The Ultimate Guide to Marine Battery Charger (2025)

Introduction: Navigating the Global Market for marine battery charger

Navigating the global market for marine battery chargers presents a unique challenge for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. With the increasing reliance on advanced marine technology, sourcing reliable and efficient marine battery chargers has become critical for maintaining operational integrity and enhancing performance in various maritime applications. This guide is designed to provide a comprehensive overview of the types of marine battery chargers available, their specific applications, and best practices for supplier vetting, ensuring that you make informed purchasing decisions.

In an era where sustainability and efficiency are paramount, understanding the nuances of marine battery chargers—from basic models to advanced smart chargers—is essential for optimizing your fleet’s performance. This guide will delve into the critical factors influencing cost, the technology behind different charger types, and the regulatory standards that may affect your purchasing strategy across different regions.

By equipping B2B buyers with actionable insights and key considerations, this resource empowers decision-makers to navigate the complexities of the marine battery charger market confidently. Whether you are looking to enhance your fleet’s capabilities in the UAE, the UK, or beyond, this guide is your essential companion in making strategic investments that drive value and operational efficiency in your marine endeavors.

Understanding marine battery charger Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smart Marine Chargers | Integrated microprocessors for optimized charging | Yachting, commercial fishing fleets | Pros: Efficient, user-friendly; Cons: Higher upfront cost. |

| Traditional Marine Chargers | Simple design, typically manual operation | Small boat owners, entry-level users | Pros: Cost-effective; Cons: Limited features, less efficient. |

| Solar Marine Chargers | Utilizes solar panels for energy | Eco-friendly operations, remote locations | Pros: Sustainable, reduces energy costs; Cons: Dependent on weather. |

| Dual Voltage Chargers | Capable of charging both 12V and 24V batteries | Versatile applications in various vessels | Pros: Flexible, accommodates different battery types; Cons: Bulkier design. |

| High-Frequency Chargers | Fast charging technology with compact design | Professional marine services, racing boats | Pros: Quick charging, space-saving; Cons: Potential heat issues. |

What are Smart Marine Chargers and Why are They Beneficial for B2B Buyers?

Smart marine chargers are equipped with advanced microprocessors that intelligently manage the charging process, ensuring optimal battery health and longevity. These chargers adjust the charging current and voltage according to the battery’s needs, making them suitable for high-performance applications such as yachting and commercial fishing fleets. B2B buyers should consider the initial investment against long-term savings on battery replacements and maintenance, as well as the enhanced efficiency and user-friendly interfaces that can reduce operational downtime.

How Do Traditional Marine Chargers Compare in Terms of Cost and Functionality?

Traditional marine chargers feature a straightforward design that often requires manual operation, making them a budget-friendly option for small boat owners and entry-level users. While these chargers are less efficient and lack advanced features found in smart models, they provide a reliable solution for businesses that prioritize cost over technology. Buyers should weigh the lower price point against potential inefficiencies and consider whether they may need to upgrade in the future as their operations expand.

What Advantages Do Solar Marine Chargers Offer for Sustainable Operations?

Solar marine chargers harness renewable energy through solar panels, making them an excellent choice for environmentally conscious businesses operating in remote locations. These chargers can significantly reduce energy costs and reliance on traditional power sources. However, B2B buyers must consider the dependency on weather conditions for effective charging and the initial investment in solar technology. Companies focused on sustainability and reducing their carbon footprint will find these chargers particularly appealing.

Why Choose Dual Voltage Chargers for Versatile Applications?

Dual voltage chargers are designed to charge both 12V and 24V batteries, making them a versatile option for various marine applications. They are particularly useful for businesses that operate different types of vessels, allowing for greater flexibility in operations. While these chargers may have a bulkier design, the ability to accommodate multiple battery types can streamline purchasing decisions and inventory management for B2B buyers.

What Makes High-Frequency Chargers Ideal for Professional Marine Services?

High-frequency chargers utilize advanced technology to provide rapid charging capabilities while maintaining a compact design. They are particularly beneficial for professional marine services and racing boats where time is critical. However, B2B buyers should be mindful of potential heat issues that can arise with high-frequency charging. The investment in this technology can lead to significant time savings and improved operational efficiency, making it a worthwhile consideration for businesses that require quick turnaround times.

Related Video: Marine Battery Wiring and install + Onboard Battery charger & fuze/breaker.

Key Industrial Applications of marine battery charger

| Industry/Sector | Specific Application of marine battery charger | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Maritime Transport | Charging batteries for commercial vessels | Ensures reliable operation and minimizes downtime | Compliance with international maritime safety standards |

| Recreational Boating | Maintenance charging for leisure craft batteries | Extends battery life and enhances user experience | Compatibility with various battery types and sizes |

| Offshore Oil & Gas | Powering emergency and auxiliary systems on rigs | Increases safety and reliability in critical operations | Robustness against harsh environmental conditions |

| Fishing Industry | Charging systems for onboard navigation equipment | Supports operational efficiency and safety at sea | Durability and ease of installation in confined spaces |

| Marine Research and Exploration | Powering research vessels and equipment | Facilitates continuous data collection and analysis | Energy efficiency and adaptability to various power needs |

How is a Marine Battery Charger Used in Maritime Transport?

In the maritime transport sector, marine battery chargers are essential for charging batteries on commercial vessels, including cargo ships and tankers. These chargers ensure that all onboard systems, from navigation to communication, remain operational. A reliable marine battery charger minimizes downtime due to power failure, which is crucial for maintaining schedules and operational efficiency. Buyers in this sector should consider chargers that comply with international maritime safety standards, ensuring they are suitable for various vessel types and battery configurations.

What Role Does a Marine Battery Charger Play in Recreational Boating?

For the recreational boating industry, marine battery chargers are vital for maintaining and charging leisure craft batteries. These chargers help extend battery life and enhance the overall user experience by ensuring that all electrical systems, such as lights and motors, function optimally. B2B buyers should focus on chargers that are compatible with different battery types and sizes, as well as those that offer smart charging features to prevent overcharging and damage.

How Do Marine Battery Chargers Enhance Safety in Offshore Oil & Gas Operations?

In the offshore oil and gas sector, marine battery chargers are critical for powering emergency and auxiliary systems on drilling rigs and support vessels. These chargers ensure that safety equipment, such as emergency lights and communication systems, remain operational during critical situations. The reliability of marine battery chargers is paramount, as any failure can lead to hazardous situations. Buyers should prioritize sourcing chargers that are robust enough to withstand harsh environmental conditions, ensuring they remain functional in extreme situations.

What Applications Exist for Marine Battery Chargers in the Fishing Industry?

Marine battery chargers are widely used in the fishing industry to charge onboard navigation and communication equipment. By ensuring that these systems are always powered, fishing operations can run more efficiently and safely. This is particularly important for vessels operating in remote areas where reliable communication is essential. Buyers in this sector should look for chargers that are durable and easy to install in confined spaces, as well as those that can handle the unique power needs of various fishing equipment.

How Do Marine Battery Chargers Support Marine Research and Exploration?

In marine research and exploration, battery chargers are crucial for powering research vessels and the equipment used for data collection and analysis. These chargers facilitate continuous operations, allowing researchers to gather data over extended periods without interruption. When sourcing marine battery chargers for this application, B2B buyers should consider energy-efficient models that can adapt to varying power needs, ensuring that all research activities can be conducted smoothly and effectively.

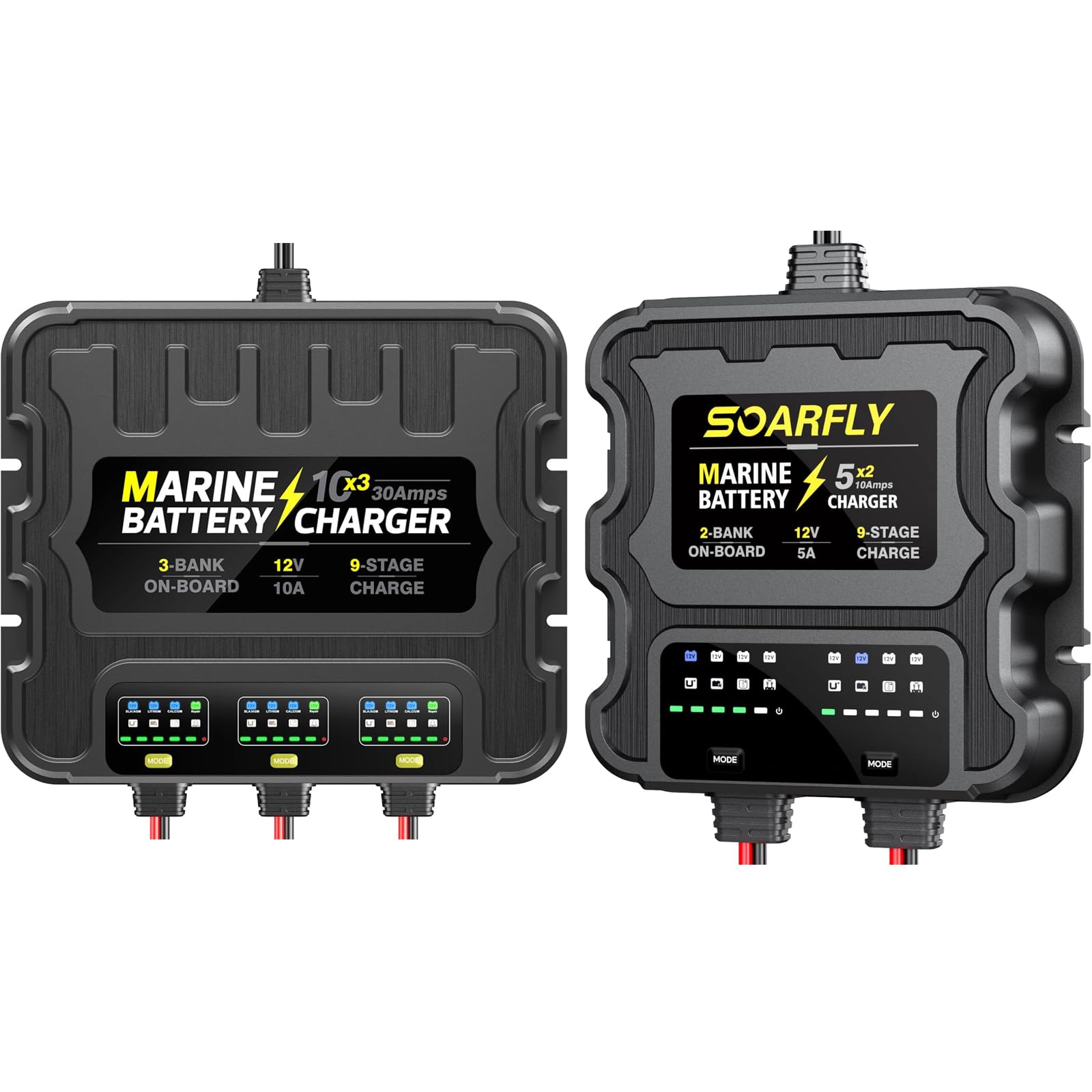

A stock image related to marine battery charger.

Related Video: How to Install an Onboard Boat Battery Charger + ProMariner Unboxing & Review

3 Common User Pain Points for ‘marine battery charger’ & Their Solutions

Scenario 1: Inconsistent Charging Performance Affects Vessel Operations

The Problem: B2B buyers often face issues with marine battery chargers that do not deliver consistent performance. This inconsistency can lead to incomplete charging cycles, which not only affects the battery life but also jeopardizes the operational efficiency of the vessels. Buyers from regions with varying climates, such as the Middle East and South America, may find that temperature extremes affect the performance of their chargers, leading to unexpected downtimes and operational delays. This can be particularly challenging for businesses that rely heavily on their marine fleet for logistics and transport.

The Solution: To combat inconsistent charging performance, buyers should prioritize marine battery chargers with adaptive charging technology. These chargers can automatically adjust their output based on the battery’s current state and environmental conditions. When sourcing chargers, look for models that provide detailed specifications on temperature ranges and charging profiles. Additionally, consider investing in chargers that feature multiple charging modes tailored for different battery chemistries (like lead-acid or lithium-ion), ensuring optimal performance under various conditions. Regular maintenance checks and firmware updates can also help ensure that the charger is functioning correctly, maximizing its lifespan and reliability.

Scenario 2: Limited Availability of Technical Support and Resources

The Problem: Many B2B buyers encounter challenges when it comes to finding reliable technical support for their marine battery chargers, especially in regions like Africa and parts of South America where access to qualified technicians may be limited. This lack of support can lead to prolonged downtime when issues arise, resulting in significant financial losses and operational inefficiencies. Buyers may also struggle to find adequate resources and documentation to troubleshoot their equipment effectively.

The Solution: To address this issue, buyers should choose suppliers that offer comprehensive after-sales support and accessible technical resources. Before making a purchase, inquire about the availability of online support tools, including manuals, troubleshooting guides, and video tutorials. Opt for suppliers that provide training sessions for your staff, either in-person or online, to ensure they are well-equipped to handle common issues. Establishing a long-term relationship with a reputable supplier who can offer remote support or on-site visits when necessary can also mitigate these challenges, ensuring your team can maintain and repair equipment efficiently.

Scenario 3: High Initial Costs with Uncertain ROI

The Problem: International B2B buyers often grapple with the high initial costs associated with marine battery chargers, which can be a significant investment for their operations. In regions with fluctuating economies, such as those in Europe and the Middle East, the uncertainty regarding the return on investment (ROI) can deter companies from upgrading their charging systems. Buyers may feel pressured to opt for lower-cost alternatives that ultimately fail to meet their operational needs, leading to higher long-term costs due to inefficiencies and replacements.

The Solution: To maximize ROI on marine battery chargers, B2B buyers should conduct a thorough cost-benefit analysis before making a purchase. Consider factors such as energy efficiency, longevity, and warranty periods in addition to the upfront costs. Invest in chargers that come with energy-saving features, as these can significantly reduce operational costs over time. Additionally, explore financing options or leasing agreements that can spread the cost over time, easing the initial financial burden. Building a case based on total cost of ownership (TCO) rather than just initial purchase price can help justify the investment to stakeholders and ensure that the long-term benefits are clearly understood.

Strategic Material Selection Guide for marine battery charger

When selecting materials for marine battery chargers, international B2B buyers must consider several factors that influence product performance, durability, and compliance with regional standards. Below, we analyze four common materials used in marine battery chargers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in Marine Battery Chargers?

Aluminum is a popular choice for marine battery chargers due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure. Its natural oxide layer provides additional protection against saltwater corrosion, making it ideal for marine environments.

Pros & Cons:

Aluminum is durable and easy to manufacture, which keeps production costs relatively low. However, it is less robust than some alternatives, which may limit its suitability for high-stress applications. Additionally, while aluminum is cost-effective, it may not perform well under extreme temperature fluctuations.

Impact on Application:

Aluminum is compatible with various media, including seawater and freshwater, making it versatile for different marine applications. However, buyers should ensure that the specific alloy used is suitable for their intended use.

Considerations for International Buyers:

Buyers in regions like the UAE and the UK should ensure compliance with ASTM standards for corrosion resistance. Understanding local regulations regarding aluminum use in marine applications is crucial.

How Does Stainless Steel Enhance Marine Battery Charger Performance?

Stainless steel is renowned for its strength and exceptional corrosion resistance, particularly in harsh marine environments. With a temperature rating exceeding 300°C, it can handle high-pressure applications effectively.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to pitting and crevice corrosion. However, it is more expensive than aluminum and can be challenging to manufacture due to its hardness. This can lead to higher production costs, which may be a consideration for budget-conscious buyers.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for marine battery chargers that may be exposed to harsh chemicals.

Considerations for International Buyers:

Buyers should look for compliance with DIN standards, particularly in Europe, where stringent regulations apply. Understanding the grade of stainless steel used is essential for ensuring the longevity and reliability of the charger.

What Role Does Plastic Play in Marine Battery Charger Design?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in marine battery chargers due to their lightweight and non-corrosive properties. They can withstand temperatures up to 80°C and offer good pressure resistance.

Pros & Cons:

Plastic is cost-effective and simplifies manufacturing processes, reducing overall production costs. However, it may not provide the same level of durability as metals, making it less suitable for high-stress applications. Additionally, plastics can degrade over time when exposed to UV light, which is a consideration for outdoor marine applications.

Impact on Application:

Plastics are generally compatible with non-corrosive media, but their use in environments with extreme temperatures or exposure to harsh chemicals should be carefully evaluated.

Considerations for International Buyers:

Buyers should ensure that the plastics used comply with relevant standards, such as JIS in Japan or ASTM in the U.S., to guarantee quality and safety.

How Does Copper Contribute to Marine Battery Charger Efficiency?

Copper is widely recognized for its excellent electrical conductivity, making it an ideal choice for components within marine battery chargers. It can operate effectively at temperatures up to 200°C and is highly resistant to corrosion when properly coated.

Pros & Cons:

Copper’s superior conductivity enhances the efficiency of battery chargers, reducing energy losses. However, it is more expensive than aluminum and can be prone to corrosion if not adequately protected. This may lead to increased maintenance costs over time.

Impact on Application:

Copper is compatible with various media, but its use in marine environments requires careful consideration of protective coatings to prevent corrosion.

Considerations for International Buyers:

Buyers should ensure compliance with international standards for copper use in marine applications, particularly in regions with strict environmental regulations.

Summary Table of Material Selection for Marine Battery Chargers

| Material | Typical Use Case for marine battery charger | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight housings and components | Excellent corrosion resistance | Less robust under extreme stress | Medium |

| Stainless Steel | Structural components in harsh environments | Exceptional durability | Higher cost and manufacturing complexity | High |

| Plastic | Enclosures and non-load bearing parts | Cost-effective and lightweight | UV degradation over time | Low |

| Copper | Electrical connections and conductors | Superior electrical conductivity | Corrosion risk if unprotected | High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for marine battery chargers, ensuring they make informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for marine battery charger

What Are the Main Stages of Manufacturing Marine Battery Chargers?

The manufacturing process of marine battery chargers involves several critical stages, each contributing to the final product’s performance and reliability. Understanding these stages is essential for B2B buyers seeking high-quality products.

Material Preparation: What Materials Are Used in Marine Battery Chargers?

The manufacturing process begins with material preparation, where high-grade materials are selected for durability and performance. Common materials include:

- Copper and Aluminum: Used for wiring and conductors due to their excellent conductivity.

- Plastic and Metal Enclosures: These materials protect the internal components from moisture and corrosion, crucial for marine applications.

- Resistors and Capacitors: Essential for circuit design, these components must meet specific electrical standards to ensure efficiency.

B2B buyers should inquire about the sourcing of these materials, as quality directly impacts performance. Sustainable sourcing practices can also enhance a supplier’s reputation.

How Are Marine Battery Chargers Formed?

Once the materials are prepared, the next step involves forming the components. This includes:

- PCB Fabrication: Printed Circuit Boards (PCBs) are manufactured using techniques like etching and layering to create the necessary circuit pathways.

- Molding and Cutting: Plastic and metal components are molded or cut to precise specifications, ensuring a perfect fit during assembly.

- Welding and Soldering: Critical connections are made using soldering techniques, ensuring electrical integrity and durability.

Buyers should evaluate suppliers based on their equipment and technology used in these processes, as advanced techniques often lead to higher quality products.

What Does the Assembly Process Entail for Marine Battery Chargers?

The assembly stage is where all the individual components come together. This process typically involves:

- Component Placement: Automated machines or skilled workers place components onto the PCB, ensuring accuracy and minimizing defects.

- Soldering: Components are soldered onto the PCB, often using reflow or wave soldering methods to ensure strong electrical connections.

- Encapsulation: In many cases, components are encapsulated in resin to protect against moisture, vibration, and corrosion.

For B2B buyers, understanding the assembly techniques used can provide insights into the reliability and longevity of the chargers. Asking about the workforce’s training and experience can also be beneficial.

What Are the Finishing Processes for Marine Battery Chargers?

Finishing touches are crucial for ensuring that the marine battery chargers are ready for market. This includes:

- Quality Control Checks: Initial quality checks are conducted to identify any defects from the assembly process.

- Labeling and Packaging: Chargers are labeled with relevant specifications and packaged to prevent damage during shipping.

- Final Testing: Each unit undergoes rigorous testing to ensure it meets performance standards.

Understanding these finishing processes can help B2B buyers gauge how seriously a manufacturer takes quality assurance.

How Is Quality Assurance Implemented in Marine Battery Charger Manufacturing?

Quality assurance (QA) is vital in the manufacturing of marine battery chargers, ensuring that every unit meets international standards and customer expectations.

What International Standards Should Marine Battery Charger Manufacturers Comply With?

International standards such as ISO 9001 are essential for ensuring quality management systems are in place. This standard focuses on meeting customer expectations and regulatory requirements, which is crucial for B2B buyers looking for reliable suppliers.

Additionally, industry-specific certifications like CE marking (for compliance with European standards) and API standards (for safety and performance) should also be considered. Buyers should ensure that potential suppliers possess these certifications, as they are indicative of adherence to quality and safety norms.

What Quality Control Checkpoints Are Commonly Used?

Quality control in marine battery charger manufacturing typically involves several key checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, regular checks ensure that each stage meets predefined standards.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that they meet all specifications and standards.

B2B buyers should inquire about the frequency and rigor of these quality control checkpoints to ensure consistent product quality.

What Common Testing Methods Are Used for Marine Battery Chargers?

Testing methods are crucial in ensuring the performance and safety of marine battery chargers. Common testing techniques include:

- Electrical Testing: This verifies the charger’s voltage, current, and power output against specifications.

- Environmental Testing: Chargers are subjected to conditions such as humidity and temperature extremes to ensure they can withstand marine environments.

- Safety Testing: Compliance with safety standards involves tests for short circuits, overloads, and insulation resistance.

Buyers should request documentation of these tests from suppliers to validate the quality and reliability of the products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is paramount. Consider the following strategies:

- Supplier Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing processes and quality control systems.

- Quality Assurance Reports: Request detailed reports outlining the results of quality checks and testing methods used.

- Third-Party Inspections: Engaging independent inspection services can offer an unbiased assessment of a supplier’s quality control practices.

Understanding the nuances of quality assurance practices can help B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, make informed decisions when selecting suppliers.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must navigate various quality control nuances, particularly when sourcing from different regions. Here are key considerations:

- Regulatory Compliance: Different regions have varying regulations; for instance, CE marking is essential for the European market, while UL certification may be more relevant in North America.

- Cultural Differences: Understanding local practices and expectations regarding quality can aid in establishing effective supplier relationships.

- Supply Chain Transparency: Buyers should seek suppliers who provide transparent supply chain information, including sourcing, manufacturing, and logistics practices.

By paying attention to these factors, B2B buyers can mitigate risks and ensure they partner with reliable suppliers who prioritize quality in their manufacturing processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘marine battery charger’

In the dynamic landscape of international trade, sourcing the right marine battery charger is critical for operational efficiency and reliability. This guide serves as a step-by-step checklist for B2B buyers, particularly in Africa, South America, the Middle East, and Europe, to streamline their procurement process. By following these steps, you can ensure a successful sourcing experience, tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to your sourcing strategy. Consider the voltage, amp rating, and compatibility with different types of marine batteries. Knowing your requirements upfront will help you filter out unsuitable products and ensure that the chargers you source meet your operational needs.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in marine battery chargers. This includes advancements in technology, such as smart chargers and energy-efficient models. Understanding these trends will not only enhance your sourcing decisions but also help you stay competitive in your market.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can deliver quality products and services. Request company profiles, product catalogs, and references from businesses in similar industries or regions. Look for suppliers with a proven track record in supplying marine battery chargers, as this can significantly reduce risks associated with procurement.

Step 4: ✅ Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications, such as ISO standards or CE marking. These certifications are indicators of quality and safety compliance. Additionally, check for any industry-specific certifications that might be relevant to your region or sector, ensuring that the products meet local regulations.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples of the marine battery chargers. This step allows you to assess the product quality and suitability for your specific applications. Conduct thorough testing to evaluate performance, durability, and compatibility with your existing systems, ensuring that the chargers will meet your operational demands.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Aim for a mutually beneficial agreement that accommodates your budget and timelines. Clear communication during this phase can prevent misunderstandings and establish a strong foundation for a long-term partnership.

Step 7: Plan for Logistics and After-Sales Support

Consider the logistics involved in shipping the marine battery chargers to your location. Factor in import duties, shipping times, and potential customs issues. Additionally, inquire about after-sales support, warranty terms, and availability of spare parts to ensure ongoing support for your investment.

By following these steps, B2B buyers can navigate the complexities of sourcing marine battery chargers effectively. This strategic approach not only mitigates risks but also enhances the likelihood of successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for marine battery charger Sourcing

What Are the Key Cost Components in Marine Battery Charger Sourcing?

Understanding the cost structure for marine battery chargers is critical for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials used in marine battery chargers significantly impact overall costs. High-grade components often lead to better performance and longevity, which can justify a higher initial investment.

-

Labor: Labor costs vary by region and can affect manufacturing prices. For instance, suppliers in countries with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient factories may pass on savings to buyers.

-

Tooling: Customization or unique specifications may require specialized tooling, which adds to upfront costs. Buyers should inquire about these costs upfront to avoid surprises later.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can increase costs. Buyers should weigh the benefits of stringent QC against potential price increases.

-

Logistics: Transportation costs, including shipping and handling, can vary significantly based on the distance and mode of transport. This is particularly important for international buyers who may face additional tariffs or import duties.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the typical margins in the marine battery charger market can help buyers gauge the fairness of a quoted price.

How Do Price Influencers Affect Marine Battery Charger Costs?

Several factors influence the pricing of marine battery chargers, which are crucial for buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs and negotiate for better pricing based on volume.

-

Specifications and Customization: Custom features or specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, CE) can affect price. Buyers should ensure that the materials meet their operational demands without overspending on unnecessary certifications.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) dictate responsibility for shipping costs and risks. Buyers should understand these terms to accurately assess total costs.

What Negotiation Strategies Can B2B Buyers Employ?

Effective negotiation can lead to more favorable pricing and terms. Here are some tips for B2B buyers:

-

Conduct Market Research: Understanding market rates and competitor pricing allows buyers to negotiate confidently and avoid overpaying.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better terms and pricing. Suppliers are often more willing to negotiate with reliable partners.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranties, and energy efficiency. A slightly higher initial cost may result in lower TCO.

-

Be Clear on Specifications: Clearly communicate specifications and expectations to avoid misunderstandings that can lead to higher costs later.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be mindful of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact costs. Buyers should consider hedging strategies if dealing in foreign currencies.

-

Import Duties and Tariffs: Understand the import regulations and potential tariffs that may apply to marine battery chargers in your region. This can significantly affect the total cost.

-

Cultural Differences in Negotiation: Different regions have varying negotiation styles. Familiarize yourself with local practices to ensure effective communication and better deals.

Disclaimer on Indicative Prices

Prices for marine battery chargers can vary widely based on the above factors. It is essential for buyers to obtain multiple quotes and conduct thorough due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing marine battery charger With Other Solutions

Understanding Alternatives to Marine Battery Chargers for B2B Buyers

In the maritime industry, choosing the right power solutions is crucial for operational efficiency and reliability. While marine battery chargers are a popular choice for maintaining battery health and performance, there are several alternative solutions that B2B buyers should consider. Each alternative comes with its own set of advantages and disadvantages, making it essential for international buyers, particularly from Africa, South America, the Middle East, and Europe, to evaluate their options thoroughly.

Comparison Table of Marine Battery Charger and Alternatives

| Comparison Aspect | Marine Battery Charger | Solar Power System | Generator Set |

|---|---|---|---|

| Performance | High efficiency in charging batteries | Variable output depending on sunlight | High power output, can run continuously |

| Cost | Moderate upfront cost, low operational cost | High initial investment, low operational cost | High initial and operational costs |

| Ease of Implementation | Simple installation, user-friendly | Requires space for panels and inverter setup | Requires space and knowledge for installation |

| Maintenance | Low maintenance, occasional checks | Low maintenance, periodic cleaning | High maintenance, fuel management needed |

| Best Use Case | Recreational boating and small vessels | Sustainable energy for off-grid applications | Backup power and large vessels |

What Are the Benefits and Drawbacks of Solar Power Systems?

Solar power systems harness energy from the sun, making them a sustainable alternative to marine battery chargers. The primary advantage is their low operational cost, as sunlight is free. However, the initial investment can be substantial, especially for high-capacity systems. They are ideal for off-grid applications or vessels that operate in sunny regions, but their performance is heavily dependent on weather conditions. Maintenance is generally minimal, involving only periodic cleaning of the solar panels.

How Do Generator Sets Compare to Marine Battery Chargers?

Generator sets provide a powerful and consistent source of energy, making them suitable for larger vessels or situations requiring significant electrical demand. They can run continuously, offering high output compared to marine battery chargers. However, they come with higher initial costs and ongoing operational expenses, including fuel and maintenance. Additionally, generators require more space and may produce noise and emissions, which can be a concern in sensitive environments. Their best use case is for backup power or in commercial shipping where power demands are substantial.

Conclusion: How Should B2B Buyers Choose the Right Power Solution?

When selecting the appropriate power solution, B2B buyers should consider specific operational needs, budget constraints, and environmental factors. Marine battery chargers offer a reliable and cost-effective solution for smaller vessels, while solar power systems present an eco-friendly option for those in sunny regions. Generator sets are best suited for high-demand applications but come with higher costs. By evaluating these factors, international buyers can make informed decisions that align with their operational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for marine battery charger

What Are the Key Technical Properties of a Marine Battery Charger?

Understanding the technical specifications of a marine battery charger is crucial for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. Here are several essential properties to consider:

1. Charging Voltage and Current Rating

The charging voltage typically ranges between 12V and 48V, while the current rating can vary based on the battery size and type. It’s important for buyers to select a charger that matches the battery’s specifications to ensure optimal performance and longevity. A mismatch can lead to overcharging or undercharging, causing damage and reduced efficiency.

2. Efficiency Rating

Efficiency indicates how effectively a charger converts input power into output power. A higher efficiency rating (usually above 85%) means less energy waste and lower operational costs. For B2B buyers, selecting a charger with a high efficiency rating not only reduces energy expenses but also enhances sustainability, a growing concern in global markets.

3. Protection Features

Marine environments are harsh, making protection features vital. Look for chargers equipped with over-voltage, over-current, and short-circuit protection. These features safeguard both the charger and the batteries, reducing the risk of damage and ensuring reliability. This is particularly important for businesses that rely on uninterrupted power supply for operations.

4. Durability and Material Grade

The materials used in the construction of marine battery chargers must withstand saltwater exposure, humidity, and temperature fluctuations. Buyers should look for chargers made from high-grade marine materials such as stainless steel or corrosion-resistant plastics. Durability translates into lower maintenance costs and longer service life, which is critical for businesses operating in challenging marine conditions.

5. Charging Modes

Different charging modes, such as bulk, absorption, and float, cater to various battery types and charging needs. Understanding these modes can help businesses optimize their charging processes, enhancing battery performance and lifespan. Buyers should inquire about a charger’s versatility in accommodating different battery technologies, such as AGM, gel, or lithium-ion.

What Trade Terminology Should B2B Buyers Understand?

Navigating the marine battery charger market requires familiarity with specific trade terminology. Here are some common terms that international buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from reputable OEMs ensures that the products meet industry standards and specifications, which is essential for quality assurance and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units that a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their purchasing capabilities, especially when dealing with suppliers from different regions.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This process allows B2B buyers to compare offers and select suppliers based on cost-effectiveness and quality. Crafting a detailed RFQ can help ensure that all relevant specifications and requirements are communicated.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and the risks involved in cross-border purchases, which is essential for effective supply chain management.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is critical for project planning and inventory control. It is advisable to factor in lead times when negotiating with suppliers to ensure timely delivery and avoid operational disruptions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing marine battery chargers, ultimately enhancing their operational efficiency and competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the marine battery charger Sector

What Are the Current Market Dynamics and Key Trends in the Marine Battery Charger Sector?

The marine battery charger market is experiencing significant transformation driven by technological advancements and shifting consumer preferences. Key trends include the growing adoption of smart technology, which integrates IoT capabilities into battery chargers, enabling remote monitoring and management. This is particularly relevant for international B2B buyers from regions like Africa and South America, where efficient resource management is crucial due to fluctuating energy costs. Additionally, the increasing focus on electrification in marine vessels, spurred by environmental regulations, is propelling demand for high-efficiency chargers capable of supporting larger battery systems.

Moreover, the rise of electric and hybrid marine vessels is reshaping sourcing strategies. Buyers are now prioritizing suppliers that offer chargers compatible with advanced battery technologies, such as lithium-ion and solid-state batteries. In Europe and the Middle East, where sustainability is a growing concern, there is a heightened emphasis on sourcing products that align with eco-friendly practices. As a result, B2B buyers must stay informed about regulatory changes and emerging technologies to make strategic procurement decisions.

How Can Sustainability and Ethical Sourcing Impact Marine Battery Charger Procurement?

A stock image related to marine battery charger.

Sustainability has become a pivotal concern in the marine battery charger sector, influencing both purchasing decisions and supplier selection. The environmental impact of battery production and disposal is significant, prompting buyers to seek suppliers who prioritize sustainable practices. This includes the use of recyclable materials, energy-efficient manufacturing processes, and adherence to strict environmental standards.

Ethical sourcing is equally important, as consumers and businesses alike are increasingly demanding transparency in supply chains. B2B buyers from Africa and the Middle East should look for suppliers who hold certifications such as ISO 14001 for environmental management and those that utilize eco-friendly materials in their products. These certifications not only enhance a company’s reputation but also ensure compliance with international environmental regulations, which can be particularly beneficial when entering European markets.

By prioritizing sustainability and ethical sourcing, buyers can mitigate risks associated with environmental liabilities and enhance their brand value in an increasingly eco-conscious marketplace.

How Has the Marine Battery Charger Sector Evolved Over Time?

The marine battery charger sector has undergone significant evolution over the past few decades. Initially focused on basic charging functions, advancements in technology have led to the development of smart chargers equipped with features like multi-stage charging, automatic voltage regulation, and battery health monitoring. This evolution is driven by the need for greater efficiency and reliability in marine applications, catering to the growing demand for electric and hybrid marine vessels.

As international regulations have tightened around emissions and energy consumption, the market has shifted towards more sustainable solutions. Today’s marine battery chargers are not only more efficient but also designed to support advanced battery technologies, reflecting the industry’s commitment to innovation and sustainability. For B2B buyers, understanding this historical context is vital in making informed sourcing decisions that align with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of marine battery charger

-

How do I solve compatibility issues with marine battery chargers?

To solve compatibility issues, first, identify the specific battery types and capacities you will be using with the charger. Consult the manufacturer’s specifications for both the battery and the charger to ensure they match in terms of voltage and chemistry (e.g., lead-acid, lithium-ion). Additionally, consider chargers that offer adjustable settings or multiple charging profiles to accommodate different battery types. Engaging with suppliers who have a proven track record in your target market can also provide insights into the best solutions for your specific needs. -

What is the best marine battery charger for large vessels?

The best marine battery charger for large vessels typically features high amperage output, multiple charging banks, and advanced features like temperature compensation and smart charging technology. Look for chargers with a power range that can handle the total capacity of the batteries on board. Brands that are well-regarded in the industry often offer models specifically designed for larger vessels, ensuring they can maintain optimal battery health during extended use. Always verify the charger’s certifications and user reviews before making a purchase. -

How can I ensure quality when sourcing marine battery chargers internationally?

To ensure quality when sourcing marine battery chargers internationally, start by vetting suppliers through certifications such as ISO 9001 or CE marking. Request samples to test performance and reliability before committing to larger orders. Establish clear communication regarding quality standards and expectations. Utilize third-party inspection services to evaluate the product quality before shipment. Finally, consider suppliers with a solid reputation and positive feedback from previous clients in your region, especially from Africa, South America, the Middle East, and Europe. -

What are the typical minimum order quantities (MOQs) for marine battery chargers?

Minimum order quantities for marine battery chargers can vary significantly by supplier and region. Generally, MOQs range from 50 to 200 units, depending on the manufacturer’s production capabilities and your specific customization needs. Some suppliers may offer flexible MOQs for first-time buyers or bulk orders. Always discuss your requirements upfront, and negotiate MOQs that align with your inventory management strategy while ensuring you receive competitive pricing. -

What payment terms should I expect when purchasing marine battery chargers from international suppliers?

When purchasing marine battery chargers from international suppliers, typical payment terms may include a 30% upfront deposit with the balance due before shipment, or net 30/60 days after delivery. It’s essential to clarify payment options, such as wire transfers or letters of credit, and to consider currency exchange rates that could impact your costs. Building a strong relationship with your supplier can also provide leverage for more favorable payment terms. -

How can I customize marine battery chargers for my specific needs?

Customizing marine battery chargers often involves specifying features such as voltage settings, charging profiles, and physical dimensions. Discuss your requirements directly with the manufacturer, as many suppliers offer tailored solutions for B2B clients. Additionally, inquire about branding options, such as adding your company logo or specific packaging. Ensure that you communicate your needs clearly and verify any additional costs associated with customization.

A stock image related to marine battery charger.

-

What logistics considerations should I keep in mind when importing marine battery chargers?

When importing marine battery chargers, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Work with freight forwarders who are familiar with your region’s import laws to avoid delays. Additionally, assess the cost implications of shipping methods—air freight is faster but more expensive than sea freight. Ensure proper documentation is in place, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. -

How do I handle warranty claims for marine battery chargers sourced internationally?

Handling warranty claims for marine battery chargers sourced internationally requires understanding the supplier’s warranty policy before purchase. Ensure that the terms are clearly defined, including the duration, coverage, and claim process. Maintain a record of all purchase documentation and correspondence with the supplier. If a warranty claim arises, communicate promptly and provide necessary evidence, such as proof of purchase and photographs of the issue. Establishing a good relationship with your supplier can help facilitate smoother resolution of warranty claims.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for marine battery charger

In navigating the complex landscape of marine battery charger procurement, international B2B buyers must prioritize strategic sourcing to achieve optimal outcomes. The key takeaways emphasize the importance of understanding local market dynamics, evaluating supplier reliability, and assessing technological advancements in battery charging solutions. By leveraging data-driven decision-making, buyers can enhance their purchasing strategies, ensuring they select products that meet both performance and regulatory standards relevant to their regions.

How Can Strategic Sourcing Impact Your Marine Battery Charger Purchases?

The value of strategic sourcing cannot be overstated. It fosters stronger supplier relationships, promotes competitive pricing, and encourages innovation in product offerings. For businesses in Africa, South America, the Middle East, and Europe, adopting a proactive sourcing strategy can significantly enhance operational efficiency and reduce costs associated with marine battery chargers.

What Should International Buyers Consider Moving Forward?

As we look to the future, the demand for sustainable and efficient marine battery charging solutions will only grow. International B2B buyers are encouraged to stay abreast of emerging technologies and market trends while fostering collaborative partnerships with suppliers. By doing so, they can position themselves to not only meet current needs but also anticipate future challenges in the marine battery sector. Engage with suppliers today to explore innovative solutions that align with your business objectives and regional requirements.