Discover Long Nipple Sourcing: The Complete Guide (2025)

Introduction: Navigating the Global Market for long nipple

Navigating the complexities of sourcing long nipples can be a daunting task for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge often lies in identifying reliable suppliers while ensuring compliance with various regional standards and specifications. This guide aims to streamline that process by providing a comprehensive overview of long nipples, including their types, applications, and the critical factors to consider when sourcing from global suppliers.

In this resource, you will find detailed insights into the different varieties of long nipples, their specific uses across industries such as plumbing, manufacturing, and automotive, as well as best practices for supplier vetting. We will also delve into cost considerations, offering strategies to help you negotiate better pricing without compromising quality. By understanding the nuances of the global market for long nipples, B2B buyers can make informed purchasing decisions that not only meet their operational needs but also align with their strategic goals.

Ultimately, this guide empowers you to navigate the global landscape with confidence, ensuring that you select the right products and partners. Whether you are based in the bustling markets of Vietnam or the dynamic business hubs of the UAE, the actionable insights provided here will help you mitigate risks and maximize your sourcing efficiency.

Understanding long nipple Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Long Nipple | Commonly used, versatile design | General plumbing and HVAC systems | Pros: Widely available, cost-effective. Cons: May not fit specialized applications. |

| Flanged Long Nipple | Features a flange for added stability | Industrial piping, construction | Pros: Enhanced grip, prevents disconnection. Cons: Higher cost compared to standard types. |

| Threaded Long Nipple | Internal threading for secure connections | Oil and gas, chemical processing | Pros: Strong connection, customizable lengths. Cons: Requires precise measurements for fitting. |

| Adjustable Long Nipple | Length can be modified as needed | Custom installations | Pros: Flexibility in application, easy to install. Cons: Potential for wear over time. |

| Specialty Long Nipple | Custom-made for specific requirements | Aerospace, automotive | Pros: Tailored solutions, high performance. Cons: Longer lead times, higher costs. |

What Are the Characteristics of Standard Long Nipples?

Standard long nipples are the most commonly found type in the market. They are typically made from materials like stainless steel or PVC, making them suitable for a variety of applications, including plumbing and HVAC systems. When purchasing, consider the specific diameter and length required for your project, as these dimensions can significantly affect compatibility with existing systems. Their affordability and widespread availability make them a go-to option for many B2B buyers.

How Do Flanged Long Nipples Enhance Stability in Applications?

Flanged long nipples are designed with a flange at one or both ends, providing a secure connection that enhances stability. They are particularly beneficial in industrial piping and construction applications where vibrations or movement can lead to disconnections. Buyers should evaluate the specific requirements of their projects to determine if the added stability justifies the higher cost associated with flanged options. This type is ideal for environments that demand a robust connection.

A stock image related to long nipple.

Why Choose Threaded Long Nipples for Secure Connections?

Threaded long nipples feature internal threading that allows for secure connections between pipes. This design is particularly advantageous in industries such as oil and gas and chemical processing, where a reliable seal is critical. When considering threaded options, it’s essential to ensure precise measurements to avoid leaks and ensure compatibility. While they offer a strong connection, the need for exact specifications may pose a challenge for some buyers.

What Are the Benefits of Adjustable Long Nipples?

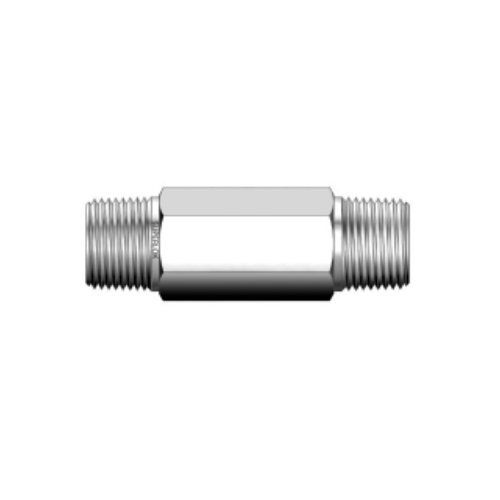

A stock image related to long nipple.

Adjustable long nipples provide the unique advantage of being able to modify their length, making them suitable for custom installations. This flexibility can be particularly useful in projects with varying requirements or space constraints. Buyers should be aware that while adjustable nipples are easy to install, they may experience wear over time, potentially affecting their longevity. Therefore, considering the application environment is crucial when choosing this type.

How Do Specialty Long Nipples Meet Specific Requirements?

Specialty long nipples are custom-made to meet specific requirements, often found in high-performance applications such as aerospace and automotive industries. These nipples are tailored to fit unique specifications, ensuring optimal performance in demanding environments. While they offer significant benefits in terms of functionality, buyers should account for longer lead times and higher costs associated with custom manufacturing. Understanding the precise needs of your project is vital when opting for specialty solutions.

Related Video: Types of Nipple

Key Industrial Applications of long nipple

| Industry/Sector | Specific Application of long nipple | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Connecting pipelines in drilling operations | Ensures safe and efficient transportation of fluids; minimizes leakage risks | Material quality (corrosion resistance), certifications, and compliance with industry standards. |

| Construction | Water supply systems and plumbing fittings | Provides robust connections that withstand high pressure; enhances system reliability | Compatibility with existing systems, pressure ratings, and local regulations. |

| Automotive | Exhaust systems and engine components | Improves performance and durability of exhaust systems; reduces emissions | Heat resistance, fitting specifications, and availability of custom sizes. |

| Food and Beverage | Beverage dispensing systems | Maintains hygiene and prevents contamination; ensures consistent flow | Compliance with food safety standards, material certifications, and ease of cleaning. |

| Chemical Processing | Chemical transfer and storage systems | Reduces the risk of chemical leaks; enhances safety and operational efficiency | Material compatibility with chemicals, pressure ratings, and certifications for hazardous materials. |

How is Long Nipple Used in the Oil and Gas Industry?

In the oil and gas sector, long nipples are crucial for connecting various pipeline segments during drilling operations. They provide a reliable connection that can withstand the extreme pressures and harsh environments typical of this industry. For international buyers, especially in regions like Africa and the Middle East, sourcing long nipples made from corrosion-resistant materials is vital due to the exposure to aggressive substances. Additionally, ensuring compliance with international standards can mitigate risks associated with leaks, which can lead to costly environmental damages.

What Role Does Long Nipple Play in Construction?

In construction, long nipples are commonly used in water supply systems and plumbing fittings. They facilitate robust connections that can handle high pressure, ensuring the reliability of water distribution systems. For buyers in South America and Europe, it is important to consider compatibility with existing plumbing systems and local building regulations. Sourcing nipples that meet specific pressure ratings can prevent future maintenance issues and enhance overall system longevity.

How is Long Nipple Utilized in Automotive Applications?

The automotive industry employs long nipples primarily in exhaust systems and engine components. They contribute to the efficient flow of exhaust gases, improving overall vehicle performance and reducing emissions. Buyers from regions like Europe, where emissions regulations are stringent, should prioritize sourcing long nipples made from heat-resistant materials that meet automotive specifications. Custom sizing may also be necessary to ensure a perfect fit within complex engine designs.

Why is Long Nipple Important in Food and Beverage Systems?

In the food and beverage industry, long nipples are essential for beverage dispensing systems. They help maintain hygiene by preventing contamination while ensuring a consistent flow of products. Buyers, particularly in Africa and the Middle East, should focus on sourcing nipples that comply with food safety standards and are made from materials that are easy to clean. This is crucial for maintaining product quality and meeting regulatory requirements in food handling.

How Does Long Nipple Function in Chemical Processing?

Long nipples are widely used in chemical processing for transferring and storing various chemicals. Their design minimizes the risk of leaks, which is crucial for safety and operational efficiency. International buyers in regions such as South America and Europe need to consider material compatibility with specific chemicals, ensuring that the long nipples can withstand the environments they will be exposed to. Additionally, sourcing products that meet certifications for hazardous materials can enhance safety and compliance in chemical handling.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

3 Common User Pain Points for ‘long nipple’ & Their Solutions

Scenario 1: Sourcing Quality Long Nipples for Diverse Applications

The Problem:

International B2B buyers often face challenges when sourcing long nipples due to variability in quality and specifications. This can lead to compatibility issues in their manufacturing processes, resulting in production delays and increased costs. Buyers from regions like Africa and South America may struggle to find reliable suppliers who meet international standards, leading to subpar products that can compromise the integrity of their systems.

The Solution:

To overcome these sourcing challenges, B2B buyers should conduct thorough supplier assessments. Start by identifying manufacturers with certifications such as ISO 9001, which indicates adherence to quality management principles. Utilize online platforms and industry directories to compare suppliers’ offerings and request samples before making bulk purchases. Additionally, consider establishing long-term partnerships with vetted suppliers to ensure consistent quality. Engage in direct communication to clarify specifications and standards, ensuring that the long nipples meet the specific requirements of your application.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem:

Another common pain point for B2B buyers is ensuring that the long nipples they purchase are compatible with existing plumbing or piping systems. Differences in thread types, materials, and sizes can lead to installation difficulties, resulting in costly adjustments or replacements. This issue is particularly pronounced in regions with diverse infrastructure standards, such as the Middle East and Europe.

The Solution:

To address compatibility concerns, buyers should invest time in understanding the specifications of their current systems. Create a detailed inventory of existing components, including sizes, thread types, and material compatibility. When sourcing long nipples, ensure that the product descriptions include comprehensive technical data. Utilize CAD software or 3D modeling tools to visualize how new components will fit within existing systems. Collaborating with engineers during the procurement process can help identify potential compatibility issues before making a purchase, thereby minimizing the risk of installation setbacks.

Scenario 3: Managing Supply Chain Disruptions

The Problem:

Supply chain disruptions pose a significant challenge for B2B buyers dealing with long nipples, particularly in the wake of global events affecting trade and logistics. Buyers from regions like Africa and South America may experience delays in receiving products, leading to halted production lines and financial losses. Additionally, fluctuating prices and limited availability can complicate budget forecasting.

The Solution:

To mitigate the risks associated with supply chain disruptions, B2B buyers should diversify their supplier base. Establish relationships with multiple suppliers across different regions to create a safety net that allows for flexibility in sourcing. Implement just-in-time inventory practices to reduce stockholding costs while ensuring that critical components are always available. Furthermore, consider utilizing technology such as supply chain management software to gain visibility into inventory levels and supplier performance. This proactive approach enables buyers to respond quickly to supply chain challenges, maintaining production continuity and minimizing financial impact.

Strategic Material Selection Guide for long nipple

When selecting materials for long nipples in various applications, it’s essential to consider the specific properties, advantages, and limitations of each option. The choice of material can significantly impact performance, durability, and compliance with industry standards, particularly for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel for Long Nipples?

Stainless steel is one of the most commonly used materials for long nipples due to its excellent mechanical properties and corrosion resistance. It typically has a temperature rating of up to 1,000°F (540°C) and can withstand high pressure, making it suitable for various industrial applications. Its resistance to rust and oxidation makes it ideal for environments where moisture is present.

Pros: Stainless steel offers high durability and longevity, making it a cost-effective choice over time. It is also relatively easy to machine, which simplifies manufacturing processes.

Cons: The initial cost of stainless steel can be high compared to other materials. Additionally, it may not be suitable for applications involving highly corrosive media unless specific grades, such as 316L, are used.

Impact on Application: Stainless steel long nipples are compatible with a wide range of media, including water, oil, and gases. However, buyers must ensure that the specific grade selected meets the media compatibility requirements.

A stock image related to long nipple.

How Does PVC Compare as a Material for Long Nipples?

Polyvinyl chloride (PVC) is a popular choice for applications requiring lightweight and corrosion-resistant materials. PVC long nipples can typically handle temperatures up to 140°F (60°C) and moderate pressure levels, making them suitable for low-pressure applications.

Pros: The primary advantage of PVC is its low cost and ease of installation. It is also resistant to many chemicals, which makes it suitable for various industrial applications.

Cons: PVC is less durable than metals and may degrade under high temperatures or UV exposure. This limits its use in high-pressure or extreme temperature applications.

Impact on Application: PVC long nipples are ideal for use in water systems, drainage, and chemical transport. However, international buyers should be aware of local regulations regarding the use of PVC in certain applications.

What are the Benefits of Using Brass for Long Nipples?

Brass is another material option for long nipples, known for its good corrosion resistance and machinability. It typically performs well in temperature ranges up to 200°F (93°C) and can handle moderate pressure.

Pros: Brass is easy to work with and offers a good balance of strength and ductility. Its aesthetic appeal also makes it suitable for applications where appearance matters.

Cons: Brass can be more expensive than plastic options and may not perform well in highly corrosive environments, particularly those involving chlorides.

Impact on Application: Brass long nipples are commonly used in plumbing and HVAC applications. Buyers should ensure compliance with local standards, such as ASTM or DIN, especially in regions with stringent regulations.

What Makes Carbon Steel a Viable Option for Long Nipples?

Carbon steel is often chosen for applications requiring high strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. However, its corrosion resistance is lower than that of stainless steel.

Pros: Carbon steel is generally less expensive than stainless steel and offers excellent mechanical properties, making it suitable for high-stress applications.

Cons: The primary disadvantage is its susceptibility to rust and corrosion, which can lead to failure if not properly coated or maintained.

Impact on Application: Carbon steel long nipples are ideal for oil and gas applications, but buyers should consider protective coatings or treatments to enhance durability. Compliance with standards such as API or ASME is crucial for international buyers.

Summary Table of Material Options for Long Nipples

| Material | Typical Use Case for Long Nipple | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil & gas, water systems | Excellent corrosion resistance | High initial cost | High |

| PVC | Chemical transport, drainage | Low cost, easy installation | Limited temperature and pressure rating | Low |

| Brass | Plumbing, HVAC | Good machinability and aesthetics | Expensive, less corrosion resistant | Medium |

| Carbon Steel | Heavy-duty applications | High strength and durability | Susceptible to rust and corrosion | Medium |

By carefully considering these materials and their characteristics, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for long nipple

What Are the Main Stages in the Manufacturing Process of Long Nipples?

Manufacturing long nipples involves several critical stages that ensure the final product meets industry standards and buyer expectations. Understanding these processes can help international B2B buyers make informed decisions when sourcing long nipples from suppliers.

-

Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials, typically metals such as stainless steel, brass, or plastic, depending on the application. This stage involves quality checks to ensure that the materials meet specified standards. Buyers should verify that suppliers source materials compliant with international quality standards, such as ASTM or ISO certifications, which guarantee material integrity and suitability for various applications. -

Forming Techniques

The forming stage encompasses various techniques such as extrusion, forging, or machining, each chosen based on the design and specifications of the long nipple. Extrusion is common for creating cylindrical shapes, while machining is used for precision components. Understanding these methods allows buyers to assess the capabilities of potential suppliers. For example, buyers should inquire whether the supplier employs CNC machining for high precision or if they use traditional methods that might be less reliable. -

Assembly Process

After forming, the long nipples may require assembly, particularly if they are part of a larger system. This stage may involve welding or threading components together to create a complete product. Quality assurance during assembly is crucial, as improper assembly can lead to leaks or failures in applications. Buyers should look for suppliers that implement rigorous assembly protocols and check for certifications that validate their assembly processes. -

Finishing Techniques

The final stage involves surface finishing treatments such as polishing, plating, or coating, which enhance the product’s durability and aesthetic appeal. This stage is important for applications that require corrosion resistance or enhanced wear properties. B2B buyers should ensure that suppliers offer finishing options that comply with relevant standards, such as RoHS or REACH, particularly when dealing with markets in Europe or strict regulations in other regions.

How Is Quality Assurance Implemented in Long Nipple Manufacturing?

Quality assurance (QA) is vital in the manufacturing of long nipples to ensure product reliability and compliance with international standards. Buyers need to understand the QA processes in place to make informed purchasing decisions.

-

What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 set out the criteria for a quality management system. Compliance with ISO standards indicates that the manufacturer has implemented processes that ensure consistent quality. Additionally, industry-specific certifications such as CE marking for products sold in Europe or API standards for oil and gas applications are critical. Buyers should verify these certifications during the supplier evaluation process to ensure compliance with regional and industry-specific requirements. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is generally divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Buyers should ensure that suppliers have a robust IQC process that includes material certification and testing.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed to monitor production processes and ensure adherence to specifications. This may involve statistical process control (SPC) techniques.

-

Final Quality Control (FQC): This final checkpoint ensures that the finished product meets all specifications and quality standards. Buyers should request FQC reports to verify compliance before shipment.

- What Common Testing Methods Are Used?

Various testing methods are employed to evaluate the integrity and performance of long nipples. These may include:

- Pressure Testing: Ensures that the product can withstand the required pressure levels without leaking.

- Dimensional Inspection: Verifies that the dimensions of the long nipple meet the specified tolerances.

- Material Testing: Confirms the chemical composition and mechanical properties of the materials used.

Buyers should inquire about the specific tests conducted by the supplier and request documentation of test results to assess product quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verification of supplier quality control processes is essential for mitigating risks associated with sourcing long nipples. Here are actionable steps buyers can take:

-

Conduct Supplier Audits

Performing regular audits of potential suppliers can provide insights into their manufacturing and QC processes. Buyers should develop a checklist that includes compliance with international standards, equipment calibration records, and employee training certifications. An on-site audit can also help assess the supplier’s commitment to quality and operational efficiency. -

Request Quality Control Reports

Suppliers should provide comprehensive QC reports that detail the results of IQC, IPQC, and FQC checks. These reports should include data on testing methods, results, and any corrective actions taken. Buyers should carefully review these documents to ensure they align with the expected quality standards. -

Engage Third-Party Inspection Services

For added assurance, B2B buyers can engage third-party inspection services to evaluate the supplier’s manufacturing processes and product quality. These independent inspections can provide unbiased assessments and help identify any potential issues before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers must be aware of specific nuances related to quality control and certification that may impact their purchasing decisions.

-

Understanding Regional Standards

Different regions have varying standards for quality and certification. For instance, products sold in the EU must adhere to stringent CE marking requirements, while buyers in the Middle East may focus more on local standards such as GCC certification. It is crucial for buyers to understand these regional differences and ensure their suppliers can meet them. -

Navigating Language Barriers

Quality control documentation may be provided in different languages, which can pose challenges for international buyers. Buyers should request that key documents be available in a language they understand or seek translation services to ensure compliance and understanding. -

Establishing Clear Communication Channels

Maintaining open communication with suppliers is vital. Buyers should establish clear expectations regarding quality standards, testing procedures, and documentation requirements. Regular communication can help address any issues early in the manufacturing process, ensuring that products meet quality standards before shipment.

By understanding these manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions when sourcing long nipples. This knowledge not only enhances buyer confidence but also fosters long-term relationships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘long nipple’

Introduction

Sourcing long nipples for industrial applications requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This guide provides a step-by-step checklist designed specifically for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these actionable steps, you can navigate the complexities of procurement and make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the long nipples. This includes dimensions, materials (such as stainless steel or brass), thread types, and any applicable industry standards.

- Consider the operational environment and any specific regulations that may apply in your region.

- Having detailed specifications will help streamline communication with potential suppliers and avoid misunderstandings later in the process.

Step 2: Conduct Market Research for Suppliers

Identifying reliable suppliers is crucial. Conduct thorough market research to compile a list of potential suppliers that specialize in long nipples.

- Utilize online directories, industry forums, and trade shows to gather information about suppliers.

- Pay attention to supplier reputation, experience in your specific market, and their ability to meet your technical requirements.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, ensure they hold the necessary certifications and comply with international standards relevant to your industry.

- Look for certifications such as ISO 9001 for quality management and any specific industry-related standards (like API for oil and gas applications).

- This step minimizes risks associated with quality assurance and regulatory compliance, especially in diverse markets.

Step 4: Request Samples for Evaluation

Once you have shortlisted potential suppliers, request samples of the long nipples to evaluate their quality and fit for your application.

- Assess the samples against your defined specifications and any industry standards.

- Testing samples can reveal important insights about material quality, craftsmanship, and overall performance.

Step 5: Engage in Pricing Negotiations

Price is a critical factor in procurement. Initiate negotiations with your shortlisted suppliers to understand their pricing structures and any potential discounts for bulk orders.

- Compare quotes while considering not only the price but also the total cost of ownership, including shipping, tariffs, and potential maintenance costs.

- Ensure transparency in pricing to avoid hidden fees that could impact your budget.

Step 6: Review Supplier Terms and Conditions

Before finalizing your order, carefully review the terms and conditions provided by the supplier.

- Pay close attention to payment terms, delivery timelines, and warranty provisions.

- Understanding these elements upfront can prevent disputes and ensure a smoother transaction process.

Step 7: Establish a Long-term Relationship

Finally, consider establishing a long-term relationship with your chosen supplier.

- Regular communication and feedback can foster collaboration and help both parties adapt to changing market conditions.

- A solid partnership can lead to better pricing, priority service, and improved product innovations tailored to your needs.

By following this checklist, you can efficiently source long nipples that meet your specifications and support your business objectives.

Comprehensive Cost and Pricing Analysis for long nipple Sourcing

What Are the Key Cost Components in Long Nipple Sourcing?

When sourcing long nipples, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for long nipples include stainless steel, brass, and plastic. Prices fluctuate based on market conditions, material quality, and availability. For instance, high-grade stainless steel will command a higher price but offers greater durability.

-

Labor: Labor costs can vary widely depending on the manufacturing location. In regions like Southeast Asia, labor tends to be more affordable, while in Europe or the UAE, labor costs are typically higher. This variation can affect the final pricing structure, especially for large-volume orders.

-

Manufacturing Overhead: This includes costs associated with production facilities, equipment, utilities, and indirect labor. Buyers should consider how these costs influence the pricing of long nipples, as manufacturers with higher operational efficiencies may offer more competitive pricing.

-

Tooling: Custom tooling can be a significant upfront investment for specialized long nipples. If your order requires unique specifications, the tooling costs must be factored into the total cost. This is particularly important for low-volume orders, where tooling costs can disproportionately affect pricing.

-

Quality Control (QC): Ensuring product quality incurs additional costs, such as inspection and testing. Buyers should prioritize suppliers with robust QC processes, as this can prevent costly defects and returns down the line.

-

Logistics: Shipping costs, including freight and insurance, play a vital role in the overall pricing. The choice of shipping method (air vs. sea) and the distance from the supplier will directly influence these costs. For international buyers, understanding Incoterms is essential to clarify who bears these costs.

-

Margin: Finally, suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on supplier reputation, market demand, and competition.

How Do Price Influencers Affect Long Nipple Sourcing?

Several factors can influence the pricing of long nipples:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-unit costs. Suppliers often provide discounts for bulk purchases, making it beneficial for buyers to consolidate orders when feasible.

-

Specifications and Customization: Customized long nipples tailored to specific needs can incur higher costs. Standard products are usually more affordable, so if customization isn’t necessary, consider opting for standard options.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or ASTM) usually result in increased costs. However, investing in certified products can lead to long-term savings by minimizing failures and ensuring compliance with industry standards.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence pricing. Established suppliers may charge a premium, but they often provide better quality assurance and customer support.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial as they dictate who is responsible for shipping costs and risks. This knowledge helps buyers accurately calculate the total landed cost.

What Tips Can Help Buyers Optimize Costs When Sourcing Long Nipples?

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially for large orders. Building a long-term relationship with suppliers can also lead to better terms over time.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This approach helps identify the most cost-effective options.

-

Evaluate Multiple Suppliers: Obtain quotes from various suppliers to compare costs and services. This not only provides leverage in negotiations but also helps identify the best value for your specific requirements.

-

Stay Informed on Market Trends: Keeping abreast of material price fluctuations and supply chain developments can provide insights into timing your purchases for optimal pricing.

-

Consider Regional Factors: When sourcing from different regions, be aware of local economic conditions and trade agreements that may affect pricing and logistics.

Disclaimer on Indicative Prices

Please note that the prices associated with long nipple sourcing can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and engage directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing long nipple With Other Solutions

Introduction: What Are the Alternatives to Long Nipple Solutions?

When considering the best solutions for specific industrial applications, B2B buyers often evaluate multiple options. The long nipple, typically used in piping and plumbing systems, has its strengths but may not always be the best choice for every scenario. Understanding the alternatives available can help businesses make informed decisions that align with their operational needs, budget constraints, and maintenance capabilities. This section compares the long nipple with two viable alternatives: the short nipple and flexible hose systems.

Comparison Table of Long Nipple and Alternatives

| Comparison Aspect | Long Nipple | Short Nipple | Flexible Hose System |

|---|---|---|---|

| Performance | High pressure resistance | Moderate pressure resistance | Variable pressure resistance |

| Cost | Moderate cost | Lower cost | Higher initial investment |

| Ease of Implementation | Requires specific fittings | Easy to install | Very easy to install |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | High-pressure applications | General plumbing | Areas needing flexibility |

What Are the Pros and Cons of Short Nipples?

Short nipples are a cost-effective solution for general plumbing applications. They are typically less expensive than long nipples, making them suitable for projects with budget constraints. Their ease of installation means that they can be quickly integrated into existing systems without extensive training or specialized tools. However, short nipples may not withstand as much pressure as long nipples, making them less ideal for high-pressure applications. This trade-off is essential for buyers to consider based on their specific project requirements.

How Do Flexible Hose Systems Compare to Long Nipples?

Flexible hose systems offer significant advantages in terms of adaptability and installation. They are particularly useful in environments where movement or vibration is expected, as they can absorb these shifts without compromising the integrity of the connection. While the initial investment for flexible hoses may be higher, their ease of installation can save time and labor costs. On the downside, flexible hoses may require more frequent maintenance and replacement compared to long nipples, especially in high-pressure scenarios. This factor should be weighed carefully by buyers looking for long-term reliability.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution for your application requires a careful analysis of the specific demands of your industry and project. B2B buyers should assess factors such as pressure requirements, budget constraints, and maintenance capabilities when choosing between long nipples, short nipples, and flexible hose systems. Conducting a thorough evaluation of these alternatives will ensure that you select a solution that not only meets your immediate needs but also provides long-term value and reliability for your operations. By understanding the unique benefits and limitations of each option, you can make a more informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for long nipple

What are the Essential Technical Properties of Long Nipples?

When sourcing long nipples, understanding their technical properties is vital for ensuring that they meet your specific application requirements. Here are several key specifications that B2B buyers should consider:

-

Material Grade

The material used for long nipples significantly influences their performance and durability. Common materials include stainless steel, brass, and PVC, each offering unique advantages. For instance, stainless steel is preferred for its corrosion resistance, making it ideal for industries like food processing and pharmaceuticals. Selecting the right material grade ensures longevity and reliability in various environmental conditions. -

Diameter and Length Tolerance

Tolerance levels refer to the allowable variations in the dimensions of the long nipple. High precision in diameter and length is critical for applications requiring tight seals and connections. A typical tolerance might be ±0.01 mm. Understanding these tolerances helps buyers ensure compatibility with existing systems, reducing the risk of leaks or failures. -

Pressure Rating

The pressure rating indicates the maximum pressure the long nipple can withstand without failing. This property is crucial in applications such as hydraulic systems, where pressure fluctuations are common. Buyers should look for long nipples that meet or exceed their system’s pressure requirements to ensure safety and functionality. -

Thread Type and Standard

The thread type (e.g., NPT, BSP) and standard (e.g., ANSI, ISO) dictate how well the long nipple will fit into existing piping systems. Different regions may have varying standards, so it is essential to specify the correct thread type to avoid compatibility issues. Proper threading is vital for creating secure connections and preventing leaks. -

Finish Type

The surface finish of a long nipple affects both its aesthetic appeal and functional performance. Common finishes include polished, galvanized, or coated options, each serving specific purposes, such as enhanced corrosion resistance or improved sealing capabilities. Understanding finish types can help buyers select products that align with their operational needs.

Which Trade Terminology Should International B2B Buyers Understand for Long Nipples?

Familiarity with industry terminology can significantly streamline the procurement process. Here are some common trade terms relevant to long nipples:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of long nipples, understanding OEM relationships can help buyers identify reliable suppliers who can provide high-quality components that meet specific requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as purchasing below the MOQ may lead to higher per-unit costs. Knowing the MOQ helps in planning purchases and negotiating better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a detailed quote for specific products, including long nipples. It typically outlines specifications, quantities, and delivery timelines. Submitting an RFQ helps buyers obtain competitive pricing and understand lead times, enabling more informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They outline who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to mitigate risks and understand their obligations in cross-border transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for effective inventory management and ensuring that production schedules are not disrupted. Buyers should inquire about lead times when negotiating with suppliers to align delivery with their project timelines.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions, minimize risks, and enhance their procurement strategies for long nipples.

Navigating Market Dynamics and Sourcing Trends in the long nipple Sector

What Are the Current Market Dynamics and Sourcing Trends in the Long Nipple Sector?

The long nipple sector has been experiencing significant growth, driven by an increase in demand across various industries, including automotive, electronics, and medical devices. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly keen on sourcing high-quality components that meet their specific industrial needs. Key trends influencing this market include the rise of automation in manufacturing processes, which enhances production efficiency and reduces costs. Furthermore, the integration of advanced technologies, such as IoT and AI, is transforming supply chain management, enabling buyers to gain real-time insights into inventory levels and order status.

Another notable trend is the increasing preference for local sourcing to mitigate supply chain risks, especially in light of recent global disruptions. Buyers are prioritizing suppliers who can offer flexible manufacturing capabilities and shorter lead times. In regions like the UAE and Vietnam, the growth of tech hubs is fostering innovation in product development, making it essential for international buyers to stay informed about emerging suppliers who can deliver cutting-edge solutions. Additionally, the emphasis on customization in product offerings is reshaping how B2B transactions are conducted, pushing suppliers to adopt more agile manufacturing practices.

How Is Sustainability Shaping Sourcing Decisions in the Long Nipple Sector?

Sustainability has become a critical factor in sourcing decisions within the long nipple sector. International B2B buyers are increasingly conscious of the environmental impact of their supply chains. This shift is prompting companies to evaluate their suppliers based on sustainability metrics, including carbon footprint, waste management practices, and resource efficiency. The importance of ethical sourcing cannot be overstated, as consumers and regulatory bodies alike are demanding greater transparency and accountability from businesses.

Buyers are seeking suppliers that adhere to recognized ‘green’ certifications, such as ISO 14001 or the Global Reporting Initiative (GRI). These certifications not only demonstrate a commitment to environmental stewardship but also enhance a company’s reputation in the marketplace. Furthermore, incorporating sustainable materials in the production of long nipples can significantly reduce environmental impact. For instance, using recycled plastics or biodegradable materials is becoming more prevalent and can serve as a unique selling proposition. As sustainability becomes a key differentiator, B2B buyers are encouraged to engage with suppliers who prioritize ethical practices and can provide proof of their sustainable initiatives.

What Is the Brief Evolution of the Long Nipple Sector?

The evolution of the long nipple sector can be traced back to its initial applications in traditional manufacturing. Over the decades, advancements in materials science and engineering have led to significant improvements in product design and functionality. Originally utilized for basic mechanical functions, long nipples have transformed into sophisticated components that meet the rigorous demands of modern industries.

As technology progressed, so did the materials used in manufacturing long nipples, with a shift towards more durable and lightweight options. The introduction of advanced manufacturing techniques, such as 3D printing and precision machining, has further refined the production process, allowing for greater customization and efficiency. This evolution has made long nipples not only essential components in various applications but also a focal point for innovation in design and sustainability, aligning with the growing demands of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of long nipple

-

How do I ensure the quality of long nipples from international suppliers?

To ensure the quality of long nipples sourced from international suppliers, conduct thorough due diligence. Request samples to evaluate material, dimensions, and overall workmanship. Investigate the supplier’s certifications, such as ISO or industry-specific standards, which indicate adherence to quality control practices. Additionally, consider third-party quality assurance services that can inspect the products before shipment. Establish clear quality specifications in your purchase agreements to hold suppliers accountable. -

What are the common materials used for manufacturing long nipples?

Long nipples are typically made from materials such as brass, stainless steel, and PVC, each offering distinct advantages. Brass is favored for its corrosion resistance and durability, making it ideal for plumbing applications. Stainless steel provides excellent strength and is suitable for high-pressure environments. PVC, while less durable under extreme conditions, is lightweight and resistant to chemical damage, making it suitable for specific applications. Understanding your application’s requirements will help you choose the right material. -

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider factors like your cash flow, the supplier’s reputation, and the transaction’s risk level. Common terms include upfront deposits, installment payments, or net 30/60/90 terms. Ensure the terms align with your financial capabilities while protecting your interests. It’s advisable to use secure payment methods like letters of credit, especially in international transactions, to safeguard against potential fraud. Always have a clear agreement documented to prevent misunderstandings. -

What minimum order quantities (MOQ) should I expect when sourcing long nipples?

Minimum order quantities for long nipples can vary significantly based on the supplier and the material used. Typically, manufacturers may set MOQs ranging from 100 to 1,000 units. Factors influencing MOQ include production costs, material availability, and customization requirements. If your needs are below the MOQ, discuss options for smaller orders or consider consolidating orders with other buyers to meet the MOQ without overextending your budget. -

How can I verify the credibility of a long nipple supplier?

To verify a supplier’s credibility, start by checking their business registration and certifications. Look for customer reviews and testimonials online, and consider reaching out to their past clients for firsthand experiences. Utilize platforms like Alibaba, ThomasNet, or industry-specific directories that feature verified suppliers. Additionally, perform a factory audit if possible, or engage a third-party service to assess their production capabilities and business practices. -

What are the logistics considerations when importing long nipples?

Logistics considerations for importing long nipples include shipping methods, customs regulations, and potential tariffs. Determine whether air or sea freight is more suitable based on your budget and delivery time requirements. Familiarize yourself with import duties and compliance regulations in your country, as these can significantly impact costs. Working with a reliable freight forwarder can streamline the process, ensuring timely delivery while navigating any bureaucratic hurdles. -

How can I customize long nipples to meet specific project requirements?

Customization of long nipples often involves adjustments in size, threading, or material specifications. When seeking customization, clearly communicate your requirements to the supplier, providing detailed drawings or specifications. Many manufacturers are open to customization but may have minimum order quantities and lead times that differ from standard products. Engage in early discussions to align your expectations with the supplier’s capabilities, ensuring a smooth production process. -

What are the common challenges faced when sourcing long nipples internationally?

Common challenges when sourcing long nipples internationally include language barriers, cultural differences, and varying quality standards. Additionally, navigating complex logistics and customs procedures can pose significant hurdles. To mitigate these issues, invest time in building strong relationships with suppliers, utilizing clear communication channels, and understanding the local business culture. Consider working with local intermediaries who can bridge the gap, ensuring smoother transactions and better compliance with local regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for long nipple

In the competitive landscape of international B2B sourcing, particularly for specialized products like long nipples, strategic sourcing emerges as a pivotal approach. Buyers from Africa, South America, the Middle East, and Europe must prioritize supplier relationships, quality assurance, and cost-effectiveness. By leveraging local insights and understanding regional market dynamics, businesses can secure reliable suppliers that not only meet technical specifications but also align with their operational goals.

How Can Strategic Sourcing Enhance Your Supply Chain for Long Nipples?

The value of strategic sourcing lies in its ability to streamline procurement processes and minimize risks associated with supply chain disruptions. Engaging in thorough market analysis and establishing long-term partnerships can lead to better pricing strategies and improved product availability. Moreover, understanding compliance and regulatory requirements unique to your region ensures that your sourcing decisions support sustainable practices.

What Should International Buyers Consider Moving Forward?

As you consider your sourcing strategies for long nipples, remain vigilant about emerging trends, such as sustainability and technological advancements in manufacturing. The future of your supply chain depends on adaptability and foresight. By embracing a proactive approach to sourcing, B2B buyers can not only optimize costs but also enhance product quality and innovation.

In conclusion, the landscape for long nipple procurement is ripe with opportunities. Now is the time to evaluate your sourcing strategies and engage with trusted suppliers to secure your position in the market. Take the next step towards a resilient supply chain by prioritizing strategic sourcing in your business operations.