Unlock Efficiency: The Ultimate Guide to 5.9 Cummins Engine (2025)

Introduction: Navigating the Global Market for 5.9 cummins engine

In the competitive landscape of industrial machinery, sourcing the right components is crucial for operational efficiency and longevity. The 5.9 Cummins engine stands out as a reliable power solution, but navigating the global market to procure it can present challenges for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Understanding the nuances of sourcing this engine—including its types, applications, supplier vetting processes, and cost implications—can significantly impact your purchasing decisions and overall business performance.

This comprehensive guide aims to equip you with the knowledge necessary to make informed choices in the global marketplace for the 5.9 Cummins engine. We will explore various engine configurations and their specific applications across different industries, ensuring you choose the right variant for your needs. Additionally, we will delve into effective strategies for vetting suppliers, helping you identify reputable sources that align with your quality and budget expectations.

By the end of this guide, you will have actionable insights that empower you to navigate the complexities of sourcing the 5.9 Cummins engine confidently. Whether you are looking to enhance your fleet’s performance or ensure compliance with local regulations, this resource is designed to facilitate your decision-making process and drive successful procurement outcomes.

Understanding 5.9 cummins engine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 5.9L ISB | Inline six-cylinder, turbocharged, high torque | Trucks, buses, construction equipment | Pros: High durability, excellent fuel efficiency. Cons: Limited power range for heavy-duty applications. |

| 5.9L QSB | Compact design, emissions compliant, low noise | Agricultural machinery, generators | Pros: Environmentally friendly, versatile. Cons: Higher initial investment compared to older models. |

| 5.9L B Series | Modular design, customizable, robust performance | Marine applications, industrial use | Pros: Flexible configurations, strong aftermarket support. Cons: May require specialized maintenance. |

| 5.9L Cummins 6BT | Mechanical fuel system, reliable performance | Light-duty trucks, RVs | Pros: Simplicity in repairs, cost-effective. Cons: Older technology, may lack modern features. |

| 5.9L ISL | Higher horsepower, advanced electronics | Heavy-duty trucks, specialty vehicles | Pros: Enhanced power delivery, advanced diagnostics. Cons: Complexity may lead to higher repair costs. |

What are the characteristics of the 5.9L ISB engine for B2B buyers?

The 5.9L ISB engine is known for its inline six-cylinder design, providing robust torque and excellent fuel efficiency. This engine is particularly suitable for medium-duty applications, such as trucks and buses, where reliability is paramount. B2B buyers should consider its durability and performance in harsh conditions, making it ideal for sectors like construction and transportation. However, potential buyers should be aware that while it excels in fuel efficiency, it may not provide the power range required for heavier applications.

How does the 5.9L QSB engine cater to diverse applications?

The 5.9L QSB engine features a compact design with emissions compliance, making it a popular choice for agricultural machinery and generators. Its low noise operation is an added advantage in urban settings. For B2B buyers, the environmental benefits and versatility of the QSB engine make it a compelling option. However, the initial investment may be higher than older models, necessitating a careful cost-benefit analysis to ensure it aligns with long-term operational goals.

What advantages does the 5.9L B Series engine offer to industrial applications?

The 5.9L B Series engine is modular and customizable, allowing businesses to tailor it to specific needs. It is robust and well-suited for marine and industrial applications, with strong aftermarket support enhancing its appeal. B2B buyers should consider the flexibility in configurations that this engine offers, which can be advantageous in specialized applications. However, the need for specialized maintenance can be a downside, requiring buyers to ensure access to qualified technicians.

What makes the 5.9L Cummins 6BT engine a cost-effective choice?

The 5.9L Cummins 6BT engine is characterized by its mechanical fuel system, providing reliability and simplicity in repairs. This engine is often used in light-duty trucks and RVs, making it a practical choice for small business operations. B2B buyers benefit from the cost-effectiveness and ease of maintenance. However, they should also consider that this older technology may lack some modern features, which could impact performance in competitive markets.

How does the 5.9L ISL engine enhance heavy-duty applications?

The 5.9L ISL engine stands out with its higher horsepower and advanced electronic controls, making it suitable for heavy-duty trucks and specialty vehicles. Its ability to deliver enhanced power and advanced diagnostics is particularly beneficial for fleet operators looking for efficiency and reliability. B2B buyers should weigh the advantages of performance against the potential for higher repair costs due to its complexity. Understanding these factors will help in making an informed purchasing decision.

Related Video: 24 Valve 5.9 Cummins Engine Sound Test Inside Truck#CumminsEngine #TruckSound

Key Industrial Applications of 5.9 cummins engine

| Industry/Sector | Specific Application of 5.9 cummins engine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Tractors and Harvesters | Improved fuel efficiency and reliability | Availability of parts and service support |

| Construction | Heavy-duty Construction Equipment | Enhanced power for demanding tasks | Compliance with local emissions regulations |

| Transportation & Logistics | Delivery Trucks and Freight Vehicles | Reduced operational costs through fuel savings | Warranty terms and after-sales service |

| Mining | Excavators and Loaders | Increased productivity and reduced downtime | Terrain adaptability and engine durability |

| Marine | Commercial Fishing Vessels | High torque for heavy loads and rough conditions | Saltwater resistance and maintenance accessibility |

How is the 5.9 Cummins Engine Used in Agriculture?

In the agriculture sector, the 5.9 Cummins engine is commonly utilized in tractors and harvesters. These engines offer exceptional fuel efficiency, allowing farmers to optimize their operational costs while ensuring reliable performance during peak seasons. International buyers, particularly from regions like Africa and South America, should consider the availability of spare parts and local service support to minimize downtime during critical farming periods.

What Role Does the 5.9 Cummins Engine Play in Construction?

The construction industry benefits significantly from the 5.9 Cummins engine, which powers heavy-duty construction equipment such as excavators and bulldozers. The engine’s robust power output is crucial for demanding tasks, ensuring that equipment can operate efficiently under heavy loads. Buyers from the Middle East and Europe should be aware of local emissions regulations and ensure compliance when sourcing these engines for construction projects.

How Does the 5.9 Cummins Engine Enhance Transportation and Logistics?

In the transportation and logistics sector, the 5.9 Cummins engine is a preferred choice for delivery trucks and freight vehicles. Its ability to provide reduced operational costs through improved fuel efficiency is a significant advantage for businesses looking to enhance their bottom line. B2B buyers should closely examine warranty terms and after-sales service offerings to ensure long-term operational efficiency and support.

What Are the Benefits of Using the 5.9 Cummins Engine in Mining?

Mining operations rely heavily on the 5.9 Cummins engine for powering excavators and loaders. This engine is designed to deliver high torque and durability, which are essential for handling the harsh conditions of mining sites. Buyers, particularly from rugged terrains in Africa and South America, need to consider the engine’s adaptability to various terrains and its overall durability to minimize operational interruptions.

How is the 5.9 Cummins Engine Utilized in the Marine Industry?

The marine sector, especially commercial fishing, benefits from the 5.9 Cummins engine due to its high torque output, which is vital for carrying heavy loads and navigating rough waters. The engine’s design offers enhanced reliability in demanding marine environments. Buyers should prioritize sourcing engines that are resistant to saltwater corrosion and ensure that maintenance services are readily available to keep vessels operational and compliant with maritime regulations.

3 Common User Pain Points for ‘5.9 cummins engine’ & Their Solutions

Scenario 1: High Maintenance Costs for the 5.9 Cummins Engine

The Problem:

B2B buyers operating in industries such as transportation or agriculture often face exorbitant maintenance costs associated with the 5.9 Cummins engine. This issue is particularly prevalent in regions like Africa and South America, where the availability of quality parts and skilled technicians can be limited. Buyers may find themselves frequently replacing components like injectors, fuel pumps, or turbochargers, leading to increased downtime and reduced productivity. The financial strain can be significant, especially for small to medium-sized enterprises that rely heavily on these engines for their operations.

The Solution:

To mitigate maintenance costs, buyers should establish relationships with reputable suppliers who offer OEM (Original Equipment Manufacturer) parts as well as reliable aftermarket alternatives. Regular maintenance schedules should be strictly adhered to, focusing on oil changes, filter replacements, and system checks to prevent minor issues from escalating into major repairs. Investing in training for local technicians can also pay dividends, as it empowers them to perform preventive maintenance and minor repairs in-house. Additionally, buyers should consider utilizing telematics systems that monitor engine performance and alert them to potential issues before they become costly problems.

Scenario 2: Lack of Performance Efficiency in Diverse Conditions

The Problem:

In regions like the Middle East and Europe, where environmental conditions can vary dramatically, the 5.9 Cummins engine may not always perform efficiently. Buyers often report issues with fuel efficiency and power output, especially when operating in extreme temperatures or altitudes. This inefficiency not only affects operational costs but can also impact the reputation of businesses that rely on timely deliveries or heavy machinery performance.

The Solution:

To enhance performance efficiency, buyers should consider customizing their 5.9 Cummins engines with performance upgrades suited for specific environmental conditions. This could include the installation of high-performance air filters, exhaust systems, or engine tuning software that adjusts fuel injection parameters based on real-time data. Additionally, utilizing fuel additives designed for extreme conditions can improve combustion efficiency and engine response. Buyers are encouraged to work closely with their suppliers to ensure that any modifications comply with local regulations and do not void warranties.

Scenario 3: Difficulty Sourcing Reliable Technical Support

The Problem:

One of the most pressing pain points for international B2B buyers of the 5.9 Cummins engine is the difficulty in sourcing reliable technical support, especially in remote areas. Many companies find themselves without access to expert advice when issues arise, leading to extended downtimes and frustration. This situation is exacerbated in regions such as Africa and parts of South America, where local expertise on specific engine models may be scarce.

The Solution:

To address this challenge, buyers should invest in building a network of support by partnering with established service centers that specialize in Cummins engines. These partnerships can provide access to not just technical support but also training for local technicians. Additionally, leveraging online forums and communities dedicated to Cummins engine users can provide valuable insights and troubleshooting advice. Buyers should also consider subscribing to maintenance management software that includes access to technical resources and support, ensuring they have guidance readily available when needed.

Strategic Material Selection Guide for 5.9 cummins engine

What Are the Key Materials Used in the 5.9 Cummins Engine?

When selecting materials for the 5.9 Cummins engine, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: Cast Iron, Aluminum, Steel Alloys, and Composite Materials. Each material has unique characteristics that can significantly impact engine performance and suitability for various applications.

How Does Cast Iron Perform in 5.9 Cummins Engines?

Cast iron is a widely used material for engine blocks and cylinder heads due to its excellent wear resistance and ability to withstand high temperatures and pressures. Its thermal conductivity allows for effective heat dissipation, which is critical in maintaining engine performance.

Pros: Cast iron is durable and has a relatively low manufacturing complexity, making it cost-effective for mass production. It also provides good vibration damping, which enhances engine longevity.

Cons: The primary limitation of cast iron is its weight, which can affect overall vehicle performance and fuel efficiency. Additionally, cast iron is prone to corrosion if not properly treated, which can lead to maintenance issues.

Impact on Application: Cast iron is compatible with various media, including oil and coolant, making it suitable for heavy-duty applications. However, international buyers should ensure compliance with local standards, such as ASTM A48 or DIN 1691.

Why Choose Aluminum for the 5.9 Cummins Engine?

Aluminum is increasingly popular in engine design due to its lightweight nature and excellent corrosion resistance. It is often used in components such as intake manifolds and engine blocks.

Pros: The primary advantage of aluminum is its weight reduction, which can significantly enhance fuel efficiency and overall vehicle performance. Additionally, aluminum has good thermal conductivity, allowing for efficient heat dissipation.

Cons: On the downside, aluminum is generally more expensive than cast iron and can be more complex to manufacture. It also has lower tensile strength, which may limit its use in high-stress applications.

Impact on Application: Aluminum is compatible with various fluids, including antifreeze and oil, making it versatile. Buyers from regions with high humidity or corrosive environments should consider coatings or treatments to enhance durability.

What Role Do Steel Alloys Play in the 5.9 Cummins Engine?

Steel alloys are commonly used in components that require high strength and durability, such as crankshafts and connecting rods. The ability of steel to withstand high stress and fatigue makes it a preferred choice for critical engine components.

Pros: Steel alloys offer excellent mechanical properties and can be tailored to specific performance requirements through heat treatment. They are also cost-effective compared to specialized materials.

Cons: The main disadvantage of steel alloys is their susceptibility to corrosion, which necessitates protective coatings or treatments. Additionally, the weight of steel can negatively impact overall vehicle efficiency.

Impact on Application: Steel alloys are suitable for high-stress applications, but international buyers must ensure compliance with standards such as ASTM A572 or JIS G3101 to maintain quality and performance.

How Do Composite Materials Enhance the 5.9 Cummins Engine?

Composite materials, such as carbon fiber reinforced polymers, are emerging in engine design due to their high strength-to-weight ratio and resistance to corrosion. They are often used in non-structural components.

Pros: The primary advantage of composites is their lightweight nature, which can lead to improved fuel efficiency. They also offer excellent resistance to corrosion and fatigue.

Cons: However, composites can be more expensive than traditional materials and may require specialized manufacturing processes. Their performance can also be sensitive to temperature changes.

Impact on Application: Composites are compatible with various engine fluids, but their use in high-temperature areas may be limited. Buyers should consider the specific application and ensure compliance with relevant standards.

Summary Table of Material Selection for 5.9 Cummins Engine

| Material | Typical Use Case for 5.9 Cummins engine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Engine blocks, cylinder heads | Excellent wear resistance | Heavy and prone to corrosion | Medium |

| Aluminum | Intake manifolds, engine blocks | Lightweight and corrosion-resistant | Higher cost and lower tensile strength | High |

| Steel Alloys | Crankshafts, connecting rods | High strength and durability | Susceptible to corrosion | Medium |

| Composite Materials | Non-structural components | High strength-to-weight ratio | Expensive and temperature sensitive | High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions when sourcing components for the 5.9 Cummins engine.

In-depth Look: Manufacturing Processes and Quality Assurance for 5.9 cummins engine

What Are the Key Stages in the Manufacturing Process of the 5.9 Cummins Engine?

The manufacturing process of the 5.9 Cummins engine involves several critical stages, ensuring that every engine meets the high standards expected in the market. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

Material preparation is the first step in the manufacturing process, where high-quality raw materials are sourced. For the 5.9 Cummins engine, this typically involves acquiring various metals and composites that can withstand the engine’s operational stresses. Suppliers should prioritize materials that comply with international standards, ensuring durability and performance.

2. Forming Techniques

Once materials are prepared, the next stage is forming, which includes processes such as casting, forging, and machining. For the 5.9 Cummins engine, advanced casting techniques are often employed to create complex shapes and improve structural integrity. Machining follows to achieve precise dimensions and tolerances, critical for engine performance.

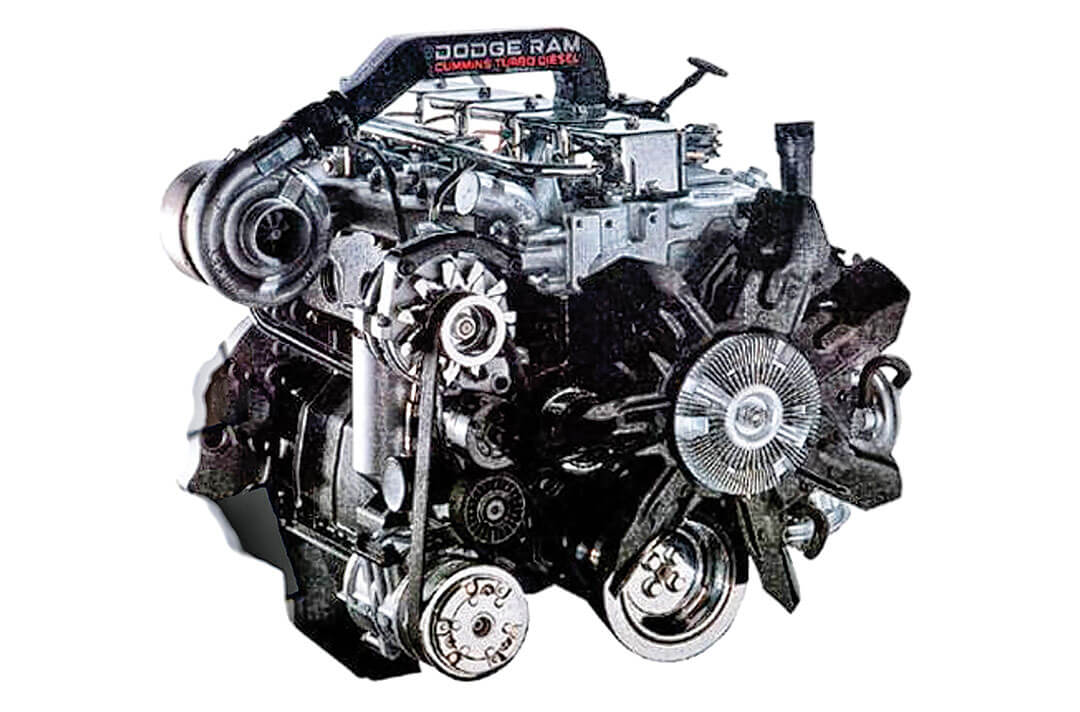

A stock image related to 5.9 cummins engine.

3. Assembly Process

The assembly process is crucial for ensuring that all components fit together seamlessly. Skilled technicians and automated systems work in tandem to assemble engine parts, including the block, cylinder head, and crankshaft. Each component undergoes a pre-assembly inspection to detect any defects early, minimizing the risk of quality issues later.

4. Finishing Touches

The finishing stage involves surface treatments and coatings to enhance the engine’s resistance to wear and corrosion. This may include processes like anodizing or painting. A thorough inspection is conducted post-finishing to ensure that all components meet the specified quality standards before the engine is sent for final testing.

How Is Quality Assurance Implemented in the Manufacturing of the 5.9 Cummins Engine?

Quality assurance (QA) is vital in the manufacturing of the 5.9 Cummins engine, ensuring that every engine meets stringent performance and safety standards. This involves adherence to various international and industry-specific standards.

Relevant International Standards for Quality Assurance

Manufacturers of the 5.9 Cummins engine often adhere to ISO 9001, which sets out criteria for a quality management system (QMS). This certification demonstrates a commitment to quality and continuous improvement. Additionally, compliance with standards such as CE marking and API (American Petroleum Institute) ensures that the engine meets safety and environmental regulations specific to the industry.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process, providing structured oversight at various stages.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival. Suppliers should provide documentation proving compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checkpoints ensure that each stage meets quality standards. This includes monitoring critical dimensions and operational parameters.

-

Final Quality Control (FQC): The final inspection occurs post-assembly, where the engine undergoes rigorous testing, including performance tests and emissions assessments, to ensure it meets all operational standards.

What Testing Methods Are Commonly Used in the Quality Assurance of 5.9 Cummins Engines?

Various testing methods are employed to ensure the reliability and performance of the 5.9 Cummins engine. Some common techniques include:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect surface and subsurface defects without damaging the components.

-

Performance Testing: Engines are subjected to simulated operating conditions to assess performance metrics such as power output, fuel efficiency, and emissions levels.

-

Durability Testing: This involves extended operational testing to determine the engine’s longevity and reliability under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are several effective strategies:

1. Conduct Supplier Audits

Regular supplier audits can help assess compliance with quality standards. These audits should focus on both the manufacturing process and the QMS in place. Buyers should request access to audit reports to ensure transparency.

2. Request Quality Control Documentation

Buyers should ask for detailed quality control documentation, including inspection reports and certification for materials used. This ensures that the supplier maintains rigorous QC practices.

3. Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can verify compliance with relevant standards and provide certification of quality.

What Are the QC Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of the nuances in quality control certification across different regions. For instance, while ISO 9001 is widely recognized, local regulations may dictate additional certifications. Buyers should familiarize themselves with these regional requirements to ensure compliance and avoid potential trade barriers.

Moreover, understanding the certification landscape can help buyers identify reputable suppliers. Certifications such as CE marking in Europe or API standards in the oil and gas sector can serve as indicators of a supplier’s commitment to quality and safety.

Conclusion

The manufacturing processes and quality assurance measures for the 5.9 Cummins engine are designed to ensure that each engine not only meets but exceeds industry standards. For B2B buyers, understanding these processes is crucial for making informed purchasing decisions. By prioritizing suppliers who adhere to rigorous quality assurance practices and international standards, buyers can mitigate risks and ensure the reliability of their engine investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5.9 cummins engine’

This sourcing guide is designed to assist international B2B buyers in effectively procuring the 5.9 Cummins engine. Whether you are operating in Africa, South America, the Middle East, or Europe, following this checklist will help streamline your purchasing process, ensuring you get the best quality products while minimizing risks.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to have a clear understanding of your technical requirements for the 5.9 Cummins engine. Consider the engine’s power output, fuel type, and intended application. This clarity will not only guide your supplier selection but also help in negotiating specifications that meet your operational needs.

- Key Considerations:

- Determine horsepower and torque requirements.

- Specify any additional features, such as emissions standards compliance.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in the 5.9 Cummins engine. Utilize online marketplaces, industry directories, and trade shows to compile a list of candidates. Reliable suppliers are crucial for ensuring product quality and after-sales support.

- Tips for Research:

- Look for suppliers with a proven track record in your region.

- Pay attention to customer reviews and testimonials.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step is vital in ensuring that the supplier can meet your quality and delivery expectations.

- What to Look For:

- Supplier certifications, such as ISO 9001.

- Evidence of successful previous projects involving the 5.9 Cummins engine.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes for the 5.9 Cummins engine. A well-structured quote should include pricing, payment terms, delivery timelines, and warranty information. Comparing quotes not only helps identify the best financial option but also reveals variations in service levels.

- Considerations:

- Look for hidden costs, such as shipping or customs duties.

- Assess the overall value rather than just the lowest price.

Step 5: Verify Compliance with International Standards

Ensure that the engine and its components comply with international quality and safety standards. This is particularly important if you plan to import the engine into your country, as non-compliance can lead to costly delays or fines.

- Compliance Checks:

- Request documentation proving adherence to environmental regulations.

- Verify that the supplier has a quality management system in place.

Step 6: Negotiate Terms and Conditions

Engage in negotiations with your chosen supplier to finalize the terms of your purchase. This should include price, delivery schedules, payment terms, and warranty provisions. Effective negotiation can lead to better pricing and additional benefits.

- Negotiation Tips:

- Be clear about your expectations and needs.

- Don’t hesitate to ask for concessions or additional services.

Step 7: Plan for After-Sales Support and Maintenance

After procuring the 5.9 Cummins engine, establish a plan for after-sales support and maintenance. Reliable support is essential for minimizing downtime and ensuring the longevity of your engine.

- What to Discuss:

- Availability of spare parts and service options.

- Warranty coverage and support response times.

By following this step-by-step checklist, international B2B buyers can confidently navigate the procurement process for the 5.9 Cummins engine, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for 5.9 cummins engine Sourcing

What Are the Key Cost Components in Sourcing a 5.9 Cummins Engine?

When sourcing a 5.9 Cummins engine, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The raw materials used in the production of the engine significantly influence the overall cost. Factors like steel prices, aluminum, and other components can fluctuate based on global market conditions.

-

Labor: Labor costs vary by region and are influenced by local wage standards and the skill level of the workforce. In regions like Africa and South America, labor may be less expensive, while Europe may see higher wage requirements.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production facilities. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial setup costs for tooling are substantial, particularly for custom or specialized engines. Buyers should consider these costs as part of their overall investment.

-

Quality Control (QC): Ensuring that the engines meet specific quality standards incurs additional costs. This is especially important for international buyers who may require certifications that comply with local regulations.

-

Logistics: Shipping and handling costs can vary greatly based on the distance and the mode of transportation. Incoterms (International Commercial Terms) will also play a role in determining who bears these costs.

-

Margin: Suppliers will incorporate their profit margin into the pricing structure. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Affect the Sourcing of 5.9 Cummins Engines?

Several factors influence the pricing of a 5.9 Cummins engine, making it essential for buyers to grasp these nuances:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to discounts. Suppliers often have a MOQ, which, if met, can significantly reduce the unit price.

-

Specifications and Customization: Customized engines or those with specific features may incur higher costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can affect pricing. Engines built with premium materials or that have undergone rigorous testing may command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: The selected Incoterms can determine cost responsibilities between buyer and seller. Understanding these terms is crucial for calculating the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing 5.9 Cummins Engines?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Suppliers often have room for negotiation, especially for bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term operational costs associated with the engine, including maintenance, fuel efficiency, and resale value.

-

Be Aware of Pricing Nuances: Understand local market conditions, currency fluctuations, and geopolitical factors that might impact pricing. This knowledge can provide leverage in negotiations.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and priority service. Suppliers value repeat business and may be more willing to offer favorable terms.

Disclaimer Regarding Indicative Prices

It is important to note that the prices for 5.9 Cummins engines can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain multiple quotations to ensure competitive pricing.

Alternatives Analysis: Comparing 5.9 cummins engine With Other Solutions

Understanding Alternatives to the 5.9 Cummins Engine

When considering the 5.9 Cummins engine for your business needs, it is essential to evaluate alternative solutions that may offer similar performance or advantages. The choice of engine can significantly impact operational efficiency, cost-effectiveness, and maintenance requirements, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Below, we provide a comparative analysis of the 5.9 Cummins engine against two viable alternatives: the Isuzu 4HK1 and the Volvo D5K engines.

Comparison Table

| Comparison Aspect | 5.9 Cummins Engine | Isuzu 4HK1 Engine | Volvo D5K Engine |

|---|---|---|---|

| Performance | 230-325 HP | 150-190 HP | 180-220 HP |

| Cost | Moderate | Lower | Higher |

| Ease of Implementation | High | Moderate | High |

| Maintenance | Moderate | Low | Moderate |

| Best Use Case | Heavy-duty vehicles | Light to medium-duty | Medium to heavy-duty |

What Are the Pros and Cons of the Isuzu 4HK1 Engine?

The Isuzu 4HK1 engine stands out for its cost-effectiveness and low maintenance requirements. This engine offers a decent performance range of 150-190 HP, making it suitable for light to medium-duty applications. Its lower initial cost is appealing for businesses looking to minimize capital expenditure. However, it may not be suitable for heavy-duty tasks, limiting its versatility in demanding environments. Additionally, while the 4HK1 is easier to maintain than the Cummins engine, it may not deliver the same power output, which could be a drawback for certain applications.

How Does the Volvo D5K Engine Compare?

The Volvo D5K engine provides a robust performance range of 180-220 HP, making it ideal for medium to heavy-duty applications. Its advanced engineering allows for better fuel efficiency and lower emissions, aligning with modern sustainability goals. However, the initial cost of the D5K engine is generally higher than that of the 5.9 Cummins engine, which could be a deterrent for budget-conscious buyers. Moreover, while the maintenance is manageable, it may not be as straightforward as that of the Isuzu 4HK1, potentially leading to higher long-term costs.

Conclusion: How Can B2B Buyers Choose the Right Engine Solution?

Choosing the right engine solution requires a thorough understanding of your operational needs, budget constraints, and maintenance capabilities. The 5.9 Cummins engine is an excellent choice for heavy-duty applications where performance is critical. In contrast, the Isuzu 4HK1 may appeal to businesses focused on cost savings and light-duty needs. Meanwhile, the Volvo D5K engine is suitable for those who prioritize efficiency and sustainability but are willing to invest more upfront. By carefully assessing these factors, B2B buyers can select an engine that aligns with their specific requirements and long-term business goals.

Essential Technical Properties and Trade Terminology for 5.9 cummins engine

What Are the Key Technical Properties of the 5.9 Cummins Engine?

Understanding the technical specifications of the 5.9 Cummins engine is crucial for international B2B buyers, as these properties directly influence performance, durability, and compatibility with various applications. Here are some essential technical properties:

-

Displacement

The 5.9 Cummins engine has a displacement of 5.9 liters. Displacement refers to the total volume of all the cylinders in the engine. A larger displacement typically means more power and torque, which is vital for heavy-duty applications such as construction and agriculture. For buyers, knowing the engine’s displacement helps assess whether it meets their power requirements. -

Torque Rating

This engine can produce a peak torque of around 1,000 lb-ft (pound-feet). Torque is a measure of rotational force, and in the context of engines, it indicates how much pulling power the engine can generate. High torque is essential for applications that require heavy towing or hauling, making it a significant factor in procurement decisions. -

Fuel Type

The 5.9 Cummins engine operates on diesel fuel. Diesel engines are known for their fuel efficiency and longevity compared to gasoline engines. For international buyers, understanding fuel compatibility is crucial, especially in regions where diesel availability may vary. -

Material Composition

The engine block is typically made from cast iron, which provides durability and resistance to wear. The choice of materials affects the engine’s performance, maintenance needs, and overall lifespan. Buyers should consider these material properties when evaluating the long-term costs associated with engine maintenance and repairs. -

Compression Ratio

The 5.9 Cummins engine has a compression ratio of about 17.5:1. A higher compression ratio usually leads to improved efficiency and power output. For B2B buyers, this ratio is vital when assessing the engine’s performance characteristics and its suitability for specific tasks.

What Are Common Trade Terms Related to the 5.9 Cummins Engine?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common trade terms relevant to the 5.9 Cummins engine:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, sourcing OEM parts ensures compatibility and quality, which is especially important for maintaining the performance of the 5.9 Cummins engine. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers looking to manage inventory effectively and negotiate favorable terms, particularly when dealing with large, international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. For B2B buyers, crafting a clear RFQ can facilitate better pricing and lead times, ensuring that they obtain competitive offers for the 5.9 Cummins engine and its parts. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and risks in the supply chain, particularly when importing the 5.9 Cummins engine from overseas. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its longevity. Understanding warranty terms is essential for buyers to assess the risk involved in their investment and to ensure they have recourse in case of defects.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing the 5.9 Cummins engine, ensuring that they select the right product for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 5.9 cummins engine Sector

What Are the Key Market Dynamics Influencing the 5.9 Cummins Engine Sector?

The global market for the 5.9 Cummins engine is experiencing significant growth, driven by rising demand in various sectors such as agriculture, construction, and transportation. As economies in Africa, South America, the Middle East, and Europe continue to develop, the need for reliable and efficient power solutions is paramount. Emerging markets are increasingly investing in infrastructure, which in turn boosts the demand for heavy-duty engines like the 5.9 Cummins. Additionally, advancements in technology are shaping the sourcing landscape, with digital platforms facilitating the procurement process and enhancing supply chain transparency.

One of the notable trends is the shift towards customization, where buyers are looking for engines tailored to specific applications. This is especially relevant in sectors such as mining and agriculture, where performance requirements can vary significantly. Furthermore, as global supply chains become more interconnected, international buyers are leveraging data analytics to make informed purchasing decisions, enabling them to identify the best suppliers and negotiate favorable terms.

How Is Sustainability Impacting Sourcing Decisions for the 5.9 Cummins Engine?

A stock image related to 5.9 cummins engine.

Sustainability has emerged as a critical consideration for international B2B buyers in the 5.9 Cummins engine sector. With growing awareness of environmental impacts, companies are increasingly prioritizing ethical sourcing practices. This includes assessing suppliers based on their environmental policies and certifications, such as ISO 14001 for environmental management and ISO 50001 for energy management.

The demand for ‘green’ certifications and materials is influencing sourcing strategies, as buyers seek engines that not only meet performance standards but also adhere to eco-friendly practices. For instance, engines that utilize renewable fuels or are designed for improved fuel efficiency can significantly reduce carbon footprints. Moreover, the trend towards circular economy practices, where materials are reused and recycled, is gaining traction. Buyers in Africa, South America, the Middle East, and Europe are encouraged to evaluate their suppliers’ sustainability initiatives, as these factors can enhance brand reputation and customer loyalty.

What Is the Historical Context of the 5.9 Cummins Engine and Its Relevance Today?

The 5.9 Cummins engine has a rich history, having been introduced in the late 1980s as a robust solution for various heavy-duty applications. Over the years, it has evolved with technological advancements, including electronic fuel injection and improved emissions control systems. This evolution reflects the industry’s response to changing regulatory standards and market demands.

Today, the engine’s legacy continues to influence its appeal among international buyers. Its reputation for durability and reliability makes it a preferred choice in markets where performance is crucial. Understanding this historical context can help buyers appreciate the engine’s value proposition and its alignment with contemporary needs, particularly in regions focused on expanding their industrial capabilities.

By recognizing these market dynamics, sustainability imperatives, and the engine’s historical significance, B2B buyers can make informed decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of 5.9 cummins engine

-

How do I solve issues with sourcing a 5.9 Cummins engine for my business?

To effectively source a 5.9 Cummins engine, start by identifying reputable suppliers with a proven track record in your region. Utilize industry trade shows, online marketplaces, and business directories to find vetted suppliers. Engage with multiple suppliers to compare prices, terms, and service offerings. Ensure you communicate your specific needs, such as engine specifications and delivery timelines, to avoid mismatches. Additionally, consider local regulations and import requirements to streamline the sourcing process. -

What is the best way to evaluate suppliers of 5.9 Cummins engines?

Evaluating suppliers involves assessing their experience, certifications, and customer reviews. Request references from previous clients to gauge their reliability and quality of service. Check if they have the necessary certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, inquire about their warranty policies and after-sales support to ensure they can address any potential issues post-purchase. Conducting a site visit can also provide insights into their operational capabilities. -

What customization options are available for the 5.9 Cummins engine?

Many suppliers offer customization options for the 5.9 Cummins engine, including modifications for specific applications such as agriculture, construction, or marine use. Customizations can include adjustments to horsepower, torque, and emissions standards to meet local regulations. Discuss your specific requirements with the supplier to explore available options, and ensure that any modifications comply with your regional standards. This tailored approach can enhance performance and suitability for your business needs. -

What are the minimum order quantities (MOQ) for purchasing a 5.9 Cummins engine?

Minimum order quantities for the 5.9 Cummins engine can vary significantly by supplier and region. Some suppliers may have an MOQ as low as one unit, while others might require bulk orders to offer competitive pricing. It’s advisable to discuss your purchasing needs directly with potential suppliers to understand their MOQ policies. If you’re a smaller business, consider joining a buying group or collaborating with other businesses to meet MOQ requirements for better pricing. -

What payment terms should I expect when buying a 5.9 Cummins engine?

Payment terms can differ widely based on supplier policies and your purchasing volume. Typically, suppliers may request a deposit upfront, followed by the balance before shipment or upon delivery. Some may offer more flexible terms, such as net 30 or net 60 days, especially for established clients. Always negotiate payment terms that align with your cash flow requirements and ensure that you fully understand any fees associated with international transactions, including currency conversion and bank charges. -

How can I ensure quality assurance when purchasing a 5.9 Cummins engine?

To ensure quality assurance, ask suppliers about their quality control processes and certifications. Request documentation such as test reports, inspection certificates, and warranty details. It’s also beneficial to conduct a pre-shipment inspection, either through a third-party service or by visiting the supplier, to verify that the engine meets your specifications. Establishing clear performance metrics and expectations upfront can also help in maintaining quality throughout the procurement process. -

What logistics considerations should I keep in mind when importing a 5.9 Cummins engine?

When importing a 5.9 Cummins engine, consider shipping methods, customs clearance, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure that all necessary documentation, including invoices and customs declarations, is in order to avoid delays. Additionally, collaborate with a reliable logistics provider familiar with international trade regulations in your region to facilitate a smooth import process. -

What are the common challenges faced by international buyers of the 5.9 Cummins engine?

International buyers often face challenges such as fluctuating exchange rates, varying quality standards, and communication barriers. Additionally, understanding local regulations regarding emissions and safety can complicate the purchasing process. To mitigate these risks, conduct thorough market research and establish clear communication with suppliers. Building relationships with local industry experts or consultants can also provide valuable insights into navigating these challenges effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 5.9 cummins engine

What Are the Key Takeaways for International B2B Buyers of the 5.9 Cummins Engine?

In conclusion, strategic sourcing for the 5.9 Cummins engine presents significant advantages for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. Understanding the unique specifications and performance capabilities of the 5.9 Cummins engine allows buyers to make informed decisions that align with their operational needs. Establishing relationships with reliable suppliers ensures not only quality products but also access to after-sales support, which is crucial for minimizing downtime in demanding environments.

How Can Strategic Sourcing Enhance Your Purchasing Decisions?

The value of strategic sourcing lies in its ability to optimize procurement processes, reduce costs, and enhance supply chain resilience. By leveraging data and market insights, buyers can negotiate better terms and secure favorable pricing, especially in competitive markets. Emphasizing long-term partnerships with manufacturers and distributors can lead to improved service and reliability, ultimately boosting operational efficiency.

A stock image related to 5.9 cummins engine.

What Does the Future Hold for the 5.9 Cummins Engine Market?

Looking ahead, the demand for the 5.9 Cummins engine is expected to remain robust, driven by its reputation for durability and performance in various applications. International B2B buyers should stay attuned to market trends and technological advancements that may influence engine specifications and fuel efficiency. Engaging in proactive sourcing strategies will position companies favorably to capitalize on emerging opportunities.

In summary, as you navigate your sourcing journey, consider prioritizing strategic partnerships and staying informed about industry developments to maximize your investments in the 5.9 Cummins engine.