Unlock Performance: The Ultimate LS1 Intake Manifold Guide (2025)

Introduction: Navigating the Global Market for ls1 intake manifold

In the ever-evolving landscape of automotive performance, sourcing the right LS1 intake manifold can pose significant challenges for international B2B buyers. As demand for high-performance components surges across Africa, South America, the Middle East, and Europe, understanding the nuances of this market becomes essential. This guide aims to demystify the complexities associated with procuring LS1 intake manifolds, providing insights on various types, applications, and the critical factors influencing supplier selection.

B2B buyers will benefit from a thorough exploration of the different LS1 intake manifold designs, tailored for diverse engine setups and performance goals. Additionally, this guide addresses essential considerations such as cost analysis, compatibility with existing systems, and performance enhancements. By offering a structured approach to supplier vetting, it empowers buyers to make informed decisions that align with their specific needs and budget constraints.

International buyers, particularly from regions like South Africa and Turkey, will discover actionable strategies for navigating local and global suppliers, ensuring they can secure high-quality components without compromising on performance or reliability. With a focus on actionable insights, this guide serves as a vital resource for businesses looking to optimize their purchasing strategies in the competitive automotive aftermarket.

Understanding ls1 intake manifold Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stock LS1 Intake Manifold | OEM design, moderate flow characteristics | General automotive applications, OEM replacements | Pros: Cost-effective, reliable. Cons: Limited performance upgrades. |

| Aftermarket Performance Manifold | High flow design, lightweight materials | Racing, high-performance builds | Pros: Increased horsepower, better throttle response. Cons: Higher cost, may require additional tuning. |

| Sheet Metal Intake Manifold | Customizable, enhanced airflow capabilities | Custom builds, extreme performance applications | Pros: Tailored to specific needs, superior performance. Cons: Expensive, longer lead times. |

| Dual Plane Intake Manifold | Improved torque delivery, versatile design | Street performance, off-road applications | Pros: Good low-end torque, broad power band. Cons: May limit high RPM performance. |

| Single Plane Intake Manifold | Optimized for high RPM, less restrictive | Drag racing, high-performance street cars | Pros: Maximum airflow at high RPM, ideal for racing. Cons: Poor low-end torque, less street-friendly. |

What are the Characteristics of the Stock LS1 Intake Manifold?

The stock LS1 intake manifold is designed for reliability and moderate performance. It features a balanced airflow design suitable for everyday driving and OEM replacements. B2B buyers seeking cost-effective solutions for standard applications will find this manifold ideal, as it provides dependable performance without the need for extensive modifications. However, its limitations in terms of performance upgrades may deter those aiming for higher horsepower outputs.

Why Choose Aftermarket Performance Manifolds?

Aftermarket performance manifolds are engineered for enhanced airflow, often utilizing lightweight materials to reduce overall vehicle weight. These manifolds are perfect for B2B buyers involved in racing or high-performance vehicle builds, as they significantly increase horsepower and throttle response. While the initial investment is higher compared to stock options, the performance gains justify the cost for serious automotive enthusiasts and competitive teams.

How Do Sheet Metal Intake Manifolds Benefit Custom Builds?

Sheet metal intake manifolds stand out due to their customizable nature and superior airflow capabilities. They are ideal for businesses focused on custom builds or extreme performance applications. Buyers should consider the tailored fit and enhanced performance they provide, albeit at a higher price point and longer lead times. This type of manifold is suitable for those seeking to push the limits of engine performance and efficiency.

What are the Advantages of Dual Plane Intake Manifolds?

Dual plane intake manifolds offer a versatile design that enhances torque delivery across a broad RPM range. This makes them suitable for street performance and off-road applications. B2B buyers looking for a balance between everyday drivability and performance will appreciate the good low-end torque that these manifolds provide. However, those seeking maximum high RPM performance may find dual plane designs limiting.

When to Consider Single Plane Intake Manifolds?

Single plane intake manifolds are optimized for high RPM performance, making them a popular choice for drag racing and high-performance street cars. They offer maximum airflow at elevated RPMs, which is crucial for competitive racing applications. However, B2B buyers should note that while they excel in high-speed scenarios, they may compromise low-end torque, making them less suitable for regular street use.

Related Video: LS1 Intake Manifold Removal

Key Industrial Applications of ls1 intake manifold

| Industry/Sector | Specific Application of ls1 intake manifold | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Performance enhancement in racing and sports cars | Increases horsepower and efficiency, leading to competitive advantage | Quality of materials, compatibility with existing systems, and performance testing |

| Heavy Machinery | Engine upgrades for construction and mining equipment | Improved fuel efficiency and reduced emissions, lowering operational costs | Supplier reliability, adherence to international standards, and after-sales support |

| Aerospace | Custom modifications for lightweight aircraft engines | Enhanced performance and fuel savings, critical for operational efficiency | Certification for aerospace applications, weight considerations, and durability |

| Marine Engineering | Upgrades for high-performance marine engines | Increased speed and reduced fuel consumption, essential for competitive maritime operations | Corrosion resistance, marine-grade materials, and compliance with maritime regulations |

| Renewable Energy | Integration in biofuel and hybrid engines | Supports sustainability goals while enhancing engine performance | Availability of eco-friendly materials, supplier certifications, and adaptability to various fuel types |

How is the LS1 Intake Manifold Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, the LS1 intake manifold is commonly employed for performance enhancement in racing and sports cars. It allows for improved airflow to the engine, which translates to increased horsepower and torque. This capability is crucial for manufacturers aiming to deliver high-performance vehicles that meet the demands of competitive racing environments. International buyers should consider the quality of materials used in the manifold, ensuring compatibility with existing engine systems and conducting thorough performance testing to validate claims made by suppliers.

What Role Does the LS1 Intake Manifold Play in Heavy Machinery?

Heavy machinery, particularly in construction and mining, benefits significantly from LS1 intake manifolds through engine upgrades. These modifications lead to enhanced fuel efficiency and reduced emissions, which are vital for lowering operational costs in industries with high fuel consumption. Buyers from regions like Africa and South America should prioritize sourcing from reliable suppliers who adhere to international standards, ensuring that the products are durable and effective in harsh working conditions.

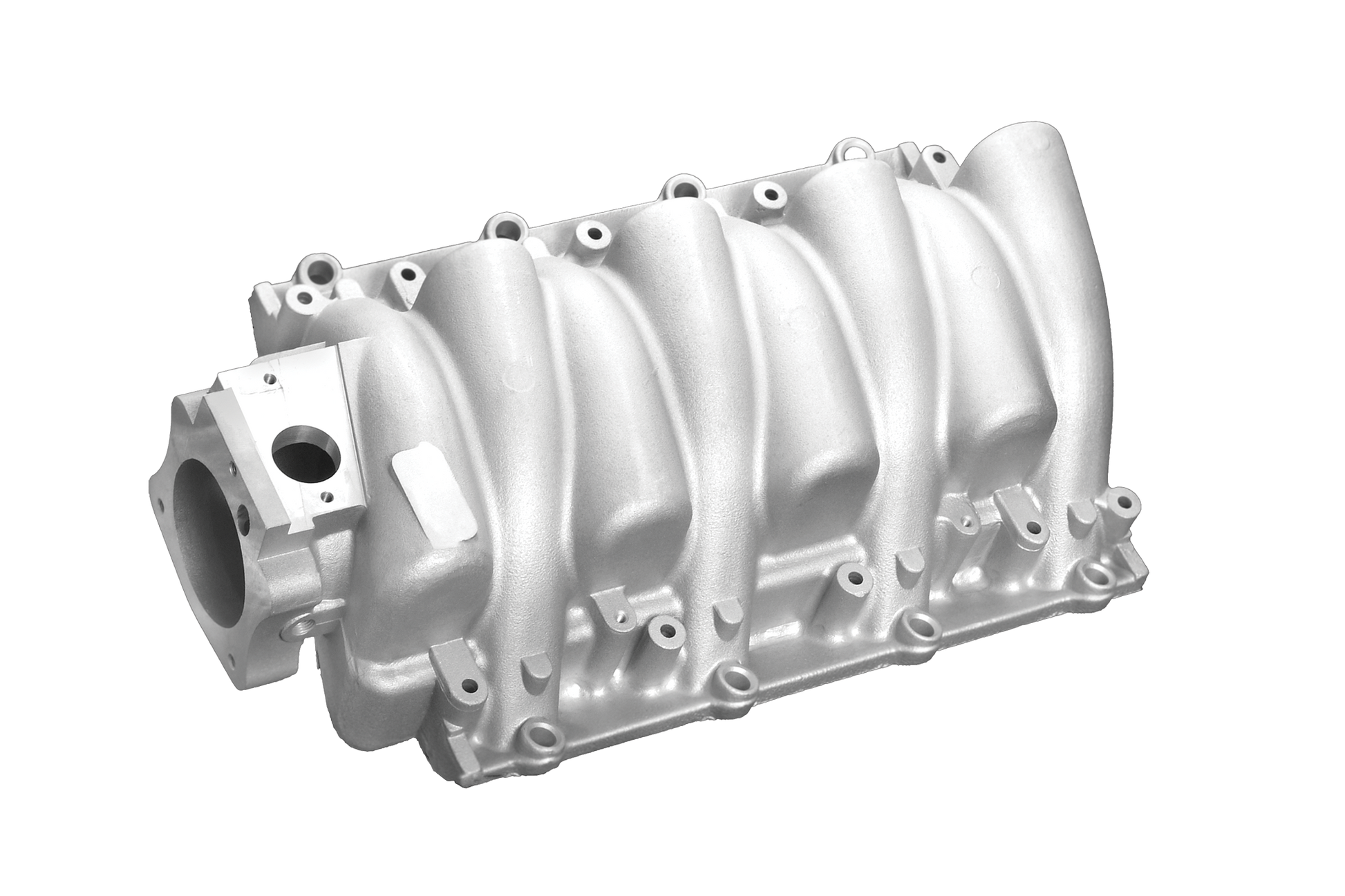

A stock image related to ls1 intake manifold.

Can the LS1 Intake Manifold Be Used in Aerospace Applications?

In the aerospace industry, the LS1 intake manifold can be adapted for custom modifications in lightweight aircraft engines. This application focuses on enhancing performance and achieving fuel savings, which are critical for operational efficiency in aviation. B2B buyers in Europe and the Middle East must ensure that the manifolds meet stringent aerospace certification requirements and are designed with weight considerations in mind, as every gram saved can significantly impact overall performance.

How is the LS1 Intake Manifold Applied in Marine Engineering?

Marine engineering leverages the LS1 intake manifold for upgrades in high-performance marine engines. These enhancements lead to increased speed and reduced fuel consumption, essential for operators in competitive maritime environments. Buyers from regions with significant maritime activities should focus on sourcing manifolds that offer corrosion resistance and are constructed from marine-grade materials to ensure longevity and compliance with maritime regulations.

What Benefits Does the LS1 Intake Manifold Offer in Renewable Energy Applications?

In the renewable energy sector, the LS1 intake manifold is integrated into biofuel and hybrid engines to support sustainability goals while enhancing performance. This application not only improves engine efficiency but also aligns with the growing global emphasis on eco-friendly technologies. B2B buyers should seek suppliers who provide eco-friendly materials and have the necessary certifications, ensuring that the manifolds are adaptable to various fuel types while meeting environmental standards.

Related Video: 5.3 LM7 LS1 Intake manifold Swap How To

3 Common User Pain Points for ‘ls1 intake manifold’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality LS1 Intake Manifolds

The Problem: B2B buyers, particularly those operating in emerging markets like South Africa and Turkey, often struggle to find reliable suppliers of high-quality LS1 intake manifolds. Many local options may not meet international quality standards, leading to concerns about performance and durability. This inconsistency can result in costly delays and dissatisfied end customers, as businesses rely on these components for competitive automotive applications.

The Solution: To overcome sourcing challenges, buyers should leverage global supplier databases and platforms that specialize in automotive parts. Conduct thorough due diligence by checking supplier certifications, customer reviews, and product samples. Engaging with manufacturers directly can also provide insights into production processes and quality controls. Establishing long-term partnerships with reputable suppliers can not only ensure consistent quality but also enable better negotiation terms and faster response times for urgent orders.

Scenario 2: Installation Challenges with LS1 Intake Manifolds

The Problem: After purchasing LS1 intake manifolds, buyers frequently encounter installation issues due to variations in vehicle models and engine configurations. These discrepancies can lead to performance setbacks, engine misfires, or even damage to the engine components. This scenario is particularly prevalent among businesses in the Middle East, where custom modifications and aftermarket enhancements are common.

The Solution: To mitigate installation challenges, it is crucial to provide detailed installation guides and support documentation alongside the products. Buyers should invest in training for their technicians or mechanics, ensuring they are familiar with specific installation nuances for various models. Additionally, sourcing LS1 intake manifolds that come with comprehensive installation kits—including gaskets, bolts, and seals—can streamline the process. Utilizing virtual consultations with experienced technicians can also help resolve specific installation concerns, ensuring optimal performance and reducing the risk of errors.

Scenario 3: Performance Optimization Issues with LS1 Intake Manifolds

The Problem: Many buyers find that the LS1 intake manifolds they procure do not deliver the expected performance enhancements. This is particularly frustrating for businesses in Europe and South America, where performance tuning is a significant market segment. The mismatch between expectations and actual performance can lead to lost sales opportunities and damage to reputation.

The Solution: To address performance optimization issues, buyers should focus on conducting comprehensive compatibility assessments before finalizing their purchases. This includes understanding the specific performance goals for their vehicles and aligning those with the characteristics of the LS1 intake manifolds. Collaborating with tuning specialists or engineers can also provide insights into how to modify or enhance the manifolds for better airflow and efficiency. Additionally, investing in data analysis tools that evaluate engine performance pre- and post-installation can help buyers make informed decisions and validate the efficacy of their chosen products. Providing feedback to manufacturers about performance experiences can lead to improvements in product design and customer satisfaction.

Strategic Material Selection Guide for ls1 intake manifold

When selecting materials for the LS1 intake manifold, it is crucial for international B2B buyers to consider various factors, including performance characteristics, manufacturing complexities, and regional compliance standards. Here, we analyze four common materials used in the production of LS1 intake manifolds: aluminum, composite plastics, cast iron, and stainless steel. Each material offers distinct advantages and disadvantages that can significantly impact the end product’s performance and suitability for specific applications.

What Are the Key Properties of Aluminum for LS1 Intake Manifolds?

Aluminum is one of the most popular choices for LS1 intake manifolds due to its excellent strength-to-weight ratio, high thermal conductivity, and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for performance applications. Additionally, aluminum manifolds can be easily cast or machined, allowing for complex designs that enhance airflow.

Pros & Cons: The primary advantages of aluminum include its lightweight nature and superior heat dissipation, which can improve engine performance. However, aluminum can be more expensive than other materials and may require additional coatings to enhance corrosion resistance in harsh environments.

Impact on Application: Aluminum is compatible with various fuel types, including gasoline and ethanol blends, making it versatile for different markets. Buyers in regions with high humidity or saline environments should consider additional protective measures to prevent corrosion.

How Do Composite Plastics Compare for LS1 Intake Manifolds?

Composite plastics, such as reinforced nylon or polyamide, are increasingly being used for LS1 intake manifolds due to their lightweight properties and resistance to thermal expansion. These materials can handle moderate temperatures and pressures, making them suitable for standard performance applications.

Pros & Cons: The main advantage of composite plastics is their cost-effectiveness and ease of manufacturing, allowing for rapid prototyping and production. However, they may not perform as well under extreme conditions compared to metals, and their long-term durability can be a concern in high-performance scenarios.

Impact on Application: Composite plastics are generally resistant to chemical corrosion, making them suitable for various fuel types. However, buyers should ensure that the specific composite material chosen can withstand the operational conditions of their application, especially in regions with high temperatures.

What Are the Benefits of Using Cast Iron for LS1 Intake Manifolds?

Cast iron is known for its durability and excellent vibration damping characteristics. It can handle high temperatures and pressures, making it a reliable choice for heavy-duty applications. Cast iron manifolds are often used in performance builds due to their ability to withstand extreme conditions.

Pros & Cons: The key advantage of cast iron is its robustness and longevity, making it ideal for high-performance engines. However, it is significantly heavier than aluminum and composite materials, which can affect overall vehicle performance. Additionally, cast iron is more challenging to manufacture, often requiring more extensive machining processes.

Impact on Application: Cast iron is compatible with various fuels but may require specific coatings to enhance corrosion resistance, especially in humid or coastal regions. Buyers should consider the weight implications for their applications, particularly in performance-oriented vehicles.

Why Choose Stainless Steel for LS1 Intake Manifolds?

Stainless steel offers excellent corrosion resistance and can withstand high temperatures and pressures, making it suitable for performance applications. Its strength and durability make it a reliable choice for intake manifolds that need to endure harsh conditions.

Pros & Cons: The primary advantage of stainless steel is its resistance to rust and corrosion, which is crucial in regions with high humidity or exposure to salt. However, it is generally more expensive than aluminum and composite materials and can be more challenging to work with during manufacturing.

Impact on Application: Stainless steel is compatible with various fuels and is particularly advantageous in environments where corrosion is a significant concern. Buyers from regions with stringent compliance standards should ensure that the stainless steel used meets local regulations.

Summary Table of Material Selection for LS1 Intake Manifold

| Material | Typical Use Case for ls1 intake manifold | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Performance engines | Lightweight and excellent thermal conductivity | Higher cost and potential corrosion issues | Medium |

| Composite Plastics | Standard performance applications | Cost-effective and easy to manufacture | Limited performance under extreme conditions | Low |

| Cast Iron | Heavy-duty and performance builds | Robustness and longevity | Heavier and complex manufacturing | Medium |

| Stainless Steel | High-performance and corrosion-sensitive applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a strategic overview for international B2B buyers looking to select the appropriate material for LS1 intake manifolds, ensuring that they make informed decisions based on performance needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ls1 intake manifold

What Are the Key Stages in the Manufacturing Process of LS1 Intake Manifolds?

A stock image related to ls1 intake manifold.

The manufacturing of LS1 intake manifolds involves several critical stages that ensure both performance and durability. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: What Materials Are Used and Why?

The process begins with material selection, typically aluminum or composite materials, due to their lightweight and excellent thermal properties. Aluminum is often favored for its strength and ability to withstand high temperatures, while composites can offer better insulation and weight reduction.

Material preparation involves cutting, machining, and treating the raw materials to achieve desired specifications. Buyers should inquire about the source of these materials and whether they comply with international standards, as this can affect performance and longevity.

How Is Forming Done in the LS1 Intake Manifold Manufacturing Process?

Forming is the next stage, which typically includes die-casting or injection molding. Die-casting is a common technique for aluminum manifolds, where molten metal is poured into a mold to create the desired shape. This method allows for precise dimensions and excellent surface finish.

For composite manifolds, injection molding is used, where heated material is injected into a mold. This process can produce complex geometries and reduce waste. B2B buyers should assess the technology used by suppliers, as advanced techniques can result in better quality and consistency.

What Is Involved in the Assembly Stage of LS1 Intake Manifolds?

Once the components are formed, they undergo assembly. This stage may involve welding, bonding, or fastening parts together. The assembly process must be meticulously managed to ensure that all components fit properly and function as intended.

Buyers should look for suppliers who utilize automated assembly techniques, as these can improve efficiency and reduce human error. Additionally, ask about the training and skills of the assembly personnel, as their expertise can significantly impact the final product’s quality.

Which Finishing Techniques Are Commonly Used for LS1 Intake Manifolds?

Finishing is crucial for enhancing the performance and aesthetics of LS1 intake manifolds. Common techniques include machining, polishing, and coating. Machining removes any excess material to ensure precise dimensions, while polishing improves the surface finish, which can enhance airflow and performance.

Coatings, such as anodizing or powder coating, are often applied for corrosion resistance and improved appearance. When considering suppliers, buyers should inquire about the finishing processes used and their impact on the product’s performance and durability.

What Quality Control Measures Are Essential for LS1 Intake Manifolds?

Quality assurance is a cornerstone of manufacturing, particularly for critical components like LS1 intake manifolds. International B2B buyers need to be aware of the quality control measures that suppliers implement to ensure product integrity.

Which International Standards Should Buyers Look For?

For global compliance, suppliers should adhere to international quality standards, such as ISO 9001. This standard focuses on quality management systems and continuous improvement. Additionally, industry-specific certifications like CE marking and API standards should be checked, as they indicate compliance with safety and performance requirements.

B2B buyers should ask suppliers for documentation proving these certifications. This can serve as a valuable indicator of a supplier’s commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production line. Buyers should confirm that suppliers conduct rigorous IQC to prevent defects.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. IPQC checks are performed at various stages to ensure compliance with specifications.

-

Final Quality Control (FQC): This final inspection guarantees that the finished product meets all required standards before shipment. Buyers should inquire about the FQC process and any testing methods employed.

What Testing Methods Are Commonly Used to Ensure Quality?

Common testing methods for LS1 intake manifolds include:

- Dimensional Inspection: Ensures that the product meets specified measurements.

- Material Testing: Confirms that materials meet strength and durability standards.

- Pressure Testing: Assesses the integrity of the manifold under simulated operating conditions.

- Performance Testing: Evaluates how the manifold performs under real-world conditions.

B2B buyers should request details about the specific testing methods used by suppliers and any certifications associated with those tests.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying the quality control processes of suppliers is vital for international B2B buyers. Here are some actionable steps:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their quality management practices. Buyers should consider third-party audits for an unbiased evaluation.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including IQC, IPQC, and FQC findings. These reports can reveal trends and areas of concern.

-

Engage Third-Party Inspection Services: Utilizing independent inspection services can help verify the quality of products before shipment, ensuring that they meet the required standards.

-

Understand Regional Compliance Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional compliance issues that may affect quality. For example, specific certifications may be required for products exported to the European Union or the Middle East.

Conclusion: Why Quality Assurance Is Crucial for LS1 Intake Manifolds

In the competitive landscape of automotive components, understanding the manufacturing processes and quality assurance measures for LS1 intake manifolds is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can ensure they are sourcing high-quality products that meet international standards. This knowledge empowers buyers to make informed decisions, ultimately leading to better partnerships and successful outcomes in their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ls1 intake manifold’

The following checklist serves as a comprehensive guide for international B2B buyers looking to source LS1 intake manifolds effectively. This step-by-step approach ensures that buyers make informed decisions while navigating the complexities of international procurement.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to establish clear technical specifications for the LS1 intake manifold. This includes dimensions, material requirements, and performance criteria tailored to your specific application. Having precise specifications helps in aligning your needs with supplier capabilities, minimizing the risk of receiving substandard products.

Step 2: Conduct Market Research

Understanding the market landscape is vital for sourcing LS1 intake manifolds. Research various suppliers, including manufacturers and distributors, focusing on their reputation and product offerings. Utilize platforms like industry forums, trade shows, and online marketplaces to gather insights about potential suppliers’ reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key factors to consider include:

– Production capacity: Ensure the supplier can meet your order volume and delivery timelines.

– Quality certifications: Verify that the supplier holds relevant certifications, such as ISO 9001, to ensure adherence to quality standards.

Step 4: Request Samples and Prototypes

Once you’ve shortlisted potential suppliers, request samples or prototypes of the LS1 intake manifolds. This step allows you to assess the quality, fit, and performance of the products firsthand. Pay attention to:

– Material quality: Ensure the materials used meet your durability and performance standards.

– Craftsmanship: Inspect the manufacturing precision to confirm it aligns with your specifications.

Step 5: Negotiate Pricing and Terms

Effective negotiation is key to securing favorable pricing and terms. Be transparent about your budget while also considering the total cost of ownership, including shipping and duties. When negotiating, focus on:

– Volume discounts: If you plan to make bulk purchases, inquire about potential discounts.

– Payment terms: Establish clear payment conditions that protect your cash flow and ensure supplier accountability.

Step 6: Assess Logistics and Shipping Options

Logistics play a significant role in the timely delivery of your LS1 intake manifolds. Discuss shipping options with your supplier and consider factors such as:

– Lead times: Confirm production and shipping timelines to avoid delays in your operations.

– Customs regulations: Ensure that the supplier can provide necessary documentation to facilitate a smooth customs process.

Step 7: Establish a Quality Control Process

Implementing a quality control process is essential for maintaining product standards. Work with your supplier to set up inspection protocols, which may include:

– In-process inspections: Regular checks during manufacturing to ensure compliance with specifications.

– Final inspections: Comprehensive evaluations upon receipt to confirm product quality before integration into your operations.

By following this checklist, B2B buyers can streamline the sourcing process for LS1 intake manifolds, ensuring quality, reliability, and cost-effectiveness in their procurement strategy.

Comprehensive Cost and Pricing Analysis for ls1 intake manifold Sourcing

What Are the Key Cost Components in Sourcing LS1 Intake Manifolds?

When sourcing LS1 intake manifolds, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for LS1 intake manifolds include aluminum and composite plastics. High-quality materials may incur higher upfront costs but can lead to better performance and durability.

-

Labor: Labor costs vary by region and the complexity of manufacturing. Skilled labor in regions with lower wage standards can reduce overall costs, but may also affect quality if not managed correctly.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Factoring in these costs is essential for a complete understanding of the price.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over the production run, so larger volumes can significantly reduce the per-unit cost.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall expense. Certifications and testing may also be necessary depending on the end-use of the manifolds.

-

Logistics: Shipping costs can vary based on destination, mode of transport, and shipping terms. Buyers should factor in not just the freight charges but also potential tariffs and customs duties.

-

Margin: Suppliers will add a profit margin on top of their costs, which can vary widely based on market conditions and the supplier’s position within the supply chain.

How Do Price Influencers Affect LS1 Intake Manifold Sourcing?

Several factors can influence the pricing of LS1 intake manifolds:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing structures. Higher volumes usually lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Customized solutions or specific performance enhancements can significantly increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and required certifications (e.g., ISO, SAE) can impact both cost and supplier selection. High-quality certifications often correlate with higher prices but can be critical for certain applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a proven track record may charge more, but they often provide better quality assurance and support.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can influence the final landed cost of products.

What Are Some Buyer Tips for Cost-Efficient Sourcing of LS1 Intake Manifolds?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing structures. Understanding their cost components can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. A slightly higher upfront cost may lead to lower TCO if the product is of higher quality.

-

Market Research: Conduct thorough market research to compare prices and suppliers. Understanding local and international market trends can help buyers make informed decisions.

-

Leverage Regional Advantages: Buyers from Africa, South America, the Middle East, and Europe should consider regional suppliers who may offer competitive pricing due to lower labor costs or favorable trade agreements.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and economic conditions in supplier countries, as these can impact pricing.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on market conditions, supplier agreements, and specific buyer requirements. Always seek multiple quotations and perform due diligence before finalizing any sourcing decisions.

Alternatives Analysis: Comparing ls1 intake manifold With Other Solutions

Understanding the Importance of Exploring Alternatives for the LS1 Intake Manifold

In the competitive landscape of automotive performance enhancements, the LS1 intake manifold is a popular choice among enthusiasts and professionals alike. However, it’s essential for international B2B buyers to explore alternative solutions that may offer unique benefits or cost advantages. This analysis will compare the LS1 intake manifold with two viable alternatives: the Holley EFI intake manifold and the Edelbrock Performer intake manifold. By understanding the strengths and weaknesses of each option, buyers can make informed decisions tailored to their specific requirements.

Comparison Table of LS1 Intake Manifold and Alternatives

| Comparison Aspect | LS1 Intake Manifold | Holley EFI Intake Manifold | Edelbrock Performer Intake Manifold |

|---|---|---|---|

| Performance | High airflow, optimized for high RPMs | Excellent for fuel efficiency and throttle response | Good mid-range performance, suitable for street use |

| Cost | Moderate pricing | Higher price due to advanced technology | Competitive pricing, often more affordable |

| Ease of Implementation | Requires specific tuning | Complex installation; may need professional assistance | Relatively straightforward installation |

| Maintenance | Low maintenance | Low maintenance, but may require tuning adjustments | Low maintenance, durable design |

| Best Use Case | Racing and high-performance applications | Street and performance vehicles needing fuel efficiency | General street use, good for mild performance builds |

In-Depth Analysis of Alternatives

What are the benefits and drawbacks of the Holley EFI Intake Manifold?

The Holley EFI intake manifold is known for its advanced design that significantly enhances fuel efficiency and throttle response. Its compatibility with electronic fuel injection systems makes it a top choice for modern performance vehicles. However, the complexity of installation often necessitates professional expertise, which can increase overall costs. For B2B buyers focusing on high-performance street applications, the Holley EFI may be worth the investment despite its higher initial price.

How does the Edelbrock Performer Intake Manifold compare?

The Edelbrock Performer intake manifold offers a balanced approach for those looking to enhance their vehicle’s performance without going to extremes. It excels in mid-range power delivery, making it ideal for everyday driving and light performance upgrades. Its installation is generally straightforward, allowing for easier adoption by less experienced mechanics. However, while it is competitively priced, it may not provide the same high-end performance as the LS1 or Holley EFI alternatives, making it less suitable for racing applications.

How to Choose the Right Solution for Your Needs

When selecting the appropriate intake manifold solution, B2B buyers should consider their specific application, performance requirements, and budget constraints. For those in the racing sector or high-performance markets, the LS1 intake manifold or Holley EFI may be ideal due to their superior airflow capabilities. Conversely, for buyers focused on cost-effectiveness and general street use, the Edelbrock Performer presents an attractive option. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make decisions that align with their operational goals and customer demands.

Essential Technical Properties and Trade Terminology for ls1 intake manifold

What are the Key Technical Properties of an LS1 Intake Manifold?

Understanding the technical properties of the LS1 intake manifold is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Here are several essential specifications to consider:

1. Material Grade

The LS1 intake manifold is typically constructed from materials such as aluminum, plastic, or composite materials. Aluminum is favored for its lightweight and durability, providing an excellent strength-to-weight ratio. For B2B buyers, selecting the right material can impact both performance and cost-effectiveness. Consideration of material grade also affects heat resistance and overall longevity, which are critical for maintaining engine performance.

2. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For intake manifolds, tight tolerances are essential to ensure proper fitment and performance. A tolerance of ±0.1mm is often acceptable, but the specific requirement may vary based on application. Understanding tolerance levels helps buyers ensure compatibility with other engine components, thus reducing the risk of operational issues.

3. Port Size and Configuration

The port size and configuration of the intake manifold significantly influence airflow and engine efficiency. LS1 manifolds come with varying port shapes and sizes, which can affect power output and fuel efficiency. B2B buyers should assess the specific needs of their engine applications to select a manifold that optimizes performance.

4. Weight

The weight of the intake manifold can impact the overall weight distribution of the vehicle, affecting handling and performance. A lightweight manifold can improve engine responsiveness and reduce fuel consumption. B2B buyers must consider the weight specifications in relation to the vehicle’s design and performance goals.

5. Surface Finish

The surface finish of the intake manifold can affect both aesthetics and performance. A smoother finish can enhance airflow, reducing turbulence and improving efficiency. Buyers should inquire about the surface treatment options available, as this can be a distinguishing factor in performance capabilities.

6. Compatibility with Aftermarket Components

For many buyers, the ability to integrate aftermarket components is crucial. Understanding compatibility with other engine parts, such as throttle bodies and fuel rails, is essential for maximizing performance. Buyers should seek manifolds that offer flexibility for upgrades and modifications, ensuring long-term value.

What Trade Terminology Should B2B Buyers Understand?

Navigating the world of LS1 intake manifolds involves familiarity with specific trade terminologies that can impact purchasing decisions. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures the original parts used in a vehicle. For B2B buyers, understanding OEM specifications is vital for ensuring that replacement parts meet the original performance standards and quality expectations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For international buyers, negotiating MOQ can be crucial for managing inventory costs and ensuring that demand is met without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. For buyers in various regions, a well-structured RFQ can lead to better pricing and terms, making it an essential tool for effective procurement.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs and risks effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is crucial for planning and managing inventory, especially when sourcing from international suppliers.

6. Warranty and Support

Warranty terms are essential for understanding the level of support and service a buyer can expect after purchase. Buyers should clarify warranty conditions to safeguard their investment and ensure ongoing support for any potential issues.

By comprehensively understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions regarding LS1 intake manifolds, ensuring optimal performance and value for their investments.

Navigating Market Dynamics and Sourcing Trends in the ls1 intake manifold Sector

What are the Current Market Dynamics for LS1 Intake Manifolds?

The LS1 intake manifold sector is witnessing significant growth driven by advancements in automotive technology and increasing demand for high-performance vehicles. Global factors such as the rise in automotive production, particularly in emerging markets like South Africa and Turkey, are propelling the demand for LS1 intake manifolds. Buyers from Africa and South America are particularly interested in sourcing these components as they enhance engine efficiency and performance, which is crucial for both commercial and personal vehicles.

Emerging B2B tech trends, such as the integration of digital platforms for sourcing and procurement, are reshaping how international buyers engage with suppliers. Online marketplaces and digital supply chains are allowing buyers to compare products, prices, and suppliers more effectively than ever before. The shift towards just-in-time (JIT) inventory systems is also influencing sourcing strategies, enabling companies to reduce holding costs while ensuring they have access to high-quality LS1 intake manifolds when needed.

Moreover, the competitive landscape is evolving, with manufacturers focusing on innovation and customization to meet specific buyer needs. International buyers should be aware of regional differences in production capabilities and quality standards, particularly when sourcing from diverse markets across Africa, the Middle East, and Europe. Understanding these dynamics can provide a strategic advantage in selecting suppliers that align with their performance and budgetary requirements.

How is Sustainability Influencing Sourcing Decisions for LS1 Intake Manifolds?

Sustainability is becoming a critical consideration for B2B buyers in the LS1 intake manifold sector. As global awareness of environmental issues increases, buyers are looking for suppliers who prioritize eco-friendly practices and materials. The production of LS1 intake manifolds can have significant environmental impacts, including carbon emissions and resource depletion. Therefore, seeking out suppliers that implement sustainable manufacturing processes is essential.

The importance of ethical sourcing cannot be overstated. Buyers should evaluate the supply chain practices of potential suppliers, ensuring they comply with international labor standards and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are increasingly sought after as they demonstrate a commitment to sustainability.

Additionally, the use of ‘green’ materials in the production of LS1 intake manifolds is gaining traction. This includes lightweight composites that not only reduce the overall weight of the vehicle, enhancing fuel efficiency, but also have a lower environmental impact compared to traditional materials. Buyers should actively seek out suppliers who can provide transparency regarding their sourcing and manufacturing processes, ensuring that their supply chain aligns with their sustainability goals.

A stock image related to ls1 intake manifold.

How Has the LS1 Intake Manifold Market Evolved Over Time?

The LS1 intake manifold market has evolved significantly since its inception in the early 1990s. Initially designed for performance vehicles, the LS1 engine architecture has become a popular choice for a wide range of applications, from street cars to racing vehicles. Over the years, advancements in materials science and manufacturing techniques have led to the development of more efficient and durable intake manifolds, catering to the growing performance demands of the automotive industry.

As the market has matured, competition has intensified, prompting manufacturers to focus on innovation and customer-centric solutions. Today, international B2B buyers are not only looking for high-performance LS1 intake manifolds but also for customization options that suit their specific needs. This evolution underscores the importance of staying informed about market trends and supplier capabilities to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of ls1 intake manifold

-

How do I choose the right LS1 intake manifold for my application?

Choosing the right LS1 intake manifold involves understanding your engine’s specific needs and intended use. Consider factors such as horsepower goals, the type of fuel you plan to use, and whether you’re aiming for street performance or racing. Research the manifold’s design—such as single vs. dual-plane—and its compatibility with other engine components. Consulting with your supplier for their expertise and customer reviews can also provide insights into which manifold will best suit your requirements. -

What is the best LS1 intake manifold for high-performance applications?

For high-performance applications, the best LS1 intake manifold typically features a design optimized for maximum airflow and throttle response. Options like the Holley LS1 intake manifold are popular due to their advanced engineering, which supports significant power increases. Additionally, consider manifolds that allow for easy modifications and upgrades as your performance goals evolve. Always ensure that the manifold aligns with your engine setup and tuning capabilities for optimal results. -

What should I consider when sourcing LS1 intake manifolds from international suppliers?

When sourcing LS1 intake manifolds from international suppliers, consider the supplier’s reputation, certifications, and experience in the automotive parts industry. Evaluate their quality assurance processes and request product samples when possible. Understanding shipping logistics, customs regulations, and import duties is crucial to avoid unexpected costs. Lastly, ensure the supplier can provide adequate support and documentation, such as installation guides and warranties. -

What are the minimum order quantities (MOQ) for LS1 intake manifolds?

Minimum order quantities (MOQ) for LS1 intake manifolds can vary significantly among suppliers. Typically, they may range from 10 to 100 units, depending on the manufacturer’s production capabilities and your negotiation skills. If you’re a smaller buyer or just starting, communicate your needs clearly and be open to discussing lower MOQs for trial orders. Some suppliers may offer flexibility, especially if you establish a long-term partnership. -

What payment terms should I expect when purchasing LS1 intake manifolds?

Payment terms for LS1 intake manifolds can vary based on the supplier’s policies and your negotiation. Common arrangements include upfront payments, a deposit followed by balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). International buyers should be aware of currency fluctuations and transaction fees. Always clarify payment options, including secure payment methods like letters of credit or escrow services to protect your investment. -

How can I ensure quality assurance for LS1 intake manifolds?

To ensure quality assurance for LS1 intake manifolds, inquire about the supplier’s quality control processes, certifications, and testing procedures. Request documentation such as ISO certifications or third-party testing reports. It’s beneficial to ask about warranty terms and what recourse you have if the product does not meet specified standards. Building a strong relationship with your supplier can also enhance trust in their quality commitments. -

What logistics considerations should I keep in mind when importing LS1 intake manifolds?

Logistics are critical when importing LS1 intake manifolds. Assess shipping options, lead times, and costs, and consider whether you need air or sea freight based on urgency and budget. Understand customs clearance procedures, including necessary documentation and duties. Collaborating with a freight forwarder can simplify the process and help navigate potential delays, ensuring your parts arrive safely and on time. -

Are there customization options available for LS1 intake manifolds?

Yes, many suppliers offer customization options for LS1 intake manifolds to meet specific performance or aesthetic needs. Customization may include modifications to the manifold design, coating finishes, or even specific port sizes to enhance compatibility with other engine components. Discuss your requirements with suppliers early in the sourcing process to determine feasibility, lead times, and additional costs associated with custom orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ls1 intake manifold

The journey toward optimizing your supply chain for LS1 intake manifolds requires a strategic approach that prioritizes quality, cost-efficiency, and supplier reliability. As highlighted throughout this guide, understanding the intricacies of sourcing LS1 intake manifolds can greatly enhance performance outcomes and customer satisfaction. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, this means leveraging local suppliers who understand regional demands while also exploring global partnerships that can provide cutting-edge technology and competitive pricing.

What are the key factors for successful sourcing of LS1 intake manifolds? It is crucial to assess suppliers based on their production capabilities, compliance with international standards, and ability to deliver on time. Additionally, establishing strong relationships with suppliers can lead to more favorable terms and better service.

Looking ahead, the market for LS1 intake manifolds is poised for growth, driven by innovations in automotive technology and increasing demand for high-performance components. B2B buyers are encouraged to stay informed about market trends and engage in proactive sourcing strategies. By prioritizing strategic sourcing, you position your business not just to compete, but to thrive in the evolving landscape of the automotive industry. Take action today to explore new partnerships and enhance your supply chain resilience.