Cut Costs with Pipe Bushing PVC: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for pipe bushing pvc

Navigating the complexities of sourcing pipe bushing PVC can be a significant challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. With a plethora of options available, identifying high-quality suppliers while ensuring compliance with local regulations can feel overwhelming. This guide is designed to demystify the process by providing a comprehensive overview of pipe bushing PVC, including its various types, applications, and key considerations for supplier vetting and cost assessment.

In the sections that follow, you will discover actionable insights tailored to your region’s unique market dynamics, enabling you to make informed purchasing decisions. We will explore the different applications of pipe bushing PVC, from industrial uses to residential plumbing, and examine the critical factors that influence cost, such as material quality and supplier reliability. Additionally, you will find strategies for effectively vetting suppliers to ensure you partner with reputable manufacturers who meet your specific needs.

By leveraging the information provided in this guide, B2B buyers can streamline their procurement processes and enhance their supply chain resilience. Whether you are a seasoned buyer or new to the international market, this resource will empower you to navigate the global landscape of pipe bushing PVC with confidence and clarity.

Understanding pipe bushing pvc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Bushing | Common size options, lightweight, corrosion-resistant | Plumbing, irrigation, HVAC systems | Pros: Cost-effective, easy to install. Cons: Limited pressure tolerance. |

| Reducing PVC Bushing | Available in various sizes, allows for size transition | Water supply, drainage systems | Pros: Versatile for different pipe sizes. Cons: May require additional fittings. |

| Threaded PVC Bushing | Features internal threads for easy connections | Industrial applications, chemical handling | Pros: Secure connections, easy to disassemble. Cons: Threads can wear over time. |

| Flush Bushing | Designed for flush mounting in wall systems | Electrical conduits, wall installations | Pros: Aesthetic finish, space-saving. Cons: Limited application scope. |

| Schedule 80 PVC Bushing | Thicker walls for higher pressure applications | Heavy-duty industrial use, high-pressure systems | Pros: Enhanced durability, higher pressure rating. Cons: Higher cost and weight. |

What Are the Characteristics of Standard PVC Bushings?

Standard PVC bushings are the most widely used type in various plumbing applications. They are known for their lightweight nature and excellent resistance to corrosion, making them suitable for both indoor and outdoor use. Their common size options simplify installation processes, allowing for quick replacements or new installations. When considering a purchase, buyers should evaluate their specific application requirements, including pressure ratings and compatibility with existing systems, to ensure optimal performance.

How Do Reducing PVC Bushings Benefit B2B Buyers?

Reducing PVC bushings are particularly valuable in systems requiring size transitions between different pipe diameters. This type allows for seamless integration into existing plumbing or drainage systems, which can be crucial for projects with varying specifications. Buyers should consider the compatibility of reducing bushings with their existing pipe sizes, as well as the potential need for additional fittings to maintain system integrity and efficiency.

What Are the Advantages of Threaded PVC Bushings?

Threaded PVC bushings provide an added layer of versatility in industrial applications, particularly in environments handling chemicals or requiring secure connections. Their internal threads facilitate easy assembly and disassembly, which is beneficial for maintenance and repairs. However, buyers should be aware that while they offer secure connections, the threads can wear over time, necessitating careful handling and periodic inspections to ensure long-term reliability.

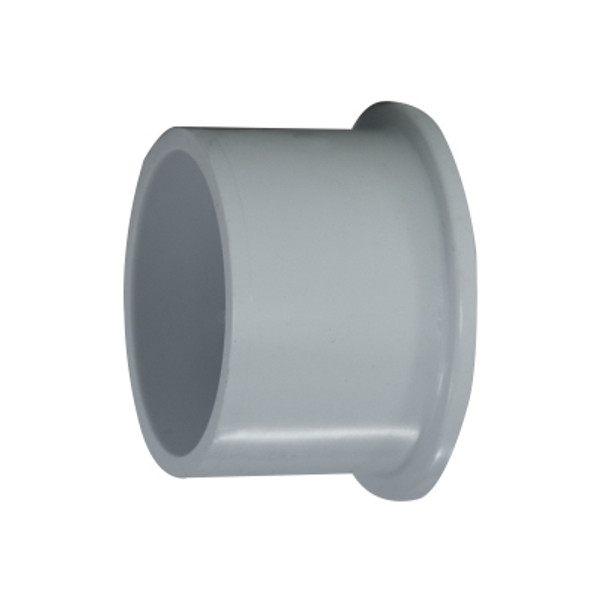

A stock image related to pipe bushing pvc.

Why Choose Flush Bushings for Electrical Applications?

Flush bushings are designed specifically for applications where a neat, finished look is required, such as in electrical conduits and wall installations. They allow for a clean transition between pipes and walls, saving space and enhancing aesthetics. However, their application scope is somewhat limited compared to other types, so buyers should assess whether their specific project requires this type of bushing for optimal visual and functional results.

What Makes Schedule 80 PVC Bushings Ideal for Heavy-Duty Use?

Schedule 80 PVC bushings feature thicker walls, making them suitable for high-pressure applications commonly found in industrial settings. Their enhanced durability is a significant advantage for buyers looking for long-lasting solutions in demanding environments. While they come at a higher cost compared to standard options, the investment can be justified by their performance and longevity, especially in applications where failure is not an option. Buyers should evaluate their pressure requirements and budget constraints when considering these bushings.

Related Video: Reducer Bushing for Schedule 40 PVC Pipe (Spig x Slip)

Key Industrial Applications of pipe bushing pvc

| Industry/Sector | Specific Application of pipe bushing pvc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Supply & Irrigation | Connecting various pipe sizes in irrigation systems | Ensures efficient water flow and reduces leakage risks | Availability of compatible sizes; resistance to UV degradation |

| Construction | Transitioning between different plumbing systems | Facilitates complex plumbing layouts with minimal friction | Compliance with local building codes; durability in varied climates |

| HVAC Systems | Adapting ductwork to different air handling units | Enhances air distribution efficiency and system longevity | Temperature resistance; compatibility with existing infrastructure |

| Chemical Processing | Connecting pipes in chemical transport systems | Maintains system integrity and prevents contamination | Chemical resistance; certification for safety standards |

| Telecommunications | Housing and connecting cables in underground conduits | Protects cables from environmental damage | Flexibility in dimensions; resistance to environmental factors |

How is Pipe Bushing PVC Used in Water Supply & Irrigation Systems?

In the water supply and irrigation sectors, pipe bushing PVC is crucial for connecting pipes of different diameters, ensuring that water flows efficiently without leaks. This application is vital in areas where water conservation is a priority, such as arid regions in Africa and the Middle East. Buyers should ensure that the bushings are compatible with existing systems and resistant to UV degradation, especially when exposed to sunlight.

What Role Does Pipe Bushing PVC Play in Construction?

In construction, pipe bushing PVC serves as a transition piece, allowing for the connection of various plumbing systems, which is essential in complex building layouts. This adaptability helps minimize friction and pressure loss, leading to better performance. B2B buyers must consider local building codes and the product’s durability in different climates, ensuring compliance and longevity in their projects.

How is Pipe Bushing PVC Beneficial in HVAC Systems?

In HVAC systems, pipe bushing PVC is used to adapt ductwork to various air handling units, facilitating efficient air distribution. This application is critical for maintaining indoor air quality and system performance. International buyers, particularly in Europe, should prioritize temperature-resistant materials that can withstand varying climatic conditions, ensuring optimal operation throughout the year.

Why is Pipe Bushing PVC Important in Chemical Processing?

In the chemical processing industry, pipe bushing PVC connects pipes in chemical transport systems, maintaining system integrity and preventing leaks that could lead to contamination. This is especially important in regions like South America, where strict environmental regulations are in place. Buyers should focus on sourcing bushings with high chemical resistance and appropriate safety certifications to meet industry standards.

How Does Pipe Bushing PVC Support Telecommunications?

In telecommunications, pipe bushing PVC is used for housing and connecting cables in underground conduits, protecting them from environmental hazards. This application is increasingly important as the demand for reliable communication infrastructure grows. B2B buyers should consider the flexibility of dimensions and the material’s resistance to environmental factors, ensuring that their installations remain secure and functional over time.

Related Video: Learn PVC Pipe Basics from an expert!

3 Common User Pain Points for ‘pipe bushing pvc’ & Their Solutions

Scenario 1: Sourcing Quality Pipe Bushing PVC for Diverse Applications

The Problem: Many B2B buyers face significant challenges when sourcing pipe bushing PVC that meets the specific requirements of diverse applications, particularly in regions such as Africa and South America, where local suppliers may not always meet international quality standards. This can lead to delays in project timelines, increased costs due to substandard materials, and potential compliance issues with local regulations. Buyers often find themselves overwhelmed by the variety of options available and unsure of how to assess the quality of these products.

The Solution: To overcome these sourcing challenges, buyers should establish partnerships with reputable manufacturers or distributors known for their quality assurance processes. Start by conducting thorough research to identify suppliers with international certifications, such as ISO or ASTM standards, which indicate adherence to stringent quality controls. Engage in direct communication with suppliers to request samples, allowing you to evaluate the materials firsthand. Additionally, consider leveraging local industry networks and trade shows to connect with trusted suppliers. Implement a checklist for evaluating pipe bushing PVC, including criteria such as durability, compatibility with existing systems, and resistance to environmental factors. This proactive approach not only ensures high-quality procurement but also strengthens supplier relationships.

Scenario 2: Compatibility Issues with Existing Infrastructure

The Problem: A common issue for B2B buyers is ensuring that newly sourced pipe bushing PVC is compatible with existing plumbing or construction infrastructure. In many cases, businesses in the Middle East and Europe find that variations in specifications can lead to costly modifications or even system failures. This is particularly critical in sectors like construction and manufacturing, where downtime can translate to significant financial losses.

The Solution: To mitigate compatibility risks, buyers should conduct a comprehensive audit of their existing systems before purchasing pipe bushing PVC. Document the specifications of current materials, including dimensions, pressure ratings, and connection types. When sourcing new products, clearly communicate these specifications to suppliers to ensure they provide compatible options. Utilize advanced technologies such as 3D modeling software to simulate the integration of new materials into existing systems, helping to identify potential issues before installation. Furthermore, consider consulting with a qualified engineer or plumbing specialist who can offer insights into the best practices for integrating new materials. This meticulous approach not only avoids compatibility issues but also enhances operational efficiency.

Scenario 3: Understanding Regulatory Compliance for Pipe Bushing PVC

The Problem: International B2B buyers often struggle with navigating the complex landscape of regulatory compliance when sourcing pipe bushing PVC. Different countries have varying regulations regarding material safety, environmental impact, and installation standards. For example, buyers in Europe must comply with the European Union’s REACH regulations, while those in Africa may face different local standards. Failing to adhere to these regulations can result in hefty fines, project delays, and reputational damage.

The Solution: To ensure compliance, buyers should familiarize themselves with the specific regulatory requirements applicable to their region and industry. Start by consulting local regulatory bodies or industry associations that provide guidelines on material safety and compliance standards. Additionally, work closely with suppliers who have a proven track record of compliance and can provide documentation certifying that their products meet necessary regulations. Consider investing in compliance management software that can help track changes in regulations and maintain records of compliance documentation. Regular training sessions for your procurement team on compliance issues can also be beneficial. By proactively addressing regulatory compliance, businesses can streamline their procurement processes and reduce the risk of costly penalties.

Strategic Material Selection Guide for pipe bushing pvc

When selecting materials for pipe bushings made from PVC, it is essential to consider various factors that affect performance, durability, and compliance with international standards. Below, we analyze four common materials used in PVC pipe bushings, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of PVC in Pipe Bushings?

1. Polyvinyl Chloride (PVC)

PVC is the most common material for pipe bushings due to its excellent balance of performance characteristics.

- Key Properties: PVC has a temperature rating of up to 60°C (140°F) and can withstand moderate pressure levels. It is inherently resistant to corrosion and chemical degradation, making it suitable for various applications.

- Pros & Cons: PVC is lightweight, cost-effective, and easy to manufacture. However, it may become brittle over time when exposed to UV light unless treated. Its lower temperature resistance compared to other materials may limit its use in high-temperature applications.

- Impact on Application: PVC is compatible with water, wastewater, and certain chemicals, making it ideal for plumbing and drainage systems.

- Considerations for International Buyers: Compliance with ASTM standards is crucial, especially in regions like Europe and North America. Buyers in the Middle East and Africa should ensure that the product meets local regulations for construction materials.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS is another popular choice for pipe bushings, known for its robustness.

- Key Properties: ABS offers a higher temperature tolerance of up to 80°C (176°F) and excellent impact resistance. It also provides good chemical resistance, making it versatile for various applications.

- Pros & Cons: The main advantage of ABS is its strength and durability, which can lead to a longer lifespan. However, it is generally more expensive than PVC and can be more challenging to work with during installation.

- Impact on Application: ABS is suitable for drainage, waste, and vent systems, especially where higher temperatures or impact resistance is required.

- Considerations for International Buyers: Buyers should check for compliance with DIN or JIS standards, particularly in Europe and Asia. The higher cost may be justified in applications requiring enhanced durability.

3. Polypropylene (PP)

Polypropylene is gaining traction in applications requiring chemical resistance and flexibility.

- Key Properties: PP has a temperature rating of up to 100°C (212°F) and is highly resistant to a wide range of chemicals. Its flexibility makes it less prone to cracking under stress.

- Pros & Cons: The primary advantage of PP is its superior chemical resistance and flexibility, making it suitable for diverse applications. However, it is less rigid than PVC and may not be suitable for high-pressure applications.

- Impact on Application: PP is ideal for transporting aggressive chemicals, making it a preferred choice in industrial applications.

- Considerations for International Buyers: Buyers should ensure compliance with relevant chemical handling regulations and standards. The cost may be higher, but the benefits in specific applications can outweigh this.

4. Chlorinated Polyvinyl Chloride (CPVC)

CPVC is a modified version of PVC that offers enhanced temperature and chemical resistance.

- Key Properties: CPVC can withstand temperatures up to 93°C (200°F) and offers better resistance to certain chemicals than standard PVC.

- Pros & Cons: The main advantage is its suitability for hot water applications and aggressive chemicals. However, it is more expensive than standard PVC and requires specialized fittings.

- Impact on Application: CPVC is commonly used in hot water plumbing and industrial applications where chemical exposure is a concern.

- Considerations for International Buyers: Compliance with ASTM and local plumbing codes is essential. The higher cost may be a consideration for budget-sensitive projects.

Summary Table of Material Properties for Pipe Bushing PVC

| Material | Typical Use Case for pipe bushing pvc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Plumbing and drainage systems | Cost-effective and lightweight | Brittle over time with UV exposure | Low |

| ABS | Drainage, waste, and vent systems | High impact resistance and durability | More expensive and harder to install | Medium |

| Polypropylene | Industrial applications with chemicals | Superior chemical resistance and flexibility | Less rigid, not suitable for high pressure | Medium |

| CPVC | Hot water plumbing and aggressive chemicals | High temperature and chemical resistance | More expensive, requires specialized fittings | High |

This comprehensive analysis provides international B2B buyers with valuable insights into the material selection process for PVC pipe bushings, ensuring informed decisions that align with specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pipe bushing pvc

What Are the Main Stages of Manufacturing Pipe Bushing PVC?

Manufacturing pipe bushings made of PVC involves several critical stages, each contributing to the product’s final quality and performance. Understanding these stages can help B2B buyers ensure they are sourcing high-quality products that meet their operational needs.

1. Material Preparation

The first stage in the manufacturing process is material preparation. PVC resin, the primary raw material for pipe bushings, is often combined with various additives to enhance its properties, such as durability and resistance to environmental factors. Manufacturers typically use bulk PVC resin and may add colorants or stabilizers to achieve the desired characteristics.

Before processing, the materials are dried to remove moisture, which can affect the quality of the final product. Proper drying techniques, such as using dehumidifying dryers, are essential to ensure that the resin flows smoothly during molding.

2. Forming Techniques

The next step is forming, where the prepared PVC material is shaped into the desired bushing form. Common techniques include:

-

Injection Molding: This is the most widely used method for producing PVC pipe bushings. In this process, the dried PVC resin is heated until it becomes molten and then injected into a mold. The mold cools, solidifying the PVC into the desired shape.

-

Compression Molding: While less common for pipe bushings, this method involves placing a pre-measured amount of PVC material into a heated mold and applying pressure to form the product. It is useful for larger or more complex shapes.

-

Extrusion: In some cases, manufacturers may use extrusion to create continuous lengths of PVC that are later cut into specific sizes for bushings.

Each forming technique has its advantages and is chosen based on the specific requirements of the product, including dimensions and production volume.

3. Assembly and Finishing

After forming, the bushings may undergo additional assembly processes, such as fitting them with seals or other components if required. Finishing processes, which can include trimming excess material, surface polishing, and applying protective coatings, ensure that the bushings meet aesthetic and functional standards.

Quality control during this stage is crucial, as any defects can lead to poor performance in the field. Manufacturers may use automated systems for trimming and polishing to maintain consistency.

How Is Quality Assurance Implemented in Pipe Bushing PVC Manufacturing?

Quality assurance (QA) is vital in the manufacturing of pipe bushings to ensure that products meet international standards and customer expectations. The following outlines the key aspects of quality assurance in this industry.

Relevant International Standards for Quality Assurance

For B2B buyers, understanding the applicable quality standards is essential. Key international standards include:

-

ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that manufacturers consistently meet customer and regulatory requirements.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry, including specific requirements for pipe fittings and bushings.

These standards not only help in maintaining product quality but also enhance the credibility of manufacturers in international markets.

What Are the Key Quality Control Checkpoints?

Quality control in the manufacturing process typically involves several checkpoints, including:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet specified standards. Buyers should inquire about the supplier’s IQC processes and whether they conduct random sampling or batch testing.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is essential. This includes checking parameters such as temperature, pressure, and material flow rates to ensure that the production process remains within defined limits.

-

Final Quality Control (FQC): After manufacturing, finished products undergo final inspections to verify that they meet all specifications. This may include dimensional checks, visual inspections, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is critical to ensuring product reliability. Here are actionable steps to conduct thorough evaluations:

Conduct Supplier Audits

Auditing suppliers is an effective way to assess their quality control practices. Buyers should request to review the manufacturer’s quality management system, including documentation of their processes and any certifications they hold. On-site audits can also provide insights into production capabilities and adherence to quality standards.

Review Quality Control Reports

Suppliers should be able to provide detailed quality control reports, including data from IQC, IPQC, and FQC processes. Buyers should look for trends in defect rates, corrective actions taken, and overall compliance with international standards.

Utilize Third-Party Inspection Services

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct random inspections and tests on behalf of the buyer, verifying that the products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must also be aware of specific nuances that can affect quality control when sourcing pipe bushings from different regions.

Understanding Regional Standards

Different regions may have varying quality standards and regulatory requirements. For instance, products intended for the European market must comply with CE marking, while those for the Middle East might need to meet local standards such as the Saudi Standards, Metrology and Quality Organization (SASO). Buyers should ensure that their suppliers are familiar with and compliant with the relevant regulations in the target market.

Language and Communication Barriers

Language differences can pose challenges in understanding quality documentation and specifications. Buyers should consider working with suppliers who can provide clear communication in a common language, particularly in technical documentation.

Conclusion

Manufacturing pipe bushings from PVC involves a series of well-defined processes and stringent quality assurance practices. By understanding these processes and implementing thorough verification methods, B2B buyers can ensure they are sourcing high-quality products that meet their operational needs. Engaging with suppliers who adhere to international standards and demonstrate robust quality control measures is essential for achieving successful procurement in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe bushing pvc’

In this guide, we provide a comprehensive checklist for B2B buyers looking to procure pipe bushing PVC. This step-by-step approach will help ensure that you make informed decisions, minimize risks, and achieve cost-effective sourcing tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline your technical requirements for the pipe bushing PVC. This includes dimensions, pressure ratings, material compatibility, and any relevant industry standards.

– Why It’s Important: Clear specifications help prevent miscommunication with suppliers and ensure that the products meet your operational needs.

– What to Look For: Ensure that your specifications align with the applications and environments in which the pipe bushings will be used.

Step 2: Research Reliable Suppliers

Investigating potential suppliers is crucial in ensuring you choose a reputable source. Utilize online platforms and industry directories to compile a list of potential vendors.

– Why It’s Important: A reliable supplier can significantly impact the quality and timeliness of your order.

– What to Look For: Pay attention to suppliers’ industry experience, customer reviews, and their specialization in pipe fittings.

Step 3: Evaluate Supplier Certifications

It’s vital to verify that your chosen suppliers hold the necessary certifications, such as ISO 9001 or ASTM standards.

– Why It’s Important: Certifications indicate compliance with industry standards and quality assurance processes.

– What to Look For: Request documentation of certifications and check their validity; this can mitigate risks associated with non-compliant products.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, ask for samples of the pipe bushing PVC.

– Why It’s Important: Evaluating samples allows you to assess the quality, fit, and performance of the product before committing to a larger order.

– What to Look For: Inspect the samples for physical characteristics, such as wall thickness, finish, and any potential defects.

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers and assessed samples, it’s time to discuss pricing and terms.

– Why It’s Important: Effective negotiation can lead to better pricing and favorable terms, including payment options, delivery schedules, and warranty conditions.

– What to Look For: Ensure that all terms are clearly documented and understand the implications of each clause in the agreement.

Step 6: Conduct a Final Due Diligence

Before placing a large order, conduct a final review of the supplier’s capabilities and reliability.

– Why It’s Important: This step helps to confirm that the supplier can meet your quantity, delivery timelines, and after-sales support.

– What to Look For: Check references, ask for case studies, and inquire about their experience with similar clients in your region.

Step 7: Establish a Relationship for Future Procurement

After successfully completing your purchase, consider establishing a long-term relationship with your supplier.

– Why It’s Important: A strong relationship can lead to better pricing, priority service, and tailored solutions for future projects.

– What to Look For: Communicate your needs clearly and seek feedback to enhance collaboration over time.

By following these steps, B2B buyers can navigate the sourcing process for pipe bushing PVC effectively, ensuring they meet both their operational requirements and quality standards.

Comprehensive Cost and Pricing Analysis for pipe bushing pvc Sourcing

What Are the Key Cost Components in Pipe Bushing PVC Sourcing?

When sourcing pipe bushings made from PVC, understanding the cost structure is critical for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of PVC resin is the largest portion of the material costs. Prices can vary based on market conditions, with fluctuations influenced by oil prices and supply chain disruptions. Buyers should consider sourcing from multiple suppliers to mitigate risks associated with material shortages.

-

Labor: Labor costs can differ significantly by region. For instance, manufacturing in low-cost labor markets, such as parts of Africa or South America, might offer savings. However, ensure that the quality of workmanship meets international standards.

-

Manufacturing Overhead: This encompasses costs related to utilities, factory maintenance, and equipment depreciation. Understanding the supplier’s overhead can provide insights into their pricing structure.

-

Tooling: Initial tooling costs can be substantial, especially for customized products. If sourcing large quantities, investing in bespoke tooling can lead to lower per-unit costs over time.

-

Quality Control (QC): Ensuring that the pipe bushings meet necessary quality standards is crucial. QC processes may add to the overall costs but are essential for maintaining product integrity, especially for buyers in regions with stringent regulations.

-

Logistics: Transportation costs depend on the shipping method and distance. International buyers should evaluate various shipping options, including Incoterms, which define who pays for shipping and at what point ownership of the goods transfers.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding typical margins in your sourcing region can help in negotiation.

How Do Price Influencers Affect Pipe Bushing PVC Costs?

Several factors can influence the pricing of PVC pipe bushings, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Buyers should assess their needs carefully to leverage volume pricing effectively.

-

Specifications and Customization: Custom specifications can increase costs. If standard sizes meet your needs, opting for these can reduce expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or ASTM compliance) often come at a premium but may be necessary for certain applications. Buyers should weigh the cost against the benefits of enhanced durability and performance.

-

Supplier Factors: Supplier reputation, reliability, and location play crucial roles in pricing. Engaging with reputable suppliers may come with a higher price tag but can reduce risks associated with quality issues.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly affect the total landed cost of goods.

What Negotiation Strategies Should B2B Buyers Consider?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some actionable tips:

-

Research Market Rates: Before negotiations, research prevailing market prices for PVC pipe bushings. This knowledge empowers buyers to negotiate from a position of strength.

-

Build Relationships: Establishing long-term relationships with suppliers can yield better pricing and terms. Suppliers are often more willing to negotiate with trusted partners.

-

Focus on Total Cost of Ownership (TCO): Consider the entire lifecycle cost of the product, including installation, maintenance, and potential downtime. Sometimes, a higher upfront cost can lead to lower TCO.

-

Explore Payment Terms: Negotiating favorable payment terms can enhance cash flow. Options like extended payment schedules or partial upfront payments can be beneficial.

-

Be Prepared for Compromise: Understand that negotiation is a two-way street. Being flexible on certain terms may lead to better overall conditions.

Conclusion

In conclusion, sourcing PVC pipe bushings requires a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies. By focusing on these aspects, international B2B buyers can optimize their procurement processes and achieve better financial outcomes. Always remember that prices may fluctuate based on market conditions, so it’s prudent to stay informed and adaptable.

Alternatives Analysis: Comparing pipe bushing pvc With Other Solutions

Alternatives to Pipe Bushing PVC: What Should B2B Buyers Consider?

When selecting piping solutions, B2B buyers must evaluate various options to ensure they choose the most effective and suitable product for their specific applications. Pipe bushing PVC is a popular choice, but alternatives may offer additional benefits depending on the context of use. Below, we present a comparison of pipe bushing PVC against two viable alternatives: metal bushings and rubber bushings.

Comparison Table

| Comparison Aspect | Pipe Bushing PVC | Metal Bushings | Rubber Bushings |

|---|---|---|---|

| Performance | Good resistance to chemicals; lightweight | High strength and durability; excellent for high-pressure applications | Flexible; good for vibration absorption |

| Cost | Generally low cost | Higher upfront cost | Moderate cost |

| Ease of Implementation | Easy to install; requires minimal tools | Installation may require specialized tools | Simple installation; may require adhesives |

| Maintenance | Low maintenance | Low maintenance; corrosion may require monitoring | Moderate; can degrade over time |

| Best Use Case | Residential and light commercial applications | Industrial settings with high pressure | Applications needing flexibility and vibration dampening |

What Are the Pros and Cons of Metal Bushings?

Metal bushings are a robust alternative to PVC options. They are particularly advantageous in industrial settings where high strength and durability are required. The primary benefits include their ability to withstand higher pressures and temperatures, making them suitable for heavy-duty applications. However, the cost of metal bushings can be significantly higher than PVC, and they may require specialized tools for installation. Moreover, they are prone to corrosion, necessitating regular maintenance checks to ensure longevity.

How Do Rubber Bushings Compare?

Rubber bushings offer a unique solution, especially in applications where flexibility and vibration dampening are critical. They excel in mitigating noise and shock, making them ideal for machinery and automotive applications. The installation process is typically straightforward, and they can be easily cut or shaped to fit specific needs. However, rubber can degrade over time due to environmental factors, leading to moderate maintenance requirements. Additionally, they may not be suitable for high-pressure applications, limiting their use in certain industries.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right piping solution involves assessing your specific requirements, including performance needs, budget constraints, and installation capabilities. Pipe bushing PVC is an excellent choice for most residential and light commercial applications due to its low cost and ease of use. However, for industrial applications requiring high strength, metal bushings may be the better option despite their higher initial investment. Conversely, if your application demands flexibility and vibration absorption, rubber bushings could be the ideal fit. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for pipe bushing pvc

What Are the Essential Technical Properties of Pipe Bushing PVC?

When selecting pipe bushings made from PVC (polyvinyl chloride), understanding the technical specifications is crucial for international B2B buyers. These properties influence performance, compatibility, and overall project success. Below are some of the most critical specifications:

1. Material Grade

Material grade defines the quality and type of PVC used. Common grades include PVC-U (unplasticized) and PVC-C (chlorinated). The grade affects the pipe’s durability, chemical resistance, and temperature tolerance. For instance, PVC-U is suitable for cold water applications, while PVC-C can withstand higher temperatures and is often used in industrial settings.

2. Pressure Rating

The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum internal pressure the pipe bushing can handle. This property is essential for ensuring safety and reliability in fluid transport systems. Buyers should select bushings with pressure ratings that meet or exceed the demands of their specific application to prevent leaks or failures.

3. Tolerance

Tolerance refers to the allowable deviation in dimensions from the specified measurements. In pipe bushings, this can affect the fit and seal when connecting to other components. Tight tolerances are critical in applications requiring precise alignment, such as in hydraulic systems. Buyers should ensure that the tolerances of the bushings align with the specifications of their piping systems to guarantee optimal performance.

4. Temperature Range

The operational temperature range indicates the minimum and maximum temperatures that the pipe bushing can withstand without degradation. This property is vital for applications in varying climates or temperature-sensitive environments. Selecting bushings with appropriate temperature resistance ensures longevity and functionality under changing conditions.

5. Chemical Resistance

PVC is known for its resistance to various chemicals, but the degree of resistance can vary based on the specific formulation of the PVC used. Understanding the chemical exposure of the intended application helps buyers select the right pipe bushing to avoid corrosion and material failure, especially in industries like agriculture and chemical processing.

What Trade Terminology Should B2B Buyers Know When Purchasing Pipe Bushing PVC?

Familiarizing oneself with industry-specific terminology can streamline the procurement process and enhance communication with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of pipe bushings, understanding whether a product is OEM can help buyers assess quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to budget effectively and manage inventory levels. It can also influence decisions regarding supplier selection, especially for smaller projects or companies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For B2B buyers, submitting an RFQ for pipe bushings can facilitate comparison shopping and ensure that they receive competitive pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping contracts. Understanding these terms is essential for buyers to navigate logistics, including who is responsible for shipping costs, insurance, and risk during transit.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For international buyers, understanding lead times is critical for project planning and inventory management. It helps in assessing whether suppliers can meet deadlines aligned with project schedules.

By grasping these technical properties and industry terminology, international B2B buyers can make informed purchasing decisions, ensuring that they select the right pipe bushings for their specific applications while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the pipe bushing pvc Sector

What Are the Current Market Dynamics and Sourcing Trends in the Pipe Bushing PVC Sector?

The global market for pipe bushing PVC is experiencing robust growth, driven by increasing demand from various sectors such as construction, agriculture, and infrastructure development. Key drivers include rapid urbanization in emerging markets in Africa and South America, where infrastructure projects are burgeoning. Additionally, the Middle East and Europe are witnessing a shift towards sustainable building practices, further propelling the demand for durable and reliable piping solutions.

Emerging B2B tech trends such as digital sourcing platforms and data analytics are revolutionizing how international buyers approach procurement. These technologies enable buyers from regions like Saudi Arabia and France to access a broader range of suppliers and optimize their purchasing processes. Moreover, the integration of embedded finance solutions is helping businesses streamline capital access, making it easier for them to invest in quality materials and services.

Market dynamics are also shifting towards greater collaboration between manufacturers and buyers. This shift is characterized by a focus on long-term relationships rather than transactional interactions. B2B buyers are increasingly seeking suppliers who can provide not only products but also value-added services such as logistics support and customized solutions to meet specific project requirements.

How Is Sustainability and Ethical Sourcing Impacting the Pipe Bushing PVC Sector?

A stock image related to pipe bushing pvc.

Sustainability has become a critical factor in the procurement of pipe bushing PVC, with buyers increasingly prioritizing products that have minimal environmental impact. The production of PVC can pose environmental challenges, particularly in terms of resource consumption and waste generation. Therefore, international B2B buyers are encouraged to seek suppliers who adopt sustainable manufacturing practices, such as using recycled materials and reducing carbon emissions during production.

Ethical sourcing is equally important, as buyers are becoming more aware of the social implications of their procurement decisions. Companies that demonstrate transparency in their supply chains and adhere to ethical labor practices are more likely to gain trust from buyers in regions like Europe and the Middle East. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

By prioritizing sustainability and ethical sourcing, international B2B buyers not only contribute to environmental preservation but also align themselves with the values of increasingly eco-conscious consumers. This alignment can enhance brand reputation and customer loyalty, ultimately driving sales growth.

What Is the Historical Context of the Pipe Bushing PVC Market?

The evolution of the pipe bushing PVC sector has been marked by technological advancements and changing market needs. Initially, PVC was favored for its cost-effectiveness and durability in plumbing and construction applications. Over the years, as environmental awareness grew, the industry began focusing on enhancing the sustainability of PVC products. Innovations in manufacturing processes have led to the development of more eco-friendly options, including the use of recycled PVC and reduced harmful additives.

This historical context is vital for B2B buyers, as it highlights the industry’s shift toward sustainability and ethical practices, which are now essential criteria for procurement decisions. Understanding this evolution can help buyers make informed choices that align with modern market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of pipe bushing pvc

-

How do I choose the right pipe bushing PVC for my project?

Selecting the appropriate pipe bushing PVC requires assessing the specific requirements of your project, such as the pipe size, pressure rating, and application environment. Consider the compatibility of the PVC material with the fluids that will flow through it, as well as any temperature fluctuations. It’s also beneficial to consult with manufacturers or suppliers who can provide technical specifications and recommendations based on your needs. -

What factors should I consider when sourcing pipe bushing PVC internationally?

When sourcing pipe bushing PVC from international suppliers, consider factors such as compliance with local regulations and standards, the supplier’s reputation, and their ability to provide quality certifications. Additionally, evaluate shipping logistics, potential tariffs, and currency exchange rates. Establishing clear communication with suppliers is crucial to ensure that all specifications and timelines are met. -

What are the typical minimum order quantities (MOQ) for pipe bushing PVC?

Minimum order quantities for pipe bushing PVC can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from a few dozen to several hundred units. It’s advisable to discuss MOQs with suppliers to see if they can accommodate smaller orders, especially for testing or initial projects, while also considering bulk discounts for larger purchases. -

What payment terms should I expect when buying pipe bushing PVC?

Payment terms for purchasing pipe bushing PVC often include options such as upfront payments, letters of credit, or net 30/60 terms depending on the supplier’s policies. It’s essential to negotiate these terms upfront to ensure clarity and to mitigate risks. Additionally, consider using secure payment methods that offer buyer protection, particularly for large transactions. -

How can I verify the quality of pipe bushing PVC before purchasing?

To ensure the quality of pipe bushing PVC, request samples from suppliers and conduct thorough quality assessments. Look for certifications from recognized standards organizations that confirm compliance with industry standards. Additionally, consider asking for references from other customers or seeking third-party inspection services to verify the supplier’s product quality. -

What are the common logistics considerations when importing pipe bushing PVC?

Logistics considerations for importing pipe bushing PVC include understanding shipping methods (air vs. sea), lead times, and customs clearance processes. Assess the total landed cost, which includes shipping, tariffs, and insurance. Partnering with a reliable freight forwarder can help navigate these complexities and ensure timely delivery while optimizing costs. -

Can pipe bushing PVC be customized for specific applications?

Yes, many manufacturers offer customization options for pipe bushing PVC to meet specific application needs. Customizations may include different sizes, pressure ratings, or specialized fittings. Discuss your requirements with suppliers, and inquire about their capabilities for creating tailored solutions that align with your project specifications. -

What are the best practices for maintaining pipe bushing PVC installations?

Maintaining pipe bushing PVC installations involves regular inspections for signs of wear, leaks, or damage. Ensure that connections are secure and free from corrosion. Periodically check for any environmental factors that could affect the integrity of the PVC, such as UV exposure or extreme temperatures. Following manufacturer guidelines for installation and maintenance will also help prolong the lifespan of the fittings.

A stock image related to pipe bushing pvc.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pipe bushing pvc

Why is Strategic Sourcing Essential for Pipe Bushing PVC?

In the rapidly evolving global market, strategic sourcing of pipe bushing PVC is crucial for international B2B buyers. By prioritizing quality suppliers and leveraging data-driven insights, businesses can ensure that they are not only meeting regulatory requirements but also optimizing cost-efficiency. Engaging with suppliers who demonstrate sustainability practices can enhance brand reputation, particularly in regions like Europe, where eco-friendly initiatives are increasingly valued.

How Can B2B Buyers Prepare for Future Trends in Pipe Bushing PVC?

As the demand for high-quality plumbing solutions grows, staying ahead of market trends is vital. Buyers should focus on developing long-term partnerships with manufacturers who can adapt to changing technologies and market conditions. Additionally, considering the integration of innovative financial solutions can streamline procurement processes, enabling quicker access to capital and reducing delays in project execution.

What Steps Should International Buyers Take Next?

To remain competitive, it’s imperative for international buyers, especially from Africa, South America, the Middle East, and Europe, to actively seek out partnerships that offer reliability and scalability. By embracing strategic sourcing methodologies and fostering supplier relationships, businesses can not only secure better pricing but also enhance their overall operational efficiency. Now is the time to take proactive steps toward building a resilient supply chain that meets the demands of the future.