Mastering Uni T Price: The Complete Guide for B2B Buyers (2025)

Introduction: Navigating the Global Market for uni t price

In today’s interconnected global marketplace, understanding the intricacies of unit price is crucial for B2B buyers looking to optimize their purchasing strategies. Whether you are sourcing essential components for manufacturing or procuring raw materials for production, the challenge of navigating fluctuating costs and diverse supplier offerings can be daunting. This guide is designed to demystify the concept of unit price, providing clarity on how to assess and compare costs effectively across various markets.

Throughout this comprehensive resource, we will explore the different types of unit pricing, their applications in various industries, and essential strategies for supplier vetting. Buyers will gain insights into the factors that influence pricing, including currency fluctuations, regional demand, and logistical considerations. Additionally, we will delve into practical tips for negotiating better deals and understanding the true cost of goods beyond just the sticker price.

By equipping international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—with the knowledge and tools needed to make informed purchasing decisions, this guide aims to empower you to navigate the complexities of the global market with confidence. Ultimately, understanding unit price not only enhances your procurement strategies but also fosters stronger relationships with suppliers, ensuring sustainable business growth in a competitive landscape.

Understanding uni t price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Unit Price | Set price per unit regardless of quantity | Bulk purchasing, manufacturing | Pros: Simplifies budgeting; Cons: May not reflect market fluctuations. |

| Tiered Pricing | Price varies based on quantity purchased | Wholesale distribution, subscription services | Pros: Encourages larger purchases; Cons: Complexity in pricing structure. |

| Dynamic Pricing | Prices fluctuate based on demand and market conditions | E-commerce, travel, and event ticketing | Pros: Maximizes profit during high demand; Cons: Unpredictable costs for buyers. |

| Cost-Plus Pricing | Base cost plus a predetermined markup | Custom manufacturing, project-based work | Pros: Transparency in pricing; Cons: May lead to higher prices without competitive bidding. |

| Freemium Pricing | Basic service offered for free with paid upgrades | Software as a Service (SaaS) | Pros: Low entry cost; Cons: Potential for high long-term costs if upgrades are needed. |

What Are the Characteristics of Fixed Unit Pricing?

Fixed unit pricing is characterized by a consistent price per unit, regardless of the quantity purchased. This pricing model is particularly suitable for B2B transactions involving bulk purchases, such as raw materials or components in manufacturing. Buyers benefit from straightforward budgeting, as they can easily calculate total costs based on the fixed price. However, it’s essential to consider that fixed pricing may not adapt to market changes, potentially leading to higher costs if market prices decrease.

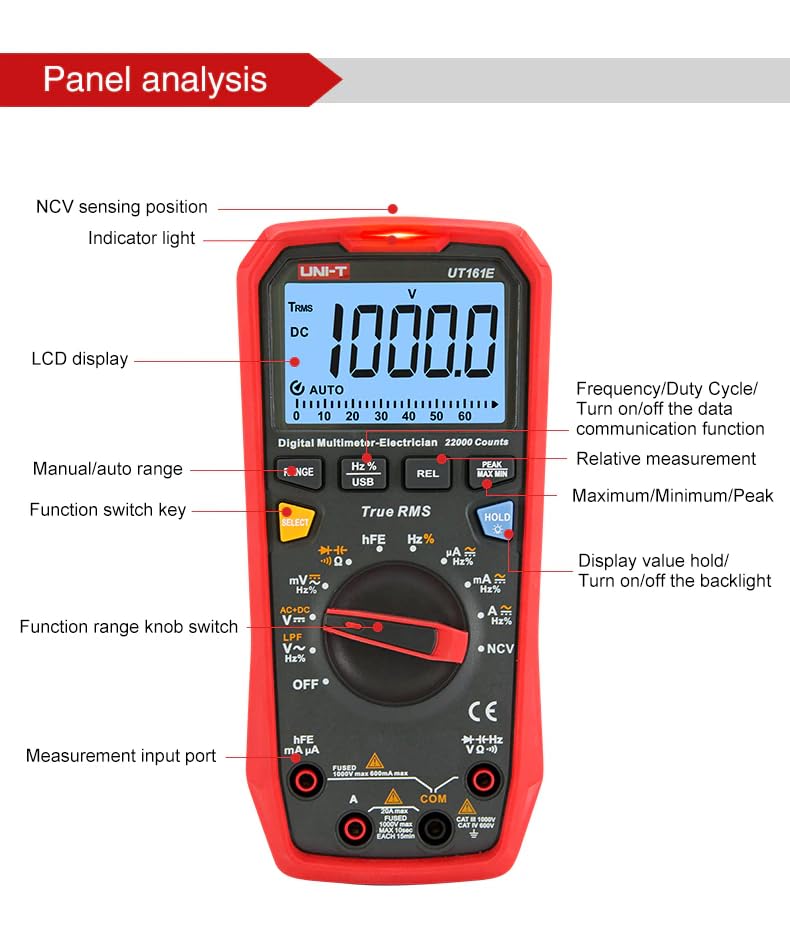

A stock image related to uni t price.

How Does Tiered Pricing Work for B2B Buyers?

Tiered pricing involves different price levels based on the quantity purchased. This model is commonly used in wholesale distribution and subscription services, where buyers can benefit from lower prices per unit as they increase their order size. The primary advantage for buyers is the incentive to purchase larger quantities, which can lead to significant savings. However, the complexity of this pricing structure can be a drawback, as buyers must carefully analyze their purchasing patterns to maximize benefits.

What Are the Implications of Dynamic Pricing in B2B Transactions?

Dynamic pricing is a flexible pricing strategy where prices fluctuate based on market demand and other external factors. This approach is prevalent in industries like e-commerce and travel, where demand can vary significantly. For B2B buyers, dynamic pricing can lead to cost savings during periods of low demand, but it can also result in unpredictable costs during peak times. Buyers must be prepared to navigate this variability, which can complicate budgeting and financial forecasting.

Why Consider Cost-Plus Pricing for Custom Projects?

Cost-plus pricing is a model where the final price is determined by adding a markup to the base cost of production. This pricing strategy is often used in custom manufacturing and project-based work, providing transparency as buyers can see how prices are derived. While this can foster trust between buyers and suppliers, it may lead to higher prices if not managed carefully. Buyers should evaluate whether competitive bidding might yield better pricing outcomes.

How Can Freemium Pricing Impact Long-Term Costs?

Freemium pricing is a strategy where basic services are offered for free, while advanced features come at a premium. This model is especially prevalent in Software as a Service (SaaS) applications. For B2B buyers, the low entry cost can be appealing, allowing businesses to test services before committing financially. However, buyers should be cautious, as the long-term costs can escalate significantly if premium features become necessary, potentially leading to budget overruns.

Related Video: 2024 Changan UNI-T – New Interior and Exterior

Key Industrial Applications of uni t price

| Industry/Sector | Specific Application of uni t price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cost estimation for raw materials | Enables accurate budgeting and financial planning | Assess supplier reliability and delivery timelines |

| Construction | Pricing for building materials and labor | Helps in project cost control and profit margin | Evaluate local regulations and import duties |

| Agriculture | Pricing of agricultural inputs like fertilizers | Supports effective resource allocation and ROI | Source from suppliers with sustainable practices |

| Energy | Pricing for renewable energy components | Reduces operational costs and enhances sustainability | Analyze technological compatibility and warranty terms |

| Retail | Costing of consumer goods for import/export | Informs pricing strategy and inventory management | Consider logistics, customs regulations, and market demand |

How is ‘uni t price’ Applied in Manufacturing?

In the manufacturing sector, ‘uni t price’ plays a crucial role in the cost estimation of raw materials. By providing a clear breakdown of material costs, businesses can ensure accurate budgeting and financial forecasting. This is particularly important for international buyers who need to navigate varying currency exchange rates and supplier pricing models. To effectively utilize ‘uni t price’, buyers should focus on the reliability of suppliers and their ability to meet delivery deadlines, which are essential for maintaining production schedules.

What Role Does ‘uni t price’ Play in Construction?

In the construction industry, ‘uni t price’ is vital for pricing building materials and labor. Accurate pricing helps contractors control project costs and maximize profit margins. For international B2B buyers, understanding local market conditions and regulations is imperative, as these factors can influence material costs and availability. Therefore, it is essential to evaluate local suppliers and their compliance with regional building codes to mitigate risks associated with project delays and budget overruns.

How is ‘uni t price’ Used in Agriculture?

In agriculture, ‘uni t price’ is utilized for pricing agricultural inputs such as fertilizers, seeds, and pesticides. This pricing mechanism supports effective resource allocation, ensuring farmers can maximize their return on investment (ROI). Buyers in this sector, especially from regions like Africa and South America, must consider sourcing from suppliers that practice sustainability, as this not only aligns with global trends but can also enhance the brand reputation of the agricultural products being marketed.

What is the Importance of ‘uni t price’ in the Energy Sector?

The energy sector increasingly relies on ‘uni t price’ for pricing renewable energy components, such as solar panels and wind turbines. By understanding the unit price, companies can significantly reduce operational costs while enhancing their sustainability efforts. International B2B buyers should analyze the technological compatibility of components with existing systems and ensure favorable warranty terms to safeguard their investments, especially in emerging markets in the Middle East and Africa.

How Does ‘uni t price’ Impact Retail Operations?

A stock image related to uni t price.

In retail, ‘uni t price’ is crucial for determining the costing of consumer goods, particularly for import/export operations. It informs pricing strategies that directly affect inventory management and profit margins. For businesses operating in Europe and South America, understanding logistics, customs regulations, and market demand is essential for effective pricing. Buyers should prioritize suppliers who can provide transparency in pricing and reliable delivery schedules to maintain competitive advantage in the marketplace.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘uni t price’ & Their Solutions

Scenario 1: Navigating Price Variability Across Markets

The Problem: For B2B buyers, especially those operating in diverse regions like Africa and South America, price variability for unit prices can be a significant hurdle. Different suppliers may offer varying unit prices based on local economic conditions, currency fluctuations, or differing cost structures. This inconsistency can lead to confusion and complicate budgeting and forecasting processes, making it challenging for businesses to maintain profitability while remaining competitive.

The Solution: To effectively manage price variability, B2B buyers should adopt a systematic approach to supplier evaluation and pricing analysis. Start by conducting a thorough market research to understand local pricing trends and economic factors influencing unit prices in your target regions. Utilize tools like price comparison websites and industry reports to gather data on average unit prices. Establish a standardized pricing framework that allows for adjustments based on local conditions while ensuring that your overall pricing strategy remains cohesive. Additionally, consider negotiating fixed pricing agreements with suppliers to lock in unit prices for longer periods, providing stability in your financial planning.

Scenario 2: Difficulty in Comparing Unit Prices Accurately

The Problem: When sourcing products from multiple suppliers, B2B buyers often face challenges in accurately comparing unit prices, especially when suppliers present their pricing in different formats or include additional costs like shipping and taxes. This lack of standardization can lead to misinformed purchasing decisions, which could result in overspending or selecting subpar suppliers.

The Solution: To streamline the comparison process, create a comprehensive pricing matrix that standardizes how you present unit prices. Include not only the base unit price but also any additional costs, such as shipping, taxes, and discounts. This allows for direct comparisons across suppliers. Consider using spreadsheet software to create a template that captures all relevant pricing data. Additionally, request detailed quotes from suppliers that break down their pricing structure, ensuring you have a clear understanding of the total cost of ownership. This practice not only aids in better decision-making but also enhances transparency in supplier relationships.

Scenario 3: Understanding the Impact of Unit Price on Total Cost of Ownership

The Problem: Many B2B buyers, particularly those new to international trade, focus heavily on the unit price without considering how it impacts the total cost of ownership (TCO). This oversight can lead to poor procurement decisions, as lower unit prices may correlate with higher long-term costs due to factors like quality issues, warranty claims, or higher maintenance needs.

The Solution: To address this pain point, it is crucial to shift your focus from unit price alone to a more holistic view of total cost of ownership. Start by analyzing the lifecycle costs associated with the products you intend to purchase. This includes not just the initial unit price but also potential costs for maintenance, repairs, and end-of-life disposal. Develop a TCO calculator that incorporates all these factors, helping you evaluate the long-term implications of your purchasing decisions. Engage with suppliers to discuss warranties, service agreements, and product longevity to gain insights into the overall value proposition of their offerings. This approach not only aids in smarter purchasing decisions but also fosters stronger partnerships with suppliers who can provide value beyond just unit pricing.

Strategic Material Selection Guide for uni t price

When selecting materials for ‘uni t price’, it is essential to consider the unique properties and applications of various materials. Here, we analyze four common materials used in the manufacturing of uni t price components, focusing on their key properties, advantages, limitations, and specific considerations for international B2B buyers.

What Are the Key Properties of Stainless Steel for uni t price?

Stainless steel is widely recognized for its excellent corrosion resistance and strength. It typically withstands high temperatures and pressures, making it suitable for a variety of applications. The most common grades, such as 304 and 316, offer different levels of resistance to corrosive environments, with 316 being preferred for marine or chemical applications due to its molybdenum content.

Pros & Cons:

Stainless steel is durable and has a long service life, which can justify its higher initial cost. However, it can be more complex to manufacture due to the need for specialized tooling and processes, which may increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including water, oils, and various chemicals, making it versatile for different industries.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and EN for stainless steel grades. Additionally, understanding local sourcing and supply chain dynamics is crucial to avoid delays.

How Does Carbon Steel Compare for uni t price Applications?

Carbon steel is another common material, known for its high strength and affordability. It is often used in structural applications where high tensile strength is required. However, its corrosion resistance is significantly lower than that of stainless steel.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for large-scale applications. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time, especially in humid or corrosive environments.

Impact on Application:

Carbon steel is suitable for applications involving dry or non-corrosive media. It is less ideal for environments where moisture or chemicals are present.

Considerations for International Buyers:

Buyers in Africa and South America should be aware of local climate conditions that may affect the longevity of carbon steel products. Compliance with local standards and certifications is also essential to ensure product quality.

What Are the Advantages of Plastic Materials for uni t price?

Plastics, such as polypropylene and polyvinyl chloride (PVC), are increasingly used in various applications due to their lightweight and corrosion-resistant properties. They can handle a range of temperatures and are often used in applications requiring chemical resistance.

Pros & Cons:

Plastics are generally less expensive and easier to manufacture compared to metals. However, they may not provide the same level of strength or durability, particularly in high-pressure applications.

Impact on Application:

Plastics are suitable for handling aggressive chemicals and are often used in the food and beverage industry due to their non-reactive nature.

Considerations for International Buyers:

For buyers in Europe and the Middle East, it is crucial to ensure that plastic materials meet food safety standards such as FDA or EU regulations. Understanding local recycling and disposal regulations is also important.

Why Choose Brass for Specific uni t price Applications?

Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It is often used in plumbing and electrical applications due to its conductivity and aesthetic appeal.

Pros & Cons:

Brass is durable and resistant to corrosion, making it suitable for outdoor applications. However, its cost can be higher than that of carbon steel, and it may not be suitable for high-pressure applications.

Impact on Application:

Brass is compatible with water and various gases, making it ideal for plumbing fixtures and fittings.

Considerations for International Buyers:

Buyers in regions like Australia and Egypt should consider the availability of brass and its compliance with local plumbing codes and standards.

Summary Table of Material Selection for uni t price

| Material | Typical Use Case for uni t price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, marine applications | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Carbon Steel | Structural components | Cost-effective | Susceptible to rust | Low |

| Plastic | Food and beverage industry | Lightweight and corrosion-resistant | Lower strength in high-pressure | Medium |

| Brass | Plumbing and electrical fittings | Good machinability and aesthetics | Higher cost than carbon steel | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for uni t price

What Are the Main Stages of Manufacturing Processes for uni t price?

The manufacturing process for uni t price typically consists of four main stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final product meets both quality standards and customer specifications.

-

Material Preparation: This initial stage involves selecting high-quality raw materials that comply with international standards. Suppliers often utilize advanced technologies such as CNC (Computer Numerical Control) machining to ensure precision. For B2B buyers, understanding the material sourcing process is vital, as it directly impacts product quality and durability.

-

Forming: In this stage, raw materials are shaped into the desired form using various techniques, including stamping, molding, and extrusion. Each method has its advantages and is chosen based on the product specifications. Buyers should inquire about the specific forming techniques used by suppliers, as this can influence both the unit price and product performance.

-

Assembly: After forming, components are assembled into the final product. This stage may involve manual labor or automated systems. For B2B buyers, it is important to understand the balance between automation and skilled labor, as it affects both production efficiency and quality control.

-

Finishing: The final stage includes processes such as coating, painting, or polishing to enhance the aesthetic and functional properties of the product. Quality assurance at this stage ensures that the finished product meets the required specifications. Buyers should ask suppliers about their finishing techniques to ensure alignment with their quality expectations.

How Do Quality Assurance Practices Impact uni t price?

Quality assurance (QA) is integral to the manufacturing process and directly influences the unit price. Implementing robust QA practices can reduce defects, minimize waste, and enhance customer satisfaction, ultimately leading to cost savings for both manufacturers and buyers.

What Are the Relevant International Standards for Quality Control?

For B2B buyers, understanding relevant international standards is essential. ISO 9001 is one of the most widely recognized quality management standards, focusing on meeting customer and regulatory requirements. Compliance with ISO 9001 indicates that a supplier has a systematic approach to managing their processes, which helps ensure product quality.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe and API standards for the oil and gas industry are critical. These certifications provide assurance that products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, typically categorized into three main stages:

-

Incoming Quality Control (IQC): This is the first checkpoint, where raw materials and components are inspected upon arrival. Ensuring that incoming materials meet specified quality criteria is crucial for preventing defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards. This stage is vital for maintaining consistent quality and minimizing waste.

-

Final Quality Control (FQC): The final inspection occurs before products are shipped to customers. This stage ensures that all products meet the necessary quality standards and specifications. Buyers should request FQC reports to verify compliance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to conduct thorough due diligence when selecting suppliers to ensure that quality control practices are up to par. Here are several actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and evaluate the effectiveness of their quality management systems.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including IQC, IPQC, and FQC documentation. These reports offer transparency and can help buyers make informed decisions based on a supplier’s historical performance.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can validate the supplier’s claims and provide assurance regarding product quality before shipment.

What Are the Common Testing Methods Used in Quality Control?

Testing methods play a crucial role in quality assurance and can vary based on the type of product being manufactured. Some common testing methods include:

-

Visual Inspection: This basic method involves examining products for obvious defects, such as surface imperfections or dimensional inaccuracies.

-

Functional Testing: Products are tested under simulated operational conditions to ensure they perform as intended. This is particularly important for technical components and machinery.

-

Destructive Testing: While not applicable for every product, destructive testing involves testing a sample until failure to determine material strength and durability. This method is often used in industries such as aerospace and automotive.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, magnetic particle testing, and X-ray inspection allow for thorough examinations without damaging the product. NDT is essential for critical applications where safety and reliability are paramount.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regional Regulations: Different regions have varying regulatory requirements. For instance, products sold in the European Union must comply with CE marking regulations, while products entering the U.S. market may require compliance with ANSI or ASTM standards. Buyers should familiarize themselves with these regulations to avoid costly compliance issues.

-

Cultural Considerations: Understanding cultural attitudes towards quality and manufacturing can aid in establishing effective partnerships. Buyers should consider how local practices may influence supplier quality control processes.

-

Communication and Documentation: Clear communication regarding quality expectations and documentation is essential. Buyers should ensure that suppliers provide detailed documentation of quality processes and certifications to facilitate smooth transactions.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance practices is vital for B2B buyers. By focusing on these areas, buyers can make informed decisions that not only ensure product quality but also optimize their supply chain efficiency and cost-effectiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘uni t price’

Introduction

Sourcing products at a competitive unit price is essential for B2B buyers looking to maximize their profit margins while maintaining quality. This step-by-step checklist will guide you through the critical actions necessary for effective procurement. By following these steps, you can ensure that you are making informed decisions that align with your business goals, especially in the diverse markets of Africa, South America, the Middle East, and Europe.

Step 1: Identify Your Budget and Cost Constraints

Establishing a clear budget is the first step in your sourcing journey. Knowing how much you can afford to spend on unit price will guide your supplier selection and negotiation processes. Consider factors like shipping, taxes, and potential tariffs that could affect the final cost.

- Tip: Set aside a percentage of your budget for unexpected costs to avoid financial strain later.

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, it’s vital to outline your product specifications. This includes dimensions, materials, compliance standards, and any unique features that your product must have. A well-defined specification helps to ensure that you receive accurate quotes and suitable products.

- Tip: Create a detailed document that can be shared with potential suppliers to minimize misunderstandings.

Step 3: Research Potential Suppliers

Conduct thorough research to identify suppliers that can meet your specifications and budget. Utilize platforms such as trade directories, industry forums, and recommendations from peers. Look for suppliers with a proven track record in your industry and region.

- Tip: Pay attention to suppliers who have experience exporting to your market, as they will be more familiar with local regulations and logistics.

Step 4: Evaluate Supplier Certifications and Compliance

Confirm that your potential suppliers hold the necessary certifications relevant to your product and industry. This is particularly important for sectors like electronics or pharmaceuticals, where compliance with international standards is critical.

- Tip: Request documentation proving compliance with quality standards, such as ISO certifications, to ensure reliability.

Step 5: Request and Analyze Quotes

Once you’ve shortlisted suppliers, request detailed quotes. Ensure that these quotes outline the unit price, payment terms, lead times, and any additional costs. Comparing multiple quotes will help you identify the best deal while considering quality.

- Tip: Look beyond the unit price; analyze the overall value, including service levels and supplier reliability.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with your selected suppliers to secure favorable terms. Discuss not only the unit price but also payment terms, delivery schedules, and warranties. Effective negotiation can lead to significant savings and improved supplier relationships.

- Tip: Be prepared to walk away if the terms do not align with your business needs; this will strengthen your negotiating position.

Step 7: Conduct a Trial Order

Before placing a large order, consider conducting a trial purchase. This allows you to assess the product quality, supplier responsiveness, and shipping efficiency. A trial order can help identify any issues before you commit to larger quantities.

- Tip: Use this opportunity to evaluate the supplier’s customer service and communication, which are crucial for long-term partnerships.

By following this checklist, international B2B buyers can navigate the complexities of sourcing unit price effectively, ensuring that they make informed decisions that contribute to their business success.

Comprehensive Cost and Pricing Analysis for uni t price Sourcing

What Are the Key Cost Components in ‘uni t price’ Sourcing?

When sourcing products priced at a ‘uni t price’, understanding the various cost components is crucial for international B2B buyers. The primary cost components include:

- Materials: The type and quality of materials significantly impact the overall cost. For instance, sourcing high-grade materials may increase the unit price but can lead to better performance and longevity.

- Labor: Labor costs vary widely across regions. In countries with lower labor costs, manufacturers can offer more competitive pricing. However, quality should not be compromised, so consider the skill level of the workforce involved.

- Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Understanding how these costs are calculated can help buyers negotiate better terms.

- Tooling Costs: Custom tooling can add significant costs to the initial order but may be necessary for specialized products. Always assess whether the tooling investment aligns with your projected volume and long-term needs.

- Quality Control (QC): Implementing stringent QC measures may incur additional costs. However, ensuring product quality can mitigate long-term risks and warranty claims, making this a worthwhile investment.

- Logistics: Transportation and shipping costs can fluctuate based on distance, mode of transport, and current fuel prices. Consider all logistics factors, including potential tariffs and customs duties, which can add to the total cost.

- Margin: Suppliers often have different pricing structures based on their desired profit margins. Understanding these margins can provide leverage during negotiations.

How Do Price Influencers Affect ‘uni t price’ Sourcing?

Several factors influence the pricing of ‘uni t price’ products, which can vary significantly based on the buyer’s requirements and market conditions:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, making it essential to evaluate your purchasing strategy. If feasible, consolidate orders to reach higher volumes and negotiate better unit prices.

- Specifications and Customization: Custom products typically come with higher costs due to the additional labor and materials involved. Clearly define specifications upfront to avoid unexpected cost increases later.

- Material Selection: The choice of materials can drastically alter the unit price. More sustainable or specialized materials may be pricier, but they can also command a higher resale value.

- Quality and Certifications: Products with certifications (e.g., ISO, CE) often carry a premium price. Ensure that the certifications align with your market’s regulatory requirements to avoid future compliance issues.

- Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may charge more but can offer better quality assurance and timely delivery.

- Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is vital. They define responsibilities for shipping, insurance, and tariffs, impacting overall costs.

What Are the Best Negotiation Tips for International B2B Buyers?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some actionable tips:

- Research Market Prices: Having a clear understanding of market pricing for similar products allows you to negotiate from a position of knowledge.

- Leverage Total Cost of Ownership (TCO): Focus on the long-term costs associated with a product, including maintenance and replacement, rather than just the initial purchase price. This approach can justify a higher upfront cost if the product offers superior quality and lower long-term expenses.

- Be Transparent About Expectations: Clear communication about your needs and expectations can foster trust and lead to more favorable pricing arrangements.

- Consider Payment Terms: Flexible payment terms can enhance cash flow and make higher unit prices more manageable. Discuss potential payment plans during negotiations.

- Establish Long-term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms over time as they come to understand your business needs.

Disclaimer on Indicative Prices

It is essential to note that the prices discussed in this analysis are indicative and can fluctuate based on various market conditions, supplier negotiations, and regional economic factors. Always conduct thorough due diligence and obtain multiple quotes before finalizing any agreements.

Alternatives Analysis: Comparing uni t price With Other Solutions

A stock image related to uni t price.

Understanding the Importance of Alternative Solutions in B2B Pricing Strategies

In the competitive landscape of international B2B transactions, understanding the alternatives to ‘uni t price’ is crucial for making informed purchasing decisions. Buyers from regions such as Africa, South America, the Middle East, and Europe must evaluate various pricing strategies and solutions that can optimize their operations and enhance profitability. This section explores how ‘uni t price’ measures up against other viable alternatives, providing a comprehensive analysis that highlights key aspects of each option.

Comparison Table of ‘Uni T Price’ Against Alternative Solutions

| Comparison Aspect | Uni T Price | Cost-Plus Pricing | Value-Based Pricing |

|---|---|---|---|

| Performance | Predictable costs | Variable profit margins | High customer satisfaction |

| Cost | Fixed per unit | Variable; depends on costs | Premium pricing possible |

| Ease of Implementation | Straightforward | Moderate complexity | High complexity due to market research |

| Maintenance | Low maintenance | Requires ongoing cost tracking | Needs continuous value assessment |

| Best Use Case | Bulk purchasing | Manufacturing sectors | Service-based industries |

What Are the Pros and Cons of Cost-Plus Pricing?

Cost-plus pricing is a traditional method where a fixed percentage is added to the total cost of production to determine the selling price.

Pros:

– Simplicity: This approach is easy to calculate, making it a popular choice for manufacturers and suppliers.

– Predictability: It allows businesses to maintain consistent profit margins.

Cons:

– Inflexibility: It does not account for market demand or customer perception, which can lead to overpricing or underpricing.

– Profit Margin Variability: Fluctuating costs can result in inconsistent profit margins, impacting financial forecasting.

How Does Value-Based Pricing Compare?

Value-based pricing sets prices primarily based on the perceived value to the customer rather than the cost of the product or service.

Pros:

– Customer-Centric: This method aligns prices with what customers are willing to pay, potentially maximizing revenue.

– Competitive Advantage: It can differentiate a business in a crowded market, especially for service-oriented sectors.

Cons:

– Complex Implementation: Requires thorough market research and customer insights, which can be resource-intensive.

– Continuous Adjustment: Pricing may need frequent recalibration based on changing customer perceptions and market conditions.

How Should B2B Buyers Choose the Right Pricing Solution?

When selecting the right pricing strategy, B2B buyers must consider their specific business goals, market conditions, and customer demographics. ‘Uni t price’ may be ideal for companies focused on large-volume sales and predictable costs, while cost-plus pricing might suit those in manufacturing with stable production costs. Conversely, value-based pricing can be advantageous for businesses that prioritize customer satisfaction and competitive differentiation.

Ultimately, the choice between these pricing methods should reflect not only the internal operational capabilities but also the external market dynamics. By thoroughly evaluating each option’s performance, cost implications, ease of implementation, maintenance needs, and best use cases, international B2B buyers can make strategic decisions that enhance their market position and profitability.

Essential Technical Properties and Trade Terminology for uni t price

What Are the Key Technical Properties That Affect Unit Price?

Understanding the essential technical properties of products can significantly influence unit pricing decisions for international B2B buyers. Here are several critical specifications to consider:

-

Material Grade

– Material grade refers to the quality and characteristics of the material used in the product. Different grades can affect durability, performance, and, ultimately, the unit price. For instance, high-grade materials often come at a premium but offer better longevity and reliability, which can be crucial for industries like construction and manufacturing. -

Tolerance

– Tolerance indicates the allowable variation in dimensions or properties of a product. In manufacturing, tighter tolerances usually mean higher precision, which can drive up costs. Understanding the necessary tolerances for your application can help you negotiate better unit prices, ensuring you are not overpaying for unnecessary precision. -

Finish Quality

– The finish quality of a product pertains to the surface treatment and appearance, which can influence both aesthetics and functionality. Products with higher finish quality may have enhanced performance characteristics, such as corrosion resistance or reduced friction. Buyers must evaluate whether the finish quality aligns with their needs and budgets. -

Weight and Size Specifications

– The weight and size of products can impact shipping costs and logistics. Heavier and bulkier items typically incur higher transportation expenses, which can affect the overall unit price. B2B buyers should consider these factors when calculating the total cost of ownership. -

Compliance Standards

– Compliance with industry standards and regulations can significantly influence unit pricing. Products that meet specific certifications may command higher prices but can also reduce liabilities and increase marketability. Buyers should ensure that their suppliers provide documentation verifying compliance with relevant standards.

What Are Common Trade Terms That Impact Unit Price Negotiations?

Familiarizing yourself with industry jargon can enhance your negotiation skills and improve your understanding of pricing structures. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify potential cost savings and leverage better pricing agreements by sourcing directly from the manufacturer. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQs can help buyers plan their purchases more effectively, especially when managing inventory. By negotiating MOQs, buyers can potentially lower unit costs or align orders with budget constraints. -

RFQ (Request for Quotation)

– An RFQ is a document that solicits price quotes from suppliers for specific products or services. Using RFQs allows buyers to compare multiple offers, making it easier to identify the best unit price and terms. Crafting a clear and detailed RFQ can lead to more accurate and competitive quotes. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for determining who bears the costs and risks during shipping. Proper knowledge of Incoterms can help buyers negotiate better deals and avoid unexpected expenses. -

Lead Time

– Lead time is the time taken from placing an order to delivery. It can vary significantly based on supplier capabilities and logistics. Buyers should factor lead times into their pricing analysis, as longer lead times may necessitate higher inventory levels, impacting overall costs.

By grasping these technical properties and trade terms, international B2B buyers can make more informed purchasing decisions, negotiate better unit prices, and ultimately optimize their supply chain strategies.

Navigating Market Dynamics and Sourcing Trends in the uni t price Sector

What are the Current Market Dynamics and Key Trends Influencing the Unit Price Sector?

The unit price sector is currently witnessing significant transformations driven by globalization, technological advancements, and shifting consumer preferences. One of the foremost global drivers is the increasing demand for transparency in pricing and sourcing, particularly from international buyers in Africa, South America, the Middle East, and Europe. Buyers are now more inclined to seek out suppliers who offer competitive pricing structures while ensuring quality and reliability.

Emerging B2B technologies, such as artificial intelligence and blockchain, are revolutionizing sourcing strategies. AI algorithms enable businesses to forecast demand more accurately, allowing for optimized inventory management, which is crucial in maintaining favorable unit prices. Meanwhile, blockchain technology enhances supply chain transparency, ensuring that international buyers can trace the origins of materials and verify the authenticity of suppliers.

Market dynamics are also influenced by regional economic conditions. For instance, fluctuating currency values can affect pricing strategies, necessitating a keen understanding of foreign exchange risks. Additionally, geopolitical factors, such as trade agreements and tariffs, play a critical role in shaping sourcing decisions. Buyers in regions like Europe and the Middle East must stay informed about these developments to capitalize on favorable sourcing opportunities.

How Does Sustainability and Ethical Sourcing Impact the Unit Price Sector?

Sustainability and ethical sourcing have become paramount in the unit price sector, reflecting broader societal shifts towards environmental stewardship and social responsibility. As international B2B buyers increasingly prioritize sustainability, suppliers are compelled to adopt environmentally friendly practices. This includes minimizing waste, reducing carbon footprints, and using renewable resources, which can directly influence unit prices.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now scrutinizing suppliers for compliance with labor laws and fair trade practices. Companies that can demonstrate their commitment to ethical sourcing often enjoy a competitive advantage, as they can justify premium pricing through enhanced brand reputation and customer loyalty.

Green certifications, such as ISO 14001 and Fair Trade, are becoming essential for suppliers aiming to attract conscientious buyers. These certifications not only validate a supplier’s sustainable practices but also provide an avenue for differentiation in a crowded marketplace. For B2B buyers, partnering with certified suppliers can lead to long-term cost savings and improved product quality, further influencing unit prices positively.

What is the Historical Evolution of the Unit Price Sector?

The unit price sector has evolved significantly over the decades, shaped by technological innovations and changing market demands. Historically, pricing strategies were often static and based on simple cost-plus models. However, as global trade expanded, especially in the late 20th century, businesses began adopting more dynamic pricing mechanisms to remain competitive.

The advent of digital technologies in the 21st century marked a pivotal shift. E-commerce platforms enabled real-time pricing adjustments, allowing suppliers to react swiftly to market fluctuations. This evolution has led to the current landscape where data-driven decision-making and advanced analytics play crucial roles in determining unit prices.

Understanding this historical context is vital for international B2B buyers. It highlights the importance of agility in sourcing strategies and the necessity to embrace technological advancements to navigate the complexities of today’s market effectively. As the sector continues to evolve, staying attuned to these changes will be essential for sustaining competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of uni t price

-

How do I determine the best unit price for my business needs?

To find the optimal unit price, start by analyzing your specific requirements, including product specifications, volume needs, and delivery timelines. Compare quotes from multiple suppliers, taking note of additional costs like shipping, customs duties, and taxes. Utilize cost breakdowns to understand what influences pricing, and consider negotiating terms to align with your budget. Establishing long-term relationships with suppliers may also yield better pricing over time. -

What factors should I consider when evaluating international suppliers for unit pricing?

When vetting international suppliers, assess their reliability, quality standards, and production capabilities. Check for certifications that align with your industry’s regulations, and review customer testimonials for credibility. Consider the supplier’s geographical location, as this impacts shipping times and costs. It’s also prudent to evaluate their responsiveness and willingness to customize products to meet your specific needs. -

What is the minimum order quantity (MOQ) and how does it affect pricing?

Minimum order quantity (MOQ) is the smallest amount a supplier is willing to sell per order. MOQs can significantly affect unit pricing; higher quantities often lead to lower unit prices due to economies of scale. However, purchasing below the MOQ might incur additional fees. Understanding MOQs helps you budget effectively and negotiate better terms, especially if your business has fluctuating demand. -

How can I negotiate better unit prices with suppliers?

To negotiate better unit prices, prepare by researching market rates and understanding your supplier’s cost structure. Be clear about your budget and volume needs, and express interest in long-term partnerships. Leverage competitive quotes from other suppliers to strengthen your position. Additionally, consider offering to pay upfront or committing to larger orders in exchange for lower unit prices. -

What payment terms should I expect when sourcing unit prices internationally?

Payment terms can vary widely among international suppliers. Common arrangements include payment in advance, partial payments, or payment upon delivery. It’s essential to clarify these terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, such as letters of credit or escrow services, especially when dealing with new suppliers. -

How can I ensure quality assurance when sourcing products internationally?

To ensure quality assurance, establish clear specifications and standards before placing orders. Request samples to evaluate quality firsthand, and consider third-party inspections during production and before shipment. Building strong communication with suppliers can also facilitate adherence to quality standards. Always review quality control processes and certifications to ensure they align with your expectations. -

What are the logistics considerations for sourcing unit prices from different countries?

Logistics play a crucial role in international sourcing. Evaluate shipping methods, transit times, and costs, as these will impact your overall pricing. Factor in customs regulations and potential tariffs that may apply to your products. Working with a reliable freight forwarder can simplify the logistics process, ensuring timely delivery while navigating complex international trade regulations. -

How do currency fluctuations affect unit pricing in international trade?

Currency fluctuations can significantly impact unit pricing in international trade. When sourcing from foreign suppliers, changes in exchange rates can either increase or decrease the final cost of products. To mitigate risks, consider pricing contracts in your local currency or utilizing hedging strategies. Staying informed about economic conditions in the supplier’s country can also help you anticipate potential price changes due to currency fluctuations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for uni t price

The importance of strategic sourcing in optimizing unit prices cannot be overstated, especially for international B2B buyers navigating complex markets in Africa, South America, the Middle East, and Europe. By adopting a data-driven approach, businesses can effectively analyze supplier performance, forecast pricing trends, and negotiate better terms that align with their long-term objectives.

What are the key takeaways for international B2B buyers regarding unit price? First, understanding the regional market dynamics is crucial; factors such as local demand, currency fluctuations, and geopolitical influences can significantly impact pricing strategies. Secondly, building strong relationships with suppliers fosters collaboration and transparency, allowing for more favorable pricing agreements and improved supply chain resilience.

Looking ahead, the landscape of unit pricing will continue to evolve with advancements in technology and data analytics. Buyers are encouraged to leverage these tools to enhance their sourcing strategies and remain competitive. As you prepare for future procurement cycles, consider how strategic sourcing can not only lower costs but also add value through innovation and sustainability. Embrace this opportunity to refine your approach and secure a competitive edge in your industry.