Convert 1.98 Meters to Feet: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for 1.98 meters to feet

In the rapidly evolving global marketplace, B2B buyers often face the challenge of accurately converting and understanding measurements, such as translating 1.98 meters to feet. This seemingly simple task can become complex when sourcing products across different regions, especially for international buyers in Africa, South America, the Middle East, and Europe. Understanding how to navigate these conversions is crucial not only for accurate communication but also for ensuring that the products sourced meet specific requirements in terms of size and functionality.

This comprehensive guide delves into the various aspects of converting 1.98 meters to feet, offering insights into its applications across multiple industries, including construction, manufacturing, and logistics. We will explore different types of measurement tools available, best practices for supplier vetting, and cost considerations that can influence purchasing decisions. By addressing these critical areas, this guide empowers B2B buyers to make informed choices that align with their operational needs.

As businesses expand their reach across continents, the importance of precise measurements cannot be overstated. This resource aims to equip buyers with the knowledge they need to streamline their procurement processes, mitigate risks associated with miscommunication, and ultimately enhance their operational efficiency. Whether you’re based in Egypt or Vietnam, understanding the conversion of 1.98 meters to feet will enable you to forge stronger supplier relationships and achieve greater success in your international ventures.

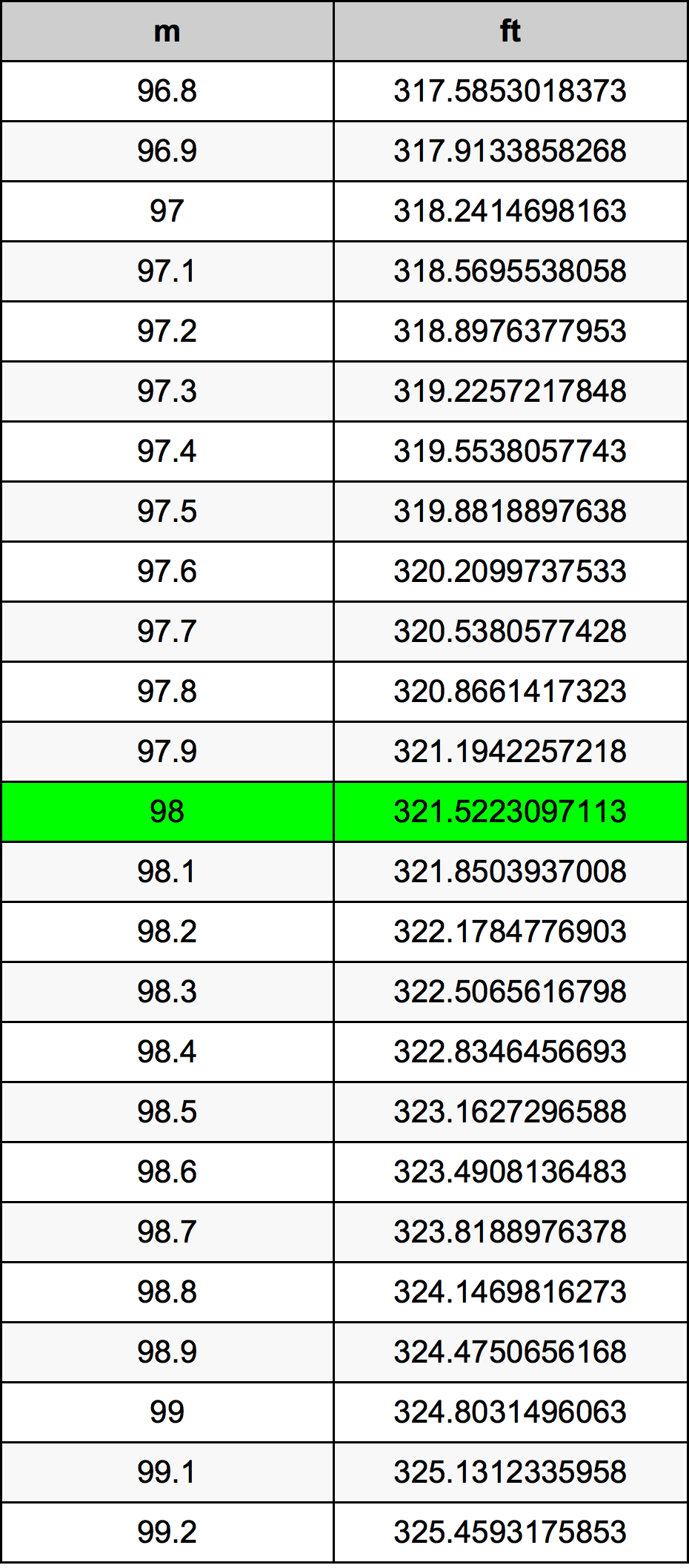

Understanding 1.98 meters to feet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Conversion | Direct conversion from meters to feet | Construction, Architecture | Pros: Simple calculation; widely accepted. Cons: May require context for accurate application. |

| Specialized Equipment | Tools calibrated to specific measurements | Manufacturing, Engineering | Pros: Precision in measurements; reduces errors. Cons: Higher initial investment. |

| Digital Conversion Tools | Software and apps for instant conversion | Logistics, Supply Chain | Pros: Fast and efficient; easy to use. Cons: Dependent on technology and internet access. |

| Educational Resources | Guides and tutorials on metric conversions | Education, Training | Pros: Enhances understanding; supports staff training. Cons: Time-consuming to implement. |

| Industry-Specific Standards | Compliance with regional measurement standards | Regulatory Compliance, Quality Assurance | Pros: Ensures adherence to local laws; builds trust. Cons: May limit flexibility in measurement practices. |

What are the Characteristics of Standard Conversion from 1.98 Meters to Feet?

Standard conversion is the most straightforward method of converting 1.98 meters to feet. It is essential in various industries such as construction and architecture where precise dimensions are critical. The conversion factor is widely recognized, with 1 meter equating to approximately 3.28084 feet. B2B buyers should ensure that their teams understand this basic conversion to avoid costly errors in project planning and execution.

How Does Specialized Equipment Enhance Measurement Accuracy?

Specialized equipment, such as laser distance meters and calibrated measuring tapes, provide precise measurements tailored for specific applications. In industries like manufacturing and engineering, where exact specifications are crucial, investing in such tools minimizes the risk of discrepancies. Buyers should consider the long-term benefits of accuracy against the initial costs, as quality equipment can significantly enhance operational efficiency.

A stock image related to 1.98 meters to feet.

Why Utilize Digital Conversion Tools for 1.98 Meters to Feet?

Digital conversion tools, including mobile apps and online calculators, offer quick and accurate conversions of 1.98 meters to feet. These tools are especially valuable in logistics and supply chain management, where rapid calculations are often necessary. While they enhance productivity, buyers should ensure that their workforce is trained to use these tools effectively and that they have reliable internet access to avoid disruptions.

How Can Educational Resources Improve Metric Understanding?

Educational resources such as guides, tutorials, and workshops can significantly enhance the understanding of metric conversions among staff. This is particularly beneficial in sectors focused on training and development. While the implementation of these resources may require time and investment, the long-term advantages include improved staff competence and reduced measurement errors, which can lead to cost savings.

What Are Industry-Specific Standards and Their Importance?

Adhering to industry-specific standards for measurements is critical for regulatory compliance and quality assurance. In regions where local measurement systems differ, understanding these standards can help businesses avoid legal issues and foster trust with clients. Buyers should be aware of the potential limitations in flexibility that come with strict adherence to these standards, but the benefits of compliance often outweigh the drawbacks, especially in regulated industries.

Related Video: How to Convert Meters to Feet and Inches in Excel Step by Step Tutorial

Key Industrial Applications of 1.98 meters to feet

| Industry/Sector | Specific Application of 1.98 meters to feet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Height specifications for scaffolding structures | Enhances safety and compliance with regulations | Ensure materials meet local safety standards and regulations. |

| Manufacturing | Machinery and equipment dimensions | Optimizes space utilization and workflow efficiency | Consider local supplier capabilities and delivery timelines. |

| Logistics & Transportation | Container stacking and loading specifications | Maximizes cargo space and minimizes shipping costs | Verify compatibility with existing transport systems and regulations. |

| Sports & Recreation | Design of sports facilities and equipment | Improves user experience and meets international standards | Assess local market preferences and safety regulations. |

| Retail & Display | Store layout planning and shelving units | Enhances customer engagement and product visibility | Source adaptable designs that cater to diverse market needs. |

How is 1.98 Meters to Feet Utilized in the Construction Sector?

In the construction industry, precise height specifications are critical for scaffolding structures. The conversion of 1.98 meters to feet, which equals approximately 6.5 feet, is often used to ensure that scaffolding meets safety regulations and provides adequate working height for construction teams. For international buyers, especially in regions like Africa and the Middle East, sourcing scaffolding that adheres to local safety standards while also being robust enough to handle various environmental conditions is essential. Compliance with local regulations can prevent costly delays and enhance worker safety.

What Role Does 1.98 Meters to Feet Play in Manufacturing?

In manufacturing, the dimensions of machinery and equipment are often measured in both metric and imperial units. The conversion of 1.98 meters to feet is crucial for optimizing space within production facilities. By ensuring that machinery fits within designated areas, companies can enhance workflow efficiency and reduce downtime. Buyers from South America and Europe should consider sourcing equipment that is adaptable to existing layouts and can accommodate future expansions, thus maximizing their investment.

How is 1.98 Meters to Feet Relevant in Logistics & Transportation?

Logistics and transportation sectors frequently utilize the conversion of 1.98 meters to feet when determining container stacking and loading specifications. Understanding these dimensions helps businesses maximize cargo space and minimize shipping costs. For B2B buyers, particularly in Africa, it is vital to verify that the containers and transportation methods used are compatible with local regulations and infrastructure. This ensures efficient logistics operations and reduces the risk of delays due to non-compliance.

How Does 1.98 Meters to Feet Impact Sports & Recreation?

In the sports and recreation industry, the design of facilities and equipment often relies on specific height measurements, including the conversion of 1.98 meters to feet. This measurement is essential for ensuring that sports facilities meet international standards and provide an optimal user experience. For international buyers, especially in Europe and the Middle East, understanding regional preferences and safety regulations is crucial when sourcing or designing sports infrastructure.

Why is 1.98 Meters to Feet Important for Retail & Display?

Retail businesses frequently utilize the conversion of 1.98 meters to feet in planning store layouts and shelving units. This measurement aids in enhancing customer engagement and product visibility, which are critical for driving sales. B2B buyers from South America and Africa should focus on sourcing adaptable shelving designs that cater to diverse market needs while ensuring compliance with local aesthetic standards and regulations. This approach not only improves the shopping experience but also aligns with local consumer preferences.

3 Common User Pain Points for ‘1.98 meters to feet’ & Their Solutions

Scenario 1: Miscommunication in Measurement Conversions

The Problem: In international trade, accurate communication of measurements is critical, especially when dealing with suppliers or clients from different regions. A common challenge arises when one party specifies dimensions in meters while the other expects feet, leading to potential misunderstandings that could affect product design or logistics. For example, a European buyer might order equipment sized at 1.98 meters, but if the supplier interprets it as feet, the resulting product could be significantly smaller than needed, causing delays and additional costs.

The Solution: To mitigate this issue, establish clear communication protocols regarding measurement units at the outset of any business transaction. Use standardized conversion tables that include not just the metric and imperial systems but also examples relevant to your industry. Additionally, consider incorporating a clause in contracts that specifies the measurement system to be used, along with a conversion confirmation step before finalizing orders. Tools like measurement conversion calculators can be integrated into your procurement process, ensuring that both parties are on the same page regarding dimensions.

Scenario 2: Inaccurate Product Sizing Leading to Returns

The Problem: Another frequent pain point for B2B buyers is the risk of ordering products that do not fit the intended space or application due to incorrect size conversions. For instance, a construction company in South America may order steel beams measuring 1.98 meters but finds that they do not fit the designated area because the supplier misinterpreted the order as feet. This not only leads to financial losses due to returns but can also delay project timelines significantly.

The Solution: To address this issue, implement a robust verification process for size specifications before placing orders. Utilize visual aids such as diagrams or CAD drawings that clearly illustrate how the measurements correspond to the intended use. When dealing with international suppliers, encourage the use of both metric and imperial measurements in product listings. Additionally, request samples or prototypes where feasible to physically verify that the dimensions meet your requirements before committing to larger orders.

Scenario 3: Compliance with Local Regulations on Dimensions

The Problem: B2B buyers often face compliance challenges when importing products that need to adhere to local regulations regarding dimensions. For instance, in the Middle East, certain building codes may specify maximum heights in feet, while suppliers may provide dimensions in meters. A buyer might assume that a product measuring 1.98 meters is compliant with local laws, only to find out it exceeds the height limit when converted to feet.

The Solution: To navigate compliance issues effectively, conduct thorough research on local regulations before initiating orders. Create a checklist of compliance requirements that includes both metric and imperial measurements for every product you intend to import. Collaborate closely with local regulatory bodies or hire a consultant familiar with the local market to ensure all products meet the necessary standards. Additionally, maintain open lines of communication with suppliers to ensure that they provide all relevant documentation in both measurement systems, facilitating a smoother compliance process.

Strategic Material Selection Guide for 1.98 meters to feet

What Are the Key Properties of Steel for 1.98 Meters to Feet Applications?

Steel is a widely used material in various applications requiring conversion from meters to feet, especially in construction and manufacturing. Key properties of steel include high tensile strength, excellent durability, and good corrosion resistance, particularly when treated or alloyed. Its temperature and pressure ratings are generally high, making it suitable for structural applications.

Pros & Cons: The primary advantage of steel is its strength-to-weight ratio, which allows for lighter structures without compromising integrity. However, its cost can be a limiting factor, especially in regions where raw materials are scarce. Manufacturing complexity can also be an issue, as steel requires precise fabrication processes to ensure safety and performance.

Impact on Application: Steel is compatible with various media, including water and chemicals, but its performance can degrade in highly corrosive environments unless properly treated. International B2B buyers must consider compliance with standards such as ASTM A36 or DIN 17100, depending on their region, to ensure quality and safety.

How Does Aluminum Compare for 1.98 Meters to Feet Applications?

Aluminum is another popular material for applications involving 1.98 meters to feet conversions, especially in lightweight structures and transport applications. It boasts excellent corrosion resistance, making it ideal for outdoor use and environments prone to moisture.

Pros & Cons: The lightweight nature of aluminum is a significant advantage, allowing for easier handling and installation. However, it is generally less strong than steel, which can limit its use in heavy-duty applications. Additionally, aluminum can be more expensive than steel, impacting budget considerations for B2B buyers.

Impact on Application: Aluminum’s compatibility with various media is generally good, but it may not perform well in high-temperature applications. Buyers from Africa, South America, the Middle East, and Europe should be aware of specific standards like JIS H 4040 and ISO 6361 to ensure compliance.

What Are the Benefits of Plastic in 1.98 Meters to Feet Conversions?

A stock image related to 1.98 meters to feet.

Plastic materials, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), are increasingly used in applications requiring conversion from meters to feet. These materials are lightweight, resistant to corrosion, and have good chemical resistance.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which can reduce overall project expenses. However, plastics may not be suitable for high-temperature or high-pressure applications, which can limit their use in certain industries.

Impact on Application: Plastics are compatible with a wide range of media, including water and chemicals, but their mechanical properties can be inferior to metals. B2B buyers should consider compliance with standards such as ASTM D638 for plastics to ensure quality and safety across different regions.

What Role Does Composite Material Play in 1.98 Meters to Feet Applications?

Composite materials, such as fiberglass and carbon fiber, are gaining popularity for applications involving 1.98 meters to feet conversions due to their unique properties. They offer high strength-to-weight ratios and excellent resistance to environmental factors.

Pros & Cons: The key advantage of composites is their exceptional durability and resistance to corrosion, making them suitable for harsh environments. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Impact on Application: Composites are compatible with various media and can perform well in both high-temperature and corrosive environments. International B2B buyers must consider compliance with standards like ASTM D3039 for composites to ensure they meet specific performance criteria.

Summary Table of Material Selection for 1.98 Meters to Feet

| Material | Typical Use Case for 1.98 Meters to Feet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural beams in construction | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight frames for transport | Excellent corrosion resistance | Lower strength compared to steel | Medium |

| Plastic | Piping systems for water transport | Low cost and easy to manufacture | Limited high-temperature applications | Low |

| Composite | Aerospace components and marine equipment | Exceptional durability and lightness | Higher cost and complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 1.98 meters to feet

What Are the Key Manufacturing Processes for Converting 1.98 Meters to Feet?

Understanding the manufacturing processes involved in converting measurements, such as 1.98 meters to feet, is crucial for B2B buyers. These processes are typically segmented into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The first step involves selecting appropriate materials based on the end application. Common materials include metals, plastics, and composites. For instance, if the measurement is part of a structural component, high-strength steel may be preferred. In contrast, for consumer products, durable plastics might be more suitable.

During material preparation, suppliers must ensure that the raw materials meet specified standards. This involves verifying the quality and specifications of the materials through rigorous testing, which can include tensile strength tests and chemical composition analysis. Buyers should inquire about the sources of these materials to ensure they comply with international quality standards.

Forming: What Techniques Are Employed?

The forming stage is where raw materials are shaped into the desired dimensions. This can involve various techniques such as cutting, molding, and machining. For instance, if you require a precise measurement conversion, CNC machining may be used for its accuracy.

Advanced technologies like laser cutting are also becoming popular due to their precision and efficiency. B2B buyers should inquire about the technologies employed by suppliers, as this can significantly affect the quality of the final product. Understanding the specific techniques will help buyers assess the reliability of the supplier.

Assembly: How Are Components Integrated?

Once individual components are formed, the next step is assembly. This may involve welding, fastening, or adhesive bonding, depending on the application. The assembly process should adhere to strict guidelines to ensure that all components fit together seamlessly.

Buyers should look for suppliers that employ automated assembly lines, as these often yield higher precision and consistency. Additionally, it’s important to ask about the assembly techniques used, as these can impact the durability and functionality of the final product.

Finishing: What Quality Enhancements Are Applied?

The final stage, finishing, involves adding any necessary coatings or treatments to enhance the product’s performance and appearance. This could include painting, anodizing, or applying protective films. The finishing process is crucial as it can affect not only the aesthetic appeal but also the longevity and usability of the product.

B2B buyers should inquire about the finishing options available and the processes used to ensure that the products meet their specifications. Understanding these options can lead to better decision-making when selecting suppliers.

What Are the Quality Assurance Practices Relevant to 1.98 Meters to Feet Manufacturing?

Quality assurance (QA) is vital in manufacturing to ensure that the final products meet specified standards. For international B2B buyers, understanding the QA practices is essential for ensuring compliance and reliability.

What International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that suppliers maintain a consistent level of quality in their processes. Additionally, industry-specific certifications like CE marking for products sold in Europe and API standards for oil and gas components are important for ensuring safety and reliability.

Buyers should verify that their suppliers possess these certifications and understand the implications of non-compliance. This not only protects the buyer but also enhances the supplier’s credibility in the market.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) in manufacturing typically includes several checkpoints, which can be categorized as follows:

-

Incoming Quality Control (IQC): This is where raw materials are inspected upon arrival. Buyers should ensure that suppliers conduct thorough inspections to verify that materials meet the required specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is essential. Techniques like statistical process control (SPC) can help identify any deviations from quality standards early on.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure that they meet all specifications. Buyers should ask for detailed reports on FQC processes to understand how thoroughly products are evaluated.

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure quality, including:

-

Destructive Testing: This involves testing materials to failure to assess their performance limits.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspections allow for quality checks without damaging the product.

B2B buyers should inquire about the types of testing methods used by their suppliers and request access to testing reports for transparency.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for mitigating risks in international trade. Here are several actionable steps B2B buyers can take:

What Are the Best Practices for Conducting Supplier Audits?

Conducting regular audits is a critical way to assess a supplier’s adherence to quality standards. Buyers should develop a checklist that includes evaluating the supplier’s manufacturing processes, quality control measures, and compliance with international standards.

Additionally, consider third-party audits, which can provide an unbiased assessment of the supplier’s operations. This is particularly important for buyers from regions like Africa and South America, where supplier reliability may vary significantly.

How Can Buyers Access Quality Reports?

Requesting quality assurance reports from suppliers is a straightforward way to verify compliance. These reports should detail the methods used for testing, results, and any corrective actions taken for non-conformance.

B2B buyers should also consider establishing a system for ongoing communication with suppliers to receive updates on quality improvements and potential issues.

What Quality Certification Nuances Should International Buyers Consider?

Navigating quality certifications can be complex, especially for international buyers. Each region may have specific requirements that must be met for compliance.

For instance, products sold in Europe must often bear the CE mark, indicating compliance with EU legislation. In contrast, buyers in the Middle East may require adherence to local standards that align with international practices.

Understanding these nuances is essential for successful international transactions. Buyers should engage with local experts or consultants familiar with the regulatory environment to ensure compliance.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices related to converting 1.98 meters to feet can empower B2B buyers to make informed decisions. By focusing on material selection, manufacturing techniques, and rigorous quality control measures, buyers can ensure they partner with reliable suppliers who meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1.98 meters to feet’

Introduction

Navigating the conversion of measurements, such as transforming 1.98 meters into feet, is essential for international B2B transactions, particularly in industries like construction, manufacturing, and logistics. This guide provides a structured checklist to assist buyers in sourcing accurate conversion tools and services while ensuring compatibility with their operational needs.

Step 1: Understand Measurement Standards in Your Region

Before initiating any procurement, familiarize yourself with the measurement standards relevant to your region. Different countries may have varying preferences for metric versus imperial units, which can influence product specifications. For example, in Europe, the metric system is widely used, while the U.S. predominantly employs imperial units.

- Research Local Regulations: Ensure compliance with local laws regarding measurement standards.

- Consider Industry Norms: Different sectors may have specific preferences for measurement systems.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the products or services you intend to procure. This includes understanding the precision needed for the conversion of 1.98 meters to feet, whether it’s for equipment, design specifications, or logistics.

- Detail Measurement Precision: Specify if you need conversions to the nearest decimal or fraction.

- Assess Application Needs: Determine if the measurement will be used in manufacturing, shipping, or architectural design.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your measurement needs effectively. Request detailed information about their products, conversion tools, and any certifications they hold.

- Check Supplier Credentials: Verify their industry certifications and experience in handling measurement conversions.

- Request Product Samples: If applicable, ask for samples of conversion tools or measurement devices to evaluate their accuracy.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications for the products you require. This is particularly important when sourcing measurement tools, as accuracy is paramount.

- Look for ISO Certifications: This indicates adherence to international quality management standards.

- Evaluate Local Certifications: Depending on your region, local standards may also apply.

Step 5: Assess Cost vs. Quality

Analyze the cost of products against their quality and reliability. While it might be tempting to choose the lowest-priced option, this could lead to inaccuracies in measurement conversions, resulting in costly errors.

- Conduct a Cost-Benefit Analysis: Weigh the potential savings against the risks of poor-quality tools.

- Consider Long-Term Value: Invest in reliable products that will perform consistently over time.

Step 6: Negotiate Terms and Conditions

Once you have identified suitable suppliers, negotiate favorable terms that protect your interests. This includes price, delivery timelines, and warranty policies.

- Clarify Payment Terms: Discuss payment methods that suit both parties, considering international transactions.

- Establish Return Policies: Ensure you have clear terms for returns in case the products do not meet your specifications.

Step 7: Implement a Quality Assurance Process

After procurement, establish a quality assurance process to regularly check the accuracy of measurement tools or services. This will help maintain standards and avoid discrepancies in future operations.

- Schedule Regular Audits: Implement a routine to review measurement accuracy and supplier performance.

- Train Staff on Measurement Protocols: Ensure that your team understands how to use and verify measurement tools effectively.

By following this checklist, international B2B buyers can effectively source the necessary tools and services for converting 1.98 meters to feet, ensuring operational efficiency and accuracy in their transactions.

Comprehensive Cost and Pricing Analysis for 1.98 meters to feet Sourcing

What are the Key Cost Components in Sourcing 1.98 Meters to Feet?

When sourcing measurements like 1.98 meters to feet, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly impacts the overall cost. For instance, sourcing high-quality aluminum or steel for manufacturing can increase material costs but may offer better durability and performance.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as those in parts of Africa or South America, you may find competitive pricing. However, be mindful of the trade-off between cost and quality.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility management. Understanding the overhead in the supplier’s region can provide insights into pricing structures.

-

Tooling Costs: If custom tooling is required for specific dimensions or designs, this will add to initial costs. Establishing clear specifications early can help control these expenses.

-

Quality Control (QC): Implementing stringent QC measures can incur additional costs but is essential for ensuring product reliability, especially when dealing with international standards.

-

Logistics: Shipping costs can vary widely based on distance, method of transport, and the supplier’s location. Consider the total logistics costs when evaluating supplier quotes.

-

Margin: Suppliers will include a margin to cover risks and profit. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of 1.98 meters to feet conversions that international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. B2B buyers should evaluate their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Customized products typically come with higher costs due to additional labor and tooling requirements. Clearly defining specifications can help avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-grade materials and certifications such as ISO or CE can increase costs but may be necessary for compliance and reliability in certain markets.

-

Supplier Factors: The reputation, reliability, and location of suppliers can significantly influence pricing. Conduct thorough research and consider supplier ratings and reviews.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for clarifying responsibilities for shipping, insurance, and tariffs. This knowledge can help avoid unexpected costs.

What Buyer Tips Can Help Achieve Cost Efficiency?

B2B buyers can implement several strategies to maximize cost efficiency when sourcing measurements like 1.98 meters to feet:

-

Negotiation Strategies: Cultivating strong relationships with suppliers can lead to better pricing and terms. Be prepared to negotiate based on volume and long-term commitments.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, shipping, and potential tariffs in your TCO analysis to make informed decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing, especially for buyers in Africa, South America, and the Middle East. Locking in prices or using hedging strategies can mitigate risks.

-

Market Research: Understanding local market conditions can provide insights into what is a competitive price. This knowledge is particularly useful in regions with diverse pricing structures.

-

Supplier Audits: Conducting audits of potential suppliers can uncover hidden costs or inefficiencies, allowing for more accurate pricing evaluations.

Disclaimer for Indicative Prices

The prices and cost components discussed are indicative and may vary significantly based on specific market conditions, supplier negotiations, and changing economic factors. Always conduct thorough due diligence and consult with industry experts to ensure accurate cost assessments tailored to your sourcing needs.

Alternatives Analysis: Comparing 1.98 meters to feet With Other Solutions

A stock image related to 1.98 meters to feet.

Understanding Alternatives for Converting 1.98 Meters to Feet

In the realm of international trade and business, the ability to convert measurements accurately is essential. For B2B buyers, especially those engaged in manufacturing, logistics, and engineering across diverse regions like Africa, South America, the Middle East, and Europe, understanding alternatives to common conversions—such as 1.98 meters to feet—can enhance decision-making processes. This section explores how 1.98 meters compares against alternative measurement solutions, offering actionable insights for international buyers.

Comparison Table of Measurement Solutions

| Comparison Aspect | 1.98 Meters to Feet | Metric Conversion Software | Manual Conversion Methods |

|---|---|---|---|

| Performance | High accuracy | Very high accuracy | Moderate accuracy |

| Cost | Low (if using online tools) | Variable (subscription-based) | No direct cost (labor-intensive) |

| Ease of Implementation | Very easy (online tools) | Moderate (requires setup) | Low (requires knowledge) |

| Maintenance | None | Regular updates required | None |

| Best Use Case | Quick conversions in business contexts | Large-scale operations needing automation | Small projects or educational purposes |

What Are the Benefits and Drawbacks of Metric Conversion Software?

Metric conversion software offers a highly accurate and efficient method for converting measurements, including the conversion of 1.98 meters to feet. These tools often come with additional features, such as batch processing and the ability to convert multiple units simultaneously, making them ideal for businesses involved in large-scale operations.

However, while the performance is robust, the cost can be a consideration as many software solutions operate on a subscription basis. Furthermore, implementation may require some initial setup, which can pose a challenge for smaller businesses without dedicated IT resources.

Why Consider Manual Conversion Methods for 1.98 Meters to Feet?

Manual conversion methods involve using simple formulas or charts to convert measurements. For instance, 1.98 meters converts to approximately 6.53 feet using the formula (1 meter = 3.28084 feet). This approach has the advantage of being free and requiring no additional tools, making it accessible for small projects or educational purposes.

However, the accuracy can be moderate, and the process can be labor-intensive, particularly if numerous conversions are needed. Additionally, it requires a certain level of knowledge about measurement conversions, which may not be readily available in all business contexts.

How Can B2B Buyers Choose the Right Measurement Solution?

When selecting the right solution for converting 1.98 meters to feet or other measurements, B2B buyers should consider their specific needs. If frequent and high-volume conversions are necessary, investing in metric conversion software may provide the best value despite the cost. Conversely, for one-off projects or smaller operations, manual methods could suffice, offering a cost-effective solution without the need for software.

Ultimately, the choice depends on factors such as the scale of operations, budget constraints, and the level of accuracy required. By assessing these aspects, international B2B buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 1.98 meters to feet

What Are the Key Technical Properties for Converting 1.98 Meters to Feet?

When dealing with the conversion of measurements, particularly in international trade, understanding the technical properties associated with dimensions is crucial. Here are some essential specifications to consider:

-

Precision of Measurement

Precision refers to the exactness of the measurement being converted. For instance, converting 1.98 meters to feet requires a high level of precision to ensure that the resulting value—approximately 6.53 feet—is accurate. This is critical for B2B transactions where precise dimensions can affect product compatibility and functionality. -

Material Tolerance

Tolerance defines the acceptable range of variation in a physical dimension. In many industries, such as manufacturing and construction, tolerances must be strictly adhered to in order to maintain quality and safety standards. For example, if a component must fit within a specific area, knowing the tolerance levels associated with its dimensions (like 1.98 meters to feet) is vital for successful assembly and performance. -

Dimensional Standards

Dimensional standards (like ISO or ASTM) provide guidelines for converting measurements and ensuring consistent application across industries. Adhering to these standards when converting 1.98 meters to feet ensures that products meet international specifications, which is particularly important for B2B buyers who operate in diverse markets. -

Weight Considerations

While converting length may seem straightforward, it’s important to consider the implications of weight, especially when dealing with large items. For example, a product’s weight can change based on its dimensions, affecting shipping costs and logistics. Understanding how to calculate and apply these conversions accurately will help B2B buyers make informed purchasing decisions. -

Metric vs. Imperial Systems

The metric system (meters) and the imperial system (feet) are used globally, and understanding the differences is essential for B2B transactions. Knowing how to effectively communicate measurements in both systems can enhance negotiation and collaboration with international partners.

What Are Common Trade Terms Related to Measurement Conversions?

Understanding industry jargon is crucial for effective communication in B2B settings. Here are some common terms that may come into play:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, knowing whether a supplier is an OEM can help in evaluating the quality and reliability of the products being sourced. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially when importing products that require specific conversions like 1.98 meters to feet. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. B2B buyers often use RFQs to gather competitive pricing and gauge supplier capabilities before making purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to avoid misunderstandings in international transactions. -

Lead Time

Lead time refers to the time between placing an order and receiving it. This is a critical factor for B2B buyers, as understanding lead times helps in planning inventory and ensuring that projects proceed without delays. -

Freight Forwarding

Freight forwarding involves the coordination and shipment of goods from one place to another via a single or multiple carriers. For international B2B transactions, knowing about freight forwarding can aid in logistics planning, especially when converting measurements for packaging or shipping purposes.

By familiarizing yourself with these technical properties and trade terms, you can navigate the complexities of converting measurements like 1.98 meters to feet more effectively, making informed decisions that enhance your business operations.

Navigating Market Dynamics and Sourcing Trends in the 1.98 meters to feet Sector

What Are the Current Market Dynamics and Sourcing Trends in the 1.98 Meters to Feet Sector?

The conversion of 1.98 meters to feet (approximately 6.5 feet) is increasingly relevant across various industries, particularly in construction, manufacturing, and textiles. Global drivers such as urbanization and population growth are fueling demand for precise measurements in building materials and products. Additionally, the rise of digital transformation in B2B transactions is reshaping how international buyers engage with suppliers. Technologies like AI-driven analytics and blockchain are enhancing transparency and efficiency in the sourcing process, allowing buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions.

Emerging trends indicate a shift towards online marketplaces and e-commerce platforms tailored for B2B transactions. These platforms offer significant advantages, including competitive pricing, access to diverse suppliers, and streamlined procurement processes. For buyers in regions like Egypt and Vietnam, leveraging these platforms can facilitate better sourcing strategies, ensuring access to quality materials at optimal costs. Furthermore, with the increasing focus on customization, suppliers are now more willing to provide tailored solutions that meet specific buyer requirements, which is particularly advantageous for niche markets.

How Can Sustainability and Ethical Sourcing Impact B2B Buying Decisions?

In today’s market, sustainability and ethical sourcing are no longer optional; they are essential components of a responsible supply chain. The environmental impact of sourcing materials—especially those related to the conversion of 1.98 meters to feet—has prompted international buyers to seek suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials, reduced carbon footprints, and responsible waste management.

For B2B buyers from Africa and South America, aligning with suppliers who hold certifications like ISO 14001 (Environmental Management) or those that utilize recycled materials can significantly enhance their brand reputation and appeal to environmentally conscious consumers. Additionally, ethical sourcing practices that focus on fair labor conditions and community engagement are becoming increasingly important. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring that their materials are sourced responsibly.

How Has the 1.98 Meters to Feet Sector Evolved Over Time?

The evolution of the 1.98 meters to feet conversion process reflects broader changes in measurement standards and global trade practices. Historically, the metric system was adopted to standardize measurements, facilitating international trade and commerce. As countries in Africa, South America, the Middle East, and Europe have integrated these standards into their industries, the conversion of measurements has become critical for manufacturing, logistics, and construction.

With the advent of digital tools and applications, the conversion process has become more accessible and efficient. This technological evolution allows B2B buyers to quickly convert measurements in real-time, ensuring accuracy in procurement and project planning. As the market continues to evolve, the importance of precise measurements in global trade will only increase, highlighting the need for robust sourcing strategies that accommodate these changes.

Frequently Asked Questions (FAQs) for B2B Buyers of 1.98 meters to feet

-

How do I convert 1.98 meters to feet accurately?

To convert 1.98 meters to feet, multiply the meter measurement by 3.28084, which is the conversion factor. Thus, 1.98 meters equals approximately 6.53 feet. This conversion is crucial for international B2B transactions where measurements might need to be standardized for compliance with local regulations or specifications in different markets. -

What is the significance of knowing measurements in feet for international trade?

Understanding measurements in feet is essential for B2B buyers engaged in international trade, especially when dealing with products that require precise specifications, such as construction materials or equipment. Different countries may use different measurement systems, and being able to convert and communicate in both metric and imperial units can enhance clarity and reduce misunderstandings during negotiations or procurement processes. -

Are there specific industries where converting meters to feet is particularly important?

Yes, industries such as construction, manufacturing, and logistics often require precise measurements. For example, in construction, knowing dimensions in feet is vital for compliance with local building codes in countries like the United States. For B2B buyers in Africa, South America, and the Middle East, understanding these conversions can streamline communications with suppliers and contractors who may operate in different measurement systems. -

What should I consider when vetting suppliers for products measured in feet?

When vetting suppliers, consider their experience in international trade and familiarity with both metric and imperial systems. Check for certifications that ensure quality standards, such as ISO certification. Additionally, request samples or specifications that include both measurement systems to confirm their capability to meet your specific needs. Establishing clear communication about measurements can prevent costly errors. -

What are the typical minimum order quantities (MOQ) for products measured in feet?

Minimum order quantities can vary significantly by supplier and product type. In many cases, suppliers might have higher MOQs for custom products or those requiring specific measurements. As a B2B buyer, it is advisable to discuss your needs directly with suppliers to negotiate favorable terms, especially if you are testing a new product line or entering a new market. -

What payment terms are commonly offered by suppliers for B2B transactions?

Payment terms can vary based on supplier policies and the nature of the goods. Common terms include net 30 or net 60 days, where payment is due within 30 or 60 days after invoice receipt. Some suppliers may require a deposit upfront, especially for custom orders. Always negotiate these terms upfront to ensure they align with your cash flow needs and risk management strategies. -

How can I ensure quality assurance (QA) when purchasing products measured in feet?

To ensure quality assurance, establish clear specifications that include both metric and imperial measurements. Request third-party inspections or certifications to validate product quality. Additionally, consider implementing a quality control process that includes regular audits of suppliers, especially if sourcing from regions with differing manufacturing standards, such as Africa or South America. -

What logistics considerations should I keep in mind when sourcing products internationally?

When sourcing products measured in feet from international suppliers, consider shipping methods, customs regulations, and potential tariffs. Plan for the logistics of transporting goods, including the mode of transport (air, sea, land) and the associated costs. It’s also important to work with logistics partners who understand the nuances of international shipping to avoid delays and ensure compliance with local laws.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 1.98 meters to feet

As the global marketplace continues to evolve, understanding the conversion from 1.98 meters to feet is not merely a matter of measurement but a strategic imperative for B2B buyers across various industries. This conversion equates to approximately 6.53 feet, and recognizing this can enhance your sourcing decisions, especially when dealing with international suppliers who may operate in different measurement systems.

How Can Strategic Sourcing Optimize Your Supply Chain?

Strategic sourcing empowers businesses to streamline procurement processes, ensuring that the right materials are acquired at the best price and quality. By leveraging this approach, companies can minimize costs, enhance product specifications, and build sustainable supplier relationships. For B2B buyers in Africa, South America, the Middle East, and Europe, this is particularly crucial, as it allows for better alignment with local regulations and market demands.

What is the Future Outlook for Sourcing in Global Markets?

Looking ahead, the demand for precise measurements and conversions will only increase as industries expand their global footprint. B2B buyers are encouraged to embrace innovative sourcing strategies that incorporate technology and data analytics. This will not only facilitate accurate conversions but also enhance decision-making processes.

In conclusion, investing in strategic sourcing practices is vital for fostering competitive advantages in today’s dynamic market. International B2B buyers should take proactive steps to refine their sourcing strategies, ensuring they remain agile and responsive to the ever-changing landscape.