Discover Noodle XXX: The Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for noodle xxx

In today’s competitive landscape, sourcing the right noodle products can be a daunting challenge for international B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the intricacies of the global noodle market—ranging from product varieties to their myriad applications—is crucial for making informed purchasing decisions. This comprehensive guide on noodle xxx will equip buyers with the essential knowledge needed to navigate this complex market, ensuring that they not only find quality products but also secure favorable terms with suppliers.

Throughout this guide, we will explore various types of noodle xxx, including their unique characteristics and applications in different culinary contexts. Additionally, we will provide actionable insights on how to effectively vet suppliers, assess pricing strategies, and understand the logistics involved in international shipping. By addressing these key components, we aim to empower B2B buyers to make strategic decisions that enhance their operations and drive profitability.

Whether you are sourcing ingredients for a restaurant chain in Argentina or importing specialty noodles for a food manufacturer in the Middle East, this guide will serve as your go-to resource. With a focus on practical solutions tailored to the needs of international buyers, we invite you to delve into the world of noodle xxx and unlock the potential for your business in the global marketplace.

Understanding noodle xxx Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rice Noodles | Made from rice flour, gluten-free, soft texture | Asian cuisine, gluten-free products | Pros: Versatile, healthy; Cons: Limited shelf life |

| Egg Noodles | Contains eggs, rich flavor, firm texture | Pasta dishes, Asian stir-fries | Pros: Flavorful, widely accepted; Cons: Contains gluten |

| Soba Noodles | Buckwheat-based, nutty flavor, high in protein | Health foods, gourmet dishes | Pros: Nutrient-dense, gluten-free options; Cons: More expensive |

| Udon Noodles | Thick, chewy, wheat-based, often served in broth | Soups, stir-fries, traditional dishes | Pros: Filling, versatile; Cons: Requires longer cooking time |

| Glass Noodles | Made from mung bean starch, translucent, chewy texture | Salads, soups, and Asian cuisine | Pros: Low-calorie, gluten-free; Cons: Can be fragile |

What Are the Key Characteristics of Rice Noodles?

Rice noodles are primarily made from rice flour, making them an excellent choice for gluten-free diets. Their soft texture allows them to absorb flavors well, making them suitable for a variety of dishes, particularly in Asian cuisine. B2B buyers should consider their applications in noodle dishes, salads, and stir-fries. While they offer versatility and health benefits, their limited shelf life means buyers must manage inventory carefully to avoid waste.

How Do Egg Noodles Stand Out in Flavor and Texture?

Egg noodles are distinguished by their inclusion of eggs, resulting in a rich flavor and firm texture. They are popular in both traditional Asian dishes and Western pasta recipes, making them a versatile ingredient for B2B buyers. When purchasing, consider the demand for both fresh and dried varieties, as they cater to different culinary needs. Although egg noodles are widely accepted, they do contain gluten, which may limit their market in gluten-sensitive regions.

What Nutritional Benefits Do Soba Noodles Offer?

Soba noodles, made from buckwheat, are known for their nutty flavor and high protein content. They are increasingly popular in health-conscious markets, making them a valuable option for B2B buyers focused on gourmet and health food segments. When sourcing soba noodles, consider the balance between quality and cost, as premium brands can be more expensive. Their gluten-free nature also opens up opportunities in health-focused markets, although they may not be as widely recognized as other noodle types.

Why Are Udon Noodles Preferred in Traditional Dishes?

Udon noodles are thick and chewy, typically made from wheat flour. Their hearty texture makes them ideal for soups and stir-fries, particularly in traditional Japanese cuisine. B2B buyers should consider the preparation time required for udon, as they often need longer cooking periods. While they are filling and versatile, the wheat content may limit their appeal in gluten-free markets, so it is essential to assess regional dietary preferences when sourcing.

What Are the Unique Features of Glass Noodles?

Glass noodles, made from mung bean starch, are translucent and have a chewy texture. They are low in calories and gluten-free, making them a popular choice in salads and soups. For B2B buyers, the appeal of glass noodles lies in their versatility and suitability for various diets. However, their fragile nature means they require careful handling during transport and storage. Buyers should also be aware of the potential for breakage, which can impact product quality upon delivery.

Related Video: Introduction to Calculus of Variations

Key Industrial Applications of noodle xxx

| Industry/Sector | Specific Application of noodle xxx | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Manufacturing | Ingredient in processed foods | Enhances product diversity and consumer appeal | Consistency in quality, compliance with food safety standards, and availability of bulk supply. |

| Hospitality & Catering | Menu item in restaurants and cafes | Boosts customer satisfaction and repeat business | Sourcing from reliable suppliers, ensuring freshness, and considering regional preferences. |

| Retail | Shelf-stable packaged goods | Extends product shelf life and reduces waste | Packaging options, shelf life duration, and alignment with consumer trends. |

| Export & Import | Exporting local noodle products | Access to new markets and increased revenue | Understanding of international regulations, tariffs, and logistics for smooth export processes. |

| Nutraceuticals | Ingredient in health-focused products | Meets growing demand for healthy eating options | Sourcing high-quality ingredients, certifications for health claims, and alignment with dietary trends. |

How is Noodle XXX Used in Food Manufacturing?

In the food manufacturing sector, noodle xxx serves as a versatile ingredient in various processed foods, such as ready-to-eat meals and snack products. It addresses the need for convenient meal solutions while enhancing the nutritional profile of products. International B2B buyers must prioritize sourcing from suppliers that ensure consistent quality and compliance with food safety standards, especially when targeting markets with strict regulations.

What Role Does Noodle XXX Play in Hospitality & Catering?

In the hospitality and catering industry, noodle xxx is a popular menu item that adds variety to culinary offerings. Its ability to cater to diverse dietary preferences can lead to increased customer satisfaction and repeat business. For B2B buyers in this sector, it is essential to source from reliable suppliers who can guarantee freshness and adapt to regional flavor profiles, ensuring the end product resonates with local clientele.

How Does Noodle XXX Benefit Retail?

In retail, noodle xxx is often found in shelf-stable packaged goods, providing consumers with convenient meal options. This application extends product shelf life, reducing waste and increasing profitability for retailers. Buyers should consider packaging options that enhance shelf appeal and ensure a longer shelf life, while also aligning with current consumer trends towards convenience and health.

Why is Noodle XXX Important for Export & Import?

Noodle xxx has significant potential for export, allowing local producers to access international markets and increase revenue. This application can be particularly lucrative for businesses in Africa, South America, and the Middle East looking to diversify their offerings. Key considerations for B2B buyers include understanding international regulations, tariffs, and logistics to facilitate smooth export processes and avoid delays.

How is Noodle XXX Integrated into Nutraceuticals?

In the nutraceuticals sector, noodle xxx is increasingly used as an ingredient in health-focused products, catering to the rising demand for healthier food options. This application solves the challenge of incorporating functional ingredients into everyday diets. Buyers in this space should focus on sourcing high-quality ingredients that meet necessary certifications for health claims, ensuring that they align with current dietary trends and consumer preferences.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘noodle xxx’ & Their Solutions

Scenario 1: Sourcing Quality Noodle Products in Emerging Markets

The Problem:

International B2B buyers often struggle with sourcing high-quality noodle products in emerging markets like Africa and South America. Many suppliers may not meet international quality standards or may lack consistent product availability. This can lead to supply chain disruptions, affecting business operations and customer satisfaction. Buyers may also face challenges in verifying the credibility of suppliers, resulting in potential losses from subpar products.

The Solution:

To overcome this sourcing challenge, B2B buyers should engage in comprehensive supplier vetting processes. This includes visiting production facilities when possible, requesting third-party quality certifications, and seeking references from other international buyers. Establishing long-term relationships with trusted local distributors can also ensure more reliable access to quality noodle products. Additionally, participating in regional trade fairs can provide valuable networking opportunities to connect with reputable suppliers who understand local market dynamics while adhering to international standards.

Scenario 2: Adapting Noodle Products for Local Palates

The Problem:

Another common pain point is the need to adapt noodle products to meet local tastes and preferences. B2B buyers in regions such as the Middle East and Europe may find that imported noodles do not align with regional culinary traditions or dietary requirements, which can lead to poor sales and customer dissatisfaction. This mismatch can be especially pronounced in multicultural markets where flavor profiles vary significantly.

The Solution:

To effectively adapt noodle products, buyers should conduct thorough market research to understand local consumer preferences and dietary restrictions. Collaborating with local chefs or culinary consultants can help in creating custom noodle recipes that resonate with the target audience. Offering a range of noodle types—such as gluten-free or whole grain—can also cater to diverse dietary needs. Additionally, leveraging social media and local tasting events can provide direct feedback from consumers, allowing for ongoing product adjustments that enhance market fit and increase sales.

Scenario 3: Navigating Import Regulations and Compliance

The Problem:

B2B buyers often encounter complex import regulations and compliance issues when bringing noodle products into their countries. This is particularly challenging for buyers in regions with stringent food safety laws, such as Europe. Failure to comply with these regulations can lead to costly fines, delays, or even the rejection of shipments, severely impacting business operations.

The Solution:

To effectively navigate import regulations, buyers should invest time in understanding the specific food safety and import requirements of their destination markets. This includes staying updated on any changes to regulations and collaborating with customs brokers who specialize in food imports. Buyers should also establish relationships with suppliers who can provide necessary documentation, such as health certificates and ingredient transparency reports. Utilizing technology, such as compliance management software, can streamline the process of tracking regulatory changes and maintaining documentation, ultimately reducing the risk of delays and ensuring smooth importation of noodle products.

Strategic Material Selection Guide for noodle xxx

What Are the Key Materials for Noodle Production?

In the production of noodle xxx, the selection of materials is critical for ensuring product quality, performance, and compliance with international standards. Below, we analyze four common materials used in noodle manufacturing, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Wheat Flour Impact Noodle Quality?

Key Properties: Wheat flour is primarily composed of starches and proteins, which are essential for noodle texture and elasticity. The gluten content in wheat flour significantly influences the noodle’s ability to withstand cooking and maintain its shape.

Pros & Cons: Wheat flour is widely available and cost-effective, making it a popular choice among manufacturers. However, its reliance on specific climate conditions for cultivation can lead to supply chain vulnerabilities. Additionally, variations in gluten content can affect the final product’s quality, necessitating careful sourcing.

Impact on Application: Wheat flour is suitable for various noodle types, including ramen and udon, due to its excellent cooking properties. However, its gluten content may not be suitable for gluten-free applications, which are increasingly demanded in international markets.

Considerations for International Buyers: Buyers must ensure compliance with local regulations regarding gluten labeling and food safety standards. In regions like Europe and South America, adherence to specific agricultural standards (e.g., EU regulations) is crucial.

What Role Does Rice Flour Play in Noodle Production?

Key Properties: Rice flour is gluten-free and has a fine texture, making it ideal for producing noodles that are light and chewy. It has a lower protein content compared to wheat flour, which affects the noodle’s structure.

Pros & Cons: The primary advantage of rice flour is its suitability for gluten-free products, catering to a growing market segment. However, it can be more expensive than wheat flour and may require additional binding agents to achieve the desired texture.

Impact on Application: Rice flour is commonly used in Asian noodle varieties such as rice vermicelli and pho. Its unique properties allow for quick cooking and absorption of flavors, making it a favorite among consumers.

Considerations for International Buyers: When sourcing rice flour, buyers should be aware of quality certifications and compliance with local food safety regulations. In regions like Africa and the Middle East, sourcing from reputable suppliers is essential to ensure product integrity.

How Does Tapioca Starch Enhance Noodle Texture?

Key Properties: Tapioca starch is derived from cassava and is known for its high viscosity and ability to create a chewy texture. It is often used in combination with other flours to enhance the overall noodle quality.

Pros & Cons: The key advantage of tapioca starch is its ability to improve the elasticity and mouthfeel of noodles. However, it can be more expensive than traditional flours and may complicate the manufacturing process due to its unique handling requirements.

Impact on Application: Tapioca starch is particularly beneficial in producing gluten-free noodles, providing a desirable texture that appeals to consumers. Its compatibility with various flavors makes it versatile for different noodle dishes.

Considerations for International Buyers: Buyers should consider the sourcing of tapioca starch, ensuring it meets local quality standards. In regions like South America, where cassava is widely cultivated, local sourcing can reduce costs and improve supply chain reliability.

What Are the Benefits of Using Egg in Noodle Production?

Key Properties: Eggs add richness and color to noodles, contributing to a firmer texture and enhanced flavor. The proteins in eggs also aid in binding the ingredients together.

Pros & Cons: The inclusion of eggs can elevate the quality of noodles, making them more appealing to consumers. However, the cost of eggs can be a significant factor, and their shelf life is shorter compared to dry ingredients.

Impact on Application: Egg noodles are popular in various cuisines, particularly in Europe and Asia, where they are valued for their unique taste and texture. They are often used in dishes that require a more substantial noodle.

Considerations for International Buyers: Buyers must ensure that egg sourcing complies with animal welfare standards and food safety regulations, which vary by region. In Europe, for instance, there are strict regulations regarding the use of eggs in food products.

Summary Table of Material Selection for Noodle xxx

| Material | Typical Use Case for noodle xxx | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wheat Flour | Ramen, Udon | Cost-effective and widely available | Gluten variability affects quality | Low |

| Rice Flour | Rice Vermicelli, Pho | Gluten-free and light texture | Higher cost and binding requirements | Medium |

| Tapioca Starch | Gluten-free noodles | Improves elasticity and mouthfeel | More expensive and complex handling | High |

| Egg | Egg noodles | Enhances flavor and texture | Higher cost and shorter shelf life | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for noodle xxx

What Are the Key Manufacturing Processes for Noodle Production?

The production of noodles involves a series of well-defined stages that ensure quality and consistency. Understanding these stages is crucial for B2B buyers looking to source noodles from international suppliers.

Material Preparation: How Are Ingredients Selected?

The first step in noodle manufacturing is the selection and preparation of raw materials. Typically, wheat flour is the primary ingredient, often supplemented by water, salt, and sometimes additives like eggs or starches, depending on the type of noodle being produced. Buyers should look for suppliers who source high-quality grains, as this significantly impacts the texture and taste of the final product.

Additionally, it’s important to inquire about the suppliers’ sourcing practices. For example, do they use organic or non-GMO ingredients? Understanding the supply chain can provide insights into the quality of the noodles.

How Is Noodle Forming Achieved?

Once the ingredients are prepared, the next step is forming the noodles. This process varies by noodle type. For instance, extruded noodles are produced using a method that forces dough through a die, creating the desired shape. Conversely, hand-pulled noodles involve skilled artisans stretching and folding the dough, which can lead to unique textures.

B2B buyers should assess the production methods used by suppliers. Automated processes may offer consistency, while traditional methods might appeal to markets seeking authentic products. The choice of forming technique can influence the product’s price point and marketability.

What Does the Assembly Stage Entail?

In the assembly phase, different noodle types may undergo various additional processes, such as cutting, shaping, or layering. For instance, lasagna noodles require specific cutting techniques to ensure even layers.

Buyers should verify whether suppliers employ standardized techniques during this stage to maintain uniformity. Consistent product dimensions are essential for packaging and cooking performance, which can impact customer satisfaction.

How Is the Finishing Process Conducted?

The finishing process often includes drying, cooling, and packaging the noodles. This stage is critical for preserving the product’s quality and extending shelf life. Buyers should look for suppliers who use advanced drying technologies to minimize nutrient loss and enhance flavor.

Moreover, effective packaging is essential for maintaining freshness during transportation. Investigating the packaging methods used by suppliers can provide valuable insights into their commitment to quality assurance.

What Quality Control Measures Are Essential for Noodle Manufacturing?

Quality control (QC) is a vital aspect of noodle production that ensures the final product meets international standards and customer expectations.

What International Standards Should B2B Buyers Consider?

When sourcing noodles, it is crucial to consider suppliers who adhere to recognized international standards, such as ISO 9001. This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the noodle type and intended market. Buyers should request documentation to verify that suppliers comply with these standards.

What Are the Key QC Checkpoints in Noodle Production?

Quality control in noodle manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This stage inspects raw materials upon arrival to ensure they meet specified quality standards. Buyers should inquire about the suppliers’ IQC processes and criteria for acceptance.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify and rectify any deviations from quality standards. Understanding the frequency and methods of IPQC can give buyers confidence in the production process.

-

Final Quality Control (FQC): Before packaging, a final inspection ensures that the noodles meet the required specifications. Buyers should ask for reports detailing FQC procedures and any testing methods employed.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods in noodle production include:

-

Physical Testing: This may involve assessing the texture, color, and moisture content of the noodles.

-

Chemical Testing: Suppliers often conduct tests to check for contaminants or verify nutritional content.

-

Microbiological Testing: This ensures that the noodles are safe for consumption by checking for harmful bacteria or pathogens.

B2B buyers should request transparency about the testing methods used and ask for access to test results or certifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for mitigating risks and ensuring product reliability. Here are actionable steps for B2B buyers:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control practices. Buyers can:

-

Schedule On-Site Audits: Visiting the manufacturing facility allows buyers to assess the production processes firsthand.

-

Request Audit Reports: Suppliers should provide documentation of past audits conducted by third-party organizations.

How Can Buyers Leverage Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These services can conduct random inspections at various stages of production and provide detailed reports.

What Documentation Should Buyers Request for Quality Assurance?

Buyers should request comprehensive documentation, including:

-

Quality Assurance Manuals: These documents outline the supplier’s quality management systems and procedures.

-

Certificates of Compliance: These certificates verify that the products meet relevant quality standards.

-

Test Reports: Access to recent test results can provide insights into the consistency and safety of the products.

What Are the QC Nuances for International B2B Buyers?

Navigating quality control in international trade can be complex. B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider the following nuances:

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations regarding food safety and quality. Buyers should familiarize themselves with the local regulations in their target markets and ensure that suppliers meet these requirements.

What Should Buyers Know About Cultural Expectations in Quality Control?

Cultural differences can influence perceptions of quality and safety. For instance, buyers from Europe may have higher expectations regarding traceability and sustainability compared to other regions. Understanding these cultural nuances can aid in selecting the right suppliers and negotiating terms.

By comprehensively understanding the manufacturing processes and quality assurance measures in noodle production, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘noodle xxx’

In the dynamic world of international trade, sourcing ‘noodle xxx’ requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This guide outlines a practical checklist that B2B buyers can use to streamline their sourcing process, particularly for markets in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Product Specifications

Before engaging with suppliers, it’s essential to clearly define the specifications of ‘noodle xxx’ you require. This includes dimensions, materials, and any special features. Having a detailed product description helps suppliers understand your needs and ensures that you receive products that meet your expectations.

- Consider regional preferences: Different markets may have unique tastes or requirements for ‘noodle xxx’.

- Quality standards: Specify any certifications or quality standards that the product must meet.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers for ‘noodle xxx’. Utilize platforms like Alibaba, Global Sources, or trade-specific directories to compile a list of potential candidates.

- Check for reviews and ratings: Look for feedback from other B2B buyers to gauge reliability and product quality.

- Consider geographical advantages: Suppliers closer to your market may reduce shipping costs and lead times.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your specifications and volume requirements. This evaluation should include production capacity, technology used, and experience in the industry.

- Request product samples: Always ask for samples to evaluate quality before making a larger commitment.

- Inquire about production processes: Understanding how ‘noodle xxx’ is made can provide insights into quality and sustainability practices.

Step 4: Verify Supplier Certifications

Before finalizing a supplier, it’s crucial to verify their certifications and compliance with industry standards. This step can help mitigate risks related to product safety and quality.

- Look for international standards: Certifications like ISO, HACCP, or local food safety standards should be prioritized.

- Request documentation: Ensure that suppliers can provide valid certification documents for your review.

Step 5: Negotiate Terms and Pricing

Once you’ve shortlisted potential suppliers, initiate negotiations to finalize terms, pricing, and payment methods. Clear and transparent negotiation can lead to better pricing and terms that benefit both parties.

- Discuss minimum order quantities (MOQs): Understanding MOQs can help you gauge initial investment and risk.

- Explore payment options: Consider options that provide security for both you and the supplier.

Step 6: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear plan for regular updates and check-ins with your supplier.

- Utilize digital tools: Tools like email, instant messaging, and video calls can enhance communication efficiency.

- Set expectations for response times: Agree on how quickly both parties will respond to inquiries or issues.

Step 7: Monitor Supplier Performance

After establishing a relationship, continuously monitor supplier performance against the agreed-upon terms. Regular evaluations will help you identify any issues early and maintain product quality.

- Implement a feedback system: Encourage open communication regarding any concerns with product quality or delivery times.

- Consider long-term partnerships: If a supplier consistently meets expectations, consider building a long-term relationship for better pricing and reliability.

By following these structured steps, B2B buyers can streamline their sourcing process for ‘noodle xxx’, ensuring they find reliable suppliers that meet their specific needs while minimizing risks associated with international procurement.

Comprehensive Cost and Pricing Analysis for noodle xxx Sourcing

What Are the Key Cost Components for Sourcing Noodle XXX?

When sourcing Noodle XXX, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of raw materials directly influence pricing. For Noodle XXX, this often includes flour, starch, and additives. Sourcing from regions with abundant raw materials can reduce costs significantly.

-

Labor: Labor costs can vary widely by region. Countries in Southeast Asia, for instance, often have lower labor costs compared to Europe. However, it’s important to consider labor quality and productivity, which can affect the overall cost.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Manufacturers with advanced technology may have higher initial costs but can offer better efficiency and product quality.

-

Tooling: For customized Noodle XXX products, tooling costs can be a significant factor. This includes molds and other production equipment that may need to be developed for specific orders.

-

Quality Control (QC): Investing in stringent QC processes ensures product consistency and safety, particularly important for food products. While it may increase upfront costs, it can prevent costly recalls and enhance brand reputation.

-

Logistics: Transportation and warehousing costs should be factored into the total cost. Different shipping methods (air vs. sea) can have varying impacts on pricing and delivery timelines.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on competition and market demand. Understanding typical margins in your target market can help in negotiations.

How Do Price Influencers Affect Noodle XXX Sourcing?

Several factors can influence the pricing of Noodle XXX, making it crucial for buyers to understand these elements:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs. Negotiating MOQs is essential, especially for smaller businesses looking to enter the market.

-

Specifications and Customization: Customization options can significantly affect pricing. Tailored products may come with higher costs due to additional production steps.

-

Materials and Quality Certifications: The choice of materials and obtaining quality certifications (like ISO or HACCP) can increase costs but also enhance product credibility in international markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more, but they often provide better quality and reliability.

-

Incoterms: Understanding Incoterms is vital for pricing. Terms like FOB (Free on Board) or CIF (Cost Insurance and Freight) can affect the final cost and risk allocation between buyer and seller.

What Are Effective Buyer Tips for Cost-Efficiency in Noodle XXX Sourcing?

To maximize cost-efficiency when sourcing Noodle XXX, consider the following strategies:

-

Negotiate Effectively: Leverage your purchasing power. Build relationships with suppliers to foster better negotiation outcomes. Always ask for discounts on bulk orders or longer-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, storage, and potential wastage when calculating TCO. This holistic view can reveal better long-term savings.

-

Understand Pricing Nuances in Different Regions: Familiarize yourself with local market conditions in regions like Africa, South America, the Middle East, and Europe. Economic conditions, trade tariffs, and local competition can greatly impact pricing.

-

Conduct Regular Market Research: Stay informed about market trends, price fluctuations, and new suppliers. This knowledge can provide leverage in negotiations and help identify cost-saving opportunities.

-

Build a Diverse Supplier Base: Relying on multiple suppliers can mitigate risks associated with price increases or supply disruptions. It also fosters competitive pricing among suppliers.

Disclaimer on Indicative Prices

It is important to note that prices for Noodle XXX can fluctuate based on numerous factors, including market demand, seasonal variations, and geopolitical events. Always conduct thorough market research and consult multiple suppliers to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing noodle xxx With Other Solutions

Understanding Alternatives in the Context of Noodle XXX

When considering a solution like noodle xxx, it’s essential for B2B buyers to explore viable alternatives that may better fit their specific needs or preferences. This analysis will provide a structured comparison against two alternative solutions, enabling buyers to make informed decisions based on performance, cost, and other critical factors.

Comparison Table of Noodle XXX and Alternatives

| Comparison Aspect | Noodle XXX | Alternative 1: Rice Noodles | Alternative 2: Whole Grain Pasta |

|---|---|---|---|

| Performance | High elasticity and flavor retention | Moderate elasticity, neutral flavor | Good texture, slightly heavier |

| Cost | Mid-range pricing | Generally lower cost | Higher cost due to specialty grains |

| Ease of Implementation | Easy to cook, versatile in recipes | Simple cooking, less versatile | Requires longer cooking time, limited recipes |

| Maintenance | Long shelf life, easy storage | Shorter shelf life, requires careful storage | Moderate shelf life, requires airtight storage |

| Best Use Case | Asian cuisines, fusion dishes | Soups, stir-fries | Health-focused meals, salads |

What Are the Pros and Cons of Rice Noodles Compared to Noodle XXX?

Rice noodles are a popular alternative, especially in Asian cuisine. They are known for their neutral flavor and ability to absorb the tastes of accompanying ingredients. One of their advantages is their lower cost, making them accessible for budget-conscious businesses. However, they may lack the elasticity and unique texture offered by noodle xxx, which can impact the overall dish quality. Additionally, rice noodles have a shorter shelf life, necessitating careful inventory management.

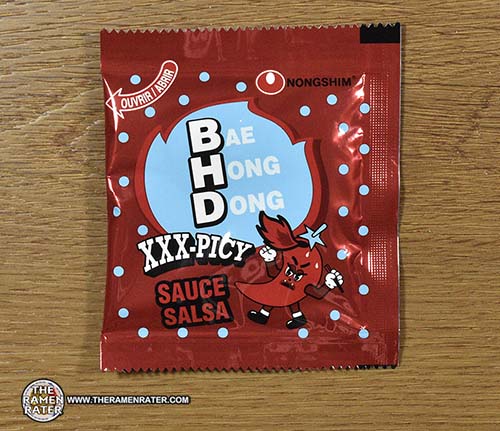

A stock image related to noodle xxx.

How Does Whole Grain Pasta Compare to Noodle XXX?

Whole grain pasta is recognized for its health benefits, being rich in fiber and nutrients. This alternative appeals to health-conscious buyers looking for nutritious meal options. While it provides a good texture, it can be heavier than noodle xxx, which may not be suitable for all recipes. The primary downside is the higher cost and longer cooking time, which can be a consideration for businesses aiming for efficiency. Whole grain pasta also has a moderate shelf life, requiring proper storage to maintain freshness.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution among noodle xxx and its alternatives depends on various factors specific to each business’s needs. Buyers should assess their target market preferences, budget constraints, and the types of dishes they plan to offer. If cost is a primary concern, rice noodles may be the best choice. However, for those focused on health and nutrition, whole grain pasta could be a superior option. Ultimately, understanding the unique characteristics and applications of each alternative will empower B2B buyers to align their choices with their culinary goals and customer expectations.

Essential Technical Properties and Trade Terminology for noodle xxx

What Are the Essential Technical Properties of Noodle xxx?

When sourcing noodle xxx for international markets, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the quality and type of ingredients used in noodle production, such as wheat flour or rice. For B2B buyers, selecting the appropriate material grade is vital as it affects the texture, taste, and nutritional value of the noodles. Higher-grade materials often correlate with better product performance and consumer satisfaction.

2. Tolerance Levels

Tolerance levels indicate the allowable variations in the dimensions and characteristics of noodle xxx. This specification is critical for manufacturers to ensure consistency in production. Buyers should pay attention to tolerance levels to avoid discrepancies that could lead to product defects, impacting overall quality and brand reputation.

3. Moisture Content

Moisture content is a key determinant of the shelf life and quality of noodle xxx. It is typically measured as a percentage of the total weight. For B2B buyers, understanding moisture levels is essential for inventory management and ensuring product freshness, particularly in regions with varying climates.

4. Cooking Time

Cooking time indicates how long noodle xxx should be boiled or prepared before consumption. This property is significant for food manufacturers and restaurants, as it affects preparation efficiency and customer satisfaction. Buyers should seek noodles with cooking times that align with their operational needs and target market preferences.

5. Nutritional Profile

The nutritional profile encompasses the macro and micronutrients present in noodle xxx, including protein, carbohydrates, and vitamins. As health-conscious consumers become more prevalent, B2B buyers should prioritize products with favorable nutritional attributes to meet market demands and enhance brand positioning.

What Trade Terminology Should You Know When Sourcing Noodle xxx?

Familiarity with industry jargon can facilitate smoother transactions and better negotiations. Here are some essential terms every B2B buyer should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods that are branded by another firm. In the context of noodle xxx, this term is relevant for buyers looking to source products that can be customized with their branding. Understanding OEM relationships can help buyers leverage manufacturing capabilities while maintaining brand identity.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is critical for budget planning and inventory management. It can also influence negotiations, especially if buyers are looking to test new products without committing to large volumes.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to solicit price quotes from suppliers. For B2B buyers, issuing an RFQ can streamline the procurement process, ensuring they receive competitive pricing and clear specifications from multiple vendors. This practice is particularly useful for establishing relationships with new suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping costs, risk management, and delivery responsibilities. Familiarity with Incoterms can prevent misunderstandings and disputes during shipping and customs clearance.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. For buyers, understanding lead times is crucial for supply chain planning and inventory management. It is especially important in markets with high demand fluctuations, allowing businesses to maintain adequate stock levels and meet customer needs promptly.

By grasping these essential technical properties and trade terminologies, international B2B buyers can navigate the complexities of sourcing noodle xxx more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the noodle xxx Sector

What Are the Current Market Dynamics and Key Trends in the Noodle Sector?

The noodle sector is witnessing transformative shifts driven by globalization, dietary trends, and technological advancements. In recent years, an increasing demand for convenience foods has propelled the growth of instant noodles across markets in Africa, South America, the Middle East, and Europe. This trend is particularly pronounced in urban areas where busy lifestyles dictate food choices. Additionally, the rise of health-conscious consumers is fueling demand for whole grain, gluten-free, and organic noodle options, creating opportunities for B2B buyers to diversify their product offerings.

Emerging technologies are also reshaping the sourcing landscape. E-commerce platforms and digital supply chain management tools are simplifying procurement processes, enabling B2B buyers to connect with suppliers worldwide more efficiently. Blockchain technology is gaining traction for its ability to enhance transparency and traceability in the supply chain, a critical factor for buyers who prioritize quality and safety.

Furthermore, market dynamics are influenced by regional variations. For instance, in South America, local flavors are driving interest in traditional noodle recipes, while Middle Eastern markets are increasingly incorporating noodles into fusion cuisines. Understanding these regional preferences is essential for international B2B buyers looking to tailor their product lines.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in the Noodle Sector?

Sustainability is becoming a cornerstone of procurement strategies for B2B buyers in the noodle sector. The environmental impact of noodle production, particularly in terms of water usage and packaging waste, has garnered attention from consumers and regulators alike. Buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly packaging materials and implementing water conservation techniques.

Ethical sourcing is equally important. Buyers must ensure that their supply chains are free from exploitation and that workers’ rights are respected. This involves vetting suppliers for adherence to ethical labor standards and considering certifications such as Fair Trade or Rainforest Alliance, which can enhance brand reputation and consumer trust.

Moreover, incorporating ‘green’ certifications into product offerings not only meets consumer demand but can also provide a competitive edge in the market. By sourcing noodles made from organic ingredients or those that comply with sustainable farming practices, B2B buyers can appeal to an increasingly eco-conscious customer base.

What Is the Historical Context of the Noodle Sector?

The history of noodles dates back thousands of years, with origins traced to ancient China around 2000 BC. Over centuries, this staple food has evolved and spread across various cultures, adapting to local tastes and ingredients. In recent decades, the global noodle market has expanded significantly, driven by increasing international trade and the globalization of food preferences.

For B2B buyers, understanding this historical context is vital for recognizing the rich heritage of noodle production and the diverse consumer preferences that have emerged. By tapping into traditional recipes while innovating with modern flavors and health trends, international buyers can create compelling product lines that resonate with consumers across different regions. This blend of tradition and innovation is essential for navigating the complexities of the current noodle market.

Frequently Asked Questions (FAQs) for B2B Buyers of noodle xxx

-

How do I solve supply chain issues when sourcing noodle xxx internationally?

To effectively address supply chain issues when sourcing noodle xxx internationally, first, establish strong relationships with multiple suppliers to ensure alternative options are available. Utilize logistics partners who are familiar with international regulations and customs to prevent delays. Additionally, implementing a robust inventory management system can help forecast demand and adjust orders accordingly. Regular communication with suppliers about potential disruptions can also mitigate risks and enhance responsiveness. -

What is the best packaging for noodle xxx to ensure freshness during international shipping?

The best packaging for noodle xxx involves using vacuum-sealed bags or airtight containers that preserve freshness and extend shelf life. Consider utilizing moisture-proof and light-resistant materials to protect the noodles from environmental factors. Additionally, including desiccants can help absorb excess moisture during transit. Ensure that the packaging is compliant with the destination country’s regulations, which may include labeling requirements and material restrictions. -

What are the minimum order quantities (MOQs) for noodle xxx when sourcing from suppliers?

Minimum order quantities (MOQs) for noodle xxx vary by supplier and can depend on factors such as production capacity and shipping considerations. Typically, MOQs can range from 500 kg to several tons. It’s essential to communicate your purchasing needs clearly and negotiate with suppliers. Some may offer flexible MOQs for first-time buyers or bulk orders, allowing you to test their product quality without committing to large quantities initially. -

How can I vet suppliers of noodle xxx to ensure quality and reliability?

To vet suppliers of noodle xxx effectively, start by checking their certifications, such as ISO or HACCP, which indicate adherence to quality standards. Request samples to evaluate product quality and assess the supplier’s production process. Additionally, consider their reputation by seeking references or reading reviews from other international buyers. Regular audits and site visits can further ensure compliance with your quality requirements. -

What payment terms should I negotiate when sourcing noodle xxx internationally?

When negotiating payment terms, consider options such as letters of credit, advance payments, or payment upon delivery, depending on your relationship with the supplier. Aim for terms that balance risk and cash flow; for instance, a 30% advance and 70% upon delivery can be mutually beneficial. Ensure that all payment terms are clearly outlined in the contract to prevent misunderstandings, and consider using escrow services for larger transactions to safeguard your investment. -

How do I handle customs clearance for noodle xxx imports?

To handle customs clearance for noodle xxx imports efficiently, familiarize yourself with the import regulations of the destination country. Prepare all necessary documentation, including commercial invoices, packing lists, and certificates of origin. Engaging a customs broker can streamline the process, ensuring compliance with local laws. Regularly communicate with your logistics partner to stay updated on any changes in regulations that may affect your shipments. -

What are the key quality assurance practices when sourcing noodle xxx?

Implementing key quality assurance practices involves establishing clear product specifications and conducting regular quality checks at various stages of production. Utilize third-party inspection services to evaluate the noodles before shipment, ensuring they meet your standards. Additionally, maintain open communication with suppliers regarding quality expectations and develop a feedback loop to address any issues promptly. Documenting all quality checks can help build trust and accountability. -

How can I optimize logistics for importing noodle xxx from different regions?

To optimize logistics for importing noodle xxx, evaluate multiple shipping methods, such as air freight for speed or sea freight for cost-effectiveness. Partner with experienced logistics providers familiar with your target regions in Africa, South America, the Middle East, and Europe. Implement a tracking system to monitor shipments in real-time and anticipate potential delays. Additionally, consider consolidating shipments from different suppliers to reduce costs and streamline customs clearance processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for noodle xxx

In the evolving landscape of international B2B trade, strategic sourcing for noodle xxx emerges as a pivotal element for businesses aiming to enhance their supply chain efficiency and product quality. By leveraging local suppliers in regions such as Africa, South America, the Middle East, and Europe, buyers can not only reduce costs but also gain access to unique, culturally relevant products that cater to diverse consumer preferences.

A stock image related to noodle xxx.

A stock image related to noodle xxx.

What are the key factors to consider in strategic sourcing for noodle xxx? Engaging with suppliers who prioritize sustainability, quality control, and innovation will be essential. Additionally, building strong partnerships with local producers can foster trust and ensure a more resilient supply chain, particularly in times of global uncertainty.

Looking ahead, international buyers should focus on the integration of technology in sourcing processes, such as data analytics and AI, to enhance decision-making and forecast trends effectively. As the market for noodle xxx continues to expand, the ability to adapt and innovate will be crucial for success.

Take action now—explore potential suppliers, invest in strategic partnerships, and harness the power of technology to remain competitive in this dynamic market. Your proactive approach will position your business at the forefront of the noodle xxx industry, ready to seize emerging opportunities.