Unlock Savings: The Ultimate Guide to SDGI Cables (2025)

Introduction: Navigating the Global Market for sdgi cables

In the rapidly evolving landscape of global trade, sourcing reliable and efficient sdgi cables can pose a significant challenge for international B2B buyers. As industries increasingly rely on advanced technology for seamless operations, the demand for high-quality sdgi cables has surged. This guide is designed to equip you with the essential knowledge to navigate the complexities of the global market, ensuring you make informed purchasing decisions that align with your business needs.

Throughout this comprehensive resource, we will delve into various types of sdgi cables, explore their diverse applications across different sectors, and outline best practices for supplier vetting. Additionally, we will provide insights into pricing structures and cost considerations that can impact your procurement strategies. Whether you are based in Africa, South America, the Middle East, or Europe, understanding these key elements will empower you to select the right cables that enhance your operational efficiency and reliability.

By the end of this guide, you will be well-prepared to engage with suppliers, assess the quality of products, and negotiate favorable terms. Our focus on actionable insights and strategic recommendations will help you overcome the hurdles of sourcing sdgi cables, ensuring your business stays competitive in today’s dynamic market.

Understanding sdgi cables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SDGI Cable | Basic design, commonly used, cost-effective | General industrial applications | Pros: Affordable, widely available. Cons: Limited durability for harsh environments. |

| High-Temperature SDGI Cable | Enhanced insulation, heat-resistant materials | Aerospace, automotive industries | Pros: Superior performance in extreme conditions. Cons: Higher initial cost. |

| Flexible SDGI Cable | Greater flexibility, ideal for dynamic applications | Robotics, automation systems | Pros: Easy to install in tight spaces. Cons: May be less robust than rigid options. |

| Shielded SDGI Cable | Additional shielding against electromagnetic interference | Telecommunications, data centers | Pros: Reduces signal loss, enhances reliability. Cons: More expensive than unshielded options. |

| Marine SDGI Cable | Corrosion-resistant, waterproof features | Offshore platforms, shipbuilding | Pros: Long-lasting in harsh marine environments. Cons: Specialized, may have limited suppliers. |

What Are the Key Characteristics of Standard SDGI Cables?

Standard SDGI cables are the most commonly used type in various industrial applications. They feature a basic design that typically includes a multi-stranded conductor and are often insulated with PVC or similar materials. Their affordability makes them an attractive option for businesses looking to minimize costs without sacrificing quality. However, potential buyers should consider that these cables may not withstand extreme environmental conditions, which could lead to premature failure in demanding applications.

When Should You Consider High-Temperature SDGI Cables?

High-temperature SDGI cables are specifically designed to endure elevated temperatures, making them ideal for industries such as aerospace and automotive. These cables utilize advanced insulation materials that can withstand heat without degrading. B2B buyers in sectors where high thermal resistance is crucial should prioritize these cables, despite their higher initial costs. The investment is often justified by their enhanced durability and reliability in extreme conditions, reducing long-term operational risks.

How Do Flexible SDGI Cables Benefit Dynamic Applications?

Flexible SDGI cables are engineered for environments where movement and bending are frequent. They are ideal for robotics and automation systems, where space constraints and dynamic applications require adaptability. The key purchasing consideration for businesses is balancing flexibility with durability; while these cables are easier to install, they may not offer the same robustness as their rigid counterparts. Buyers should assess the specific movement requirements of their applications to ensure optimal performance.

Why Choose Shielded SDGI Cables for Communication Needs?

Shielded SDGI cables are designed to minimize electromagnetic interference (EMI), making them essential for telecommunications and data center applications. The additional shielding enhances signal integrity and reliability, which is crucial for high-speed data transfer. While these cables come at a premium compared to unshielded options, the investment can lead to significant improvements in performance and reduced downtime. B2B buyers should consider their specific communication needs and the potential for signal degradation in their operational environments.

What Makes Marine SDGI Cables Unique for Offshore Applications?

Marine SDGI cables are specially constructed to resist corrosion and withstand harsh marine environments. They are essential for applications in offshore platforms and shipbuilding, where exposure to water and salt can severely impact cable integrity. Buyers should note that while these cables offer exceptional longevity and reliability, they are often more specialized and may have limited suppliers. Businesses in the maritime sector should prioritize these cables to ensure safety and operational efficiency in challenging conditions.

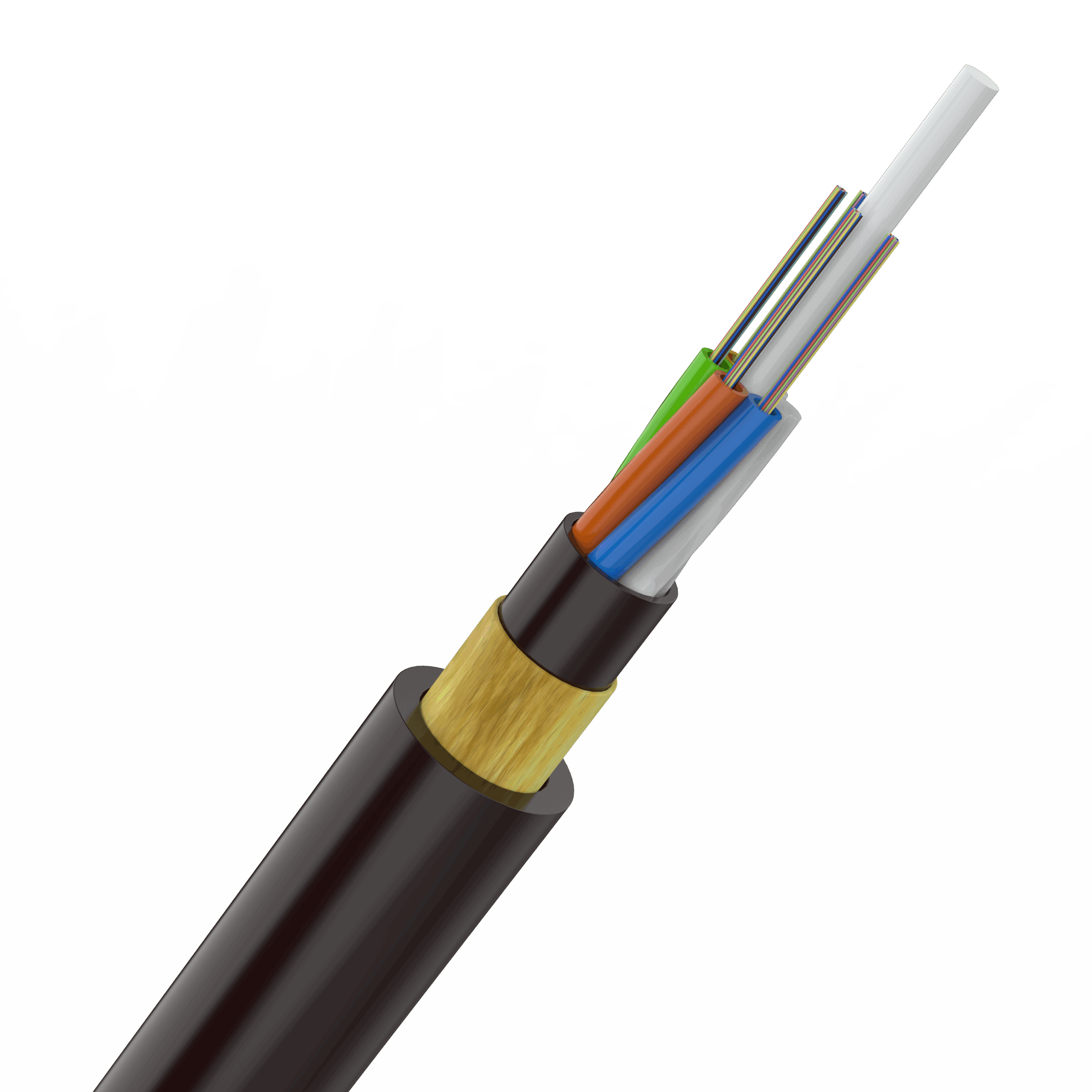

A stock image related to sdgi cables.

Related Video: Understanding Fibre Optic Cables & Types with Network Switches & Patch Panels

Key Industrial Applications of sdgi cables

| Industry/Sector | Specific Application of sdgi cables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Connection of solar panels and wind turbines | Enhanced energy efficiency and reliability | Compliance with international standards and certifications |

| Telecommunications | Data transmission for broadband networks | Increased bandwidth and reduced latency | Compatibility with existing infrastructure and future scalability |

| Manufacturing | Automation and control systems in production lines | Improved operational efficiency and reduced downtime | Durability in harsh environments and resistance to wear |

| Mining and Resources | Power supply for heavy machinery and equipment | Ensured safety and continuous operation | Local regulations and environmental impact assessments |

| Transportation and Logistics | Vehicle charging infrastructure and fleet management | Cost savings through optimized energy use | Availability of local support and maintenance services |

How Are sdgi Cables Used in Renewable Energy Applications?

In the renewable energy sector, sdgi cables are essential for connecting solar panels and wind turbines to the grid. These cables facilitate the efficient transmission of electricity generated from renewable sources. By utilizing sdgi cables, businesses can enhance energy efficiency, ensuring minimal loss during transmission. International buyers must consider compliance with local and international standards, ensuring that the cables are certified for use in their specific regions, especially in Africa and South America, where regulatory frameworks may vary.

What Role Do sdgi Cables Play in Telecommunications?

In telecommunications, sdgi cables are employed for data transmission across broadband networks. They help increase bandwidth and reduce latency, which are critical factors for service providers aiming to deliver high-speed internet. For B2B buyers, sourcing sdgi cables requires a focus on compatibility with existing infrastructure. Additionally, as the demand for digital services grows in the Middle East and Europe, ensuring that these cables can support future scalability is paramount.

How Are sdgi Cables Beneficial in Manufacturing?

In the manufacturing industry, sdgi cables are used in automation and control systems that drive production lines. These cables contribute to improved operational efficiency by ensuring reliable communication between machinery and control systems. For buyers, it is crucial to consider the durability of sdgi cables, particularly in harsh manufacturing environments. Resistance to wear and tear is essential to minimize downtime and maintain productivity, especially in regions with challenging operational conditions.

What Are the Applications of sdgi Cables in Mining and Resources?

In the mining sector, sdgi cables provide the necessary power supply for heavy machinery and equipment. This ensures safety and continuity of operations in environments that may pose risks to equipment. B2B buyers must be aware of local regulations and environmental impact assessments when sourcing these cables, particularly in regions like Africa and South America, where mining activities are often subject to stringent regulations.

How Do sdgi Cables Enhance Transportation and Logistics?

In the transportation and logistics sector, sdgi cables are crucial for developing vehicle charging infrastructure and fleet management systems. They enable optimized energy use, leading to significant cost savings for businesses. Buyers should prioritize the availability of local support and maintenance services when sourcing these cables, as this can greatly affect the operational efficiency of logistics operations, particularly in regions such as Europe and the Middle East where electric vehicle adoption is increasing.

Related Video: What is a Sensor? Different Types of Sensors, Applications

3 Common User Pain Points for ‘sdgi cables’ & Their Solutions

Scenario 1: Inconsistent Power Supply and Equipment Damage

The Problem: For many B2B buyers, particularly in emerging markets in Africa and South America, the inconsistency of power supply can lead to significant challenges. Fluctuations in voltage can cause SDGI cables to malfunction, resulting in equipment damage and costly downtimes. This issue is exacerbated in regions where infrastructure is still developing, making reliable power sources a rare commodity. Buyers often find themselves facing not only the immediate costs of repairs but also the long-term implications of lost productivity.

The Solution: To mitigate this problem, B2B buyers should prioritize the sourcing of SDGI cables that are specifically designed to handle voltage fluctuations. When selecting cables, look for products that have a high tolerance for voltage spikes and drops. Additionally, investing in voltage regulation equipment can protect both the SDGI cables and the connected devices. Conduct thorough tests to determine the voltage stability in your area and choose cables with an appropriate rating. It’s also advisable to consult with manufacturers or suppliers who have experience in your specific regional challenges, as they can offer tailored recommendations that ensure longevity and reliability.

Scenario 2: Difficulty in Compliance with International Standards

The Problem: B2B buyers in Europe and the Middle East often face stringent regulations regarding electrical equipment, including SDGI cables. Non-compliance with international safety and quality standards can result in financial penalties, project delays, and reputational damage. Navigating these complex regulations can be overwhelming, especially for companies looking to expand into new markets where standards may differ.

The Solution: Buyers should familiarize themselves with the relevant standards for SDGI cables, such as IEC, UL, and ISO certifications. Partnering with reputable suppliers who provide documentation and proof of compliance can streamline this process. Additionally, consider engaging with industry consultants or legal advisors who specialize in electrical compliance to ensure that all products meet local and international standards. Regularly training staff on compliance issues and keeping updated with regulatory changes will also help maintain adherence and avoid costly mistakes.

Scenario 3: Limited Supplier Options and Poor Quality Control

The Problem: In many regions, particularly in Africa and South America, there is a scarcity of reliable suppliers for SDGI cables, leading to a reliance on local vendors who may not adhere to strict quality control standards. This can result in purchasing subpar cables that fail to perform as expected, leading to project delays, increased costs, and safety hazards.

The Solution: To combat this issue, B2B buyers should broaden their supplier search by considering international manufacturers with proven track records in quality and reliability. Utilize platforms that allow for the comparison of suppliers and customer reviews to ensure that you are sourcing from reputable companies. Implement a robust vendor evaluation process that includes assessing their quality control measures, certifications, and warranty policies. Additionally, establishing long-term relationships with trusted suppliers can lead to better pricing and priority service, enhancing overall supply chain stability. Investing in sample testing before large purchases can also help in verifying product quality and performance.

Strategic Material Selection Guide for sdgi cables

When selecting materials for sdgi cables, international B2B buyers must consider a variety of factors that affect performance, durability, and compliance with regional standards. Below, we analyze four common materials used in sdgi cables, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyvinyl Chloride (PVC) in sdgi Cables?

Polyvinyl Chloride (PVC) is a widely used material in the manufacturing of sdgi cables. It boasts excellent electrical insulation properties, making it suitable for various applications. PVC can withstand temperatures ranging from -15°C to 70°C and is resistant to moisture, which enhances its durability in humid environments. Additionally, PVC exhibits good chemical resistance, although it may not perform well against certain solvents.

Pros & Cons:

The main advantages of PVC include its low cost and ease of manufacturing, which make it a popular choice for many applications. However, its limitations include reduced flexibility at lower temperatures and potential environmental concerns regarding its production and disposal.

Impact on Application:

PVC is particularly effective for indoor applications where exposure to harsh chemicals is minimal. It is compatible with a range of media, but its limitations in extreme conditions may restrict its use in outdoor or high-temperature environments.

Considerations for International Buyers:

Buyers should ensure that the PVC used meets local compliance standards, such as ASTM or DIN. In regions like Africa and South America, where humidity levels can be high, selecting a high-quality PVC variant can mitigate performance issues.

How Does Cross-Linked Polyethylene (XLPE) Enhance sdgi Cable Performance?

Cross-Linked Polyethylene (XLPE) is another material commonly used in sdgi cables, known for its superior thermal and electrical properties. XLPE can handle temperatures up to 90°C continuously and has excellent resistance to chemicals and UV radiation. This makes it suitable for both indoor and outdoor applications.

Pros & Cons:

XLPE offers high durability and flexibility, making it ideal for environments that experience temperature fluctuations. However, it tends to be more expensive than PVC and requires more complex manufacturing processes, which can impact overall cost.

Impact on Application:

XLPE is particularly beneficial for applications requiring high thermal performance and resistance to environmental factors. It is compatible with a wide range of media, including oils and solvents, making it a versatile choice for various industries.

Considerations for International Buyers:

Buyers should verify that XLPE cables conform to local standards, such as JIS in Japan or IEC in Europe. In regions like the Middle East, where temperatures can soar, XLPE’s high-temperature rating is a significant advantage.

What Are the Benefits of Thermoplastic Elastomers (TPE) for sdgi Cables?

Thermoplastic Elastomers (TPE) combine the properties of rubber and plastic, providing excellent flexibility and resilience. TPE can operate effectively within a temperature range of -40°C to 105°C and is resistant to various chemicals, making it suitable for diverse applications.

Pros & Cons:

The primary advantage of TPE is its flexibility and ability to withstand mechanical stress without compromising performance. However, TPE can be more costly than traditional materials like PVC and may require specialized manufacturing techniques.

Impact on Application:

TPE is particularly advantageous in applications where flexibility is crucial, such as in robotics and automotive industries. Its compatibility with different media types enhances its versatility.

Considerations for International Buyers:

Buyers should consider the specific grades of TPE that meet regional standards, especially in Europe, where environmental regulations may influence material selection.

Why Is Polypropylene (PP) a Suitable Choice for sdgi Cables?

Polypropylene (PP) is known for its lightweight and chemical resistance properties. It can operate effectively at temperatures up to 80°C and is resistant to moisture and various chemicals, making it suitable for many industrial applications.

Pros & Cons:

The advantages of PP include its low cost and ease of processing, which contribute to its widespread use. However, it has lower thermal stability compared to XLPE and may not perform well in high-temperature applications.

Impact on Application:

PP is suitable for applications where weight reduction is essential, such as in automotive and aerospace sectors. Its chemical resistance allows it to be used in environments where exposure to solvents is a concern.

Considerations for International Buyers:

Buyers should ensure that PP materials comply with relevant standards, particularly in Europe and South America, where environmental regulations may dictate material choices.

Summary Table of Material Selection for sdgi Cables

| Material | Typical Use Case for sdgi cables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor electrical installations | Low cost and easy to manufacture | Reduced flexibility at low temps | Low |

| XLPE | Outdoor and high-temperature applications | High thermal and chemical resistance | Higher cost and complex manufacturing | High |

| TPE | Flexible applications in robotics | Excellent flexibility and resilience | Higher cost and specialized processing | Medium |

| PP | Lightweight industrial applications | Low cost and good chemical resistance | Lower thermal stability | Low |

This guide provides actionable insights for international B2B buyers, enabling informed decisions when selecting materials for sdgi cables tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sdgi cables

What Are the Key Stages in the Manufacturing Process of SDGI Cables?

The manufacturing of SDGI (Self-Distributing Grounding Interconnect) cables involves several critical stages that ensure the final product meets performance and safety standards. Understanding these processes is crucial for B2B buyers seeking reliable suppliers.

1. Material Preparation

The first stage in the manufacturing of SDGI cables is material preparation. This includes sourcing high-quality raw materials such as copper, aluminum, and insulation compounds. B2B buyers should prioritize suppliers who provide certifications for their materials, ensuring they meet international standards. Suppliers often conduct tests on materials to verify their conductivity, tensile strength, and corrosion resistance before they are used in production.

2. Forming the Cable Structure

Once the materials are prepared, the next step is forming the cable structure. This involves processes such as:

- Wire Drawing: Reducing the diameter of metal rods into thin wires.

- Stranding: Twisting multiple wires together to form a strand, which enhances flexibility and strength.

- Insulation Application: Applying insulation materials to the conductors, which is critical for safety and performance.

For B2B buyers, understanding these techniques can help in assessing the supplier’s capabilities. Techniques like cold forming or extrusion may be used, each offering different benefits in terms of durability and flexibility.

3. Assembly of Components

The assembly stage involves bringing together all the individual components of the SDGI cable. This includes the conductors, insulation, and any additional elements such as shielding. Advanced manufacturing techniques, such as automated assembly lines, are often employed to ensure precision and consistency. Buyers should inquire about the machinery and technology used by suppliers, as modern techniques can significantly impact the quality of the final product.

4. Finishing Touches

After assembly, the cables undergo finishing processes. This may include cutting to specified lengths, applying protective coatings, and labeling. Quality at this stage is crucial, as it prepares the cables for shipping and installation. B2B buyers should ensure that their suppliers have robust finishing processes in place to prevent defects that could lead to failures in the field.

How Is Quality Assurance Integrated into SDGI Cable Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for SDGI cables. It ensures that the cables meet both international and industry-specific standards, which is essential for maintaining reliability and safety.

Relevant International Standards for SDGI Cables

B2B buyers should look for suppliers who adhere to recognized quality standards. Key certifications include:

- ISO 9001: This standard outlines the criteria for a quality management system, focusing on continuous improvement and customer satisfaction.

- CE Marking: Essential for products sold within the European Economic Area, CE marking indicates compliance with safety and health requirements.

- API Standards: For cables used in the oil and gas sector, API standards ensure that products meet industry-specific performance criteria.

Verifying these certifications can help buyers ensure they are partnering with reputable manufacturers.

What Are the Quality Control Checkpoints in SDGI Cable Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and maintain product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Regular inspections during manufacturing ensure that processes remain within defined parameters.

- Final Quality Control (FQC): The finished cables undergo rigorous testing for electrical performance, insulation integrity, and physical durability.

Understanding these checkpoints allows B2B buyers to assess the thoroughness of a supplier’s QC processes.

What Testing Methods Are Commonly Used for SDGI Cables?

Several testing methods are employed to verify the quality and performance of SDGI cables:

- Electrical Testing: Verifying the conductivity and insulation resistance to ensure the cables can handle operational demands.

- Mechanical Testing: Assessing tensile strength, flexibility, and resistance to environmental factors.

- Thermal Testing: Evaluating performance under various temperature conditions to prevent overheating and failures.

B2B buyers should ask suppliers for detailed reports of these tests to confirm that products meet the necessary standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

-

Supplier Audits: Conducting audits of manufacturing facilities allows buyers to directly assess the quality control processes in place. This can include reviewing documentation, observing practices, and interviewing personnel.

-

Requesting Quality Reports: Suppliers should provide comprehensive reports detailing their QC processes, including test results and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly beneficial for buyers in regions like Africa and South America, where local supply chains may vary in reliability.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers must navigate various challenges when assessing the quality control of suppliers:

-

Regulatory Compliance: Different regions have varying regulations and standards. For instance, European buyers must ensure compliance with CE marking, while those in the Middle East may need to consider local certifications.

-

Cultural Differences: Understanding the cultural context of suppliers can influence negotiation and communication regarding quality expectations.

-

Logistical Challenges: Shipping and handling can affect product quality. Buyers should discuss packaging and shipping methods with suppliers to mitigate risks during transport.

By focusing on these aspects, B2B buyers can make informed decisions when selecting suppliers for SDGI cables, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sdgi cables’

This practical sourcing guide aims to provide international B2B buyers with a clear and actionable checklist for procuring SDGI cables. By following these steps, buyers can ensure they select the right supplier and product to meet their specific needs, while also navigating the complexities of international trade.

Step 1: Define Your Technical Specifications

Before beginning your sourcing journey, it’s essential to establish clear technical specifications for the SDGI cables you require. This includes understanding the cable’s intended use, performance standards, and any regulatory compliance relevant to your industry. Detailed specifications help prevent misunderstandings with suppliers and ensure the product meets your operational requirements.

- Consider factors such as voltage ratings, insulation materials, and environmental conditions the cables will be exposed to.

- Document all specifications in detail to streamline communication with potential suppliers.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers of SDGI cables. Utilize online platforms, industry trade shows, and referrals from industry contacts to compile a list of candidates. A diverse supplier base can provide options that cater to different price points and lead times.

- Focus on suppliers with a proven track record in your region or industry.

- Look for suppliers that specialize in SDGI cables, as they will have deeper expertise and better product offerings.

Step 3: Verify Supplier Certifications and Compliance

Before finalizing any supplier, verify their certifications and compliance with international standards. This step is crucial for ensuring product quality and safety, particularly in regions with stringent regulations.

- Check for ISO certifications, industry-specific approvals, and compliance with local regulations in your target market.

- Request copies of relevant certifications and assess their validity through the issuing organizations.

Step 4: Request Samples for Testing

Once you have narrowed down your list of potential suppliers, request samples of the SDGI cables for testing. This allows you to evaluate the quality and performance of the cables before making a bulk purchase.

- Assess samples for physical characteristics, such as flexibility, insulation integrity, and overall construction quality.

- Conduct performance tests that mimic real-world conditions to ensure reliability.

Step 5: Evaluate Pricing and Payment Terms

Understanding pricing structures and payment terms is vital in the sourcing process. Evaluate quotes from different suppliers to determine competitive pricing while considering the total cost of ownership, including shipping, tariffs, and potential duties.

- Inquire about bulk purchase discounts, payment terms, and warranty options.

- Be cautious of significantly low prices, which may indicate inferior quality.

Step 6: Check References and Customer Reviews

Before making a final decision, check references and customer reviews for your shortlisted suppliers. This step provides insight into the supplier’s reliability, customer service, and product performance.

- Reach out to past clients to gain firsthand accounts of their experiences.

- Look for reviews on independent platforms to get an unbiased view of the supplier’s reputation.

Step 7: Finalize the Contract and Terms of Delivery

Once you have selected a supplier, finalize the contract and agree on terms of delivery. Ensure all aspects of your agreement are clearly defined, including lead times, delivery schedules, and responsibilities for shipping and handling.

- Include clauses that protect your interests, such as quality assurance measures and recourse for defective products.

- Confirm that the supplier understands the logistics involved in international shipping to your specific region.

By following this checklist, international B2B buyers can make informed decisions when sourcing SDGI cables, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for sdgi cables Sourcing

What Are the Key Cost Components in Sourcing sdgi Cables?

When sourcing sdgi cables, understanding the cost structure is crucial for international B2B buyers. The primary components contributing to the overall cost include:

-

Materials: The quality and type of materials used in sdgi cable production significantly impact costs. High-grade copper and specialized insulation materials may increase upfront costs but can offer enhanced performance and longevity.

-

Labor: Labor costs vary by region and can affect the total price. Regions with higher wage standards may lead to increased production costs. However, skilled labor can result in better quality output.

-

Manufacturing Overhead: This includes expenses related to utilities, factory maintenance, and administrative costs. Efficient manufacturing processes can help reduce these overheads, impacting overall pricing.

-

Tooling: Initial tooling costs for custom cable designs can be significant. While these costs can be amortized over larger production runs, they can substantially affect pricing for lower volume orders.

-

Quality Control (QC): Investing in quality assurance processes can lead to higher initial costs but may reduce long-term expenses by minimizing defects and returns.

-

Logistics: Shipping and handling costs must also be considered, especially for international transactions. Factors such as distance, shipping method, and weight can influence logistics costs.

-

Margin: Suppliers typically add a margin on top of their costs, which can vary based on market demand, competition, and supplier reputation.

What Price Influencers Should B2B Buyers Consider When Sourcing sdgi Cables?

Several factors can influence the pricing of sdgi cables, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders, making it essential to assess your purchasing needs. Negotiating lower MOQs can also help manage inventory costs.

-

Specifications and Customization: Customized cables with specific features or certifications will typically cost more. Clearly defining your requirements can help suppliers provide more accurate quotes.

-

Material Quality and Certifications: Premium materials and industry certifications can increase costs but are essential for ensuring compliance with local regulations and performance standards.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can also influence pricing. Established suppliers may offer better quality but at a higher cost.

-

Incoterms: Understanding Incoterms is crucial as they define responsibilities for shipping, insurance, and tariffs. Different terms can lead to variations in total costs.

How Can International B2B Buyers Negotiate Better Prices for sdgi Cables?

Negotiation is key when it comes to sourcing sdgi cables, particularly for international buyers from diverse regions like Africa, South America, the Middle East, and Europe. Here are some actionable tips:

-

Conduct Market Research: Understanding the market rates for sdgi cables in different regions can give you leverage during negotiations. This knowledge can help you identify fair pricing.

-

Explore Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors like installation, maintenance, and potential downtime costs. A higher upfront cost may be justified if the product offers lower long-term expenses.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Suppliers may be more willing to negotiate with buyers they trust.

-

Leverage Competitive Quotes: Obtaining multiple quotes from various suppliers can provide negotiating power. Make sure to compare the specifications and terms of each offer.

-

Be Flexible with Payment Terms: Offering to pay upfront or negotiating longer payment terms can sometimes lead to discounts.

What Should B2B Buyers Keep in Mind Regarding Indicative Prices?

A stock image related to sdgi cables.

It’s important for B2B buyers to approach pricing with caution. Prices can vary widely based on fluctuating material costs, currency exchange rates, and regional economic conditions. Always seek updated quotes and be prepared for price adjustments based on market trends. Keeping abreast of these changes will help in making informed purchasing decisions and maintaining budgetary control.

Alternatives Analysis: Comparing sdgi cables With Other Solutions

Understanding the Importance of Alternative Solutions in Cable Technology

In the ever-evolving landscape of B2B technology, selecting the right cable solution can significantly impact operational efficiency and cost-effectiveness. While sdgi cables are known for their specific advantages, it’s essential for international buyers to consider alternative technologies that may offer comparable or enhanced benefits. This analysis will compare sdgi cables with two viable alternatives: Fiber Optic Cables and Copper Cables, allowing buyers to make informed decisions based on their unique requirements.

Comparison Table of Cable Solutions

| Comparison Aspect | Sdgi Cables | Fiber Optic Cables | Copper Cables |

|---|---|---|---|

| Performance | High data transfer rate | Very high data transfer rate | Moderate data transfer rate |

| Cost | Moderate initial investment | Higher initial investment | Lower initial investment |

| Ease of Implementation | Moderate complexity | High complexity | Easy to implement |

| Maintenance | Low maintenance | Moderate maintenance | High maintenance |

| Best Use Case | Industrial applications | High-speed communication | General wiring needs |

What Are the Advantages and Disadvantages of Fiber Optic Cables?

Fiber optic cables are renowned for their superior performance, especially in high-speed data transmission. They can carry signals over longer distances without degradation, making them ideal for telecommunications and data centers. However, their higher initial investment and installation complexity can be barriers for some businesses. Additionally, while they require less maintenance than copper cables, any damage to the fiber can be costly to repair.

What Are the Key Features of Copper Cables?

Copper cables are the traditional choice for many electrical and telecommunication applications. Their lower upfront costs and ease of installation make them attractive for smaller businesses or projects with budget constraints. However, copper cables generally provide moderate data transfer rates and are prone to interference and signal degradation over distance. Additionally, they require more frequent maintenance compared to sdgi and fiber optic cables, which could result in higher long-term costs.

How to Choose the Right Cable Solution for Your Business Needs?

When selecting a cable solution, international B2B buyers must assess their specific needs, such as data transfer requirements, budget constraints, and installation capabilities. Sdgi cables offer a balanced solution for industrial applications where performance and maintenance are crucial. In contrast, fiber optic cables excel in environments requiring rapid data transmission over long distances, albeit with a higher cost. Copper cables, while economically viable for basic applications, may not meet the demands of more advanced technological environments.

Conclusion: Making an Informed Choice

Choosing the right cable solution involves a thorough evaluation of performance, cost, implementation complexity, and maintenance needs. By comparing sdgi cables with fiber optic and copper cables, buyers can align their selection with their operational goals and budgetary constraints. Consideration of these aspects will ensure that your business invests in a solution that maximizes efficiency and supports future growth.

Essential Technical Properties and Trade Terminology for sdgi cables

What Are the Key Technical Properties of SDGI Cables?

Understanding the technical properties of SDGI cables is crucial for B2B buyers to ensure optimal performance and compatibility with their applications. Here are some essential specifications:

1. Material Grade

The material grade of SDGI cables primarily refers to the quality of the conductors and insulation used in their manufacture. Typically, high-grade copper or aluminum is preferred for conductors due to their excellent conductivity and durability. Buyers should prioritize cables with materials compliant with international standards (e.g., IEC, ASTM) to guarantee reliability and longevity in various environments.

2. Voltage Rating

The voltage rating indicates the maximum voltage that a cable can safely handle without risk of failure. For SDGI cables, voltage ratings may range from low voltage (up to 1 kV) to high voltage (above 1 kV). Understanding the voltage requirements of your application helps prevent electrical failures and enhances the safety of your operations.

3. Temperature Rating

The temperature rating defines the operational temperature range of the cable. SDGI cables can be designed to function in extreme temperatures, often from -40°C to +90°C. This property is vital for buyers in regions with harsh climates, as it ensures that the cables maintain their performance and integrity under various environmental conditions.

4. Tolerance Levels

Tolerance levels refer to the acceptable deviations from specified dimensions in the cable’s construction. Precise tolerances are essential for ensuring compatibility with connectors and fittings. Buyers should seek cables with tight tolerance levels to minimize installation issues and maintain system efficiency.

5. Flame Resistance

Flame resistance is a critical property, especially in industrial and commercial applications where fire hazards are a concern. SDGI cables can be manufactured with flame-retardant materials that meet or exceed international safety standards. Investing in flame-resistant cables is not only a regulatory requirement in many regions but also a proactive measure to enhance workplace safety.

What Are Common Trade Terms Used in the SDGI Cables Industry?

Familiarity with industry jargon can help international B2B buyers navigate the purchasing process more effectively. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers of SDGI cables, understanding OEM relationships is essential, as it often affects pricing, availability, and warranty conditions.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity of cables that a supplier is willing to sell in a single order. Buyers should be aware of MOQs to plan their procurement strategy effectively, especially when dealing with manufacturers in different regions. Knowing the MOQ can help in budget allocation and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests a quote from suppliers for specific products or services. For SDGI cables, issuing an RFQ allows buyers to compare prices, terms, and lead times from multiple vendors, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping, insurance, and delivery responsibilities, reducing potential disputes and misunderstandings.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are received. For B2B buyers in industries where SDGI cables are critical, understanding lead times can aid in project planning and resource allocation, ensuring that operations run smoothly without unnecessary delays.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing SDGI cables, ultimately leading to better project outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the sdgi cables Sector

What Are the Current Market Dynamics and Key Trends in the SDGI Cables Sector?

The SDGI cables sector is experiencing significant transformation driven by technological advancements and evolving market demands. One of the primary global drivers is the increasing focus on renewable energy sources and smart grid technology, which necessitate enhanced cable solutions for efficiency and reliability. Emerging markets in Africa and South America are witnessing substantial investments in infrastructure, leading to heightened demand for SDGI cables, particularly in sectors such as telecommunications and power distribution.

International B2B buyers must pay attention to several current and emerging sourcing trends. The rise of digitalization in procurement processes, including the use of AI and blockchain technology, is revolutionizing how companies source SDGI cables. These technologies facilitate greater transparency and efficiency in supply chains, making it easier for buyers to evaluate suppliers and track product origins. Additionally, there is a growing trend toward local sourcing, particularly in the Middle East and Europe, where companies prefer to engage with regional manufacturers to reduce lead times and transportation costs.

Another notable trend is the increasing importance of customization. B2B buyers are seeking tailored solutions that meet specific project requirements, prompting manufacturers to develop specialized SDGI cable products. As competition intensifies, companies that can offer innovative and customized solutions will stand out in the marketplace.

How Is Sustainability Shaping the Sourcing of SDGI Cables?

Sustainability has become a critical consideration for B2B buyers in the SDGI cables sector. The environmental impact of cable production and disposal has prompted a shift towards more sustainable practices within supply chains. Buyers are increasingly prioritizing suppliers that adhere to environmental regulations and demonstrate a commitment to reducing carbon footprints.

Ethical sourcing is also gaining traction, with companies being held accountable for their supply chain practices. B2B buyers should seek suppliers that provide transparency regarding their sourcing methods, labor practices, and environmental policies. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the demand for ‘green’ materials is rising. This includes the use of recycled materials and eco-friendly production processes in the manufacturing of SDGI cables. Buyers are encouraged to inquire about the sustainability practices of potential suppliers, ensuring that their sourcing decisions align with broader corporate social responsibility (CSR) goals.

How Has the SDGI Cables Sector Evolved Over Time?

The evolution of the SDGI cables sector can be traced back to the increasing demand for reliable and efficient electrical solutions in the 20th century. Initially, the focus was primarily on basic conductivity and durability. However, as technology advanced, the need for enhanced performance characteristics, such as flexibility, thermal resistance, and electromagnetic compatibility, became apparent.

In recent decades, the sector has seen an influx of innovation driven by the digital revolution. The integration of smart technologies into cable systems has become a focal point, particularly in the context of smart grids and renewable energy applications. This evolution not only reflects technological advancements but also aligns with the growing emphasis on sustainability and ethical practices, shaping the future landscape of the SDGI cables market.

By understanding these market dynamics and trends, international B2B buyers can make informed sourcing decisions that align with their operational goals and sustainability commitments, ultimately driving success in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of sdgi cables

-

How do I solve compatibility issues with sdgi cables in my existing systems?

To address compatibility issues, start by reviewing the specifications of your current systems and the sdgi cables you intend to use. Check for compatibility in voltage, current rating, and connector types. Consulting with the manufacturer or supplier can provide insights into whether modifications or adapters are needed. Additionally, consider conducting a pilot test with a small batch of cables to ensure they work seamlessly with your equipment before scaling up your order. -

What is the best sdgi cable for industrial applications?

The best sdgi cable for industrial applications typically features robust insulation and shielding to withstand harsh environments. Look for cables that are rated for high-temperature resistance and chemical exposure, as these factors are crucial in industrial settings. Additionally, consider the cable’s flexibility and bend radius, especially if it will be installed in tight spaces. Consulting with manufacturers about industry-specific certifications can also guide you toward the right choice for your needs. -

How can I ensure the quality of sdgi cables before purchasing?

To ensure quality, request samples from potential suppliers and conduct thorough testing based on your specific application requirements. Check for certifications such as ISO 9001, CE, or RoHS compliance, which indicate adherence to international quality standards. Additionally, inquire about the supplier’s manufacturing processes and quality assurance measures. Engaging in third-party inspections or audits can also provide an extra layer of assurance regarding the quality of the products. -

What are the typical minimum order quantities (MOQs) for sdgi cables?

Minimum order quantities for sdgi cables can vary widely based on the supplier and the specific type of cable. Generally, MOQs can range from 100 meters to several kilometers. It’s advisable to discuss your needs directly with suppliers, as some may be willing to accommodate smaller orders, especially for first-time buyers or pilot projects. Understanding the implications of larger orders, such as cost savings and lead times, can also influence your purchasing decision. -

What payment terms should I expect when sourcing sdgi cables internationally?

Payment terms can vary significantly based on the supplier’s policies and the relationship you establish. Common terms include a deposit upfront (usually 30-50%) with the balance due upon delivery or net 30/60 days after shipment. In international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing the order to avoid any misunderstandings. -

How do I vet suppliers for sdgi cables in international markets?

Vetting suppliers involves several steps. Start by researching their business history and customer reviews. Utilize platforms like Alibaba or ThomasNet to find reputable suppliers. Request references from other clients, particularly those in your region or industry, to gauge reliability. Conducting site visits or virtual inspections can also help assess their manufacturing capabilities and quality control processes, ensuring they meet your standards. -

What are the logistics considerations when importing sdgi cables?

When importing sdgi cables, consider shipping options, lead times, and customs regulations. Choose a freight forwarder familiar with your region’s import laws to streamline the process. Understand the incoterms involved, such as CIF (Cost, Insurance, and Freight) or FOB (Free on Board), as these will affect your total costs. Additionally, prepare for potential delays by factoring in buffer time for customs clearance and transportation. -

How can I customize sdgi cables to meet specific requirements?

Most manufacturers offer customization options for sdgi cables, including length, insulation material, and connector types. When approaching a supplier, clearly outline your specific requirements and discuss any technical specifications necessary for your application. Additionally, inquire about the lead times for custom orders and whether there are any minimum order quantities associated with customizations. Engaging in early discussions can help ensure your needs are met without unexpected delays.

A stock image related to sdgi cables.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sdgi cables

In the rapidly evolving landscape of sdgi cables, strategic sourcing emerges as a critical driver for success among international B2B buyers. By prioritizing quality and sustainability in sourcing decisions, businesses can enhance their operational efficiency and reduce long-term costs. Engaging with reliable manufacturers not only ensures compliance with international standards but also fosters innovation, enabling companies to stay competitive in their respective markets.

For buyers in Africa, South America, the Middle East, and Europe, understanding the regional dynamics and market trends is essential. Leveraging local suppliers can yield significant benefits, including improved supply chain resilience and reduced lead times. Furthermore, establishing strong partnerships with manufacturers who prioritize ethical practices can enhance brand reputation and customer loyalty.

Looking ahead, the demand for sdgi cables is expected to grow as industries increasingly adopt advanced technologies. Now is the time for B2B buyers to reassess their sourcing strategies, focusing on collaboration and sustainability. By making informed decisions today, businesses can not only secure their supply chains but also position themselves for success in an increasingly interconnected global market. Embrace the opportunities presented by strategic sourcing to drive your business forward.