Discover Cost-Saving Benefits of TR Band Solutions (2025)

Introduction: Navigating the Global Market for tr band

In the rapidly evolving landscape of global trade, sourcing the right tr band for your business can pose significant challenges, particularly for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for specialized products, the complexity of supply chains, and diverse market regulations, making informed purchasing decisions is crucial. This comprehensive guide aims to demystify the process of acquiring tr bands, covering essential aspects like types, applications, supplier vetting, and cost considerations.

By delving into the intricacies of the tr band market, this guide equips buyers with actionable insights to navigate the global marketplace effectively. You will discover various types of tr bands tailored for specific applications, ensuring you select the right product for your needs. Additionally, the guide emphasizes the importance of thorough supplier vetting, providing criteria and best practices to mitigate risks and enhance product quality.

Whether you are a buyer from Colombia seeking reliable suppliers or a procurement manager in Europe looking for competitive pricing, this guide is designed to empower you with the knowledge necessary to make strategic purchasing decisions. By understanding the nuances of the tr band market, you can enhance your supply chain efficiency and drive greater value for your organization.

Understanding tr band Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard TR Band | Traditional design, versatile size options | General-purpose applications | Pros: Cost-effective, widely available. Cons: May lack advanced features. |

| High-Performance TR Band | Enhanced materials for durability and strength | Industrial and heavy-duty uses | Pros: Superior performance, longer lifespan. Cons: Higher initial cost. |

| Eco-Friendly TR Band | Made from sustainable materials | Green initiatives, eco-conscious buyers | Pros: Supports sustainability, often tax incentives. Cons: Limited availability in some regions. |

| Customizable TR Band | Tailored designs to meet specific needs | Specialized industries (e.g., aerospace, automotive) | Pros: Exact fit for requirements, innovative solutions. Cons: Longer lead times, potentially higher costs. |

| Smart TR Band | Integrated technology for monitoring and data | IoT applications, advanced logistics | Pros: Real-time tracking, improved efficiency. Cons: Complexity in setup and potential need for training. |

What are the Characteristics of the Standard TR Band?

The Standard TR Band is the most commonly used variation, characterized by its traditional design and a range of size options. This type is suitable for a wide array of general-purpose applications, making it a go-to choice for many B2B buyers. When purchasing, consider the availability of this type in your region and its compatibility with your existing systems. Its cost-effectiveness is a significant advantage, though it may not incorporate advanced features that other types offer.

How Does the High-Performance TR Band Stand Out?

The High-Performance TR Band is crafted from enhanced materials that provide superior durability and strength, making it ideal for industrial and heavy-duty applications. This type is particularly relevant for businesses that require reliability under extreme conditions. While its initial cost may be higher, the long lifespan and reduced maintenance needs can lead to significant cost savings over time. B2B buyers should assess their operational demands to determine if the investment aligns with their long-term goals.

Why Choose an Eco-Friendly TR Band?

The Eco-Friendly TR Band is designed with sustainable materials, appealing to businesses focused on environmental responsibility. This type is increasingly relevant in markets where green initiatives are prioritized. B2B buyers may benefit from tax incentives for choosing sustainable options, although availability can be limited in certain regions. When considering this type, assess the balance between sustainability goals and supply chain capabilities.

What Are the Advantages of a Customizable TR Band?

Customizable TR Bands are tailored to meet specific industry needs, making them ideal for specialized sectors such as aerospace and automotive. This type allows businesses to innovate and optimize their operations by ensuring a precise fit for unique applications. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom designs. It is essential to evaluate whether the benefits of customization justify the investment.

How Can a Smart TR Band Enhance Operations?

The Smart TR Band integrates technology that enables real-time monitoring and data collection, making it suitable for IoT applications and advanced logistics. This type is particularly beneficial for businesses seeking to improve operational efficiency and accuracy. While the complexity of setup and potential training needs can be a barrier, the long-term benefits of enhanced tracking and data insights can significantly outweigh these challenges. B2B buyers should consider their technological readiness and the potential ROI of adopting smart solutions.

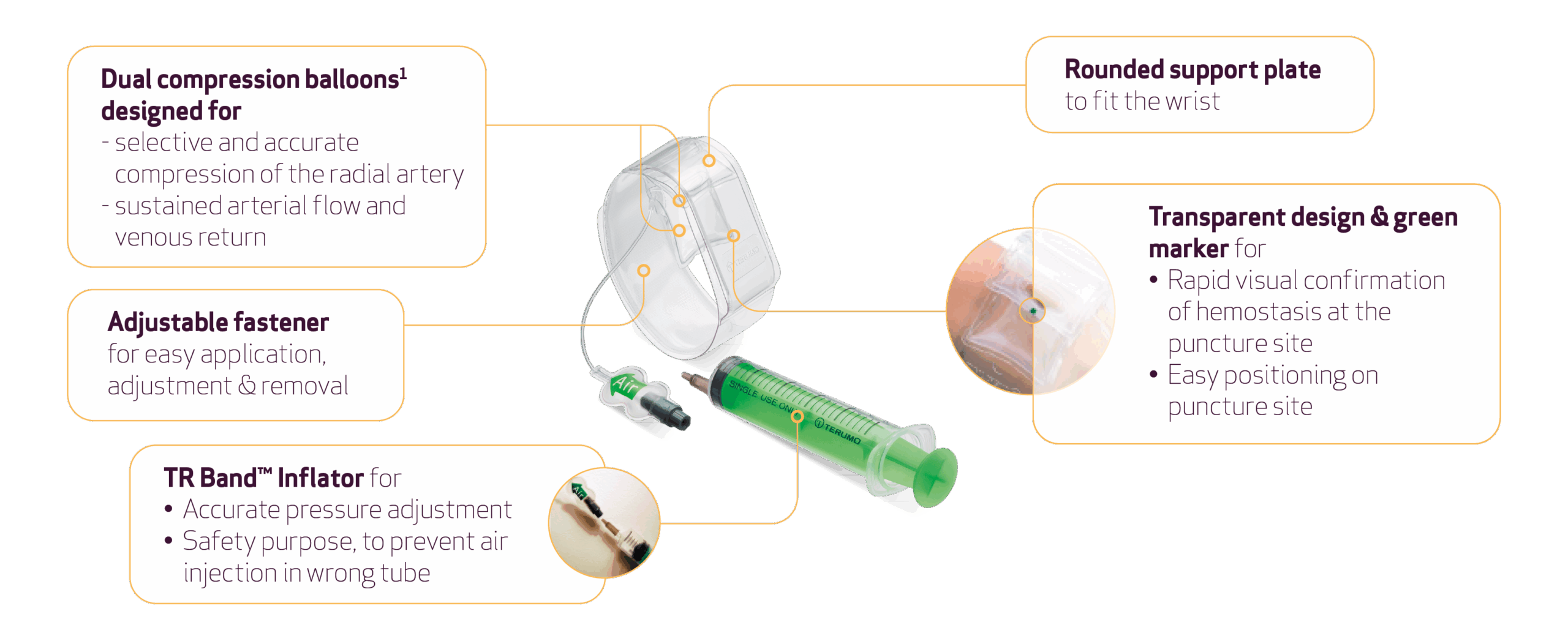

Related Video: TR Band Application and Removal with Michael Martinelli, MD | Terumo Interventional Systems

Key Industrial Applications of tr band

| Industry/Sector | Specific Application of tr band | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Network Infrastructure Enhancements | Improved signal quality and coverage, reducing downtime | Compliance with local regulations, compatibility with existing systems, and scalability options |

| Automotive | Vehicle Telematics and Tracking Systems | Enhanced fleet management and operational efficiency | Durability in harsh environments, integration with various vehicle types, and cost-effectiveness |

| Manufacturing | Machine Condition Monitoring | Proactive maintenance, reduced downtime, and cost savings | Reliability under industrial conditions, ease of installation, and support for data analytics |

| Agriculture | Precision Farming Solutions | Increased yield and resource efficiency | Adaptability to diverse climates, ease of integration with existing farming equipment, and data security |

| Healthcare | Patient Monitoring Systems | Improved patient outcomes and operational efficiency | Compliance with health regulations, data privacy, and integration with hospital systems |

How is ‘tr band’ Used in Telecommunications?

In the telecommunications sector, ‘tr band’ is crucial for enhancing network infrastructure. It enables better signal quality and coverage, which is essential for minimizing downtime and ensuring reliable connectivity. International B2B buyers, especially from regions like Africa and South America, should consider local regulatory compliance and the compatibility of ‘tr band’ with existing systems. Scalability is also a vital factor, as businesses need to adapt to growing demands without incurring excessive costs.

What Role Does ‘tr band’ Play in Automotive Applications?

In the automotive industry, ‘tr band’ is utilized in telematics and tracking systems, which are essential for managing fleets effectively. These systems provide real-time data on vehicle locations and performance, leading to enhanced operational efficiency and reduced costs. Buyers must ensure that the ‘tr band’ solutions they choose are durable enough to withstand harsh environments, compatible with various vehicle types, and offer a cost-effective solution for their fleet management needs.

How Does ‘tr band’ Benefit Manufacturing?

Within the manufacturing sector, ‘tr band’ is instrumental in machine condition monitoring. By enabling proactive maintenance, it helps businesses reduce downtime and save costs associated with unexpected equipment failures. International buyers should focus on sourcing reliable solutions that can perform well under industrial conditions, are easy to install, and support data analytics for better decision-making.

What Are the Applications of ‘tr band’ in Agriculture?

In agriculture, ‘tr band’ facilitates precision farming solutions, which optimize resource use and increase crop yields. This technology allows farmers to monitor field conditions in real-time, leading to more informed decision-making. Buyers from diverse climates, particularly in Africa and South America, should consider the adaptability of ‘tr band’ systems to local farming equipment and ensure robust data security measures are in place.

How is ‘tr band’ Used in Healthcare?

In healthcare, ‘tr band’ is integral to patient monitoring systems that enhance patient outcomes and operational efficiency in hospitals. These systems provide real-time data on patient vitals, allowing for timely interventions. B2B buyers in this sector must prioritize compliance with health regulations, ensure data privacy, and seek solutions that easily integrate with existing hospital systems to facilitate seamless operations.

3 Common User Pain Points for ‘tr band’ & Their Solutions

Scenario 1: Inconsistent Product Quality Across Suppliers

The Problem: B2B buyers often face challenges with inconsistent quality when sourcing ‘tr band’ from various suppliers. This inconsistency can lead to unexpected production delays, increased costs, and potential reputational damage. For instance, a company in South America that relies on ‘tr band’ for medical applications might find that one supplier’s product fails to meet necessary standards, leading to costly recalls and loss of customer trust.

The Solution: To mitigate quality inconsistencies, it is essential to conduct thorough supplier audits and establish clear quality benchmarks before making bulk purchases. Buyers should request samples and conduct rigorous testing in their own facilities to ensure the ‘tr band’ meets their specific requirements. Additionally, consider using third-party quality assurance services to verify that suppliers adhere to international standards. Forming long-term partnerships with a select number of reliable suppliers can also help standardize quality and streamline sourcing processes, minimizing the risk of encountering inferior products.

Scenario 2: Difficulty in Understanding Technical Specifications

The Problem: Many international buyers, particularly from regions like Africa and the Middle East, may struggle with the technical specifications of ‘tr band’. This can lead to confusion over product compatibility and performance, especially when comparing options from different manufacturers. For instance, a buyer may misinterpret tensile strength or elongation properties, resulting in the procurement of unsuitable products that can compromise their operations.

The Solution: To overcome this challenge, B2B buyers should invest time in educational resources that explain the technical aspects of ‘tr band’. Engaging with knowledgeable industry consultants or attending webinars can provide valuable insights. Furthermore, establishing a clear communication channel with suppliers to clarify specifications is crucial. Buyers should develop a checklist of essential technical criteria tailored to their specific applications and ensure that all suppliers can provide detailed documentation. This proactive approach will enhance understanding and facilitate better decision-making.

Scenario 3: Limited Local Availability Leading to Supply Chain Disruptions

The Problem: B2B buyers in regions like Europe and South America may encounter supply chain disruptions due to limited local availability of ‘tr band’. This can be particularly problematic in industries such as automotive or healthcare, where timely access to materials is critical. Delays in receiving ‘tr band’ can halt production lines, leading to financial losses and missed deadlines.

The Solution: To address supply chain vulnerabilities, buyers should consider diversifying their sourcing strategies. This involves identifying multiple suppliers across different geographical locations to reduce dependency on a single source. Establishing strategic partnerships with local distributors can also help ensure a more reliable supply chain. Additionally, implementing just-in-time inventory practices can minimize excess stock while ensuring that adequate materials are available when needed. Leveraging technology, such as supply chain management software, can provide real-time insights into inventory levels and supplier performance, allowing buyers to proactively manage their procurement needs.

Strategic Material Selection Guide for tr band

When selecting materials for tr bands, it is essential to consider various factors that directly impact product performance and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of tr bands: rubber, silicone, polyurethane, and metal. Each material has unique properties that cater to different operational requirements and market preferences.

What Are the Key Properties of Rubber for tr Bands?

Rubber is a widely used material for tr bands due to its excellent elasticity and resilience. It typically operates effectively in temperature ranges from -40°C to 100°C, making it suitable for various environments. Rubber exhibits good abrasion resistance and is generally resistant to water and many chemicals. However, it can be susceptible to degradation from UV exposure and ozone, which may limit its outdoor applications.

Pros & Cons: Rubber tr bands are cost-effective and easy to manufacture, making them an attractive option for many buyers. However, their durability may not match that of synthetic alternatives, and they may require more frequent replacement in harsh conditions.

Impact on Application: Rubber is compatible with a wide range of media, including water, oils, and some chemicals, making it versatile for various industries.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local climate conditions that may affect rubber longevity. Compliance with international standards such as ASTM D2000 can ensure quality and performance.

How Does Silicone Perform as a Material for tr Bands?

Silicone is another popular choice for tr bands, particularly in applications requiring high temperature and chemical resistance. It can withstand temperatures ranging from -60°C to 230°C, making it suitable for extreme environments. Silicone also exhibits excellent flexibility and is resistant to UV light, ozone, and many chemicals.

Pros & Cons: While silicone tr bands offer superior durability and longevity, they tend to be more expensive than rubber. Their manufacturing process can also be more complex, which may lead to longer lead times.

Impact on Application: Silicone is particularly effective in applications involving high-temperature fluids or aggressive chemicals, making it ideal for industries such as pharmaceuticals and food processing.

Considerations for International Buyers: Buyers from the Middle East and Europe should ensure compliance with relevant food safety standards (e.g., FDA, EU regulations) when using silicone in food-related applications.

What Are the Benefits of Using Polyurethane for tr Bands?

Polyurethane is known for its impressive abrasion resistance and flexibility, making it a strong candidate for tr bands. It operates effectively in temperature ranges from -30°C to 80°C and offers excellent resistance to wear and tear. Polyurethane tr bands are also resistant to many chemicals, including oils and solvents.

Pros & Cons: The durability of polyurethane makes it ideal for heavy-duty applications. However, it can be more costly than rubber and may not perform as well in extreme temperatures.

Impact on Application: Polyurethane is particularly suitable for applications in automotive and industrial sectors where wear resistance is crucial.

Considerations for International Buyers: Buyers in Europe should be aware of REACH compliance when sourcing polyurethane materials, ensuring they meet environmental regulations.

When Should Metal Be Considered for tr Bands?

Metal tr bands, often made from stainless steel or other alloys, are used in high-stress applications where strength and durability are paramount. They can withstand high temperatures and pressures, making them suitable for demanding environments.

Pros & Cons: Metal bands provide unmatched durability and resistance to deformation. However, they can be heavy and may require specialized manufacturing processes, leading to higher costs.

Impact on Application: Metal tr bands are ideal for applications in heavy machinery, aerospace, and automotive industries where maximum strength is required.

Considerations for International Buyers: Buyers from regions like Australia should ensure compliance with local standards (e.g., AS/NZS) for metal components to guarantee safety and performance.

Summary Table of Material Selection for tr Bands

| Material | Typical Use Case for tr band | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General industrial applications | Cost-effective and flexible | UV degradation over time | Low |

| Silicone | High-temperature and chemical applications | Excellent durability | Higher cost and complexity | High |

| Polyurethane | Heavy-duty industrial and automotive sectors | Superior abrasion resistance | Limited temperature range | Medium |

| Metal | High-stress machinery and aerospace | Unmatched strength and durability | Heavier and more expensive | High |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tr band

What Are the Key Stages of Manufacturing Processes for TR Bands?

The manufacturing of TR bands involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Are the Raw Materials Used in TR Band Production?

The initial step in manufacturing TR bands is material preparation. Common materials include high-quality elastomers, metals, and polymers. These materials must be sourced from reputable suppliers to ensure they meet the necessary quality standards. For international B2B buyers, it’s crucial to verify that the raw materials used are compliant with local and international regulations.

A stock image related to tr band.

Forming: How Are TR Bands Shaped and Molded?

The forming stage utilizes various techniques such as injection molding, extrusion, and compression molding. Each method has its advantages, depending on the design and specifications of the TR band. For instance, injection molding allows for intricate designs and tighter tolerances, making it a popular choice. Buyers should inquire about the specific forming techniques employed by suppliers to ensure they align with their quality expectations.

Assembly: What Is Involved in the Assembly of TR Bands?

Once the components are formed, the assembly process begins. This may involve bonding different materials, integrating electronic components, or adding features that enhance functionality. Effective assembly techniques are crucial, as they directly impact the durability and performance of the TR bands. Buyers should look for suppliers that demonstrate expertise in assembly processes, as this can be a significant differentiator in quality.

Finishing: How Is the Final Product Enhanced?

The finishing stage includes processes such as surface treatment, coating, and quality inspection. These processes not only improve the aesthetic appeal of TR bands but also enhance their performance characteristics. Buyers should consider suppliers that offer advanced finishing techniques, as these can contribute to the longevity and effectiveness of the product.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is an essential aspect of TR band manufacturing. It ensures that products meet specified standards and customer requirements. B2B buyers should be aware of the following QA measures:

What Are the Relevant International Standards for TR Bands?

A stock image related to tr band.

International standards such as ISO 9001 play a crucial role in quality assurance. ISO 9001 outlines the requirements for a quality management system (QMS) and helps organizations ensure that they consistently meet customer and regulatory requirements. Additionally, industry-specific standards like CE marking and API certification may also apply, depending on the intended use of the TR bands. Buyers should request evidence of these certifications from their suppliers.

How Do Quality Control Checkpoints Work?

Quality control (QC) checkpoints are critical in the manufacturing process. The main checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this step helps identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): This final inspection ensures that the finished product adheres to the required specifications before it is shipped to customers.

B2B buyers should inquire about the QC processes implemented by their suppliers to ensure comprehensive oversight throughout the manufacturing process.

What Common Testing Methods Are Used in TR Band Quality Assurance?

Various testing methods are employed to verify the quality and performance of TR bands. These include:

- Tensile Testing: Measures the material’s strength and elasticity.

- Fatigue Testing: Evaluates how the material performs under repeated stress.

- Environmental Testing: Assesses the product’s performance under various environmental conditions, such as temperature and humidity.

- Leak Testing: Ensures that the TR bands maintain their integrity under pressure.

By understanding these testing methods, B2B buyers can better evaluate the quality assurance processes of potential suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is vital for B2B buyers. Here are several strategies to consider:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and procedures. This can be done through on-site visits or third-party audits.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QA processes and outcomes. Look for documentation that outlines their QC checkpoints, testing methods, and any corrective actions taken.

- Third-Party Inspection: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly beneficial for international buyers who may not have local expertise.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certifications is crucial. Different regions may have varying standards and regulations, which can impact the importation and usability of TR bands.

- Regional Compliance: Buyers should ensure that the products meet the specific regulatory requirements of their respective countries. For example, CE marking is essential for products sold in the European market, while other regions may have their own compliance standards.

- Cultural Considerations: Be aware of cultural differences that may influence supplier practices and quality expectations. Establishing clear communication and understanding local business practices can facilitate better partnerships.

- Documentation: Ensure that all necessary documentation, including certificates of conformity and test results, are provided. This documentation is vital for customs clearance and can prevent delays in delivery.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make more informed decisions when selecting suppliers for TR bands, ultimately leading to higher quality products and successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tr band’

The purpose of this practical sourcing guide is to equip international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with a structured approach to procuring ‘tr band’. By following this checklist, you can ensure that your sourcing process is efficient, effective, and tailored to meet your specific business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the ‘tr band’. This includes dimensions, materials, performance characteristics, and any certifications necessary for compliance. Understanding your needs upfront helps streamline the selection process and avoids costly mistakes later on.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ‘tr band’. Utilize online directories, trade shows, and industry networks to compile a list of candidates. Focus on suppliers with a proven track record and positive customer reviews, as this can provide insight into their reliability and quality.

Step 3: Evaluate Supplier Capabilities

It’s essential to assess the capabilities of your shortlisted suppliers. Inquire about their production capacity, technology, and quality control processes. Look for suppliers who can demonstrate their ability to meet your volume requirements and maintain consistent quality over time.

Step 4: Request Samples and Prototypes

Before finalizing your choice, request samples or prototypes of the ‘tr band’ from potential suppliers. This allows you to evaluate the quality, functionality, and compatibility with your applications. Testing samples in real-world scenarios can provide invaluable insights and help you make a more informed decision.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold the necessary certifications and comply with international standards relevant to ‘tr band’. This may include ISO certifications, safety standards, and environmental regulations. Verification of these credentials is crucial to mitigate risks associated with quality and compliance.

Step 6: Negotiate Terms and Conditions

Once you have identified a preferred supplier, engage in discussions to negotiate terms and conditions that align with your business objectives. Key factors to consider include pricing, payment terms, delivery schedules, and warranty provisions. A well-negotiated agreement can enhance the partnership and ensure smoother transactions.

Step 7: Establish a Clear Communication Plan

Effective communication is vital for successful sourcing. Establish a clear communication plan with your supplier to ensure alignment on expectations, timelines, and any potential issues that may arise. Regular updates and open channels for feedback can foster a collaborative relationship, leading to better outcomes.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing ‘tr band’, ensuring a successful procurement process that meets their business needs and standards.

Comprehensive Cost and Pricing Analysis for tr band Sourcing

What Are the Key Cost Components for tr band Sourcing?

When considering sourcing tr band, understanding the intricate cost structure is crucial for international B2B buyers. The main cost components typically include:

-

Materials: The quality and type of materials used significantly influence the price. Higher-grade materials can lead to increased durability and performance, but they also raise costs.

-

Labor: Labor costs can vary widely depending on the region of production. For instance, sourcing from regions with lower wage rates may provide cost advantages, but it’s essential to evaluate the skill levels and expertise of the workforce.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help in reducing overhead costs.

-

Tooling: The cost of tooling is an important factor, especially if custom designs are required. Initial tooling investments can be substantial, but they are amortized over larger production runs, impacting the per-unit cost.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to overall costs. However, investing in QC can prevent costly returns and reputational damage in the long run.

-

Logistics: Transportation, warehousing, and handling fees can greatly affect the total cost. International shipping logistics can be particularly complex, necessitating a thorough understanding of shipping routes and customs regulations.

-

Margin: Suppliers will add their profit margin to the total cost, which can vary based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of tr band?

Several key factors can influence the pricing of tr band, making it essential for buyers to understand these nuances:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to reduced per-unit costs. Suppliers may have MOQ policies that impact the overall pricing structure, so negotiating these terms can yield significant savings.

-

Specifications and Customization: Tailoring products to specific requirements can increase costs. Buyers should weigh the benefits of customization against the associated price increases.

-

Materials and Quality Certifications: The presence of certifications (like ISO or industry-specific standards) can justify higher prices. Buyers should assess whether these certifications are necessary for their target markets.

-

Supplier Factors: The reliability, reputation, and production capacity of suppliers can affect pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms can help buyers optimize their total costs.

What Are the Best Buyer Tips for Cost-Efficient tr band Sourcing?

To maximize value when sourcing tr band, buyers should consider the following actionable tips:

-

Negotiate with Suppliers: Building strong relationships with suppliers can open doors for better pricing. Don’t hesitate to negotiate terms, especially around volume discounts and payment terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices to consider the TCO, which includes maintenance, operational costs, and potential savings from quality improvements.

-

Understand Pricing Nuances for Different Regions: Prices can vary significantly based on geographic locations. For instance, buyers in Africa and South America may find different cost structures compared to those in Europe or the Middle East. Researching regional market conditions can provide insights into potential cost advantages.

-

Stay Informed on Market Trends: Keeping abreast of global supply chain trends, material shortages, and economic shifts can provide a strategic advantage in timing your purchases and negotiations.

-

Consider Alternative Suppliers: Expanding your supplier base can lead to competitive pricing and reduce dependency on a single source. This diversification can also mitigate risks associated with supply chain disruptions.

Disclaimer on Indicative Prices

Prices for tr band can fluctuate based on various factors such as market demand, geopolitical events, and raw material availability. It is essential for buyers to conduct thorough market research and obtain updated quotations from suppliers to ensure accurate budgeting and cost planning.

Alternatives Analysis: Comparing tr band With Other Solutions

Exploring Alternatives to tr band: What Are Your Options?

In the ever-evolving landscape of B2B solutions, understanding the alternatives to a product or method is critical for making informed purchasing decisions. Buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, need to evaluate various options that align with their specific business needs, budget constraints, and operational capabilities. In this section, we will compare ‘tr band’ against two viable alternatives, shedding light on their unique advantages and disadvantages.

| Comparison Aspect | ‘Tr Band’ | Alternative 1: TechBand | Alternative 2: FlexiStrap |

|---|---|---|---|

| Performance | High reliability for data transfer | Moderate reliability, suitable for smaller applications | High adaptability but variable performance based on conditions |

| Cost | Mid-range pricing | Lower initial cost | Higher initial investment but cost-effective long-term |

| Ease of Implementation | Requires specialized training | User-friendly, minimal training needed | Moderate; requires some technical knowledge |

| Maintenance | Low maintenance; periodic checks | Minimal maintenance required | Regular maintenance necessary to ensure optimal performance |

| Best Use Case | Ideal for large-scale operations | Best for startups and small projects | Suitable for flexible and diverse applications |

What Are the Key Benefits and Drawbacks of TechBand?

TechBand is an alternative that offers a lower initial cost, making it an attractive option for startups and small projects. Its user-friendly interface requires minimal training, allowing businesses to get up and running quickly. However, while it is adequate for smaller applications, TechBand may not deliver the same reliability as tr band in larger-scale operations, which can be a significant drawback for companies anticipating growth or needing robust performance.

Why Consider FlexiStrap as an Alternative?

FlexiStrap stands out for its adaptability, making it suitable for a variety of applications. It excels in environments where flexibility is required, allowing businesses to modify their approach as needs change. However, this flexibility comes at a cost; the initial investment is higher compared to tr band, and it demands regular maintenance to ensure consistent performance. For companies that prioritize versatility and are willing to invest in ongoing upkeep, FlexiStrap could be a fitting choice.

How to Choose the Right Solution for Your Business Needs?

When evaluating alternatives to tr band, B2B buyers should consider their specific operational requirements, budget constraints, and long-term objectives. For organizations focusing on scalability and reliability, tr band remains a strong contender, particularly for large-scale operations. Conversely, if cost-effectiveness and ease of implementation are top priorities, TechBand may be the best fit. Finally, for businesses needing a flexible solution that can adapt to diverse conditions, FlexiStrap offers unique benefits despite its higher costs. Ultimately, the right choice will depend on a careful analysis of each solution’s strengths and weaknesses in relation to the buyer’s strategic goals.

Essential Technical Properties and Trade Terminology for tr band

What Are the Key Technical Properties of tr band?

When sourcing tr bands, understanding the essential technical properties is vital for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade of tr bands typically refers to the quality and type of material used in their construction, such as stainless steel or aluminum. The choice of material affects durability, corrosion resistance, and overall performance. For B2B buyers, selecting the right material grade ensures that the product meets specific application requirements, reducing the risk of failure in demanding environments.

2. Tolerance Levels

Tolerance levels indicate the allowable variations in dimensions and physical properties of the tr band. This is crucial for ensuring that the bands fit properly in their intended applications. For businesses, understanding tolerance is essential to avoid costly errors during installation or operation, which can lead to downtime or increased maintenance costs.

3. Load Capacity

Load capacity refers to the maximum load that a tr band can handle without failure. This specification is especially important for industries such as construction and manufacturing, where safety and reliability are paramount. Buyers should assess their operational needs against the load capacities of available products to ensure they select a tr band that can withstand the required forces.

4. Temperature Resistance

Temperature resistance indicates the range of temperatures within which the tr band can operate effectively. This property is particularly important for applications in extreme environments, such as automotive or aerospace sectors. B2B buyers must evaluate the thermal conditions of their operations to ensure that the tr bands they purchase will not degrade or fail under heat or cold stress.

5. Finish Type

The finish type of a tr band can influence its appearance, corrosion resistance, and overall longevity. Common finishes include anodized, painted, or polished. Selecting the right finish can enhance the product’s performance and aesthetics, making it vital for B2B buyers who need to meet specific industry standards or customer preferences.

What Are the Common Trade Terms Related to tr band?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms associated with tr bands:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. For B2B buyers, partnering with an OEM can lead to cost savings and access to specialized products that meet specific application needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for businesses to manage inventory and cash flow effectively. Buyers should negotiate MOQs based on their consumption rates to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ allows for comparison of different suppliers and ensures that they receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international B2B transactions, as it helps prevent misunderstandings and disputes over delivery responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. Understanding lead times is essential for B2B buyers to plan production schedules and manage supply chain logistics effectively.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make more informed purchasing decisions regarding tr bands, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the tr band Sector

A stock image related to tr band.

What Are the Key Market Dynamics and Trends Affecting the TR Band Sector?

The TR band sector is currently experiencing robust growth driven by several global factors. First, the demand for enhanced communication technologies is surging, particularly in regions like Africa and South America, where mobile penetration is accelerating. The emergence of 5G and IoT applications is reshaping the landscape, requiring businesses to adapt their sourcing strategies accordingly. Furthermore, international B2B buyers are increasingly leaning towards digital platforms for procurement, driven by the need for efficiency and cost-effectiveness.

Another significant trend is the rise of collaborative sourcing, where businesses form partnerships to leverage shared resources and knowledge. This is particularly prevalent in the Middle East and Europe, where companies are pooling their expertise to tackle complex supply chain challenges. Additionally, the influence of data analytics in decision-making is growing. B2B buyers are utilizing predictive analytics to forecast demand and optimize inventory management, which is crucial for maintaining competitiveness in the TR band market.

How Can Sustainability and Ethical Sourcing Impact the TR Band Sector?

Sustainability is becoming a critical factor for B2B buyers in the TR band sector. Environmental concerns are prompting companies to scrutinize their supply chains for ecological impact. This is especially important in regions such as Africa and South America, where environmental degradation can have far-reaching effects on local communities and economies. Ethical sourcing practices are essential to mitigate these risks, ensuring that suppliers adhere to environmental regulations and labor standards.

The demand for ‘green’ certifications and materials is also on the rise. Buyers are increasingly seeking suppliers that offer sustainable options, such as recyclable materials and energy-efficient production processes. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can provide assurance that suppliers are committed to sustainable practices. For international B2B buyers, partnering with certified suppliers not only enhances brand reputation but also meets the growing consumer demand for ethical products.

What Is the Historical Context of the TR Band Sector for B2B Buyers?

The TR band sector has evolved significantly over the past few decades. Initially focused on traditional communication systems, it has transformed into a dynamic field driven by technological advancements. In the early 2000s, the introduction of digital communication technologies revolutionized the market, allowing for greater efficiency and reliability.

As the demand for mobile and wireless solutions grew, so did the need for more sophisticated sourcing strategies. International B2B buyers began to recognize the importance of diversifying their supplier base to mitigate risks associated with geopolitical tensions and economic fluctuations. This historical context is vital for understanding current market dynamics and the importance of adaptability in sourcing strategies for B2B buyers across Africa, South America, the Middle East, and Europe.

Frequently Asked Questions (FAQs) for B2B Buyers of tr band

-

How do I solve quality assurance issues when sourcing tr bands?

To address quality assurance concerns, it is essential to establish clear quality standards before engaging with suppliers. Request samples to evaluate the product’s durability and performance. Implement a comprehensive inspection process, including third-party audits and factory visits, to ensure compliance with international standards. Additionally, consider certifications relevant to your region, such as ISO or ASTM, to verify the supplier’s credibility. Regular communication and feedback loops can help maintain quality throughout the production process. -

What is the best way to vet suppliers for tr bands?

Vetting suppliers is crucial for ensuring reliability and quality. Begin by researching potential suppliers through platforms like Alibaba, Global Sources, or trade fairs specific to your industry. Check for company certifications, customer reviews, and case studies of their previous work. Conduct interviews or site visits to assess their manufacturing capabilities. Additionally, consider requesting references from other clients, especially those in your region, to gauge their experience and satisfaction with the supplier’s service. -

What are the minimum order quantities (MOQ) for tr bands?

Minimum order quantities can vary significantly between suppliers and depend on factors such as material type, customization, and production capacity. Generally, MOQs for tr bands can range from 100 to 1,000 units. To negotiate favorable terms, clarify your requirements and discuss potential flexibility with suppliers. If you are a smaller buyer, consider partnering with other businesses to meet MOQ requirements or seeking suppliers who specialize in low-volume orders. -

How can I ensure timely delivery of tr bands in international trade?

To guarantee timely delivery, work closely with your supplier to establish a clear timeline for production and shipping. Utilize reliable logistics partners who have experience in international shipping to avoid delays. Implement tracking systems to monitor shipment status. It is also beneficial to factor in potential customs delays by preparing all necessary documentation in advance. Open communication with your supplier and logistics provider can help address any issues proactively. -

What payment terms should I negotiate when sourcing tr bands?

When negotiating payment terms, aim for conditions that protect your investment while remaining fair to the supplier. Common practices include a deposit (20-30%) upfront with the balance due upon delivery or after inspection. Consider using secure payment methods like letters of credit or escrow services for large transactions to mitigate risk. Discuss currency fluctuations and whether to fix the exchange rate in advance, especially when dealing with suppliers from different regions. -

Can I customize tr bands to meet specific requirements?

Most reputable suppliers offer customization options for tr bands, including size, color, and material specifications. Clearly outline your requirements in advance and ask for a detailed proposal from the supplier. Be prepared to provide technical drawings or samples for reference. Keep in mind that customization may affect pricing and lead times, so discuss these factors early in the negotiation process to avoid surprises later. -

What regulations should I be aware of when importing tr bands into my region?

Import regulations vary by country and can include tariffs, safety standards, and environmental compliance. Research the specific requirements for your region, such as labeling, documentation, and any import licenses needed for tr bands. Engaging a customs broker can facilitate the process, ensuring all regulations are met and reducing the risk of delays or fines. Stay updated on changes in trade policies that may impact your importation process. -

How do I handle disputes with suppliers when sourcing tr bands?

Disputes can arise due to quality issues, delivery delays, or misunderstandings regarding terms. To handle conflicts effectively, maintain open communication with your supplier and document all agreements and communications. If a dispute occurs, first attempt to resolve it amicably through negotiation. If that fails, consult your contract for dispute resolution clauses, which may include mediation or arbitration. Keeping a professional demeanor and focusing on solutions can often lead to a satisfactory outcome for both parties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tr band

As international B2B buyers increasingly navigate the complexities of sourcing tr band solutions, the importance of strategic sourcing cannot be overstated. Companies across Africa, South America, the Middle East, and Europe must prioritize building robust supplier relationships and leveraging data-driven insights to optimize their purchasing decisions. By focusing on total cost of ownership rather than just upfront costs, businesses can achieve greater value and sustainability in their procurement strategies.

What are the key trends shaping the future of tr band sourcing? The rise of digital platforms and automation is streamlining procurement processes, allowing buyers to access a broader range of suppliers and negotiate better terms. Additionally, sustainability practices are becoming a critical factor in supplier selection, influencing buyer decisions and enhancing brand reputation.

Looking ahead, it is crucial for B2B buyers to remain adaptable and informed about market dynamics. Engaging in continuous market research and fostering innovative partnerships will position organizations to capitalize on emerging opportunities. Take action today—evaluate your current sourcing strategies and explore new suppliers to enhance your competitive advantage in the tr band market. The future is bright for those who embrace strategic sourcing as a cornerstone of their operational success.