Enhance Connectivity: The Ultimate Cat 6e Cable Guide (2025)

Introduction: Navigating the Global Market for cat 6e cable

In today’s interconnected world, sourcing reliable cat 6e cables is crucial for businesses aiming to enhance their network performance and connectivity. However, international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, often face significant challenges in navigating the complexities of global suppliers, varying standards, and fluctuating prices. This guide serves as an essential resource, empowering you to make informed purchasing decisions that align with your organization’s specific needs.

Throughout this comprehensive guide, we will explore various types of cat 6e cables, their applications across different industries, and the critical factors to consider when selecting a supplier. We will delve into the nuances of vetting suppliers to ensure quality and reliability, as well as provide insights into pricing strategies that can help optimize your procurement budget. Furthermore, we will address the importance of compliance with local and international standards, which is vital for maintaining operational efficiency.

By equipping you with actionable insights and a clear understanding of the cat 6e cable market, this guide aims to simplify your procurement process. Whether you are a buyer in Poland seeking the best deals or a tech manager in South America looking to upgrade your infrastructure, you will find valuable information tailored to your region and business context. Join us as we navigate the global market for cat 6e cables and unlock the potential for enhanced connectivity in your organization.

Understanding cat 6e cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Unshielded Twisted Pair (UTP) | No additional shielding, cost-effective | Office networking, data centers | Pros: Affordable, widely available. Cons: Less resistant to interference. |

| Shielded Twisted Pair (STP) | Additional shielding to reduce interference | Industrial environments, high-speed networks | Pros: Better performance in noisy environments. Cons: Higher cost and bulkier. |

| Foiled Twisted Pair (FTP) | Each pair is shielded with foil | Telecommunications, broadcasting | Pros: Balanced cost and performance. Cons: Less effective than STP in extreme interference. |

| Category 6e Plenum | Rated for plenum spaces, fire-resistant | Air-handling spaces in commercial buildings | Pros: Safety compliant, reduces fire hazards. Cons: More expensive than standard cables. |

| Category 6e Outdoor | UV-resistant and waterproof | External installations, outdoor networks | Pros: Durable, weatherproof. Cons: Limited availability and higher cost. |

What are the Characteristics of Unshielded Twisted Pair (UTP) Cables?

Unshielded Twisted Pair (UTP) cables are the most common type of Cat 6e cable, characterized by their cost-effectiveness and simplicity. They consist of pairs of wires twisted together to reduce crosstalk. UTP is suitable for standard office networking and data center applications where electromagnetic interference (EMI) is minimal. When purchasing UTP cables, B2B buyers should consider the environment in which the cables will be installed, as their lack of shielding makes them less effective in areas with high interference.

Why Choose Shielded Twisted Pair (STP) Cables for Industrial Applications?

Shielded Twisted Pair (STP) cables incorporate shielding that protects against external interference, making them ideal for industrial settings or high-speed networks where EMI is prevalent. The added shielding can enhance signal quality, thus reducing data loss. Buyers in sectors like manufacturing and telecommunications should prioritize STP cables when operating in electrically noisy environments, despite the higher cost and bulkiness compared to UTP.

What are the Benefits of Using Foiled Twisted Pair (FTP) Cables?

Foiled Twisted Pair (FTP) cables provide a middle ground between UTP and STP. Each twisted pair is shielded with foil, offering moderate protection against interference. This makes FTP suitable for telecommunications and broadcasting applications where some level of shielding is beneficial but where conditions are not as severe as in industrial environments. B2B buyers should evaluate the specific interference levels in their application to determine if the balance of cost and performance offered by FTP is suitable.

When Should You Consider Category 6e Plenum Cables?

Category 6e Plenum cables are designed for installation in plenum spaces, which are areas used for air circulation in heating and air conditioning systems. These cables are fire-resistant and comply with safety standards, making them essential for commercial buildings. B2B buyers need to weigh the safety benefits against the higher costs when considering plenum-rated cables, especially in environments where safety regulations are stringent.

How Do Outdoor Category 6e Cables Stand Out?

Outdoor Category 6e cables are engineered to withstand harsh weather conditions, featuring UV-resistant and waterproof materials. This makes them ideal for external installations and outdoor networking applications. B2B buyers looking for durability and longevity in outdoor environments must consider these cables, despite their limited availability and higher price point compared to standard cables.

Related Video: CAT6 CABLE RUN AND CAT6 WALL FISHING – HOW TO – QUICK & EASY!

Key Industrial Applications of cat 6e cable

| Industry/Sector | Specific Application of cat 6e cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed internet infrastructure | Enhanced connectivity and bandwidth for data-intensive operations | Ensure compatibility with existing network systems and standards |

| Manufacturing | Industrial automation and control systems | Improved data transfer rates for real-time monitoring and control | Look for cables that can withstand harsh environments |

| Healthcare | Medical imaging and diagnostic equipment | Reliable data transmission for critical patient information | Consider cables with shielding to reduce interference |

| Education | Campus-wide networking solutions | Seamless connectivity for online learning and administration | Evaluate installation support and scalability options |

| Retail | Point of Sale (POS) systems integration | Faster transaction processing and improved customer experience | Assess compatibility with various POS systems and devices |

How is Cat 6e Cable Used in Telecommunications?

In the telecommunications sector, Cat 6e cables are vital for establishing high-speed internet infrastructure. They support extensive data transmission, which is crucial for businesses that rely on cloud services or large-scale data processing. By using Cat 6e cables, companies can improve their connectivity and bandwidth, enabling them to handle increased traffic without compromising performance. International buyers should prioritize sourcing cables that meet local and international standards to ensure compatibility with existing systems.

What Role Does Cat 6e Cable Play in Manufacturing?

In manufacturing, Cat 6e cables are extensively used for industrial automation and control systems. They facilitate the transfer of data between machinery and monitoring systems, allowing for real-time adjustments and enhanced operational efficiency. This capability is essential for businesses aiming to optimize production processes and reduce downtime. Buyers should consider the environmental conditions of their facilities, ensuring that the cables can endure factors like temperature fluctuations and mechanical stress.

Why is Cat 6e Cable Important in Healthcare?

The healthcare industry benefits significantly from Cat 6e cables, particularly in the realm of medical imaging and diagnostic equipment. These cables ensure the reliable transmission of critical patient data, which is essential for timely and accurate diagnoses. The high bandwidth capabilities of Cat 6e cables support the large file sizes associated with imaging technologies. Buyers in this sector should look for cables with shielding properties to minimize interference, ensuring that patient data remains secure and accurate.

How Does Cat 6e Cable Enhance Education?

In educational institutions, Cat 6e cables are essential for campus-wide networking solutions. They provide seamless connectivity for online learning platforms and administrative functions, enhancing the overall educational experience. Reliable internet access supports both students and faculty in accessing resources and collaborating effectively. B2B buyers in this sector should evaluate the scalability of the cabling solutions to accommodate future growth in student populations and technological advancements.

What is the Significance of Cat 6e Cable in Retail?

In the retail industry, Cat 6e cables are integral to the integration of Point of Sale (POS) systems. They enable faster transaction processing, which is critical for enhancing customer experiences and operational efficiency. By ensuring that POS systems are connected with minimal latency, retailers can improve service speed and accuracy. Buyers should assess the compatibility of Cat 6e cables with various POS systems to ensure a smooth integration process.

Related Video: What is Cat6 cable? CAT6 Cabling ( CAT6 Ethernet Cable)

3 Common User Pain Points for ‘cat 6e cable’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Existing Infrastructure

The Problem:

B2B buyers often face challenges when integrating Cat 6e cables with existing network infrastructure. For companies that have invested in older cabling systems, the fear of compatibility issues can be a significant barrier. This situation is particularly common in regions where technology upgrades have lagged, such as parts of Africa and South America. Buyers may worry that the new cables will not function optimally with older hardware, leading to downtime and increased costs.

The Solution:

To mitigate compatibility concerns, it’s crucial to conduct a thorough assessment of the current network infrastructure before purchasing Cat 6e cables. Start by evaluating the existing cabling standards, connectors, and hardware specifications. It’s advisable to consult with a network engineer who can provide insights into potential compatibility issues. When sourcing Cat 6e cables, opt for those that offer backward compatibility with older standards like Cat 5e or Cat 6. Ensure that the cables are certified and come with a warranty, as this can provide peace of mind regarding their performance. Additionally, investing in modular components that facilitate easy upgrades can enhance long-term compatibility and scalability.

Scenario 2: Poor Installation Leading to Network Performance Issues

The Problem:

Another common pain point for B2B buyers is the improper installation of Cat 6e cables, which can significantly impact network performance. In many regions, including the Middle East and Europe, companies may rely on third-party contractors for installation, which can lead to subpar workmanship. Issues such as improper bending, inadequate cable management, or incorrect termination can result in reduced bandwidth and increased latency, undermining the benefits of investing in high-quality cabling.

The Solution:

To ensure optimal installation of Cat 6e cables, companies should prioritize choosing experienced and certified installers. It’s beneficial to establish clear installation guidelines that align with industry best practices. Providing comprehensive training for installation teams can also be advantageous, particularly in regions where technical skills may vary. Moreover, consider conducting pre-installation site surveys to identify potential challenges, such as physical obstructions and environmental factors that could affect cable performance. After installation, conducting thorough testing with a cable certification tester can help identify any issues before the network goes live, ensuring that performance standards are met.

Scenario 3: Navigating Regulatory Compliance and Standards

The Problem:

B2B buyers often struggle to navigate the complex landscape of regulatory compliance and industry standards related to cabling systems. This issue is particularly pronounced in Europe, where strict regulations govern telecommunications infrastructure. Buyers may find it challenging to ensure that their chosen Cat 6e cables meet local and international compliance requirements, which can lead to legal issues and additional costs.

The Solution:

To effectively navigate regulatory compliance, it’s essential for B2B buyers to stay informed about the latest standards and regulations applicable to their region. Engaging with local industry associations or regulatory bodies can provide valuable insights into the specific requirements for cabling installations. When sourcing Cat 6e cables, always look for products that are certified by recognized standards organizations, such as ISO or IEC, to ensure compliance. Additionally, consider working with suppliers who have a proven track record of adhering to local regulations. Creating a checklist that outlines necessary compliance measures can streamline the procurement process and reduce the risk of non-compliance penalties.

Strategic Material Selection Guide for cat 6e cable

When selecting materials for Cat 6e cables, it’s essential for international B2B buyers to understand the properties, advantages, and limitations of various materials. The choice of material not only affects performance but also compliance with regional standards and overall project costs. Below, we analyze four common materials used in Cat 6e cables: copper, aluminum, PVC, and LSZH.

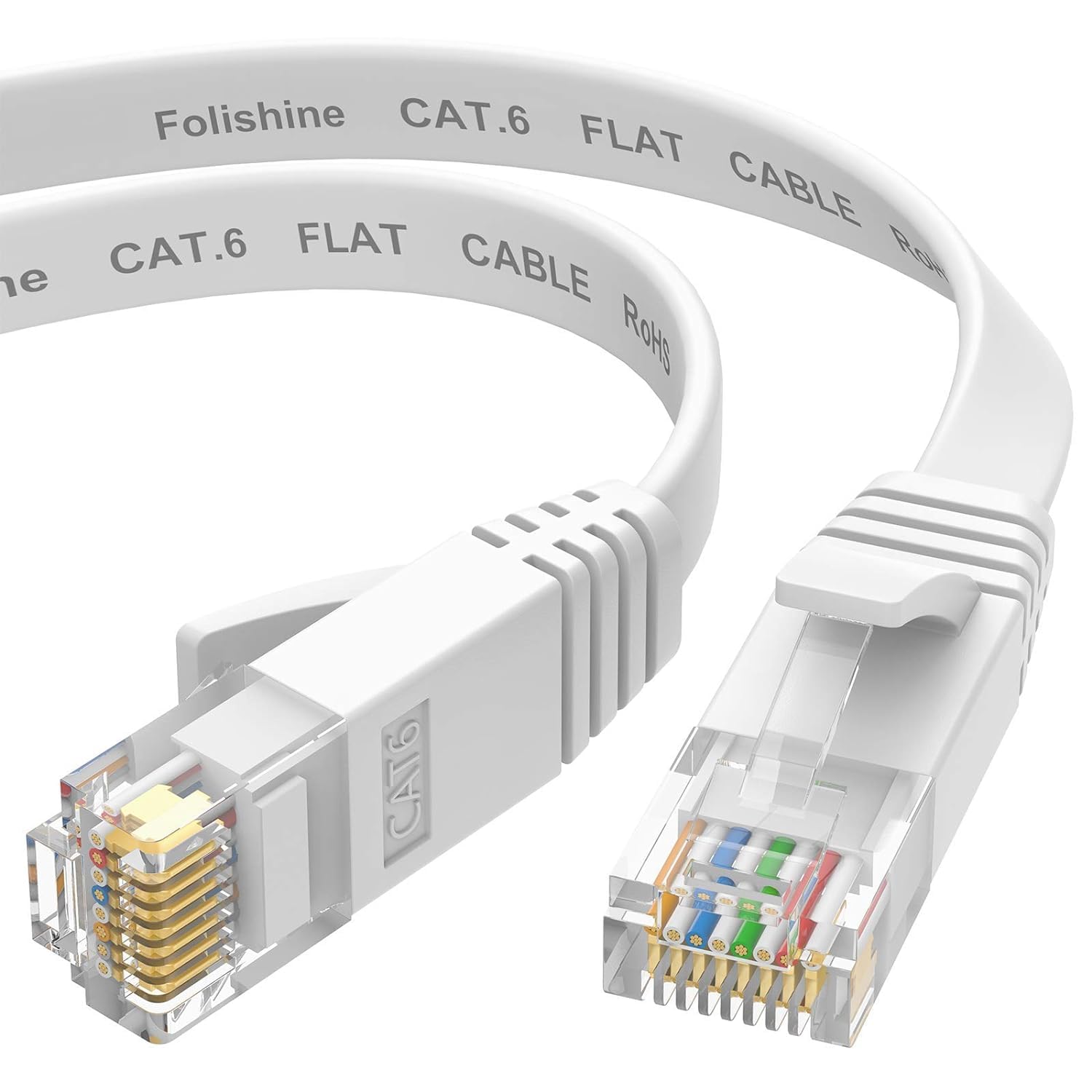

A stock image related to cat 6e cable.

What Are the Key Properties of Copper for Cat 6e Cables?

Copper is the most widely used conductor material for Cat 6e cables due to its excellent electrical conductivity, thermal properties, and mechanical strength. It typically operates effectively within a temperature range of -20°C to 60°C. Additionally, copper exhibits good resistance to corrosion, making it suitable for various environmental conditions.

Pros and Cons of Using Copper

The primary advantage of copper is its superior conductivity, which ensures minimal signal loss and high data transmission rates. However, copper is more expensive than other materials, which can be a significant factor for B2B buyers in cost-sensitive markets. The manufacturing process for copper cables can also be complex, requiring skilled labor and specialized equipment.

Impact on Application

Copper’s compatibility with high-frequency signals makes it ideal for applications requiring high data rates, such as data centers and enterprise networks. Buyers must also consider compliance with international standards, such as ASTM and DIN, to ensure product quality.

How Does Aluminum Compare as a Material for Cat 6e Cables?

Aluminum is a lighter and less expensive alternative to copper. Although it has lower conductivity, advancements in alloy technology have improved its performance for data transmission. Aluminum cables typically have a temperature rating similar to copper, around -20°C to 60°C, but they may be less resistant to corrosion.

Pros and Cons of Using Aluminum

The main advantage of aluminum is its lower cost and weight, making it easier to install and transport. However, the trade-off is reduced conductivity, which can lead to higher attenuation rates. This makes aluminum less suitable for long-distance data transmission without additional amplification.

Impact on Application

Aluminum is often used in less critical applications where cost is a primary concern. B2B buyers should be cautious about the potential for signal degradation and ensure that the application does not exceed the material’s limitations.

What Are the Benefits of PVC in Cat 6e Cables?

Polyvinyl Chloride (PVC) is a common insulation material used in Cat 6e cables. It is known for its durability and resistance to moisture, chemicals, and UV radiation. PVC cables typically operate effectively within a temperature range of -15°C to 70°C.

Pros and Cons of Using PVC

PVC offers excellent mechanical strength and is cost-effective, making it a popular choice for many applications. However, it can emit toxic fumes when burned, which may raise safety concerns in certain environments. Additionally, PVC is less flexible than other materials, which can complicate installation in tight spaces.

Impact on Application

PVC is suitable for indoor applications and environments where exposure to harsh conditions is minimal. Buyers must consider local regulations regarding fire safety and material compliance, especially in regions with stringent building codes.

Why Choose LSZH for Cat 6e Cables?

Low Smoke Zero Halogen (LSZH) materials are designed to emit minimal smoke and no halogen when exposed to fire. This makes LSZH an excellent choice for environments where safety is a concern, such as public buildings and transportation systems.

Pros and Cons of Using LSZH

The primary advantage of LSZH is its safety profile, significantly reducing the risk of toxic smoke in case of fire. However, LSZH materials can be more expensive than PVC and may have slightly lower mechanical properties, which can affect durability.

Impact on Application

LSZH is ideal for applications in densely populated areas or where safety regulations are stringent. B2B buyers should ensure that LSZH products comply with local fire safety standards and certifications.

Summary Table of Material Properties for Cat 6e Cables

| Material | Typical Use Case for Cat 6e Cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Data centers, enterprise networks | Superior conductivity and low signal loss | High cost and complex manufacturing | High |

| Aluminum | Cost-sensitive applications | Lightweight and cost-effective | Lower conductivity and higher attenuation | Medium |

| PVC | Indoor installations | Durable and moisture-resistant | Toxic fumes when burned, less flexible | Low |

| LSZH | Public buildings, transport systems | Low smoke and halogen emissions | Higher cost and reduced durability | Medium |

By understanding these materials’ properties and implications, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements, ensuring successful project outcomes.

In-depth Look: Manufacturing Processes and Quality Assurance for cat 6e cable

What Are the Key Stages in the Manufacturing Process of Cat 6e Cable?

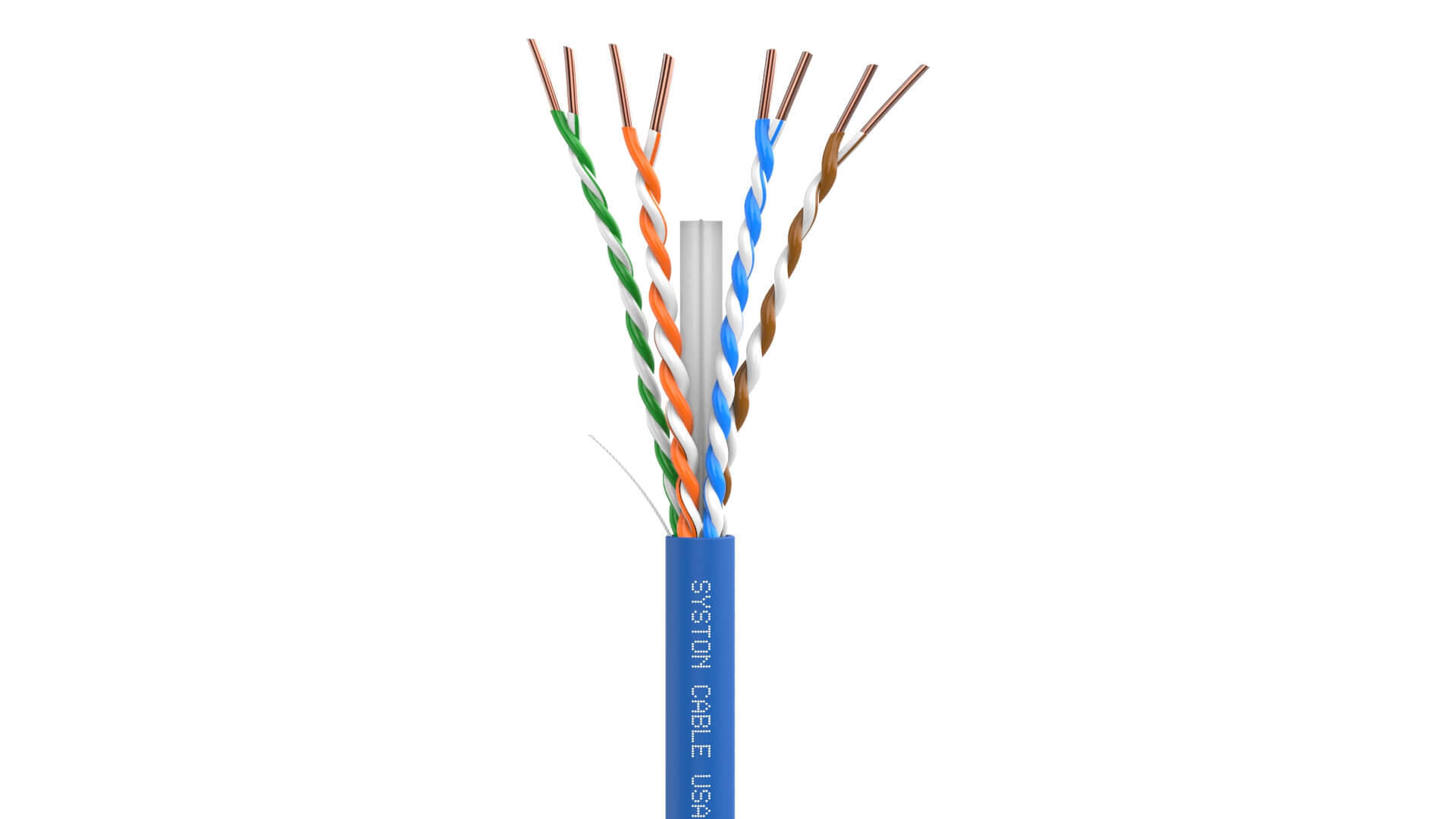

A stock image related to cat 6e cable.

The manufacturing of Cat 6e cables involves several critical stages that ensure high performance and reliability. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

-

Material Preparation

The first step in manufacturing Cat 6e cables is the preparation of raw materials. This typically involves selecting high-quality copper wires for the conductors and ensuring that insulation materials meet specific standards. The choice of materials significantly affects the cable’s performance, particularly in terms of attenuation and crosstalk. -

Forming

During the forming stage, the copper wires are drawn down to the required diameter and twisted into pairs. The twisting is essential for reducing electromagnetic interference. Precision in this stage is crucial, as improper twisting can lead to signal degradation. -

Assembly

After forming, the cable undergoes assembly, where the twisted pairs are grouped and encased in a protective jacket. This stage may include the addition of shielding to further reduce interference. The assembly process must be conducted in a dust-free environment to avoid contamination that could impact performance. -

Finishing

The finishing stage involves cutting the cables to the desired lengths, applying connectors, and conducting final inspections. It’s essential that this stage adheres to strict quality standards to ensure that the finished product meets international specifications.

How Is Quality Assurance Implemented in Cat 6e Cable Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of Cat 6e cables, ensuring that the final products meet both international standards and customer expectations. Here’s how quality assurance is structured:

-

Understanding International Standards

Cat 6e cables must comply with various international standards, including ISO 9001 for quality management systems. Additional industry-specific standards, such as CE marking in Europe and UL certification in the USA, are also relevant. Buyers should familiarize themselves with these standards to ensure they are sourcing compliant products. -

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is necessary to detect any deviations from standard practices.

- Final Quality Control (FQC): Before shipping, a final inspection ensures that the product is free from defects and meets all specifications.

- Common Testing Methods for Cat 6e Cables

Various tests are performed to assess the performance of Cat 6e cables, including:

- Electrical Testing: Measures parameters like attenuation, crosstalk, and return loss.

- Mechanical Testing: Evaluates the cable’s flexibility and durability.

- Environmental Testing: Assesses performance under varying temperature and humidity conditions.

What Steps Can B2B Buyers Take to Verify Supplier Quality Assurance?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is crucial. Here are actionable steps:

-

Conduct Supplier Audits

Regular audits can help assess a supplier’s adherence to quality standards. Buyers should request audit reports that detail compliance with ISO and industry-specific standards. Engaging third-party auditors can provide an unbiased view of the supplier’s practices. -

Request Documentation and Certifications

Buyers should require documentation, including quality management system certifications, test reports, and compliance certificates. This documentation serves as proof of the supplier’s commitment to quality. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can further validate the quality of the cables. These services can perform random inspections at various stages of the manufacturing process, providing additional assurance of product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the quality control landscape can be complex for international buyers. Here are some nuances to consider:

-

Regional Standards Variability

Quality standards may vary significantly between regions. For instance, while CE marking is essential in Europe, other regions may have different certification requirements. Buyers should ensure that suppliers are compliant with the standards relevant to their specific market. -

Understanding the Supply Chain

It’s essential for buyers to understand the entire supply chain involved in the production of Cat 6e cables. This includes assessing the quality control practices of all suppliers involved, from raw material providers to component manufacturers. -

Building Long-Term Relationships

Establishing a long-term relationship with suppliers can lead to better quality assurance practices. Regular communication and feedback can help suppliers improve their processes, ultimately leading to higher-quality products.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for Cat 6e cables is vital for international B2B buyers. By focusing on the key stages of manufacturing, implementing robust quality control measures, and verifying supplier practices, buyers can ensure they procure high-quality cables that meet their business needs. This proactive approach not only enhances product performance but also fosters trust and reliability in supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cat 6e cable’

The purpose of this guide is to provide international B2B buyers with a structured approach to sourcing Cat 6e cables. As the demand for high-speed internet connectivity continues to rise, ensuring that you procure the right cables from reliable suppliers is crucial for maintaining network performance and reliability. This checklist will help you navigate the sourcing process effectively, minimizing risks and enhancing your procurement strategy.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications of the Cat 6e cable you require. Consider factors such as cable length, shielding type (STP or U/FTP), and installation environment (indoor vs. outdoor). Providing these details helps suppliers tailor their offerings to your needs and ensures compatibility with your existing infrastructure.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for Cat 6e cables can give you leverage during negotiations. Analyze price fluctuations in different regions, especially in Africa, South America, the Middle East, and Europe. Utilize industry reports and online marketplaces to gauge average costs and identify potential suppliers who offer competitive pricing without compromising on quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong track record in delivering Cat 6e cables and verify their ability to meet your volume requirements and delivery timelines.

- Supplier Certifications: Check for relevant certifications such as ISO 9001, which indicates a commitment to quality management.

- Customer Reviews: Read reviews and testimonials from past customers to gauge reliability and service quality.

Step 4: Request Samples and Test Quality

Always request samples of the Cat 6e cables before making a bulk order. Testing these samples for performance metrics—such as bandwidth capabilities and resistance to interference—can save you from costly mistakes. Ensure the cables meet industry standards, such as TIA/EIA-568-B, to guarantee optimal performance.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate favorable terms and conditions. Pay attention to payment terms, warranty policies, and return procedures. Clear agreements on these aspects can protect your investment and ensure a smooth procurement process.

- Volume Discounts: Inquire about pricing tiers based on order volume.

- Delivery Schedules: Confirm lead times and logistics to avoid disruptions in your project timelines.

Step 6: Establish a Communication Plan

Effective communication with your supplier throughout the procurement process is vital. Establish a point of contact and set up regular check-ins to discuss order status and address any concerns. This proactive approach fosters a collaborative relationship and helps mitigate potential issues before they escalate.

Step 7: Monitor Delivery and Inspect Upon Arrival

Upon delivery, inspect the Cat 6e cables for any damage or discrepancies against your order. This step is crucial to ensure that you receive the correct quantities and specifications. Document any issues immediately and communicate with the supplier to resolve them promptly, safeguarding your project timeline and budget.

By following this checklist, B2B buyers can streamline their sourcing process for Cat 6e cables, ensuring they make informed decisions that align with their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for cat 6e cable Sourcing

What Are the Key Cost Components in Cat 6e Cable Sourcing?

When sourcing Cat 6e cables, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing Cat 6e cables significantly influence pricing. Copper, for instance, is a primary material, and fluctuations in copper prices can directly affect overall costs. Additionally, the insulation and shielding materials chosen can also impact pricing.

-

Labor: Labor costs can vary widely depending on the region where the cables are manufactured. Countries with lower labor costs may offer more competitive pricing, but this can sometimes result in trade-offs in quality.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can lower overhead, which can translate to more competitive pricing for buyers.

-

Tooling: The initial investment in tooling and machinery can be significant, especially for custom specifications. Buyers should consider whether the supplier has the necessary capabilities to produce the required specifications without incurring excessive tooling costs.

-

Quality Control (QC): Stringent quality control processes ensure that products meet international standards. While higher QC standards may raise production costs, they can ultimately reduce the risk of returns and warranty claims, benefiting the buyer in the long run.

-

Logistics: Shipping costs can vary based on the distance from the manufacturer to the buyer, shipping methods, and regional tariffs. Understanding these logistics costs is essential to calculate the total cost of ownership accurately.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary widely based on the supplier’s market positioning, brand reputation, and the competitive landscape.

How Do Price Influencers Impact Cat 6e Cable Costs?

Several factors influence the pricing of Cat 6e cables, making it essential for buyers to be aware of these elements:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the per-unit cost. Buyers should negotiate for favorable terms based on their anticipated order volume to secure better pricing.

-

Specifications and Customization: Customization can lead to increased costs. Buyers should clearly define their specifications upfront to avoid unexpected price hikes during the production process.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., UL, ISO) can lead to increased costs, but they also offer better performance and reliability. It is advisable for buyers to weigh the long-term benefits against the initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge higher prices due to perceived quality and service levels. Conducting thorough supplier evaluations can help identify the best value.

-

Incoterms: Understanding the chosen Incoterms is vital for cost management. Different terms dictate who bears the cost and risk at various stages of transportation, which can affect overall pricing and logistics planning.

What Buyer Tips Can Enhance Cost-Efficiency in Cat 6e Cable Sourcing?

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing Cat 6e cables:

-

Negotiation Skills: Strong negotiation can yield significant savings. Buyers should come prepared with market research and comparable quotes to leverage better pricing.

-

Understanding Total Cost of Ownership (TCO): Evaluating TCO, which includes purchase price, logistics, maintenance, and potential failure costs, can provide a clearer picture of the true cost of sourcing decisions.

-

Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe must be aware of regional pricing trends and potential import duties or tariffs that could affect costs. Engaging local experts or consultants can provide insights into these nuances.

Disclaimer on Indicative Prices

Prices for Cat 6e cables can vary significantly based on the aforementioned factors, and it is essential to conduct thorough market research and supplier negotiations to obtain accurate pricing. The insights provided here are indicative and should be used as a guideline for better decision-making in sourcing Cat 6e cables.

Alternatives Analysis: Comparing cat 6e cable With Other Solutions

Understanding Alternatives to Cat 6E Cable

When considering networking solutions, it’s crucial to evaluate various options available in the market. While Cat 6E cable offers high performance and reliability, several alternative technologies can also meet the needs of international B2B buyers. This section will compare Cat 6E cable with fiber optic cables and Cat 7 cables, highlighting their respective strengths and weaknesses.

| Comparison Aspect | Cat 6E Cable | Fiber Optic Cable | Cat 7 Cable |

|---|---|---|---|

| Performance | Up to 10 Gbps at 55 meters | Up to 100 Gbps over long distances | Up to 10 Gbps over 100 meters |

| Cost | Moderate cost | Higher initial investment | Higher than Cat 6E, lower than Fiber Optic |

| Ease of Implementation | Relatively easy to install | More complex installation | Requires specialized connectors |

| Maintenance | Low maintenance | Very low maintenance | Low maintenance |

| Best Use Case | Small to medium networks | Large enterprises needing high speed over distances | Data centers requiring high bandwidth |

What are the Pros and Cons of Fiber Optic Cables?

Fiber optic cables transmit data using light, which allows for incredibly high speeds and bandwidth capabilities. One of the most significant advantages of fiber optics is their ability to cover long distances without losing signal quality. This makes them ideal for large enterprises or organizations with extensive networking needs. However, the installation process can be complex and may require specialized expertise, leading to higher upfront costs. Additionally, while fiber optic cables are generally more durable, they can be more fragile than traditional copper cables.

How Does Cat 7 Compare to Cat 6E Cables?

Cat 7 cables provide similar performance levels to Cat 6E but with improved shielding and reduced crosstalk. This makes them suitable for environments with high electromagnetic interference, such as data centers or industrial settings. Cat 7 supports higher frequencies, allowing for faster data rates over longer distances compared to Cat 6E. However, they tend to be more expensive and may require specialized connectors that can complicate installation. For businesses prioritizing performance in challenging environments, Cat 7 may be a worthwhile investment.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate networking solution, B2B buyers should evaluate their specific requirements, including budget constraints, installation capabilities, and performance needs. For small to medium enterprises with straightforward networking demands, Cat 6E cables provide an excellent balance of performance and cost. However, organizations anticipating high data traffic over long distances or those in challenging environments may find fiber optic or Cat 7 solutions more suitable. Understanding the nuances of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for cat 6e cable

What Are the Key Technical Properties of Cat 6e Cable?

When assessing Cat 6e cable for your business needs, understanding its technical properties is vital. These specifications influence performance, reliability, and the overall effectiveness of your networking infrastructure.

1. Material Grade: Why Is It Crucial for Performance?

Cat 6e cables typically utilize high-quality copper conductors, which are essential for maintaining signal integrity and minimizing attenuation. The standard copper wire gauge for Cat 6e is 23 AWG (American Wire Gauge), which balances flexibility and performance. For B2B buyers, selecting cables with superior material grades ensures better longevity and less frequent replacements, reducing long-term costs.

2. Bandwidth: How Does It Impact Data Transmission?

Bandwidth refers to the maximum data transfer rate of the cable. Cat 6e cables support bandwidths up to 1 Gbps (Gigabits per second) over 100 meters, with some capable of 10 Gbps over shorter distances. This high bandwidth is essential for businesses that rely on heavy data transmission, such as video conferencing or large file transfers, ensuring that operations run smoothly without bottlenecks.

3. Length and Tolerance: What Should Buyers Consider?

The effective length of Cat 6e cables can significantly impact performance. The recommended maximum length is 100 meters to maintain signal quality. Tolerance, which refers to the allowable deviation in length and electrical performance, is crucial for ensuring that installations meet specific networking requirements. Buyers should ensure that their suppliers adhere to these tolerances to avoid performance issues.

4. Shielding: How Does It Protect Against Interference?

Shielding refers to the protective layer around the conductors that reduces electromagnetic interference (EMI) and crosstalk between cables. Cat 6e cables may come in unshielded twisted pair (UTP) or shielded twisted pair (STP) configurations. For businesses in high-EMI environments, such as manufacturing or telecommunications, selecting STP cables can significantly improve signal quality and reliability.

What Are Common Trade Terms Related to Cat 6e Cable?

Understanding trade terminology is essential for making informed purchasing decisions. Here are some key terms that B2B buyers should be familiar with.

1. OEM (Original Equipment Manufacturer): What Does It Mean for Your Purchase?

OEM refers to companies that produce components that are used in another company’s end products. When dealing with Cat 6e cables, understanding the OEM can help buyers gauge quality and compatibility with existing systems. Opting for cables from reputable OEMs can ensure better performance and support.

2. MOQ (Minimum Order Quantity): How Does It Affect Bulk Purchases?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For businesses looking to purchase Cat 6e cables in bulk, knowing the MOQ is essential for budgeting and supply chain planning. It can also affect negotiations, as suppliers may offer better pricing for larger orders.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a document that a buyer submits to potential suppliers to solicit price quotes for specific products or services. For Cat 6e cables, an RFQ helps buyers compare pricing, terms, and conditions from different suppliers, ensuring they secure the best deal for their networking needs.

4. Incoterms: What Are They and How Do They Impact Shipping Costs?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, including shipping costs and risk management. Understanding Incoterms is crucial for B2B buyers, as they can significantly impact the total cost of procurement for Cat 6e cables, especially for international shipments.

Conclusion

Navigating the technical properties and trade terminology of Cat 6e cables can empower B2B buyers to make informed decisions. By understanding these critical elements, businesses from Africa, South America, the Middle East, and Europe can optimize their networking investments and ensure reliable communication infrastructure.

Navigating Market Dynamics and Sourcing Trends in the cat 6e cable Sector

What Are the Current Market Dynamics Driving the Cat 6e Cable Sector?

The Cat 6e cable sector is experiencing robust growth, driven by the increasing demand for high-speed internet connectivity and the expansion of data centers globally. Key markets in Africa, South America, the Middle East, and Europe, particularly Poland and the UK, are witnessing significant investments in telecommunications infrastructure. This surge is fueled by the rise of cloud computing, IoT devices, and smart city initiatives, which require reliable and fast networking solutions.

Emerging trends include a shift towards greater customization of cabling solutions to meet specific industrial needs, such as those in manufacturing and healthcare. Additionally, the rise of remote work has led to an increase in demand for robust home networking solutions, prompting manufacturers to innovate and enhance the performance of Cat 6e cables. Furthermore, the push for 5G technology is influencing the market as businesses prepare for faster data transmission speeds and lower latency.

International B2B buyers should also consider the impact of geopolitical factors and trade policies on sourcing. Tariffs and regulations can affect pricing and availability, making it essential to stay informed about the political climate in sourcing regions. Engaging with local suppliers can mitigate risks associated with international logistics and provide insights into regional market demands.

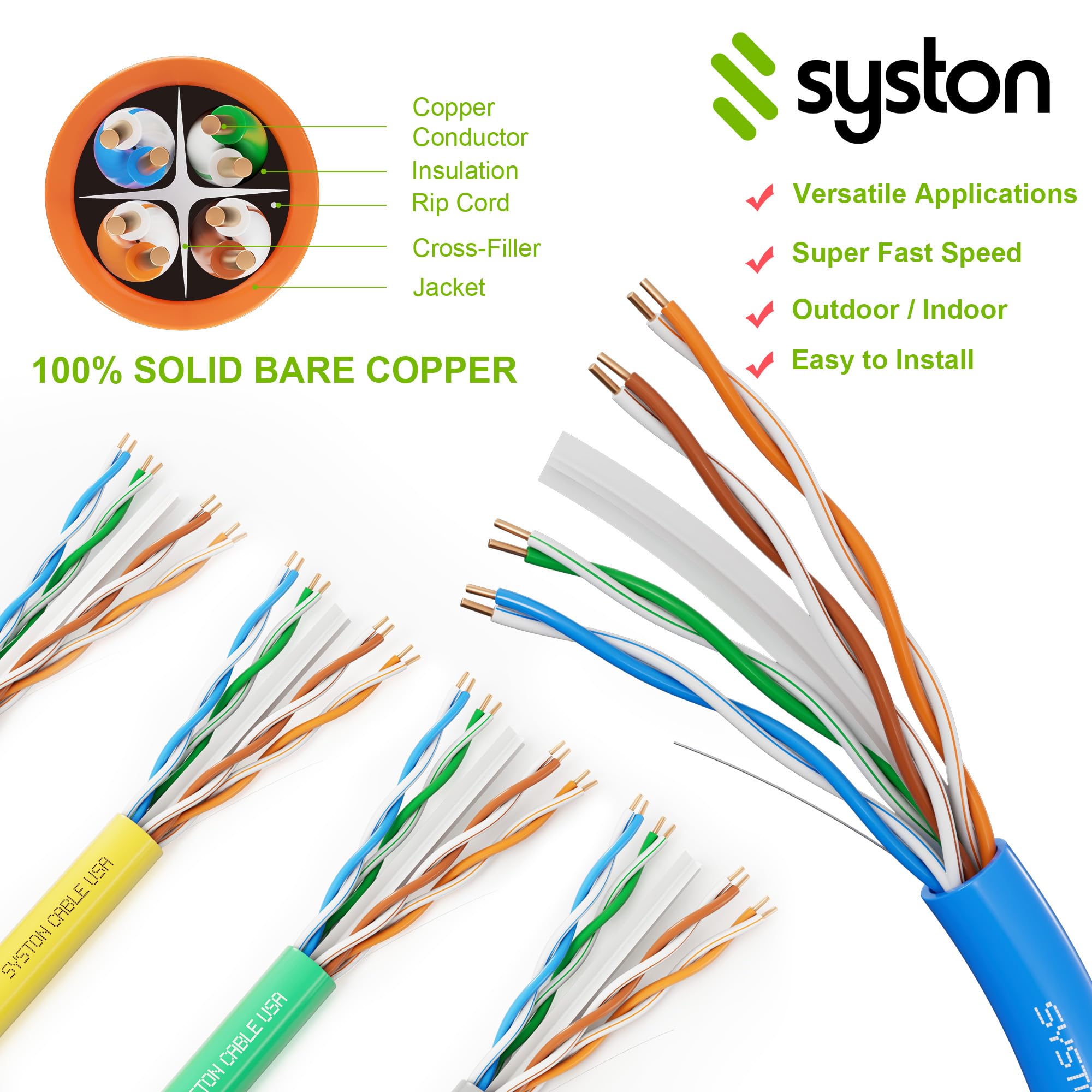

A stock image related to cat 6e cable.

How Can Sustainability and Ethical Sourcing Impact Your Cat 6e Cable Procurement?

As global awareness of environmental issues grows, sustainability and ethical sourcing have become critical considerations for B2B buyers in the Cat 6e cable market. The production of cables often involves materials that can have a significant environmental impact, including plastics and metals. Buyers are increasingly prioritizing suppliers who adopt sustainable practices and use eco-friendly materials.

The importance of ethical supply chains cannot be overstated. B2B buyers should seek manufacturers who comply with international environmental standards and hold certifications such as ISO 14001. These certifications indicate a commitment to reducing environmental impact and promoting sustainable practices throughout the supply chain.

Moreover, the use of “green” materials in cable production, such as recyclable plastics and low-impact manufacturing processes, is becoming a market differentiator. International buyers can enhance their brand reputation and appeal to environmentally conscious clients by aligning their procurement strategies with sustainability goals. This not only helps in meeting regulatory requirements but also positions companies as responsible corporate citizens in a competitive landscape.

How Has the Cat 6e Cable Market Evolved Over Time?

The Cat 6e cable market has evolved significantly since its inception, adapting to the rapid advancements in technology and changing consumer needs. Initially designed to support data transmission speeds of up to 1 Gbps, the Cat 6e cables have undergone enhancements to accommodate higher bandwidth demands, supporting speeds of up to 10 Gbps over short distances.

The evolution of networking technology, such as the advent of PoE (Power over Ethernet), has further driven innovations in cable design and functionality. As businesses increasingly rely on high-performance networking solutions, the Cat 6e cable has established itself as a reliable choice for both commercial and residential applications.

This historical perspective is essential for B2B buyers looking to make informed purchasing decisions. Understanding the evolution of Cat 6e cables helps in evaluating current offerings and anticipating future trends, ensuring that investments align with long-term technological advancements and market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of cat 6e cable

-

How do I choose the right cat 6e cable supplier for my business needs?

Selecting the right supplier for cat 6e cables involves evaluating several key factors. Start by assessing their industry reputation and experience, particularly in international markets. Look for suppliers who provide certifications and compliance with international standards like ISO and ANSI/TIA. Additionally, request samples to test the quality of their cables and verify their performance specifications. Consider their ability to customize products to meet your specific requirements, as well as their customer service and support for troubleshooting. Lastly, check reviews and testimonials from other businesses in your region. -

What are the benefits of using cat 6e cables for my network infrastructure?

Cat 6e cables offer several advantages for modern network infrastructure. They support high-speed data transmission up to 10 Gbps over short distances, making them ideal for bandwidth-intensive applications. The enhanced shielding reduces crosstalk and interference, which is crucial for maintaining network performance. Additionally, cat 6e cables are backward compatible with earlier standards, allowing for flexible network upgrades. This versatility makes them a cost-effective choice for businesses looking to future-proof their operations while ensuring reliable connectivity. -

What minimum order quantities (MOQ) should I expect when sourcing cat 6e cables?

Minimum order quantities for cat 6e cables can vary significantly depending on the supplier and your location. Many manufacturers may set a MOQ of 100 to 500 meters, while others might allow smaller quantities for trial orders. When negotiating with suppliers, inquire about their flexibility on MOQ, especially if you are a smaller business or new to the market. Establishing a relationship with your supplier may also lead to more favorable terms in the future, such as reduced MOQs for repeat orders. -

What payment terms are common when purchasing cat 6e cables internationally?

Payment terms for international purchases of cat 6e cables can differ based on the supplier’s policies and your negotiation. Common terms include advance payment, letters of credit, or payment upon delivery. It’s advisable to discuss and agree on payment methods that minimize risk, such as escrow services for large orders. Additionally, consider the impact of currency exchange rates and transaction fees on your total costs. Establishing clear payment terms upfront can help avoid misunderstandings and foster a smoother transaction process. -

How can I ensure quality assurance (QA) for cat 6e cables purchased internationally?

To ensure quality assurance for your cat 6e cables, request detailed product specifications and certifications from your supplier, such as UL, CE, or RoHS compliance. Conducting factory audits or third-party inspections can further validate the quality of the products before shipment. Establishing a clear return policy and warranty terms will also protect your investment in case the cables do not meet your expectations. Engaging with suppliers who have a proven track record in quality control can significantly enhance your confidence in the products you receive. -

What logistics considerations should I keep in mind when importing cat 6e cables?

When importing cat 6e cables, logistics play a crucial role in your overall supply chain efficiency. Consider shipping methods that balance cost and delivery time, such as air freight for urgent needs or sea freight for larger orders. Be aware of customs regulations and import duties that may apply to your products, as these can significantly impact your total costs. Partnering with a reliable logistics provider can streamline the process, ensuring timely delivery and compliance with international trade regulations. -

Are there customization options available for cat 6e cables?

Many suppliers offer customization options for cat 6e cables to meet specific business needs. Customization can include variations in length, color coding, and shielding types based on your network environment. Some manufacturers may also provide branding options, such as printing your company logo on the cables. When discussing customization with suppliers, be clear about your requirements and any associated costs. This flexibility can help you create a tailored solution that fits your operational needs and enhances your brand identity. -

What should I consider regarding warranty and after-sales support for cat 6e cables?

When sourcing cat 6e cables, it’s essential to consider the warranty and after-sales support offered by your supplier. A robust warranty typically covers defects in materials and workmanship, giving you peace of mind regarding product longevity. Additionally, inquire about the supplier’s after-sales support, including technical assistance and troubleshooting. Establishing a good relationship with your supplier can facilitate easier communication and faster resolution of any issues that may arise post-purchase, ensuring your network remains operational and efficient.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cat 6e cable

As international B2B buyers navigate the complexities of sourcing Cat 6e cables, it becomes evident that strategic sourcing is not merely an option but a necessity. By prioritizing quality, compliance, and supplier relationships, organizations can ensure they are investing in reliable infrastructure that meets both current and future network demands. Key takeaways include the importance of evaluating suppliers based on their certifications, production capabilities, and track record in delivering high-performance cabling solutions.

What are the benefits of investing in Cat 6e cables for your business? These cables not only support higher data rates but also enhance network reliability, making them an ideal choice for businesses looking to future-proof their operations. Additionally, fostering relationships with reputable suppliers can lead to better pricing, improved service, and access to innovative technologies.

Looking ahead, the demand for Cat 6e cables is expected to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. B2B buyers in these regions should take proactive steps to engage with trusted manufacturers and distributors to secure their supply chains. Embrace this opportunity to elevate your network infrastructure and position your business for success in an increasingly connected world.