Unlock Cost Savings: The Ultimate T Post Fence Guide (2025)

Introduction: Navigating the Global Market for t post fence

In the competitive landscape of fencing solutions, international B2B buyers face the critical challenge of sourcing reliable and cost-effective t post fences. These versatile fencing options are essential for various applications, from agricultural demarcation to security enclosures in both rural and urban settings. As buyers from regions such as Africa, South America, the Middle East, and Europe (including Mexico and Brazil) seek to make informed purchasing decisions, understanding the nuances of the global market for t post fences becomes paramount.

This comprehensive guide delves into the multifaceted world of t post fencing, covering essential topics such as types of t post fences, their applications across different industries, and strategies for effective supplier vetting. Additionally, it examines the cost factors that influence purchasing decisions, helping buyers identify the best value without compromising quality. By equipping B2B buyers with actionable insights and expert knowledge, this guide empowers them to navigate the complexities of international trade and establish robust supply chains.

Whether you are looking to enhance your agricultural operations, improve security measures, or invest in sustainable fencing solutions, this guide is designed to assist you in making strategic decisions that align with your business goals. With the right information at your fingertips, you can confidently approach the global market for t post fences, ensuring a seamless procurement process that meets your specific needs.

Understanding t post fence Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard T Post Fence | Made of galvanized steel, typically 6-8 feet tall | Agricultural fencing, property lines | Pros: Durable, cost-effective; Cons: Limited aesthetic appeal. |

| Heavy-Duty T Post Fence | Thicker gauge steel for increased strength and stability | Industrial sites, high-security areas | Pros: Enhanced durability, withstands harsh conditions; Cons: Higher initial cost. |

| Electric T Post Fence | Integrates electric wiring with traditional T post design | Livestock containment, security barriers | Pros: Effective for deterring intruders; Cons: Requires power source and maintenance. |

| Decorative T Post Fence | Features ornamental designs or coatings | Residential properties, parks | Pros: Aesthetic appeal; Cons: Generally more expensive and less durable. |

| Composite T Post Fence | Made from recycled materials, combines wood and plastic | Eco-friendly projects, residential areas | Pros: Environmentally friendly, low maintenance; Cons: May not be as strong as metal variants. |

What Are the Characteristics of a Standard T Post Fence?

The Standard T Post Fence is a widely utilized fencing solution made from galvanized steel. Typically ranging from 6 to 8 feet in height, it is favored for its cost-effectiveness and durability. This type is particularly suitable for agricultural applications such as livestock fencing and property demarcation. When considering a purchase, buyers should evaluate the local climate, as prolonged exposure to moisture can lead to rusting, despite the galvanization process.

How Does a Heavy-Duty T Post Fence Differ from Standard Options?

Heavy-Duty T Post Fences are designed with a thicker gauge of steel, providing enhanced strength and stability. They are ideal for industrial sites and high-security areas where durability is paramount. B2B buyers in sectors that face harsh environmental conditions or require stringent security measures will find this type advantageous. However, the higher initial investment may be a consideration for budget-conscious buyers.

Why Choose an Electric T Post Fence for Livestock and Security?

Electric T Post Fences combine traditional fencing with electric wiring, making them effective for livestock containment and security applications. They deter unauthorized access while ensuring that livestock remain within designated areas. B2B buyers must consider the availability of a reliable power source and the ongoing maintenance required to keep the electric system functioning. This type of fencing is particularly relevant in regions where security threats are prevalent.

What Are the Benefits of a Decorative T Post Fence?

Decorative T Post Fences provide an aesthetic alternative to traditional fencing, featuring ornamental designs or decorative coatings. These fences are commonly used in residential properties and public parks to enhance visual appeal. While they offer a stylish option, buyers should be aware that they may come with a higher price tag and may not offer the same durability as standard or heavy-duty options. Evaluating the long-term benefits versus the initial investment is crucial.

How Do Composite T Post Fences Contribute to Eco-Friendly Initiatives?

Composite T Post Fences are manufactured from recycled materials, combining wood and plastic to create a sustainable fencing solution. They are increasingly popular in eco-friendly projects and residential areas. B2B buyers should consider the long-term maintenance benefits and environmental impact when choosing this type. While they may not match the strength of metal variants, their low maintenance requirements and aesthetic appeal make them an attractive option for environmentally conscious businesses.

Related Video: The Strongest and Fastest T-Post Fence DIY Install Ever Recorded

Key Industrial Applications of t post fence

| Industry/Sector | Specific Application of t post fence | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop Protection Fencing | Safeguards crops from wildlife and livestock damage | Durability, corrosion resistance, and height specifications |

| Livestock Management | Containment Fencing for Livestock | Ensures secure enclosures for livestock management | Strength, ease of installation, and maintenance needs |

| Construction and Infrastructure | Temporary Site Fencing | Provides safety and security on construction sites | Compliance with local regulations, material quality |

| Landscaping and Gardening | Garden and Landscape Borders | Enhances aesthetic appeal while providing structure | Design versatility, weather resistance, and height options |

| Industrial Warehousing | Perimeter Security Fencing | Protects valuable assets and restricts unauthorized access | Material strength, installation speed, and adaptability |

How is t post fence utilized in agriculture for crop protection?

In the agriculture sector, t post fencing is primarily employed for crop protection against wildlife and livestock. This fencing solution is crucial for farmers who face challenges from roaming animals that can cause significant damage to crops. By providing a durable barrier, t post fences help mitigate losses, allowing for a more reliable yield. For international buyers, particularly in regions like Africa and South America, sourcing t post fencing that is resistant to rust and corrosion is essential due to varying environmental conditions.

What role does t post fence play in livestock management?

In livestock management, t post fencing serves as a secure containment solution for animals. It is vital for farmers to maintain the safety and well-being of their livestock while preventing them from straying or being exposed to hazards. T post fences are favored for their strength and ease of installation, which is particularly beneficial for large-scale operations. Buyers in the Middle East and Europe should consider factors such as the height and gauge of the fencing to ensure it meets the specific needs of their livestock.

How is t post fence applied in construction and infrastructure?

Temporary site fencing made from t post materials is commonly used in the construction and infrastructure sector. This type of fencing is essential for ensuring safety and security on job sites, protecting workers, and minimizing liability. For international B2B buyers, compliance with local regulations regarding construction site safety is a critical consideration. Additionally, sourcing high-quality materials that can withstand harsh weather conditions will enhance the longevity of the fencing.

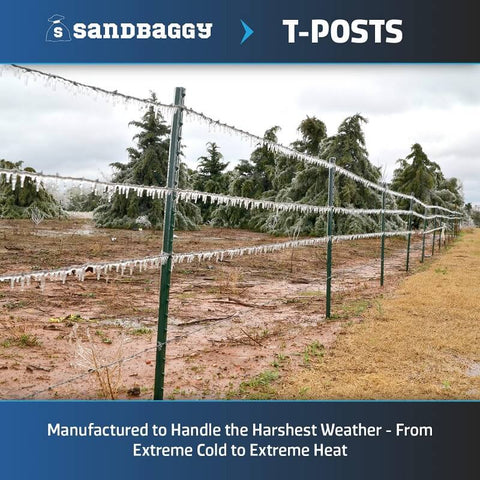

A stock image related to t post fence.

What benefits does t post fence offer in landscaping and gardening?

In landscaping and gardening, t post fencing is utilized to create borders and define spaces within outdoor environments. This fencing not only serves a functional purpose but also enhances the aesthetic appeal of gardens and landscaped areas. Buyers from Europe and South America should look for t post options that offer design versatility, weather resistance, and customization in height to suit various landscaping needs.

How does t post fence enhance perimeter security in industrial warehousing?

In industrial warehousing, t post fencing is crucial for perimeter security, protecting valuable assets and restricting unauthorized access. This application is particularly important for businesses that handle sensitive materials or equipment. When sourcing t post fencing, international buyers should prioritize material strength and the speed of installation, as well as the adaptability of the fencing to their specific site layouts and security requirements.

Related Video: In-depth Review & Demo of the Heavy Duty T-Post & Fence Post Puller

3 Common User Pain Points for ‘t post fence’ & Their Solutions

Scenario 1: Durability Concerns in Harsh Environments

The Problem: For international B2B buyers, especially those in regions with extreme weather conditions like Africa and the Middle East, the durability of ‘t post fences’ can be a significant concern. Buyers worry about the fence’s ability to withstand high temperatures, heavy rainfall, or corrosive environments. This challenge often leads to increased maintenance costs and the risk of having to replace the fence more frequently than anticipated, impacting budget forecasts and operational efficiency.

The Solution: To address durability concerns, buyers should prioritize sourcing ‘t post fences’ made from high-quality materials, such as galvanized steel or coated with protective finishes. When evaluating suppliers, request detailed specifications about the material’s resistance to environmental factors. Additionally, consider utilizing advanced installation techniques that enhance stability, such as deeper post setting or reinforced anchoring systems. Buyers can also explore options for customized coatings that suit specific environmental conditions, ensuring that the investment in fencing yields long-lasting results. Regular maintenance checks can further extend the lifespan of the fence, making it a wise investment in the long run.

Scenario 2: Difficulty in Installation and Maintenance

The Problem: Many B2B buyers encounter challenges during the installation and maintenance of ‘t post fences’, particularly in remote areas of South America or Europe where access to skilled labor may be limited. These challenges can lead to delays in project timelines and increased labor costs, as poorly installed fences may require additional adjustments or replacements.

The Solution: To mitigate installation difficulties, buyers should consider partnering with suppliers who offer comprehensive installation support and training resources. Look for vendors that provide detailed installation guides, videos, and even on-site training sessions for local teams. Additionally, investing in user-friendly installation tools and equipment can significantly reduce labor costs and installation time. For maintenance, establishing a routine inspection schedule and providing local teams with proper training on upkeep can prevent minor issues from escalating, ensuring the fence remains functional and visually appealing.

Scenario 3: Cost Management and Value Perception

The Problem: Cost is a critical factor for B2B buyers, particularly in developing markets in Africa and South America, where budget constraints can limit purchasing decisions. Buyers often struggle to justify the upfront costs of ‘t post fences’ against their long-term value, leading to hesitation in making purchases or opting for cheaper alternatives that may not meet their needs.

The Solution: To effectively manage costs and enhance value perception, buyers should conduct a thorough total cost of ownership (TCO) analysis. This analysis should include not only the initial purchase price but also installation, maintenance, and potential replacement costs over time. Suppliers can assist by providing case studies or testimonials that demonstrate the long-term savings and benefits associated with high-quality ‘t post fences’. Additionally, exploring financing options or bulk purchasing discounts can help buyers stretch their budgets further. Engaging in negotiations with suppliers to tailor solutions that meet specific needs while remaining cost-effective can also lead to better financial outcomes. By focusing on the overall value rather than just the price, buyers can make more informed decisions that align with their business goals.

Strategic Material Selection Guide for t post fence

When selecting materials for t post fences, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. This guide explores four common materials used in t post fencing: steel, aluminum, plastic, and wood. Each material has distinct properties, advantages, and limitations that can significantly impact the application and overall value of the fencing solution.

What Are the Key Properties of Steel for T Post Fences?

Steel is one of the most widely used materials for t post fences due to its strength and durability. It typically has a high tensile strength, making it suitable for various environmental conditions. Steel posts can withstand significant pressure and are resistant to bending or warping. However, they are susceptible to corrosion, especially in humid or coastal areas, necessitating protective coatings or galvanization.

Pros and Cons of Steel T Post Fences

The primary advantage of steel is its durability and long lifespan, which can exceed 20 years with proper maintenance. Steel is also relatively cost-effective compared to other materials, making it a popular choice for large-scale projects. The downside includes the potential for rusting and the need for regular maintenance, which can increase long-term costs. Additionally, the manufacturing process can be complex, impacting lead times.

Impact on Application

Steel is compatible with various media and is ideal for agricultural and industrial applications. However, buyers in regions with high humidity or salinity should consider additional protective measures to prevent corrosion.

How Does Aluminum Compare as a Material for T Post Fences?

Aluminum is another popular choice for t post fences, particularly in regions where weight and corrosion resistance are critical. Aluminum is lightweight and has excellent corrosion resistance, making it suitable for coastal areas and environments with high moisture levels. It also has a good strength-to-weight ratio, allowing for easy installation.

Pros and Cons of Aluminum T Post Fences

The key advantage of aluminum is its low maintenance requirements and resistance to rust, which can lead to lower lifetime costs. However, aluminum is generally more expensive than steel and may not provide the same level of strength, making it less suitable for high-stress applications. Additionally, the manufacturing process can be more complex and energy-intensive.

Impact on Application

Aluminum t post fences are ideal for residential and decorative applications, as well as in environments where aesthetics are important. Buyers should ensure compliance with local standards, as aluminum can be subject to specific regulations regarding its use in fencing.

What Are the Benefits and Limitations of Plastic T Post Fences?

Plastic, often made from high-density polyethylene (HDPE), is gaining popularity for t post fences due to its lightweight and weather-resistant properties. Plastic posts are impervious to moisture, do not rust, and are resistant to UV degradation, making them suitable for various climates.

Pros and Cons of Plastic T Post Fences

The primary advantage of plastic is its low weight and ease of installation, which can reduce labor costs. Additionally, plastic requires minimal maintenance and is available in various colors and styles. However, plastic may not offer the same level of structural integrity as metal options, making it less suitable for high-stress applications. The initial cost can also be higher compared to traditional materials.

Impact on Application

Plastic t post fences are ideal for residential and light agricultural applications. Buyers should verify compliance with local regulations, as some regions may have restrictions on the use of plastic materials in fencing.

What Role Does Wood Play in T Post Fencing Solutions?

Wood has been a traditional choice for t post fences for many years, offering a natural aesthetic that is appealing in many settings. Commonly used woods include cedar and treated pine, which provide good strength and durability when properly maintained.

Pros and Cons of Wood T Post Fences

The main advantage of wood is its natural appearance and ability to blend seamlessly into various landscapes. However, wood is susceptible to rot, insect damage, and warping, which can significantly reduce its lifespan. Additionally, the cost can vary widely based on the type of wood and treatment, leading to potential budget fluctuations.

Impact on Application

Wood t post fences are best suited for residential applications and decorative purposes. Buyers should consider local climate conditions and potential pest issues, as well as compliance with environmental regulations regarding wood sourcing and treatment.

Summary Table of Material Selection for T Post Fences

| Material | Typical Use Case for T Post Fence | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Agricultural and industrial applications | High durability and strength | Susceptible to corrosion; requires maintenance | Medium |

| Aluminum | Residential and decorative applications | Lightweight and corrosion-resistant | Higher initial cost; lower strength | High |

| Plastic | Residential and light agricultural applications | Low maintenance and weather-resistant | Less structural integrity; higher initial cost | Medium |

| Wood | Residential and decorative applications | Natural aesthetic | Susceptible to rot and insects; variable cost | Low to Medium |

In conclusion, the choice of material for t post fences should align with the specific needs of the application, taking into account factors such as durability, maintenance, cost, and compliance with regional standards. By understanding the properties and implications of each material, international B2B buyers can make informed decisions that enhance the value and effectiveness of their fencing solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for t post fence

What Are the Main Stages in the Manufacturing Process of T Post Fences?

The manufacturing of t post fences involves several key stages that ensure both the structural integrity and functionality of the final product. Understanding these processes is crucial for B2B buyers looking to source high-quality fencing solutions.

1. Material Preparation

The first stage begins with the selection and preparation of raw materials, typically high-strength steel or galvanized metal. This involves sourcing materials that meet international standards for durability and corrosion resistance. Manufacturers often conduct tests on these materials to ensure they can withstand environmental factors specific to the buyer’s region, such as humidity in South America or aridity in the Middle East.

2. Forming

Once the materials are prepared, the next step is forming. This process can include techniques such as cold rolling or hot rolling, depending on the desired thickness and strength of the posts. Advanced machinery is used to shape the steel into the T-post profile, which includes specific dimensions for height, width, and flange design. This stage is critical, as precise forming contributes to the overall strength and stability of the fence.

3. Assembly

After forming, the components are assembled. This may involve welding or mechanical fastening, depending on the design specifications. Quality control during assembly is essential to ensure that the structural integrity of the posts is maintained. Automated assembly lines are often employed to enhance efficiency, but manual inspections are necessary to catch any defects that may arise during the process.

4. Finishing

The final stage involves applying protective coatings, such as galvanization or powder coating, to prevent rust and corrosion. This finishing process not only extends the lifespan of the t post fence but also enhances its aesthetic appeal. Manufacturers should adhere to specific environmental regulations during this stage, especially in regions like Europe, where compliance with sustainability standards is mandatory.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of the manufacturing process for t post fences. It ensures that the products meet both safety and performance standards, which is particularly important for international buyers.

ISO 9001 Certification

One of the most recognized international standards is ISO 9001, which focuses on quality management systems. Manufacturers with this certification demonstrate their commitment to consistent quality and customer satisfaction. B2B buyers should prioritize suppliers who hold ISO 9001 certification as it reflects a systematic approach to quality management.

Industry-Specific Certifications

In addition to ISO 9001, other certifications may be relevant, depending on the intended use of the t post fences. For instance, CE marking is crucial for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. Similarly, the American Petroleum Institute (API) certification may be required for fencing used in oil and gas applications.

What Are the Key Quality Control Checkpoints in T Post Fence Manufacturing?

Implementing rigorous quality control (QC) checkpoints throughout the manufacturing process is essential for ensuring that t post fences meet required specifications.

Incoming Quality Control (IQC)

At the IQC stage, incoming raw materials are inspected for quality and compliance with specifications. This step helps prevent defects from entering the production line. B2B buyers should inquire about the protocols suppliers have in place for IQC, as it sets the foundation for overall product quality.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves monitoring production parameters to ensure that the forming and assembly processes are performed correctly. This can include visual inspections and measurements taken at various stages of production. Regular audits of IPQC procedures can help B2B buyers verify that their suppliers maintain high standards throughout the manufacturing cycle.

Final Quality Control (FQC)

The FQC stage is critical as it involves comprehensive testing of the finished products before they are shipped. Common testing methods include tensile strength tests, corrosion resistance tests, and dimensional inspections. Buyers should request FQC reports to ensure that the products meet the required standards before delivery.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Due diligence is essential for B2B buyers when selecting a supplier for t post fences. Here are several strategies to verify the quality control processes:

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control is to conduct a comprehensive audit of their manufacturing facility. This allows buyers to observe the processes in action, review documentation, and assess the overall quality management system in place. Audits can be performed by the buyer or through third-party inspection services.

Requesting Quality Assurance Reports

Buyers should request detailed quality assurance reports, including IQC, IPQC, and FQC documentation. These reports provide insights into the supplier’s quality management practices and highlight any areas for improvement. Consistent and transparent reporting indicates a supplier’s commitment to quality.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. These services can conduct inspections at various stages of production, ensuring that the products meet both international and local standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing t post fences from international suppliers, buyers must be aware of specific nuances that can impact quality control:

Understanding Regional Standards

Different regions may have varying standards for manufacturing and quality assurance. For instance, European buyers must ensure compliance with EU regulations, while buyers in Africa and South America may encounter different local standards. Understanding these nuances is crucial for ensuring that the products meet regional requirements.

Navigating Import Regulations

International trade often involves navigating complex import regulations. Buyers should be familiar with the documentation and certifications required for importing t post fences into their respective countries. This can include customs documentation, import permits, and compliance certificates.

Building Relationships with Suppliers

Establishing strong relationships with suppliers can facilitate better communication regarding quality control processes. Frequent engagement and feedback can help suppliers improve their practices and ensure that the products meet the buyer’s expectations.

By understanding the manufacturing processes and quality assurance standards associated with t post fences, international B2B buyers can make informed decisions that lead to successful sourcing and procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘t post fence’

Introduction

In the competitive landscape of international B2B procurement, sourcing ‘t post fence products effectively is crucial for establishing robust fencing solutions. This step-by-step checklist serves as a practical guide for buyers from Africa, South America, the Middle East, and Europe, helping you navigate the complexities of sourcing while ensuring you make informed decisions. By following these steps, you can streamline your procurement process and secure quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline your technical requirements clearly. Consider factors such as the intended use of the ‘t post fence, material specifications, height, gauge, and any coating or treatment preferences.

- Purpose: Establishing detailed specifications prevents miscommunication with suppliers and ensures that the product will meet your operational needs.

- Standards: Be aware of regional standards for fencing materials that may affect your specifications, especially if you are importing from different countries.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for ‘t post fence products is vital. Conduct thorough research to identify price fluctuations, popular materials, and emerging suppliers in different regions.

- Market Analysis: Utilize online resources, industry reports, and trade publications to gather insights on market conditions.

- Budgeting: Knowing the market price helps you set a realistic budget and negotiate better deals with suppliers.

Step 3: Identify Potential Suppliers

Create a list of potential suppliers who specialize in ‘t post fence products. Look for manufacturers and distributors with a proven track record in your target regions.

- Supplier Directories: Use industry-specific directories and platforms such as Alibaba or ThomasNet to find reputable suppliers.

- Local Trade Shows: Attend trade fairs in your region to meet suppliers face-to-face and evaluate their offerings directly.

Step 4: ✅ Verify Supplier Certifications

It’s crucial to ensure that your selected suppliers possess the necessary certifications and quality assurance measures.

- Quality Standards: Check for ISO certifications or other relevant quality management systems that demonstrate a commitment to product quality.

- Compliance: Ensure that the products comply with local regulations and standards, particularly if you are importing them across borders.

Step 5: Request Samples for Evaluation

Before finalizing your order, request samples of the ‘t post fence products. This allows you to assess the quality and suitability of the materials.

- Quality Assessment: Evaluate the samples for durability, finish, and adherence to your specifications.

- Trial Use: Consider using the samples in a small project to test their performance under real conditions.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, it’s time to negotiate the terms of the contract. This includes pricing, payment terms, delivery schedules, and warranties.

- Clarity: Ensure that all terms are clearly outlined to avoid misunderstandings later.

- Flexibility: Be open to negotiating terms that can benefit both parties, such as bulk order discounts or extended payment terms.

Step 7: Establish a Communication Plan

Effective communication with your supplier throughout the procurement process is essential for success.

- Regular Updates: Set up a schedule for regular updates on the order status, especially for long lead times.

- Feedback Loop: Create a system for providing feedback on product quality and service, which can help in refining future orders.

By adhering to this comprehensive checklist, international B2B buyers can ensure a smooth sourcing process for ‘t post fence products, leading to successful project outcomes and long-lasting supplier relationships.

Comprehensive Cost and Pricing Analysis for t post fence Sourcing

What Are the Key Cost Components in T Post Fence Sourcing?

Understanding the cost structure of t post fencing is crucial for international B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of steel used significantly affects the cost. Galvanized steel, for example, offers durability and rust resistance, but it may come at a higher price point than uncoated options. Additionally, sourcing raw materials locally versus internationally can influence costs due to fluctuations in shipping and tariffs.

-

Labor: Labor costs vary by region. In countries with lower labor rates, such as parts of South America and Africa, you may find more cost-effective manufacturing options. However, consider the skill level and productivity of the workforce, as this can impact the overall quality and efficiency of production.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs, which is essential for competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers should assess whether a supplier can offer flexible tooling options that allow for adjustments in design without incurring excessive costs.

-

Quality Control (QC): Investing in quality control measures ensures that the products meet specifications and reduce the risk of returns or failures. Be prepared to pay a premium for suppliers who prioritize QC, as this can lead to long-term savings.

-

Logistics: Transportation costs can vary widely based on the distance from the manufacturing facility to the destination. Incoterms play a critical role here, as they define who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers negotiate better shipping arrangements.

-

Margin: Finally, the supplier’s profit margin will influence the final price. Suppliers in competitive markets may offer lower margins to attract business, while those with unique offerings or certifications may justify higher margins.

How Do Price Influencers Affect T Post Fence Costs?

Several factors can influence the pricing of t post fencing, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specific specifications can increase costs. It’s essential to weigh the benefits of customization against the additional expenses involved.

-

Material Quality and Certifications: Products with higher quality standards or certifications (e.g., ISO, ASTM) can command premium prices. Buyers should consider the long-term benefits of investing in quality over the initial cost.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more, but they often provide better service and product consistency.

-

Incoterms: Understanding the implications of different Incoterms is crucial. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of the fencing.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

To optimize costs when sourcing t post fencing, buyers should consider the following strategies:

-

Effective Negotiation: Build strong relationships with suppliers and be prepared to negotiate terms. Leverage your purchasing power, especially if you can commit to larger volumes.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, evaluate the total cost of ownership, including maintenance and potential replacement costs. Investing in higher-quality products may lead to lower overall expenses.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, trade tariffs, and import duties that can affect pricing. Collaborating with local experts can provide valuable insights into market conditions and pricing trends.

-

Request Detailed Quotes: When seeking quotes, ask suppliers for a breakdown of costs. This transparency allows for better comparison and understanding of where savings can be made.

-

Monitor Market Trends: Stay informed about global steel prices and market trends that could affect the costs of raw materials. This knowledge can provide leverage during negotiations.

Conclusion

Sourcing t post fencing requires a thorough understanding of the cost components and pricing influencers that affect the overall expenditure. By focusing on negotiation strategies, total cost of ownership, and the nuances of international pricing, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions that lead to cost-efficient sourcing. Always remember that prices can vary widely, and it’s advisable to seek multiple quotes to ensure the best deal possible.

Alternatives Analysis: Comparing t post fence With Other Solutions

When considering fencing solutions, it’s crucial for B2B buyers to evaluate various options available in the market. Each solution has unique characteristics that can impact the effectiveness and cost-efficiency of a fencing project. Below, we compare the traditional t post fence with two alternative solutions: barbed wire fencing and chain link fencing. This analysis will provide insights for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Comparison Table of Fencing Solutions

| Comparison Aspect | T Post Fence | Barbed Wire Fencing | Chain Link Fencing |

|---|---|---|---|

| Performance | Moderate durability and strength for livestock containment | High deterrent for intruders; effective for livestock | Strong and durable; excellent visibility and airflow |

| Cost | Moderate initial investment; low long-term costs | Low initial investment; requires regular maintenance | Higher initial costs; low maintenance over time |

| Ease of Implementation | Relatively easy to install with basic tools | Requires more effort to install securely | Requires professional installation for best results |

| Maintenance | Minimal maintenance needed | Moderate maintenance; barbs can rust or become ineffective | Low maintenance; occasional tensioning may be required |

| Best Use Case | Ideal for agricultural settings, light-duty applications | Best for rural properties needing security | Suitable for urban environments needing visibility and security |

In-Depth Analysis of Alternatives

How Does Barbed Wire Fencing Compare to T Post Fence?

Barbed wire fencing is a common alternative that excels in providing security and deterring intruders. Its low initial cost makes it appealing for large properties, especially in rural areas. However, the maintenance can be a drawback, as barbs may rust or become ineffective over time, requiring regular inspections. Additionally, while barbed wire is effective for keeping livestock in, it may not be as safe for animals that can get entangled, which could lead to injuries.

What Are the Benefits of Chain Link Fencing Over T Post Fence?

Chain link fencing offers a robust solution that combines strength with visibility. It is particularly suitable for urban settings where security and aesthetics are vital. Although the initial investment is higher than t post fencing, it typically requires less maintenance over the long term. The major drawback is the need for professional installation, which can add to the overall costs. Chain link fencing is less effective for containing livestock compared to t post fences, as animals can easily escape through the links.

How Can B2B Buyers Choose the Right Fencing Solution?

When selecting the appropriate fencing solution, B2B buyers should consider their specific operational needs, budget constraints, and the intended purpose of the fence. For agricultural settings where livestock containment is paramount, t post fencing may be the most efficient option. In contrast, businesses focused on security and visibility in urban areas might find chain link fencing more suitable. Barbed wire fencing serves as a cost-effective solution for larger rural properties but comes with its own maintenance considerations. By carefully evaluating these factors, buyers can make informed decisions that align with their operational requirements and financial goals.

Essential Technical Properties and Trade Terminology for t post fence

When considering the procurement of t post fences, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This knowledge not only aids in evaluating product quality but also facilitates smoother negotiations and transactions across international markets.

What Are the Key Technical Properties of T Post Fences?

1. Material Grade

The material grade of a t post fence typically refers to the steel used in its construction. Common grades include mild steel and high-strength steel, with the latter offering increased durability and resistance to bending or warping. For B2B buyers, selecting the appropriate material grade is essential for ensuring the fence can withstand environmental stresses and meet specific project requirements.

2. Coating Type

T post fences are often coated to enhance corrosion resistance, with common options including galvanized and powder-coated finishes. Galvanization involves applying a zinc layer, while powder coating provides a more aesthetically pleasing finish. Understanding the coating type is vital for buyers in regions with high humidity or salt exposure, as this affects the fence’s lifespan and maintenance needs.

3. Tolerance Specifications

Tolerance specifications refer to the allowable deviations in the dimensions of the t post, such as height, width, and thickness. These tolerances are crucial for ensuring that the fence fits seamlessly into the intended installation area. Buyers should request tolerance specifications to avoid complications during installation and to ensure compatibility with existing fencing systems.

4. Weight and Length

The weight and length of t posts are significant considerations, as they impact transportation costs and installation logistics. Longer posts may require specialized handling equipment, while heavier posts can lead to increased shipping fees. Buyers should evaluate their project needs and consider these factors when placing orders, especially in international contexts where shipping regulations may vary.

5. Load-Bearing Capacity

The load-bearing capacity indicates how much weight the t post can support without bending or breaking. This property is especially important in agricultural or industrial applications where the fence may need to support additional loads, such as barbed wire or mesh. Understanding this capacity can help buyers ensure that their fencing solutions will perform adequately in their specific environments.

What Trade Terminology Should B2B Buyers Understand?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of t post fences, understanding whether the supplier is an OEM can help buyers gauge the quality and reliability of the products they are sourcing.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it directly impacts inventory management and cash flow. Understanding the MOQ can help buyers plan their purchases accordingly and avoid overstocking or understocking situations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other information for specific products. For B2B buyers, submitting an RFQ allows for comparison shopping and ensures that they receive detailed quotes tailored to their needs. This process is essential for effective budget management and cost control.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international buyers to understand their obligations and the associated risks throughout the shipping process.

5. Lead Time

Lead time refers to the time it takes from placing an order to delivery. For B2B buyers, understanding lead times is essential for project planning and scheduling. Delays in lead time can significantly impact project timelines, making it crucial to communicate effectively with suppliers to ensure timely deliveries.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions regarding t post fences, ensuring that they choose the right products for their specific needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the t post fence Sector

What Are the Current Market Dynamics and Key Trends in the T Post Fence Sector?

A stock image related to t post fence.

The t post fence sector is experiencing significant shifts driven by globalization, technological advancements, and changing consumer preferences. With the demand for secure and durable fencing solutions rising globally, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers are navigating a complex landscape. Key trends include the increasing adoption of smart fencing technologies, which integrate IoT and automation for enhanced security and monitoring. This trend is particularly appealing to buyers in urban and suburban areas where property security is paramount.

Another driver is the shift towards local sourcing, spurred by supply chain disruptions from the COVID-19 pandemic and geopolitical tensions. International buyers are now prioritizing suppliers who can provide timely delivery and flexibility. In the African and South American markets, where agriculture plays a crucial role, there’s a growing need for fencing solutions that cater to livestock management and land demarcation, presenting unique opportunities for suppliers. Additionally, the rise of e-commerce platforms has made it easier for buyers to access a wider range of products and suppliers, allowing for more competitive pricing and better product comparisons.

How Is Sustainability and Ethical Sourcing Shaping the T Post Fence Industry?

Sustainability is becoming a focal point for international B2B buyers in the t post fence sector. The environmental impact of traditional fencing materials, such as treated wood and metal, is under scrutiny, prompting buyers to seek alternatives that minimize their carbon footprint. Sustainable sourcing practices are increasingly important, with buyers favoring suppliers who adhere to ethical standards and environmental regulations.

The use of recycled materials, such as repurposed metals and plastics, is gaining traction as a viable option for t post fencing. Moreover, obtaining ‘green’ certifications can enhance a supplier’s credibility and appeal to environmentally conscious buyers. Certifications like the Forest Stewardship Council (FSC) for wood products or ISO 14001 for environmental management systems can significantly influence purchasing decisions. B2B buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability, as this not only aligns with corporate social responsibility goals but also meets the growing consumer demand for eco-friendly products.

What Has Been the Evolution of the T Post Fence Sector?

The t post fence sector has evolved significantly over the decades, adapting to changing agricultural practices and urbanization. Initially designed for agricultural purposes, the t post fencing system has expanded to serve a variety of applications, including residential and commercial uses. The introduction of galvanized steel in the mid-20th century revolutionized the industry, providing a durable and weather-resistant option that significantly outperformed traditional wooden posts.

In recent years, the focus has shifted towards integrating technology into fencing solutions, responding to the needs of modern consumers for security and convenience. This evolution reflects broader trends in construction and manufacturing, where innovation and sustainability are increasingly at the forefront. As the sector continues to grow, understanding its historical context can provide valuable insights for B2B buyers looking to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of t post fence

-

How do I solve the challenge of finding reliable suppliers for t post fences?

To find reliable suppliers for t post fences, consider leveraging online B2B marketplaces such as Alibaba, Global Sources, or TradeIndia. Look for suppliers with verified credentials, positive customer reviews, and a track record of international shipping. Additionally, request references and conduct background checks. It’s beneficial to attend industry trade shows and exhibitions in your region, as this allows for direct interaction and assessment of suppliers. Establishing a good rapport can also lead to better negotiation terms and understanding of product quality. -

What is the best material for t post fences in diverse climates?

The best material for t post fences largely depends on the climate of your region. For humid areas, galvanized steel or coated metal t posts are ideal as they resist rust and corrosion. In contrast, for dry and arid climates, aluminum or treated wood may offer sufficient durability and less maintenance. Understanding local weather patterns will help you select the right material, ensuring longevity and effectiveness of the fencing solution. -

How can I customize t post fences to meet my specific requirements?

Customization of t post fences can be achieved by discussing your needs directly with suppliers. Most manufacturers offer options for height, gauge, and coatings based on your requirements. Provide detailed specifications regarding color, design, and any additional features such as barbed wire or privacy slats. Engaging in an iterative design process with your supplier can ensure that the final product aligns with your project goals. -

What are the typical minimum order quantities (MOQ) for t post fences?

Minimum order quantities for t post fences can vary significantly based on the supplier and the specifics of your order. Generally, MOQs range from 100 to 1,000 units, but some suppliers may accommodate smaller orders for new customers. It’s advisable to negotiate MOQs, especially if you are a first-time buyer or looking to test the market. Always clarify this detail upfront to avoid any misunderstandings later in the procurement process. -

What payment terms should I expect when sourcing t post fences internationally?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the balance due upon shipment or delivery. Depending on the supplier’s credibility, you may negotiate better terms, especially if you have a longstanding relationship. It’s also essential to consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Ensure clarity on all terms to avoid any payment disputes. -

How can I ensure quality assurance when purchasing t post fences?

To ensure quality assurance, request product samples before placing a large order. Additionally, inquire about the supplier’s quality control processes, certifications, and compliance with international standards. Consider engaging a third-party inspection service to evaluate the product quality before shipment. Establishing a clear set of specifications in your purchase agreement can also help maintain quality throughout the production process. -

What logistics considerations should I keep in mind when importing t post fences?

When importing t post fences, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose reliable freight forwarders who understand the import regulations of your country. Calculate total landed costs, including duties and taxes, to avoid surprises. Additionally, assess the supplier’s ability to handle logistics efficiently, as this can significantly impact your delivery schedule and overall project timeline. -

What are the benefits of sourcing t post fences from different regions?

Sourcing t post fences from different regions can provide various benefits, including cost savings, access to unique materials, and diverse manufacturing techniques. For instance, suppliers in South America may offer competitive pricing due to lower labor costs, while European suppliers might provide higher quality and advanced engineering. Diversifying your supplier base can also mitigate risks associated with supply chain disruptions and enhance your negotiation leverage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for t post fence

In conclusion, the strategic sourcing of t post fences presents a significant opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging local suppliers and understanding regional regulations, businesses can optimize their procurement processes, reduce costs, and ensure product availability. Key takeaways include the importance of evaluating supplier reliability, assessing the quality of materials, and understanding the logistical considerations involved in sourcing t post fences.

A stock image related to t post fence.

How can businesses enhance their strategic sourcing for t post fences? One effective approach is to establish long-term partnerships with reliable suppliers who can offer competitive pricing and consistent quality. Additionally, investing in market research can help identify emerging trends and technologies that may influence the t post fence market, ensuring that buyers remain ahead of the curve.

Looking forward, the demand for sustainable and durable fencing solutions will continue to rise. B2B buyers should be proactive in exploring innovative materials and practices that align with sustainability goals. Embrace these opportunities to enhance your sourcing strategy and position your business for success in an evolving market. Start engaging with potential suppliers today to secure the best deals for your t post fence needs.