Maximize Efficiency: The Ultimate Pedestal Grinder Guide (2025)

Introduction: Navigating the Global Market for pedestal grinder

As international B2B buyers increasingly seek reliable equipment, sourcing a pedestal grinder can present significant challenges. Understanding the diverse types of pedestal grinders, their applications across various industries, and the nuances of supplier vetting is crucial for making informed purchasing decisions. This guide provides a comprehensive overview of the pedestal grinder market, addressing essential factors such as technical specifications, cost considerations, and operational requirements.

In the context of diverse markets like Africa, South America, the Middle East, and Europe, including countries like France and Spain, navigating the complexities of international procurement can be daunting. Buyers need to consider local regulations, logistical challenges, and supplier reliability to ensure they invest wisely. This guide empowers B2B buyers by offering actionable insights into evaluating suppliers, comparing prices, and understanding the total cost of ownership associated with pedestal grinders.

Whether you are looking for equipment to enhance your manufacturing capabilities or improve your workshop’s efficiency, this resource equips you with the knowledge needed to make strategic decisions. From identifying the right type of pedestal grinder to understanding market trends and supplier assessments, our guide serves as your essential roadmap in the global market for pedestal grinders.

Understanding pedestal grinder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Pedestal Grinder | Fixed base, typically features a single or dual grinding wheel | Metalworking, woodworking, fabrication | Pros: Versatile, durable. Cons: Limited mobility. |

| Variable Speed Grinder | Adjustable RPM settings for different materials | Tool sharpening, precision grinding | Pros: Enhanced control, suitable for diverse tasks. Cons: Higher initial cost. |

| Bench Grinder | Smaller footprint, often portable, suitable for light tasks | Small workshops, DIY projects | Pros: Space-efficient, easy to use. Cons: Limited power for heavy-duty tasks. |

| Heavy-Duty Grinder | Robust construction, designed for continuous operation | Industrial settings, high-volume production | Pros: Long-lasting, handles tough materials. Cons: Requires more space and investment. |

| Wet Grinder | Uses water to cool and lubricate grinding surfaces | Specialty applications, tool maintenance | Pros: Reduces heat, improves finish quality. Cons: Additional maintenance required. |

What are the characteristics of a Standard Pedestal Grinder?

The Standard Pedestal Grinder is characterized by its robust, fixed base and typically features either a single or dual grinding wheel setup. This type of grinder is widely used in metalworking and woodworking applications, making it a staple in workshops and fabrication shops. When considering a purchase, B2B buyers should evaluate the grinder’s durability and versatility, as it can handle a range of materials. However, its fixed nature may limit mobility, which could be a drawback for businesses requiring frequent relocation of equipment.

How does a Variable Speed Grinder enhance B2B operations?

Variable Speed Grinders offer adjustable RPM settings, allowing users to tailor the grinding speed to different materials. This adaptability makes them ideal for applications such as tool sharpening and precision grinding, where control over the grinding process is essential. B2B buyers should consider the added value of enhanced control and versatility, especially if their operations involve a variety of materials. However, the initial investment may be higher compared to standard models, necessitating a cost-benefit analysis.

In what scenarios is a Bench Grinder most suitable?

Bench Grinders are known for their smaller footprint and portability, making them perfect for light tasks in small workshops or DIY projects. They are easy to use and can be moved as needed, providing flexibility for operations with limited space. For B2B buyers, the key consideration should be the balance between the grinder’s power and the types of tasks required. While they are user-friendly, Bench Grinders may not be suitable for heavy-duty applications, which could limit their utility in more demanding environments.

What advantages do Heavy-Duty Grinders offer in industrial settings?

Heavy-Duty Grinders are built with robust construction to withstand continuous operation, making them ideal for industrial settings and high-volume production environments. Their ability to handle tough materials and perform under heavy use is a significant advantage for B2B buyers in sectors like manufacturing. However, these grinders require more space and a larger investment, so businesses should assess their production needs and budget before committing to a purchase.

How do Wet Grinders contribute to tool maintenance?

Wet Grinders utilize water to cool and lubricate grinding surfaces, significantly reducing heat during the grinding process. This feature is particularly beneficial for specialty applications and tool maintenance, as it helps improve the quality of the finish. B2B buyers should consider the advantages of using a Wet Grinder, especially for precision work that demands a high-quality finish. However, the additional maintenance required for water management may be a consideration for some businesses.

Related Video: Pedestal Grinder Improvements and Wheel Installation

Key Industrial Applications of pedestal grinder

| Industry/Sector | Specific Application of Pedestal Grinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Sharpening and finishing tools | Improved tool longevity and precision | Durability, precision grinding capabilities, safety features |

| Automotive Manufacturing | Reconditioning automotive parts | Enhanced performance and reduced downtime | Compatibility with various materials, ease of use, maintenance support |

| Aerospace | Precision grinding of components | High precision and compliance with strict standards | Certification compliance, vibration control, after-sales service |

| Construction | Surface preparation for concrete and metal | Increased adhesion and surface quality | Versatility, power requirements, portability |

| Electrical Engineering | Finishing electrical contacts and components | Improved electrical conductivity and reliability | Precision, compatibility with electrical components, safety features |

How is the Pedestal Grinder Used in Metal Fabrication?

In the metal fabrication industry, pedestal grinders are primarily used for sharpening and finishing various tools, such as chisels, drill bits, and blades. This application is crucial as it enhances the longevity and precision of tools, thus reducing costs associated with frequent replacements. Buyers from regions like Africa and South America may seek grinders with robust construction to withstand harsh working environments, while those in Europe may prioritize precision and energy efficiency. When sourcing, businesses should focus on durability, precision grinding capabilities, and essential safety features to ensure compliance with local regulations.

What Role Does the Pedestal Grinder Play in Automotive Manufacturing?

In automotive manufacturing, pedestal grinders are utilized for reconditioning automotive parts, including crankshafts and camshafts. This process enhances the performance of these components, ultimately reducing machine downtime and improving overall efficiency. B2B buyers in the Middle East and Europe should consider grinders that can handle various materials used in automotive applications, ensuring compatibility with both ferrous and non-ferrous metals. Additionally, ease of use and reliable maintenance support are critical factors when selecting a pedestal grinder for this sector.

Why is Precision Grinding Important in Aerospace Applications?

The aerospace industry demands high precision in component manufacturing, making pedestal grinders essential for achieving tight tolerances in parts like turbine blades and landing gear components. These grinders help ensure compliance with stringent industry standards, directly impacting safety and performance. Buyers, especially from Europe, should look for grinders that meet specific certification requirements and offer vibration control to maintain precision. After-sales service and technical support are also vital considerations to ensure long-term operational efficiency.

How Does the Pedestal Grinder Contribute to Construction Projects?

In construction, pedestal grinders are employed for surface preparation tasks, such as grinding concrete and metal surfaces to enhance adhesion for coatings and finishes. This application is vital for ensuring the longevity and durability of structures. Buyers in Africa and South America may prioritize versatility and portability in their grinding solutions, while European buyers may focus on power requirements and energy efficiency. When sourcing, businesses should evaluate the grinder’s ability to handle various surface materials and its overall performance in demanding environments.

What Benefits Does the Pedestal Grinder Offer in Electrical Engineering?

In the electrical engineering sector, pedestal grinders are used for finishing electrical contacts and components to improve conductivity and reliability. This application is critical in ensuring the performance of electrical systems. B2B buyers should seek grinders that provide high precision and compatibility with various electrical components. Safety features are paramount, particularly in environments where electrical hazards may be present. Evaluating the grinder’s precision and after-sales support will help buyers make informed decisions that align with their operational needs.

3 Common User Pain Points for ‘pedestal grinder’ & Their Solutions

Scenario 1: Struggling with Inconsistent Grinding Performance

The Problem: Many B2B buyers in the manufacturing sector face challenges with pedestal grinders that yield inconsistent grinding results. This inconsistency can lead to wasted materials, increased labor time, and ultimately, a decline in product quality. For businesses in competitive markets like those in Europe and South America, maintaining high-quality standards is essential. Additionally, operators often find that varying levels of experience lead to discrepancies in how the machine is used, further exacerbating the problem.

The Solution: To address this issue, it’s crucial to invest in a high-quality pedestal grinder equipped with variable speed controls and adjustable grinding parameters. Buyers should seek grinders that allow for fine-tuning based on the specific material being processed. Additionally, providing comprehensive training for operators on the proper use and maintenance of the grinder can mitigate performance inconsistencies. Establishing standard operating procedures (SOPs) for different materials and tasks can also ensure that all operators are on the same page, leading to more consistent outcomes.

Scenario 2: Dealing with Safety Concerns in the Workplace

The Problem: Safety is a paramount concern for B2B buyers, particularly in industries where pedestal grinders are used extensively. Many users are apprehensive about the potential hazards associated with grinding operations, including sparks, noise, and the risk of injury from the rotating wheel. In regions like Africa and the Middle East, where safety regulations may vary, ensuring a safe working environment becomes an even greater challenge.

The Solution: To enhance safety, buyers should prioritize acquiring pedestal grinders that come with integrated safety features, such as emergency stop buttons, protective guards, and noise dampening systems. Regular safety audits and training sessions on the proper use of grinding equipment can also foster a culture of safety within the workplace. Additionally, implementing personal protective equipment (PPE) protocols, such as goggles, gloves, and ear protection, will help mitigate risks and ensure compliance with local safety regulations.

Scenario 3: Navigating Maintenance and Downtime Issues

The Problem: Frequent maintenance and unexpected downtime can significantly hinder productivity for companies that rely on pedestal grinders. In regions with limited access to parts and service, such as parts of South America and Africa, this can be particularly problematic. B2B buyers often find themselves struggling to maintain equipment, leading to costly delays and disruptions in operations.

The Solution: To combat maintenance challenges, businesses should consider establishing a proactive maintenance plan that includes regular inspections and timely replacements of wear parts. Opting for pedestal grinders from reputable manufacturers that offer robust warranties and readily available spare parts can also minimize downtime. Furthermore, investing in training for maintenance personnel will ensure that minor issues are addressed before they escalate into major problems. Buyers should also explore the option of remote monitoring technologies, which can alert teams to potential equipment failures before they occur, thus enhancing overall operational efficiency.

Strategic Material Selection Guide for pedestal grinder

What Are the Key Materials Used in Pedestal Grinders?

When selecting materials for pedestal grinders, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials used in pedestal grinders: cast iron, steel, aluminum, and composite materials.

How Does Cast Iron Perform in Pedestal Grinders?

Key Properties: Cast iron is known for its excellent wear resistance and ability to withstand high temperatures. It has a good compressive strength and can absorb vibrations, making it ideal for heavy-duty applications.

Pros & Cons: The durability of cast iron is one of its key advantages, as it can last for many years under normal operating conditions. However, it is relatively heavy, which can make the grinder cumbersome to move. Additionally, cast iron can be brittle, making it susceptible to cracking under extreme stress.

Impact on Application: Cast iron is particularly suitable for grinding applications involving hard materials, as it can maintain its integrity under high pressure. However, it may not be the best choice for environments with high moisture, as it can corrode over time.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for material durability and corrosion resistance. Understanding ASTM or DIN standards can help in making informed decisions.

What Are the Benefits of Using Steel in Pedestal Grinders?

Key Properties: Steel offers high tensile strength and excellent ductility, making it a versatile choice for various applications. It can withstand high temperatures and is generally more resistant to impact than cast iron.

Pros & Cons: The primary advantage of steel is its strength-to-weight ratio, allowing for lighter designs without sacrificing durability. However, steel can be more expensive than cast iron and may require additional treatments to improve corrosion resistance.

Impact on Application: Steel is suitable for a wide range of grinding tasks, including those involving softer materials. Its adaptability makes it a preferred choice for manufacturers looking to offer versatile products.

Considerations for International Buyers: Compliance with international standards is crucial, especially in Europe, where regulations on manufacturing materials are stringent. Buyers should also consider the availability of high-quality steel in their region.

Why Choose Aluminum for Pedestal Grinders?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it suitable for portable pedestal grinders. It also has decent thermal conductivity, which helps in heat dissipation during grinding.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which enhances portability. However, it is less durable than steel or cast iron and may not perform well under heavy loads.

Impact on Application: Aluminum is ideal for applications that require mobility and ease of use. It is best suited for lighter grinding tasks, particularly in workshops where space is limited.

Considerations for International Buyers: Buyers in South America and Europe should be aware of the recycling potential of aluminum, which can be a selling point. Additionally, they should check for compliance with environmental regulations regarding aluminum production and disposal.

How Do Composite Materials Compare for Pedestal Grinders?

Key Properties: Composite materials are engineered to combine the best properties of various substances, offering high strength while being lightweight. They can be designed for specific applications, providing tailored solutions.

Pros & Cons: The flexibility in design is a significant advantage, allowing for customized solutions. However, composite materials can be more expensive to manufacture and may require specialized knowledge for maintenance.

Impact on Application: Composites are suitable for specialized applications where traditional materials may fail. They can withstand corrosive environments better than metals, making them ideal for specific industrial applications.

Considerations for International Buyers: Buyers should consider the long-term costs associated with composite materials, including maintenance and potential replacement. Understanding local manufacturing capabilities for composites is also essential.

Summary Table of Material Selection for Pedestal Grinders

| Material | Typical Use Case for Pedestal Grinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Heavy-duty grinding | Excellent durability | Brittle under extreme stress | Medium |

| Steel | Versatile applications | High strength-to-weight ratio | More expensive than cast iron | High |

| Aluminum | Portable grinders | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Composite | Specialized applications | Customizable and lightweight | Higher manufacturing costs | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pedestal grinder

What Are the Key Stages in the Manufacturing Process of a Pedestal Grinder?

The manufacturing process of a pedestal grinder typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is integral to ensuring the grinder’s performance, durability, and compliance with international quality standards.

Material Preparation

The first step involves selecting the appropriate raw materials, usually high-grade steel for the frame and base, and high-performance grinding wheels. The materials undergo rigorous testing to confirm their composition and structural integrity. Common practices include chemical analysis and mechanical testing to evaluate tensile strength and hardness. This stage is crucial as the quality of raw materials directly impacts the grinder’s longevity and efficiency.

Forming

In the forming stage, the prepared materials are shaped into the various components of the pedestal grinder. Techniques such as forging, casting, and machining are employed. For instance, the base is typically cast or welded, while components like the spindle and housing are machined to precise specifications. CNC (Computer Numerical Control) machining is often used to ensure high accuracy and repeatability, allowing for complex geometries that enhance the grinder’s functionality.

Assembly

Following the forming process, the components are assembled. This stage requires skilled labor to ensure that all parts fit together correctly and function as intended. Assembly often includes the installation of electrical components and safety features, such as guards and emergency stop buttons. Quality control checks are performed at this stage to confirm that each assembly meets the design specifications.

Finishing

The finishing stage encompasses surface treatments and coatings to improve durability and resistance to wear and corrosion. Techniques such as powder coating, anodizing, or galvanizing are commonly used. This not only enhances the aesthetic appeal of the grinder but also prolongs its operational life. After finishing, the product undergoes final inspections to ensure that it meets all design and quality standards before packaging.

How Is Quality Assurance Implemented in Pedestal Grinder Manufacturing?

Quality assurance is a cornerstone of manufacturing, especially for international B2B buyers who demand reliability and performance. Various international and industry-specific standards guide the quality assurance process for pedestal grinders.

What International Standards Should B2B Buyers Be Aware Of?

The ISO 9001 standard is widely recognized in quality management systems and is crucial for manufacturers aiming to ensure consistent quality in their products. Compliance with ISO 9001 demonstrates that the manufacturer has established a quality management system that meets international standards. Other relevant certifications may include CE marking for compliance with European safety directives and API (American Petroleum Institute) standards for grinders used in oil and gas applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to monitor quality at various stages.

Incoming Quality Control (IQC)

At the IQC stage, raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for defects, verifying dimensions, and conducting chemical analyses. Only materials that pass these inspections proceed to the next stage.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves regular inspections to monitor the quality of components as they are being manufactured. This includes checking the tolerances of machined parts and ensuring that assembly procedures are followed correctly. Non-conforming items are flagged for rework or rejection, minimizing the risk of defects in the final product.

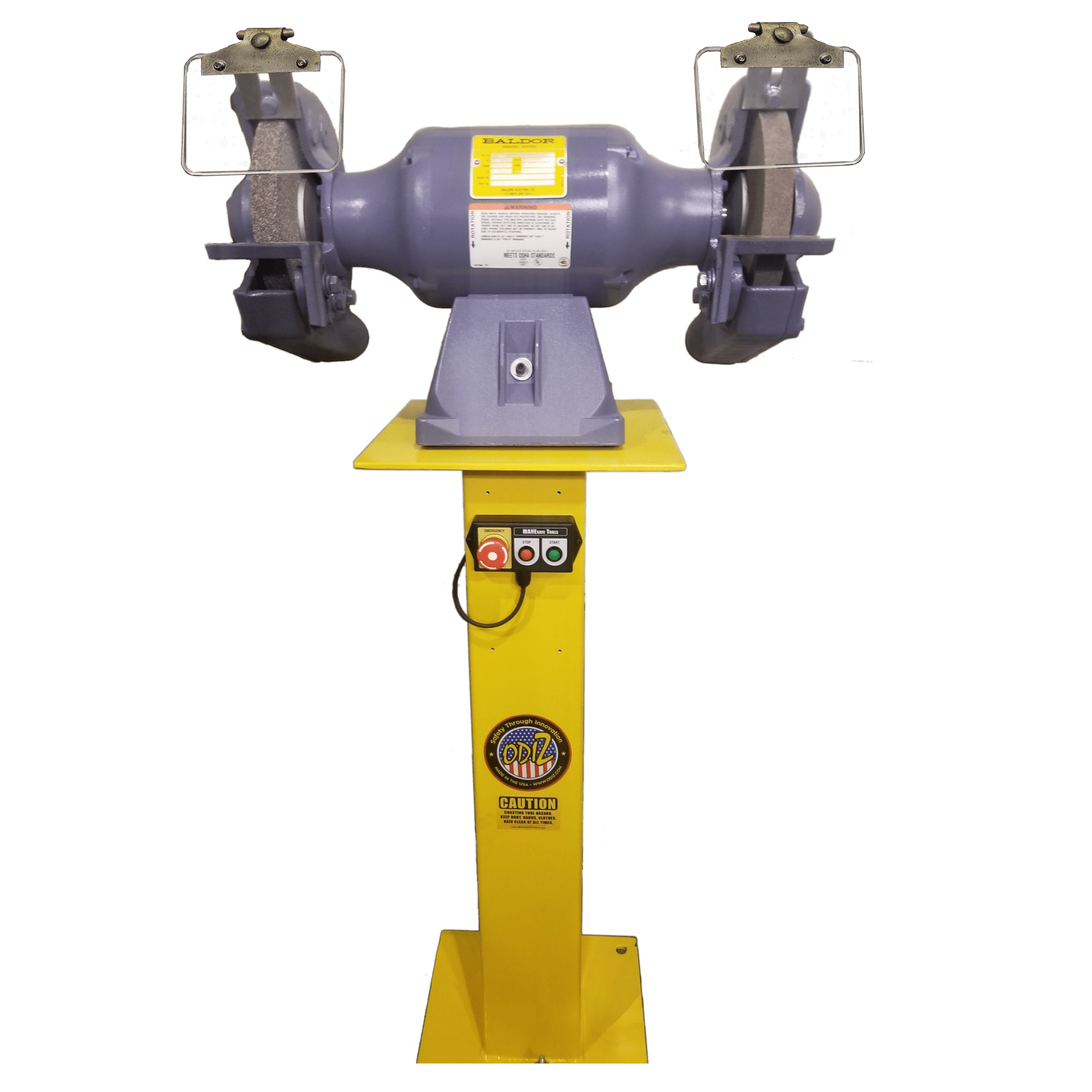

A stock image related to pedestal grinder.

Final Quality Control (FQC)

Once assembly is complete, FQC involves a thorough examination of the entire pedestal grinder. This includes functional testing, where the grinder is operated under various conditions to ensure it performs as expected. Additionally, visual inspections are conducted to detect any cosmetic defects.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Audit Processes Should Be Considered?

Conducting audits is one of the most effective ways to assess a supplier’s quality management system. Buyers can either perform these audits directly or hire third-party inspectors to evaluate the supplier’s facilities and processes. During an audit, buyers should look for compliance with quality standards, the effectiveness of the QC checkpoints, and the documentation of quality records.

How Important Are Quality Reports and Certifications?

A stock image related to pedestal grinder.

Quality reports, including test results and compliance certificates, provide insight into the supplier’s adherence to quality standards. Buyers should request these documents as part of their due diligence. Certifications from recognized organizations can serve as a valuable indicator of a supplier’s commitment to quality.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers must navigate various nuances in quality control and certification, especially when dealing with suppliers from different regions. For instance, while ISO 9001 is a global standard, the interpretation and implementation of quality practices can vary significantly across countries.

What Should Buyers Look For in Terms of Compliance?

Buyers should be aware of local regulations and international standards that may affect the quality of the pedestal grinders they are purchasing. Understanding the compliance requirements specific to their region can help buyers avoid potential legal and operational issues.

Conclusion

A thorough understanding of the manufacturing processes and quality assurance practices for pedestal grinders is essential for international B2B buyers. By focusing on the key stages of production and recognizing the importance of quality control, buyers can make informed decisions when sourcing these critical tools. Verifying supplier practices through audits, quality reports, and an understanding of international standards will further enhance the reliability of their procurement process.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pedestal grinder’

In the realm of industrial machinery, acquiring a pedestal grinder involves a thoughtful approach to ensure that your investment meets both quality standards and operational needs. This guide provides a systematic checklist for B2B buyers looking to source pedestal grinders effectively, particularly in the diverse markets of Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right pedestal grinder. Consider factors such as wheel size, motor power, and the types of materials you will be grinding. Detailing these requirements upfront helps narrow your options and ensures compatibility with your operational processes.

- Wheel Size: Determine the diameter and thickness required for your applications.

- Motor Power: Assess the horsepower needed based on the materials and production volume.

Step 2: Research Market Trends and Innovations

Understanding current market trends can significantly influence your purchasing decision. Investigate the latest advancements in pedestal grinder technology, such as energy-efficient motors or enhanced safety features. This knowledge can provide leverage when negotiating with suppliers and help you make an informed choice.

- Energy Efficiency: Look for models that reduce operational costs through lower energy consumption.

- Safety Features: Prioritize grinders with built-in safety mechanisms to protect operators.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage in direct conversations to assess their capabilities and support services.

- Company Reputation: Check online reviews and ratings on platforms relevant to your industry.

- Local Support: Ensure the supplier offers adequate after-sales support, especially for maintenance and repairs.

Step 4: Request Quotations and Compare Offers

Once you have a shortlist of potential suppliers, request detailed quotations that include pricing, delivery timelines, and warranty terms. Comparing these offers will help you identify the best value for your investment, balancing cost against quality and service.

- Breakdown of Costs: Look for transparency in pricing, including shipping and installation fees.

- Warranty Coverage: Evaluate the length and terms of warranty to safeguard your investment.

Step 5: Verify Compliance with Standards and Certifications

Ensure that the pedestal grinders comply with international safety and quality standards, such as ISO certifications. This verification not only mitigates risk but also guarantees that the equipment meets necessary regulatory requirements in your region.

- ISO Certifications: Confirm the supplier’s adherence to ISO standards relevant to manufacturing and safety.

- Local Regulations: Be aware of any specific regulations applicable in your country or region.

Step 6: Assess Delivery and Installation Services

Consider the logistics involved in transporting and installing the pedestal grinder. A supplier that offers comprehensive delivery and installation services can simplify the process and minimize downtime.

- Delivery Timeframes: Clarify expected delivery dates and any potential delays.

- Installation Support: Check if the supplier provides on-site installation assistance or training for your team.

Step 7: Establish Payment Terms and Conditions

Finally, negotiate payment terms that align with your budget and financial planning. This could include options for installment payments or discounts for early settlement.

- Flexible Payment Options: Discuss various payment methods and terms that suit your cash flow.

- Contractual Clarity: Ensure all agreements are documented clearly to avoid misunderstandings later.

By following these steps, B2B buyers can streamline the sourcing process for pedestal grinders, ensuring they make informed decisions that align with their operational needs and budgetary constraints.

Comprehensive Cost and Pricing Analysis for pedestal grinder Sourcing

Understanding the cost structure of pedestal grinders is crucial for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. A comprehensive analysis of the various cost components and influencing factors can help buyers make informed purchasing decisions.

What Are the Key Cost Components of Pedestal Grinders?

-

Materials: The primary raw materials used in manufacturing pedestal grinders include high-quality steel and other alloys. The cost of these materials can fluctuate based on global market trends, impacting the final price. Buyers should inquire about the material specifications to ensure durability and performance.

-

Labor: Labor costs vary significantly across regions. For instance, manufacturing in countries with lower labor costs may yield more competitive pricing. However, the skill level of the workforce can affect the quality of the finished product. Buyers should evaluate the supplier’s labor practices and expertise in producing pedestal grinders.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs down, which is beneficial for buyers looking for cost-effective solutions.

-

Tooling: The initial setup costs for machinery and tools can be substantial. Custom tooling for specific grinder configurations may increase costs. Buyers should consider whether standard models will suffice or if customization is necessary, as this can significantly impact pricing.

-

Quality Control (QC): Rigorous QC processes ensure that the pedestal grinders meet industry standards and specifications. While this adds to the manufacturing cost, it is essential for ensuring product reliability, particularly for buyers who prioritize quality.

-

Logistics: Transportation costs can vary based on distance, shipping methods, and Incoterms. Buyers should consider these costs in their total purchase price, especially for international shipments.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary depending on the supplier’s market position and the volume of orders.

How Do Price Influencers Impact Pedestal Grinder Costs?

-

Volume/MOQ: Bulk purchasing often leads to lower unit prices. Buyers looking to source multiple units should negotiate minimum order quantities (MOQ) to leverage better pricing.

-

Specifications and Customization: Custom features or high specifications can significantly increase costs. Buyers should assess whether the additional features are necessary for their operations.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO standards) can lead to increased costs but provide long-term value through enhanced performance and reduced maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but offer better service and product quality.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential, as these can affect the total cost. Buyers should clarify responsibilities for shipping costs and risks.

What Are the Best Tips for Negotiating Pedestal Grinder Prices?

-

Research and Prepare: Before entering negotiations, conduct market research to understand typical pricing and available features. This knowledge can empower buyers during discussions.

-

Leverage Total Cost of Ownership (TCO): Consider not only the initial purchase price but also maintenance, operational costs, and potential downtime. A slightly higher upfront cost may lead to lower TCO if the grinder is more durable.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Loyalty can often be rewarded with discounts or favorable terms.

-

Be Open to Alternative Solutions: If a supplier cannot meet your budget, consider discussing alternative models or payment terms that could align better with your financial constraints.

-

Stay Informed About Market Trends: Fluctuations in material costs and economic conditions can impact pricing. Keeping abreast of these trends can help buyers negotiate more effectively.

Disclaimer on Indicative Prices

Prices for pedestal grinders are subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. It is advisable for buyers to request detailed quotes from multiple suppliers to ensure they receive competitive pricing reflective of current market conditions.

Alternatives Analysis: Comparing pedestal grinder With Other Solutions

When evaluating the effectiveness of a pedestal grinder, it’s essential for international B2B buyers to consider alternative solutions that may better suit their operational needs. Understanding the strengths and weaknesses of various grinding technologies can lead to more informed purchasing decisions. Below is a comparative analysis of the pedestal grinder against two alternative grinding solutions: the bench grinder and the belt sander.

Comparison Table

| Comparison Aspect | Pedestal Grinder | Bench Grinder | Belt Sander |

|---|---|---|---|

| Performance | High precision for sharpening and grinding hard materials | Good for sharpening and shaping metals | Excellent for smoothing and finishing surfaces |

| Cost | Moderate (varies by model) | Generally lower | Moderate to high |

| Ease of Implementation | Requires dedicated space and setup | Easy to set up, portable | Moderate, requires space for operation |

| Maintenance | Moderate; regular wheel replacement needed | Low; minimal maintenance required | Moderate; belt replacement needed |

| Best Use Case | Industrial sharpening and grinding tasks | General DIY tasks and light metalworking | Woodworking and finishing tasks |

What Are the Advantages and Disadvantages of Each Alternative?

Bench Grinder

Bench grinders are versatile tools primarily used for sharpening and shaping metal tools. They are typically smaller and more portable than pedestal grinders, making them suitable for light-duty applications in workshops and home garages.

Pros:

– Cost-Effective: Generally more affordable, which is beneficial for small businesses or startups.

– Ease of Use: Simple setup and operation, allowing for quick tasks without extensive training.

Cons:

– Limited Capacity: Not suitable for heavy-duty tasks or large-scale industrial applications.

– Precision: While effective for general tasks, they may not offer the same precision as a pedestal grinder.

Belt Sander

Belt sanders are primarily used for smoothing and finishing surfaces, especially in woodworking. They operate using a continuous belt covered with abrasive material, making them excellent for removing material quickly.

Pros:

– Surface Finishing: Ideal for achieving smooth finishes on wood and other materials, making them a favorite among woodworkers.

– Speed: Can remove material quickly, reducing overall project time.

Cons:

– Specialized Use: Primarily designed for woodworking, which may limit their application in metalworking or other industries.

– Cost: Higher-end models can be expensive, impacting budget considerations for buyers.

How Can B2B Buyers Choose the Right Grinding Solution?

When selecting the appropriate grinding solution, B2B buyers should first assess their specific needs and operational requirements. Consider factors such as the primary material being worked on, the volume of work, and the desired finish quality.

For companies focused on metalworking and precision tasks, a pedestal grinder may be the best option due to its superior performance and durability. Conversely, businesses engaged in woodworking or those requiring portable solutions might find a bench grinder or belt sander more suitable. Additionally, evaluating the total cost of ownership, including maintenance and consumables, will help in making a financially sound decision.

Ultimately, the right choice will depend on aligning the equipment’s capabilities with the specific demands of your projects, ensuring optimal efficiency and productivity.

Essential Technical Properties and Trade Terminology for pedestal grinder

What Are the Key Technical Properties of a Pedestal Grinder?

When evaluating pedestal grinders for purchase, understanding specific technical properties is crucial for ensuring optimal performance and suitability for your operations. Here are some essential specifications to consider:

1. Motor Power (HP or kW)

The motor power rating indicates the grinder’s ability to handle various materials and workloads. For heavy-duty applications, a higher power rating (typically between 1 HP to 5 HP) is preferred. This specification is critical for B2B buyers to ensure the grinder can meet their production demands without overheating or failing.

2. Wheel Size and Type

The diameter of the grinding wheels (commonly ranging from 6 inches to 14 inches) affects the speed and efficiency of the grinding process. Different materials and types of wheels (such as aluminum oxide or silicon carbide) are designed for specific applications. Understanding wheel specifications helps buyers select a grinder that matches their material processing needs.

3. Spindle Speed (RPM)

Spindle speed, measured in revolutions per minute (RPM), indicates how fast the grinding wheel rotates. Higher RPMs can improve grinding efficiency but may generate more heat. Knowing the optimal spindle speed for the materials being worked on is essential for achieving desired results without damaging the workpiece.

4. Material Grade

The construction material of the grinder’s body, often made from cast iron or steel, impacts durability and stability during operation. A robust material grade ensures longevity and reduces vibrations, leading to better grinding precision. Buyers should assess the material quality to ensure their investment withstands the rigors of industrial use.

5. Tolerance and Accuracy

Tolerance refers to the permissible limit of variation in a physical dimension. For pedestal grinders, maintaining tight tolerances is vital for precision machining tasks. Buyers should inquire about the grinder’s accuracy specifications to ensure it meets their quality standards for finished products.

What Are Common Trade Terms Related to Pedestal Grinders?

Understanding industry jargon is equally important for making informed purchasing decisions. Here are some commonly used terms in the pedestal grinder market:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. When buying a pedestal grinder, knowing whether the components are sourced from an OEM can assure buyers of quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand their purchasing requirements and budget constraints, especially when dealing with international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. Buyers should utilize RFQs to compare different offers and negotiate better deals on pedestal grinders, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers from Africa, South America, the Middle East, and Europe navigate shipping logistics and costs effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time is essential for B2B buyers, as it affects production schedules and inventory management. Buyers should inquire about lead times to plan their operations accordingly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing pedestal grinders, ultimately enhancing their operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the pedestal grinder Sector

What Are the Current Market Dynamics and Key Trends in the Pedestal Grinder Sector?

The global pedestal grinder market is experiencing robust growth, driven by increasing industrialization and manufacturing activities across various regions. Particularly in Africa and South America, a surge in infrastructure projects is boosting demand for reliable machining tools. In the Middle East, the ongoing expansion of the oil and gas sectors necessitates precision tools, while European countries like France and Spain focus on enhancing production efficiency and workplace safety.

Emerging B2B technology trends in the pedestal grinder sector include the integration of automation and IoT (Internet of Things) capabilities. Smart grinders equipped with sensors can monitor performance metrics, reducing downtime and maintenance costs. Moreover, the rise of e-commerce platforms has transformed sourcing strategies, allowing international buyers to access a broader range of suppliers and products. This shift encourages competitive pricing and improved supply chain transparency, which are critical for buyers in regions with fluctuating currency values.

Furthermore, the emphasis on precision engineering and customization is reshaping market dynamics. B2B buyers are increasingly looking for suppliers that offer tailored solutions to meet specific operational needs, enhancing productivity and product quality. As manufacturers strive to innovate, understanding these trends is crucial for international buyers seeking to make informed purchasing decisions.

How Important Is Sustainability and Ethical Sourcing in the Pedestal Grinder Sector?

Sustainability and ethical sourcing have become paramount in the pedestal grinder market, reflecting a broader industry shift towards environmental responsibility. The manufacturing of grinding tools often involves materials and processes that can negatively impact the environment. Therefore, B2B buyers are increasingly considering the environmental footprint of their suppliers. This includes assessing energy consumption during production, waste management practices, and the use of non-toxic materials.

Ethical supply chains are also gaining traction as buyers prioritize suppliers who adhere to fair labor practices and contribute positively to local communities. Certifications such as ISO 14001 for environmental management systems and Fair Trade certifications are becoming essential for buyers looking to ensure responsible sourcing.

Moreover, many manufacturers are now investing in ‘green’ materials, such as recycled metals and biodegradable components, which not only reduce environmental impact but also enhance brand reputation. For international buyers, especially in Europe, aligning procurement strategies with sustainability goals can lead to competitive advantages and compliance with stricter regulations.

What Is the Brief Evolution and History of Pedestal Grinders?

The pedestal grinder has evolved significantly since its inception during the Industrial Revolution. Initially designed for basic grinding tasks, these tools have undergone technological advancements that have enhanced their functionality and efficiency. The introduction of electric motors in the early 20th century marked a pivotal moment, allowing for more powerful and versatile machines.

Over the years, advancements in materials science have led to the development of high-performance grinding wheels and improved machine designs, which cater to a variety of industrial applications. Today, pedestal grinders are integral to manufacturing and maintenance operations, serving as essential tools for precision machining and metalworking. This historical context underscores the importance of innovation and adaptability in meeting the demands of modern industry, providing valuable insights for B2B buyers navigating this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of pedestal grinder

-

How do I solve issues with a pedestal grinder’s performance?

To resolve performance issues with a pedestal grinder, start by checking the wheel’s balance and integrity. Ensure that the grinding wheel is properly installed and free from cracks. Regular maintenance, such as cleaning the dust and debris from the machine and lubricating moving parts, can significantly enhance performance. If problems persist, consult the manufacturer’s manual for troubleshooting tips or seek professional assistance to inspect for deeper mechanical issues. -

What is the best pedestal grinder for small manufacturing businesses?

For small manufacturing businesses, a bench-top pedestal grinder with a 6 to 8-inch wheel diameter is often ideal. These models typically offer sufficient power for most grinding tasks while occupying less floor space. Look for grinders with variable speed controls and adjustable tool rests, which enhance versatility. Brands known for reliability, such as Baldor or Jet, are often recommended for their durability and performance in small-scale operations. -

What are the key considerations when sourcing a pedestal grinder from international suppliers?

When sourcing a pedestal grinder internationally, consider factors such as supplier reputation, compliance with safety standards, and after-sales support. Verify the supplier’s certifications and read customer reviews to gauge reliability. Additionally, inquire about warranty terms and the availability of spare parts. Establishing clear communication regarding specifications, delivery timelines, and payment terms is also crucial to ensure a smooth transaction. -

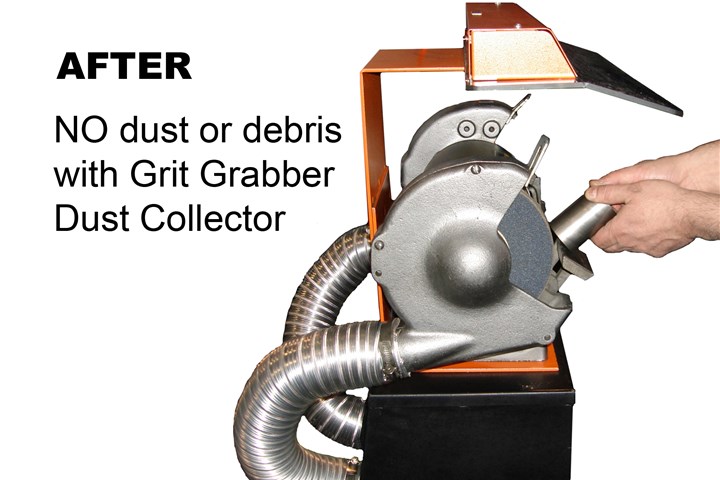

What customization options are available for pedestal grinders?

Customization options for pedestal grinders can include wheel size, motor power, and additional features like dust collection systems or safety guards. Many manufacturers offer tailored solutions to meet specific operational needs. When discussing customization, provide detailed requirements to your supplier and ask for their recommendations based on your production volume and workspace constraints. -

What is the minimum order quantity (MOQ) for pedestal grinders from international suppliers?

The minimum order quantity (MOQ) for pedestal grinders can vary significantly among suppliers, typically ranging from 1 to 50 units. Smaller quantities may be available from local distributors or through online marketplaces. However, purchasing in larger quantities often results in better pricing and terms. Always clarify MOQ details during initial negotiations to avoid any surprises later in the procurement process. -

What payment terms should I expect when purchasing a pedestal grinder internationally?

Payment terms for international purchases of pedestal grinders usually include options such as advance payment, letters of credit, or payment upon delivery. Suppliers may request a deposit (often 30-50%) before production, with the balance due upon shipment. Be sure to discuss and agree on payment methods that provide security for both parties, considering factors like currency exchange rates and transaction fees. -

How can I ensure quality assurance when sourcing pedestal grinders?

To ensure quality assurance when sourcing pedestal grinders, request product samples before placing a bulk order. Establish clear quality standards and specifications with your supplier, including tolerance levels and material grades. Additionally, consider arranging third-party inspections or audits of the manufacturing facility to verify compliance with your quality requirements. Maintain open lines of communication throughout the process to address any concerns proactively. -

What logistics considerations are important for shipping pedestal grinders?

When shipping pedestal grinders, key logistics considerations include selecting a reliable freight forwarder and understanding import regulations in your country. Ensure that the shipping method chosen can accommodate the weight and size of the grinders. Additionally, factor in customs duties and taxes, as well as insurance coverage for potential damages during transit. Planning for lead times and delivery schedules is essential to avoid disruptions in your production workflow.

A stock image related to pedestal grinder.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pedestal grinder

What Are the Key Takeaways for International B2B Buyers of Pedestal Grinders?

In the competitive landscape of manufacturing and metalworking, strategic sourcing of pedestal grinders is crucial for optimizing production efficiency and cost-effectiveness. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer high-quality equipment with robust after-sales support and flexible delivery options. Engaging with suppliers who understand regional market dynamics can lead to better pricing strategies and tailored solutions that meet specific operational needs.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing not only streamlines procurement but also fosters long-term partnerships with manufacturers and distributors. This approach encourages buyers to assess suppliers based on total cost of ownership rather than just initial purchase price, considering factors like energy efficiency, maintenance costs, and longevity of the equipment. By leveraging this comprehensive view, businesses can significantly enhance their operational capabilities and reduce downtime.

What Does the Future Hold for Pedestal Grinder Buyers?

As technology advances, we anticipate increased integration of smart features in pedestal grinders, enhancing productivity and precision. International buyers should stay informed about emerging trends and innovations, ensuring their sourcing strategies are adaptable to future developments. Now is the time to engage with trusted suppliers and invest in machinery that not only meets current demands but also positions your business for future growth. Embrace strategic sourcing as a pathway to operational excellence and competitive advantage in your industry.