Discover the Best Huber Needle: The Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for huber needle

Navigating the complex landscape of medical supplies can be a daunting task for international B2B buyers, especially when it comes to sourcing specialized equipment like the Huber needle. This essential device, used primarily for accessing implanted ports in patients requiring long-term intravenous therapy, demands careful consideration in terms of quality, supplier reliability, and regulatory compliance. With a growing global demand for Huber needles, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the market dynamics is crucial for making informed purchasing decisions.

This comprehensive guide delves into the various types of Huber needles available, their specific applications in healthcare settings, and the critical factors to consider when vetting suppliers. We will explore the cost implications associated with different Huber needle brands and models, providing insights into pricing trends and value-for-money considerations. Additionally, we will address the regulatory landscape governing medical device imports, ensuring that you are equipped to navigate compliance challenges effectively.

By empowering B2B buyers with actionable insights and expert advice, this guide aims to streamline the sourcing process for Huber needles, ultimately enhancing the quality of care provided to patients. Whether you are a healthcare provider, distributor, or procurement officer, understanding the intricacies of this market will enable you to make strategic decisions that align with your organization’s goals and patient needs.

Understanding huber needle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Huber Needle | Straight, non-coring design | Oncology, long-term IV therapy | Pros: Versatile, reliable; Cons: Limited to specific applications. |

| Safety Huber Needle | Integrated safety mechanisms | Hospitals, outpatient clinics | Pros: Reduces needlestick injuries; Cons: Slightly higher cost. |

| Pediatric Huber Needle | Smaller gauge, designed for children | Pediatric oncology, pediatric intensive care | Pros: Minimizes trauma; Cons: May not be suitable for adults. |

| Dual-Lumen Huber Needle | Two lumens for simultaneous access | Chemotherapy, dialysis | Pros: Increases efficiency; Cons: More complex handling. |

| Implantable Port Huber Needle | Subcutaneous placement for long-term access | Long-term medication delivery | Pros: Reduces frequency of access; Cons: Requires surgical placement. |

What Are the Key Characteristics of Standard Huber Needles?

Standard Huber needles are characterized by their straight, non-coring design, which minimizes the risk of tissue trauma during insertion. They are typically used in oncology and long-term intravenous (IV) therapy, making them a staple in many healthcare settings. B2B buyers should consider the versatility and reliability of standard Huber needles, although their application may be limited to specific patient populations.

How Do Safety Huber Needles Enhance Workplace Safety?

Safety Huber needles incorporate integrated safety mechanisms designed to prevent needlestick injuries, a significant concern in healthcare environments. These needles are widely used in hospitals and outpatient clinics, where safety protocols are paramount. While they may come at a slightly higher cost, the investment is often justified by the enhanced safety features that protect healthcare workers and patients alike.

What Makes Pediatric Huber Needles Unique?

Pediatric Huber needles are specially designed for smaller patients, featuring a smaller gauge to reduce trauma during insertion. These needles find their primary application in pediatric oncology and intensive care units. B2B buyers should consider their unique suitability for children, ensuring that healthcare providers can deliver treatments with minimal discomfort. However, it is essential to note that these needles are not ideal for adult patients.

What Are the Advantages of Dual-Lumen Huber Needles?

Dual-lumen Huber needles offer two lumens, allowing for simultaneous access to the vascular system. This feature is especially beneficial in applications such as chemotherapy and dialysis, where multiple treatments may be required concurrently. While dual-lumen needles increase efficiency in treatment delivery, they also require more complex handling and training, which B2B buyers should account for when considering procurement.

Why Choose Implantable Port Huber Needles for Long-Term Access?

Implantable port Huber needles are designed for subcutaneous placement, providing long-term access for medication delivery. These devices are particularly advantageous for patients requiring ongoing treatment, as they reduce the frequency of needle insertions. However, B2B buyers must consider the surgical placement requirement and associated costs. The long-term benefits often outweigh these initial challenges, making them a valuable option for healthcare providers focused on patient comfort and compliance.

Related Video: What Is A Huber Needle And When Is It Used? – First Response Medicine

Key Industrial Applications of huber needle

| Industry/Sector | Specific Application of Huber Needle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Chemotherapy and Infusion Therapy | Enhanced patient comfort and reduced treatment time | Regulatory compliance, quality assurance, and sterility standards |

| Pharmaceuticals | Drug Delivery Systems | Precision in drug administration and improved therapeutic outcomes | Compatibility with various formulations and delivery systems |

| Veterinary Medicine | Long-term Catheter Placement in Animals | Improved care for chronic conditions in pets | Sourcing from reputable manufacturers with veterinary certifications |

| Research Laboratories | Sample Collection and Analysis | Accurate data collection for research studies | Availability of specialized needles for different sample types |

| Blood Banks | Blood Product Collection | Efficient and safe collection methods | Compliance with health regulations and safety standards |

How is Huber Needle Used in Healthcare for Chemotherapy and Infusion Therapy?

In the healthcare sector, Huber needles are primarily utilized for chemotherapy and infusion therapy. These specialized needles are designed to access implanted ports, allowing for safe and repeated access to the vascular system without damaging surrounding tissues. This is crucial for patients undergoing prolonged treatment, as it enhances comfort and minimizes the risk of complications. For international B2B buyers in regions like Africa and South America, sourcing Huber needles requires attention to regulatory compliance and quality assurance, ensuring that the products meet local health standards.

What Role Does Huber Needle Play in Pharmaceuticals for Drug Delivery Systems?

In the pharmaceuticals industry, Huber needles are integral to drug delivery systems, particularly for biologics and other sensitive formulations. Their design ensures precise drug administration, which is critical for achieving optimal therapeutic outcomes. This precision can significantly affect patient outcomes and satisfaction. B2B buyers in the Middle East and Europe should consider sourcing Huber needles that are compatible with various drug formulations and delivery methods, as this will enhance their operational efficiency.

How is Huber Needle Beneficial in Veterinary Medicine for Long-term Catheter Placement?

For veterinary medicine, Huber needles are often used in long-term catheter placements for pets with chronic conditions, such as diabetes or cancer. This application allows for easier management of treatment protocols and improves the quality of life for animals. Buyers in regions like South America need to prioritize sourcing from manufacturers that provide veterinary-certified products, ensuring safety and efficacy in animal care.

Why are Huber Needles Important in Research Laboratories for Sample Collection?

In research laboratories, Huber needles facilitate the collection of samples for analysis, particularly in studies involving blood or other bodily fluids. Their design allows for minimal tissue trauma, which is essential for obtaining accurate data. International B2B buyers, especially in Europe, should look for specialized Huber needles tailored for different sample types, as this can significantly impact the reliability of research outcomes.

How Do Huber Needles Enhance Blood Banks for Blood Product Collection?

In blood banks, Huber needles are crucial for the efficient and safe collection of blood products. Their design minimizes discomfort for donors while ensuring a high level of safety and sterility. For B2B buyers in the Middle East and Africa, it’s vital to source Huber needles that comply with health regulations and safety standards, as this not only protects donors but also enhances the overall reputation of the blood bank.

Related Video: LifeGuard Safety Huber Needle Tutorial: Accessing/De-accessing an ImplantablePort

3 Common User Pain Points for ‘huber needle’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Huber Needles for Diverse Markets

The Problem: B2B buyers often encounter challenges when sourcing high-quality huber needles that meet specific regulatory standards across different regions. This is particularly prevalent for companies operating in Africa and South America, where there may be a lack of reliable local suppliers. Inconsistent product quality can lead to complications in patient care and compliance issues, which can tarnish a company’s reputation and lead to financial losses.

The Solution: To overcome sourcing challenges, buyers should conduct thorough market research to identify reputable manufacturers and distributors with a proven track record in their specific region. Engaging with industry associations or attending medical device expos can provide valuable insights into reliable suppliers. Additionally, implementing a quality assurance process, such as requiring samples for testing or certifications that comply with local regulations, can help ensure that the products meet the necessary standards. Forming partnerships with local distributors who understand regional compliance requirements can also streamline the sourcing process.

Scenario 2: Misunderstanding the Technical Specifications of Huber Needles

The Problem: Another common pain point is the misunderstanding of the technical specifications associated with huber needles, such as gauge size, length, and type of catheter. This is especially crucial for B2B buyers in the Middle East and Europe, where precise specifications are necessary for optimal patient outcomes. An incorrect choice can lead to complications such as infiltration or phlebitis, negatively impacting patient safety and increasing healthcare costs.

The Solution: To address this issue, buyers should invest time in understanding the technical specifications of huber needles. Collaborating with clinical experts or medical professionals can provide clarity on the appropriate choices for different procedures. Utilizing resources like product catalogs and technical datasheets from manufacturers can also aid in making informed decisions. Additionally, participating in training workshops or webinars offered by suppliers can enhance understanding of product applications and ensure that the selected huber needles are suitable for the intended use.

Scenario 3: Navigating Supply Chain Disruptions for Huber Needles

The Problem: Supply chain disruptions are a significant concern for B2B buyers, particularly in regions like Africa and South America, where logistical challenges are common. Delays in obtaining huber needles can lead to inventory shortages, affecting service delivery in healthcare facilities. This not only impacts patient care but can also lead to financial strain on medical institutions and a loss of trust among stakeholders.

The Solution: To mitigate supply chain risks, B2B buyers should adopt a proactive inventory management strategy. This includes forecasting demand based on historical data and potential market fluctuations. Establishing relationships with multiple suppliers can provide alternative sources in case of disruptions. Additionally, implementing just-in-time inventory practices can optimize stock levels while minimizing waste. Regular communication with suppliers about their production capabilities and lead times is also crucial. Buyers may consider exploring local manufacturing options or regional partnerships to reduce dependency on international shipping and enhance reliability in the supply chain.

Strategic Material Selection Guide for huber needle

When selecting materials for huber needles, it is essential to consider their properties and how they align with the intended applications. Below, we analyze four common materials used in the manufacturing of huber needles, focusing on their performance characteristics, advantages and disadvantages, and specific considerations for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel for Huber Needles?

Stainless steel is a widely used material for huber needles due to its excellent mechanical properties and corrosion resistance. It typically has a temperature rating that can withstand high-pressure applications, making it suitable for various medical and industrial uses. Stainless steel is also biocompatible, which is crucial for applications involving human interaction.

Pros and Cons:

Stainless steel is known for its durability and strength, ensuring a long service life. However, its manufacturing complexity can lead to higher costs compared to other materials. Additionally, while stainless steel is resistant to many chemicals, it may not be suitable for highly corrosive environments.

Impact on Application:

Stainless steel huber needles are compatible with a wide range of media, including saline solutions and blood products, making them ideal for medical applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM F138 and ISO 10993 for biocompatibility. In regions like Europe, adherence to the Medical Device Regulation (MDR) is also critical.

How Does Polycarbonate Compare for Huber Needle Applications?

Polycarbonate is a thermoplastic material known for its impact resistance and clarity. While not as commonly used as stainless steel, it can be beneficial in specific applications where visibility is essential.

Pros and Cons:

The primary advantage of polycarbonate is its lightweight nature, which can reduce fatigue during prolonged use. However, it has lower temperature and pressure ratings compared to metals, limiting its applications. Additionally, polycarbonate is more susceptible to chemical degradation, which can be a significant drawback in certain environments.

Impact on Application:

Polycarbonate huber needles are typically used in applications where visibility of the fluid is necessary, such as in certain laboratory settings.

Considerations for International Buyers:

Buyers should be aware of the specific chemical compatibility of polycarbonate with the intended media. Compliance with relevant standards, such as ASTM D6400 for biodegradability, may also be necessary in certain regions.

What are the Benefits of Titanium for Huber Needles?

Titanium is a premium material known for its exceptional strength-to-weight ratio and excellent corrosion resistance. It is particularly advantageous in applications that require high performance under extreme conditions.

Pros and Cons:

Titanium is highly durable and biocompatible, making it suitable for long-term medical applications. However, it is more expensive than stainless steel and polycarbonate, and its manufacturing processes can be complex, leading to higher costs.

Impact on Application:

Titanium huber needles are ideal for use in corrosive environments or where strength is paramount, such as in certain surgical applications.

Considerations for International Buyers:

Buyers should ensure that titanium products meet international standards like ASTM F136 for titanium alloys used in surgical implants. Understanding the regulatory landscape in regions like the Middle East, where specific certifications may be required, is also crucial.

Why is Glass a Viable Option for Huber Needles?

Glass is less common but can be used in specialized applications due to its inert properties and clarity. It is particularly useful in environments where chemical reactivity is a concern.

Pros and Cons:

The primary advantage of glass is its chemical inertness, making it suitable for use with aggressive media. However, glass is fragile and can break easily, which poses a risk in high-stress applications. Additionally, glass manufacturing can be more complex and costly.

Impact on Application:

Glass huber needles are often used in laboratory settings where sample integrity is critical, and contamination must be avoided.

Considerations for International Buyers:

Buyers should ensure that glass products comply with relevant safety standards, such as ISO 80369 for small-bore connectors, particularly in Europe.

Summary Table of Material Selection for Huber Needles

| Material | Typical Use Case for huber needle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical applications | Excellent durability and strength | Higher manufacturing complexity | Medium |

| Polycarbonate | Laboratory applications | Lightweight and impact-resistant | Lower temperature/pressure ratings | Low |

| Titanium | Surgical applications | Exceptional corrosion resistance | High cost and complex manufacturing | High |

| Glass | Laboratory settings | Chemical inertness | Fragile and prone to breakage | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various materials used for huber needles. Understanding these factors will help buyers make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for huber needle

What Are the Key Stages in the Manufacturing Process of Huber Needles?

The manufacturing process of Huber needles involves several critical stages designed to ensure precision, safety, and quality. Understanding these processes is vital for international B2B buyers seeking reliable suppliers.

1. Material Preparation

The first stage of Huber needle manufacturing involves the selection and preparation of high-grade materials. Typically, stainless steel is the primary material due to its biocompatibility and resistance to corrosion. Before production begins, the raw materials undergo rigorous checks to confirm their quality and compliance with international standards. This includes assessments for mechanical properties and chemical composition.

2. Forming Techniques

Once the materials are prepared, the next step is forming. Huber needles are produced using advanced techniques such as:

- Precision Machining: This method ensures that the needles are accurately shaped, which is crucial for their performance in medical applications.

- Cold Heading: This technique is used to shape the needle body without heating, maintaining the integrity of the material.

- Laser Cutting: Often employed for creating the needle tip, laser cutting provides high precision, ensuring that the needle can penetrate tissue effectively.

These forming techniques are critical for producing needles that meet specific medical requirements and regulations.

3. Assembly Process

After forming, the components of the Huber needle are assembled. This includes attaching the needle to the hub, which must be done under sterile conditions to prevent contamination. Automation plays a significant role in this stage, as it enhances consistency and minimizes human error. Some manufacturers also employ manual assembly for delicate components, ensuring that quality is maintained.

4. Finishing Touches

The final stage involves finishing processes such as polishing and coating. Polishing enhances the needle’s surface finish, reducing friction and improving insertion capabilities. Coating with biocompatible materials can also be applied to enhance performance. This stage is critical for ensuring that the Huber needle meets the necessary safety and efficacy standards.

How Is Quality Assurance Implemented in Huber Needle Production?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product is safe and effective for medical use. Various international standards and checkpoints are employed to maintain high-quality production.

1. International Standards for Quality Control

Manufacturers of Huber needles often adhere to several international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers have a systematic approach to managing their processes.

- ISO 13485: Specifically for medical devices, this standard emphasizes the need for effective quality management systems that meet regulatory requirements.

- CE Marking: Required in Europe, CE marking indicates that a product meets EU safety, health, and environmental protection requirements.

Understanding these certifications is crucial for B2B buyers when assessing potential suppliers.

2. What Are the Key Quality Control Checkpoints?

Quality control is implemented through various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before production begins. Suppliers must provide certificates of analysis (CoA) to verify material quality.

- In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various stages to ensure that production parameters are within acceptable limits. This includes monitoring dimensional accuracy and surface finish.

- Final Quality Control (FQC): After production, each batch of needles undergoes extensive testing to ensure they meet predefined specifications. This may include functional testing, sterilization validation, and packaging inspections.

Which Testing Methods Are Commonly Used for Huber Needles?

To ensure the highest quality, several testing methods are utilized throughout the manufacturing process. These include:

- Mechanical Testing: This assesses the tensile strength and flexibility of the needle to ensure it can withstand use without breaking.

- Sterility Testing: Essential for medical devices, this testing ensures that the needles are free from viable microorganisms.

- Dimensional Inspection: Automated systems often perform this testing to measure the needle’s dimensions accurately and ensure they conform to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps to consider:

1. Conduct Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance systems. Buyers should look for suppliers who are open to audits and can demonstrate compliance with international standards.

2. Request Quality Reports

Suppliers should be able to provide detailed quality reports that outline their quality control processes and results. These reports should include information from IQC, IPQC, and FQC stages, demonstrating a commitment to quality.

3. Engage Third-Party Inspection Services

Using third-party inspection services can add an additional layer of assurance. These independent organizations can conduct audits and testing to verify that suppliers meet international quality standards.

What Are the Specific QC and Certification Nuances for International Buyers?

When sourcing Huber needles, international buyers must navigate various certification and quality control nuances:

- Regional Regulations: Different regions may have specific regulations regarding medical devices. For example, while CE marking is essential in Europe, FDA approval is required in the United States.

- Documentation Requirements: Buyers should ensure that suppliers provide all necessary documentation, including CoA, compliance certificates, and detailed quality reports.

- Cultural and Language Barriers: Buyers from diverse regions may face challenges in communication. It is advisable to engage suppliers who have experience in international trade and can provide support in multiple languages.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting suppliers for Huber needles, ensuring that they source high-quality, compliant products for their markets.

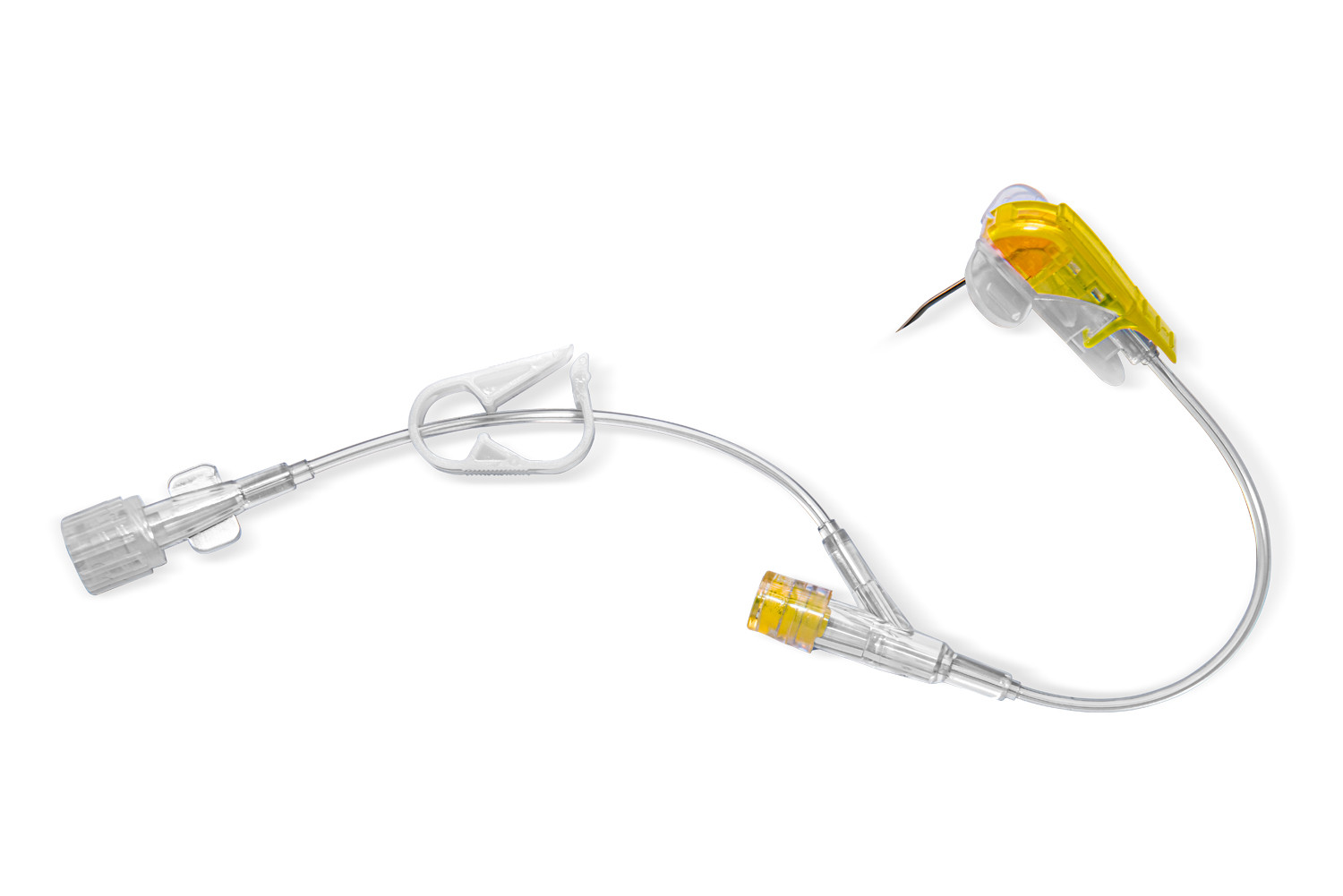

A stock image related to huber needle.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘huber needle’

Introduction: How to Effectively Source Huber Needles for Your Business

A stock image related to huber needle.

Sourcing the right medical supplies, such as Huber needles, is a critical process for B2B buyers in the healthcare sector. This guide provides a step-by-step checklist to help you navigate the complexities of procuring Huber needles, ensuring that you select high-quality products from reputable suppliers. By following this checklist, you will mitigate risks and enhance your purchasing efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. This includes defining the size, gauge, and features specific to the Huber needles you require. Consider the intended application, whether for chemotherapy or other uses, as this will influence your purchasing decision.

Step 2: Conduct Market Research

Understanding the market landscape is crucial in making informed decisions. Research current suppliers, pricing trends, and product availability in your target regions, including Africa, South America, the Middle East, and Europe. Utilize industry reports and online marketplaces to gather comprehensive data on potential vendors.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s essential to conduct a thorough evaluation. Request company profiles, product catalogs, and client testimonials to gauge their reliability. Look for suppliers with experience in your specific market, as they will better understand regional regulations and quality standards.

- Check for Industry Certifications: Verify that suppliers possess relevant certifications such as ISO 13485 or CE marking, which indicate compliance with international quality standards.

- Assess Production Capabilities: Ensure that the supplier can meet your volume requirements and delivery timelines.

Step 4: Request Samples for Quality Assurance

To ensure the Huber needles meet your quality standards, request product samples before finalizing your order. Testing samples allows you to evaluate the product’s performance and compatibility with your existing systems. This step can help prevent costly mistakes down the line.

Step 5: Understand Pricing Structures and Payment Terms

Clarifying pricing and payment terms upfront can help avoid misunderstandings later. Discuss not only the unit prices but also any potential bulk discounts, shipping costs, and payment schedules. Inquire about terms like letters of credit or payment upon delivery to optimize cash flow.

Step 6: Negotiate Contracts and Terms

Once you have selected a supplier, it’s time to negotiate the contract. Focus on key elements such as warranty terms, return policies, and service agreements. A well-structured contract protects your interests and ensures clarity on both sides.

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital for ongoing operations. Set up a regular check-in schedule to discuss order status, address any concerns, and manage expectations. This proactive approach fosters a strong partnership and can lead to better service and support.

By following these steps, you will be well-equipped to source Huber needles that meet your organization’s needs while establishing strong supplier relationships that can benefit your business in the long term.

Comprehensive Cost and Pricing Analysis for huber needle Sourcing

What Are the Key Cost Components in Huber Needle Sourcing?

When sourcing huber needles, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the final price. High-grade stainless steel and specialized coatings enhance durability and performance but can increase costs. Buyers should seek suppliers who provide a clear breakdown of material costs.

-

Labor: Labor costs vary by region and can significantly influence pricing. In areas with higher wage standards, such as parts of Europe, labor may constitute a larger portion of the cost structure. It’s beneficial to evaluate suppliers in regions with competitive labor costs without compromising on quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Buyers should inquire about the overhead percentages that suppliers apply, as these can vary widely.

-

Tooling: Custom tooling can add upfront costs but may lead to long-term savings through enhanced production efficiency. Buyers should assess whether the supplier has the necessary tooling capabilities for their specific needs.

-

Quality Control (QC): Rigorous QC processes are essential in medical device manufacturing. While these processes may increase costs, they are crucial for ensuring product reliability and compliance with regulatory standards.

-

Logistics: Shipping costs, including freight and insurance, must be factored into the total cost. This can vary based on the supplier’s location, shipping method, and destination.

-

Margin: Supplier profit margins can vary based on market conditions and competition. Buyers should understand the typical margins in the industry to gauge whether pricing is fair.

How Do Price Influencers Impact Huber Needle Costs?

Several factors can influence the pricing of huber needles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in reduced unit costs due to economies of scale. Negotiating lower MOQs can also be beneficial for smaller enterprises.

-

Specifications and Customization: Customized huber needles tailored to specific applications or user preferences can incur higher costs. It’s advisable to clearly define specifications upfront to avoid unexpected charges.

-

Materials and Quality Certifications: The use of premium materials and certifications (e.g., ISO, CE marking) can add to the cost but are often necessary for compliance in certain markets. Buyers should weigh the importance of these certifications against potential price increases.

-

Supplier Factors: The reputation, reliability, and production capabilities of suppliers can affect pricing. Established suppliers with a track record may charge a premium for their products due to perceived quality and service.

-

Incoterms: Understanding the terms of sale is crucial. Incoterms define the responsibilities of buyers and sellers in shipping and logistics, impacting total costs. Buyers should negotiate terms that minimize their risk and expenses.

What Are Effective Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing huber needles, consider the following tips:

-

Negotiate Wisely: Leverage competitive quotes from multiple suppliers to negotiate better pricing. Establishing long-term relationships may also yield favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, potential failures, and replacement. A slightly higher upfront cost may lead to lower TCO.

-

Understand Pricing Nuances for International Transactions: International buyers should be aware of currency fluctuations, import duties, and taxes that may affect overall costs. Being informed about local regulations in target markets is also essential.

-

Regularly Review Supplier Performance: Continuously assess supplier performance in terms of quality, delivery, and pricing. This can help identify opportunities for renegotiation or alternative sourcing options.

Disclaimer on Indicative Prices

Prices for huber needles can vary widely based on the factors outlined above. The information provided serves as a general guide. Buyers are encouraged to conduct thorough market research and obtain specific quotes tailored to their needs before making purchasing decisions.

Alternatives Analysis: Comparing huber needle With Other Solutions

In the dynamic landscape of medical devices, particularly for vascular access, the Huber needle is a prominent choice for its specialized design. However, international B2B buyers should also consider alternative solutions that may fit their specific operational needs or budget constraints. This analysis will compare the Huber needle against two viable alternatives: the Peripheral IV Catheter and the Port-a-Cath system.

Comparison Table of Huber Needle and Alternatives

| Comparison Aspect | Huber Needle | Peripheral IV Catheter | Port-a-Cath System |

|---|---|---|---|

| Performance | High (specialized for long-term access) | Moderate (short-term access) | High (long-term access with less tissue trauma) |

| Cost | Moderate to High | Low to Moderate | High |

| Ease of Implementation | Moderate (requires training) | Easy (widely used) | Moderate (requires surgical placement) |

| Maintenance | Moderate (requires regular monitoring) | Low (easy to replace) | High (requires regular flushing) |

| Best Use Case | Long-term medication delivery (e.g., chemotherapy) | Short-term IV therapy | Long-term venous access for patients with chronic conditions |

What Are the Benefits and Drawbacks of the Peripheral IV Catheter?

The Peripheral IV Catheter is a commonly used device that offers short-term vascular access for patients. Its primary advantages are its lower cost and ease of implementation, making it ideal for acute care settings where immediate access is necessary. However, it is not designed for long-term use, and patients may experience complications such as phlebitis or infiltration. For B2B buyers in regions with high patient turnover, the Peripheral IV Catheter may be an attractive option, but it lacks the durability needed for chronic treatment scenarios.

A stock image related to huber needle.

Why Consider the Port-a-Cath System?

The Port-a-Cath system is designed for patients requiring long-term venous access, similar to the Huber needle. Its primary advantage lies in its reduced risk of infection and tissue trauma, as it is implanted beneath the skin. However, the initial costs are higher, and the implantation procedure requires surgical intervention, which may not be feasible for all healthcare facilities. For organizations in Africa or South America, where surgical resources may be limited, this option may be less accessible but is highly effective for patients with ongoing treatment needs.

How to Choose the Right Solution for Your Needs

When determining the most suitable vascular access solution, B2B buyers should assess their specific use cases, budget constraints, and patient demographics. For long-term therapies, the Huber needle and Port-a-Cath system may be more appropriate, while the Peripheral IV Catheter could suffice for short-term needs. It’s essential to consider not just the initial costs but also the long-term implications of maintenance and patient outcomes. Engaging with suppliers who understand local healthcare challenges can provide valuable insights to make an informed decision. By carefully evaluating these alternatives, buyers can align their choices with operational goals and patient care standards.

Essential Technical Properties and Trade Terminology for huber needle

What Are the Key Technical Properties of a Huber Needle?

When sourcing a Huber needle, understanding its technical properties is crucial for ensuring it meets the specific needs of your medical applications. Here are some essential specifications to consider:

1. Material Grade

Huber needles are typically made from high-grade stainless steel. This material is chosen for its corrosion resistance, durability, and ability to maintain sharpness, which is vital for minimizing patient discomfort during insertion. In B2B contexts, ensuring that the material grade meets international standards (such as ISO or ASTM) can impact both product reliability and regulatory compliance.

2. Needle Gauge

The gauge of a Huber needle refers to its diameter, with a higher gauge indicating a thinner needle. Common gauges range from 18 to 25, affecting the flow rate of fluids and the ease of insertion. Understanding the appropriate gauge for your application is essential for optimizing patient comfort and treatment efficacy. Buyers should assess the required gauge based on the specific medical procedures they will be performing.

3. Length and Configuration

Huber needles come in various lengths, typically ranging from 1 to 2 inches. The length chosen can influence the depth of penetration required for effective access to implanted ports. Additionally, some needles feature a curved design, which may facilitate easier access in certain anatomical locations. B2B buyers must consider these factors to ensure compatibility with their existing medical devices or procedures.

4. Tolerance Levels

Tolerance in needle manufacturing indicates the allowable variance in dimensions during production. Tight tolerances ensure that needles fit securely into ports, reducing the risk of leakage and enhancing safety. For international buyers, understanding the tolerance specifications can help in evaluating the reliability of suppliers and the consistency of their products.

5. Coating Options

Some Huber needles come with special coatings, such as silicone or heparin, which can reduce friction during insertion and minimize the risk of clot formation. Buyers should assess the benefits of these coatings based on their intended use, as they can significantly affect both performance and patient outcomes.

What Are Common Trade Terms Associated with Huber Needles?

Familiarity with industry jargon can greatly enhance communication and negotiation in B2B transactions. Here are some common trade terms relevant to Huber needles:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Huber needles, understanding whether a supplier is an OEM can influence decisions about product quality and brand reputation. Buyers often prefer OEMs for their reliability and adherence to industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Huber needles, MOQs can vary significantly depending on the manufacturer. Buyers should consider their purchasing volume and budget when negotiating MOQs, as larger orders may lead to cost savings.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. It is a key step in the procurement process, allowing buyers to compare offers and negotiate terms. Crafting a clear and detailed RFQ for Huber needles can facilitate a more efficient sourcing process.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers navigate international logistics and avoid unexpected costs.

Why Understanding These Properties and Terms Matters for B2B Buyers

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, grasping the technical properties and trade terminology associated with Huber needles can streamline purchasing decisions. This knowledge not only enhances negotiation capabilities but also ensures compliance with industry standards, ultimately leading to better product quality and patient care.

Navigating Market Dynamics and Sourcing Trends in the huber needle Sector

What Are the Key Market Dynamics and Sourcing Trends in the Huber Needle Sector?

The huber needle market is experiencing significant growth driven by advancements in medical technology and an increasing demand for minimally invasive procedures. As healthcare systems globally prioritize patient comfort and efficient treatment methods, the demand for huber needles—commonly used in accessing implanted ports—has surged. Key trends indicate that international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should anticipate a shift towards more innovative designs that enhance usability and reduce the risk of complications.

Emerging technologies, such as smart needles that integrate real-time monitoring capabilities, are poised to revolutionize the sector. Additionally, the rise of telemedicine and remote patient monitoring has led to increased requirements for reliable and sterile medical supplies, including huber needles. Buyers should also be aware of the growing importance of digital sourcing platforms that facilitate transparent supplier interactions, allowing for better negotiation terms and faster procurement processes.

How Can International B2B Buyers Ensure Sustainable and Ethical Sourcing of Huber Needles?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the huber needle market. The environmental impact of medical waste and the importance of responsible manufacturing practices cannot be overstated. Buyers from Africa, South America, the Middle East, and Europe should seek suppliers that prioritize eco-friendly materials and processes. The industry is seeing a shift towards the use of biodegradable or recyclable materials in packaging, which can significantly reduce the overall environmental footprint.

Moreover, ethical supply chains are paramount in ensuring that suppliers adhere to fair labor practices and uphold human rights standards. Buyers should look for certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. These certifications not only indicate a commitment to sustainability but also enhance the credibility of the suppliers in the eyes of international customers. Engaging with suppliers who are transparent about their sourcing practices fosters trust and aligns with the growing consumer demand for responsible business practices.

What Is the Brief Evolution of the Huber Needle?

The huber needle, introduced in the late 1980s, was designed to provide a safe and effective method for accessing implanted ports used in chemotherapy and other long-term intravenous therapies. Over the years, advancements in needle design and materials have improved safety features, such as safety shields and non-coring tips, which minimize the risk of complications and infections. As the healthcare landscape continues to evolve, the huber needle is adapting to meet the demands of modern medicine, with ongoing research focused on enhancing its functionality and patient safety. International buyers should stay informed about these innovations to make well-informed sourcing decisions that align with the latest industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of huber needle

-

How do I choose the right supplier for huber needles?

Choosing the right supplier for huber needles involves several key considerations. Start by evaluating the supplier’s reputation and experience in the medical device industry. Look for certifications such as ISO 13485, which indicates adherence to quality management systems for medical devices. Request samples to assess product quality and performance. Additionally, engage with previous clients for feedback. Establish clear communication regarding your needs, including customization options and minimum order quantities (MOQs), to ensure the supplier can meet your requirements. -

What are the key features to look for in a huber needle?

When sourcing huber needles, prioritize features that enhance usability and patient safety. Look for needles with a safety-engineered design to minimize the risk of needlestick injuries. Ensure they have a clear labeling system for easy identification of gauge size and length. Biocompatibility is crucial, so select products made from high-quality materials that reduce the risk of allergic reactions. Additionally, consider the needle’s flexibility and sharpness, which can influence patient comfort and procedural efficiency. -

What are the typical minimum order quantities (MOQs) for huber needles?

Minimum order quantities for huber needles can vary significantly based on the supplier and the specific product line. Generally, MOQs can range from a few hundred to several thousand units. When negotiating with suppliers, clarify your needs and explore whether they can accommodate smaller orders, especially if you are a new buyer or entering a new market. Some suppliers may offer tiered pricing based on order volumes, which can help you optimize costs. -

What payment terms should I expect when sourcing huber needles internationally?

Payment terms for international purchases of huber needles typically include options such as wire transfers, letters of credit, or payment upon delivery. Be prepared for initial deposits, often ranging from 30% to 50% of the total order value. Ensure you discuss payment timelines and conditions upfront to avoid misunderstandings. It’s advisable to use secure payment platforms and consider the currency exchange rates, especially when dealing with suppliers from different regions like Africa, South America, or the Middle East. -

How can I ensure quality assurance for huber needles?

To ensure quality assurance when sourcing huber needles, request documentation such as Certificates of Compliance and test reports from the supplier. Verify that the supplier adheres to international quality standards like ISO 13485, which ensures consistent quality in medical devices. Additionally, consider conducting third-party audits or inspections to assess manufacturing processes. Establish a clear return policy and quality inspection protocol upon delivery to address any discrepancies in product quality. -

What logistics considerations are important for international shipping of huber needles?

When planning the logistics for shipping huber needles internationally, consider factors such as shipping methods, lead times, and customs regulations. Choose reliable logistics partners with experience in handling medical devices to ensure timely delivery. Familiarize yourself with the import regulations of your country, including any necessary documentation and permits. Additionally, assess the costs associated with shipping, insurance, and potential tariffs to budget effectively for your procurement. -

Can huber needles be customized for specific medical applications?

Yes, many suppliers offer customization options for huber needles to meet specific medical requirements. Customization can include variations in needle length, gauge size, or the addition of specialized coatings for enhanced performance. When discussing customization, provide detailed specifications and any relevant clinical data to ensure the supplier understands your needs. Be mindful that customized products may involve longer lead times and higher costs, so plan accordingly. -

What are the common challenges faced when sourcing huber needles internationally?

Common challenges in sourcing huber needles internationally include navigating different regulatory environments, language barriers, and varying quality standards. It’s essential to conduct thorough due diligence on potential suppliers and understand the regulatory requirements in your target market. Delays in shipping and customs clearance can also impact your procurement timeline, so build buffer time into your project plans. Establishing strong communication channels with suppliers can help mitigate these challenges and enhance collaboration.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for huber needle

In today’s competitive landscape, the strategic sourcing of huber needles is paramount for international B2B buyers seeking quality, reliability, and cost-effectiveness. By understanding the intricacies of sourcing these specialized medical devices, companies can enhance their supply chain efficiency and ensure they meet regulatory standards across diverse markets, including Africa, South America, the Middle East, and Europe.

What key factors should B2B buyers consider when sourcing huber needles? Prioritizing suppliers with a proven track record in quality assurance and compliance with international standards is essential. Additionally, fostering relationships with manufacturers who can provide customization options can lead to better patient outcomes and operational efficiency.

As the demand for advanced medical devices continues to rise, international B2B buyers must remain agile and informed. Embracing a strategic sourcing approach not only optimizes procurement processes but also positions businesses to respond effectively to market shifts and emerging technologies.

Looking ahead, the landscape of medical device procurement will evolve, presenting new opportunities for innovation and collaboration. B2B buyers are encouraged to actively engage with suppliers, leverage data-driven insights, and explore new partnerships to ensure their sourcing strategies align with future industry trends. The time to invest in strategic sourcing for huber needles is now—unlock potential and elevate your business’s success.