Improve Quality: The Ultimate Rubber Granulaat Mat Guide (2025)

Introduction: Navigating the Global Market for rubber granulaat mat

In today’s competitive landscape, sourcing high-quality rubber granulaat mats presents a significant challenge for international B2B buyers. These versatile products are essential for various applications, from sports facilities to playgrounds, providing safety and durability. However, navigating the complexities of the global market requires an understanding of product types, supplier reliability, and cost implications. This guide is designed to equip you with the knowledge needed to make informed purchasing decisions, ensuring that your investments yield the highest returns.

Throughout this comprehensive guide, we will explore the diverse types of rubber granulaat mats available in the market, including their unique features and benefits. We will delve into the various applications, helping you identify the right solutions tailored to your specific needs. Additionally, we will provide insights into effective supplier vetting processes, highlighting key criteria that should influence your selection. Understanding cost factors and pricing trends will also be covered, allowing you to budget effectively and avoid common pitfalls.

This guide is particularly valuable for B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Italy and Poland. By addressing the unique challenges faced by these markets, we aim to empower you with actionable insights that enhance your purchasing strategies and ensure successful outcomes in sourcing rubber granulaat mats.

Understanding rubber granulaat mat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Recycled Rubber Mat | Made from post-consumer tires, eco-friendly | Playgrounds, fitness centers, industrial use | Pros: Cost-effective, sustainable Cons: Variable quality, potential odor |

| Interlocking Rubber Mat | Modular design, customizable sizes | Gym floors, event spaces, warehouses | Pros: Easy installation, versatile Cons: Higher initial cost, requires precise alignment |

| Rubber Granule Mat | Composed of small rubber granules, shock-absorbent | Sports facilities, outdoor surfaces | Pros: Excellent cushioning, durable Cons: Limited color options, maintenance required |

| Anti-Slip Rubber Mat | Textured surface for enhanced grip | Commercial kitchens, bathrooms, entryways | Pros: Safety features, easy to clean Cons: May wear over time, specific installation needs |

| Soundproof Rubber Mat | Designed to reduce noise transmission | Recording studios, residential buildings | Pros: Effective sound insulation, durable Cons: Higher cost, heavier weight |

What are the Characteristics of Recycled Rubber Mats?

Recycled rubber mats are primarily made from post-consumer tires, making them an eco-friendly option for B2B buyers. These mats are highly versatile and can be used in various applications, including playgrounds, fitness centers, and industrial environments. When considering recycled rubber mats, buyers should evaluate the quality, as it can vary significantly based on the manufacturing process. Additionally, while these mats are cost-effective and sustainable, they may emit an odor and require careful inspection for quality assurance.

How Do Interlocking Rubber Mats Enhance Flexibility?

Interlocking rubber mats feature a modular design that allows for customizable configurations and easy installation. This type of mat is particularly popular in gym floors, event spaces, and warehouses due to its adaptability. B2B buyers should consider the initial investment, as these mats can be more expensive than traditional options. However, their ease of installation and ability to create seamless surfaces make them a worthwhile investment for businesses looking for flexibility and durability.

Why Choose Rubber Granule Mats for Sports Facilities?

Rubber granule mats are composed of small rubber particles, providing excellent shock absorption and cushioning. This makes them ideal for sports facilities and outdoor surfaces where safety and performance are critical. When purchasing rubber granule mats, buyers should assess the durability and maintenance requirements. While these mats offer superior cushioning, they may come in limited color options, which could affect aesthetic preferences for certain applications.

What Benefits Do Anti-Slip Rubber Mats Provide?

Anti-slip rubber mats are designed with textured surfaces to enhance grip and safety, making them suitable for environments like commercial kitchens, bathrooms, and entryways. B2B buyers should appreciate the safety features these mats offer, as they can significantly reduce the risk of slips and falls. However, potential drawbacks include wear over time and specific installation needs that may complicate the procurement process.

How Do Soundproof Rubber Mats Improve Acoustic Quality?

Soundproof rubber mats are specifically engineered to reduce noise transmission, making them ideal for recording studios and residential buildings. These mats are highly effective at sound insulation, providing a quieter environment for both work and leisure. However, B2B buyers should be aware of the higher cost and increased weight of these mats, which may influence shipping and installation logistics. Overall, soundproof rubber mats represent a significant investment in quality and comfort for businesses prioritizing acoustic performance.

Related Video: Car floor mats types – how to select right floor mat? | 3D 5D 7D floor mats explained | Budget?

Key Industrial Applications of rubber granulaat mat

| Industry/Sector | Specific Application of rubber granulaat mat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Recreation | Flooring for gyms and sports facilities | Enhanced safety and shock absorption | Durability, compliance with safety standards, and ease of maintenance. |

| Construction and Renovation | Impact-absorbing underlayment for flooring | Reduces noise and improves comfort | Material quality, thickness, and moisture resistance. |

| Agriculture and Livestock | Flooring for animal shelters and barns | Improved hygiene and animal comfort | Non-toxic materials, ease of cleaning, and slip resistance. |

| Automotive and Transportation | Soundproofing and vibration dampening in vehicles | Increased comfort and reduced operational noise | Weight, durability, and compatibility with vehicle materials. |

| Industrial Warehousing | Anti-slip mats for loading docks and work areas | Enhanced safety and reduced workplace injuries | Surface texture, thickness, and resistance to chemicals. |

How is Rubber Granulaat Mat Used in Sports and Recreation Facilities?

Rubber granulaat mats are extensively used in gyms and sports facilities due to their superior shock absorption and slip-resistant properties. These mats provide a safe environment for athletes, reducing the risk of injuries from falls or impacts. For international buyers, especially from regions with varying climate conditions, it is crucial to consider mats that are durable and can withstand heavy foot traffic while meeting local safety standards. Additionally, ease of maintenance and resistance to mold and mildew are important factors to ensure long-term usability.

What Role Does Rubber Granulaat Mat Play in Construction and Renovation?

In the construction sector, rubber granulaat mats serve as impact-absorbing underlayment for various flooring types. They are particularly beneficial in reducing noise transmission between floors, which enhances comfort in residential and commercial buildings. B2B buyers should prioritize sourcing mats that meet specific thickness and moisture resistance requirements to ensure optimal performance in diverse environments, especially in areas with high humidity or temperature fluctuations.

How Can Rubber Granulaat Mat Improve Conditions in Agriculture and Livestock?

In agriculture, rubber granulaat mats are utilized in animal shelters and barns, providing a comfortable and hygienic environment for livestock. These mats help to reduce stress on animals’ joints and provide insulation from cold floors. When sourcing for agricultural applications, buyers must ensure that the materials are non-toxic and easy to clean, as hygiene is paramount in livestock management. Additionally, mats with slip-resistant surfaces can significantly reduce the risk of injuries among animals.

Why is Rubber Granulaat Mat Essential for Automotive Applications?

In the automotive industry, rubber granulaat mats are employed for soundproofing and vibration dampening within vehicles. By reducing noise levels, these mats enhance passenger comfort and overall driving experience. International buyers in the automotive sector should focus on sourcing mats that are lightweight yet durable, ensuring compatibility with various vehicle materials. Additionally, the ability of the mats to withstand temperature variations and chemical exposure is critical for long-term performance.

How Does Rubber Granulaat Mat Contribute to Safety in Industrial Warehousing?

Rubber granulaat mats are increasingly used in industrial warehousing, particularly in loading docks and work areas, to provide anti-slip surfaces that enhance workplace safety. By reducing the likelihood of slips and falls, these mats help to minimize workplace injuries, thereby lowering insurance costs and enhancing productivity. B2B buyers should consider sourcing mats with specific surface textures and thicknesses that offer optimal grip and resistance to various industrial chemicals, ensuring a safe working environment.

Related Video: Rubber compounding – Rubber compounds production process

3 Common User Pain Points for ‘rubber granulaat mat’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Rubber Granulaat Mat

The Problem:

Many B2B buyers, particularly those in emerging markets like Africa and South America, face challenges in sourcing high-quality rubber granulaat mat. The local suppliers often offer products that do not meet international quality standards, resulting in mats that degrade quickly or fail to perform as expected. This issue can lead to significant setbacks in projects, increased costs due to replacements, and potential damage to the buyer’s reputation when products don’t meet safety and performance standards.

The Solution:

To overcome this sourcing challenge, buyers should focus on establishing relationships with reputable manufacturers or distributors known for their quality products. Conduct thorough research to identify suppliers with certifications such as ISO 9001 or environmental certifications that ensure the sustainability of the materials used. Request samples to evaluate the quality of the rubber granulaat mat before making bulk purchases. Additionally, consider leveraging online platforms and trade shows that connect international buyers with verified suppliers, allowing for direct communication regarding specifications and quality assurance. This proactive approach will help mitigate risks associated with sourcing inferior products.

Scenario 2: Inadequate Understanding of Product Specifications

The Problem:

A common pain point for B2B buyers is a lack of clarity regarding the specifications and applications of rubber granulaat mat. Different projects may require varying thickness, density, and surface texture, and without proper understanding, buyers might procure mats that are ill-suited for their specific applications. This misalignment can lead to performance issues, safety hazards, and wasted investment in unsuitable materials.

The Solution:

To address this knowledge gap, it is essential for buyers to engage with technical experts or consultants who specialize in rubber products. Conducting a needs assessment before purchasing can clarify the required specifications based on the intended use, whether it’s for sports facilities, playgrounds, or industrial settings. Buyers should also utilize online resources, such as webinars or detailed product guides, that explain the properties of rubber granulaat mats. Additionally, requesting detailed product datasheets from suppliers can provide insight into the material’s durability, shock absorption capabilities, and compliance with safety standards, ensuring that the right product is selected for each unique application.

Scenario 3: Challenges in Installation and Maintenance

The Problem:

Installation and maintenance of rubber granulaat mats can often pose challenges for B2B buyers, especially in regions with varying climatic conditions. Issues such as improper installation can lead to premature wear and tear, while inadequate maintenance routines can compromise the mat’s performance and safety. These challenges can result in additional costs for repairs or replacements and may also impact the operational efficiency of facilities relying on these mats.

The Solution:

To mitigate installation and maintenance challenges, buyers should invest in training for their installation teams or hire professional installers who specialize in rubber flooring systems. Providing clear installation guidelines and ensuring that the team understands the importance of substrate preparation and adhesive application will yield better results. Furthermore, establishing a regular maintenance schedule that includes cleaning and inspections can prolong the lifespan of the mats. Buyers should also consult with suppliers for recommendations on appropriate cleaning products and techniques that are safe for rubber materials. By prioritizing proper installation and maintenance, buyers can enhance the durability and performance of their rubber granulaat mats, ultimately saving costs in the long term.

Strategic Material Selection Guide for rubber granulaat mat

When selecting materials for rubber granulaat mats, international B2B buyers must consider various factors such as performance properties, application suitability, and compliance with regional standards. Below, we analyze four common materials used in the manufacturing of rubber granulaat mats, focusing on their key properties, advantages and disadvantages, and implications for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What are the Key Properties of Natural Rubber for Rubber Granulaat Mats?

Natural rubber is derived from the sap of rubber trees and is known for its excellent elasticity and resilience. It can withstand a wide range of temperatures, typically from -40°C to 80°C, making it suitable for various environments. Additionally, natural rubber exhibits good abrasion resistance, which is crucial for high-traffic areas.

Pros & Cons: The main advantage of natural rubber is its superior flexibility and durability, which translates to a longer lifespan for mats. However, it is susceptible to degradation from UV exposure and ozone, which can limit its outdoor applications. Furthermore, the cost of natural rubber can be higher than synthetic alternatives, affecting budget considerations for B2B buyers.

Impact on Application: Natural rubber mats are ideal for indoor environments and applications where flexibility is paramount. However, they may not be suitable for areas exposed to direct sunlight or harsh chemicals.

How Does Synthetic Rubber Compare for Rubber Granulaat Mats?

Synthetic rubber, including materials like SBR (Styrene-Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer), offers a range of properties tailored for specific applications. SBR is known for its good abrasion resistance and aging stability, while EPDM excels in weather resistance and temperature tolerance, withstanding temperatures from -50°C to 120°C.

Pros & Cons: The key advantage of synthetic rubber is its ability to resist environmental factors such as UV rays and ozone, making it suitable for outdoor use. However, synthetic rubber can be less elastic than natural rubber, which may impact comfort in certain applications. Additionally, while generally more cost-effective, the manufacturing complexity can vary, affecting lead times.

Impact on Application: Synthetic rubber mats are often used in outdoor play areas, gyms, and industrial settings where exposure to the elements is a concern. Buyers must ensure that the specific type of synthetic rubber aligns with their application requirements.

What Role Does Recycled Rubber Play in Rubber Granulaat Mats?

Recycled rubber, often sourced from used tires, is an eco-friendly option for rubber granulaat mats. It offers good durability and is resistant to abrasion and impact, making it suitable for high-traffic areas. The temperature range for recycled rubber typically mirrors that of synthetic options.

Pros & Cons: The primary advantage of recycled rubber is its sustainability, appealing to environmentally conscious buyers. It is also often more affordable than virgin rubber materials. However, the quality can vary significantly based on the source, and there may be concerns regarding consistency and performance.

Impact on Application: Recycled rubber is commonly used in playgrounds, sports facilities, and flooring solutions. Buyers should verify compliance with local regulations regarding recycled materials, particularly in regions with strict environmental standards.

What Are the Benefits of Foam Rubber for Rubber Granulaat Mats?

Foam rubber, often made from polyurethane or similar materials, provides excellent cushioning and shock absorption. It is lightweight and can be manufactured in various densities, allowing for customization based on specific needs.

Pros & Cons: The main advantage of foam rubber is its comfort and impact resistance, making it ideal for applications requiring safety, such as gyms and play areas. However, it may not be as durable as other rubber types and can wear out more quickly under heavy use, which could lead to higher replacement costs.

Impact on Application: Foam rubber mats are particularly suitable for indoor applications where comfort and safety are priorities. B2B buyers should consider the expected foot traffic and potential wear when selecting foam rubber mats.

Summary Table of Material Selection for Rubber Granulaat Mats

| Material | Typical Use Case for rubber granulaat mat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Indoor gym mats | Superior flexibility and durability | Susceptible to UV and ozone damage | High |

| Synthetic Rubber | Outdoor play areas, industrial settings | Excellent weather resistance | Less elastic than natural rubber | Medium |

| Recycled Rubber | Playgrounds, sports facilities | Eco-friendly and cost-effective | Quality can vary by source | Low |

| Foam Rubber | Indoor gyms, play areas | Excellent cushioning and comfort | Less durable under heavy use | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on application needs, regional compliance, and budget considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber granulaat mat

What Are the Main Stages of Manufacturing Rubber Granulaat Mats?

The manufacturing process for rubber granulaat mats involves several critical stages, each contributing to the quality and functionality of the final product. Understanding these stages can help B2B buyers assess suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Used in Rubber Granulaat Mats?

The first step in the manufacturing process is the preparation of raw materials. Typically, rubber granules are sourced from recycled tires or other rubber products. The granules are then cleaned and sorted to ensure uniformity in size and quality.

In addition to rubber granules, additives such as colorants, anti-oxidants, and bonding agents may be introduced during this phase to enhance the properties of the mats. Buyers should inquire about the sources of these materials, as the quality can significantly impact the durability and performance of the mats.

How Are Rubber Granulaat Mats Formed?

After material preparation, the next stage is forming. This involves mixing the rubber granules with the additives in a process known as compounding. The mixture is then subjected to heat and pressure in a mold to form the desired shape of the mat.

Key techniques in this stage include:

- Compression Molding: A traditional method where the rubber mixture is placed into a heated mold and compressed. This technique is often favored for its efficiency and ability to produce mats with intricate designs.

- Extrusion: This method involves forcing the rubber mixture through a die to create continuous sheets, which can then be cut into mats of various sizes.

B2B buyers should assess the manufacturing capabilities of suppliers, particularly their equipment and technologies, to ensure they can produce mats that meet specific requirements.

What Finishing Processes Are Involved in Rubber Granulaat Mat Production?

The finishing stage is critical for enhancing the appearance and performance of rubber granulaat mats. This may include processes such as trimming, surface treatment, and coating.

Common finishing techniques include:

- Surface Texturing: This enhances grip and aesthetic appeal.

- Edge Finishing: This ensures that mats have smooth edges, reducing wear and improving safety.

Quality buyers should verify that suppliers employ finishing techniques that align with industry standards and customer expectations.

How Is Quality Assurance Implemented in Rubber Granulaat Mat Manufacturing?

Quality assurance (QA) is paramount in the rubber granulaat mat manufacturing process. Effective QA ensures that the mats not only meet customer specifications but also comply with international standards.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards that govern the manufacturing of rubber products. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area (EEA), CE marking signifies that the mats comply with EU safety, health, and environmental protection standards.

- API Standards: For mats intended for industrial use, especially in oil and gas, compliance with American Petroleum Institute (API) standards may be necessary.

Understanding these standards can help buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, random samples are taken to verify that production is proceeding according to standards.

- Final Quality Control (FQC): Before packaging and shipping, finished products undergo a comprehensive inspection to ensure they meet all specifications.

B2B buyers should ask suppliers about their QC processes and request documentation to confirm adherence to these checkpoints.

What Testing Methods Are Commonly Used for Rubber Granulaat Mats?

To ensure the performance and safety of rubber granulaat mats, various testing methods are employed. Common tests include:

- Tensile Strength Testing: Measures the force required to stretch the material, indicating its durability.

- Hardness Testing: Assesses the firmness of the rubber, which affects its wear resistance.

- Slip Resistance Testing: Evaluates how well the mat will perform in wet or slippery conditions.

Buyers should ensure that suppliers have access to accredited laboratories for these tests and can provide certificates of compliance.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verifying the quality control measures of potential suppliers is essential for B2B buyers to mitigate risks. Here are actionable steps:

- Conduct Audits: Regular on-site audits can help assess the manufacturing processes and QC protocols. Buyers should consider employing third-party auditors for impartial evaluations.

- Request Quality Reports: Suppliers should provide regular quality reports detailing QC outcomes, compliance with international standards, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an additional layer of assurance, particularly for large orders or new suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial.

- Regional Standards: Different regions may have varying standards and regulations. Buyers should ensure that suppliers are compliant with both local and international requirements.

- Cultural and Logistical Considerations: Communication barriers and logistical challenges can impact the manufacturing and delivery process. Establishing clear expectations and maintaining open lines of communication with suppliers can help mitigate these issues.

By understanding the manufacturing processes and quality assurance measures in rubber granulaat mat production, B2B buyers can make more informed decisions and select suppliers that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber granulaat mat’

Introduction

Sourcing rubber granulaat mats requires a strategic approach to ensure quality, compliance, and value for money. This guide serves as a practical checklist for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and make informed decisions that align with your business needs.

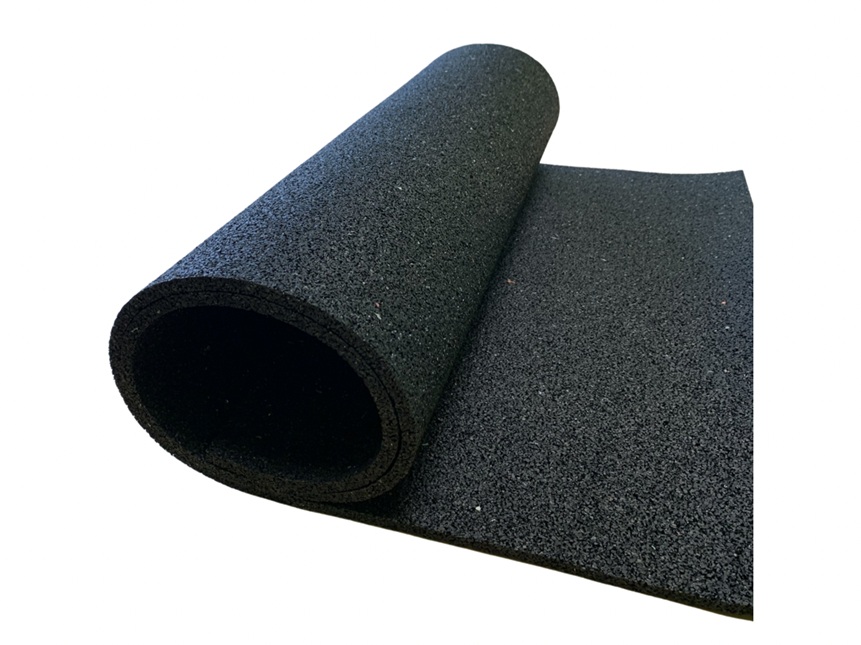

A stock image related to rubber granulaat mat.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the rubber granulaat mats meet your operational requirements. Consider factors such as thickness, size, color, and performance attributes like slip resistance and durability. Documenting these specifications helps in communicating your needs effectively to suppliers and aids in evaluating product samples.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in rubber granulaat mats. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors. Focus on suppliers with a proven track record and positive reviews from other businesses in your region, as this can indicate reliability and quality.

Step 3: Evaluate Supplier Certifications and Compliance

Before making any commitments, verify that potential suppliers hold necessary certifications and comply with relevant industry standards. Look for certifications such as ISO 9001 for quality management and any environmental certifications that demonstrate sustainability practices. Compliance with local regulations is crucial to avoid legal issues and ensure product safety.

Step 4: Request Product Samples for Testing

Always request product samples before finalizing your order. Testing samples allows you to evaluate the quality, texture, and performance of the rubber granulaat mats firsthand. Pay attention to factors such as flexibility, odor, and overall finish, as these can affect the usability and aesthetic appeal of the mats in your intended application.

Step 5: Assess Pricing and Payment Terms

Price is a critical factor in sourcing rubber granulaat mats, but it should not be the sole consideration. Compare pricing across different suppliers while considering the total cost of ownership, including shipping and potential tariffs. Additionally, discuss payment terms to ensure they align with your cash flow and financial strategies. Look for flexible payment options that can facilitate smoother transactions.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted suppliers, engage in negotiations to secure favorable terms. This includes discussing lead times, minimum order quantities, and warranty conditions. Effective negotiation can lead to better pricing and service agreements, ultimately enhancing your procurement strategy.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Regular updates on order status, delivery timelines, and any potential issues are vital for maintaining a strong supplier relationship. Effective communication can help mitigate risks and ensure that your business receives the products on time and as specified.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for rubber granulaat mats, ensuring that they make informed decisions that contribute to their operational success.

Comprehensive Cost and Pricing Analysis for rubber granulaat mat Sourcing

What Are the Key Cost Components for Sourcing Rubber Granulaat Mats?

When considering the sourcing of rubber granulaat mats, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of rubber granules significantly impact the overall cost. Sourcing from reputable suppliers who provide certified materials may incur higher initial costs but can result in long-term savings through durability and performance.

-

Labor: Labor costs vary by region and can affect production rates. In countries with lower labor costs, such as parts of South America and Africa, buyers may find competitive pricing. However, it’s essential to consider the skill level and expertise of the workforce, as these factors influence product quality.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, equipment maintenance, and facility management. Buyers should inquire about the supplier’s operational efficiency, as lower overhead can lead to more competitive pricing.

-

Tooling: Custom molds and tooling can be a significant upfront investment. If your requirements include specific dimensions or designs, factor in these costs when negotiating pricing.

-

Quality Control (QC): Implementing stringent QC measures can increase costs but is essential for ensuring product reliability. Buyers should evaluate suppliers on their QC processes to mitigate risks associated with defects.

-

Logistics: Shipping and handling costs can vary widely based on distance, method of transport, and Incoterms. Understanding these logistics costs is vital for calculating the total cost of ownership.

-

Margin: Supplier margins can vary based on market demand, competition, and geographic location. Buyers should seek transparency in pricing to better understand how margins are incorporated into the final cost.

How Do Price Influencers Affect the Cost of Rubber Granulaat Mats?

Several factors can influence the pricing of rubber granulaat mats, impacting overall sourcing costs:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing and optimize inventory management.

-

Specifications and Customization: Custom specifications can drive costs up. Buyers should assess whether standard products meet their needs or if customization is necessary.

-

Materials and Quality Certifications: Higher quality materials or specific certifications (e.g., ISO, REACH) may lead to increased costs. However, these investments can yield higher performance and compliance with international standards.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all influence pricing. It’s advisable to conduct thorough due diligence on potential suppliers.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding these terms can help buyers manage costs and risks associated with international shipping.

What Are the Best Negotiation Tips for International B2B Buyers?

Negotiating effectively is crucial for obtaining favorable pricing on rubber granulaat mats. Here are some actionable tips:

-

Conduct Market Research: Understanding current market prices and trends will empower buyers during negotiations. This knowledge can help in assessing supplier offers and justifying counter-offers.

-

Build Long-term Relationships: Establishing a partnership with suppliers can lead to better pricing over time. Consider negotiating terms that benefit both parties.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and logistics costs to understand the true expense of sourcing rubber mats.

-

Be Open to Alternatives: If a supplier cannot meet pricing expectations, be willing to explore other options, such as alternative materials or suppliers that may offer better terms.

What Pricing Nuances Should Buyers Consider in Different Regions?

Buyers from Africa, South America, the Middle East, and Europe (including Italy and Poland) should be aware of regional pricing nuances. For instance:

-

Currency Fluctuations: International buyers must account for currency exchange rates, which can affect pricing.

-

Trade Tariffs and Duties: Import tariffs can significantly impact costs. Understanding local regulations in the buyer’s country can aid in cost planning.

-

Cultural Differences: Negotiation styles vary by region, and being culturally aware can enhance communication and lead to better deals.

Conclusion: Why Is It Important to Understand Pricing Dynamics?

Understanding the cost structure and pricing dynamics of rubber granulaat mats is essential for making informed purchasing decisions. By analyzing cost components, identifying price influencers, and implementing effective negotiation strategies, international B2B buyers can achieve significant savings while ensuring product quality and compliance. Always remember that indicative prices can fluctuate based on market conditions, so staying informed is key to successful sourcing.

Alternatives Analysis: Comparing rubber granulaat mat With Other Solutions

When exploring solutions for flooring and surfacing needs, particularly in sports facilities, playgrounds, or industrial environments, it is essential to consider various alternatives to rubber granulaat mats. These alternatives can vary significantly in terms of performance, cost, implementation, and maintenance. This analysis will provide B2B buyers with a clear understanding of how rubber granulaat mats compare with other viable options.

Comparison Table: Rubber Granulaat Mat vs. Alternatives

| Comparison Aspect | Rubber Granulaat Mat | Interlocking Foam Tiles | Artificial Turf |

|---|---|---|---|

| Performance | High shock absorption; slip-resistant | Moderate shock absorption; less durable | Excellent for outdoor use; requires infill for shock absorption |

| Cost | Moderate initial investment; long lifespan | Lower upfront cost; shorter lifespan | High initial investment; ongoing maintenance costs |

| Ease of Implementation | Requires professional installation | DIY-friendly; easy to install | Requires professional installation; site preparation needed |

| Maintenance | Low maintenance; occasional cleaning | Moderate maintenance; may need replacement | High maintenance; requires grooming and infill replacement |

| Best Use Case | Playgrounds, gyms, and fitness areas | Indoor play areas, home gyms | Sports fields, landscaping |

What Are the Pros and Cons of Interlocking Foam Tiles?

Interlocking foam tiles are a popular alternative to rubber granulaat mats, especially for indoor applications. Their lightweight nature makes them easy to handle and install, making them a suitable option for DIY projects. However, while they provide moderate shock absorption, they do not offer the same level of durability as rubber mats, which can be a drawback in high-traffic areas. The lower initial cost is appealing, but the shorter lifespan and moderate maintenance requirements may lead to higher long-term expenses.

How Does Artificial Turf Compare to Rubber Granulaat Mats?

Artificial turf is another alternative that excels in outdoor applications, particularly in sports fields and landscaping. It provides an excellent playing surface but requires an infill material to enhance shock absorption. The installation process for artificial turf can be complex and often necessitates professional assistance, which may drive up costs. Moreover, while it offers a visually appealing and durable surface, the ongoing maintenance—such as grooming and periodic infill replacement—can be significant. Thus, while it may be suitable for specific outdoor environments, the total cost of ownership can be higher than that of rubber granulaat mats.

Conclusion: How Should B2B Buyers Choose the Right Flooring Solution?

A stock image related to rubber granulaat mat.

When evaluating flooring solutions, B2B buyers must consider the specific needs of their applications. Rubber granulaat mats provide excellent performance and durability, making them ideal for high-traffic environments. In contrast, interlocking foam tiles may offer a cost-effective and easily implementable solution for less demanding indoor applications. Artificial turf, while suitable for outdoor sports, requires a more substantial investment and ongoing maintenance. Ultimately, understanding the unique requirements of your project—such as budget constraints, expected foot traffic, and maintenance capabilities—will guide you in selecting the most appropriate flooring solution.

Essential Technical Properties and Trade Terminology for rubber granulaat mat

What Are the Key Technical Properties of Rubber Granulaat Mat?

Rubber granulaat mat, commonly used in various applications ranging from playgrounds to sports facilities, has several essential technical properties that B2B buyers should consider. Understanding these specifications helps ensure that the product meets the specific requirements of your project.

1. Material Grade

The material grade of rubber granulaat mat refers to the quality and type of rubber used in its production. This can range from recycled rubber to virgin rubber. For B2B buyers, selecting the appropriate material grade is crucial as it directly impacts durability, elasticity, and performance. Higher-grade materials generally provide better resistance to wear and tear, making them suitable for high-traffic areas.

2. Thickness

The thickness of rubber granulaat mat typically ranges from 10mm to 50mm. Thicker mats offer better shock absorption, which is vital for safety in environments like playgrounds or gymnasiums. For international buyers, understanding the required thickness for specific applications helps in making informed purchasing decisions, especially considering local safety regulations.

3. Tolerance Levels

Tolerance levels indicate the permissible variation in the mat’s dimensions and properties. This specification is important for ensuring proper fit and functionality. For instance, if the mats are to be installed in a specific area, knowing the tolerance levels ensures they will fit correctly without gaps or overlaps. Inaccurate tolerances can lead to additional costs and installation delays.

4. Density

Density measures the mass per unit volume of the rubber granulaat mat. A higher density usually correlates with improved durability and performance. For B2B buyers, selecting a mat with the appropriate density is vital for the intended use; heavier mats may be better for outdoor applications exposed to weather elements, while lighter options may be sufficient for indoor settings.

5. Color and Aesthetic Options

While functionality is key, the aesthetic appeal of rubber granulaat mat cannot be overlooked, especially in commercial settings. Options for color and finish can enhance the visual aspect of a space. For international buyers, understanding the availability of custom colors or designs can be a deciding factor in their purchasing decisions.

What Are Common Trade Terms Related to Rubber Granulaat Mat?

Navigating the B2B marketplace for rubber granulaat mat requires familiarity with essential trade terminology. Understanding these terms can streamline communication and negotiation processes.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rubber granulaat mat, identifying OEM suppliers can ensure that you receive high-quality products that meet your specifications. Buyers should ask about OEM capabilities when sourcing materials.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. For international buyers, knowing the MOQ helps in assessing whether a supplier can meet their needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products. For B2B buyers, issuing an RFQ for rubber granulaat mat can clarify costs and lead times, allowing for informed decision-making. Providing detailed specifications in the RFQ can result in more accurate quotes.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with Incoterms is essential for international transactions to avoid misunderstandings regarding shipping costs, insurance, and risk management. Buyers should clarify which Incoterms apply to their purchase to ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is critical for project planning and inventory management. B2B buyers should inquire about lead times when negotiating contracts to ensure that products arrive when needed, particularly in regions with longer shipping durations.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions and foster successful partnerships in the rubber granulaat mat industry.

Navigating Market Dynamics and Sourcing Trends in the rubber granulaat mat Sector

What Are the Current Market Dynamics Affecting Rubber Granulaat Mat Buyers?

The rubber granulaat mat sector is currently influenced by several key global drivers. Increasing awareness of health and safety standards in various industries, particularly in sports and playgrounds, is pushing demand for high-quality rubber mats. Furthermore, the rise of e-commerce platforms has facilitated easier access for international buyers, especially from emerging markets in Africa and South America. In Europe, particularly in countries like Italy and Poland, there is a growing trend towards customization of rubber mats, catering to specific requirements such as size, color, and texture, which enhances the user experience.

Technological advancements in manufacturing processes, such as the adoption of automated production lines and 3D printing, are also shaping the market. These innovations not only improve efficiency but also allow for the production of more sustainable products. The integration of data analytics in supply chain management is enabling buyers to make more informed decisions, optimizing sourcing strategies and reducing costs. As a result, international B2B buyers are increasingly seeking suppliers who can offer transparency and flexibility in their operations.

How Does Sustainability Influence Sourcing in the Rubber Granulaat Mat Sector?

Sustainability is becoming a critical factor for B2B buyers in the rubber granulaat mat market. The environmental impact of rubber production, including deforestation and carbon emissions, has led to heightened scrutiny from consumers and regulatory bodies alike. Buyers from regions like the Middle East and Europe are increasingly prioritizing ethical sourcing practices. This includes selecting suppliers who adhere to environmentally friendly practices, such as using recycled materials or sourcing rubber from sustainably managed plantations.

Moreover, certifications like the Global Recycled Standard (GRS) and Forest Stewardship Council (FSC) are becoming essential for suppliers aiming to attract international buyers. These certifications not only demonstrate a commitment to sustainability but also help mitigate risks associated with supply chain disruptions. B2B buyers are advised to conduct thorough due diligence on potential suppliers, ensuring they align with sustainability goals and ethical standards. This approach not only benefits the environment but also enhances brand reputation, making it a crucial consideration for long-term success.

How Has the Rubber Granulaat Mat Sector Evolved Over Time?

The rubber granulaat mat sector has seen significant evolution over the past few decades. Initially, the market was dominated by basic rubber mats primarily used for industrial applications. However, as awareness of safety and environmental issues grew, the product range expanded to include specialized mats for sports, fitness, and playgrounds, catering to a broader audience. Innovations in material science have introduced more resilient and versatile products, enhancing performance while reducing environmental impact.

Today, the sector is characterized by a focus on customization and sustainability. Buyers are looking for products that not only meet functional requirements but also align with their corporate social responsibility goals. This evolution has necessitated a shift in sourcing strategies, with international buyers increasingly favoring suppliers who can offer innovative solutions and demonstrate a commitment to ethical practices. As the market continues to develop, staying informed about these trends will be crucial for B2B buyers aiming to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber granulaat mat

-

How do I choose the right rubber granulaat mat for my specific needs?

Selecting the right rubber granulaat mat involves assessing the specific requirements of your application. Consider factors such as the intended use (e.g., gym flooring, playgrounds, or industrial settings), the thickness of the mat, and the type of rubber used. It’s also essential to evaluate the mat’s resistance to moisture, UV exposure, and heavy traffic. Consult with suppliers who can provide samples and technical specifications to ensure the mat meets your operational demands while adhering to local regulations. -

What are the key features to look for in high-quality rubber granulaat mats?

When sourcing high-quality rubber granulaat mats, prioritize durability, slip resistance, and sound absorption. Look for mats made from recycled rubber, which not only supports sustainability but also offers excellent performance. Verify certifications that reflect compliance with safety standards, such as EN 1177 for impact-absorbing surfaces. Additionally, inquire about warranty terms, as reputable suppliers often provide guarantees that reflect their confidence in the product’s longevity and quality. -

What are the common customization options for rubber granulaat mats?

Many suppliers offer customization options for rubber granulaat mats, including color, thickness, and surface texture. Custom logos or patterns can also be incorporated to enhance branding. Discuss your specific needs with potential suppliers to understand their capabilities and minimum order quantities (MOQs) for customized products. Ensure that the customization aligns with your intended use, as certain features may impact performance, safety, and aesthetics. -

What minimum order quantities (MOQs) should I expect when sourcing rubber granulaat mats?

MOQs for rubber granulaat mats can vary significantly based on the supplier, customization options, and production capabilities. Typically, MOQs range from 100 to 500 square meters for standard products, while customized orders may require larger quantities. It’s advisable to discuss your needs upfront with suppliers to negotiate MOQs that fit your project requirements without incurring excessive costs or delays. -

What payment terms are standard for international B2B transactions involving rubber granulaat mats?

Standard payment terms for international B2B transactions often include options such as Letters of Credit (LC), advance payments, or net payment terms (30, 60, or 90 days). It’s essential to establish clear payment conditions upfront to avoid misunderstandings. Suppliers may also require a deposit before production begins, especially for customized orders. Ensure that your chosen payment method offers adequate protection against fraud and provides a clear outline of responsibilities for both parties. -

How can I effectively vet suppliers of rubber granulaat mats?

To vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their certifications and compliance with relevant standards, such as ISO or CE marking. Request samples to assess product quality and arrange for factory visits or virtual tours if feasible. Additionally, establish clear communication channels to gauge responsiveness and willingness to address your specific needs. -

What logistics considerations should I keep in mind when importing rubber granulaat mats?

When importing rubber granulaat mats, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling rubber products to ensure timely delivery. Familiarize yourself with import duties and documentation requirements to avoid delays at customs. Additionally, assess the supplier’s ability to provide necessary shipping documents, such as certificates of origin and quality assurance. -

How do I ensure quality assurance for rubber granulaat mats before finalizing my order?

To ensure quality assurance, request detailed product specifications and testing certifications from suppliers. Conduct a thorough inspection of samples before placing a bulk order. If possible, arrange for third-party quality inspections during production and before shipment. Establish clear quality standards in your purchase agreement, including tolerance levels for dimensions and material properties, to protect your investment and ensure compliance with your project requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rubber granulaat mat

In the ever-evolving landscape of rubber granulaat mat sourcing, strategic procurement remains a cornerstone for international B2B buyers. The key takeaways emphasize the importance of understanding market dynamics, supplier capabilities, and regional trends. Establishing relationships with reliable suppliers can lead to enhanced product quality and cost efficiency, ultimately driving competitive advantage.

A stock image related to rubber granulaat mat.

What are the future trends in rubber granulaat mat sourcing? As demand for eco-friendly and sustainable materials rises, buyers should consider suppliers who prioritize environmental responsibility. Moreover, leveraging technology, such as data analytics and supply chain management tools, can streamline procurement processes and improve decision-making.

For B2B buyers in Africa, South America, the Middle East, and Europe, it is crucial to remain proactive in identifying emerging markets and potential partnerships. By adopting a forward-thinking approach, buyers can not only secure better pricing but also ensure a steady supply of high-quality rubber granulaat mats tailored to their specific needs.

Now is the time to refine your sourcing strategies and explore innovative partnerships that can elevate your business. Engage with suppliers who share your commitment to quality and sustainability, and position your company for success in the global marketplace.