integrated Consoles?

Cloud-based integrated consoles are designed for accessibility and scalability, allowing businesses to access their systems from anywhere with an internet connection. This type of console is particularly beneficial for organizations with remote workforces or those needing to collaborate across borders. When considering a cloud solution, B2B buyers should evaluate the provider’s security measures, uptime guarantees, and support services, as these factors are critical in maintaining operational continuity.

How Do On-Premises Integrated Consoles Offer Control?

On-premises integrated consoles provide businesses with complete control over their data and systems, as they are hosted on the company’s servers. This setup is ideal for industries that handle sensitive information, such as finance or healthcare. Buyers should weigh the benefits of enhanced security and compliance against the higher initial investment and ongoing maintenance costs associated with on-premises solutions. Additionally, organizations must assess their IT capabilities to manage such systems effectively.

Why Choose a Hybrid Integrated Console?

Hybrid integrated consoles merge the advantages of both cloud and on-premises solutions, offering flexibility and tailored features. This type is particularly suited for large enterprises with diverse operational needs that require both robust security and the ability to scale. When purchasing a hybrid solution, B2B buyers should focus on integration capabilities, as managing two environments can introduce complexity. Understanding the vendor’s support for seamless integration is crucial to ensuring a smooth operational flow.

What Are the Benefits of Mobile Integrated Consoles?

Mobile integrated consoles are specifically optimized for mobile devices, providing real-time access to data and systems while on the go. They are particularly useful for field operations, allowing employees to input and retrieve data instantly. Buyers should consider the balance between convenience and functionality; while mobile solutions offer flexibility, they may lack some features found in desktop versions. Evaluating the user interface and ease of use is essential for maximizing productivity.

How Do Industry-Specific Integrated Consoles Cater to Niche Markets?

Industry-specific integrated consoles are tailored to meet the unique needs of particular sectors, such as healthcare, manufacturing, or retail. These consoles often include specialized features that enhance compliance and operational efficiency. B2B buyers should assess the long-term value of such solutions, considering both the customization benefits and the potential for vendor lock-in. Understanding how these consoles align with industry regulations and standards is critical for informed purchasing decisions.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

Key Industrial Applications of integrated solutions console

| Industry/Sector | Specific Application of integrated solutions console | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Real-time production monitoring and control | Enhanced efficiency and reduced downtime | Compatibility with existing machinery and scalability options |

| Logistics and Supply Chain | Integrated inventory management systems | Improved accuracy in stock levels and order fulfillment | Integration capabilities with ERP systems and data analytics tools |

| Energy and Utilities | Centralized energy management and monitoring systems | Cost savings through optimized energy usage | Regulatory compliance and adaptability to local energy markets |

| Healthcare | Patient management and data integration systems | Streamlined operations and improved patient outcomes | Data security and compliance with health regulations |

| Agriculture | Smart farming solutions integrating IoT and data analytics | Increased yield and resource efficiency | Local market adaptation and technology support |

How is the Integrated Solutions Console Used in Manufacturing?

In the manufacturing sector, the integrated solutions console serves as a comprehensive platform for real-time production monitoring and control. It enables businesses to track machine performance, manage workflows, and analyze production data seamlessly. This application addresses common challenges such as equipment malfunctions and inefficiencies that lead to downtime. For international buyers, especially in regions like Africa and South America, sourcing consoles that can integrate with existing machinery and scale with production needs is vital for maximizing operational efficiency.

What Role Does the Integrated Solutions Console Play in Logistics and Supply Chain Management?

In logistics and supply chain management, the integrated solutions console facilitates effective inventory management by providing a centralized view of stock levels and order statuses. This application not only improves accuracy in inventory tracking but also enhances order fulfillment processes. For businesses in the Middle East and Europe, it is essential to consider sourcing consoles that can seamlessly integrate with existing ERP systems and utilize advanced data analytics tools to optimize supply chain operations.

How Does the Integrated Solutions Console Enhance Energy Management?

In the energy and utilities sector, the integrated solutions console is pivotal for centralized energy management and monitoring. It allows organizations to analyze energy consumption patterns, identify inefficiencies, and implement cost-saving measures. This application is especially relevant for businesses in Europe, where regulatory compliance and sustainability are critical. Buyers must focus on sourcing solutions that can adapt to local energy markets and meet regulatory standards.

How is the Integrated Solutions Console Transforming Healthcare Operations?

The integrated solutions console plays a significant role in healthcare by providing patient management and data integration systems. This application streamlines operations, enhances patient outcomes, and facilitates better data sharing among healthcare providers. For buyers in the healthcare sector, particularly in Africa and South America, ensuring data security and compliance with health regulations is paramount when sourcing these solutions.

What Benefits Does the Integrated Solutions Console Bring to Agriculture?

In agriculture, the integrated solutions console supports smart farming solutions that leverage IoT and data analytics. This application helps farmers increase yield and optimize resource usage, addressing challenges such as climate variability and resource scarcity. For international buyers, especially in emerging markets, it is crucial to source consoles that can adapt to local agricultural practices and provide ongoing technology support for effective implementation.

Related Video: AMR vs AGV Robotic Solutions in Warehouse Automation

3 Common User Pain Points for ‘integrated solutions console’ & Their Solutions

Scenario 1: Integrating Diverse Systems for Seamless Operations

The Problem: Many B2B buyers face the challenge of integrating multiple legacy systems with modern technology within their organizations. For companies in regions like Africa and South America, where infrastructure may vary significantly, this can lead to operational inefficiencies. Buyers often struggle with data silos, where information from one system is not accessible in another, causing delays in decision-making and complicating workflows.

The Solution: To address this issue, buyers should prioritize the selection of an integrated solutions console that offers robust API capabilities and supports various data formats. When sourcing these solutions, it’s essential to conduct a thorough needs assessment to identify the specific systems that require integration. Engage with vendors that provide customization options and consult their technical teams to create a tailored integration plan. Additionally, implementing a phased rollout can allow teams to adapt to the new system gradually, minimizing disruption.

Scenario 2: Ensuring Data Security and Compliance Across Borders

The Problem: As businesses expand internationally, especially in regions like the Middle East and Europe, they encounter stringent data protection regulations such as GDPR. This poses a significant challenge for B2B buyers who need to ensure that their integrated solutions console complies with these regulations while still allowing for seamless data flow across different jurisdictions. Failing to comply can result in hefty fines and reputational damage.

The Solution: Buyers should look for integrated solutions consoles that come with built-in compliance features, such as data encryption and user access controls. It’s crucial to work closely with vendors to understand how their solutions address local and international compliance requirements. Additionally, conducting regular compliance audits and leveraging the console’s reporting tools can help monitor data handling practices. Investing in training for staff on compliance best practices related to the console will further mitigate risks.

Scenario 3: Managing Change Resistance Within the Organization

The Problem: Introducing an integrated solutions console often meets resistance from employees who are accustomed to existing processes. This change can lead to frustration and decreased productivity, particularly in regions with a strong cultural preference for traditional methods, like parts of Europe and Africa. Buyers need to navigate this change management challenge effectively.

The Solution: To foster acceptance, B2B buyers should implement a comprehensive change management strategy that includes clear communication about the benefits of the new system. Involve key stakeholders early in the decision-making process to garner support and input. Providing hands-on training sessions and ongoing support can significantly ease the transition. Moreover, showcasing early successes from pilot implementations can help build enthusiasm and confidence in the new integrated solutions console, ultimately leading to a smoother adoption process.

Strategic Material Selection Guide for integrated solutions console

What Are the Key Properties of Common Materials Used in Integrated Solutions Consoles?

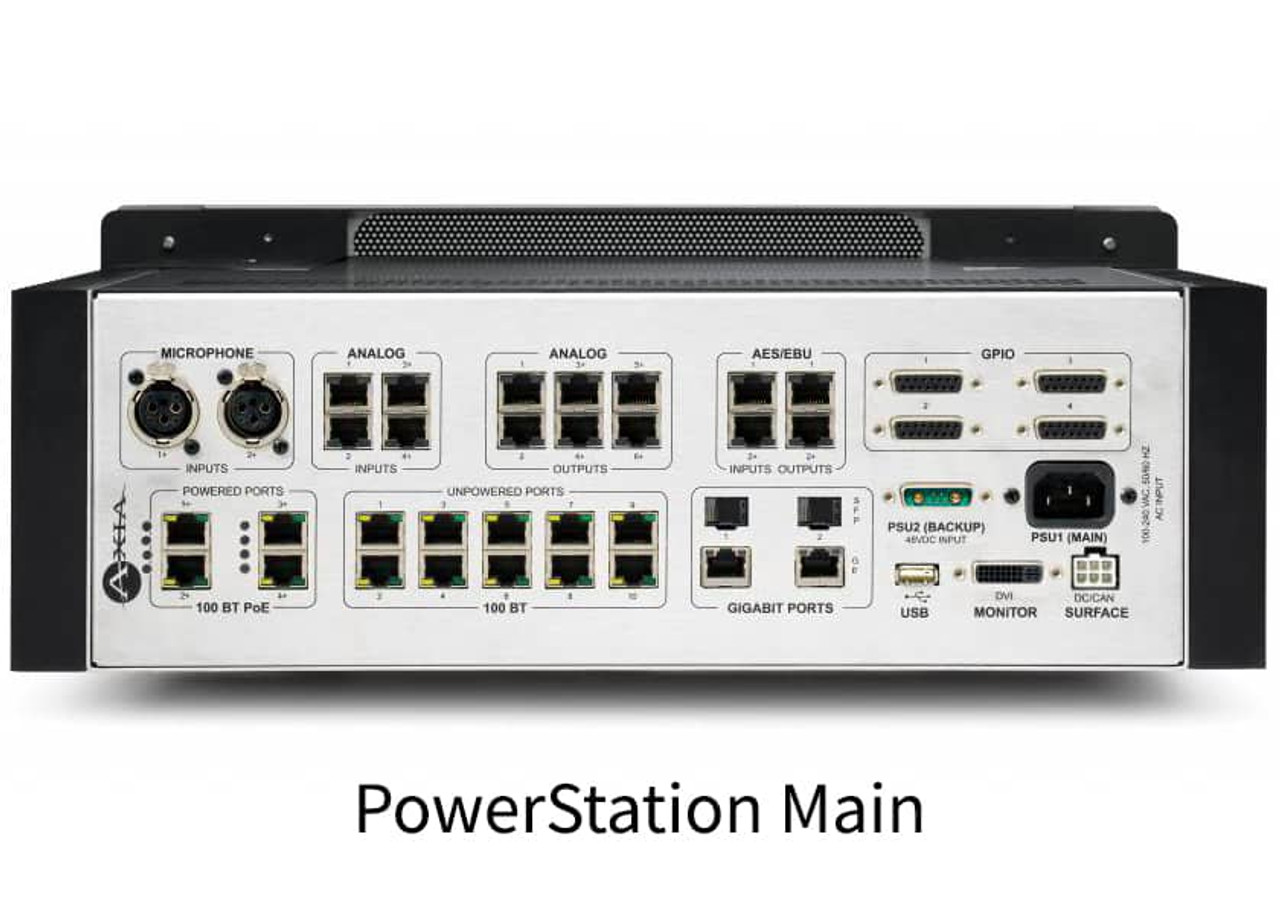

When selecting materials for integrated solutions consoles, it is essential to consider their key properties, which directly affect product performance. The most common materials used include stainless steel, aluminum, plastics, and composites. Each material offers unique benefits and drawbacks that can influence the overall success of the application.

How Does Stainless Steel Perform in Integrated Solutions Consoles?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for environments exposed to moisture or harsh chemicals. It typically has high-temperature and pressure ratings, which are crucial for applications involving steam or high-pressure gases.

Pros: Stainless steel is highly durable and can withstand extreme conditions, making it suitable for long-term use. It is also relatively easy to clean and maintain, which is a significant advantage in industries like food processing and pharmaceuticals.

Cons: The primary drawback of stainless steel is its cost, which can be significantly higher than other materials. Additionally, manufacturing complexity can increase due to the need for specialized tools and techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, which makes it a versatile choice for many industries.

Considerations for International Buyers: Buyers from regions like Europe, Africa, and the Middle East should ensure compliance with international standards such as ASTM and DIN. In Germany, for example, specific grades of stainless steel are preferred for their mechanical properties.

What Advantages Does Aluminum Offer for Integrated Solutions Consoles?

Aluminum is lightweight and has excellent thermal conductivity, making it suitable for applications where weight savings are crucial. It also exhibits good corrosion resistance, especially when anodized.

Pros: The lightweight nature of aluminum allows for easier handling and installation. Additionally, it is often more cost-effective than stainless steel, making it an attractive option for budget-conscious projects.

Cons: Aluminum has lower strength compared to stainless steel and may not be suitable for high-pressure applications. Its susceptibility to scratching and denting can also be a concern in rugged environments.

Impact on Application: Aluminum is compatible with various media but may not perform well with certain chemicals, requiring careful selection based on the specific application.

Considerations for International Buyers: Buyers should be aware of the local standards for aluminum alloys, such as JIS in Japan or EN in Europe, which dictate the material properties and performance criteria.

How Do Plastics Compare in Terms of Performance and Cost?

Plastics, including polycarbonate and PVC, are often used for integrated solutions consoles due to their versatility and low cost. They are lightweight and can be molded into complex shapes.

Pros: Plastics are generally resistant to corrosion and can be manufactured in various colors and finishes. They are also less expensive than metals, making them a popular choice for many applications.

Cons: The primary limitation of plastics is their lower strength and heat resistance compared to metals. They may also degrade over time when exposed to UV light or certain chemicals.

Impact on Application: Plastics are suitable for non-structural components and applications where weight is a concern, but compatibility with specific media should be evaluated to avoid degradation.

Considerations for International Buyers: Buyers should ensure that the selected plastics meet relevant safety and environmental standards, such as RoHS compliance in Europe.

What Role Do Composites Play in Integrated Solutions Consoles?

Composites, such as fiberglass-reinforced plastics, offer a unique combination of strength and lightweight properties. They are increasingly used in applications where high performance is required without the weight penalty of metals.

A stock image related to integrated solutions console.

Pros: Composites provide excellent corrosion resistance and can be tailored to meet specific performance requirements. They are also lightweight, which can reduce shipping and handling costs.

Cons: The manufacturing process for composites can be complex and costly, which may limit their use in certain applications. Additionally, they may not be as widely accepted in traditional industries compared to metals.

Impact on Application: Composites are suitable for specialized applications, particularly in industries like aerospace and automotive, where weight and performance are critical.

Considerations for International Buyers: Buyers should consider the availability of composite materials and their compliance with local standards, especially in regions with stringent regulations.

Summary Table of Material Selection for Integrated Solutions Consoles

| Material | Typical Use Case for Integrated Solutions Console | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure applications in harsh environments | Exceptional strength and durability | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight structures and components | Cost-effective and lightweight | Lower strength and scratch susceptibility | Medium |

| Plastics | Non-structural components and enclosures | Corrosion-resistant and versatile | Lower strength and heat resistance | Low |

| Composites | Specialized applications in aerospace and automotive | Tailored performance and lightweight | Complex manufacturing process | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for integrated solutions console

What Are the Main Stages of Manufacturing an Integrated Solutions Console?

The manufacturing of an integrated solutions console involves several critical stages that ensure the final product meets the necessary specifications and quality standards. These stages include:

-

Material Preparation: This initial phase involves selecting the right materials based on the console’s design specifications. Common materials include metals such as aluminum or steel for structural components, and plastics for enclosures. Material quality is paramount, and suppliers should provide certifications for the materials used, ensuring they meet international standards.

-

Forming: The forming process involves shaping the raw materials into the desired components. Techniques such as stamping, bending, and machining are frequently employed. Advanced technologies like CNC (Computer Numerical Control) machining allow for precise shaping, which is crucial for high-quality assembly.

-

Assembly: During the assembly stage, various components are brought together to create the integrated solutions console. This may involve both manual and automated processes. Attention to detail is vital here, as any misalignment can lead to performance issues. Employing skilled labor alongside automated systems can enhance efficiency and consistency.

-

Finishing: The final stage includes surface treatments and coatings to enhance durability and aesthetics. Techniques such as powder coating, anodizing, or painting are commonly used. This stage also provides an opportunity for additional quality checks to ensure that the finished product meets all specifications before shipping.

Which Key Techniques Are Used in the Manufacturing of Integrated Solutions Consoles?

Several key techniques are integral to the manufacturing process of integrated solutions consoles.

-

Computer-Aided Design (CAD): CAD software is crucial for designing components that are not only functional but also manufacturable. It allows for simulations and modifications before the actual manufacturing begins, reducing errors and waste.

-

Robotics and Automation: Automated systems can significantly increase production efficiency and consistency. Robotic arms are often used in assembly lines to handle repetitive tasks, ensuring precision and reducing the risk of human error.

-

Lean Manufacturing: This approach focuses on minimizing waste while maximizing productivity. Implementing lean principles can help manufacturers streamline processes, reduce costs, and improve product quality.

What Quality Assurance Standards Should B2B Buyers Look For?

International quality assurance standards play a crucial role in ensuring the reliability and safety of integrated solutions consoles. B2B buyers should look for the following certifications:

-

ISO 9001: This globally recognized standard focuses on quality management systems. It ensures that organizations consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For consoles used in industries such as oil and gas, adherence to American Petroleum Institute (API) standards is critical for ensuring the equipment’s reliability and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality Control (QC) is integrated at various stages of the manufacturing process to ensure that the final product meets the desired specifications. The key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection focuses on the raw materials received from suppliers. It ensures that materials comply with predefined specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): This ongoing inspection occurs during the manufacturing process. It involves monitoring key parameters and making adjustments in real-time to prevent defects.

-

Final Quality Control (FQC): After assembly, a thorough inspection is conducted to verify that the entire console meets all quality standards and specifications. This includes functional testing and performance validation.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to ensure the quality of integrated solutions consoles:

-

Functional Testing: This method checks whether the console operates as intended under normal and extreme conditions.

-

Stress Testing: This involves subjecting the console to extreme conditions to assess its durability and reliability.

-

Environmental Testing: This ensures that the console can withstand various environmental conditions, such as humidity, temperature fluctuations, and exposure to chemicals.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of their suppliers:

-

Audits: Conducting regular audits of suppliers can help assess their quality management systems. This includes reviewing documentation, processes, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their quality control measures and testing results.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of several nuances when it comes to quality control:

-

Cultural Differences: Understanding the local manufacturing culture and practices can help buyers navigate potential challenges. For instance, quality standards may vary significantly across regions.

-

Regulatory Compliance: Different regions may have specific regulations that must be adhered to. Buyers should ensure that their suppliers are compliant with local regulations and international standards.

-

Supply Chain Transparency: Establishing clear communication channels with suppliers can enhance transparency throughout the supply chain, allowing for better quality assurance and risk management.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for integrated solutions consoles. Understanding the intricacies of manufacturing and quality control is essential for ensuring that the products meet both performance and regulatory standards, ultimately leading to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘integrated solutions console’

Introduction

In today’s competitive business landscape, procuring an integrated solutions console can significantly enhance operational efficiency and decision-making capabilities. This guide serves as a practical checklist for B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to navigate the sourcing process effectively. Each step is designed to ensure that you make informed decisions, mitigate risks, and achieve optimal value from your investment.

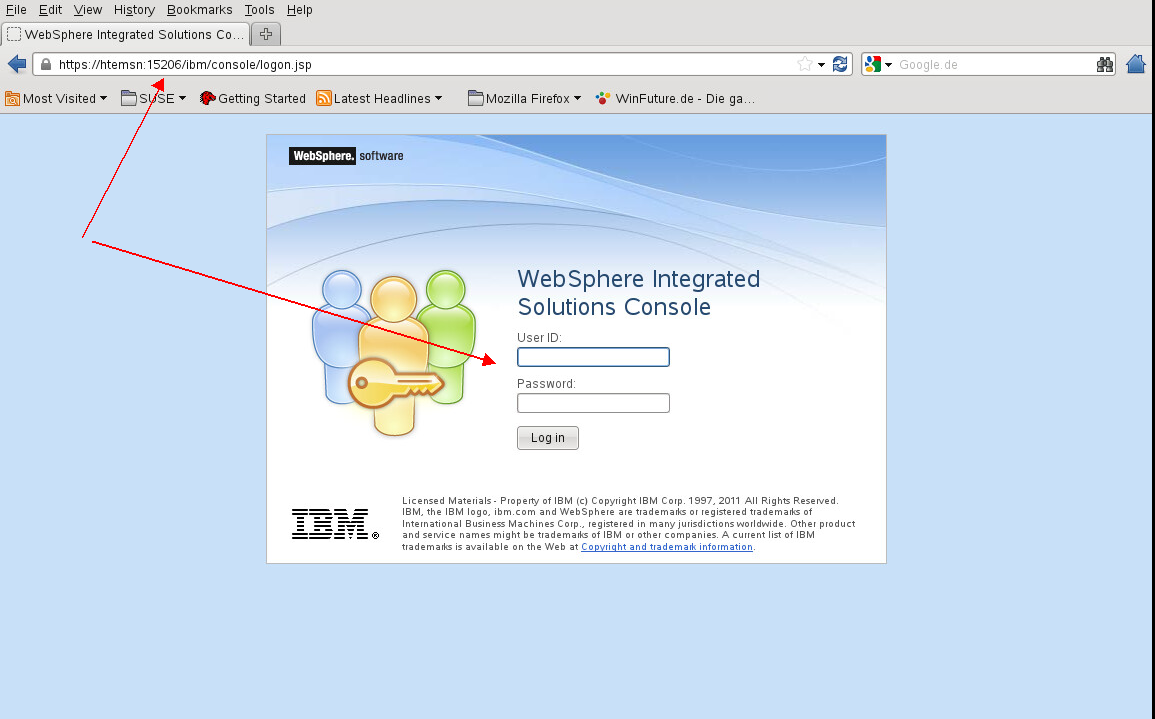

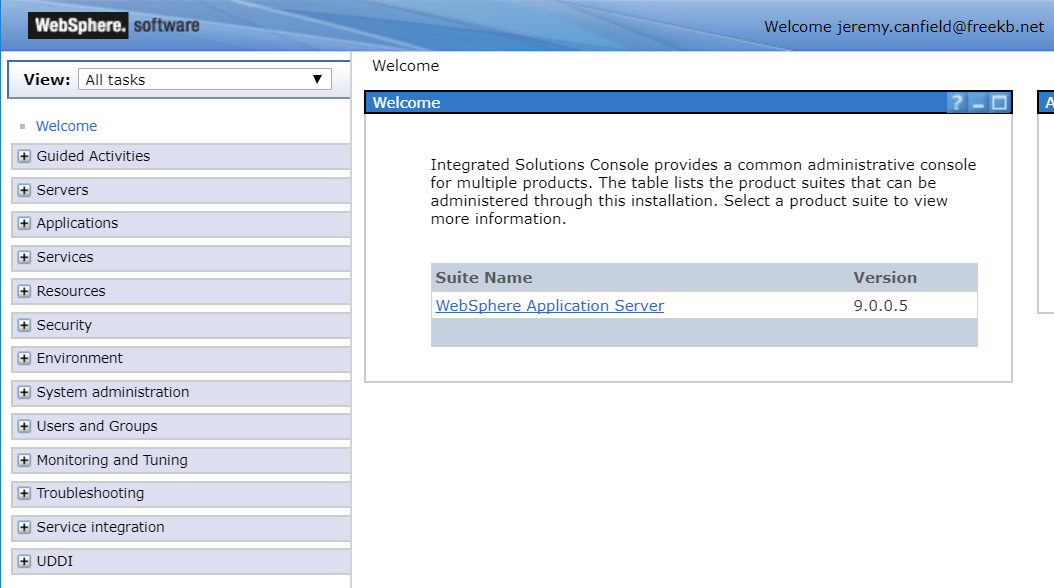

Step 1: Define Your Technical Specifications

A stock image related to integrated solutions console.

Start by clearly outlining your technical requirements for the integrated solutions console. This includes understanding the functionalities needed, such as data integration capabilities, user interface preferences, and system compatibility.

- Identify key features: Determine essential features like real-time analytics, multi-user access, and security protocols that align with your business needs.

- Consider scalability: Ensure the solution can grow with your business, accommodating increased data loads or additional users without performance degradation.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in providing integrated solutions consoles.

- Utilize industry resources: Leverage online databases, industry reports, and trade shows to compile a list of reputable vendors.

- Check regional expertise: Focus on suppliers who have experience in your specific market, as they may better understand local regulations and challenges.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Assess previous projects: Look for evidence of successful implementations that demonstrate the supplier’s capability to deliver on your specifications.

- Engage with current clients: Reach out to existing customers to inquire about their satisfaction levels and any challenges faced during the integration process.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and compliance standards relevant to your industry.

- Check for quality certifications: Certifications such as ISO 9001 or similar can indicate a commitment to quality management practices.

- Understand data protection standards: Inquire about compliance with data protection regulations like GDPR or CCPA, especially if your operations involve sensitive information.

Step 5: Request Detailed Proposals

Once you have narrowed down your supplier options, request detailed proposals that outline their offerings, pricing, and implementation plans.

- Compare offerings: Look for comprehensive details on functionalities, support services, and pricing structures to make an apples-to-apples comparison.

- Ask about customization options: Ensure the supplier can tailor the solution to meet your specific requirements, which can be vital for optimal integration into your existing systems.

Step 6: Conduct a Risk Assessment

Evaluate potential risks associated with each supplier and their proposed solutions.

- Identify operational risks: Consider factors such as supplier reliability, potential delays in delivery, and the impact on your operations during the integration phase.

- Plan for contingencies: Develop a risk mitigation plan that includes backup suppliers and alternative solutions to safeguard your operations.

Step 7: Negotiate Terms and Finalize the Agreement

Finally, engage in negotiations to secure favorable terms and conditions before finalizing the agreement.

- Discuss payment terms: Ensure payment structures align with your budget and cash flow needs.

- Clarify support and maintenance: Confirm the level of ongoing support and maintenance included in the contract to avoid unexpected costs later on.

By following this step-by-step checklist, you can effectively source an integrated solutions console that meets your business requirements while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for integrated solutions console Sourcing

What Are the Key Cost Components in Sourcing Integrated Solutions Consoles?

When sourcing integrated solutions consoles, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: This encompasses all raw materials required to manufacture the console, including metals, plastics, and electronic components. Prices can fluctuate based on global supply chain dynamics and the availability of specific materials.

-

Labor: Labor costs vary significantly by region. In countries with higher wage standards, such as Germany, the labor cost may be a major factor. Conversely, sourcing from regions with lower labor costs, like parts of Africa or South America, may yield savings but could impact quality and lead times.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can minimize overhead, thus reducing overall costs.

-

Tooling: Custom tooling for specific designs can be a significant initial investment. However, once established, this cost can be amortized over the production volume, making it essential to consider the expected quantity when evaluating tooling costs.

-

Quality Control (QC): Ensuring the product meets quality standards incurs costs associated with inspections, testing, and certifications. Quality assurance is especially critical for international buyers to maintain compliance with various regulatory standards.

A stock image related to integrated solutions console.

-

Logistics: Shipping, handling, and storage costs can significantly affect the final price. Buyers should account for the logistics involved in international shipping, including potential tariffs and delays.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding typical margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Integrated Solutions Console Costs?

Several factors influence the pricing of integrated solutions consoles. These include:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom features can increase costs. It is essential to clearly define specifications to avoid unexpected expenses.

-

Material Choices: The type and quality of materials used directly affect pricing. Opting for premium materials may enhance durability but at a higher cost.

-

Quality Certifications: Certifications such as ISO or CE mark can lead to higher costs but may be necessary for compliance in certain markets.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can all influence pricing. Establishing relationships with reliable suppliers can lead to better pricing and terms.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting the total cost.

What Are Effective Buyer Tips for Cost-Efficiency in International Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider the following tips to enhance cost efficiency:

-

Negotiation: Always negotiate terms and prices. Suppliers may have flexibility, especially for larger orders or repeat business.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider ongoing costs like maintenance, energy consumption, and potential downtime, which can significantly impact overall expenses.

-

Understand Pricing Nuances: Different regions may have unique pricing structures influenced by local market conditions, currency fluctuations, and demand. Conducting thorough market research can provide insights into fair pricing.

-

Build Long-Term Relationships: Establishing long-term partnerships with suppliers can yield benefits such as better pricing, priority service, and access to innovations.

-

Stay Informed on Market Trends: Keeping abreast of global supply chain trends, material costs, and technological advancements can empower buyers to make informed sourcing decisions.

Disclaimer on Pricing

The prices discussed are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing integrated solutions console With Other Solutions

In today’s competitive landscape, choosing the right integrated solutions console is critical for businesses looking to streamline operations and enhance efficiency. However, several alternatives exist that may align better with specific organizational needs. This section provides an analysis of the integrated solutions console against a few viable alternatives, highlighting their respective strengths and weaknesses.

| Comparison Aspect | Integrated Solutions Console | Alternative 1: ERP Software | Alternative 2: Custom Software Development |

|---|---|---|---|

| Performance | High efficiency with real-time data integration across various systems. | Generally good, but may suffer from data silos if not properly configured. | Highly customizable, performance varies by development quality. |

| Cost | Moderate initial investment with ongoing subscription fees. | Often involves high upfront costs but can provide long-term savings. | Variable costs based on project scope; can be high if extensive features are required. |

| Ease of Implementation | Quick to deploy with standardized processes and features. | Implementation can be lengthy due to complexity and training requirements. | Time-consuming; requires detailed requirements gathering and iterative development. |

| Maintenance | Regular updates included; requires minimal internal IT support. | Maintenance can be resource-intensive, requiring specialized IT staff. | Ongoing support necessary, which can lead to additional costs. |

| Best Use Case | Ideal for businesses seeking an all-in-one solution for operational efficiency. | Best for large enterprises needing comprehensive resource planning. | Suitable for businesses with unique processes requiring tailored solutions. |

What Are the Key Benefits and Drawbacks of ERP Software as an Alternative?

Enterprise Resource Planning (ERP) software is a robust alternative to the integrated solutions console. One of its key strengths is its ability to manage various business functions from finance to supply chain within a single system. However, ERP implementations can be complex and time-consuming, often requiring significant training for users. While the potential for long-term cost savings exists, the initial investment can be substantial, making it a less attractive option for smaller businesses.

How Does Custom Software Development Compare?

Custom software development offers unparalleled flexibility, allowing organizations to create solutions tailored specifically to their needs. This can lead to optimized performance and a perfect fit for unique business processes. However, the development process can be lengthy and costly, and the quality is heavily dependent on the developers’ expertise. Additionally, ongoing maintenance and support are crucial, which can add to the total cost of ownership over time.

Conclusion: How Should B2B Buyers Select the Right Solution?

For B2B buyers, the choice between an integrated solutions console, ERP software, or custom software development hinges on specific business needs, budget constraints, and the desired level of customization. Companies focused on rapid deployment and operational efficiency may find the integrated solutions console most appealing. In contrast, those with complex resource management needs or unique business processes might lean towards ERP or custom solutions. Ultimately, a thorough assessment of organizational goals and existing infrastructure will guide buyers in making the most informed decision.

Essential Technical Properties and Trade Terminology for integrated solutions console

What Are the Key Technical Properties of an Integrated Solutions Console?

When evaluating integrated solutions consoles, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

– The material grade of an integrated solutions console significantly affects its durability and performance. High-grade materials such as aluminum or stainless steel are often preferred for their strength and resistance to corrosion. This is particularly important for consoles used in harsh environments, as it ensures longevity and minimizes replacement costs. -

Tolerance Levels

– Tolerance refers to the permissible limit or limits of variation in a physical dimension. In the context of integrated solutions consoles, tight tolerances are critical for ensuring compatibility with other components and systems. Understanding tolerance levels helps B2B buyers ensure that the console will fit seamlessly into existing setups, thus avoiding costly modifications or downtimes. -

Power Consumption

– An integrated solutions console’s power consumption is a vital consideration for both operational costs and environmental impact. Low power consumption models can lead to significant savings over time and are often favored in regions with high electricity costs. Buyers should assess energy efficiency ratings to ensure compliance with local regulations and sustainability goals. -

User Interface Compatibility

– The compatibility of the console with existing software and hardware interfaces is essential for smooth operations. A console with a versatile user interface can easily integrate with various systems, reducing the need for additional training or resources. This compatibility is particularly beneficial for companies operating in diverse markets like Africa and South America, where technology standards may vary. -

Environmental Ratings

– Environmental ratings, such as IP (Ingress Protection) ratings, indicate how well the console can withstand dust, moisture, and other environmental factors. For B2B buyers in industries such as manufacturing or outdoor applications, selecting a console with appropriate environmental ratings is essential to maintain operational integrity and reduce maintenance costs.

What Are the Common Trade Terms Used in Integrated Solutions Console Transactions?

Understanding trade terminology is vital for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of integrated solutions consoles, knowing the OEM can help buyers assess the quality and reliability of the products they are purchasing. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, especially when considering bulk purchases or when entering new markets. Knowing the MOQ can help in planning inventory and budgeting effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ can lead to competitive pricing and better terms, as it encourages suppliers to provide their best offers. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which are used in international commercial transactions. Understanding these terms is essential for B2B buyers to clarify responsibilities regarding shipping, insurance, and tariffs, thus avoiding potential disputes. -

Lead Time

– Lead time is the time taken from the initiation of a process until its completion. For integrated solutions consoles, knowing the lead time is crucial for planning and ensuring that products are delivered when needed, especially in industries where timing is critical. -

Warranty Period

– The warranty period is the duration for which a product is guaranteed against defects. Understanding warranty terms can protect buyers against unexpected costs and ensure that they are covered in case of product failures.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can navigate the complexities of purchasing integrated solutions consoles more effectively, ensuring that they make well-informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the integrated solutions console Sector

What Are the Current Market Dynamics and Key Trends in the Integrated Solutions Console Sector?

The integrated solutions console sector is witnessing significant transformation driven by advancements in technology and changing buyer behaviors. Key global drivers include the increasing demand for seamless integration of various systems, which enhances operational efficiency and user experience. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly prioritizing solutions that offer interoperability, real-time data analytics, and customizable interfaces. This shift is particularly relevant for industries such as manufacturing, logistics, and energy, where integrated solutions can lead to substantial cost savings and improved productivity.

Emerging trends indicate a growing emphasis on cloud-based solutions that offer scalability and flexibility. Buyers are also seeking solutions that incorporate artificial intelligence and machine learning capabilities to automate processes and enhance decision-making. As businesses navigate a post-pandemic landscape, the focus on digital transformation has accelerated, prompting buyers to explore integrated solutions that can streamline operations and facilitate remote work. Moreover, the rise of Industry 4.0 is pushing organizations to adopt integrated solutions that support IoT connectivity and smart manufacturing practices.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Integrated Solutions Console Market?

Sustainability is becoming a paramount concern for B2B buyers in the integrated solutions console sector. The environmental impact of sourcing practices is under scrutiny, with stakeholders demanding transparency and accountability from suppliers. Buyers are increasingly prioritizing partners who demonstrate a commitment to sustainable practices, such as using renewable materials and minimizing waste in their production processes.

Ethical sourcing is also gaining traction, with buyers seeking to align their procurement strategies with corporate social responsibility (CSR) goals. This includes ensuring fair labor practices throughout the supply chain and sourcing materials that are certified green or eco-friendly. Certifications such as ISO 14001 for environmental management and Energy Star for energy efficiency are becoming essential criteria for evaluating potential suppliers. By focusing on sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products and services.

How Has the Integrated Solutions Console Sector Evolved Over Time?

The evolution of the integrated solutions console sector reflects the broader trends in technology and business processes. Initially, these consoles were limited to basic functionalities, primarily focusing on hardware integration. However, as digital transformation gained momentum in the late 20th century, the sector evolved to incorporate software solutions that allowed for enhanced data integration and real-time analytics.

The introduction of cloud computing in the early 2000s marked a significant turning point, enabling more flexible and scalable solutions. Today, integrated solutions consoles are at the forefront of Industry 4.0, leveraging IoT, AI, and big data to provide comprehensive solutions that meet the complex needs of modern businesses. This historical context underscores the importance of staying informed about technological advancements and market trends for international B2B buyers seeking to invest in integrated solutions that align with their strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of integrated solutions console

-

How do I ensure the quality of integrated solutions consoles when sourcing internationally?

To ensure quality, it’s essential to conduct thorough supplier vetting. Start by checking the manufacturer’s certifications, such as ISO or other relevant industry standards. Request samples to evaluate the product firsthand. Additionally, consider third-party inspections or audits to verify compliance with quality standards. Engaging with suppliers who have a proven track record in your region can also enhance trust and reliability. -

What are the common payment terms for integrated solutions consoles in international trade?

Payment terms can vary widely depending on the supplier and the region. Common practices include payment in advance, letters of credit, or net 30/60/90 days after delivery. For international transactions, consider using secure payment platforms that offer buyer protection. Always clarify terms before finalizing the order, and ensure that they are documented in the purchase agreement to avoid disputes. -

What is the minimum order quantity (MOQ) for integrated solutions consoles?

MOQs can differ significantly between suppliers and may depend on the type of console and customization options. Typically, manufacturers may set MOQs to cover production costs. If you are concerned about high MOQs, consider reaching out to suppliers who specialize in smaller batch productions or negotiating terms based on your specific needs. Ensure that the MOQ aligns with your inventory and cash flow management strategies. -

How can I customize an integrated solutions console to fit my business needs?

Many manufacturers offer customization options for their consoles, including software integration, hardware specifications, and branding. To initiate the process, clearly outline your requirements and expectations. Discuss customization capabilities with potential suppliers, and request case studies or examples of past projects. Engaging in a collaborative design process can ensure that the final product meets your operational demands effectively. -

What logistics considerations should I keep in mind when importing integrated solutions consoles?

Logistics play a crucial role in the timely delivery of integrated solutions consoles. Key considerations include understanding shipping methods (air, sea, or land), customs regulations, and potential tariffs or taxes. Work closely with your supplier to ensure they provide accurate shipping documentation. Additionally, having a reliable logistics partner can help streamline the import process and mitigate delays. -

What are the best practices for supplier vetting in the integrated solutions console market?

Begin by researching potential suppliers through online platforms, trade shows, and industry referrals. Evaluate their reputation by checking customer reviews and testimonials. Request detailed information about their production capabilities, lead times, and post-sale support. Conducting site visits or virtual tours can also provide insight into their operational practices and quality control measures. -

How do I address potential communication barriers with international suppliers?

Effective communication is vital when dealing with international suppliers. To overcome language barriers, consider using clear, straightforward language and visual aids to convey your message. Establish regular check-ins through video calls or messaging apps to build rapport. Utilizing translation services or hiring bilingual staff can also facilitate smoother interactions and help clarify any misunderstandings. -

What after-sales support should I expect from suppliers of integrated solutions consoles?

After-sales support is critical for maintaining operational efficiency. Suppliers should provide technical support, warranty information, and training for your staff on using the console. Clarify the terms of service regarding repairs, replacements, and troubleshooting assistance before purchase. Having a dedicated support contact can significantly enhance your experience and ensure that any issues are resolved promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for integrated solutions console

The integration of solutions consoles into your operational framework is no longer just an option; it is essential for maintaining competitiveness in the global marketplace. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, understanding the value of strategic sourcing becomes paramount. This approach not only optimizes procurement processes but also enhances collaboration across various departments, leading to significant cost savings and improved efficiency.

What are the key benefits of strategic sourcing for integrated solutions consoles? By leveraging data analytics, businesses can make informed decisions that align with their strategic goals. This results in streamlined operations, reduced risks, and the ability to respond swiftly to market changes. For buyers in emerging markets, this means accessing innovative technologies and solutions that can propel growth and foster sustainability.

Looking ahead, the demand for integrated solutions will continue to rise. Buyers are encouraged to engage with trusted partners and invest in technologies that enhance integration capabilities. By prioritizing strategic sourcing, businesses can position themselves for long-term success in an increasingly interconnected global economy. Embrace this opportunity to transform your sourcing strategy and unlock new avenues for growth.