The Ultimate Guide to Ford Ranger 3.2L Pisto Specifications (2025)

Introduction: Navigating the Global Market for ford ranger 3.2l pisto specifications

In the ever-evolving landscape of the global automotive market, sourcing the right specifications for components like the Ford Ranger 3.2L piston can pose significant challenges for international B2B buyers. With diverse regulatory environments, varying quality standards, and an array of suppliers to choose from, making an informed decision is crucial for ensuring optimal vehicle performance and longevity. This guide is designed to demystify the complexities surrounding Ford Ranger 3.2L piston specifications, empowering buyers to navigate their options effectively.

Within this comprehensive resource, you will find detailed insights into the various types of pistons available, their applications in different markets, and the critical factors to consider when vetting suppliers. We’ll also delve into cost analysis, helping you understand the pricing structures across different regions, including Africa, South America, the Middle East, and Europe.

By the end of this guide, international B2B buyers will be equipped with the knowledge needed to make strategic purchasing decisions. Whether you’re looking to enhance your fleet’s performance or ensure compliance with local regulations, understanding the nuances of Ford Ranger 3.2L piston specifications is essential. Let this guide be your roadmap to successful sourcing and procurement in the global automotive marketplace.

Understanding ford ranger 3.2l pisto specifications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ford Ranger 3.2L XLS | Standard features, mid-range pricing | Construction, logistics | Pros: Good balance of cost and features. Cons: Limited advanced tech options. |

| Ford Ranger 3.2L XLT | Enhanced comfort and technology | Fleet management, transportation | Pros: Higher comfort and features. Cons: Higher initial investment. |

| Ford Ranger 3.2L Wildtrak | Premium features, off-road capabilities | Adventure tourism, specialized transport | Pros: Superior off-road performance. Cons: Higher maintenance costs. |

| Ford Ranger 3.2L Raptor | Performance-oriented, aggressive styling | Sports and recreational use | Pros: Exceptional power and handling. Cons: Fuel consumption can be high. |

| Ford Ranger 3.2L Limited | Luxury features, high-end materials | Executive transport, high-profile clients | Pros: Premium comfort and tech. Cons: Costly for budget-conscious buyers. |

What Are the Key Characteristics of the Ford Ranger 3.2L XLS?

The Ford Ranger 3.2L XLS is designed for businesses seeking a reliable workhorse. It features a standard 3.2L turbocharged diesel engine, providing a solid blend of power and efficiency. The XLS is often favored in construction and logistics due to its durability and cost-effectiveness. When considering this model, B2B buyers should weigh its essential features against the specific needs of their operations, especially if advanced technology is not a priority.

How Does the Ford Ranger 3.2L XLT Cater to Fleet Management Needs?

The Ford Ranger 3.2L XLT enhances the XLS with additional comfort and technological features, making it suitable for fleet management and transportation services. This model includes upgraded infotainment systems and improved interior quality, appealing to businesses that prioritize driver and passenger comfort. For B2B buyers, the XLT offers a compelling balance between functionality and comfort, although it comes with a higher initial cost compared to the XLS.

Why Choose the Ford Ranger 3.2L Wildtrak for Off-Road Applications?

The Ford Ranger 3.2L Wildtrak is tailored for businesses involved in adventure tourism or those requiring off-road capabilities. With its robust suspension and advanced four-wheel-drive system, it excels in challenging terrains. B2B buyers should consider this model for its superior off-road performance, although they must also account for potentially higher maintenance costs due to its specialized features.

What Makes the Ford Ranger 3.2L Raptor Ideal for Sports Use?

The Ford Ranger 3.2L Raptor stands out for its performance-oriented design and aggressive styling, making it a top choice for sports and recreational applications. It boasts a powerful engine and enhanced handling, ideal for businesses that require a vehicle capable of high-speed performance. However, B2B buyers must be mindful of its fuel consumption, which can be higher than other models, affecting long-term operating costs.

How Does the Ford Ranger 3.2L Limited Serve High-Profile Client Needs?

The Ford Ranger 3.2L Limited is designed for executive transport and high-profile clients, featuring luxurious interiors and advanced technology. This model is perfect for businesses that prioritize comfort and prestige in their transport solutions. While it offers premium features, buyers should consider the higher price point and ensure that it aligns with their budget constraints and client expectations.

Related Video: “Ford Ranger 2026 Full Review: Interior, Engine, and Off-Road Power!”

Key Industrial Applications of ford ranger 3.2l pisto specifications

| Industry/Sector | Specific Application of Ford Ranger 3.2L Pisto Specifications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty transportation of materials and equipment | Enhances efficiency in project timelines and reduces operational costs | Reliability of vehicle performance under load; availability of spare parts |

| Agriculture | Transporting agricultural produce and equipment | Increases productivity through reliable logistics and mobility | Terrain adaptability; fuel efficiency; maintenance support |

| Mining | Hauling minerals and equipment across rough terrains | Improves operational efficiency and safety in challenging environments | Durability under extreme conditions; payload capacity; service network |

| Logistics and Distribution | Last-mile delivery of goods | Streamlines supply chain operations and reduces delivery times | Load capacity; fuel consumption rates; compatibility with logistics systems |

| Tourism and Adventure | Transporting tourists and adventure gear in rugged terrains | Enhances customer experience through reliable and comfortable transport | Comfort features; safety ratings; local service availability |

How is the Ford Ranger 3.2L Pisto Used in the Construction Industry?

In the construction sector, the Ford Ranger 3.2L Pisto serves as a robust vehicle for transporting heavy materials, tools, and equipment to job sites. Its powerful engine and high towing capacity ensure that it can handle the demands of construction logistics. This utility vehicle helps reduce project delays by providing timely transportation solutions, which is critical in competitive markets. Buyers should prioritize sourcing vehicles that demonstrate reliability and have a strong network for spare parts to minimize downtime.

What Role Does the Ford Ranger 3.2L Pisto Play in Agriculture?

The agricultural industry benefits from the Ford Ranger 3.2L Pisto through its capability to transport produce and farming equipment efficiently. With its sturdy build and off-road capabilities, it can navigate various terrains, making it ideal for rural and remote areas. This versatility helps farmers increase productivity by ensuring timely deliveries and reducing spoilage. International buyers should consider fuel efficiency and maintenance support when sourcing this vehicle, as these factors are vital for long-term operational success.

How Does the Ford Ranger 3.2L Pisto Support Mining Operations?

In mining operations, the Ford Ranger 3.2L Pisto is essential for hauling minerals and equipment across rugged and uneven landscapes. Its design caters to the harsh conditions often found in mining sites, providing durability and safety for operators. By utilizing this vehicle, companies can enhance their operational efficiency and ensure the safety of their workforce. When sourcing, buyers should focus on the vehicle’s payload capacity and the availability of a service network to support ongoing maintenance needs.

Why is the Ford Ranger 3.2L Pisto Important for Logistics and Distribution?

For logistics and distribution companies, the Ford Ranger 3.2L Pisto is a reliable option for last-mile delivery of goods. Its compact design and efficient fuel consumption enable businesses to navigate urban environments and deliver products promptly. This vehicle plays a crucial role in streamlining supply chain operations, ultimately reducing delivery times and enhancing customer satisfaction. B2B buyers should evaluate load capacity and compatibility with existing logistics systems when considering this vehicle for their operations.

How Can the Ford Ranger 3.2L Pisto Enhance Tourism and Adventure Services?

In the tourism sector, the Ford Ranger 3.2L Pisto is utilized for transporting tourists and their gear in challenging terrains. This vehicle’s comfort features and safety ratings make it an attractive option for tour operators aiming to provide a memorable experience. By ensuring reliable transportation, businesses can enhance customer satisfaction and loyalty. When sourcing, it’s important for international buyers to consider local service availability and the vehicle’s performance in various weather conditions to ensure operational reliability.

Related Video: Jason Mantzoukas Uses His Celebrity Lookalike | Taskmaster Series 19 | Channel 4 Entertainment

3 Common User Pain Points for ‘ford ranger 3.2l pisto specifications’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Replacement Parts

The Problem:

International B2B buyers often struggle to find reliable suppliers for high-quality replacement parts for the Ford Ranger 3.2L piston specifications. This challenge is particularly pronounced in regions like Africa and South America, where local suppliers may not have the necessary inventory or knowledge about the specific requirements of the 3.2L engine. This lack of access can lead to increased downtime, higher operational costs, and ultimately, a negative impact on business efficiency.

The Solution:

To address this issue, buyers should develop relationships with reputable suppliers that specialize in automotive parts for the Ford Ranger. Conduct thorough research to identify suppliers with a proven track record in your region. Utilize online platforms and forums to connect with other businesses that have successfully sourced parts. Additionally, consider establishing partnerships with suppliers who can provide not just parts, but also technical support and guidance on installation and maintenance. This proactive approach ensures that you have a reliable source for quality parts, minimizing downtime and maintaining operational efficiency.

Scenario 2: Understanding Technical Specifications and Compatibility Issues

The Problem:

Another significant challenge for B2B buyers is navigating the complex technical specifications related to the Ford Ranger 3.2L piston. Buyers may find it difficult to ensure that the components they are sourcing are compatible with their existing fleet, particularly if they are managing multiple vehicle models. This confusion can lead to costly errors, such as purchasing incorrect parts that do not fit or function properly, ultimately delaying projects and affecting profitability.

The Solution:

To mitigate compatibility issues, buyers should invest time in understanding the specific technical specifications of the Ford Ranger 3.2L piston. Create a detailed inventory of the specifications for each vehicle in your fleet, including engine type, model year, and any modifications that may have been made. Engage with technical experts or engineers who can provide clarity on the specifications and compatibility of parts. Furthermore, when sourcing components, always request detailed specifications and compatibility information from suppliers. Implementing a systematic approach to documentation and communication will significantly reduce the risk of errors and enhance procurement efficiency.

Scenario 3: Managing Costs and Budget Constraints

The Problem:

Cost management is a perennial concern for B2B buyers, especially when dealing with the specific requirements of the Ford Ranger 3.2L piston specifications. Buyers often face budget constraints, which can make it challenging to procure the necessary parts without sacrificing quality. This can lead to difficult decisions, such as opting for cheaper, lower-quality alternatives that may not meet the durability and performance standards required for long-term use.

The Solution:

To effectively manage costs while ensuring quality, buyers should adopt a strategic approach to procurement. Begin by conducting a comprehensive cost analysis to identify where you can optimize expenses without compromising on quality. Explore bulk purchasing options with suppliers, as many offer discounts for larger orders. Additionally, consider establishing long-term contracts with preferred suppliers to secure more favorable pricing. It may also be beneficial to evaluate alternative high-quality brands that meet the specifications of the Ford Ranger 3.2L piston. By diversifying your sourcing strategy and maintaining open communication with suppliers about your budget constraints, you can ensure that you obtain the best possible value while adhering to quality standards.

Strategic Material Selection Guide for ford ranger 3.2l pisto specifications

When selecting materials for the Ford Ranger 3.2L piston specifications, it is crucial for international B2B buyers to consider the unique properties and performance characteristics of various materials. This guide will analyze four common materials used in piston manufacturing, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in Ford Ranger 3.2L Piston Specifications?

Aluminum is a widely used material for pistons due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 300°C and can withstand significant pressure, making it suitable for high-performance applications. Additionally, aluminum exhibits good corrosion resistance, which is essential for durability in various environments.

Pros & Cons: The primary advantage of aluminum pistons is their weight, which contributes to improved fuel efficiency and engine performance. However, they can be more expensive than other materials and may require complex manufacturing processes to achieve the desired precision.

Impact on Application: Aluminum pistons are compatible with a wide range of fuels and lubricants, making them versatile for different engine types. However, they may not perform as well in extreme conditions compared to other materials.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and JIS. In regions with high temperatures, like parts of Africa and the Middle East, the thermal properties of aluminum should be a key consideration.

How Does Cast Iron Compare for Ford Ranger 3.2L Piston Specifications?

Cast iron is another common material used in piston manufacturing, known for its excellent wear resistance and ability to withstand high temperatures and pressures. It can handle temperatures up to 400°C, making it suitable for heavy-duty applications.

Pros & Cons: The primary advantage of cast iron is its durability and low cost, making it an economical choice for mass production. However, its heavier weight can lead to reduced fuel efficiency and performance.

Impact on Application: Cast iron pistons are well-suited for high-compression engines, but they may not be the best choice for performance-oriented applications due to their weight.

Considerations for International Buyers: Buyers in Europe and South America should be aware of local manufacturing standards and regulations regarding emissions, as cast iron may not meet stringent requirements in some regions.

What Are the Benefits of Forged Steel for Ford Ranger 3.2L Piston Specifications?

Forged steel is a premium material choice for high-performance pistons, offering superior strength and resilience. It can withstand extreme temperatures, often rated above 500°C, and high pressures, making it ideal for racing and heavy-duty applications.

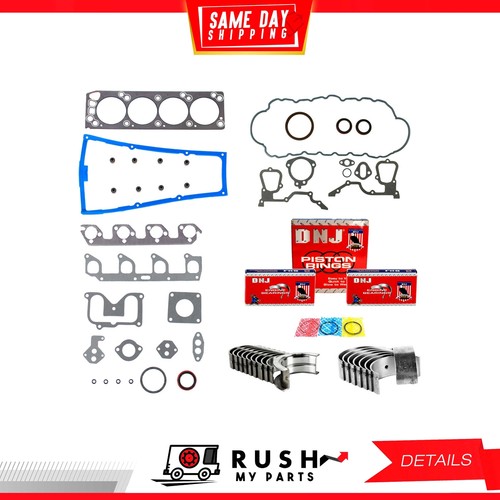

A stock image related to ford ranger 3.2l pisto specifications.

Pros & Cons: The key advantage of forged steel is its exceptional durability and ability to handle extreme conditions. However, the manufacturing process is complex and costly, which can impact the overall price of the pistons.

Impact on Application: Forged steel pistons are compatible with various fuels and lubricants, making them versatile for performance engines. They also provide better thermal expansion characteristics compared to aluminum.

Considerations for International Buyers: Buyers should consider the cost-benefit ratio, especially in regions where high-performance vehicles are popular. Compliance with international standards is also crucial, particularly in Europe, where regulations are stringent.

What Role Does Composite Material Play in Ford Ranger 3.2L Piston Specifications?

Composite materials, often a blend of metals and polymers, are gaining popularity for their lightweight and high-strength properties. They can handle temperatures up to 400°C and provide excellent corrosion resistance.

Pros & Cons: The main advantage of composite materials is their lightweight nature, which can enhance engine efficiency. However, they can be more expensive to produce and may require specialized manufacturing processes.

Impact on Application: Composite pistons are suitable for various engine types but may not be as durable as traditional metals in extreme conditions.

Considerations for International Buyers: Buyers should evaluate the long-term benefits versus initial costs, especially in emerging markets where budget constraints are significant. Compliance with local standards is also essential.

Summary Table of Material Selection for Ford Ranger 3.2L Piston Specifications

| Material | Typical Use Case for ford ranger 3.2l pisto specifications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight pistons for improved fuel efficiency | Excellent thermal conductivity | Higher manufacturing complexity | Medium |

| Cast Iron | Heavy-duty applications with high wear resistance | Cost-effective and durable | Heavier, may reduce performance | Low |

| Forged Steel | High-performance and racing applications | Superior strength and resilience | Complex and costly manufacturing | High |

| Composite | Lightweight applications with corrosion resistance | Enhanced engine efficiency | Expensive and specialized production | High |

This strategic material selection guide provides a comprehensive overview of the materials available for Ford Ranger 3.2L pistons, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ford ranger 3.2l pisto specifications

What Are the Key Stages in the Manufacturing Process of Ford Ranger 3.2L Pistons?

The manufacturing process for Ford Ranger 3.2L pistons is a multi-stage procedure that ensures precision and durability. Understanding these stages is crucial for international B2B buyers looking to source high-quality components.

1. Material Preparation

The first step involves selecting high-grade materials, typically aluminum alloy, due to its lightweight and thermal properties. Suppliers must ensure that the raw materials meet specific industry standards. Quality assurance begins here, as impurities in the material can lead to defects in the final product. Buyers should verify that suppliers conduct thorough material inspections, often backed by certificates of analysis (CoA) that confirm compliance with international material standards.

2. Forming

In the forming stage, the prepared materials undergo processes such as casting or forging. For pistons, die-casting is commonly used to achieve the required shape and structural integrity. This stage is critical, as the precision of the forming process directly affects the performance of the piston. B2B buyers should inquire about the forming techniques used by suppliers, ensuring they adopt advanced technologies such as CNC machining to achieve tighter tolerances.

3. Assembly

Once the individual components are formed, they proceed to assembly. This stage may involve integrating various piston elements, such as piston rings and pins. Efficient assembly lines often use automated systems to enhance precision and reduce human error. For B2B buyers, it’s essential to assess the supplier’s assembly capabilities and whether they employ lean manufacturing principles to optimize productivity and minimize waste.

4. Finishing

The finishing stage includes processes like surface treatment, machining, and polishing. These processes are vital for enhancing the durability and performance of the pistons. Techniques such as anodizing or shot peening may be employed to improve wear resistance. Buyers should request details on the finishing techniques used by their suppliers, as these can significantly impact the longevity and functionality of the pistons.

How is Quality Assurance Implemented in the Manufacturing of Ford Ranger 3.2L Pistons?

Quality assurance is a crucial component of the manufacturing process for Ford Ranger 3.2L pistons, ensuring that every product meets stringent standards.

Adherence to International Standards: Why Is ISO 9001 Important?

ISO 9001 certification is a widely recognized international standard for quality management systems. Suppliers of Ford Ranger pistons should be certified to ensure they adhere to best practices in quality management. This certification helps guarantee consistency in manufacturing processes, which is particularly important for B2B buyers in Africa, South America, the Middle East, and Europe seeking reliable suppliers. Buyers should request proof of certification and regularly review the supplier’s adherence to these standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected for quality before they enter the production line. Suppliers should perform thorough inspections and maintain records of material quality.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes remain within defined parameters. This includes monitoring machining tolerances and ensuring that forming processes are executed correctly.

-

Final Quality Control (FQC): At this stage, the finished pistons undergo rigorous testing and inspections to verify compliance with specifications. Buyers should inquire about the specific tests performed, such as dimensional checks and performance evaluations.

What Common Testing Methods Are Used for Ford Ranger Pistons?

Several testing methods are utilized to ensure the quality of Ford Ranger 3.2L pistons:

-

Dimensional Inspection: This involves measuring critical dimensions using precision tools to ensure they meet specifications.

-

Mechanical Testing: Tests such as tensile strength and fatigue testing assess the material properties of the pistons, ensuring they can withstand operational stress.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection help detect internal defects without damaging the pistons.

B2B buyers should seek detailed reports on these testing methods from suppliers to verify that their quality assurance processes are robust.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verifying a supplier’s quality control measures is crucial for B2B buyers, particularly when sourcing from different regions. Here are some actionable steps:

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their quality management practices. Buyers should develop an audit checklist that includes evaluating manufacturing processes, quality control checkpoints, and compliance with international standards.

Request Detailed QC Reports

Suppliers should provide comprehensive QC reports that outline inspection results, testing methods used, and any corrective actions taken for identified issues. This transparency can build trust and confidence in the supplier’s capabilities.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These organizations can conduct audits and testing, offering additional assurance regarding product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

A stock image related to ford ranger 3.2l pisto specifications.

For international B2B buyers, understanding the nuances of quality control and certification is essential, particularly when sourcing from regions like Africa, South America, the Middle East, and Europe.

Regional Compliance Standards

Different regions may have specific compliance standards beyond ISO 9001. For example, CE marking is required for products sold in the European market, while API standards may be relevant for certain industrial applications. Buyers should ensure that suppliers are familiar with and comply with these regional standards.

Language and Documentation Challenges

Language barriers and differing documentation practices can complicate the verification process. Buyers should ensure that suppliers can provide documentation in a language they understand and that the documentation meets international standards.

By comprehensively understanding the manufacturing processes and quality assurance practices for Ford Ranger 3.2L pistons, B2B buyers can make informed decisions that ensure they source high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ford ranger 3.2l pisto specifications’

Introduction

Sourcing the right components for the Ford Ranger 3.2L piston specifications is crucial for international B2B buyers looking to ensure quality, performance, and compatibility in their automotive projects. This practical guide provides a step-by-step checklist to help you navigate the sourcing process effectively, from defining technical specifications to evaluating suppliers. By following these steps, you can streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear and precise technical specifications is the foundation of successful sourcing. Determine the specific requirements for the Ford Ranger 3.2L piston, such as dimensions, materials, weight, and performance standards.

– Consider the application: Identify whether the pistons will be used in standard or high-performance engines.

– Consult industry standards: Ensure compliance with relevant automotive industry standards to avoid compatibility issues.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in automotive components, particularly pistons for the Ford Ranger 3.2L.

– Utilize online marketplaces: Platforms like Alibaba or TradeIndia can provide a broad range of suppliers.

– Seek recommendations: Engage with industry peers or trade associations to find reputable suppliers with proven track records.

Step 3: Evaluate Supplier Certifications

Before moving forward, it’s essential to verify that your potential suppliers hold the necessary certifications. This step ensures that the suppliers adhere to quality management systems and industry regulations.

– Look for ISO certifications: ISO 9001 is particularly relevant for quality assurance.

– Check for automotive-specific certifications: Such as IATF 16949, which emphasizes continuous improvement and defect prevention.

Step 4: Request Product Samples

Requesting product samples is a critical step to assess the quality of the pistons before making a bulk purchase.

– Evaluate fit and performance: Test the samples in your specific application to ensure compatibility and performance.

– Assess material quality: Inspect the material used for manufacturing to confirm it meets your specifications.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– Consider total cost of ownership: Look beyond the initial price and evaluate factors like shipping costs, duties, and potential tariffs.

– Establish clear terms: Ensure that all terms are documented to avoid misunderstandings later.

Step 6: Review Logistics and Supply Chain Options

Understanding the logistics involved in sourcing the Ford Ranger 3.2L pistons is vital for timely delivery.

– Assess shipping methods: Determine the most efficient shipping options based on your location and urgency.

– Evaluate supplier’s logistics capabilities: Confirm that the supplier can meet your delivery timelines and has experience with international shipping.

Step 7: Finalize the Purchase Order

After confirming all details and ensuring both parties are aligned, finalize the purchase order.

– Include all specifications and terms: Clearly outline the technical specifications, pricing, and delivery terms in the purchase order.

– Establish a communication plan: Set up a process for updates and notifications throughout the order fulfillment process.

By following this checklist, international B2B buyers can effectively navigate the complexities of sourcing Ford Ranger 3.2L piston specifications, ensuring they secure quality products while optimizing costs and delivery timelines.

Comprehensive Cost and Pricing Analysis for ford ranger 3.2l pisto specifications Sourcing

What Are the Key Cost Components for Sourcing Ford Ranger 3.2L Pisto Specifications?

When considering sourcing Ford Ranger 3.2L pisto specifications, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The raw materials for manufacturing pistons, such as aluminum alloys or cast iron, significantly impact the overall cost. Sourcing high-quality materials may require higher initial expenditure but can lead to long-term savings through improved durability and performance.

-

Labor: Labor costs vary by region and can influence the final price. Countries with lower labor costs may offer competitive pricing; however, it’s essential to consider the trade-off in terms of quality and expertise.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these overheads.

-

Tooling: The costs associated with creating molds and tools for production can be substantial. Buyers should inquire about the tooling costs upfront, as these can be amortized over larger order quantities.

-

Quality Control (QC): Implementing stringent quality control measures can increase costs but is necessary to ensure that the pistons meet required specifications and certifications.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the destination. Consideration of Incoterms is essential to understand who bears the cost and risk at various stages of the shipping process.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins in your region can aid in negotiation.

How Do Price Influencers Affect Sourcing Ford Ranger 3.2L Pistons?

Several factors can influence the pricing of Ford Ranger 3.2L pistons:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Understanding the supplier’s MOQ policy can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom specifications or modifications can increase costs. Buyers should clarify their requirements early in the sourcing process to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-grade materials and internationally recognized certifications (like ISO or TS) can lead to higher prices but may be necessary for compliance and performance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms can significantly impact the total landed cost. For example, opting for FOB (Free on Board) may mean that buyers are responsible for shipping costs, while DDP (Delivered Duty Paid) includes all shipping and customs costs in the quoted price.

What Are Effective Buyer Tips for Sourcing Ford Ranger 3.2L Pistons?

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Always be prepared to negotiate pricing and terms. Leverage your purchasing power, especially if you can commit to larger volumes.

-

Focus on Cost-Efficiency: Consider not only the purchase price but also the Total Cost of Ownership (TCO), which includes maintenance, operation, and replacement costs over the product’s lifecycle.

-

Understand Pricing Nuances: Be aware of local market conditions and economic factors that might affect pricing. Currency fluctuations can impact costs, so consider hedging strategies if dealing in foreign currencies.

-

Evaluate Suppliers Thoroughly: Conduct due diligence on potential suppliers. Look for reviews, ask for references, and consider visiting their facilities if possible to assess their capabilities firsthand.

-

Stay Informed About Regulatory Changes: Regulations regarding manufacturing and import/export can change frequently. Staying updated on these can help avoid unexpected costs and delays.

Disclaimer on Indicative Prices

Prices for Ford Ranger 3.2L pistons are subject to change based on market conditions, supplier negotiations, and other factors. Always seek updated quotes and conduct thorough market research to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing ford ranger 3.2l pisto specifications With Other Solutions

Understanding Alternatives in the Automotive Sector

When assessing the suitability of the Ford Ranger 3.2L Pisto for various business needs, it is essential to consider viable alternatives in the market. Different vehicles may offer similar functionalities, catering to diverse operational requirements and budgets. This section provides a comparative analysis of the Ford Ranger 3.2L Pisto against two notable alternatives: the Toyota Hilux and the Isuzu D-Max, highlighting key aspects that B2B buyers should evaluate.

Comparison Table

| Comparison Aspect | Ford Ranger 3.2L Pisto Specifications | Toyota Hilux | Isuzu D-Max |

|---|---|---|---|

| Performance | 3.2L turbo-diesel engine, 197 hp | 2.8L turbo-diesel engine, 201 hp | 1.9L turbo-diesel engine, 148 hp |

| Cost | Mid-range pricing, approx. $38,000 | Slightly higher, approx. $40,000 | Lower, approx. $35,000 |

| Ease of Implementation | Requires specialized training for maintenance | Similar training required | Basic training sufficient |

| Maintenance | Moderate upkeep, parts availability good | Higher maintenance costs | Generally lower costs |

| Best Use Case | Off-road, heavy loads, rugged terrain | Urban, light off-road, reliability | Urban, agricultural use |

In-Depth Analysis of Alternatives

What Advantages Does the Toyota Hilux Offer?

The Toyota Hilux is renowned for its reliability and durability. With a slightly higher performance output than the Ford Ranger 3.2L Pisto, it is well-suited for urban environments and light off-road conditions. However, this vehicle comes with a higher initial purchase price and tends to incur greater maintenance costs over its lifespan. The Hilux is an excellent choice for businesses prioritizing brand reputation and resale value, especially in markets across Europe and Africa.

How Does the Isuzu D-Max Compare?

The Isuzu D-Max presents a cost-effective solution for B2B buyers looking for a reliable utility vehicle. With a lower purchase price than both the Ford Ranger and Toyota Hilux, the D-Max is particularly appealing for agricultural and urban applications. Its maintenance costs are generally lower, making it an economical choice for businesses operating on tight budgets. However, its performance may not match that of the Ranger or Hilux, particularly in heavy-duty applications, which could be a consideration for buyers needing rugged performance in challenging terrains.

Making the Right Choice for Your Business Needs

When selecting between the Ford Ranger 3.2L Pisto and its alternatives, B2B buyers should align their choice with specific operational requirements. If your business demands high performance and rugged capabilities, the Ford Ranger might be the most suitable option despite its higher price tag. Conversely, if cost-efficiency and reliability are paramount, the Isuzu D-Max could serve your needs effectively. The Toyota Hilux stands out for businesses looking for a balanced vehicle with a strong reputation, albeit at a higher investment. Ultimately, a thorough evaluation of performance, cost, and maintenance will guide you to the best solution tailored to your operational goals.

Essential Technical Properties and Trade Terminology for ford ranger 3.2l pisto specifications

What Are the Key Technical Properties of Ford Ranger 3.2L Piston Specifications?

When considering the Ford Ranger 3.2L piston specifications, several critical technical properties play a vital role in performance and compatibility. Understanding these properties is essential for international B2B buyers, particularly when sourcing components or negotiating contracts.

-

Material Grade

The material grade of the piston is crucial, as it determines its strength, durability, and performance under high temperatures and pressures. Typically, pistons are made from aluminum alloys due to their lightweight and excellent thermal conductivity. For B2B buyers, selecting the right material grade ensures longevity and reliability of the engine components, reducing maintenance costs and downtime. -

Diameter and Height Specifications

The diameter and height of the piston affect the engine’s displacement and overall performance. These measurements must align with the engine’s cylinder bore for optimal function. Buyers should ensure these specifications are compatible with their existing engine setups to avoid costly modifications or performance issues. -

Piston Ring Configuration

The piston ring configuration is vital for maintaining compression and controlling oil consumption. A typical Ford Ranger 3.2L piston may feature multiple rings designed to manage different functions. Buyers must understand the configuration to select the correct replacement parts, ensuring efficient engine operation and compliance with emissions standards. -

Tolerance Levels

Tolerance refers to the acceptable deviation from specified measurements. Tight tolerances in piston manufacturing are crucial for ensuring a proper fit within the engine, which directly impacts performance and efficiency. B2B buyers should prioritize suppliers who adhere to strict tolerance levels to avoid potential issues related to engine wear and tear. -

Weight

The weight of the piston can influence engine dynamics, including acceleration and fuel efficiency. Lighter pistons can enhance performance but must maintain structural integrity. Buyers should consider the balance between weight and strength when sourcing pistons, as this can significantly impact the vehicle’s overall performance.

What Are Common Trade Terms Relevant to Ford Ranger 3.2L Piston Specifications?

In addition to technical properties, understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle, ensuring compatibility and quality. Buyers often prefer OEM components for their reliability, though they may come at a premium. Understanding the difference between OEM and aftermarket parts can aid in making informed purchasing decisions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, understanding MOQ is crucial for budgeting and supply chain planning. Buyers should negotiate MOQs with suppliers to align with their inventory needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quotation for specific products. Crafting a detailed RFQ can help buyers receive competitive pricing and better understand the market. Including precise specifications for the Ford Ranger 3.2L pistons in an RFQ can streamline the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers navigate shipping, insurance, and delivery responsibilities effectively. This knowledge is essential for reducing risks and ensuring timely delivery of components. -

Lead Time

Lead time refers to the time taken from placing an order until its delivery. Understanding lead times is critical for B2B buyers to manage project timelines and inventory levels effectively. Buyers should inquire about lead times when negotiating contracts to align their operational needs with supplier capabilities.

By grasping these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the ford ranger 3.2l pisto specifications Sector

What Are the Current Market Dynamics Affecting Ford Ranger 3.2L Pisto Specifications?

The market for Ford Ranger 3.2L pisto specifications is influenced by several global drivers, including the increasing demand for high-performance vehicles, the growth of the automotive aftermarket, and advancements in technology. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is crucial to understand these dynamics to make informed sourcing decisions.

Emerging trends in B2B technology are reshaping how buyers engage with suppliers. Innovations such as digital supply chain management and predictive analytics are streamlining sourcing processes, allowing businesses to anticipate market needs and optimize inventory levels. Furthermore, the rise of e-commerce platforms specifically designed for automotive components is facilitating easier access to a wider range of suppliers and products, enhancing competition and driving down costs.

Additionally, international buyers must navigate fluctuating currency exchange rates and varying import regulations, which can impact pricing and availability. Understanding local market conditions, including consumer preferences and regulatory environments, is essential for making strategic sourcing decisions that align with business goals.

How Important Is Sustainability and Ethical Sourcing in the Ford Ranger 3.2L Pisto Specifications Sector?

Sustainability is becoming increasingly vital in the automotive sector, particularly for B2B buyers focused on Ford Ranger 3.2L pisto specifications. The environmental impact of vehicle production and the lifecycle of automotive parts raises significant concerns. Buyers are urged to prioritize suppliers who implement sustainable practices, such as reducing emissions during manufacturing and utilizing recycled materials.

Ethical sourcing is equally important, as consumers and businesses alike are becoming more conscious of the ethical implications of their purchases. This includes ensuring fair labor practices within the supply chain and sourcing materials that are conflict-free. Buyers should actively seek suppliers who hold certifications such as ISO 14001 for environmental management or Fair Trade certifications, which can provide assurance of ethical practices.

By integrating sustainability into sourcing strategies, international buyers can not only meet regulatory requirements but also enhance their brand reputation, attract eco-conscious customers, and gain a competitive edge in the market.

How Has the Ford Ranger 3.2L Pisto Specifications Market Evolved Over Time?

The Ford Ranger 3.2L pisto specifications market has undergone significant evolution since its introduction. Initially, the focus was primarily on performance and utility, catering to a niche market of off-road enthusiasts and commercial users. Over time, the demand for enhanced fuel efficiency and advanced safety features has led manufacturers to innovate and improve product offerings.

As global awareness of environmental issues has increased, there has been a marked shift towards integrating sustainable practices in production and sourcing. This evolution reflects a broader trend within the automotive industry, where ethical sourcing and sustainability are becoming non-negotiable factors for B2B buyers.

Understanding this historical context allows international buyers to appreciate the current landscape and anticipate future trends, ultimately making more informed decisions that align with both market demands and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of ford ranger 3.2l pisto specifications

-

How do I verify the quality of Ford Ranger 3.2L piston specifications from suppliers?

To ensure the quality of Ford Ranger 3.2L pistons, conduct thorough supplier vetting. Request certifications such as ISO 9001 to confirm adherence to quality management standards. Additionally, ask for product samples and perform independent testing if possible. Collaborating with local automotive experts can provide insights into the supplier’s reputation and reliability. Engage in discussions about their production processes to gauge their commitment to quality. -

What is the best way to assess the reliability of Ford Ranger 3.2L piston suppliers?

Evaluating supplier reliability involves checking their history in the automotive industry, including customer testimonials and case studies. Utilize platforms like LinkedIn to see their connections and endorsements. Request references from previous clients, particularly those in your region, to understand their experiences. Additionally, consider their production capacity and lead times to ensure they can meet your demands consistently. -

What are the typical minimum order quantities (MOQs) for Ford Ranger 3.2L pistons?

Minimum order quantities (MOQs) for Ford Ranger 3.2L pistons can vary significantly based on the supplier and region. Generally, MOQs can range from 100 to 500 units. It’s advisable to negotiate these terms, especially if you are a smaller buyer. Some suppliers may offer flexibility on MOQs for long-term contracts or bulk orders, so always inquire about options that suit your purchasing strategy. -

What payment terms should I expect when purchasing Ford Ranger 3.2L pistons internationally?

International payment terms for Ford Ranger 3.2L pistons typically include options like Letter of Credit (LC), advance payment, or net 30/60 days. The choice often depends on the buyer’s relationship with the supplier and the perceived risk level. Ensure to clarify these terms before finalizing your order to prevent misunderstandings. Additionally, consider using secure payment platforms to protect your transaction. -

How can I customize Ford Ranger 3.2L pistons to meet specific requirements?

Customization options for Ford Ranger 3.2L pistons may be available, depending on the supplier’s capabilities. Discuss your specific needs regarding material composition, design features, or performance specifications directly with the supplier. Ensure they have the necessary technology and expertise to accommodate your requests. It’s also prudent to request prototypes before committing to a large order to validate the customizations. -

What logistics considerations should I keep in mind when sourcing Ford Ranger 3.2L pistons?

When sourcing Ford Ranger 3.2L pistons internationally, consider shipping methods, timelines, and customs regulations. Ensure the supplier has experience in exporting to your region and can handle necessary documentation. Evaluate shipping costs and potential delays, especially in regions with complex logistics networks. Partnering with a logistics provider familiar with automotive parts can streamline the process. -

How do I ensure compliance with international standards for Ford Ranger 3.2L pistons?

To ensure compliance with international standards, confirm that your supplier adheres to regulations such as CE marking for Europe or other local standards relevant to your region. Request documentation that demonstrates compliance, including test reports and quality certifications. Familiarize yourself with the specific regulatory requirements of your target market to avoid potential legal issues or product recalls. -

What are the common issues faced when sourcing Ford Ranger 3.2L pistons, and how can I mitigate them?

Common issues include quality discrepancies, delivery delays, and communication barriers. To mitigate these risks, establish clear communication channels and set realistic timelines with your supplier. Conduct regular quality inspections and maintain an open dialogue to address any concerns promptly. Additionally, consider working with local agents who understand the market dynamics and can facilitate smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ford ranger 3.2l pisto specifications

As the automotive landscape evolves, the strategic sourcing of components such as the Ford Ranger 3.2L pistons becomes increasingly vital for international B2B buyers. Understanding the specifications and sourcing dynamics of these pistons allows businesses to enhance their supply chain efficiency and product quality. The Ford Ranger 3.2L pistons are recognized for their durability and performance, making them a prime choice for various applications across diverse markets.

Why is Strategic Sourcing Important for International B2B Buyers?

Effective strategic sourcing not only reduces costs but also enhances supplier relationships, ensuring a consistent supply of high-quality components. Buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with reliable manufacturers who can deliver on both specifications and timelines. Leveraging local suppliers while also considering global options can provide a competitive edge, particularly in regions with growing automotive markets.

What is the Future Outlook for Sourcing Ford Ranger 3.2L Pistons?

As demand for the Ford Ranger continues to rise, so too will the need for innovative sourcing strategies. B2B buyers should stay informed about market trends, technological advancements, and regulatory changes that could impact sourcing decisions. Engaging in proactive sourcing initiatives will empower businesses to meet customer needs effectively while optimizing their operational costs.

In conclusion, international B2B buyers are encouraged to embrace a forward-thinking approach to sourcing Ford Ranger 3.2L pistons. By fostering strong supplier relationships and staying attuned to market dynamics, companies can ensure sustainable growth and success in their respective markets.