Optimize Your Setup: The Ultimate Dart Board Height Guide (2025)

Introduction: Navigating the Global Market for dart board height

In the competitive landscape of the global market, sourcing the right dart board height can present significant challenges for international B2B buyers. Whether you are a distributor in South Africa, a retailer in France, or a supplier in the Middle East, understanding the optimal dart board height is crucial for ensuring compliance with international standards and enhancing customer satisfaction. This guide delves into the various factors influencing dart board height, including industry standards, applications in recreational and professional settings, and the importance of selecting the right materials.

Navigating the complexities of sourcing dart boards involves more than just understanding height requirements; it encompasses a thorough examination of supplier vetting processes, cost analysis, and market trends. Our comprehensive guide offers actionable insights into these aspects, empowering buyers to make informed purchasing decisions. We provide a detailed overview of the types of dart boards available, the specific applications suited to different heights, and how to evaluate potential suppliers to ensure quality and reliability.

For B2B buyers in Africa, South America, the Middle East, and Europe, this resource serves as a vital tool in streamlining procurement processes. By addressing the key challenges associated with dart board height, we aim to equip you with the knowledge necessary to enhance your product offerings and meet the diverse needs of your clientele. As you navigate the global market, let this guide be your trusted companion in achieving success and fostering lasting partnerships.

Understanding dart board height Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Height | Set at 5 feet 8 inches from the floor | Competitive leagues, bars, clubs | Pros: Widely recognized; standardization. Cons: May not suit all player heights. |

| Adjustable Height | Allows customization of height | Home use, training facilities | Pros: Flexibility for various users. Cons: Potential stability issues if not secured. |

| Electronic Height | Integrated technology for automated scoring | Entertainment venues, arcades | Pros: Engaging for users; accurate scoring. Cons: Higher initial investment. |

| Wall-Mounted Height | Fixed installation on a wall | Permanent setups in sports centers | Pros: Space-saving; professional look. Cons: Difficult to relocate. |

| Portable Height | Designed for easy transport and setup | Outdoor events, trade shows | Pros: Versatile; easy to move. Cons: May lack durability compared to permanent options. |

What Are the Characteristics of Standard Height Dart Boards?

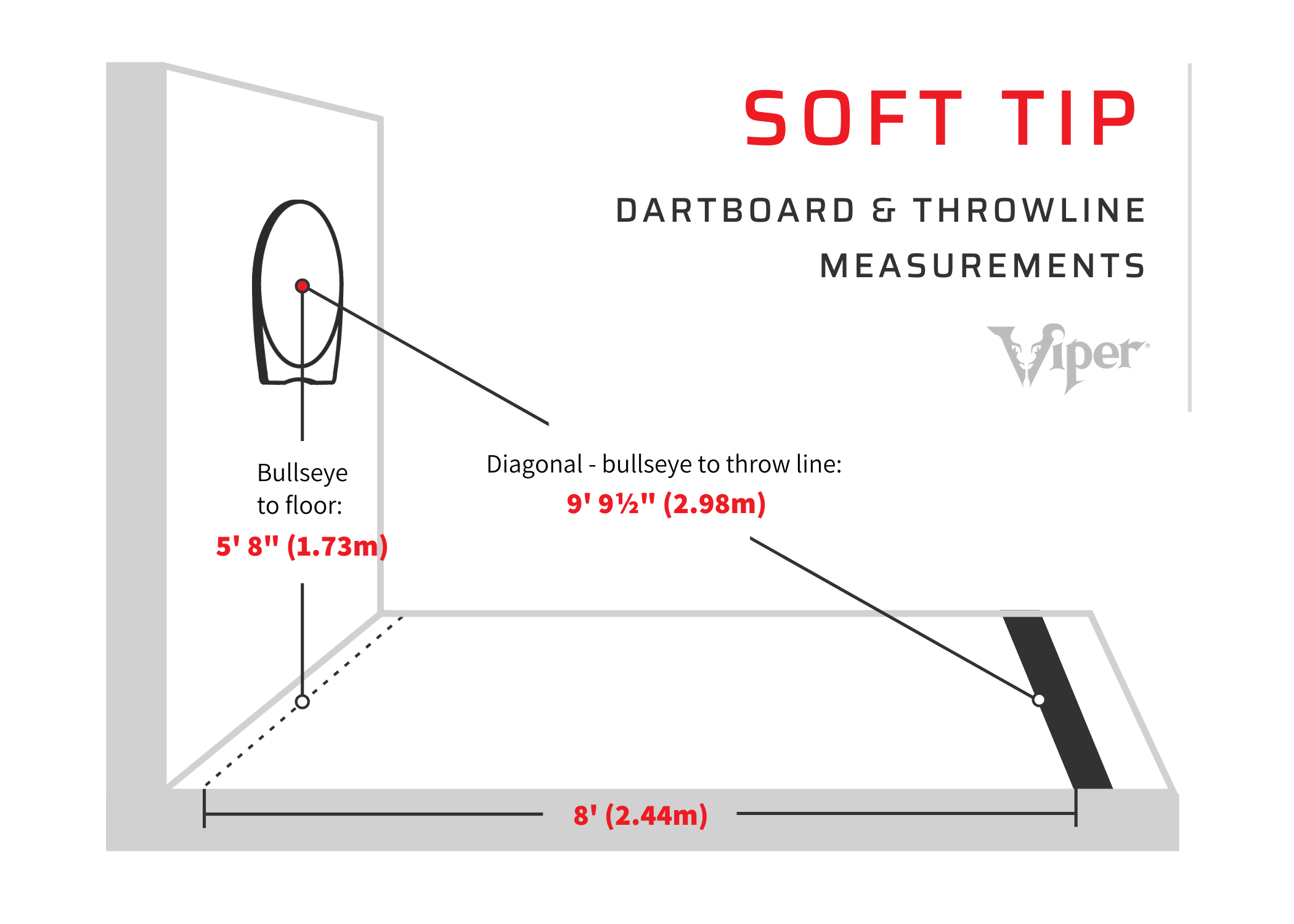

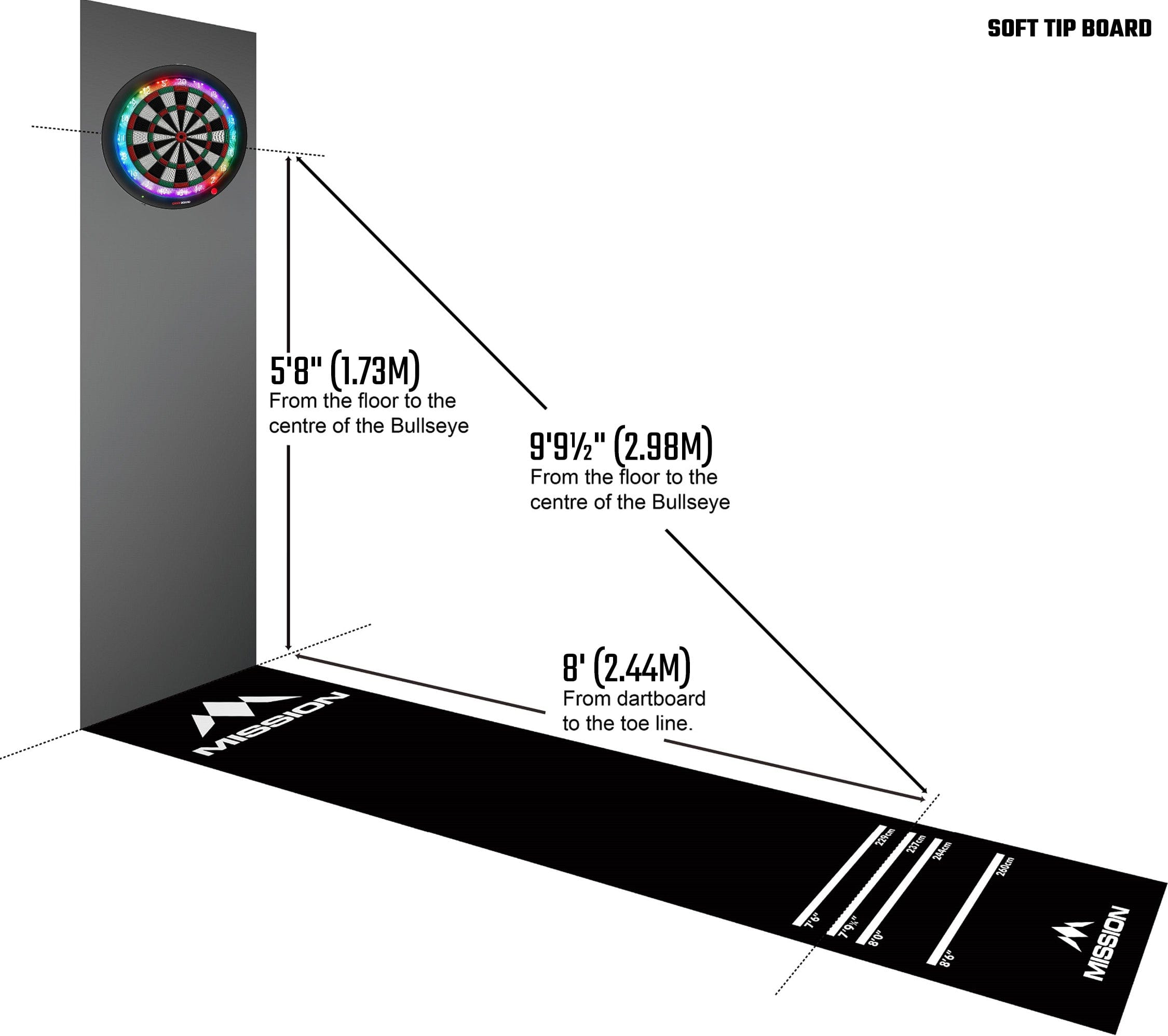

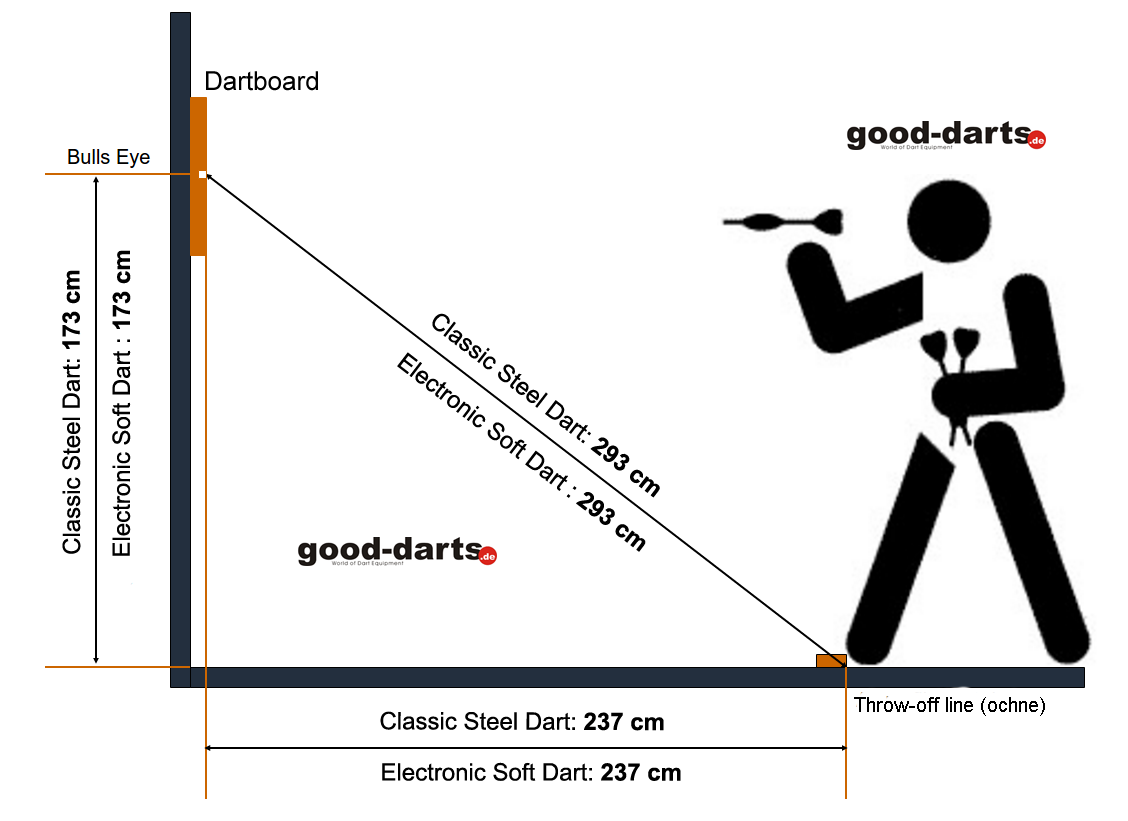

Standard height dart boards are universally set at 5 feet 8 inches (1.73 meters) from the floor to the center of the bullseye. This height is recognized internationally, making it ideal for competitive play in leagues, bars, and clubs. B2B buyers should consider investing in standard height boards for environments focused on serious play, ensuring compliance with tournament regulations. However, the fixed height may not accommodate all player heights, which could be a drawback in casual settings.

How Do Adjustable Height Dart Boards Benefit Users?

Adjustable height dart boards provide the flexibility to modify the board’s height, catering to a diverse range of users. This feature is particularly beneficial for home setups or training facilities where various players may use the equipment. When purchasing, B2B buyers should evaluate the ease of adjustment and stability of the board to ensure safety and usability. While these boards offer versatility, they might face stability issues if not properly secured, potentially impacting the playing experience.

What Are the Advantages of Electronic Height Dart Boards?

Electronic height dart boards come equipped with scoring technology that automates the scoring process, enhancing user engagement. They are particularly popular in entertainment venues and arcades, where the interactive experience can attract more customers. B2B buyers should consider the initial investment and maintenance costs associated with electronic boards. Although they provide an engaging experience and accurate scoring, the higher upfront costs may be a barrier for some businesses.

Why Choose Wall-Mounted Height Dart Boards for Permanent Installations?

Wall-mounted dart boards are fixed installations that provide a professional appearance and save space in sports centers or dedicated gaming areas. This type is ideal for businesses looking to create a permanent setup without the need for frequent relocation. Buyers should assess the wall structure and ensure it can support the board securely. While these boards offer a polished look, relocating them can be challenging and may require additional wall repairs.

What Makes Portable Height Dart Boards Ideal for Events?

Portable height dart boards are designed for easy transport, making them suitable for outdoor events, trade shows, and temporary setups. Their versatility allows businesses to engage with customers in various locations. When selecting portable boards, B2B buyers should prioritize durability and ease of assembly. Although they provide flexibility, these boards may not withstand heavy use compared to their permanent counterparts, which could limit their longevity in high-traffic environments.

Related Video: Correct Dart Board Height

Key Industrial Applications of dart board height

| Industry/Sector | Specific Application of dart board height | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Equipment Manufacturing | Designing regulation-standard dart boards | Ensures compliance with international standards, enhancing marketability | Material quality, durability, and precision in measurements |

| Recreation and Leisure | Establishing dart-playing areas in recreational facilities | Increases customer satisfaction and engagement through proper setup | Ergonomic design, safety standards, and user demographic analysis |

| Education and Training | Implementing dart sports in schools and training programs | Promotes physical activity and coordination among students | Adjustable height features, safety regulations, and bulk purchasing options |

| Event Management | Setting up dart competitions and tournaments | Enhances professionalism and credibility of events | Standardization, transportability, and setup efficiency |

| Hospitality and Entertainment | Integrating dart boards into bars and entertainment venues | Attracts customers, increasing foot traffic and sales | Aesthetic design, durability for high-traffic use, and maintenance requirements |

How is Dart Board Height Used in Sports Equipment Manufacturing?

In the sports equipment manufacturing industry, dart board height is critical for designing products that comply with international standards. Manufacturers must ensure that their dart boards meet official height specifications to cater to both amateur and professional markets. This adherence to standards not only enhances product credibility but also opens opportunities in diverse global markets. Buyers should prioritize sourcing materials that offer durability and precision in manufacturing to maintain quality across various regions, including Africa and Europe.

What Role Does Dart Board Height Play in Recreation and Leisure Facilities?

Recreation and leisure facilities utilize dart board height to establish engaging dart-playing areas that enhance user experience. Proper height installation is essential for player comfort and performance, which directly impacts customer satisfaction. Facilities should consider ergonomic designs that cater to different age groups and skill levels, ensuring inclusivity. B2B buyers should focus on sourcing dart boards that comply with safety standards, as well as those that can withstand frequent use in high-traffic environments, particularly in South America and the Middle East.

How Can Dart Board Height Enhance Education and Training Programs?

In educational institutions, dart board height is instrumental in promoting physical activity and developing coordination skills among students. Implementing dart sports in schools can foster teamwork and strategic thinking. Buyers in this sector should look for dart boards that feature adjustable height options to accommodate various age groups and skill levels. Safety regulations are paramount, and purchasing in bulk can provide cost benefits while ensuring all equipment meets educational standards across different regions.

Why is Dart Board Height Important for Event Management?

Event management companies rely on precise dart board height to set up competitions and tournaments professionally. Proper installation ensures that events adhere to recognized standards, enhancing the credibility of the competition. For B2B buyers in this sector, sourcing standardized dart boards that are easy to transport and set up is crucial. Event organizers should also consider the aesthetics of the boards, as visually appealing setups can attract more participants and spectators, boosting overall success.

How Does Dart Board Height Impact Hospitality and Entertainment Venues?

In bars and entertainment venues, the correct dart board height is vital for creating an inviting atmosphere that encourages patron engagement. Properly installed dart boards can significantly increase customer foot traffic and sales, making them a valuable addition to any venue. Buyers should seek dart boards designed for durability in high-traffic settings while also considering maintenance requirements. Aesthetic appeal is also important, as it can enhance the overall ambiance of the establishment, particularly in European markets where design plays a significant role in customer experience.

Related Video: LABORATORY APPARATUS AND THEIR USES

3 Common User Pain Points for ‘dart board height’ & Their Solutions

Scenario 1: Ensuring Optimal Dart Board Height for Competitive Play

The Problem: In the competitive dart-playing environment, establishing the correct dart board height is crucial for performance. B2B buyers, especially those supplying dart-related equipment to clubs or sporting venues, often struggle to meet the regulations set by international dart organizations. This can lead to dissatisfaction from players and potential loss of business if the setup is not conducive to fair play. Additionally, many buyers are unaware that variations in player height and throwing style can impact the ideal board height, resulting in a one-size-fits-all approach that fails to satisfy all users.

The Solution: To address this challenge, B2B buyers should invest in adjustable dart board mounts that allow for easy height modification. This flexibility enables venues to cater to a diverse range of players while complying with official standards, typically set at 1.73 meters (5 feet 8 inches) from the floor to the center of the bullseye. Buyers should also consider providing guidelines or instructional materials that inform players about personal adjustments they can make based on their height and throwing technique. Partnering with local dart organizations can further enhance credibility and ensure adherence to competitive standards, leading to improved player satisfaction and retention.

Scenario 2: Managing Space Limitations in Dart Venues

The Problem: Many venues in Africa, South America, the Middle East, and Europe often face space constraints that complicate the installation of dart boards at the recommended height. These limitations can stem from smaller facility sizes or the need to accommodate multiple activities in a shared space. Buyers may find it challenging to create an environment that meets both safety regulations and player expectations, which can lead to operational inefficiencies and reduced customer experience.

The Solution: B2B buyers should consider modular dart board systems that can be easily retracted or adjusted based on usage. For example, wall-mounted boards that can fold up when not in use or that allow for height adjustment can maximize space without compromising player access. Additionally, educating venue operators about the importance of maintaining the recommended throwing distance of 2.37 meters (7 feet 9.25 inches) from the board can lead to better spatial planning. Implementing smart design principles and engaging with architects or designers who specialize in recreational spaces can provide innovative solutions that enhance both functionality and player experience.

Scenario 3: Addressing Compliance and Safety Concerns

The Problem: Safety and compliance are critical concerns for B2B buyers in the dart board market. In regions with strict health and safety regulations, improperly installed dart boards can pose risks to players and spectators alike. Buyers may struggle to ensure that installations meet local regulations, which can vary significantly between countries, leading to potential legal issues and liability concerns.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing dart boards from manufacturers who adhere to international safety standards. This includes ensuring that the boards are made from non-toxic materials and feature rounded edges to minimize injury. Buyers should also conduct thorough site assessments to confirm that the installation space meets safety requirements, such as adequate clearance around the dart board. Furthermore, creating a compliance checklist that outlines local regulations and safety best practices can help venues maintain standards and protect themselves from potential liabilities. Offering training sessions for venue staff on proper installation and safety protocols will further enhance compliance and foster a safer playing environment.

Strategic Material Selection Guide for dart board height

When selecting materials for dart board height, it is essential to consider the properties and performance characteristics of various materials. This guide analyzes four common materials used in the manufacturing of dart boards, focusing on their suitability for different applications, particularly for international B2B buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Wood for Dart Boards?

Wood, particularly softwoods like pine or cedar, is a traditional material for dart boards. Its natural fibers allow for self-healing, which helps maintain the board’s integrity over time.

- Key Properties: Wood is generally lightweight and can withstand moderate pressure. However, it is susceptible to moisture, which can lead to warping or mold growth.

- Pros & Cons: The main advantage of wood is its aesthetic appeal and traditional feel, making it popular in recreational settings. However, it has a shorter lifespan compared to synthetic materials and requires regular maintenance, which can increase long-term costs.

- Impact on Application: Wood dart boards are best suited for indoor environments where humidity and temperature can be controlled. They are not ideal for outdoor use or humid climates.

- Considerations for International Buyers: Buyers in regions like South Africa or Brazil should ensure compliance with local regulations regarding wood sourcing and treatment to prevent pest infestations.

How Does Synthetic Material Compare for Dart Board Height?

Synthetic materials, such as high-density fiberboard (HDF) and polypropylene, are increasingly popular for dart boards due to their durability and resistance to environmental factors.

- Key Properties: Synthetic materials typically have high pressure ratings and are resistant to moisture, making them suitable for a variety of environments.

- Pros & Cons: The key advantage is their longevity and low maintenance requirements. However, they may lack the traditional aesthetic appeal of wood, which can be a disadvantage in certain markets.

- Impact on Application: Synthetic boards can be used in both indoor and outdoor settings, making them versatile for different climates, particularly in humid regions like parts of the Middle East.

- Considerations for International Buyers: Buyers should verify that synthetic materials comply with relevant safety standards such as ASTM or EN standards, especially in Europe.

What Role Does Cork Play in Dart Board Manufacturing?

Cork is another material that is often used in dart boards due to its unique properties.

- Key Properties: Cork is lightweight, has excellent self-healing capabilities, and is resistant to moisture.

- Pros & Cons: The primary advantage of cork is its eco-friendliness and sustainability, appealing to environmentally conscious buyers. However, it can be more expensive than synthetic options and may not be as durable under heavy use.

- Impact on Application: Cork boards are ideal for light to moderate use in controlled environments. They may not withstand the rigors of heavy play, making them less suitable for commercial applications.

- Considerations for International Buyers: Buyers in Europe may prefer cork due to its sustainability credentials, but they should ensure that it meets local environmental regulations.

Why is Steel Important in Dart Board Construction?

Steel is primarily used in the construction of the dart board frame and the wiring that holds the board together.

- Key Properties: Steel is known for its high tensile strength and resistance to deformation under pressure.

- Pros & Cons: The advantage of steel is its durability and ability to withstand heavy impacts. However, it can be prone to rust if not properly treated, which can be a concern in humid climates.

- Impact on Application: Steel components are essential for maintaining the structural integrity of the dart board, especially in high-use environments.

- Considerations for International Buyers: Buyers should look for galvanized or stainless steel options to prevent corrosion, particularly in coastal areas.

Summary Table of Material Selection for Dart Board Height

| Material | Typical Use Case for Dart Board Height | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Indoor recreational dart boards | Aesthetic appeal and traditional feel | Short lifespan, high maintenance | Medium |

| Synthetic | Indoor and outdoor dart boards | High durability and low maintenance | Lacks traditional aesthetic | Medium |

| Cork | Light-use indoor dart boards | Eco-friendly and sustainable | Higher cost, less durable | High |

| Steel | Structural components for dart boards | High strength and durability | Prone to rust without treatment | Medium |

This guide provides a comprehensive overview of the materials available for dart board height considerations, enabling international B2B buyers to make informed decisions based on their specific needs and regional requirements.

A stock image related to dart board height.

In-depth Look: Manufacturing Processes and Quality Assurance for dart board height

What Are the Main Manufacturing Processes for Dart Board Height?

The manufacturing of dart boards involves several critical stages to ensure that the final product meets both functional and aesthetic standards. The primary processes include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Dart Board Manufacturing?

The manufacturing journey begins with the selection of appropriate materials. Dart boards can be made from various materials, including sisal fibers, cork, and MDF (medium-density fiberboard). Sisal is particularly favored for its self-healing properties, which allows the board to recover after darts are removed. Suppliers should ensure that the raw materials meet international quality standards to minimize defects.

After sourcing, the materials undergo a rigorous quality inspection to check for consistency in quality and compliance with specifications. Buyers should inquire about the sourcing practices of their suppliers, especially concerning sustainability and ethical considerations, which are increasingly important in global trade.

How Are Dart Boards Formed During Production?

Once the materials are prepared, the next step is forming. For sisal dart boards, the fibers are compressed and bonded using a combination of heat and adhesive to create a dense board. This process requires precision to ensure uniform density, which affects the dart board’s performance.

Cork boards are typically cut from large sheets and assembled into the desired thickness, while MDF boards are shaped using cutting machines. Buyers should look for manufacturers that utilize advanced technology and machinery to enhance accuracy in this stage.

What Is Involved in the Assembly Process of Dart Boards?

The assembly process involves attaching the dart board components, including the wiring for electronic scoring systems, if applicable. The alignment of the board’s segments and the mounting hardware is crucial to ensure that the dart board is level and stable once installed.

Manufacturers often employ automated systems for quality consistency during assembly. B2B buyers should verify the assembly techniques used by suppliers, particularly the use of automated versus manual processes, as this can impact the overall quality and consistency of the product.

How Does Finishing Enhance the Quality of Dart Boards?

Finishing is the final stage of manufacturing and involves surface treatment and packaging. For sisal boards, this may include applying a protective coating to enhance durability and resistance to wear. In contrast, cork boards may be sanded and sealed to provide a smooth surface.

Packaging is also crucial; manufacturers should use protective materials to prevent damage during transportation. B2B buyers should inquire about the finishing processes and materials used, as these can significantly affect the durability and lifespan of the dart boards.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is essential to ensure that dart boards meet safety and performance standards. International standards like ISO 9001 provide a framework for quality management systems, ensuring consistency and improvement in manufacturing processes.

Which International Standards Are Relevant for Dart Board Manufacturing?

In addition to ISO 9001, industry-specific certifications such as CE marking in Europe and other regional standards may apply. These certifications indicate compliance with safety and environmental regulations. B2B buyers should request documentation of these certifications from potential suppliers to ensure that products meet legal and safety requirements in their respective markets.

What Are the Key Quality Control Checkpoints in Dart Board Manufacturing?

Quality control (QC) checkpoints throughout the manufacturing process are vital for maintaining product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify defects early.

- Final Quality Control (FQC): A thorough examination of finished products before packaging and shipping.

B2B buyers should understand these checkpoints and ask suppliers for detailed QC reports and protocols.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure the reliability of their suppliers, international B2B buyers should consider several verification methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, equipment, and QC processes directly. This firsthand observation can reveal a lot about the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed QC reports, including data on defects, returns, and customer feedback, provides insight into the supplier’s performance history.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased assessment of product quality before shipment. This is especially important for buyers in regions with stringent import regulations.

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Different regions may have specific regulatory requirements and standards. For instance, buyers from Europe must be aware of CE marking regulations, while those in South America may need to comply with local safety standards.

Additionally, buyers should consider the implications of tariffs and trade agreements that could affect the importation of dart boards. Familiarizing oneself with these regulations can prevent costly delays and compliance issues.

Conclusion: Ensuring Quality in Dart Board Manufacturing

In summary, understanding the manufacturing processes and quality assurance practices for dart boards is critical for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control standards and verification methods, buyers can make informed decisions. This knowledge not only ensures that they source high-quality products but also strengthens their competitive position in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dart board height’

Introduction

Sourcing the right dart board height for your business can significantly influence customer satisfaction and sales. Understanding the optimal height for dart boards is essential for both recreational and professional settings, ensuring a consistent experience for players. This guide provides a step-by-step checklist to streamline your procurement process, helping international B2B buyers—especially from Africa, South America, the Middle East, and Europe—make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to determine the specific requirements for the dart boards you intend to source. This includes the standard height, material preferences, and design specifications.

- Consider the target audience and whether the boards will be used in homes, pubs, or professional tournaments.

- Research standard dart board heights (typically 5 feet 8 inches or 1.73 meters from the floor to the center of the bullseye) to ensure compliance with global standards.

Step 2: Research Market Trends and Preferences

Understanding current market trends can inform your purchasing decisions. Investigate popular styles and materials used in dart boards, focusing on what appeals to your target market.

- Conduct surveys or gather feedback from potential customers in your region to identify preferences.

- Stay updated on competitors’ offerings to ensure your products stand out in the market.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Look for suppliers with a proven track record in delivering high-quality dart boards and compliance with international standards.

- Verify their production capacity and lead times to ensure they can meet your demands.

Step 4: Verify Supplier Certifications and Compliance

Ensure that potential suppliers possess the necessary certifications and comply with relevant safety and quality standards. This step is crucial to mitigate risks associated with product liability and safety.

- Check for certifications such as ISO 9001 for quality management systems and any specific certifications relevant to sports equipment.

- Review their adherence to regional regulations, particularly if you are sourcing from international suppliers.

Step 5: Request Samples for Quality Assurance

Before finalizing your order, request samples to evaluate the quality of the dart boards firsthand. This step allows you to assess the craftsmanship, material durability, and overall performance.

- Pay attention to the weight, thickness, and material of the dart boards to ensure they meet your specifications.

- Test the boards in various settings to gauge performance and durability under different conditions.

Step 6: Negotiate Pricing and Payment Terms

Once you have selected a supplier, engage in negotiations regarding pricing and payment terms. Understanding the financial aspects is vital for maintaining profitability.

- Compare quotes from multiple suppliers to ensure competitive pricing without compromising quality.

- Discuss payment options, including upfront payments, payment upon delivery, or credit terms, to find a solution that aligns with your cash flow needs.

Step 7: Plan for Shipping and Logistics

Consider logistics when sourcing dart boards, especially when dealing with international suppliers. Efficient shipping and handling can significantly impact your overall costs and timelines.

- Evaluate shipping options and costs, factoring in customs duties and import regulations based on your location.

- Collaborate with logistics partners who specialize in international shipping to ensure timely delivery of your products.

By following this comprehensive checklist, B2B buyers can effectively navigate the procurement process for dart board heights, ensuring a successful sourcing experience tailored to their market needs.

Comprehensive Cost and Pricing Analysis for dart board height Sourcing

What Are the Key Cost Components for Sourcing Dart Boards?

When sourcing dart boards, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used (e.g., sisal, cork, or bristle) significantly affects the overall cost. High-quality materials tend to be more expensive but can offer better durability and performance, justifying a higher price point.

-

Labor: Labor costs can vary widely based on the manufacturing location. Regions with lower labor costs may offer competitive pricing but may impact quality. Conversely, countries with higher labor costs often provide superior craftsmanship.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses. Efficient production facilities can help minimize these costs, which in turn can lower the final price of the dart boards.

-

Tooling: The initial investment in tooling and molds can be substantial. However, these costs are typically amortized over larger production runs, affecting unit pricing.

-

Quality Control (QC): Ensuring that dart boards meet international standards and certifications incurs additional costs. A robust QC process can prevent defects, ultimately saving money in the long run.

-

Logistics: Shipping costs, including freight and insurance, can significantly affect total expenses, especially for international buyers. Understanding the logistics involved in transporting products from the manufacturer to the end-user is crucial.

-

Margin: Suppliers typically add a margin on top of the production costs. This margin can vary based on market demand and competitive pricing strategies.

What Influences the Price of Dart Boards in International Markets?

Several factors influence the pricing of dart boards, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often result in lower per-unit costs. Establishing a clear understanding of MOQs with suppliers can lead to better pricing strategies.

-

Specifications and Customization: Customized dart boards, such as those with specific branding or sizes, can incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Products that are certified for quality (e.g., ISO certifications) may come at a premium. Buyers should assess whether these certifications align with their market needs.

-

Supplier Factors: Relationships with suppliers, their market reputation, and negotiation skills can all influence pricing. Building long-term partnerships often leads to better pricing arrangements.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) affect the final cost. Buyers must be clear on the responsibilities and costs associated with each Incoterm to avoid unexpected charges.

How Can Buyers Optimize Costs When Sourcing Dart Boards?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs is crucial. Here are some practical tips:

-

Negotiate Effectively: Leverage your purchasing power and market knowledge to negotiate better terms. Building rapport with suppliers can also lead to favorable pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, logistics, and potential quality issues.

-

Evaluate Pricing Nuances: Understand the local market dynamics in the supplier’s region. Factors such as currency fluctuations, economic stability, and local competition can all impact pricing.

-

Research Multiple Suppliers: Obtaining quotes from various suppliers allows for a comparative analysis. This research can help identify the best balance between cost and quality.

-

Plan for Logistics: Factor in all logistics costs when evaluating supplier quotes. Look for suppliers who can offer competitive shipping rates or have distribution centers closer to your location.

Disclaimer on Indicative Prices

Prices for dart boards can fluctuate based on various factors, including market conditions, exchange rates, and supplier pricing strategies. Therefore, it is advisable for buyers to conduct thorough market research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing dart board height With Other Solutions

Exploring Alternatives to Dart Board Height

In the realm of dart games, the height at which a dartboard is mounted is crucial for optimal performance and player experience. However, businesses seeking to enhance their dart-playing environments may consider alternative solutions that address similar goals. This section compares ‘dart board height’ with two viable alternatives: electronic dart scoring systems and adjustable dartboard mounts.

Comparison Table of Dart Board Height and Alternatives

| Comparison Aspect | Dart Board Height | Electronic Dart Scoring Systems | Adjustable Dartboard Mounts |

|---|---|---|---|

| Performance | Standardized height improves accuracy and consistency in play. | Provides instant scoring and analytics; enhances competitive play. | Allows players to customize height for individual preferences. |

| Cost | Generally low cost (dartboard and mounting hardware). | Higher initial investment, but can lead to savings on scorekeeping. | Moderate cost, depending on technology and materials. |

| Ease of Implementation | Simple installation with minimal tools required. | Requires electrical setup and understanding of software. | Relatively easy, but may need professional installation for advanced models. |

| Maintenance | Low maintenance; periodic checks for stability. | Requires software updates and battery replacements. | Low maintenance; durability depends on materials used. |

| Best Use Case | Ideal for traditional play and casual settings. | Best for competitive environments and tournaments. | Suited for diverse player heights or mixed-use venues. |

What Are the Benefits and Drawbacks of Electronic Dart Scoring Systems?

Electronic dart scoring systems offer a modern twist on traditional play by automating scoring and providing analytics. This technology is particularly beneficial in competitive environments where accuracy and speed are paramount. However, the initial investment can be significant, and businesses must consider the ongoing costs associated with software maintenance and potential repairs. Moreover, reliance on technology may deter players who prefer the traditional, tactile experience of manual scoring.

How Do Adjustable Dartboard Mounts Enhance Player Experience?

A stock image related to dart board height.

Adjustable dartboard mounts cater to a diverse range of player preferences by allowing the height of the dartboard to be modified easily. This flexibility can enhance player comfort and accuracy, making it suitable for venues that host various events or cater to mixed groups of players. The primary drawback is the potential complexity in installation, especially for advanced models that may require professional setup. Nonetheless, once in place, adjustable mounts offer low maintenance and durability, making them a long-term solution for adaptable environments.

Conclusion: Which Solution Is Right for Your Business?

When deciding between dart board height and its alternatives, B2B buyers should consider their specific needs and the context in which the dartboard will be used. For traditional settings focused on casual play, maintaining the standard dartboard height might suffice. However, for businesses aiming to elevate the competitive edge or accommodate diverse player preferences, investing in electronic scoring systems or adjustable mounts could provide enhanced value. Ultimately, the choice should align with the overall goals of the venue, budget constraints, and the desired player experience.

Essential Technical Properties and Trade Terminology for dart board height

Understanding the technical specifications and trade terminology associated with dart board height is crucial for international B2B buyers looking to make informed purchasing decisions. This section will cover essential properties and terms that will aid in navigating the complexities of sourcing dart boards effectively.

What Are the Key Technical Properties of Dart Board Height?

-

Height Specification

– The standard height for a dart board is 1.73 meters (5 feet 8 inches) from the floor to the center of the bullseye. Understanding this specification is critical for buyers as it ensures compliance with international standards, which is essential for both recreational and competitive play. Adhering to this height can influence customer satisfaction and product acceptance in various markets. -

Material Grade

– Dart boards are often made from different materials, including sisal, cork, and wood. The grade of the material affects the board’s durability, playability, and overall performance. Buyers should prioritize high-quality materials like premium sisal, which can self-heal after dart impact, offering longevity and consistent play. This consideration can lead to reduced replacement costs and improved customer retention. -

Tolerance Levels

– Tolerance levels refer to the allowable deviation from specified measurements, particularly in the thickness and diameter of the dart board. Typically, a tolerance of ±1 mm is standard for professional boards. Understanding these tolerances is vital for manufacturers and buyers to ensure product consistency and compatibility with darts. This attention to detail can prevent issues during production and enhance the end-user experience. -

Weight

– The weight of a dart board can vary based on the materials used. A standard board weighs between 1.5 to 2 kg. This specification is important for logistics and shipping, as heavier boards may incur higher shipping costs. Buyers should consider the weight in relation to their target market’s preferences and the intended usage—whether for casual play or professional tournaments. -

Finishing Techniques

– The finishing of a dart board, including the type of coating and treatment, influences its surface properties and durability. A well-finished board can resist wear and tear better, providing a consistent playing surface over time. Buyers should inquire about finishing techniques to ensure they are getting a product that meets their quality standards and expectations.

What Common Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help in sourcing high-quality dart boards that meet specific branding requirements or standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers, especially when managing inventory and costs. This term can impact purchasing strategies, particularly for smaller businesses or those entering new markets. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting price quotes for specific products or services. It is a crucial tool for B2B buyers to compare offers and negotiate better deals. Providing detailed specifications in an RFQ can lead to more accurate quotations and better supplier relationships. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is vital for B2B buyers to understand shipping costs, risk, and delivery responsibilities, ensuring smoother transactions across borders. -

Lead Time

– Lead time is the period between placing an order and receiving it. For B2B buyers, understanding lead times is critical for inventory management and ensuring product availability. Factors such as manufacturing capacity and shipping routes can affect lead times, influencing purchasing decisions and supply chain strategies.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, optimize their purchasing strategies, and ultimately enhance their business operations in the dart board market.

Navigating Market Dynamics and Sourcing Trends in the dart board height Sector

What Are the Key Market Dynamics and Trends in the Dart Board Height Sector?

The dart board height sector has experienced significant shifts driven by evolving consumer preferences and technological advancements. Globally, there is an increasing demand for standardized dart board heights, particularly due to the rise of professional and recreational dart leagues. This trend is particularly notable in regions such as Europe, where dart games enjoy substantial popularity. Moreover, the integration of technology into traditional games has led to the development of smart dart boards that provide real-time analytics, enhancing player engagement and experience.

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of the growing trend toward customization. Businesses are increasingly seeking tailored solutions that meet specific market needs, such as dart boards designed for various skill levels or spaces. Additionally, the global push for digital transformation is influencing sourcing practices, with many buyers exploring e-commerce platforms for sourcing dart boards. This digital shift allows for better price comparison and access to a broader range of suppliers, making it easier to navigate the complexities of international logistics.

A stock image related to dart board height.

How Is Sustainability Influencing Dart Board Height Sourcing Decisions?

Sustainability has become a critical factor in B2B sourcing decisions across industries, including the dart board height sector. The environmental impact of production processes, such as the sourcing of materials and manufacturing methods, is under increasing scrutiny. Buyers are encouraged to prioritize suppliers who implement sustainable practices, such as using renewable materials and minimizing waste during production.

Ethical sourcing is also gaining traction, with businesses striving to ensure that their supply chains are transparent and responsible. This includes verifying that materials used in dart boards, such as wood and plastics, are sourced from suppliers who adhere to ethical labor practices. Certifications like Forest Stewardship Council (FSC) for wood products or Global Recycle Standard (GRS) for recycled materials can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers with these certifications, B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of Dart Board Height Standards?

The evolution of dart board height standards dates back to the late 19th century when the game gained popularity in pubs and social venues in the UK. Initially, there were no standardized measurements, leading to inconsistencies that affected gameplay. The establishment of official regulations in the early 20th century, particularly by organizations like the National Darts Association, helped standardize dart board heights to 5 feet 8 inches from the floor to the center of the bullseye.

Over the years, the standardization process has influenced the design and manufacturing of dart boards globally. As the game has spread to various cultures and regions, adaptations have been made to suit local preferences while still adhering to the core principles of dart play. Understanding this historical context is vital for B2B buyers, as it underscores the importance of compliance with established standards in product sourcing and the impact of cultural adaptations on market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of dart board height

-

How do I determine the correct height for a dartboard installation?

To ensure compliance with international standards, a dartboard should be positioned at a height of 1.73 meters (5 feet 8 inches) from the floor to the center of the bullseye. This measurement is critical for maintaining consistency in gameplay, which is especially important for competitive environments. When sourcing dartboards, confirm that suppliers adhere to this standard to ensure player satisfaction and fair play. -

What is the best dartboard height for different types of players?

While the standard height of 1.73 meters is widely accepted, adjustments can be made for specific demographics. For example, when targeting youth players or children, you might consider lowering the board slightly to accommodate their height. Discuss customization options with suppliers to ensure that the dartboards cater to your target audience, potentially enhancing player engagement and enjoyment. -

How can I verify the quality of dartboards sourced from international suppliers?

When sourcing dartboards, it’s essential to conduct thorough due diligence on potential suppliers. Request samples to assess materials and craftsmanship. Look for certifications or compliance with international standards, such as ISO or ASTM, which indicate quality assurance. Additionally, seek references or reviews from other buyers to gain insights into the supplier’s reliability and product quality. -

What are the minimum order quantities (MOQ) for dartboards from manufacturers?

MOQs for dartboards can vary significantly depending on the manufacturer and the material used. Generally, established suppliers may have a MOQ ranging from 50 to 500 units. It is advisable to communicate directly with potential suppliers to negotiate terms that align with your purchasing capabilities. This approach also allows you to explore bulk discounts, which can improve your overall cost-effectiveness. -

What payment terms should I expect when sourcing dartboards internationally?

Payment terms can differ widely among suppliers, but typical arrangements include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer flexible terms, such as net 30 or net 60 days, depending on your relationship and order volume. Always clarify payment conditions in advance to avoid misunderstandings and ensure smooth transactions. -

How do I handle logistics when importing dartboards from overseas suppliers?

Logistics can be complex when importing dartboards, particularly regarding shipping regulations and customs duties. Choose a reliable freight forwarder familiar with international shipping processes. Ensure that your supplier provides all necessary documentation, such as commercial invoices and packing lists, to facilitate customs clearance. Understanding the destination country’s import regulations is also crucial to avoid delays. -

What customization options are available for dartboards to meet specific market needs?

Many manufacturers offer customization options, including branding, colors, and materials used. For instance, you can request dartboards with your company logo or specific designs to cater to local preferences. Discuss these possibilities with suppliers upfront to ensure that the final product aligns with your marketing strategy and resonates with your target audience. -

How can I ensure compliance with safety regulations when sourcing dartboards?

Safety compliance is paramount when sourcing dartboards, particularly in regions with strict regulations. Verify that the products meet safety standards applicable in your target market, such as EN 71 in Europe, which governs toy safety. Request documentation from suppliers to confirm compliance and consider third-party testing for additional assurance. This proactive approach protects your business from liability and enhances customer trust.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dart board height

The importance of strategic sourcing in the context of dart board height cannot be overstated, especially for B2B buyers operating in diverse markets like Africa, South America, the Middle East, and Europe. By understanding the optimal dart board height—5 feet 8 inches (1.73 meters) from the floor to the center of the bullseye—businesses can better cater to the recreational needs of their customers, whether for commercial venues or home installations.

Investing in quality dart boards that meet these specifications can enhance customer satisfaction and loyalty, ultimately driving revenue. Furthermore, sourcing from reputable manufacturers ensures compliance with international standards, which is particularly crucial for buyers in regions with varying regulations.

As the global market for recreational products continues to evolve, maintaining a strategic approach to sourcing will empower B2B buyers to stay competitive. By establishing strong supplier relationships and staying informed about market trends, businesses can capitalize on emerging opportunities.

Looking ahead, we encourage international B2B buyers to leverage the insights from this guide to enhance their sourcing strategies. Take proactive steps to engage with suppliers who prioritize quality and compliance, ensuring that your offerings resonate with your target market. The future of your dart board product line depends on the strategic decisions you make today.