Master BNC Connections: How to Right Angle BNC KiCad (2025)

Introduction: Navigating the Global Market for how to right angle bnc kicad

In the ever-evolving landscape of electronic components, sourcing the right angle BNC connectors using KiCad can be a pivotal challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, the task of effectively navigating supplier options while ensuring compatibility and reliability is crucial. This guide is designed to demystify the process, offering insights into various types of right angle BNC connectors, their applications across different industries, and the best practices for using KiCad to design your projects.

Understanding the nuances of component sourcing is essential for making informed purchasing decisions. This comprehensive resource covers vital aspects such as supplier vetting processes, pricing strategies, and cost-effective sourcing methods tailored to your regional context. By equipping you with knowledge on selecting high-quality components, we aim to empower your business to make decisions that enhance productivity and reduce project lead times.

For buyers in emerging markets like Egypt and Kenya, or established markets in Europe, this guide addresses common pitfalls and offers actionable strategies to streamline your procurement process. With a focus on practical insights and a solution-oriented approach, this guide serves as a valuable tool in your journey to successfully integrate right angle BNC connectors into your electronic designs using KiCad.

Understanding how to right angle bnc kicad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Right Angle BNC | Commonly used, 50 Ohm impedance, robust design | Telecommunications, Broadcasting | Pros: Cost-effective, widely available. Cons: Limited in specialized applications. |

| Miniature Right Angle BNC | Compact size, 75 Ohm impedance, lightweight | Consumer Electronics, Mobile Devices | Pros: Space-saving, suitable for tight spaces. Cons: May not handle high power. |

| High-Frequency Right Angle BNC | Enhanced performance, low-loss materials | RF Communication, Aerospace | Pros: Excellent signal integrity. Cons: Higher cost, requires careful handling. |

| Waterproof Right Angle BNC | Sealed design, resistant to moisture and dust | Outdoor Equipment, Industrial Applications | Pros: Durable in harsh environments. Cons: Heavier and more expensive. |

| Custom Right Angle BNC | Tailored specifications, various materials | Specialized Equipment, Prototyping | Pros: Meets specific needs, unique designs. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of Standard Right Angle BNC Connectors?

Standard Right Angle BNC connectors are the backbone of many telecommunications and broadcasting applications. They typically feature a 50 Ohm impedance and are designed for robust performance in a variety of environments. These connectors are ideal for B2B buyers looking for a cost-effective solution that is widely available and compatible with standard equipment. When purchasing, consider the volume needed, as bulk orders can often lead to discounted pricing.

How Do Miniature Right Angle BNC Connectors Differ?

Miniature Right Angle BNC connectors are designed to fit into compact spaces, featuring a 75 Ohm impedance that makes them suitable for consumer electronics and mobile devices. Their lightweight nature is an advantage in portable applications. For B2B buyers, the primary consideration should be the balance between size constraints and performance requirements. While they offer significant space-saving benefits, they may not handle high power levels as effectively as larger connectors.

What Makes High-Frequency Right Angle BNC Connectors Unique?

High-Frequency Right Angle BNC connectors are engineered for enhanced performance, utilizing low-loss materials to ensure excellent signal integrity. These connectors are crucial in RF communication and aerospace applications, where high-frequency signals are prevalent. B2B buyers should weigh the benefits of superior performance against the higher costs and handling requirements. These connectors require more careful installation and maintenance, making them suitable for specialized applications where performance is critical.

Why Choose Waterproof Right Angle BNC Connectors?

Waterproof Right Angle BNC connectors feature a sealed design that protects against moisture and dust, making them ideal for outdoor equipment and industrial applications. Their durability in harsh environments is a significant advantage for B2B buyers in sectors that require reliable performance under challenging conditions. However, the trade-off may include a heavier design and higher price point. Buyers should assess the environmental conditions their equipment will face to determine if the investment is justified.

When Should You Consider Custom Right Angle BNC Connectors?

Custom Right Angle BNC connectors offer tailored specifications and can be made from various materials to suit specific applications. They are particularly beneficial in specialized equipment and prototyping scenarios. For B2B buyers, the main considerations include lead times and costs, as custom solutions may take longer to produce and can be more expensive. However, they provide the unique advantage of meeting specific operational needs that off-the-shelf connectors cannot fulfill.

Related Video: BNC Male to BNC Female Right Angle Adapter – 50 Ohm

Key Industrial Applications of how to right angle bnc kicad

| Industry/Sector | Specific Application of how to right angle bnc kicad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Designing RF signal transmission systems | Improved signal integrity and reduced interference | Quality of components, compliance with international standards |

| Aerospace and Defense | Development of avionics systems | Enhanced reliability in critical applications | Supplier certification, lead times, and technological support |

| Medical Devices | Creation of diagnostic imaging equipment | Accurate imaging and patient safety | Regulatory compliance, durability, and precision specifications |

| Industrial Automation | Implementation in control systems for manufacturing | Increased efficiency and reduced downtime | Customization options, integration capabilities, and after-sales support |

| Broadcasting and Media | Use in video transmission systems | High-quality signal transmission and reduced latency | Compatibility with existing systems, availability of technical support |

How is ‘how to right angle bnc kicad’ Used in Telecommunications?

In the telecommunications sector, right angle BNC connectors designed using KiCad are crucial for creating RF signal transmission systems. These connectors minimize the risk of signal loss and interference, which is vital for maintaining high-quality communication channels. For international buyers, particularly from regions like Africa and South America, ensuring that the components meet local telecommunications standards is essential. Buyers should prioritize sourcing from manufacturers that can provide detailed compliance documentation and robust customer support.

What Role Does ‘how to right angle bnc kicad’ Play in Aerospace and Defense?

In aerospace and defense, the reliability of avionics systems is paramount. Right angle BNC connectors designed with KiCad are used to interconnect various electronic systems, ensuring that data transmission remains stable under extreme conditions. International buyers in this sector must focus on sourcing components from certified suppliers who adhere to rigorous industry standards. The ability to provide technical documentation and support is also a significant consideration for businesses in regions like the Middle East and Europe.

How is ‘how to right angle bnc kicad’ Applied in Medical Devices?

In the medical device industry, right angle BNC connectors are integral to diagnostic imaging equipment such as ultrasound and MRI machines. These connectors facilitate accurate signal transmission, which directly impacts imaging quality and patient safety. For buyers in Africa and Europe, it’s crucial to work with suppliers who understand the regulatory landscape and can guarantee compliance with health and safety standards. The durability and precision of these components must also be evaluated to ensure long-term functionality.

A stock image related to how to right angle bnc kicad.

How Does ‘how to right angle bnc kicad’ Enhance Industrial Automation?

In industrial automation, right angle BNC connectors are often employed in control systems that manage manufacturing processes. By utilizing KiCad for design, companies can optimize the layout for space-saving applications while ensuring reliable connections. This leads to increased efficiency and reduced downtime in operations. International B2B buyers, especially from South America and Africa, should consider customization options from suppliers to meet specific operational needs, as well as the availability of after-sales support to troubleshoot any issues.

What is the Importance of ‘how to right angle bnc kicad’ in Broadcasting and Media?

In broadcasting and media, right angle BNC connectors are essential for video transmission systems. They help maintain high-quality signal integrity and reduce latency, which is critical for live broadcasts. Buyers in this sector, particularly in Europe and the Middle East, should ensure that the connectors are compatible with existing systems and that the supplier offers reliable technical support. Evaluating the supplier’s track record in delivering quality components on time is also vital to avoid disruptions in broadcasting operations.

Related Video: How to solder a BNC connector. Properly.

3 Common User Pain Points for ‘how to right angle bnc kicad’ & Their Solutions

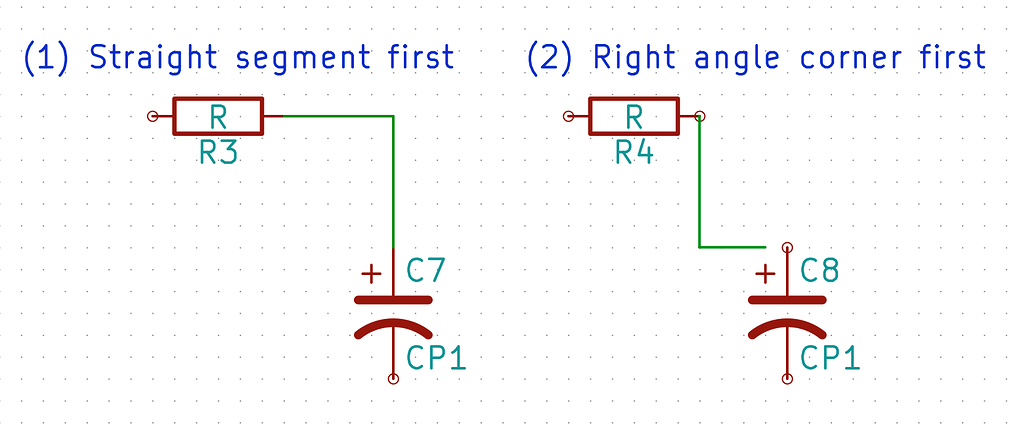

Scenario 1: Difficulty in Properly Specifying Right Angle BNC Connectors in KiCad

The Problem:

Many B2B buyers, particularly those in emerging markets like Egypt and Kenya, struggle with accurately specifying the dimensions and electrical characteristics of right angle BNC connectors when designing PCBs in KiCad. This often leads to compatibility issues during the manufacturing phase, resulting in increased costs and delayed project timelines. The challenge is compounded by the lack of standardized component libraries, making it hard to find suitable alternatives that meet both design and performance criteria.

The Solution:

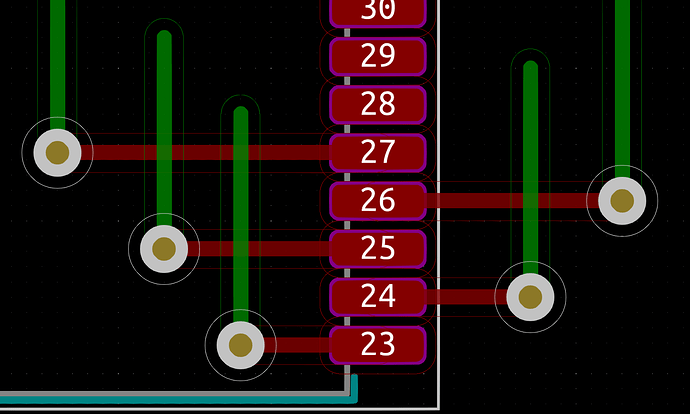

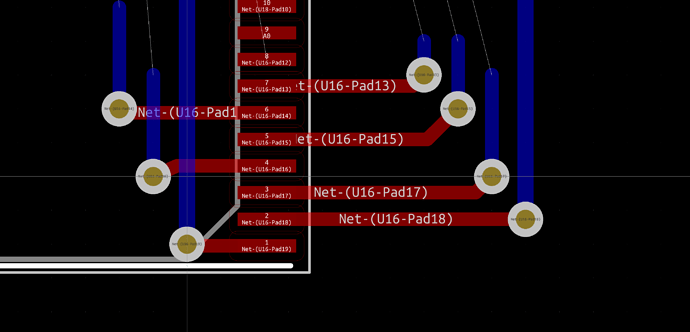

To overcome this issue, buyers should begin by leveraging KiCad’s extensive library of components or creating custom footprints tailored to their specific project requirements. Start by gathering detailed specifications of the right angle BNC connectors you plan to use, including dimensions and pin configurations. Utilize KiCad’s footprint editor to create a precise footprint that reflects these specifications. Furthermore, consider collaborating with component manufacturers or local suppliers who can provide technical support and library files, ensuring that the connectors you select will fit seamlessly into your PCB design. Regularly updating your library with manufacturer-specific components can also save time and prevent future discrepancies.

Scenario 2: Challenges in Simulation and Testing of Right Angle BNC Connectors

The Problem:

Another common pain point arises during the simulation and testing phase of PCB designs that incorporate right angle BNC connectors. Buyers may find it difficult to predict the performance of the connectors under various operational conditions due to inadequate simulation tools or a lack of understanding of how to set them up in KiCad. This can lead to unforeseen issues in signal integrity and connector performance when the product is deployed in the field.

The Solution:

To address this challenge, it is crucial to incorporate simulation tools that are compatible with KiCad. Tools like LTspice or Qucs can be integrated to simulate signal pathways effectively. Buyers should invest time in learning how to set up simulations that account for the specific characteristics of right angle BNC connectors, such as impedance and capacitance. Additionally, consider conducting real-world testing with prototypes before mass production. This practical approach allows you to validate simulations and make necessary adjustments early in the design process, ultimately saving costs and ensuring product reliability.

Scenario 3: Sourcing Quality Right Angle BNC Connectors for Diverse Markets

The Problem:

Sourcing high-quality right angle BNC connectors can be particularly challenging for B2B buyers operating in regions with limited access to international suppliers. Buyers in South America and the Middle East may face difficulties in finding connectors that meet both their technical specifications and budget constraints. Additionally, concerns about the quality and reliability of local suppliers can lead to hesitance in making procurement decisions.

The Solution:

To effectively source right angle BNC connectors, buyers should establish a diverse network of suppliers that includes both local and international sources. Leverage online platforms and trade shows to connect with manufacturers who specialize in electronic components. When evaluating potential suppliers, request samples to assess quality firsthand and verify that the connectors meet your specifications. Moreover, consider forming partnerships with suppliers who offer comprehensive support, including documentation and after-sales services. This not only ensures you receive quality components but also builds a reliable supply chain, essential for maintaining production schedules and meeting market demands.

Strategic Material Selection Guide for how to right angle bnc kicad

When selecting materials for right angle BNC connectors in KiCad designs, various factors such as performance, compatibility, and cost must be considered. Below is an analysis of several common materials used in these applications, tailored for international B2B buyers in regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Brass for Right Angle BNC Connectors?

Brass is a popular choice for BNC connectors due to its excellent electrical conductivity and mechanical strength. It typically has a temperature rating of up to 150°C and demonstrates good corrosion resistance, particularly in dry environments.

Pros: Brass connectors are durable and can handle high-frequency signals effectively, making them suitable for telecommunications and broadcasting applications. They are also relatively easy to manufacture, which can lead to lower costs in mass production.

Cons: However, brass can corrode in humid or saline environments, which may limit its use in coastal regions or areas with high moisture levels. Its weight can also be a disadvantage for portable applications.

Impact on Application: Brass connectors are compatible with a wide range of media, including RF signals, making them ideal for various electronic applications.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards for electrical components and consider local corrosion resistance requirements, especially in humid climates like those found in parts of Africa and South America.

How Does Plastic Compare as a Material for Right Angle BNC Connectors?

Plastic, particularly high-grade thermoplastics, is another viable option for BNC connectors. These materials can withstand temperatures up to 85°C and offer good insulation properties.

Pros: The primary advantage of plastic connectors is their lightweight nature and resistance to corrosion, making them suitable for outdoor applications. They are also cost-effective and can be produced in various colors for identification purposes.

Cons: On the downside, plastic connectors may not support high-frequency signals as effectively as metal alternatives. They may also have lower mechanical strength, which could be a concern in high-stress environments.

Impact on Application: Plastic connectors are particularly suitable for low-frequency applications and environments where moisture resistance is crucial.

Considerations for International Buyers: Buyers should verify compliance with international standards such as IEC and JIS for plastic materials, especially in regions with stringent electrical safety regulations.

What are the Advantages of Stainless Steel in Right Angle BNC Connectors?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it an excellent choice for BNC connectors in harsh environments. It can typically withstand temperatures up to 300°C.

Pros: The durability of stainless steel ensures a long lifespan, even in challenging conditions. It is also compatible with a variety of media, including corrosive substances, which expands its application range.

Cons: The primary drawback of stainless steel is its cost, which is generally higher than that of brass or plastic. Additionally, manufacturing processes can be more complex, potentially leading to longer lead times.

Impact on Application: Stainless steel connectors are ideal for industrial applications, especially in the oil and gas sector, where exposure to harsh chemicals is common.

Considerations for International Buyers: Buyers should look for compliance with DIN and ASTM standards, particularly in Europe, where regulations for industrial components are stringent.

How Does Aluminum Perform in Right Angle BNC Connectors?

Aluminum is another material option for BNC connectors, offering a balance between weight and strength. It typically has a temperature rating of around 120°C.

Pros: Aluminum connectors are lightweight and resistant to corrosion, especially when anodized. They are also cost-effective, making them a popular choice for budget-conscious projects.

Cons: However, aluminum’s conductivity is lower than that of brass, which may affect performance in high-frequency applications. Additionally, it can be prone to mechanical wear if not properly treated.

Impact on Application: Aluminum connectors are suitable for applications where weight savings are critical, such as in aerospace or portable electronic devices.

Considerations for International Buyers: Buyers should ensure compliance with ISO standards for aluminum components, particularly in regions where lightweight materials are preferred.

Summary of Material Selection for Right Angle BNC Connectors

| Material | Typical Use Case for how to right angle bnc kicad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Telecommunications and broadcasting applications | Excellent conductivity and durability | Corrosion in humid environments | Medium |

| Plastic | Low-frequency and moisture-resistant applications | Lightweight and cost-effective | Lower mechanical strength | Low |

| Stainless Steel | Industrial applications, especially in harsh environments | Exceptional strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace and portable devices | Lightweight and cost-effective | Lower conductivity than brass | Medium |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions on material selection for right angle BNC connectors in KiCad designs.

In-depth Look: Manufacturing Processes and Quality Assurance for how to right angle bnc kicad

What Are the Main Stages of Manufacturing Right Angle BNC Connectors in KiCad?

The manufacturing process for right angle BNC connectors involves several critical stages, each designed to ensure precision and quality. The primary phases include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically brass or stainless steel, for the connector housing and gold or nickel plating for the contact surfaces. Suppliers must ensure that materials meet international standards to guarantee durability and conductivity. In regions like Africa or South America, sourcing these materials can be challenging, so establishing relationships with reliable suppliers is essential.

-

Forming: This stage involves shaping the raw materials into the desired connector form. Techniques such as stamping and machining are commonly employed. Stamping is efficient for mass production, while machining offers precision for custom designs. B2B buyers should inquire about the methods used by manufacturers to ensure they can meet specific design requirements.

-

Assembly: Once the components are formed, they are assembled. This may involve manual assembly or automated processes, depending on the production scale. It is crucial to have skilled labor or advanced automation to minimize defects. B2B buyers should assess the manufacturer’s assembly capabilities and workforce expertise.

-

Finishing: The final stage includes surface treatments such as plating, polishing, and quality checks. These processes enhance the connector’s performance and aesthetic appeal. B2B buyers should look for manufacturers that employ advanced finishing techniques to ensure longevity and reliability.

How Is Quality Assurance Implemented in the Manufacturing of Right Angle BNC Connectors?

Quality assurance (QA) is an integral part of the manufacturing process for right angle BNC connectors. It ensures that products not only meet customer expectations but also comply with international standards.

-

International Standards: Compliance with standards such as ISO 9001 is vital. This certification indicates that a manufacturer has established a quality management system that consistently meets customer and regulatory requirements. B2B buyers should prioritize suppliers with these certifications to ensure reliability.

-

Industry-Specific Standards: In addition to ISO, specific industries may require adherence to other standards, such as CE marking in Europe or API standards in oil and gas applications. Understanding these requirements can be crucial, especially for buyers in regulated industries.

-

Quality Control Checkpoints: Quality control (QC) processes are typically divided into several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Checks are performed during the manufacturing stages to catch defects early.

– Final Quality Control (FQC): A thorough inspection occurs before products are packaged and shipped.

B2B buyers should inquire about the QC processes in place to ensure that these checkpoints are strictly followed.

What Testing Methods Are Commonly Used in Quality Assurance for Right Angle BNC Connectors?

Testing is a crucial aspect of the QC process to verify that connectors perform as expected under various conditions. Common testing methods include:

-

Electrical Testing: This evaluates the connector’s performance in terms of resistance, insulation, and continuity. Testing for RF performance is particularly important for BNC connectors, which are often used in high-frequency applications.

-

Mechanical Testing: This assesses the connector’s durability through stress tests, including pull and torque tests, to ensure it can withstand physical forces during operation.

-

Environmental Testing: Connectors may undergo exposure to extreme temperatures, humidity, and corrosive environments to ensure they maintain performance under challenging conditions.

B2B buyers should request documentation of these testing procedures and results to verify the quality of the products they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for B2B buyers to ensure product reliability and compliance with standards. Here are effective strategies:

-

Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s manufacturing processes and QA practices firsthand. This can be a collaborative process where both parties can discuss improvements and expectations.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including results from IQC, IPQC, and FQC. This documentation provides insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing capabilities and QC measures. This is particularly important for international buyers who may face challenges in conducting on-site audits.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control and certification. Here are some nuances to consider:

-

Understanding Local Regulations: Each region has its own set of regulations and standards that must be met. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Language Barriers: Communication can be a challenge when dealing with international suppliers. Buyers should ensure that documentation is available in a language they understand and that there are clear channels for communication.

-

Cultural Differences: Different cultures may have varying approaches to quality and business practices. Understanding these differences can help in building stronger supplier relationships and ensuring smoother transactions.

-

Logistical Challenges: International shipping can introduce risks related to product quality during transit. Buyers should work with suppliers who have robust packaging and shipping practices to mitigate these risks.

By being informed and proactive in these areas, B2B buyers can navigate the complexities of sourcing right angle BNC connectors effectively, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to right angle bnc kicad’

Introduction: How Can You Source Right Angle BNC Connectors in KiCad Effectively?

Sourcing right angle BNC connectors for your electronics projects can be a complex task, especially for international B2B buyers in diverse markets. This guide provides a practical step-by-step checklist designed to streamline your procurement process, ensuring you find the right components that meet your technical requirements while aligning with your budget and timeline.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to clearly outline your technical requirements for the right angle BNC connectors. This includes specifications such as impedance, frequency range, and connector size.

– Why It Matters: A well-defined specification helps in narrowing down potential suppliers and ensures that you receive components that meet your project needs.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers who specialize in electronic components, particularly BNC connectors. Utilize online directories, trade shows, and industry forums to compile a list of candidates.

– What to Look For: Focus on suppliers with a strong track record, positive reviews, and those who have experience dealing with international clients, especially in your target regions like Africa or South America.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your shortlisted suppliers possess the necessary certifications, such as ISO 9001, RoHS, and other relevant industry standards.

– Importance of Compliance: Certifications indicate that the supplier adheres to quality management systems and environmental regulations, which is vital for maintaining the integrity of your products.

Step 4: Request Samples for Testing

Before placing a large order, request samples of the right angle BNC connectors from your selected suppliers. This allows you to evaluate the quality and compatibility of the components with your designs.

– Testing Benefits: Sampling helps mitigate risks by ensuring the connectors perform as expected in your specific application, saving you potential costs associated with faulty components later.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier based on quality and compliance, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– Key Considerations: Be clear about your budget constraints and any bulk order discounts. Also, discuss warranty terms and after-sales support to ensure you are covered in case of defects.

Step 6: Assess Logistics and Shipping Options

Consider the logistics involved in shipping the connectors to your location. Evaluate different shipping methods, customs clearance processes, and potential delays.

– Logistical Insight: Understanding the shipping landscape is essential for managing delivery timelines, especially when sourcing from suppliers in Europe or the Middle East.

Step 7: Establish a Long-Term Relationship

Once you’ve successfully sourced your right angle BNC connectors, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority support, and access to new products.

– Long-Term Benefits: Building a partnership can provide strategic advantages, including insights into product developments and improved supply chain reliability.

By following these steps, international B2B buyers can effectively navigate the complexities of sourcing right angle BNC connectors in KiCad, ensuring they find the right products at competitive prices while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for how to right angle bnc kicad Sourcing

What Are the Key Cost Components in Right Angle BNC KiCAD Sourcing?

When sourcing right angle BNC connectors designed in KiCAD, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly affects the pricing. High-quality metals for connectors, such as brass or stainless steel, can increase costs. Additionally, sourcing materials locally versus internationally can also impact the price.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers might offer more competitive pricing. However, this can come with trade-offs in terms of quality and lead time.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and facility costs. Companies with efficient operations may pass savings onto buyers.

-

Tooling: Custom tooling for specific designs or modifications can incur significant upfront costs. Consider whether the tooling is a one-time investment for a unique project or a long-term requirement for ongoing production.

-

Quality Control (QC): Ensuring that the connectors meet international standards often involves rigorous QC processes, which can add to the overall cost. Certifications for quality can also influence pricing.

-

Logistics: Shipping costs can vary based on the Incoterms agreed upon in the contract. International shipping from manufacturers in Europe to Africa or South America might involve higher costs due to customs duties and tariffs.

-

Margin: Suppliers will typically build in a margin to cover risks and ensure profitability. Understanding the supplier’s margin expectations can provide room for negotiation.

How Do Price Influencers Affect Right Angle BNC KiCAD Connector Costs?

Several factors can influence the pricing of right angle BNC connectors, which are crucial for international buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, which can be beneficial for businesses planning to scale.

-

Specifications and Customization: Customized connectors that meet specific technical requirements will generally cost more. Buyers should assess whether customization is necessary or if standard products will suffice.

-

Material Quality and Certifications: Connectors with recognized quality certifications (like ISO or RoHS compliance) may command higher prices. However, investing in certified products can enhance reliability and minimize failures.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but offer better support and assurance of quality.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding who bears the shipping risks can lead to more cost-effective sourcing strategies.

What Buyer Tips Can Enhance Cost Efficiency in BNC KiCAD Sourcing?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost efficiency:

-

Negotiate Terms: Always engage in negotiations with suppliers. Discussing payment terms, lead times, and bulk discounts can yield significant savings.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes maintenance, logistics, and potential downtime costs. A lower initial price might not be the best long-term investment.

-

Conduct Market Research: Understanding regional market dynamics can provide leverage in negotiations. Familiarize yourself with local suppliers and their offerings.

-

Leverage Technology: Use platforms like KiCAD for prototyping and testing designs before committing to large orders. This reduces waste and ensures you are sourcing exactly what you need.

-

Stay Informed About Pricing Trends: Being aware of material costs and market trends can help in timing purchases effectively, possibly locking in lower prices before they rise.

Disclaimer on Indicative Prices

It is essential to note that the prices for right angle BNC connectors can vary widely based on the factors discussed. Buyers should seek multiple quotes and conduct thorough due diligence to understand the current market rates and ensure they are making cost-effective decisions.

Alternatives Analysis: Comparing how to right angle bnc kicad With Other Solutions

Understanding the Importance of Alternative Solutions for BNC Right-Angle Connections

In the realm of electronic design automation (EDA), particularly when dealing with RF (radio frequency) applications, the method of creating right-angle BNC connections in KiCad can significantly impact the overall design and functionality of a circuit. However, it is crucial for B2B buyers, especially those in emerging markets in Africa, South America, the Middle East, and Europe, to explore alternative solutions that may better meet their specific requirements. This section provides a detailed comparison of the “How to Right Angle BNC KiCad” method against other viable alternatives, enabling informed decision-making.

Comparison Table of BNC Connection Solutions

| Comparison Aspect | How To Right Angle BNC KiCad | Alternative 1: Manual Soldering | Alternative 2: Using BNC Connectors with Pre-Made Cables |

|---|---|---|---|

| Performance | High precision and repeatability | Varies based on skill level | Consistent performance with minimal assembly effort |

| Cost | Moderate initial investment | Low cost but time-intensive | Higher upfront cost due to pre-made components |

| Ease of Implementation | Requires software proficiency | Requires soldering skills | Plug-and-play, easy to use for non-technical users |

| Maintenance | Low, if designed correctly | Moderate; can require rework | Minimal; simply replace the cable if damaged |

| Best Use Case | Complex PCB designs | Prototyping and hobby projects | Quick setups and temporary installations |

In-Depth Analysis of Alternative Solutions

What Are the Advantages and Disadvantages of Manual Soldering?

Manual soldering is a traditional method that involves physically connecting the BNC connectors to the PCB. This approach offers a low-cost alternative, especially for smaller projects or prototyping. The main advantage is its accessibility; most engineers have soldering tools at their disposal. However, the performance can vary significantly based on the technician’s skill level, which may lead to inconsistent connections. Furthermore, manual soldering can be time-consuming and may require rework if the connections are not made correctly.

How Do Pre-Made Cables Compare to KiCad’s Right Angle Method?

Using BNC connectors with pre-made cables is an increasingly popular choice for many businesses due to its simplicity and reliability. The plug-and-play nature of pre-made cables allows for quick installations, making it ideal for temporary setups or environments where time is of the essence. However, this method can be more expensive upfront compared to creating custom connections in KiCad. Additionally, while maintenance is minimal, any damage to the cable necessitates complete replacement, which may not be cost-effective in the long run.

Making the Right Choice: Which Solution is Best for Your Business?

When selecting the most suitable method for right-angle BNC connections, B2B buyers should consider their specific project requirements, budget constraints, and technical capabilities. For complex PCB designs that demand precision, the “How to Right Angle BNC KiCad” method may be the best choice, despite its initial learning curve. Conversely, for quick setups or prototyping, manual soldering or pre-made cables could provide more immediate benefits. Ultimately, understanding the trade-offs of each approach will empower businesses to select a solution that aligns with their operational goals and technical expertise.

Essential Technical Properties and Trade Terminology for how to right angle bnc kicad

What Are the Essential Technical Properties for Right Angle BNC Connectors in KiCad?

When designing PCBs with right angle BNC connectors in KiCad, understanding key technical properties is crucial for ensuring product reliability and performance. Below are some of the most important specifications to consider:

1. Material Grade

The material grade of the connector affects its durability and performance. Common materials include brass, stainless steel, and various types of plastics. Brass is widely used for its excellent conductivity and corrosion resistance, while stainless steel offers enhanced strength in harsh environments. For B2B buyers, selecting the right material is vital to match the application requirements and environmental conditions, especially in regions like Africa and the Middle East where humidity and temperature can vary significantly.

2. Impedance

BNC connectors typically come in 50-ohm or 75-ohm impedance ratings, crucial for ensuring signal integrity in RF applications. The choice of impedance affects the performance of the transmission line and can lead to signal loss if mismatched. For international buyers, understanding the implications of impedance on system performance can guide purchasing decisions, particularly for telecommunications and broadcasting applications.

3. Tolerance

Tolerance refers to the allowable deviation in dimensions of the connector components. A tighter tolerance can enhance the connector’s performance by reducing the risk of signal loss or distortion. In B2B transactions, specifying the required tolerance levels in RFQ (Request for Quotation) documents ensures that suppliers provide components that meet quality standards, which is essential for maintaining system reliability.

4. Operating Temperature Range

The operating temperature range defines the environmental limits within which the connector can function without failure. For example, some connectors may operate efficiently in temperatures ranging from -40°C to +85°C. Buyers in regions with extreme weather conditions, such as South America and parts of Europe, should ensure that the connectors meet these specifications to avoid operational failures.

5. Mechanical Durability

Mechanical durability refers to the connector’s ability to withstand physical stress, including vibration and repeated insertions. Connectors designed for high mechanical durability are essential in applications such as automotive and industrial equipment. This property is particularly relevant for B2B buyers seeking long-lasting solutions that minimize maintenance costs.

What Are the Common Trade Terms Used in BNC Connector Procurement?

Understanding industry terminology is equally important for effective communication and successful transactions. Below are key terms often encountered in B2B contexts:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of BNC connectors, OEMs often provide customized solutions tailored to specific needs. B2B buyers should consider working with reputable OEMs to ensure quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. For buyers in emerging markets, negotiating MOQs can help reduce upfront costs while ensuring a steady supply of components.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should clearly outline their requirements, including specifications and quantities, to receive accurate quotations. This process is essential for budgeting and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify responsibilities between buyers and sellers. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can help B2B buyers from different regions understand their obligations regarding shipping and delivery.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times helps B2B buyers plan their projects effectively, especially in industries where timely delivery is critical. Buyers should communicate their needs clearly to suppliers to avoid delays.

By mastering these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing right angle BNC connectors for their projects.

Navigating Market Dynamics and Sourcing Trends in the how to right angle bnc kicad Sector

What Are the Current Market Dynamics in the Right Angle BNC KiCad Sector?

A stock image related to how to right angle bnc kicad.

The right angle BNC connector sector is influenced by several global drivers that shape the market landscape. A significant trend is the increasing demand for high-frequency data transmission in telecommunications and broadcasting, particularly in regions such as Africa and South America, where infrastructure development is rapidly evolving. The shift towards 5G technology is also driving the need for reliable and efficient connectivity solutions, prompting B2B buyers to prioritize sourcing high-quality connectors that can handle increased bandwidth.

Emerging B2B tech trends, such as the adoption of Industry 4.0 practices, are further impacting sourcing strategies. Businesses are increasingly integrating IoT devices, necessitating connectors that support robust data transfer while minimizing signal loss. Additionally, international buyers are observing a trend towards customization in connector manufacturing. This enables companies to tailor solutions to specific project needs, offering a competitive edge in diverse markets.

Market dynamics are also shaped by geopolitical factors, trade agreements, and economic conditions. Buyers from the Middle East and Europe may find that tariffs or trade restrictions affect sourcing decisions, leading to a more localized approach in procurement. Understanding these dynamics allows international buyers to make informed decisions, ensuring they align their sourcing strategies with current market conditions.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy?

Sustainability is becoming increasingly vital in the B2B landscape, especially in the right angle BNC connector sector. The environmental impact of manufacturing processes and materials used in connectors cannot be overlooked. Companies are now expected to prioritize sustainability by opting for eco-friendly materials and production methods that reduce carbon footprints. This shift is particularly relevant for buyers in Africa and South America, where sustainable practices can enhance brand reputation and market acceptance.

Ethical sourcing is also a critical consideration. Buyers are encouraged to evaluate their supply chains for transparency and adherence to labor laws. Partnering with manufacturers that uphold ethical standards not only contributes to social responsibility but also mitigates risks associated with supply chain disruptions. Certifications such as ISO 14001 for environmental management or Fair Trade can serve as benchmarks for ethical sourcing in the industry.

Incorporating sustainability into procurement strategies can provide a competitive advantage. B2B buyers should look for suppliers who use recycled materials in their products or offer ‘green’ certifications. These practices not only align with global sustainability goals but also cater to an increasingly eco-conscious market, ultimately influencing purchase decisions.

How Has the Right Angle BNC Connector Sector Evolved Over Time?

The right angle BNC connector sector has witnessed significant evolution over the past few decades, primarily driven by advancements in technology and changing market demands. Initially, BNC connectors were predominantly used in analog applications. However, with the rise of digital communication systems, the need for connectors that could support higher frequencies and data rates became paramount.

As industries like telecommunications and broadcasting expanded, the design and functionality of BNC connectors also evolved. The introduction of right angle configurations provided solutions for space-constrained applications, enabling easier routing of cables in tight spaces. This evolution reflects the industry’s responsiveness to technological advancements and the need for innovative solutions that meet the demands of modern applications.

Today, the sector continues to adapt, with a focus on enhancing performance and reliability in increasingly complex systems. International B2B buyers must stay informed about these historical shifts to better understand current offerings and anticipate future trends, ensuring that their procurement strategies remain relevant and competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of how to right angle bnc kicad

-

How do I solve issues with right angle BNC connectors in KiCad?

To address issues with right angle BNC connectors in KiCad, ensure you have the correct footprint and schematic symbol. Check for compatibility with your PCB design and verify that the dimensions align with your layout requirements. Utilize the KiCad library manager to search for existing components or create a custom footprint if necessary. Additionally, consult user forums or documentation for troubleshooting tips and best practices shared by the KiCad community. -

What is the best way to source right angle BNC connectors for KiCad designs?

The best way to source right angle BNC connectors is to identify reputable suppliers with a proven track record in electronic components. Look for distributors that offer high-quality products and have a wide range of options to meet your specific design needs. Consider suppliers that provide comprehensive datasheets and technical support to ensure compatibility with your KiCad designs. Online marketplaces and local electronics distributors in your region can also be valuable resources. -

How can I verify the quality of right angle BNC connectors from suppliers?

To verify the quality of right angle BNC connectors, request samples before placing a bulk order. Evaluate the connectors based on their material, durability, and performance specifications. Check for compliance with international standards (such as RoHS or ISO) and review customer testimonials or case studies. Establish a quality assurance process with your supplier that includes regular inspections and testing of the connectors to ensure they meet your expectations. -

What are typical minimum order quantities (MOQ) for right angle BNC connectors?

Minimum order quantities (MOQ) for right angle BNC connectors can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 50 to 1,000 units. It’s essential to communicate directly with suppliers to negotiate terms that fit your project needs, especially if you are a small business or startup. Some suppliers may offer flexibility on MOQs for first-time orders or for long-term partnerships. -

What payment terms should I expect when ordering BNC connectors internationally?

When ordering BNC connectors internationally, payment terms typically range from upfront payment to 30, 60, or even 90-day terms, depending on the supplier’s policies and your relationship with them. Common payment methods include bank transfers, letters of credit, and payment platforms like PayPal. Discuss payment terms upfront to ensure clarity and avoid potential disputes, especially in cross-border transactions. -

How do I manage logistics for importing right angle BNC connectors?

Managing logistics for importing right angle BNC connectors involves selecting reliable freight forwarders and understanding customs regulations specific to your country. Ensure that you have the necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance. Plan for shipping costs, lead times, and potential delays by working closely with your suppliers and logistics partners, particularly when sourcing from regions like Europe or Asia.

A stock image related to how to right angle bnc kicad.

-

What customization options are available for right angle BNC connectors?

Many suppliers offer customization options for right angle BNC connectors, such as specific lengths, materials, and plating finishes. Discuss your requirements with the supplier to explore available options and any associated costs. Customization can help ensure that the connectors fit seamlessly into your KiCad designs and meet your performance criteria. Be sure to request detailed specifications and prototypes if necessary. -

How can I find reliable suppliers for BNC connectors in Africa and South America?

To find reliable suppliers for BNC connectors in Africa and South America, leverage online platforms like Alibaba or industry-specific directories. Attend trade shows and exhibitions focused on electronics to connect with manufacturers and distributors. Additionally, consider joining local industry associations or forums to gain insights and recommendations from peers. Establishing strong relationships with suppliers in your region can lead to better pricing, support, and logistical advantages.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for how to right angle bnc kicad

In conclusion, effectively sourcing right angle BNC connectors in KiCad can significantly enhance the design process for businesses across various industries. By leveraging strategic sourcing, international B2B buyers can not only reduce costs but also ensure high-quality components that meet specific technical requirements. It’s essential for buyers from regions like Africa, South America, the Middle East, and Europe to prioritize suppliers with a proven track record in reliability and customer service.

How Can Strategic Sourcing Benefit Your B2B Operations?

Understanding the nuances of the sourcing process allows companies to align their procurement strategies with market demands, thereby improving their competitive edge. By fostering relationships with trusted manufacturers, businesses can also benefit from tailored solutions that support their unique design needs in KiCad.

What’s Next for International B2B Buyers in Electronics?

Looking ahead, the landscape for sourcing electronic components is evolving rapidly. By staying informed about emerging trends and technologies, such as automation in manufacturing and sustainable sourcing practices, buyers can position themselves for success. Engage with suppliers who are committed to innovation and quality assurance to ensure your projects not only meet today’s standards but are also future-ready.

Take the next step in optimizing your sourcing strategy and explore partnerships that can drive your business forward in the dynamic electronics marketplace.