Discover the Benefits of a Centrifugal Clutch (2025)

Introduction: Navigating the Global Market for centrifugal clutch

In the ever-evolving landscape of industrial machinery, sourcing a reliable centrifugal clutch can pose significant challenges for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The centrifugal clutch is an essential component in various applications, ranging from automotive to agricultural machinery, and its performance directly impacts operational efficiency. Navigating the global market requires an understanding of the types available, their specific applications, and the suppliers who can provide high-quality products at competitive prices.

This comprehensive guide aims to empower B2B buyers by delving into the intricacies of the centrifugal clutch market. It covers various types of centrifugal clutches, their applications across different industries, and critical factors to consider when vetting suppliers. Furthermore, we will explore cost considerations and provide actionable insights to help you make informed purchasing decisions.

By equipping buyers with the knowledge they need, this guide serves as a valuable resource for those looking to enhance their procurement strategies. Whether you are a manufacturer in Argentina seeking to optimize your production line or a distributor in Europe looking for reliable suppliers, understanding the centrifugal clutch market can lead to more strategic investments and improved operational outcomes.

Understanding centrifugal clutch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Centrifugal Clutch | Engages and disengages based on RPM; simple design | Small engines, go-karts, lawn equipment | Pros: Cost-effective, easy to install. Cons: Limited torque capacity. |

| Variable Ratio Centrifugal Clutch | Adjustable engagement speed; allows for torque variation | Motorcycles, ATVs, and agricultural machinery | Pros: Enhanced performance, adaptable. Cons: More complex, higher cost. |

| Multi-Plate Centrifugal Clutch | Multiple friction plates for increased torque handling | Heavy machinery, industrial applications | Pros: High torque capacity, durable. Cons: Bulkier, requires more maintenance. |

| Hydraulic Centrifugal Clutch | Utilizes hydraulic fluid for engagement; smooth operation | Construction equipment, marine applications | Pros: Smooth engagement, less wear. Cons: More expensive, complex installation. |

| Spring-Loaded Centrifugal Clutch | Uses springs to control engagement speed; adjustable settings | Lawn mowers, snowmobiles, and small engines | Pros: Adjustable, good for varied applications. Cons: Limited torque compared to multi-plate. |

What Are the Characteristics of Standard Centrifugal Clutches?

Standard centrifugal clutches are widely recognized for their straightforward design, which allows them to engage and disengage based on engine RPM. These clutches are particularly suited for small engines, such as those found in go-karts and lawn equipment. When considering a purchase, B2B buyers should focus on compatibility with engine specifications and ease of installation. The cost-effectiveness of standard centrifugal clutches makes them an appealing choice, but their limited torque capacity may not meet the needs of more demanding applications.

How Do Variable Ratio Centrifugal Clutches Enhance Performance?

Variable ratio centrifugal clutches stand out due to their ability to adjust engagement speeds, allowing for torque variation. This feature is particularly beneficial in applications such as motorcycles and ATVs, where performance can be optimized for different conditions. Buyers should consider the specific performance requirements of their machinery when selecting this type. While variable ratio clutches provide enhanced adaptability and performance, their complexity and higher cost may deter some B2B buyers looking for simpler solutions.

In What Situations Are Multi-Plate Centrifugal Clutches Preferred?

Multi-plate centrifugal clutches consist of multiple friction plates, enabling them to handle higher torque loads. They are commonly used in heavy machinery and industrial applications where durability and reliability are paramount. B2B buyers should evaluate the torque requirements of their equipment to determine suitability. Although multi-plate clutches offer significant advantages in terms of torque capacity, their bulkier design and the need for regular maintenance may pose challenges for some users.

What Advantages Do Hydraulic Centrifugal Clutches Offer?

Hydraulic centrifugal clutches utilize hydraulic fluid for engagement, providing a smoother operation compared to traditional mechanical clutches. These clutches are ideal for use in construction equipment and marine applications, where consistent performance is critical. When purchasing hydraulic clutches, B2B buyers should assess the complexity of installation and potential maintenance needs. While they offer smooth engagement and reduced wear, the higher cost and intricate setup may be a consideration for budget-conscious buyers.

Why Choose Spring-Loaded Centrifugal Clutches for Varied Applications?

Spring-loaded centrifugal clutches utilize springs to control engagement speed, allowing for customizable settings based on application needs. This type is commonly found in lawn mowers, snowmobiles, and other small engines. B2B buyers should consider the versatility of spring-loaded clutches, which can adapt to various operational demands. While they provide adjustable performance, their torque capacity is limited compared to multi-plate options, making them less suitable for heavy-duty applications.

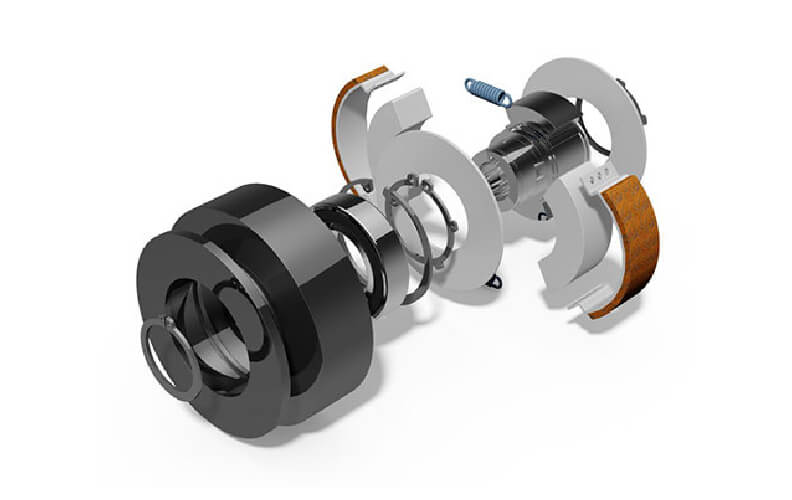

Related Video: Centrifugal Clutch Working | Types of Clutches | Automobile Basics | Automobile Engineering | Parts

Key Industrial Applications of centrifugal clutch

| Industry/Sector | Specific Application of Centrifugal Clutch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Power transmission in agricultural machinery | Improved efficiency in machinery operation, reducing downtime and maintenance costs. | Durability, compatibility with existing equipment, and availability of replacement parts. |

| Automotive | Starter systems in small engines | Enhanced reliability and reduced wear on engine components, leading to longer service life. | Size, torque capacity, and compliance with industry standards. |

| Construction | Drive systems in heavy equipment | Better load management and smoother operation, increasing productivity on job sites. | Strength, weight, and adaptability to various environmental conditions. |

| Marine | Propulsion systems in small boats | Efficient power transfer, leading to better fuel economy and reduced emissions. | Corrosion resistance, size, and compatibility with marine engines. |

| Industrial Equipment | Conveyor systems in manufacturing | Increased operational efficiency and reduced risk of mechanical failure, improving throughput. | Load capacity, speed control features, and ease of integration with existing systems. |

How is Centrifugal Clutch Used in Agriculture?

In the agriculture sector, centrifugal clutches are integral to the power transmission systems of various machinery, such as tractors and harvesters. By engaging and disengaging automatically based on engine speed, these clutches enhance operational efficiency and reduce the risk of mechanical failures. For international B2B buyers, particularly from Africa and South America, sourcing clutches that are durable and compatible with existing equipment is crucial. They must also consider local availability of replacement parts to minimize downtime during peak agricultural seasons.

What Role Does Centrifugal Clutch Play in the Automotive Industry?

Centrifugal clutches are widely used in small engine starter systems, particularly in motorcycles and lawn equipment. They provide enhanced reliability by ensuring smooth engagement and disengagement, which reduces wear on engine components. For automotive B2B buyers in Europe and the Middle East, it is essential to consider size and torque capacity to meet specific engine requirements. Compliance with local automotive standards and regulations also plays a vital role in the sourcing process.

How is Centrifugal Clutch Beneficial for Construction Equipment?

In the construction industry, centrifugal clutches are employed in the drive systems of heavy equipment like excavators and bulldozers. They facilitate better load management and ensure smoother operation, significantly enhancing productivity on job sites. B2B buyers from regions with challenging construction environments, such as Africa and the Middle East, need to prioritize sourcing clutches that exhibit exceptional strength and can withstand harsh conditions. Adaptability to various machinery types is also a critical consideration.

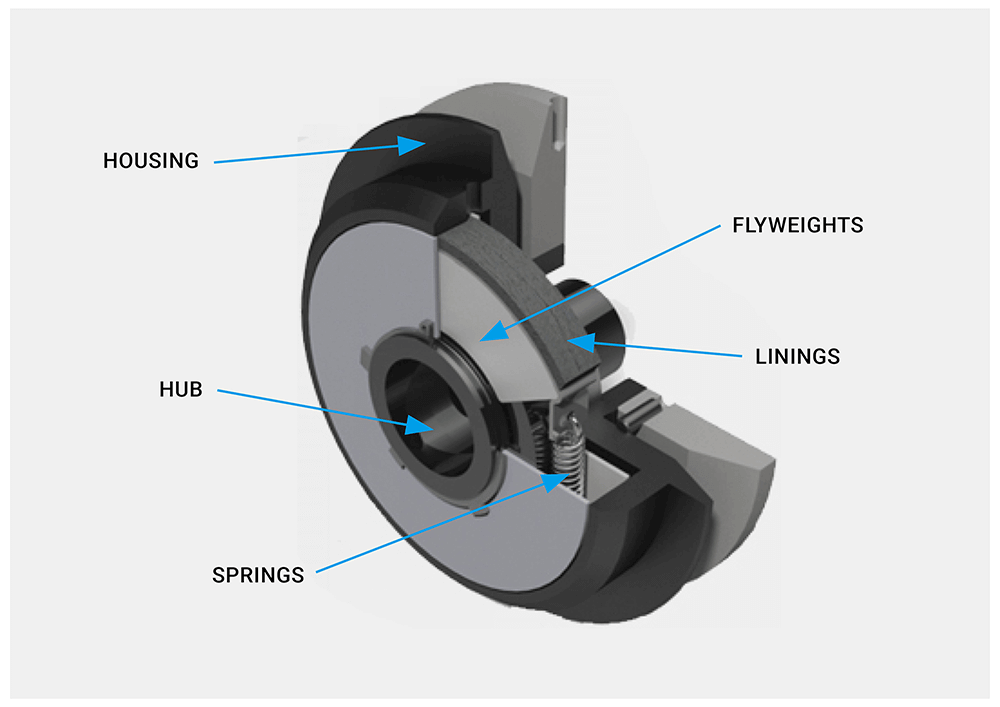

A stock image related to centrifugal clutch.

What is the Application of Centrifugal Clutch in Marine Propulsion Systems?

Centrifugal clutches are essential in the propulsion systems of small boats, where they optimize power transfer from the engine to the propeller. This results in improved fuel economy and reduced emissions, aligning with global sustainability goals. For international buyers in regions like South America and Europe, sourcing clutches with corrosion resistance is crucial due to the marine environment. Size and compatibility with existing marine engines are also key factors to consider.

How Does Centrifugal Clutch Enhance Industrial Equipment Performance?

In manufacturing, centrifugal clutches are commonly used in conveyor systems, where they contribute to increased operational efficiency and reduced mechanical failure risks. By providing smooth engagement, these clutches enhance throughput and productivity. B2B buyers from Europe and the Middle East should focus on load capacity and speed control features when sourcing. Additionally, ease of integration with existing systems is a significant consideration to ensure seamless operations.

Related Video: How does a Centrifugal Clutch work? | Skill-Lync

3 Common User Pain Points for ‘centrifugal clutch’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Centrifugal Clutches

The Problem:

B2B buyers often encounter challenges when sourcing centrifugal clutches that meet their specific requirements. For example, a manufacturer in Argentina may struggle to find suppliers who provide clutches compatible with their machinery. This can lead to delays in production, increased costs, and frustration as they navigate a landscape filled with unreliable suppliers. Additionally, varying quality standards across regions can complicate procurement, resulting in poor performance or premature failure of the clutches.

The Solution:

To overcome sourcing difficulties, buyers should conduct thorough research to identify reputable manufacturers and suppliers. Start by leveraging industry-specific platforms and trade fairs that feature centrifugal clutch suppliers. It’s also beneficial to reach out to industry associations that can provide recommendations based on member experiences. When evaluating suppliers, ask for samples and detailed technical specifications to ensure compatibility with your machinery. Establishing clear communication about your requirements and quality standards upfront can also help mitigate risks associated with sourcing. Finally, consider forming partnerships with suppliers who offer a warranty or guarantee, as this can provide peace of mind and assurance of quality.

Scenario 2: Performance Issues Leading to Downtime

The Problem:

Another common pain point for B2B buyers is the performance of centrifugal clutches in high-demand applications. For instance, a construction company in the Middle East may experience frequent breakdowns due to improper clutch engagement, leading to costly downtime. This not only affects productivity but also strains relationships with clients who rely on timely project completion. Performance issues can stem from incorrect installation, lack of maintenance, or using clutches that do not match the operational demands.

The Solution:

To address performance issues, it’s crucial to select the right type of centrifugal clutch for your specific application. Buyers should conduct a detailed analysis of the load requirements and operational conditions to ensure that the chosen clutch can handle the demands without failure. Additionally, proper installation is vital—investing in training for your maintenance staff on correct installation and adjustment techniques can significantly enhance performance. Regular maintenance checks and monitoring clutch performance can also preemptively address issues before they lead to downtime. Consider developing a maintenance schedule that includes inspections and adjustments as necessary to prolong the life of the clutches and keep operations running smoothly.

Scenario 3: Lack of Technical Support and Knowledge

The Problem:

Many B2B buyers find themselves lacking the technical knowledge needed to effectively utilize centrifugal clutches, which can hinder their operational efficiency. For example, a buyer in Europe might purchase a centrifugal clutch but struggle to understand its operational parameters, leading to suboptimal performance and inefficient use of resources. The absence of accessible technical support can exacerbate this issue, leaving buyers feeling overwhelmed and unsupported.

The Solution:

To mitigate the knowledge gap, buyers should actively seek out suppliers that offer comprehensive technical support and educational resources. This includes detailed product manuals, installation guides, and access to customer support teams who can provide assistance when needed. Engaging in training sessions or workshops offered by manufacturers can also equip your team with the necessary skills to operate and maintain the clutches effectively. Additionally, consider creating a knowledge-sharing culture within your organization where team members can share insights and best practices related to centrifugal clutches. This proactive approach will not only enhance operational efficiency but also foster a more informed workforce capable of making better purchasing and operational decisions.

Strategic Material Selection Guide for centrifugal clutch

When selecting materials for centrifugal clutches, it is essential to consider the performance characteristics that align with specific applications and operational environments. Here, we analyze four common materials used in centrifugal clutches, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in Centrifugal Clutches?

Aluminum is a popular choice for centrifugal clutches due to its lightweight nature and excellent thermal conductivity. It typically exhibits good corrosion resistance, making it suitable for various environments. The material can withstand moderate temperature variations, with a melting point around 660°C (1220°F).

Pros & Cons:

Aluminum is durable and offers a good strength-to-weight ratio, which enhances the efficiency of the clutch. However, it may not perform well under extreme temperatures or high-stress conditions, potentially leading to deformation over time. Its manufacturing processes are relatively straightforward, but the cost can be higher than some alternatives.

Impact on Application:

Aluminum is compatible with a variety of media, making it versatile for multiple applications, including automotive and industrial machinery. However, buyers should ensure that the specific aluminum alloy used meets their operational requirements.

Considerations for International Buyers:

For buyers from Africa, South America, the Middle East, and Europe, it’s crucial to verify compliance with international standards such as ASTM and DIN. Additionally, understanding local market preferences for aluminum grades can influence procurement decisions.

How Does Steel Perform as a Material for Centrifugal Clutches?

Steel is widely recognized for its strength and durability, making it a common choice for high-performance centrifugal clutches. It has a high melting point (around 1370°C or 2500°F) and can withstand significant pressure and stress.

Pros & Cons:

The primary advantage of steel is its exceptional tensile strength and wear resistance, which translates to longer service life in demanding applications. However, steel is heavier than aluminum, which may not be suitable for all designs. The manufacturing complexity can also lead to higher costs, particularly if specialized treatments are required for corrosion resistance.

Impact on Application:

Steel clutches are ideal for heavy-duty applications, such as construction machinery and high-performance vehicles. However, they may require additional coatings or treatments to prevent rust and corrosion in humid or saline environments.

Considerations for International Buyers:

Buyers should consider the local availability of specific steel grades and their compliance with international standards. Understanding regional regulations regarding material sourcing and treatment can also affect procurement strategies.

What Role Does Composite Material Play in Centrifugal Clutch Applications?

Composite materials, often made from a combination of plastics and fibers, are increasingly used in centrifugal clutches due to their lightweight and high strength. They offer excellent corrosion resistance and can operate effectively at moderate temperatures.

Pros & Cons:

The main advantage of composites is their reduced weight, which can improve efficiency and performance. They also allow for more complex shapes and designs. However, composites may not be suitable for high-temperature applications, and their manufacturing processes can be more complex and costly.

Impact on Application:

Composites are particularly suitable for applications where weight reduction is critical, such as in aerospace and high-performance automotive sectors. However, their temperature limitations should be carefully considered.

Considerations for International Buyers:

When sourcing composite materials, buyers should ensure compliance with relevant standards and certifications. Additionally, understanding the local market’s acceptance of composite materials can influence product design and selection.

Why Is Cast Iron a Viable Option for Centrifugal Clutches?

Cast iron is another material option for centrifugal clutches, known for its excellent wear resistance and ability to dampen vibrations. It has a high melting point (around 1200°C or 2200°F) and can handle significant pressure.

Pros & Cons:

Cast iron is durable and cost-effective, making it suitable for mass production. However, it is heavier than aluminum and can be brittle under certain conditions, which may lead to cracking. The manufacturing process can also be more complex, impacting overall production costs.

Impact on Application:

Cast iron clutches are often used in industrial applications where durability is paramount. However, their weight may limit their use in applications requiring lightweight components.

Considerations for International Buyers:

Buyers should be aware of the specific grades of cast iron available in their region and ensure they meet international standards. Additionally, understanding the local demand for cast iron components can influence purchasing decisions.

Summary Table of Material Selection for Centrifugal Clutches

| Material | Typical Use Case for centrifugal clutch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and industrial machinery | Lightweight and corrosion-resistant | Limited high-temperature performance | Medium |

| Steel | Heavy-duty machinery and vehicles | High strength and durability | Heavier and more complex to manufacture | High |

| Composite | Aerospace and high-performance vehicles | Reduced weight and design flexibility | Temperature limitations | High |

| Cast Iron | Industrial applications | Cost-effective and durable | Heavier and brittle under stress | Low |

This guide provides a comprehensive overview of material options for centrifugal clutches, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal clutch

What Are the Main Stages of Manufacturing a Centrifugal Clutch?

The manufacturing process for a centrifugal clutch typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the required performance specifications and quality standards.

-

Material Preparation: The first step involves selecting the right materials, which usually include high-quality metals such as steel or aluminum, and composite materials for certain components. Suppliers should provide detailed specifications on the materials used, ensuring they meet industry standards for durability and strength.

-

Forming: This stage includes processes such as casting, machining, and stamping. Advanced techniques like CNC machining are often employed to achieve precise dimensions and tolerances. B2B buyers should inquire about the machinery and technology used in the forming process, as this can significantly impact the quality and performance of the centrifugal clutch.

-

Assembly: Once individual components are formed, they are assembled. This may involve manual or automated assembly lines. The assembly process should be meticulously controlled to avoid defects. Buyers should look for suppliers who have standardized assembly procedures and documentation to ensure consistency.

-

Finishing: The final stage involves surface treatments such as anodizing, plating, or painting to enhance corrosion resistance and aesthetics. Proper finishing not only improves the product’s lifespan but also its performance. Buyers should ensure that suppliers adhere to best practices in finishing to prevent premature wear and failure.

How Is Quality Assurance Implemented in Centrifugal Clutch Manufacturing?

Quality assurance (QA) is vital in the production of centrifugal clutches to ensure that they meet international and industry-specific standards. Key aspects of QA include compliance with standards, quality checkpoints, and testing methods.

-

International Standards Compliance: Many manufacturers adhere to international quality standards like ISO 9001, which outlines the criteria for a quality management system. Compliance with such standards indicates that a supplier has a systematic approach to managing quality. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended application of the clutch.

-

Quality Checkpoints: Quality Control (QC) checkpoints are established throughout the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): Assessing raw materials for compliance with specifications.

– In-Process Quality Control (IPQC): Monitoring the manufacturing process to catch defects early.

– Final Quality Control (FQC): Conducting thorough inspections and tests on finished products before shipment. -

Common Testing Methods: Various testing methods are employed to verify the quality of centrifugal clutches. These can include:

– Dimensional Inspection: Using tools like calipers and micrometers to ensure components meet specified dimensions.

– Performance Testing: Simulating operational conditions to evaluate the clutch’s engagement and disengagement performance.

– Durability Testing: Running the clutch through cycles to assess wear and tear over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure that suppliers adhere to high-quality standards:

-

Conducting Audits: Buyers should perform regular audits of their suppliers. This can include site visits to observe manufacturing processes and QC measures in action. Audits can reveal potential issues with quality management systems and compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports, testing results, and certifications. This transparency is key to building trust and ensuring that products meet the required specifications.

-

Utilizing Third-Party Inspectors: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control. These inspectors can conduct thorough evaluations of manufacturing practices, product quality, and compliance with international standards.

-

Understanding QC and Certification Nuances: It’s essential for buyers to understand the nuances of quality certifications that may vary by region. For instance, certifications recognized in Europe may not hold the same weight in South America or Africa. Buyers should ensure that the certifications held by suppliers are relevant and recognized in their specific market.

What Challenges Do International B2B Buyers Face Regarding Quality Assurance?

International B2B buyers face several challenges when navigating quality assurance in centrifugal clutch manufacturing. These challenges can include:

-

Communication Barriers: Differences in language and cultural understanding can lead to misinterpretations of quality standards and expectations. Establishing clear communication channels and documentation is critical to overcoming these barriers.

-

Varying Standards and Regulations: Each region may have different standards and regulations governing product quality. Buyers must be well-versed in the specific requirements applicable in their markets to ensure compliance.

-

Logistical Issues: Shipping and transportation of centrifugal clutches can introduce risks such as damage or delays, which may affect product quality. It’s advisable for buyers to work with reliable logistics partners who understand the importance of handling products carefully.

-

Supplier Reliability: Not all suppliers maintain consistent quality control practices. Conducting thorough due diligence and establishing long-term partnerships with reliable manufacturers can mitigate risks associated with inconsistent quality.

Conclusion: Ensuring Quality in Centrifugal Clutch Procurement

In conclusion, understanding the manufacturing processes and quality assurance measures for centrifugal clutches is essential for international B2B buyers. By thoroughly evaluating suppliers, verifying compliance with international standards, and implementing robust quality control checks, buyers can ensure they procure high-quality products that meet their operational needs. This proactive approach not only enhances product performance but also fosters long-term business relationships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal clutch’

In the competitive landscape of B2B procurement, sourcing a centrifugal clutch requires a structured approach to ensure that the selected product meets your operational needs and standards. This guide provides a comprehensive checklist for international buyers, helping you navigate the intricacies of procurement with confidence.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the centrifugal clutch you require. This includes parameters such as size, material, torque ratings, and operating conditions. Precise specifications help you communicate effectively with suppliers and ensure that you receive products that align with your machinery and operational requirements.

Step 2: Conduct Market Research on Suppliers

Investigate potential suppliers from various regions, focusing on those with a proven track record in manufacturing centrifugal clutches. Explore their experience in your industry and the geographic markets they serve. Look for suppliers that have established credibility and positive reviews, as this can significantly impact the quality and reliability of your procurement.

Step 3: Evaluate Supplier Certifications and Compliance

It’s essential to verify that suppliers hold relevant certifications and comply with international quality standards, such as ISO 9001. Certifications assure you that the supplier adheres to stringent quality control processes. Additionally, check for compliance with regional regulations, particularly if you’re sourcing from different continents, to avoid legal and operational hurdles.

Step 4: Request Samples and Technical Documentation

Before finalizing any orders, request samples of the centrifugal clutches along with technical documentation. This allows you to assess the quality and compatibility of the product with your equipment. Look for detailed specifications, performance data, and installation guidelines to ensure that the product meets your operational needs.

Step 5: Compare Pricing and Payment Terms

Gather pricing information from multiple suppliers and compare it against the quality and specifications of the products offered. Be cautious of prices that are significantly lower than the market average, as they may indicate inferior quality. Additionally, negotiate payment terms that suit your cash flow, considering options like letters of credit or installment payments for larger orders.

Step 6: Assess After-Sales Support and Warranty Options

Inquire about the after-sales support offered by potential suppliers. A reliable supplier should provide technical support, spare parts availability, and warranty coverage. Understanding the warranty conditions is critical as it protects your investment and ensures you have recourse in case of product failures.

Step 7: Finalize the Contract with Clear Terms

Once you have selected a supplier, finalize the contract with clear terms regarding delivery schedules, payment terms, and quality assurance measures. Include clauses that address potential issues such as delays or defective products. A well-structured contract minimizes misunderstandings and safeguards your interests throughout the procurement process.

By following this checklist, you can enhance your sourcing strategy for centrifugal clutches, ensuring that you make informed decisions that align with your business goals and operational requirements.

Comprehensive Cost and Pricing Analysis for centrifugal clutch Sourcing

What Are the Key Cost Components in Centrifugal Clutch Sourcing?

Understanding the cost structure of centrifugal clutches is vital for international B2B buyers aiming to optimize their sourcing strategy. The primary cost components include:

-

Materials: The choice of raw materials, such as aluminum alloys, steel, and composite materials, significantly influences the overall cost. High-quality materials can enhance performance but may increase initial expenses.

-

Labor: Labor costs vary by region and impact the total manufacturing cost. Countries with higher labor costs may offer better-skilled workers, which can lead to improved product quality.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient factories typically have lower overheads, which can be passed on as savings to buyers.

-

Tooling: Custom tooling can be a substantial upfront investment, especially for specialized or high-volume orders. Buyers should factor in these costs when negotiating prices.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to the overall cost. Buyers should assess the balance between quality assurance and budget constraints.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, vary significantly based on the destination and shipping method. Understanding local regulations and potential tariffs is essential for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to their costs. This margin varies based on market conditions and supplier reputation.

How Do Price Influencers Affect Centrifugal Clutch Costs?

Several factors can influence the pricing of centrifugal clutches, making it essential for buyers to understand these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices due to economies of scale. Buyers should negotiate favorable terms that align with their production needs.

-

Specifications and Customization: Customized clutches may incur additional design and production costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (such as ISO or CE) can justify higher prices. Buyers should weigh the benefits of investing in quality against potential long-term savings.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may charge a premium but offer better service and product consistency.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

What Are Effective Buyer Tips for Centrifugal Clutch Sourcing?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should employ strategic approaches to sourcing centrifugal clutches:

-

Negotiate Effectively: Engage in negotiations with a clear understanding of your budget and requirements. Leverage volume commitments to secure better pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), including initial purchase price, maintenance costs, and potential downtime. A lower initial cost may not always equate to better long-term value.

-

Understand Pricing Nuances: Be aware of regional pricing differences influenced by local demand, currency fluctuations, and economic conditions. Buyers should also consider the implications of geopolitical factors that may affect supply chains.

-

Establish Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Consider establishing partnerships that benefit both parties.

Disclaimer on Indicative Prices

Prices for centrifugal clutches can vary widely based on the aforementioned factors and are subject to change due to market conditions. It is advisable for buyers to request updated quotes and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing centrifugal clutch With Other Solutions

Exploring Alternatives to Centrifugal Clutches: What Are the Options?

In the quest for efficient power transmission solutions, B2B buyers must consider various alternatives to centrifugal clutches. Understanding the strengths and weaknesses of each option is crucial for making informed decisions that align with specific operational needs. Below, we compare centrifugal clutches with two viable alternatives: hydraulic couplings and friction clutches.

Comparison Table of Alternatives

| Comparison Aspect | Centrifugal Clutch | Hydraulic Coupling | Friction Clutch |

|---|---|---|---|

| Performance | Excellent for high-torque applications; engages automatically | Smooth engagement; adjustable torque transfer | Versatile across various loads; strong grip |

| Cost | Moderate initial investment; long-term durability | Higher upfront costs; may require more maintenance | Generally lower cost; potential for wear |

| Ease of Implementation | Straightforward installation; minimal space required | More complex setup; requires hydraulic lines | Simple installation; compatible with various systems |

| Maintenance | Low maintenance; periodic inspection needed | Moderate maintenance; hydraulic fluid checks required | Regular maintenance needed; wear parts may need replacement |

| Best Use Case | Ideal for small engines, go-karts, and outdoor power equipment | Best for heavy machinery and applications needing variable speed | Suitable for automotive applications and heavy-duty machinery |

What Are the Pros and Cons of Hydraulic Couplings?

Hydraulic couplings offer a smooth and adjustable torque transfer, making them ideal for applications requiring variable speed control. Their design allows for better shock absorption and reduced wear on connected components. However, the complexity of installation can be a drawback, as it involves hydraulic lines and fluid management. Additionally, the initial costs tend to be higher, which may not be suitable for all budgets, particularly in emerging markets in Africa and South America.

How Do Friction Clutches Compare?

Friction clutches are a well-known alternative, especially in automotive applications. They provide a strong grip and are versatile enough to handle a range of loads. Their lower initial cost makes them attractive for businesses looking to minimize expenses. However, friction clutches can suffer from wear and may require more frequent maintenance, which can lead to higher long-term costs. They are best suited for environments where the load conditions can vary significantly.

Conclusion: Which Solution Should B2B Buyers Choose?

Choosing the right solution among centrifugal clutches, hydraulic couplings, and friction clutches largely depends on specific operational requirements and budget constraints. For high-torque applications with minimal maintenance, centrifugal clutches are often the best fit. Conversely, if smooth operation and flexibility are paramount, hydraulic couplings might be the ideal choice. Friction clutches are advantageous for those prioritizing cost but can entail higher maintenance. By assessing these factors, B2B buyers can make informed decisions that enhance their operational efficiency and align with their long-term strategies.

Essential Technical Properties and Trade Terminology for centrifugal clutch

What Are the Key Technical Properties of a Centrifugal Clutch?

Understanding the technical specifications of a centrifugal clutch is crucial for international B2B buyers. These properties can significantly influence performance, durability, and compatibility with various applications. Here are some essential technical properties to consider:

-

Material Grade

The material used in the construction of a centrifugal clutch impacts its strength and wear resistance. Common materials include cast iron, aluminum, and high-strength polymers. Buyers should prioritize high-grade materials that can withstand high rotational speeds and varying environmental conditions, ensuring longevity and reliability in their applications. -

Torque Capacity

Torque capacity refers to the maximum torque a centrifugal clutch can handle before slipping occurs. This specification is vital for applications requiring precise power transfer, such as in motorcycles or industrial machinery. Buyers should assess their specific torque requirements to ensure the clutch selected can handle the demands of their operations without failure. -

Operating Speed Range

The operating speed range indicates the minimum and maximum speeds at which the centrifugal clutch can function effectively. This property is particularly important for applications that involve variable speed motors or engines. Buyers should ensure that the clutch operates efficiently within the intended speed range to avoid premature wear and operational issues. -

Tolerance Levels

Tolerance levels define the acceptable limits of variation in the dimensions of the clutch components. Precise tolerances are crucial for ensuring proper fit and function, especially in high-performance applications. Buyers should look for manufacturers that adhere to strict tolerance standards to guarantee optimal performance and minimize maintenance costs. -

Engagement and Disengagement Mechanism

This property describes how the clutch engages and disengages during operation. A well-designed mechanism can improve responsiveness and control in applications such as go-karts or lawn equipment. Buyers should consider clutches with reliable engagement systems to enhance overall performance and reduce wear.

Which Trade Terms Should International B2B Buyers Understand?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key trade terms relevant to centrifugal clutches:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM standards is crucial for buyers seeking quality components that meet specific industry requirements. Ensure that the centrifugal clutches sourced are from reputable OEMs to guarantee consistency and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for international buyers who need to balance inventory costs with supply chain efficiency. Understanding the MOQ can help buyers negotiate better terms and optimize their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price quotes for specific products or services. Buyers should utilize RFQs to gather competitive pricing and evaluate potential suppliers. A well-structured RFQ can streamline the procurement process and help in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. They cover aspects such as shipping, insurance, and customs clearance. Familiarizing yourself with relevant Incoterms can help mitigate risks and ensure smooth transactions, especially when dealing with suppliers across continents. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for effective inventory management, especially for businesses in fast-paced industries. Buyers should communicate their timelines clearly with suppliers to ensure timely delivery and avoid disruptions in production. -

Warranty Terms

Warranty terms outline the conditions under which a product is guaranteed against defects or failures. Knowing the warranty details is essential for buyers to protect their investments and ensure long-term reliability. Always review warranty terms before finalizing purchases to align with your operational needs.

A stock image related to centrifugal clutch.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing centrifugal clutches, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the centrifugal clutch Sector

What Are the Current Market Dynamics Affecting the Centrifugal Clutch Sector?

A stock image related to centrifugal clutch.

The centrifugal clutch market is experiencing dynamic shifts driven by several global factors. Increased demand for automation in various industries, including automotive, agriculture, and power equipment, is propelling the growth of centrifugal clutches. Moreover, the rise of electric vehicles (EVs) and hybrid technologies is creating new opportunities for clutch manufacturers to innovate and diversify their product lines. International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the ongoing shift towards integrating advanced materials and IoT technologies into clutch systems, enhancing their performance and reliability.

Emerging B2B sourcing trends are also evident. Companies are moving towards direct sourcing models, leveraging digital platforms to connect with manufacturers globally. This approach not only reduces costs but also allows buyers to access a broader range of products and suppliers. Furthermore, the trend of regional sourcing is gaining traction as businesses aim to mitigate risks associated with global supply chains, especially in light of recent geopolitical tensions and logistical challenges. Buyers from regions like South America and Africa should explore local suppliers who can offer competitive pricing while ensuring quality and timely delivery.

How Can Sustainability and Ethical Sourcing Impact the Centrifugal Clutch Market?

Sustainability is becoming a crucial consideration in the centrifugal clutch sector. Environmental impacts associated with manufacturing processes, such as emissions and waste management, are increasingly under scrutiny. B2B buyers are now prioritizing suppliers that demonstrate commitment to sustainable practices, including the use of eco-friendly materials and energy-efficient production methods.

The importance of ethical supply chains cannot be overstated. Buyers should engage with manufacturers who are transparent about their sourcing processes and labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are indicators of a supplier’s commitment to sustainability and ethical standards. Moreover, the adoption of ‘green’ materials, such as recyclable metals and biodegradable composites, is becoming a competitive differentiator. International buyers can leverage these insights to not only enhance their brand reputation but also align with the growing consumer demand for sustainable products.

What Is the Historical Context of the Centrifugal Clutch Sector?

The centrifugal clutch has evolved significantly since its inception in the early 20th century. Originally designed for simple applications in motorcycles and small engines, advancements in materials and engineering have led to its widespread adoption across various industries. The introduction of automated systems and digital controls has further refined clutch performance, making them integral to modern machinery and vehicles.

In recent years, technological advancements have allowed for greater customization and efficiency, catering to the diverse needs of global markets. B2B buyers should consider this historical context when evaluating potential suppliers, as established companies may possess valuable experience and expertise that newer entrants lack. Understanding the evolution of centrifugal clutches can help buyers make informed decisions, ensuring they select suppliers capable of meeting contemporary demands while anticipating future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal clutch

-

How do I solve performance issues with centrifugal clutches?

Performance issues with centrifugal clutches can often be traced back to improper installation, incorrect sizing, or inadequate maintenance. Ensure that the clutch is installed according to the manufacturer’s specifications and that it is compatible with your engine’s RPM range. Regular maintenance, including cleaning and lubrication, can prevent wear and tear. If problems persist, consult with the supplier for troubleshooting assistance or consider seeking expert advice for a deeper analysis. -

What is the best centrifugal clutch for small engine applications?

The best centrifugal clutch for small engine applications typically features a lightweight design and a low engagement RPM. Look for clutches made from durable materials that can withstand high temperatures and resist wear. Brands known for their reliability in small engine applications include Comet and Max-Torque. Always consult with your supplier to ensure compatibility with your specific engine model and intended application. -

What should I consider when sourcing centrifugal clutches internationally?

When sourcing centrifugal clutches from international suppliers, consider factors such as product quality, compliance with local standards, and the supplier’s reputation. Verify the supplier’s certifications and check for reviews from other B2B buyers. Additionally, assess the logistics involved, including shipping times and costs, to ensure timely delivery. Engaging with suppliers who have experience in your region can also mitigate potential challenges. -

What are the minimum order quantities (MOQ) for centrifugal clutches?

Minimum order quantities for centrifugal clutches can vary significantly depending on the manufacturer and type of clutch. Some suppliers may offer MOQs as low as 10 units, while others might require orders of 100 units or more. It’s advisable to discuss your specific needs with the supplier, as they may be willing to negotiate terms, especially for first-time buyers or bulk orders. -

What payment terms should I expect when purchasing centrifugal clutches?

Payment terms for purchasing centrifugal clutches can range from upfront payment to net 30 or net 60 days. Some suppliers may also accept letters of credit or escrow services to protect both parties. Always clarify payment terms before finalizing the order, and consider using secure payment methods that provide buyer protection. Establishing a good relationship with your supplier can also lead to more favorable payment terms in the future. -

How can I ensure the quality of centrifugal clutches before purchase?

To ensure the quality of centrifugal clutches, request samples or prototypes before making a large purchase. Conduct thorough inspections based on industry standards and specifications. Inquire about the supplier’s quality assurance processes, including any testing or certifications the product has undergone. Additionally, consider third-party quality audits if sourcing from overseas suppliers to ensure compliance with your quality expectations. -

What logistics considerations should I keep in mind when importing centrifugal clutches?

When importing centrifugal clutches, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who understands the complexities of international shipping, particularly in your region. Factor in lead times for production and shipping, and ensure that you have the necessary documentation for customs clearance. Effective communication with your supplier regarding shipping schedules can prevent delays. -

Can centrifugal clutches be customized for specific applications?

Yes, many manufacturers offer customization options for centrifugal clutches to meet specific application requirements. This may include modifications in size, engagement RPM, or materials used. When considering customization, provide detailed specifications and discuss your needs with the supplier. Be aware that custom orders may have longer lead times and potentially higher costs, so plan accordingly in your procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for centrifugal clutch

What Are the Key Takeaways for B2B Buyers in the Centrifugal Clutch Market?

In summary, the centrifugal clutch market presents significant opportunities for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. Strategic sourcing is critical, enabling companies to optimize costs while ensuring quality and reliability in their supply chains. Buyers should prioritize partnerships with manufacturers who demonstrate both technical expertise and a commitment to sustainable practices, as these factors can enhance operational efficiency and brand reputation.

How Can Strategic Sourcing Enhance Your Business Operations?

Effective strategic sourcing goes beyond price; it involves evaluating suppliers based on their innovation capabilities, responsiveness, and overall value proposition. For buyers in emerging markets, leveraging local suppliers can mitigate risks associated with international shipping and import regulations while fostering economic growth within their regions.

What Is the Future Outlook for the Centrifugal Clutch Market?

Looking ahead, the centrifugal clutch industry is poised for growth, driven by advancements in technology and increasing demand across various sectors, including automotive and industrial applications. B2B buyers are encouraged to stay informed about market trends and innovations, as these insights will be pivotal in making informed sourcing decisions.

In conclusion, by embracing strategic sourcing principles, businesses can not only enhance their procurement strategies but also position themselves favorably in an increasingly competitive landscape. Engage with suppliers who align with your business goals and invest in relationships that will drive mutual growth. The future is bright for those ready to adapt and innovate in the centrifugal clutch market.