Improve Water Quality: The Complete TDS Measurement Meter Guide (2025)

Introduction: Navigating the Global Market for tds measurement meter

In the realm of water quality assessment, sourcing a reliable TDS measurement meter is a critical challenge for international B2B buyers. Total Dissolved Solids (TDS) meters are essential tools for industries ranging from agriculture to manufacturing, ensuring compliance with health standards and optimizing operational efficiency. As businesses expand their global footprint, understanding the diverse offerings and applications of TDS measurement meters becomes paramount.

This comprehensive guide delves into the various types of TDS meters available on the market, including handheld, benchtop, and in-line models, tailored for specific applications. We will also explore the importance of supplier vetting, offering insights on how to identify reputable manufacturers, particularly in regions like Africa, South America, the Middle East, and Europe. Furthermore, the guide addresses cost considerations, helping buyers evaluate the return on investment for different models and brands.

By equipping international B2B buyers with actionable insights and strategic approaches, this guide empowers informed purchasing decisions. Whether you are based in Colombia or Spain, the knowledge provided here will assist you in navigating the complexities of sourcing TDS measurement meters effectively, ensuring that your organization maintains high-quality standards and meets regulatory requirements.

Understanding tds measurement meter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable TDS Meters | Handheld, battery-operated, easy to use | Field testing, water quality assessment | Pros: Highly portable, quick readings. Cons: Limited accuracy compared to lab models. |

| Benchtop TDS Meters | Larger, more precise, often with advanced features | Laboratory testing, industrial processes | Pros: High precision, multiple measurement options. Cons: Less portable, requires power source. |

| Inline TDS Meters | Installed in pipelines, continuous monitoring | Water treatment facilities, aquaculture | Pros: Real-time data, automated monitoring. Cons: Installation complexity, higher initial cost. |

| Digital TDS Meters | Digital display, often with temperature compensation | Aquariums, hydroponics, agriculture | Pros: Easy to read, often features data logging. Cons: May require calibration, battery-dependent. |

| Analog TDS Meters | Simple dial display, no batteries needed | Basic water quality checks, education | Pros: Low cost, no power needed. Cons: Less accurate, not suitable for detailed analysis. |

What Are Portable TDS Meters and When Should You Use Them?

Portable TDS meters are handheld devices designed for quick and easy testing of total dissolved solids in water. They are battery-operated and ideal for field testing, making them suitable for industries that require immediate results, such as environmental monitoring and field research. When purchasing a portable TDS meter, consider factors like measurement range, battery life, and ease of calibration, especially for applications in remote locations.

How Do Benchtop TDS Meters Differ from Other Types?

Benchtop TDS meters are larger, more sophisticated devices that provide precise measurements and often include advanced features like multiple measurement modes and data logging capabilities. They are predominantly used in laboratories and industrial settings where accuracy is critical. B2B buyers should focus on features such as sample volume requirements, calibration frequency, and the ability to connect to other laboratory equipment when considering a benchtop model.

What Are the Advantages of Inline TDS Meters for Continuous Monitoring?

Inline TDS meters are integrated into water systems for continuous monitoring of total dissolved solids levels. They are essential in applications such as water treatment facilities and aquaculture, where maintaining consistent water quality is vital. Buyers should evaluate the ease of installation, maintenance requirements, and compatibility with existing systems, as these factors can significantly impact operational efficiency.

Why Choose Digital TDS Meters for Specific Applications?

Digital TDS meters feature an easy-to-read display and often come with temperature compensation, making them suitable for precise applications in aquariums, hydroponics, and agriculture. They typically offer data logging capabilities, which can be crucial for regulatory compliance and trend analysis. When selecting a digital TDS meter, consider the display type, battery life, and additional features like Bluetooth connectivity for data transfer.

Are Analog TDS Meters Still Relevant in Today’s Market?

Analog TDS meters use a simple dial to indicate total dissolved solids levels and do not require batteries, making them a cost-effective option for basic water quality checks and educational purposes. While they lack the precision and advanced features of digital models, they can still be useful for businesses operating on a tight budget. B2B buyers should assess the trade-off between cost and accuracy, particularly if detailed analysis is not required.

Related Video: How to Measure Conductivity and TDS with Digital Conductivity Meter || TDS Measurement of Water

Key Industrial Applications of tds measurement meter

| Industry/Sector | Specific Application of TDS Measurement Meter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Monitoring water quality in treatment facilities | Ensures compliance with health standards and regulations | Accuracy, calibration frequency, and portability |

| Agriculture | Irrigation water quality assessment | Optimizes crop yield and resource management | Durability in field conditions, ease of use, and data logging capabilities |

| Food and Beverage | Quality control in beverage production | Maintains product consistency and safety | Calibration standards, compliance with food safety regulations, and ease of integration |

| Pharmaceutical | Water quality testing for drug formulation | Ensures efficacy and safety of pharmaceutical products | Precision, regulatory compliance, and validation processes |

| Aquaculture | Monitoring water conditions in fish farming | Enhances fish health and growth rates | Robustness, real-time data access, and compatibility with existing systems |

How is TDS Measurement Used in Water Treatment Facilities?

In water treatment facilities, TDS measurement meters are essential for monitoring the quality of water throughout the purification process. These devices help ensure that the water meets health standards and regulatory requirements, which is critical for public safety. Buyers from regions like Africa and South America should prioritize meters with high accuracy and calibration frequency to adapt to varying water conditions. Portability can also be a significant advantage, allowing for on-site testing in remote locations.

What Role Does TDS Measurement Play in Agriculture?

In agriculture, TDS measurement is crucial for assessing the quality of irrigation water. High TDS levels can indicate the presence of harmful salts and minerals that may affect crop yield and soil health. By utilizing TDS meters, farmers can optimize their irrigation strategies, ensuring that they use water that promotes healthy crop growth. For international buyers, particularly in the Middle East, the durability of the equipment is essential due to harsh environmental conditions, along with user-friendly features and data logging capabilities for effective monitoring.

How is TDS Measurement Important for Food and Beverage Quality Control?

In the food and beverage industry, TDS measurement meters are used for quality control during production processes. These meters help maintain product consistency and safety by ensuring that water used in production meets specific quality standards. Buyers in Europe, such as those in Spain, should focus on meters that comply with stringent food safety regulations and offer reliable calibration standards. Additionally, ease of integration into existing production systems is a critical consideration for maximizing operational efficiency.

Why is TDS Measurement Critical in Pharmaceutical Water Quality Testing?

Pharmaceutical companies utilize TDS measurement meters to ensure the purity of water used in drug formulation. High TDS levels can compromise the efficacy and safety of pharmaceutical products, making accurate measurement vital. International B2B buyers in this sector should prioritize precision and regulatory compliance when sourcing TDS meters, as these factors are crucial for meeting industry standards. Validation processes for the equipment are also important to ensure reliable performance in critical applications.

How Does TDS Measurement Benefit Aquaculture Operations?

In aquaculture, monitoring water conditions is vital for maintaining fish health and optimizing growth rates. TDS measurement meters provide insights into the overall water quality, helping farmers make informed decisions about water management. Buyers from regions with significant aquaculture activities should consider the robustness of the meter, as well as its capability for real-time data access to facilitate timely interventions. Compatibility with existing monitoring systems can also enhance operational efficiency in fish farming operations.

Related Video: How to – TDS Meter Instructions

3 Common User Pain Points for ‘tds measurement meter’ & Their Solutions

Scenario 1: Inaccurate Readings Leading to Poor Decision-Making

The Problem:

B2B buyers, particularly in industries like water treatment or agriculture, often face significant challenges with inaccurate TDS measurement readings. These inaccuracies can stem from using low-quality meters or improper calibration. For instance, a water purification company in South America might find that their TDS meter consistently overestimates the dissolved solids in their water supply, leading to unnecessary filtration costs or even regulatory compliance issues. Such inaccuracies not only inflate operational costs but can also damage the company’s reputation if clients receive subpar products.

The Solution:

To ensure accurate TDS measurements, buyers should invest in high-quality, calibrated TDS measurement meters from reputable manufacturers. When sourcing these devices, it’s crucial to consider features such as automatic temperature compensation and a robust calibration process. Regularly calibrating the meter against known standards is essential to maintain accuracy. Additionally, buyers should establish a routine maintenance schedule, including cleaning the electrode and replacing it when necessary, to ensure consistent performance. By prioritizing quality and maintenance, businesses can make informed decisions based on reliable data, ultimately improving their operational efficiency.

Scenario 2: Limited Understanding of TDS and Its Impact on Operations

The Problem:

Many international B2B buyers, especially in emerging markets like Africa and parts of the Middle East, struggle with a limited understanding of Total Dissolved Solids (TDS) and how it affects their business operations. For example, a coffee producer in Colombia may not realize that high TDS levels can negatively impact the flavor profile of their product, leading to customer dissatisfaction. This knowledge gap can result in missed opportunities for product improvement and market competitiveness.

The Solution:

Investing in training and education around TDS measurement is essential for businesses looking to enhance their product quality. Companies can partner with suppliers of TDS meters to provide workshops or online resources that explain the significance of TDS levels and best practices for measurement. Additionally, creating a comprehensive guide or manual that outlines the correlation between TDS levels and product quality can empower employees to make informed decisions. By fostering a culture of continuous learning and understanding, businesses can leverage TDS data to enhance product offerings and meet customer expectations.

Scenario 3: High Costs of TDS Measurement Equipment

The Problem:

For many B2B buyers, particularly small to medium-sized enterprises (SMEs) in regions such as Europe and South America, the upfront investment for high-quality TDS measurement equipment can be daunting. These businesses may be tempted to opt for cheaper, subpar alternatives that ultimately lead to higher costs due to inaccuracies and frequent replacements. A small water bottling company might struggle with the decision to invest in a reliable TDS meter, fearing that it could strain their budget.

The Solution:

To address the issue of high equipment costs, buyers should consider the total cost of ownership rather than just the initial purchase price. Investing in a reliable TDS measurement meter may come with a higher upfront cost but can lead to significant savings over time through reduced operational errors and lower maintenance expenses. Furthermore, buyers should explore financing options or leasing agreements that allow them to access high-quality equipment without immediate financial strain. Engaging with manufacturers that offer warranties and customer support can also provide peace of mind and protection for the investment. By taking a long-term view of their equipment needs, businesses can ensure they are making financially sound decisions that support their operational goals.

Strategic Material Selection Guide for tds measurement meter

When selecting materials for TDS (Total Dissolved Solids) measurement meters, it is crucial to consider the properties and performance characteristics of different materials. This section analyzes four common materials used in the construction of TDS measurement meters, providing insights that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can leverage for informed purchasing decisions.

What Are the Key Properties of Plastic in TDS Measurement Meters?

Plastic is widely used in TDS measurement meters due to its versatility and cost-effectiveness. Common types include polycarbonate and polypropylene, which offer good chemical resistance and lightweight properties.

Pros & Cons: Plastics are generally durable and resistant to corrosion, making them suitable for various environments. However, they may not withstand high temperatures or pressures as effectively as metals, which could limit their application in industrial settings.

Impact on Application: Plastic is compatible with a wide range of media, including water and mild chemicals. However, it may not be suitable for more aggressive substances, which could lead to degradation over time.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding plastic materials, especially in regions with stringent environmental standards. For example, in Europe, adherence to REACH regulations is essential.

How Does Stainless Steel Perform in TDS Measurement Meters?

Stainless steel is another popular choice for TDS measurement meters, particularly in industrial applications. Its properties include excellent corrosion resistance, high durability, and the ability to withstand elevated temperatures and pressures.

Pros & Cons: The primary advantage of stainless steel is its longevity and robustness, making it ideal for harsh environments. However, it tends to be more expensive than plastic and may require more complex manufacturing processes.

Impact on Application: Stainless steel is compatible with a broad range of fluids, including aggressive chemicals, making it suitable for various industries, including food and beverage, pharmaceuticals, and water treatment.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel suitable for their applications, as different grades offer varying levels of corrosion resistance. Compliance with standards such as ASTM and ISO is also crucial, especially in Europe and North America.

What Are the Advantages of Glass in TDS Measurement Meters?

Glass is often used for the electrodes in TDS measurement meters due to its excellent chemical resistance and inert properties.

Pros & Cons: Glass provides high accuracy and reliability in measurements, making it a preferred choice for laboratory settings. However, it is fragile and can be prone to breakage, which may not be suitable for all environments.

Impact on Application: Glass is compatible with a wide variety of solutions, including corrosive substances, which enhances its utility in specialized applications.

Considerations for International Buyers: Buyers should consider the fragility of glass and ensure adequate protective measures during transport and use. Additionally, compliance with safety standards is essential, especially in regions like Africa and South America, where handling practices may vary.

Why Consider Ceramic in TDS Measurement Meters?

Ceramic materials are emerging as a viable option for TDS measurement meters, particularly for their durability and resistance to high temperatures.

Pros & Cons: Ceramics offer excellent stability and are highly resistant to wear and chemical attack. However, they can be more expensive and may present manufacturing challenges due to their brittleness.

Impact on Application: Ceramics are suitable for high-temperature applications and can be used in environments where plastic and glass might fail.

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of using ceramics versus other materials, especially in regions where budget constraints are a concern. Compliance with local manufacturing standards is also important.

Summary Table of Material Selection for TDS Measurement Meters

| Material | Typical Use Case for tds measurement meter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General water quality testing | Lightweight and cost-effective | Limited temperature/pressure tolerance | Low |

| Stainless Steel | Industrial applications | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Glass | Laboratory settings | High accuracy and reliability | Fragile and prone to breakage | Medium |

| Ceramic | High-temperature applications | Excellent stability and wear resistance | Higher cost and manufacturing challenges | High |

This strategic material selection guide provides a comprehensive overview of the materials used in TDS measurement meters, helping international B2B buyers make informed decisions that align with their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tds measurement meter

What Are the Main Stages in the Manufacturing Process of TDS Measurement Meters?

The manufacturing process of TDS (Total Dissolved Solids) measurement meters involves several critical stages that ensure the final product meets the required specifications and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality raw materials, which typically include plastic casings, electronic components, and sensors. For B2B buyers, it is crucial to verify the quality and origin of these materials, as they directly influence the durability and accuracy of the TDS meter.

-

Forming: In this stage, the raw materials are shaped into their final form. Techniques such as injection molding for plastic components and machining for metal parts are commonly employed. Buyers should inquire about the manufacturing techniques used, as these can affect production efficiency and cost.

-

Assembly: This phase combines all components into the final product. Precision is key; therefore, automated assembly lines are often utilized to ensure consistent quality. B2B buyers should look for suppliers that use advanced assembly techniques to minimize defects.

-

Finishing: The final stage involves quality checks and surface treatments to enhance the meter’s appearance and functionality. This may include calibration, testing for waterproofing, and applying coatings for durability. Buyers should seek detailed information about the finishing processes, as they can significantly impact the meter’s reliability in diverse environments.

What Quality Assurance Measures Are Essential in TDS Meter Production?

Quality assurance (QA) is a vital aspect of the manufacturing process for TDS measurement meters, ensuring that products meet international and industry-specific standards. Understanding these measures is essential for B2B buyers looking to source reliable products.

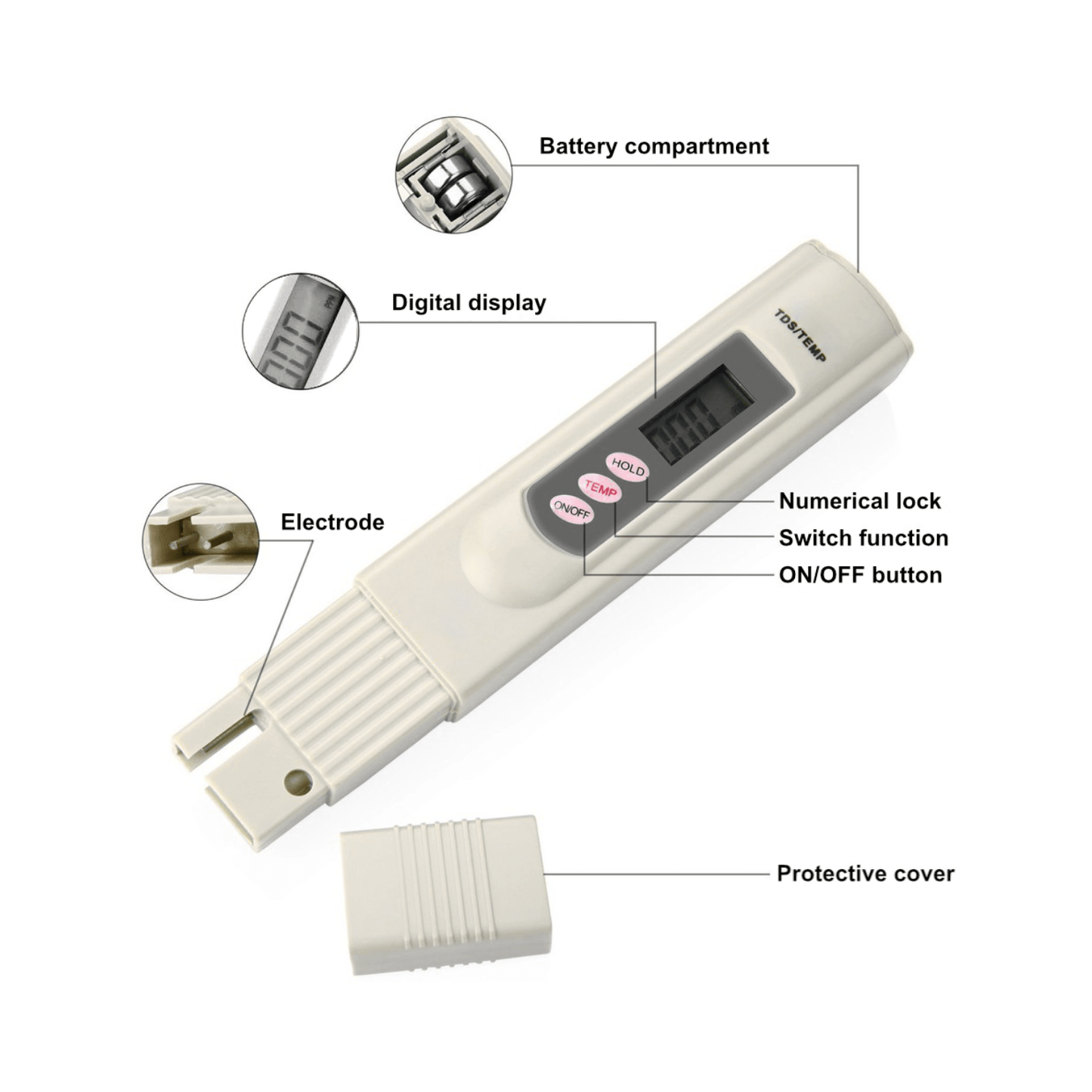

A stock image related to tds measurement meter.

Which International Standards Should B2B Buyers Consider?

The manufacturing of TDS meters is often governed by international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that a supplier adheres to best practices in production and quality control.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for meters used in industrial applications are crucial. Buyers from regions like Africa and South America should ensure that suppliers comply with relevant local regulations as well.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of incoming materials. Suppliers should have robust procedures to verify the specifications of materials before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checkpoints ensure that production adheres to defined standards. Regular monitoring during assembly helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly, FQC involves rigorous testing of finished products. This includes calibration tests, functionality checks, and environmental stress tests to ensure that the meters perform accurately under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount.

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing practices and quality assurance protocols. Buyers should develop a checklist based on international standards and specific needs to ensure thorough evaluations.

-

Requesting Quality Reports: Suppliers should be able to provide documentation that outlines their quality control processes, including test results and compliance certificates. This information is crucial for buyers to assess the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of TDS measurement meters. These independent inspections can offer unbiased assessments and help mitigate risks associated with sourcing from unfamiliar suppliers.

What Common Testing Methods Are Used for TDS Meters?

To ensure that TDS measurement meters function accurately and reliably, manufacturers employ a variety of testing methods throughout the production process. Understanding these methods can help B2B buyers make informed decisions.

-

Calibration Testing: This method involves comparing the meter’s readings against known standards. Proper calibration ensures accuracy and is critical for applications in water quality testing.

-

Environmental Testing: TDS meters must withstand various environmental conditions. Testing for factors such as temperature extremes, humidity, and exposure to chemicals is essential to ensure durability.

-

Performance Testing: This encompasses a range of tests that assess the meter’s functionality, including response time, measurement range, and battery life. Buyers should look for suppliers that document their performance testing results.

How Do QC and Certification Nuances Affect International B2B Buyers?

Understanding the nuances of quality control and certification is essential for international B2B buyers. Compliance with local regulations, particularly in regions like Africa and South America, can vary significantly from European standards.

-

Regional Compliance: Buyers should be aware of specific certifications required in their regions. For example, CE marking is mandatory in Europe, while local certifications may exist in African and South American markets.

-

Cultural Considerations: Different regions may have varying attitudes towards quality and compliance. Understanding these cultural nuances can help buyers negotiate better terms and establish stronger partnerships with suppliers.

-

Risk Management: Engaging with suppliers who have robust quality assurance processes reduces risks associated with product failures and non-compliance. Buyers should prioritize suppliers with a proven track record of meeting international standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for TDS measurement meters is crucial for B2B buyers. By focusing on the key stages of production, relevant standards, quality control checkpoints, and verification methods, buyers can make informed decisions that lead to successful sourcing and long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tds measurement meter’

In the world of B2B procurement, sourcing a TDS (Total Dissolved Solids) measurement meter requires careful consideration and strategic planning. This guide outlines essential steps that international buyers, particularly those from Africa, South America, the Middle East, and Europe, should follow to ensure a successful purchase. By adhering to this checklist, buyers can make informed decisions that align with their operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing a TDS measurement meter. Consider factors such as measurement range, accuracy, and the specific applications for which the meter will be used, such as water quality testing or industrial processes. This clarity will help you target suppliers that offer products matching your operational needs.

Step 2: Research and Identify Reputable Suppliers

Begin your supplier search by leveraging industry directories, trade shows, and online marketplaces. Look for suppliers with a proven track record in the TDS measurement sector and those who cater to your specific geographic region. Pay attention to reviews and testimonials to assess their reputation and reliability.

Step 3: Verify Supplier Certifications

It is crucial to ensure that potential suppliers hold the necessary certifications and quality standards relevant to your industry. Certifications such as ISO 9001 or CE marking can indicate a commitment to quality and regulatory compliance. Request documentation to verify these certifications and check for any industry-specific standards that may apply.

Step 4: Request Product Samples

Before making a bulk order, ask suppliers for product samples. This allows you to evaluate the meter’s performance, durability, and ease of use in real-world conditions. Testing samples can also help identify any potential issues, such as calibration errors or user interface challenges, before finalizing your decision.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare prices effectively. Be sure to consider not only the initial cost of the TDS measurement meter but also shipping fees, taxes, and potential tariffs. Additionally, discuss payment terms and conditions, such as deposit requirements and payment methods, to ensure they align with your financial practices.

Step 6: Evaluate After-Sales Support and Warranty Policies

After-sales support is a critical factor that can impact your long-term satisfaction with the product. Inquire about warranty terms, repair services, and technical support availability. A supplier that offers robust after-sales support can save your business time and money in case of equipment malfunctions or questions regarding operation.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, draft a comprehensive purchase agreement that outlines all terms, including delivery timelines, payment schedules, and return policies. Ensure that both parties clearly understand their obligations to avoid any future disputes. Having a well-defined agreement protects your investment and fosters a positive supplier relationship.

By following these steps, B2B buyers can navigate the sourcing process for TDS measurement meters with confidence, ensuring they make informed and strategic purchasing decisions that meet their specific needs.

Comprehensive Cost and Pricing Analysis for tds measurement meter Sourcing

What Are the Key Cost Components in TDS Measurement Meter Sourcing?

When sourcing TDS measurement meters, understanding the cost structure is critical for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality and type of materials used in the manufacturing process significantly affect the cost. High-grade sensors and durable casings increase the price but enhance the longevity and performance of the meters.

-

Labor: Labor costs vary by region. In countries with lower labor costs, you may find competitive pricing; however, this can sometimes impact the quality of workmanship. It’s essential to balance labor costs with product quality.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs associated with production. A well-managed manufacturing process can lead to lower overheads, benefiting the final price.

-

Tooling: The initial investment in tooling and equipment can be substantial, especially for customized or specialized TDS meters. These costs are typically amortized over the production run, affecting unit pricing.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability, but it also adds to the overall cost. Buyers should consider the long-term savings associated with quality products that reduce returns and failures.

-

Logistics: Shipping and handling costs can vary significantly based on distance, shipping methods, and freight terms. International buyers must account for these expenses, which can impact the total cost.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure sustainability. Understanding the market norms for margins can assist buyers in evaluating pricing.

How Do Price Influencers Impact TDS Measurement Meter Costs?

Several factors can influence the pricing of TDS measurement meters. Buyers should consider the following:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to significant discounts. Suppliers may have tiered pricing structures that reward bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized meters tailored to specific applications or industries will typically incur higher costs. Buyers should weigh the benefits of customization against standard options.

-

Materials and Quality Certifications: The materials used in production and certifications (such as ISO or CE) can drive up costs. Ensure that the certification aligns with local regulations, especially in regions with strict compliance requirements.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers with proven track records may charge higher prices but offer better quality assurance and service.

-

Incoterms: Understanding the chosen Incoterms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will determine who bears the shipping costs and risks, which can ultimately affect the pricing structure.

What Tips Can Help International Buyers Optimize Costs When Sourcing TDS Measurement Meters?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate prices, payment terms, and delivery schedules. Establishing a good relationship can yield better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the TDS meters, including maintenance, operational efficiency, and potential replacements. A lower upfront cost may not always translate to savings in the long run.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies due to local demand, supply chain logistics, and market competition. For instance, prices in Colombia may differ from those in Spain due to local economic factors.

-

Stay Informed About Market Trends: Regularly monitor market trends and technological advancements in TDS measurement meters. This knowledge can provide leverage during negotiations and help you make informed purchasing decisions.

Disclaimer for Indicative Prices

Prices for TDS measurement meters can vary widely based on the aforementioned factors and market conditions. It is advisable to seek multiple quotes and conduct thorough market research to understand the prevailing pricing landscape before making procurement decisions.

Alternatives Analysis: Comparing tds measurement meter With Other Solutions

Understanding Alternative Solutions to TDS Measurement

When it comes to measuring Total Dissolved Solids (TDS) in water, businesses often face the challenge of choosing the right technology or method for their specific needs. While TDS measurement meters are widely used due to their precision and ease of use, several alternative solutions exist that may better suit certain applications or budgets. This analysis will compare TDS measurement meters with two viable alternatives: conductivity meters and chemical titration methods.

Comparison Table

| Comparison Aspect | TDS Measurement Meter | Conductivity Meter | Chemical Titration |

|---|---|---|---|

| Performance | High accuracy for TDS | Good for conductivity; less direct for TDS | High accuracy for specific ions |

| Cost | Moderate | Low to moderate | Moderate to high |

| Ease of Implementation | User-friendly | User-friendly | Requires training |

| Maintenance | Low | Low | Moderate; requires chemicals |

| Best Use Case | Water quality testing | Industrial applications | Laboratory analysis |

What Are the Benefits and Drawbacks of Using a Conductivity Meter?

Conductivity meters measure the electrical conductivity of water, which correlates with TDS levels. This method is often less expensive than TDS meters and is suitable for various industrial applications, including wastewater treatment and aquaculture. However, while it provides a general estimate of TDS, it may not be as accurate for specific dissolved solids. Additionally, conductivity readings can be influenced by temperature and other factors, requiring more careful calibration.

How Does Chemical Titration Compare for TDS Measurement?

Chemical titration is a laboratory method that provides precise measurements of specific ions in water, allowing for a comprehensive analysis of water quality. This method is highly accurate and can identify the concentration of various dissolved substances. However, it requires more time and expertise, making it less practical for on-site testing. Moreover, the costs associated with chemicals and lab equipment can add up, making it a less favorable option for businesses looking for cost-effective solutions.

How Can B2B Buyers Choose the Right TDS Measurement Solution?

Selecting the right TDS measurement solution hinges on several factors, including the specific needs of your business, budget constraints, and the environment in which the measurements will be taken. For businesses that require immediate, user-friendly solutions with moderate costs, TDS measurement meters are often the best choice. However, if your operations are more industrial or require ongoing monitoring of conductivity, then conductivity meters could provide a more economical alternative. On the other hand, if precise analysis is paramount and you have the resources for laboratory testing, chemical titration might be the most effective approach.

In conclusion, understanding the strengths and weaknesses of each method will empower international B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions tailored to their operational needs. Whether prioritizing cost, accuracy, or ease of use, there is a solution available to fit every unique requirement.

Essential Technical Properties and Trade Terminology for tds measurement meter

What Are the Key Technical Properties of TDS Measurement Meters?

When considering the purchase of a TDS (Total Dissolved Solids) measurement meter, understanding its technical specifications is crucial for making an informed decision. Here are some essential properties to consider:

1. Measurement Range

The measurement range indicates the span of TDS levels the meter can accurately detect, typically expressed in parts per million (ppm) or milligrams per liter (mg/L). A broader measurement range allows for versatility in various applications, from drinking water quality testing to industrial processes. For international buyers, especially in regions with varying water quality, selecting a meter with an appropriate range is essential.

2. Accuracy and Precision

Accuracy refers to how close the measured value is to the actual value, while precision indicates the repeatability of measurements under identical conditions. High accuracy and precision are vital for industries requiring strict compliance with regulations, such as food and beverage or pharmaceuticals. B2B buyers should look for meters with specifications that guarantee low margins of error to ensure reliability in results.

3. Calibration Method

The calibration method of a TDS meter can significantly impact its performance. Common methods include manual calibration with standard solutions or automatic calibration features. For businesses that may lack technical expertise, opting for meters with automatic calibration can save time and reduce the likelihood of errors, leading to more consistent product quality.

4. Sensor Type

The sensor type affects how the meter interacts with the sample being tested. Common types include resistive and capacitive sensors. Resistive sensors are often more affordable but may have limitations in high TDS environments. Capacitive sensors, while typically more expensive, provide better performance in a wider range of conditions. Understanding the sensor type can help buyers select a meter that meets their specific application needs.

5. Material Grade and Durability

The material grade of the TDS meter’s construction impacts its longevity and suitability for various environments. Meters made with high-grade plastics or stainless steel are more resistant to corrosion and wear, which is particularly important for industries operating in harsh conditions. Buyers should consider their operational environment when evaluating material durability.

What Are Common Trade Terms Associated with TDS Measurement Meters?

Familiarity with industry terminology can help international B2B buyers navigate the procurement process more effectively. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. For TDS meters, knowing whether you are dealing with an OEM can help you understand the quality and reliability of the meter being purchased.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for businesses in Africa and South America where initial order sizes might vary significantly.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on providing goods or services. When sourcing TDS meters, submitting a well-structured RFQ can help businesses receive competitive pricing and ensure they get the specifications they need.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and delivery obligations when importing TDS measurement meters from other countries.

5. Warranty and Support Terms

Understanding warranty and support terms is vital when purchasing technical equipment like TDS meters. Buyers should clarify what is covered, the duration of the warranty, and the availability of technical support, as these factors can significantly impact the total cost of ownership.

By grasping these technical properties and trade terms, international B2B buyers can make more informed purchasing decisions, ensuring they select TDS measurement meters that meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the tds measurement meter Sector

What Are the Current Market Dynamics Influencing the TDS Measurement Meter Sector?

The TDS (Total Dissolved Solids) measurement meter sector is witnessing significant growth driven by increasing awareness of water quality and the need for effective monitoring solutions across various industries. Key global drivers include stringent regulatory frameworks aimed at ensuring water safety, which are particularly pertinent in regions like Europe and the Middle East. Moreover, the rise of smart technologies and IoT (Internet of Things) applications is reshaping sourcing trends. These innovations facilitate real-time data collection and remote monitoring, creating opportunities for international B2B buyers to enhance operational efficiency.

Emerging trends also highlight a shift towards digital solutions in TDS measurement. Companies are increasingly integrating advanced analytics and data visualization tools into their meters, allowing for more informed decision-making. For B2B buyers from Africa and South America, this presents an opportunity to invest in technology that not only meets regulatory standards but also provides actionable insights into water management practices. As the market continues to evolve, there is a growing emphasis on customization, enabling businesses to tailor TDS meters to specific industrial needs, whether in agriculture, water treatment, or food processing.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the TDS Measurement Meter Sector?

A stock image related to tds measurement meter.

Sustainability has become a critical focus for businesses worldwide, including those involved in the TDS measurement meter sector. The environmental impact of manufacturing processes and product life cycles is under scrutiny, prompting B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are eco-friendly and ensuring that production methods minimize waste and energy consumption.

Ethical sourcing is equally important, especially in regions such as Africa and South America, where social responsibility is gaining traction. B2B buyers should seek out suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Investing in TDS measurement meters that utilize ‘green’ materials not only supports environmental initiatives but also enhances brand reputation and customer trust. As consumers and businesses alike increasingly prioritize sustainability, aligning sourcing decisions with these values can provide a competitive edge in both local and international markets.

What Is the Historical Context of TDS Measurement Technology?

The evolution of TDS measurement technology dates back several decades, with initial devices primarily designed for laboratory use. Over time, advancements in technology have led to the development of portable, user-friendly meters suitable for various applications. In the early 2000s, the introduction of digital meters revolutionized the industry, providing more accurate readings and user-friendly interfaces.

Today, TDS measurement meters have advanced significantly, incorporating features such as automatic temperature compensation and Bluetooth connectivity for data sharing. This historical context highlights the importance of innovation in meeting the changing demands of B2B buyers. As businesses seek reliable and efficient solutions, understanding the trajectory of TDS measurement technology can inform purchasing decisions and foster strategic partnerships with suppliers who are at the forefront of these advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of tds measurement meter

-

How do I choose the right TDS measurement meter for my business needs?

Selecting the appropriate TDS measurement meter involves evaluating your specific application requirements. Consider factors such as measurement range, accuracy, and the environment in which the meter will be used. If your business is in the water treatment sector, for instance, opt for a meter that offers high accuracy and is durable in harsh conditions. Additionally, assess whether you need a handheld device or a more advanced continuous monitoring system. Engage with suppliers to understand the features that best suit your operational needs. -

What are the essential features to look for in a TDS measurement meter?

Key features to consider include measurement range, accuracy, calibration options, and ease of use. Look for meters with automatic temperature compensation to ensure accurate readings across varying temperatures. A backlit display can be beneficial for readability in low-light conditions. Additionally, consider devices with data logging capabilities if you require record-keeping for compliance or analysis purposes. Supplier consultations can help identify models that incorporate these features effectively. -

What are the common applications of TDS measurement meters in B2B industries?

TDS measurement meters are widely used in various industries, including water treatment, aquaculture, agriculture, and food processing. In water treatment, they help monitor water quality to ensure compliance with health standards. In aquaculture, they are crucial for maintaining optimal water conditions for aquatic life. Understanding your industry’s specific requirements can guide you in selecting the most suitable meter for your operations. -

How do I verify the credibility of a TDS meter supplier?

To ensure you are partnering with a reputable supplier, start by reviewing their certifications and compliance with international standards. Seek out customer testimonials and case studies that demonstrate their expertise. Additionally, consider requesting samples to evaluate product quality firsthand. Engaging in discussions about their manufacturing processes and quality assurance practices can also provide insights into their reliability. Utilizing platforms like Alibaba or ThomasNet can help you find verified suppliers. -

What are the minimum order quantities (MOQs) for TDS measurement meters?

MOQs can vary significantly depending on the supplier and the specific model of the TDS meter. Many manufacturers may set an MOQ of 50 to 100 units for standard models, while custom orders might have higher MOQs. When negotiating, express your specific needs and inquire about flexibility, especially if you are entering a new market or testing a product. Suppliers often value long-term partnerships and may accommodate lower MOQs for reliable clients. -

What payment terms should I expect when sourcing TDS measurement meters internationally?

Payment terms can vary widely among suppliers, but common practices include advance payment, partial payment upon order confirmation, and the remainder upon delivery. Consider using secure payment methods such as letters of credit or escrow services to protect your transaction. It’s crucial to negotiate terms that align with your cash flow and risk management strategy. Always clarify the payment process before finalizing your order to avoid misunderstandings. -

How can I ensure the quality assurance (QA) of TDS measurement meters?

Quality assurance can be ensured by sourcing meters from suppliers who adhere to recognized quality standards, such as ISO 9001. Request detailed information on their QA processes, including testing procedures and product certifications. Regular audits of suppliers can also help maintain quality. Additionally, consider implementing a post-purchase testing protocol to verify that the meters meet your specifications and performance expectations. -

What logistics considerations should I keep in mind when importing TDS measurement meters?

When importing TDS measurement meters, consider factors such as shipping costs, customs duties, and lead times. Collaborate with logistics providers experienced in handling electronic equipment to ensure compliance with regulations. Understanding the import regulations specific to your country is crucial to avoid delays. Additionally, inquire about the supplier’s shipping methods and track your shipment closely to manage any potential issues proactively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tds measurement meter

A stock image related to tds measurement meter.

As the global demand for reliable water quality measurement continues to rise, particularly in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of TDS measurement meters is crucial for B2B buyers aiming to enhance their operational efficiency. By leveraging local suppliers and manufacturers, businesses can not only reduce costs but also ensure faster delivery times and improved service support.

What are the key factors to consider when sourcing TDS measurement meters? It is essential to evaluate product specifications, supplier reliability, and after-sales service. Additionally, engaging with suppliers who prioritize sustainability can help align your procurement strategy with global environmental standards, thereby enhancing your brand’s reputation.

Looking ahead, international B2B buyers should embrace a proactive approach to sourcing, emphasizing collaboration with trusted suppliers and investing in technology that ensures accurate measurements. By doing so, businesses can mitigate risks and capitalize on emerging market opportunities. The evolving landscape of water quality testing presents significant potential for growth—seize this opportunity to refine your sourcing strategies and position your company for success in the global marketplace.