Discover Cost-Saving Benefits of Shoulder Bolt Sourcing (2025)

Introduction: Navigating the Global Market for shoulder bolt

In today’s competitive landscape, sourcing the right shoulder bolt can be a daunting task for international B2B buyers. The challenge lies not only in finding high-quality products but also in navigating a complex supply chain that varies significantly across regions like Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the global market for shoulder bolts, providing insights into various types, applications, and sourcing strategies that can streamline your procurement process.

As a critical component in machinery and assembly applications, shoulder bolts must meet stringent specifications and quality standards. Buyers will benefit from a thorough understanding of the different materials, sizes, and configurations available in the market. Additionally, the guide will cover essential aspects such as supplier vetting processes, cost considerations, and tips for negotiating favorable terms, empowering you to make informed purchasing decisions.

By leveraging the insights and strategies outlined in this guide, B2B buyers from diverse regions, including the UAE and Germany, can enhance their sourcing capabilities and mitigate risks associated with international procurement. Whether you are looking to establish long-term supplier relationships or optimize your inventory management, this resource is designed to equip you with the knowledge needed to succeed in the global marketplace for shoulder bolts.

Understanding shoulder bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shoulder Bolt | Uniform shoulder diameter, threaded end | Machinery assembly, automotive, furniture | Pros: Versatile, widely available. Cons: Limited load capacity. |

| Flanged Shoulder Bolt | Integrated flange for increased stability | Heavy equipment, construction, aerospace | Pros: Enhanced load distribution. Cons: Higher cost than standard. |

| Shoulder Bolt with Locking Mechanism | Prevents loosening under vibration | Robotics, automotive, industrial equipment | Pros: Reliable under dynamic loads. Cons: More complex installation. |

| Adjustable Shoulder Bolt | Adjustable length for customized fit | Custom machinery, prototypes | Pros: Flexible applications. Cons: May require additional components. |

| Metric Shoulder Bolt | Available in metric sizes and threads | European machinery, automotive, electronics | Pros: Compatibility with international standards. Cons: Limited availability in non-metric regions. |

What Are the Characteristics of Standard Shoulder Bolts?

Standard shoulder bolts are characterized by their uniform shoulder diameter and a threaded end, which allows for easy installation and removal. They are typically made from steel or stainless steel, providing adequate strength for various applications. Suitable for general machinery assembly and automotive components, these bolts are widely available and versatile. However, buyers should consider their limited load capacity, which might not meet the demands of heavier applications.

How Do Flanged Shoulder Bolts Enhance Stability?

Flanged shoulder bolts come with an integrated flange that helps distribute load and provides additional stability in applications. This design is particularly beneficial in heavy equipment and construction settings where load-bearing is critical. The flanged design can also simplify assembly by eliminating the need for separate washers. While they offer enhanced performance, buyers should be aware that flanged shoulder bolts typically come at a higher cost compared to standard options.

Why Choose Shoulder Bolts with Locking Mechanisms?

Shoulder bolts equipped with locking mechanisms are designed to prevent loosening due to vibrations, making them ideal for applications in robotics and automotive sectors. Their reliability under dynamic loads is a significant advantage for B2B buyers concerned about maintaining structural integrity. However, these bolts may involve more complex installation processes, which can be a consideration for companies looking to streamline their assembly lines.

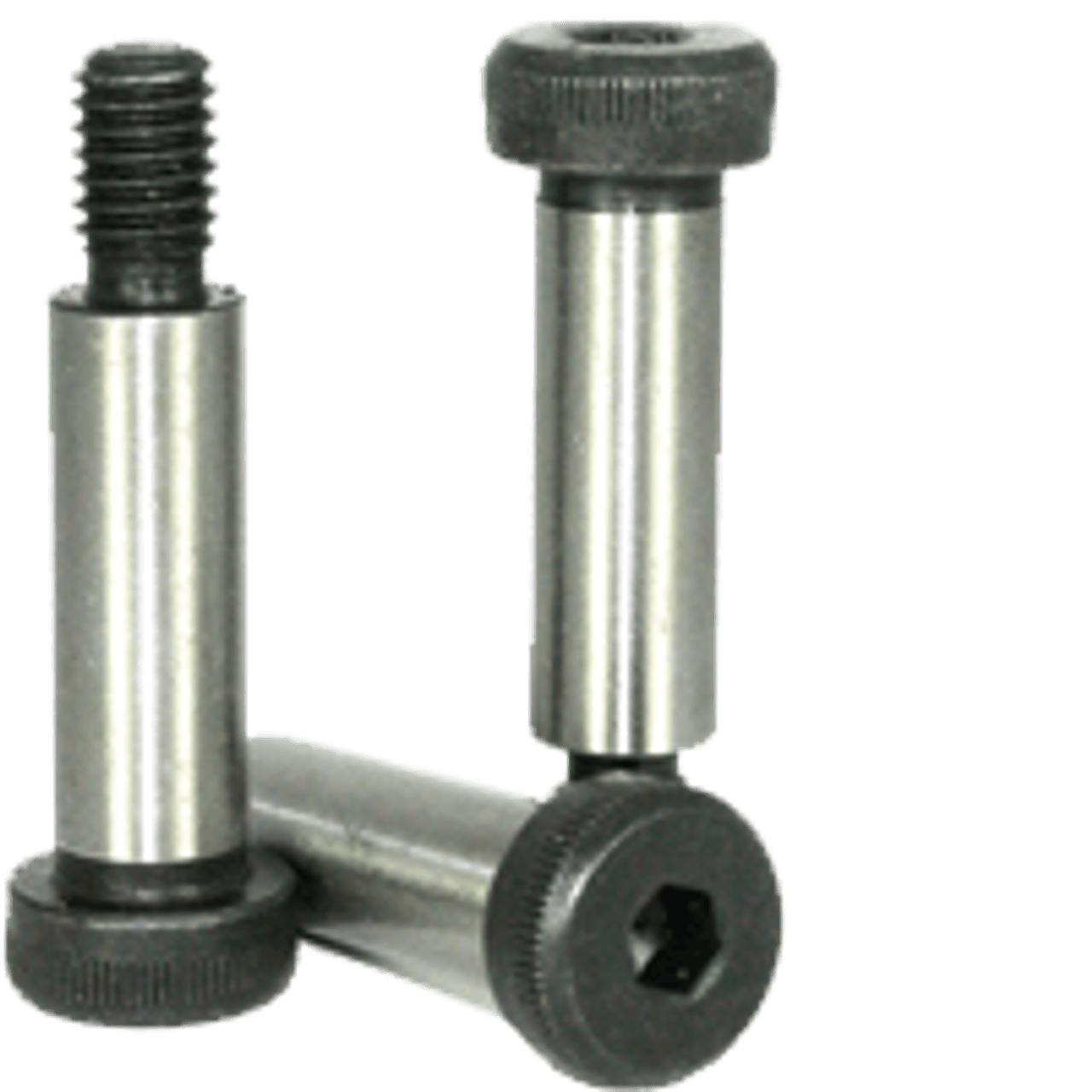

A stock image related to shoulder bolt.

What Are the Benefits of Adjustable Shoulder Bolts?

Adjustable shoulder bolts provide flexibility with their customizable lengths, allowing for tailored solutions in custom machinery and prototypes. This adaptability can be particularly advantageous for businesses that require precision in their assembly processes. However, buyers should note that adjustable bolts may necessitate additional components or tools for proper installation, which could increase overall project costs.

How Do Metric Shoulder Bolts Cater to International Standards?

Metric shoulder bolts are designed to meet international standards, making them essential for European machinery and automotive applications. Their availability in various metric sizes and threads ensures compatibility with a wide range of equipment. While they offer significant advantages for businesses operating in metric regions, buyers in non-metric regions may find these bolts less accessible, potentially impacting procurement strategies.

Related Video: Understanding Shoulder Bolts & Cool Creations Winner | Fasteners 101

Key Industrial Applications of shoulder bolt

| Industry/Sector | Specific Application of Shoulder Bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Mounting suspension components | Ensures stability and safety in vehicle performance | Material strength, corrosion resistance, and compliance with automotive standards |

| Manufacturing | Machinery assembly and alignment | Enhances precision in assembly processes | Availability in bulk, customization options, and lead times |

| Aerospace | Securing aircraft components | Critical for safety and reliability | Certification requirements, weight considerations, and traceability |

| Electronics | Mounting circuit boards and components | Provides secure and reliable connections | Compatibility with various electronic designs and standards |

| Renewable Energy | Wind turbine assembly and maintenance | Increases efficiency and longevity of equipment | Durability in harsh environments, sourcing from certified suppliers |

How Are Shoulder Bolts Used in the Automotive Industry?

In the automotive sector, shoulder bolts are essential for mounting suspension components, which play a critical role in vehicle stability and safety. These bolts are designed to withstand high stress and loads, ensuring that the suspension system operates effectively under various driving conditions. International B2B buyers in this industry should prioritize sourcing shoulder bolts that meet stringent automotive standards, focusing on materials that offer both strength and corrosion resistance. This is particularly crucial in regions with diverse climates, such as the Middle East and Europe, where environmental factors can affect bolt performance.

What Role Do Shoulder Bolts Play in Manufacturing?

In manufacturing, shoulder bolts are commonly used for machinery assembly and alignment. Their design allows for precise positioning of components, which is vital for maintaining the efficiency of production lines. By utilizing shoulder bolts, manufacturers can enhance the accuracy of their assembly processes, leading to reduced downtime and increased productivity. B2B buyers should consider sourcing options that offer bulk availability and customization to meet specific machinery requirements, especially in regions like South America, where industrial growth is accelerating.

Why Are Shoulder Bolts Important in Aerospace Applications?

In the aerospace industry, shoulder bolts are critical for securing aircraft components, where safety and reliability are non-negotiable. These bolts must adhere to rigorous certification standards to ensure they can withstand extreme conditions during flight. International buyers from Europe and the Middle East should focus on sourcing shoulder bolts that provide traceability and compliance with industry regulations. Additionally, weight considerations are paramount in aerospace applications, making it essential to select materials that offer strength without adding unnecessary weight.

How Are Shoulder Bolts Utilized in Electronics?

Shoulder bolts are pivotal in the electronics sector for mounting circuit boards and various components securely. Their unique design ensures stable connections, which is crucial for the performance of electronic devices. B2B buyers in this field should look for shoulder bolts that are compatible with different electronic designs and adhere to industry standards. Sourcing from suppliers who offer a variety of sizes and materials can help companies in Africa and South America meet the demands of rapidly evolving technology.

What Benefits Do Shoulder Bolts Provide in Renewable Energy?

In the renewable energy sector, particularly in wind turbine assembly and maintenance, shoulder bolts are vital for securing components that must endure harsh environmental conditions. The use of high-quality shoulder bolts can enhance the efficiency and longevity of wind energy systems, contributing to overall operational success. International buyers should consider sourcing shoulder bolts that are durable and resistant to corrosion, particularly from suppliers with a proven track record in renewable energy applications. This is increasingly important as the global demand for sustainable energy solutions grows.

3 Common User Pain Points for ‘shoulder bolt’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Shoulder Bolts

The Problem:

B2B buyers, particularly in regions like Africa and South America, often encounter challenges when sourcing high-quality shoulder bolts. This issue can arise due to limited local suppliers or inconsistent product quality. Buyers may receive products that do not meet their specifications, leading to costly production delays and potential damage to equipment. In a competitive market, the inability to secure reliable components can hinder operational efficiency and compromise project timelines.

The Solution:

To overcome sourcing challenges, buyers should prioritize establishing relationships with reputable manufacturers and suppliers. Conduct thorough research to identify suppliers with a proven track record in the production of shoulder bolts, focusing on certifications such as ISO 9001 for quality management. Engaging with suppliers who specialize in specific industries, such as automotive or aerospace, can also provide assurance of quality and compliance with industry standards. Additionally, consider using platforms that connect buyers with verified manufacturers globally, ensuring a wide selection of products. Finally, implementing a quality assurance process, including sample testing before bulk orders, can mitigate the risk of receiving subpar products.

Scenario 2: Misunderstanding Technical Specifications of Shoulder Bolts

The Problem:

B2B buyers often face confusion regarding the technical specifications of shoulder bolts, such as shoulder diameter, length, and material grade. This misunderstanding can lead to incorrect orders that do not fit or function as intended in their applications. For instance, a buyer in the Middle East may order bolts that are too short or made from an unsuitable material, resulting in mechanical failures and increased costs for replacements.

The Solution:

To address this issue, buyers should invest time in understanding the technical specifications relevant to their applications. Create a detailed checklist that outlines the necessary measurements and material properties required for the specific use case of the shoulder bolt. Collaborating with engineering teams can help clarify these specifications. Additionally, suppliers should be consulted for guidance on the best options based on the intended application. Providing suppliers with precise details about the intended usage can facilitate better recommendations. Utilizing CAD software to visualize and model the application can also help ensure compatibility before placing an order.

Scenario 3: Inconsistent Supply Chain and Delivery Issues

The Problem:

International buyers, especially those in Europe and the Middle East, frequently experience disruptions in the supply chain that lead to delivery delays for shoulder bolts. These delays can stem from geopolitical factors, customs regulations, or logistical challenges. When production schedules are impacted, the costs can escalate due to idle machinery or delayed project timelines, adversely affecting client relationships and revenue.

The Solution:

To mitigate supply chain risks, B2B buyers should diversify their supplier base across different regions to reduce dependency on a single source. Establishing agreements with multiple suppliers can provide backup options in case of disruptions. Additionally, implementing an inventory management system that tracks stock levels and lead times can help anticipate shortages. Building strong relationships with logistics providers is also crucial; they can offer insights into potential delays and alternative shipping options. Regular communication with suppliers about anticipated demand can ensure that they are prepared to meet your needs, thereby smoothing out any potential bumps in the supply chain.

Strategic Material Selection Guide for shoulder bolt

When selecting materials for shoulder bolts, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in shoulder bolt manufacturing, highlighting their properties, advantages, disadvantages, and implications for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel Shoulder Bolts?

Stainless steel is a popular choice for shoulder bolts due to its excellent corrosion resistance and mechanical properties. It typically withstands temperatures up to 800°F (427°C) and offers good tensile strength. The most common grades used are AISI 304 and AISI 316, with the latter providing enhanced corrosion resistance, especially in saline environments.

Pros & Cons: Stainless steel shoulder bolts are durable and suitable for a wide range of applications, including marine and chemical environments. However, they can be more expensive than carbon steel options, and manufacturing complexity may increase due to the need for specialized machining.

Impact on Application: Stainless steel’s compatibility with various media makes it ideal for applications in food processing, pharmaceuticals, and marine industries. Buyers should ensure compliance with standards such as ASTM A193 or DIN 931.

How Does Carbon Steel Affect Shoulder Bolt Performance?

A stock image related to shoulder bolt.

Carbon steel shoulder bolts are known for their high strength and affordability. They typically have a temperature rating of up to 400°F (204°C) and can be treated to improve hardness and wear resistance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it suitable for high-volume applications. However, its susceptibility to corrosion can limit its use in environments where moisture or chemicals are present, requiring additional surface treatments like galvanization.

Impact on Application: Carbon steel is often used in automotive and construction applications. Buyers in regions with high humidity or exposure to corrosive elements should consider protective coatings or alternative materials.

What Are the Benefits of Using Alloy Steel for Shoulder Bolts?

Alloy steel shoulder bolts, which may contain elements such as chromium, molybdenum, or nickel, offer enhanced mechanical properties and can withstand higher temperatures and pressures. They are often rated for temperatures up to 1,200°F (649°C).

Pros & Cons: The main advantage of alloy steel is its superior strength and toughness, making it ideal for heavy-duty applications. However, it can be more expensive and complex to manufacture, requiring specialized heat treatment processes.

Impact on Application: Alloy steel shoulder bolts are commonly used in heavy machinery and aerospace applications. Buyers should verify compliance with standards like ASTM A574 or JIS B 1180, especially in regulated industries.

Why Choose Plastic Shoulder Bolts for Specific Applications?

Plastic shoulder bolts, typically made from materials like nylon or polycarbonate, are lightweight and resistant to corrosion and chemicals. They can function effectively in temperature ranges from -40°F to 185°F (-40°C to 85°C).

Pros & Cons: The primary advantage of plastic shoulder bolts is their non-conductive properties and resistance to corrosion, making them suitable for electrical applications. However, they have lower tensile strength compared to metal options and may not be suitable for high-load applications.

Impact on Application: Plastic shoulder bolts are often used in electronics and light-duty machinery. Buyers should ensure that the selected plastic material meets relevant standards for strength and thermal performance.

Summary Table of Material Selection for Shoulder Bolts

| Material | Typical Use Case for shoulder bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine and chemical applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Automotive and construction | Cost-effective and high strength | Susceptible to corrosion | Low |

| Alloy Steel | Heavy machinery and aerospace | Superior strength and toughness | More expensive and complex to manufacture | Med |

| Plastic | Electronics and light-duty machinery | Lightweight and corrosion-resistant | Lower tensile strength | Low |

In conclusion, selecting the right material for shoulder bolts is crucial for ensuring product performance and longevity. B2B buyers should carefully evaluate the specific requirements of their applications and consider regional compliance standards to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for shoulder bolt

What Are the Key Stages in the Manufacturing Process of Shoulder Bolts?

Shoulder bolts are critical components widely used in various industries, and understanding their manufacturing process can help international B2B buyers make informed purchasing decisions. The production of shoulder bolts typically involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting high-quality raw materials, commonly steel, stainless steel, or other alloys. The choice of material directly influences the bolt’s strength, corrosion resistance, and overall performance. Once the material is selected, it undergoes various treatments, such as heat treatment, to enhance its mechanical properties. During this phase, suppliers should ensure that the materials meet specific international standards, such as ASTM or ISO, to guarantee reliability and performance.

How Are Shoulder Bolts Formed?

The forming stage includes several techniques to shape the raw material into the desired dimensions. Common methods include:

- Cold Heading: This process involves deforming the metal at room temperature, which increases its strength due to work hardening.

- Machining: After heading, machining processes such as turning and milling are used to achieve precise tolerances and surface finishes.

- Thread Rolling: This technique creates threads without removing material, enhancing the bolt’s strength and surface integrity.

The choice of forming technique can significantly impact the final product’s quality and cost. B2B buyers should inquire about the methods used by suppliers to ensure they align with their quality requirements.

What Is Involved in the Assembly Process for Shoulder Bolts?

In the assembly stage, various components, such as washers or nuts, may be added to the shoulder bolts, depending on their intended application. This process can involve:

- Manual Assembly: Skilled workers may assemble components, ensuring high attention to detail.

- Automated Assembly: For larger production runs, automation can improve efficiency and consistency.

B2B buyers should consider suppliers’ assembly methods, as they can affect lead times and product consistency.

What Finishing Techniques Are Commonly Used for Shoulder Bolts?

Finishing processes are crucial to enhancing the appearance and performance of shoulder bolts. Common techniques include:

- Plating: Electroplating with materials like zinc or nickel can improve corrosion resistance.

- Coating: Applying a protective coating can help prevent wear and tear.

- Passivation: This chemical treatment enhances corrosion resistance, particularly for stainless steel bolts.

When selecting a supplier, B2B buyers should verify the finishing techniques used, as they can significantly impact the product’s lifespan and performance.

What Quality Assurance Standards Are Relevant for Shoulder Bolts?

Quality assurance (QA) is paramount in ensuring that shoulder bolts meet the necessary performance and safety standards. Internationally recognized standards, such as ISO 9001, provide a framework for quality management systems. Additionally, industry-specific certifications, such as CE marking for the European market or API specifications for the oil and gas sector, may be required.

How Are Quality Control Checkpoints Structured?

Quality control (QC) is integrated into the manufacturing process through several checkpoints, including:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify any deviations from quality standards early.

- Final Quality Control (FQC): The final inspection assesses the completed products against quality benchmarks before shipment.

B2B buyers should inquire about these QC checkpoints when evaluating suppliers, as they can provide insights into the supplier’s commitment to quality.

What Testing Methods Are Commonly Used in Shoulder Bolt Manufacturing?

Several testing methods are employed to ensure that shoulder bolts meet quality standards. Common methods include:

- Tensile Testing: This test evaluates the strength of the bolt under tension.

- Hardness Testing: Measuring the hardness of the material ensures it meets specifications for durability.

- Dimensional Inspection: Verifying that the dimensions of the bolt conform to design specifications is crucial for fit and function.

B2B buyers should request detailed test reports from suppliers to confirm that products have undergone rigorous testing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially those sourcing from international markets. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality systems, and compliance with standards.

- Requesting Quality Reports: Suppliers should provide documentation of their QA processes and test results to demonstrate compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these verification methods is crucial to mitigate risks and ensure product quality.

What Quality Control and Certification Nuances Should International Buyers Consider?

Different regions may have varying requirements and expectations regarding quality control and certification. For example, European buyers might prioritize CE marking, while buyers in the Middle East may focus on compliance with local standards. Understanding these nuances can help buyers navigate the complexities of international procurement.

Additionally, buyers should be aware of the implications of sourcing from countries with different regulatory environments. This includes understanding potential challenges related to customs, tariffs, and compliance with international trade agreements.

Conclusion

Understanding the manufacturing processes and quality assurance practices for shoulder bolts is essential for international B2B buyers. By focusing on key stages such as material preparation, forming, assembly, and finishing, along with rigorous quality control measures, buyers can ensure they are sourcing high-quality components that meet their specific needs. Engaging with suppliers about their QA processes and certifications will further enhance the reliability of their procurement decisions, fostering successful international business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoulder bolt’

In the dynamic landscape of international manufacturing and assembly, sourcing high-quality shoulder bolts is critical for operational efficiency. This step-by-step checklist serves as a practical guide for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to ensure a streamlined and effective procurement process.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your technical requirements for shoulder bolts. This includes dimensions, materials (e.g., stainless steel, carbon steel), load capacity, and any specific coatings or treatments needed. Properly defined specifications help in communicating your needs to suppliers and prevent costly errors down the line.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for shoulder bolts is essential. Conduct research on different suppliers and manufacturers in your target regions. Look for fluctuations in pricing due to material costs or demand spikes, as this knowledge will empower you to negotiate better terms and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, product catalogs, and references from other clients, especially those in similar industries or regions. Consider their production capabilities, quality control processes, and any past performance indicators to ensure reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers hold relevant certifications and comply with international standards, such as ISO 9001 for quality management or ASTM standards for materials. This verification not only mitigates risks but also assures you of the quality and safety of the shoulder bolts you are procuring.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the shoulder bolts. Testing samples for compatibility with your applications and assessing their performance under load conditions is crucial. This step minimizes the risk of receiving faulty products and confirms that the supplier meets your quality expectations.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a reliable supplier, engage in negotiations regarding price, payment terms, and delivery schedules. Be transparent about your needs, and don’t hesitate to ask for better terms, especially if you are making a large order. Establishing favorable conditions can significantly impact your overall procurement costs.

Step 7: Establish a Clear Communication Plan

Finally, create a communication plan that outlines how you will interact with the supplier throughout the procurement process. Regular updates on order status, shipping, and any issues that arise will help maintain a productive relationship. Clear communication is key to resolving potential issues before they escalate.

By following this comprehensive sourcing checklist, B2B buyers can ensure a more effective and efficient procurement process for shoulder bolts, ultimately enhancing their operational capabilities and supply chain reliability.

Comprehensive Cost and Pricing Analysis for shoulder bolt Sourcing

What Are the Key Cost Components in Shoulder Bolt Sourcing?

When sourcing shoulder bolts, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for shoulder bolts include stainless steel, alloy steel, and brass, with stainless steel often commanding a premium due to its corrosion resistance and strength.

-

Labor: Labor costs vary by region and manufacturing processes. Countries with higher labor costs, like Germany, may have increased pricing compared to manufacturers in regions with lower labor rates, such as parts of Africa or South America.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses associated with production. Different regions will have varied overhead costs, influenced by local regulations and economic conditions.

-

Tooling: The initial investment in tooling can be significant, especially for custom shoulder bolts. Buyers should consider whether the supplier has the necessary tools readily available or if additional costs will arise for custom tooling.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet specifications and quality standards, which can add to the overall cost. Buyers should evaluate the supplier’s QC practices to gauge potential expenses.

-

Logistics: Shipping costs are influenced by distance, weight, and mode of transport. Understanding the logistics involved in international shipping, including customs duties and taxes, is critical to calculating total costs.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary widely based on competition, demand, and the supplier’s positioning in the market.

How Do Price Influencers Affect Shoulder Bolt Costs?

Several factors influence the pricing of shoulder bolts, which international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Ordering larger quantities often leads to bulk discounts. Be aware of suppliers’ MOQs, as these can affect overall costs significantly.

-

Specifications and Customization: Standard shoulder bolts may be less expensive than customized versions. If your project requires specific dimensions or features, be prepared for a potential price increase.

-

Material Selection: The material choice not only affects the cost but also influences performance. Higher-quality materials may reduce long-term costs by decreasing failure rates.

-

Quality Certifications: Products that meet international quality standards (e.g., ISO, ASTM) may come at a premium. However, investing in certified products can lead to savings in the long run by minimizing defects and ensuring reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of shoulder bolts.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

To maximize value when sourcing shoulder bolts, international buyers should consider the following strategies:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may be willing to offer better terms for larger orders or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, potential downtime, and the longevity of the bolts to assess the TCO.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing trends in the regions you are sourcing from. This knowledge can empower you during negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may offer better insights into regional pricing structures.

-

Stay Informed on Market Trends: Keep an eye on fluctuations in material costs and economic conditions that could impact pricing. Being informed allows for better timing when making purchases.

Disclaimer on Indicative Prices

Pricing for shoulder bolts can vary widely based on the factors discussed above. The information provided here serves as a guideline and should not be construed as definitive pricing. Always consult multiple suppliers and obtain quotes tailored to your specific requirements to ensure you are making the best purchasing decision.

Alternatives Analysis: Comparing shoulder bolt With Other Solutions

In the realm of fastening solutions, selecting the right component can significantly influence operational efficiency and product durability. While shoulder bolts are a popular choice for various applications, it’s important for international B2B buyers to consider alternative solutions that may better suit their specific needs. This section will compare shoulder bolts against two viable alternatives: dowel pins and threaded rods.

Comparison Table: Shoulder Bolt vs. Alternatives

| Comparison Aspect | Shoulder Bolt | Dowel Pin | Threaded Rod |

|---|---|---|---|

| Performance | High shear strength; precise alignment | Moderate strength; ideal for location fixing | Strong tension; versatile in applications |

| Cost | Moderate to high | Low | Low to moderate |

| Ease of Implementation | Requires specific drilling | Simple insertion | Requires threading and nuts |

| Maintenance | Low maintenance required | Minimal maintenance | Moderate; may require checking |

| Best Use Case | Machinery assembly, precision alignment | Woodworking, fixture assembly | Structural applications, adjustable tension |

What Are the Advantages and Disadvantages of Dowel Pins?

Dowel pins are cylindrical rods used to align and join two components. They are particularly effective in woodworking and applications where precise alignment is critical. The primary advantage of dowel pins is their cost-effectiveness; they are generally less expensive than shoulder bolts. However, they offer moderate strength and are not suitable for high-stress applications. Dowel pins are easy to install, requiring only a simple hole, but they do not provide the same level of shear strength as shoulder bolts.

How Do Threaded Rods Compare to Shoulder Bolts?

Threaded rods are versatile fastening solutions that can provide strong tension in various applications. They are typically used in structural frameworks and can be adjusted easily, making them suitable for applications requiring flexibility. While they are generally less expensive than shoulder bolts, threaded rods require additional components, such as nuts and washers, for effective use, which can complicate installation. Moreover, while they excel in tension applications, they may not provide the precise alignment that shoulder bolts offer, which can be a critical factor in machinery assembly.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right fastening solution requires a thorough understanding of the specific application and operational demands. Buyers should consider factors such as the level of stress the joint will endure, the materials being joined, and the importance of alignment precision. For high-stress environments where precision is crucial, shoulder bolts may be the best choice despite their higher cost. Conversely, if budget constraints are a priority and the application does not require high shear strength, dowel pins or threaded rods may be more suitable. Ultimately, understanding the unique requirements of your project will guide you toward the most effective fastening solution.

Essential Technical Properties and Trade Terminology for shoulder bolt

What Are the Key Technical Properties of Shoulder Bolts?

Understanding the technical specifications of shoulder bolts is crucial for international B2B buyers, especially those involved in industries such as manufacturing, automotive, and machinery. Here are some essential properties:

-

Material Grade

Shoulder bolts can be made from various materials, including stainless steel, carbon steel, and alloys. The material grade affects the strength, corrosion resistance, and durability of the bolt. For example, a shoulder bolt made from AISI 304 stainless steel offers excellent corrosion resistance, making it ideal for outdoor applications or in humid environments, commonly seen in regions like the Middle East. -

Shoulder Diameter

The diameter of the shoulder is a critical specification that determines the bolt’s load-bearing capacity and fit in the assembly. A precise shoulder diameter ensures that the bolt can pivot freely when used as a pivot point, which is essential in mechanical designs. Buyers should verify this measurement to ensure compatibility with their components. -

Length of the Shoulder

The length of the shoulder must align with the application requirements. A longer shoulder provides more surface area for load distribution, which can enhance stability. Understanding the required shoulder length helps buyers avoid issues related to insufficient support or overhang, which can lead to mechanical failures. -

Tolerance

Tolerance defines the permissible limits of variation in dimensions. For shoulder bolts, tight tolerances are crucial for applications requiring precise alignment and functionality. This property is particularly important for OEMs (Original Equipment Manufacturers) who demand exact specifications to ensure interoperability with other components. -

Coating and Finish

The surface finish and any coatings applied to shoulder bolts can significantly impact their performance and longevity. For instance, zinc plating provides a layer of protection against corrosion, while a black oxide finish may reduce glare and enhance aesthetics. Buyers should consider the environmental conditions their products will face to choose the appropriate coating.

What Are Common Trade Terms Related to Shoulder Bolts?

Familiarizing oneself with industry terminology can streamline the purchasing process and enhance communication with suppliers. Here are some commonly used terms in the context of shoulder bolts:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that may be marketed by another manufacturer. For shoulder bolts, OEMs often require specific designs and materials tailored to their machinery, making it essential for buyers to understand their exact needs when sourcing. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding the MOQ is vital for budgeting and inventory management. International buyers should negotiate MOQs that align with their production needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and terms for a specific product, such as shoulder bolts. Buyers should prepare detailed RFQs that outline their specifications to receive accurate quotes and avoid miscommunication. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the risk and costs at various stages of shipping. Understanding Incoterms is crucial for buyers to mitigate risks and ensure smooth delivery processes. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For shoulder bolts, lead times can vary based on manufacturing processes and supplier location. Buyers should factor in lead times when planning production schedules to avoid delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they procure the right shoulder bolts for their specific applications while optimizing their supply chain processes.

Navigating Market Dynamics and Sourcing Trends in the shoulder bolt Sector

What Are the Key Market Dynamics Driving the Shoulder Bolt Sector?

The shoulder bolt market is currently experiencing significant growth driven by various global factors. The increasing demand for precision-engineered components in industries such as automotive, aerospace, and manufacturing is reshaping the landscape. Notably, emerging markets in Africa and South America are witnessing a surge in infrastructure development, which is driving the demand for high-quality fastening solutions like shoulder bolts. Moreover, the push for automation and Industry 4.0 is prompting manufacturers to source advanced fastening solutions that enhance efficiency and reliability.

In addition to traditional sourcing methods, B2B buyers are increasingly leveraging digital platforms and e-commerce solutions to streamline procurement processes. This shift is particularly relevant for buyers from the Middle East and Europe, where advanced technologies are being integrated into supply chain management. The rise of data analytics and artificial intelligence is enabling businesses to predict market trends, optimize inventory, and improve supplier relationships. For international buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with their operational needs.

How Can B2B Buyers Incorporate Sustainability in Sourcing Shoulder Bolts?

Sustainability has emerged as a critical consideration for B2B buyers in the shoulder bolt sector. The environmental impact of manufacturing processes and the importance of ethical supply chains are now paramount. Buyers should prioritize suppliers who adhere to sustainable manufacturing practices, such as minimizing waste, reducing carbon emissions, and utilizing renewable energy sources.

Moreover, certifications like ISO 14001 for environmental management and adherence to RoHS (Restriction of Hazardous Substances) are becoming increasingly important. These certifications not only ensure compliance with regulations but also signal a commitment to sustainability. International buyers should seek suppliers who offer eco-friendly materials, such as recycled metals or biodegradable coatings, which can contribute to a more sustainable supply chain.

As global consumers become more environmentally conscious, sourcing shoulder bolts from ethical suppliers can enhance a company’s brand reputation and appeal to a broader customer base. By investing in sustainable sourcing practices, B2B buyers can not only fulfill their corporate social responsibility but also drive innovation in their procurement processes.

A stock image related to shoulder bolt.

What Is the Historical Context of Shoulder Bolts in B2B Markets?

The shoulder bolt has evolved significantly since its inception, adapting to the changing needs of various industries. Initially used in simple mechanical applications, shoulder bolts have transformed into critical components for high-performance machinery. Over the decades, advancements in materials science and manufacturing technology have led to the development of shoulder bolts that offer greater strength, durability, and precision.

As industries have progressed, so too has the complexity of shoulder bolt designs. Today’s market features a wide range of options, including custom sizes and materials tailored to specific applications. This evolution reflects the broader trends in manufacturing and engineering, where precision and reliability are non-negotiable. Understanding this historical context can help B2B buyers appreciate the technological advancements that influence their sourcing decisions today.

In summary, navigating the shoulder bolt sector requires international B2B buyers to stay informed about market dynamics, embrace sustainability, and recognize the historical evolution of these essential components. By leveraging this knowledge, buyers can make strategic decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of shoulder bolt

-

How do I choose the right shoulder bolt for my application?

Choosing the right shoulder bolt involves understanding your specific application requirements, including load capacity, dimensions, and material compatibility. Start by identifying the diameter and length you need, as well as the shoulder length, which affects how the bolt fits into the assembly. Consider the material, such as stainless steel for corrosion resistance or carbon steel for strength. Consult with suppliers to ensure the shoulder bolt meets industry standards and can withstand the operational conditions of your project. -

What factors should I consider when sourcing shoulder bolts internationally?

When sourcing shoulder bolts internationally, consider factors such as supplier reliability, material quality, compliance with international standards, and shipping logistics. It’s essential to vet suppliers by checking their certifications, industry experience, and customer reviews. Additionally, evaluate potential tariffs and import regulations in your country, as these can impact costs and delivery times. Establish clear communication channels to discuss technical specifications and ensure that the supplier can accommodate your needs. -

What are the typical minimum order quantities (MOQs) for shoulder bolts?

Minimum order quantities for shoulder bolts can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 100 to several thousand units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new design or entering a new market. Some manufacturers may offer lower MOQs for customized or high-value products, allowing you to manage inventory risks effectively. -

What payment terms are common when purchasing shoulder bolts from international suppliers?

Common payment terms for international purchases of shoulder bolts include options such as advance payment, letter of credit, and open account. Advance payments may be required for new suppliers, while established relationships might allow for credit terms. Understand the payment structure, including any fees associated with currency conversion or international transfers. Always ensure that payment terms are documented in your purchase agreement to avoid disputes. -

How can I ensure the quality of shoulder bolts from my supplier?

To ensure quality, request detailed product specifications and certifications from your supplier, such as ISO 9001 or other relevant industry standards. Consider implementing a quality assurance process, which may include third-party inspections or audits of the manufacturing facility. Additionally, ask for samples before committing to a larger order to assess the product’s quality firsthand. Regular communication with your supplier about quality expectations is crucial for maintaining standards. -

What are the best logistics practices for importing shoulder bolts?

Effective logistics practices for importing shoulder bolts involve selecting reliable shipping methods and understanding customs regulations in your country. Work with experienced freight forwarders who can handle documentation, customs clearance, and transportation. It’s also advisable to plan for potential delays by allowing extra time for shipping and customs processing. Tracking shipments and maintaining clear communication with your supplier can help mitigate risks associated with international logistics. -

Can shoulder bolts be customized for specific applications?

Yes, many manufacturers offer customization options for shoulder bolts, including alterations in dimensions, materials, and finishes. Customization can help you meet specific application requirements or design constraints. Discuss your needs with potential suppliers, providing detailed drawings or specifications. Be mindful that customized products may have longer lead times and higher costs, so factor these into your procurement planning. -

What are the common industries that utilize shoulder bolts?

Shoulder bolts are commonly used across various industries, including automotive, aerospace, machinery, and electronics. They are particularly beneficial in applications requiring precise alignment and load distribution, such as in assembly systems or hinge mechanisms. Understanding the industries that frequently utilize shoulder bolts can help you target your sourcing efforts and identify suppliers with relevant expertise and product offerings tailored to your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for shoulder bolt

The strategic sourcing of shoulder bolts is a pivotal aspect for businesses looking to enhance their operational efficiency and product quality. By understanding the various factors influencing pricing, availability, and supplier reliability, international B2B buyers can make informed decisions that align with their strategic goals. Key takeaways include the importance of diversifying supplier networks, leveraging technological advancements for procurement processes, and maintaining an agile approach to inventory management.

What are the benefits of strategic sourcing for shoulder bolts? Strategic sourcing not only reduces costs but also fosters stronger relationships with suppliers, ensuring consistent quality and timely delivery. For buyers in Africa, South America, the Middle East, and Europe, developing a robust sourcing strategy can lead to significant competitive advantages in their respective markets.

Looking ahead, businesses should remain proactive in adapting to market trends and shifts in demand. By investing in supplier partnerships and embracing innovative sourcing solutions, international buyers can position themselves for long-term success. It’s time to take the next step—evaluate your current sourcing strategies and explore how optimizing your shoulder bolt procurement can drive operational excellence and growth in your organization.