Discover the Best Prices: Alambre Malla Ciclonica en Honduras (2025)

Introduction: Navigating the Global Market for precio de alambre malla ciclonica en honduras

In an increasingly interconnected world, sourcing the right materials can be a daunting task for international B2B buyers. The “precio de alambre malla ciclonica en Honduras” is a prime example of a product that, while essential for various applications such as fencing, construction, and agriculture, poses unique challenges in terms of pricing, quality, and supplier reliability. This guide is designed to navigate these complexities, offering insights into the current market landscape, types of cyclone wire mesh available, and their specific applications across different sectors.

Throughout this comprehensive resource, you will discover actionable strategies for vetting suppliers, understanding cost dynamics, and identifying quality standards to ensure that your purchasing decisions align with your business objectives. By focusing on the needs of international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Italy and Egypt—this guide empowers you to make informed decisions that enhance your procurement process.

Whether you are looking to establish a long-term partnership with a reliable supplier or simply seeking the best price for cyclone wire mesh, this guide equips you with the knowledge and tools necessary to thrive in the global market. Prepare to delve into the intricacies of sourcing cyclone wire mesh in Honduras, and ensure your business remains competitive and well-informed in a rapidly evolving landscape.

Understanding precio de alambre malla ciclonica en honduras Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Galvanized Wire Fencing | Made from galvanized steel, resistant to corrosion | Agricultural fencing, construction | Pros: Cost-effective, durable. Cons: Limited aesthetic appeal. |

| PVC Coated Wire Fencing | Coated with PVC for added protection and color options | Residential and commercial properties | Pros: Enhanced aesthetics, increased lifespan. Cons: Higher initial cost. |

| Heavy-Duty Chain Link Fencing | Thicker gauge wire for enhanced strength and security | Industrial sites, high-security areas | Pros: Superior strength, long-lasting. Cons: Heavier and more expensive. |

| Privacy Slats in Chain Link Fencing | Additional slats inserted for privacy and wind blockage | Residential, commercial, and parks | Pros: Improved privacy, customizable. Cons: Increased installation complexity. |

| Welded Wire Fencing | Welded mesh construction for a rigid and sturdy design | Livestock containment, gardens | Pros: Excellent strength, low maintenance. Cons: Less flexible than chain link. |

What Are the Characteristics of Standard Galvanized Wire Fencing?

Standard galvanized wire fencing is the most common type used in various sectors. It is made from steel wire that is coated with zinc to prevent rusting, making it ideal for outdoor use. This type of fencing is typically cost-effective, making it a popular choice for agricultural applications and construction sites. B2B buyers should consider its durability and low maintenance requirements, but they should also be aware that it may lack aesthetic appeal, which could be a factor in residential applications.

How Does PVC Coated Wire Fencing Differ?

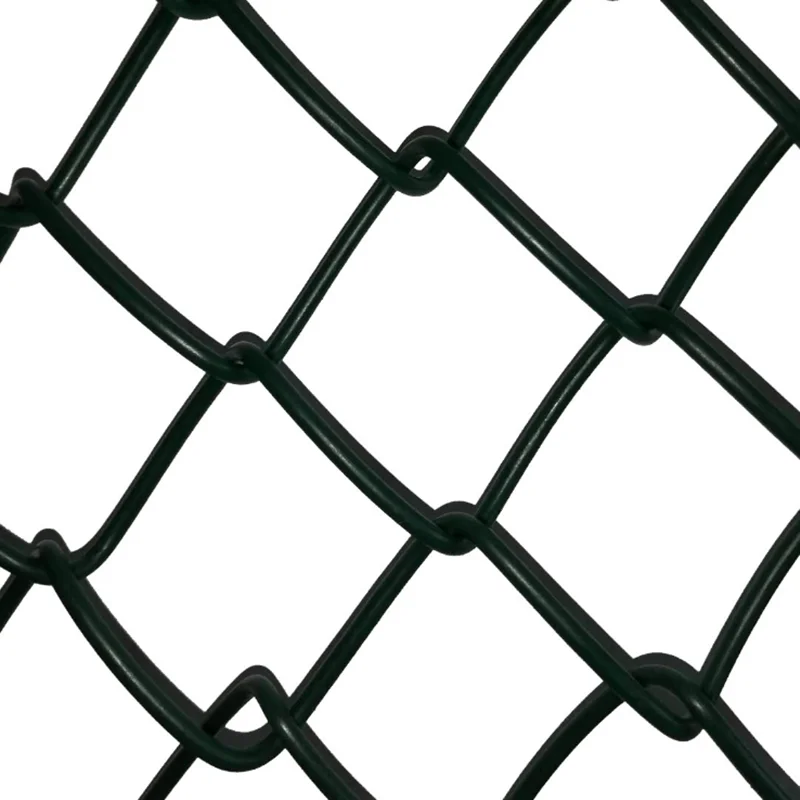

PVC coated wire fencing offers additional protection and comes in various colors, enhancing its visual appeal. This variation is suitable for both residential and commercial properties, where aesthetics may be a priority. The PVC coating increases the lifespan of the fencing by protecting it from the elements. Buyers should weigh the higher initial costs against the long-term benefits, including reduced maintenance and improved appearance.

Why Choose Heavy-Duty Chain Link Fencing?

Heavy-duty chain link fencing is designed for applications requiring enhanced security and durability. It utilizes thicker gauge wire, making it suitable for industrial sites and high-security areas. This type of fencing is resistant to tampering and damage, ensuring long-term reliability. B2B buyers need to consider the increased weight and cost, but the investment can be justified by the security benefits it provides.

What Are the Benefits of Privacy Slats in Chain Link Fencing?

Privacy slats can be added to chain link fencing to provide additional privacy and wind blockage. This variation is particularly useful in residential areas, parks, and commercial properties where privacy is a concern. The slats can be customized in various colors and materials, allowing for personalization. Buyers should consider the complexity of installation and potential additional costs, but the benefits of enhanced privacy can outweigh these factors.

When Should You Use Welded Wire Fencing?

Welded wire fencing is constructed from welded mesh, providing a rigid and sturdy design. This type is particularly effective for livestock containment and garden protection. It offers excellent strength and low maintenance, making it a practical choice for agricultural and landscaping applications. B2B buyers should note that while welded wire fencing is less flexible than chain link options, its durability and reliability make it a preferred choice for many long-term installations.

Related Video: precio de mano de obra de instalación de malla ciclonica │instalación de malla

Key Industrial Applications of precio de alambre malla ciclonica en honduras

| Industry/Sector | Specific Application of precio de alambre malla ciclonica en honduras | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Fencing for livestock and crop protection | Protects crops and livestock from predators, increasing yield | Durability, corrosion resistance, and local availability of materials |

| Construction | Site security and perimeter fencing | Enhances safety and security on construction sites | Compliance with local regulations and ease of installation |

| Mining | Barricades and security enclosures | Safeguards mining operations and prevents unauthorized access | Strength and resistance to environmental factors |

| Transportation | Temporary fencing for event management and traffic control | Improves safety at events and construction zones | Portability and ease of setup |

| Industrial Facilities | Security fencing around warehouses and manufacturing plants | Reduces theft and enhances safety for employees | Customization options and maintenance requirements |

How is ‘precio de alambre malla ciclonica en honduras’ Used in Agriculture?

In the agricultural sector, ‘precio de alambre malla ciclonica en honduras’ is primarily utilized for fencing to protect livestock and crops. This type of wire mesh is effective in keeping predators at bay, thereby safeguarding the investments of farmers. International buyers must consider the durability and corrosion resistance of the product, especially in regions with harsh weather conditions. Additionally, local sourcing can reduce lead times and shipping costs.

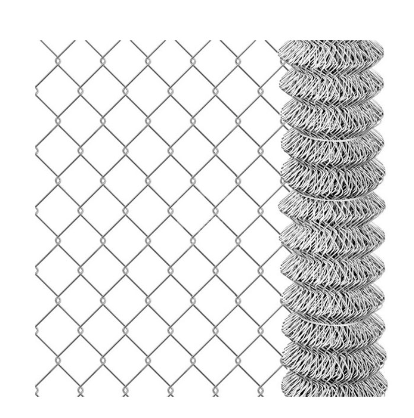

A stock image related to precio de alambre malla ciclonica en honduras.

What Role Does ‘precio de alambre malla ciclonica en honduras’ Play in Construction?

A stock image related to precio de alambre malla ciclonica en honduras.

In construction, this wire mesh serves as an essential component for site security and perimeter fencing. It helps to deter unauthorized access, thereby enhancing the safety of the site and protecting valuable equipment. Buyers from international markets should ensure that the fencing complies with local regulations and standards. Ease of installation is also a crucial factor, as construction timelines are often tight.

How is ‘precio de alambre malla ciclonica en honduras’ Applied in Mining Operations?

Within the mining industry, ‘precio de alambre malla ciclonica en honduras’ is used to create barricades and secure enclosures around mining sites. This application is vital for safeguarding operations and preventing unauthorized access, which can lead to theft or accidents. International buyers need to focus on the strength of the material and its resistance to environmental factors, such as moisture and corrosion, which are prevalent in mining environments.

Why is ‘precio de alambre malla ciclonica en honduras’ Important for Transportation?

In the transportation sector, this wire mesh is often employed for temporary fencing solutions during events or construction activities. It enhances safety by controlling traffic flow and protecting pedestrians from potential hazards. Buyers should consider the portability of the fencing and the ease with which it can be set up and dismantled, especially for short-term projects.

How Does ‘precio de alambre malla ciclonica en honduras’ Benefit Industrial Facilities?

For industrial facilities, ‘precio de alambre malla ciclonica en honduras’ is utilized for security fencing around warehouses and manufacturing plants. This application is crucial for reducing theft and ensuring the safety of employees working in potentially hazardous environments. Buyers should look for customization options to suit specific facility layouts and consider the maintenance requirements of the fencing to ensure long-term effectiveness.

Related Video: Máquina de malla ciclonica

3 Common User Pain Points for ‘precio de alambre malla ciclonica en honduras’ & Their Solutions

Scenario 1: Understanding Fluctuating Prices of Alambre Malla Ciclonica in Honduras

The Problem: B2B buyers often face the challenge of fluctuating prices for alambre malla ciclonica, which can significantly impact project budgets. For international buyers, particularly those operating in Africa and South America, sudden price changes can create financial strain, especially if contracts have already been signed based on previous pricing. Additionally, currency exchange rates and import duties can further complicate the cost structure, leading to unexpected expenses.

The Solution: To mitigate the impact of price fluctuations, buyers should establish long-term relationships with reliable suppliers in Honduras. This could involve negotiating fixed-price contracts that lock in rates for a specified duration, ensuring budget stability. Additionally, conducting thorough market research to understand seasonal price trends and sourcing multiple quotes from different suppliers can provide leverage during negotiations. Buyers should also consider utilizing forward contracts in foreign exchange to hedge against currency fluctuations, ensuring more predictable costs.

Scenario 2: Difficulty in Sourcing High-Quality Alambre Malla Ciclonica

The Problem: Many international buyers struggle to find high-quality alambre malla ciclonica that meets their specific standards. This is particularly pertinent for projects in sectors such as agriculture and construction, where the durability and strength of fencing materials are crucial. Without proper quality assurance, buyers risk purchasing subpar products that may lead to higher long-term costs due to repairs or replacements.

The Solution: To ensure sourcing of high-quality materials, buyers should implement a rigorous supplier evaluation process. This includes requesting certifications and quality control documentation from potential suppliers, as well as seeking references from previous clients. Conducting site visits or inspections of manufacturing facilities can also provide valuable insights into the production processes and quality assurance practices employed by the supplier. Additionally, consider collaborating with local experts who understand the market dynamics and can provide recommendations on reputable manufacturers.

Scenario 3: Navigating Import Regulations and Logistics Challenges

The Problem: Importing alambre malla ciclonica into regions such as the Middle East and Europe can be fraught with regulatory hurdles and logistical challenges. Buyers may encounter issues with customs documentation, tariffs, and compliance with local regulations, which can delay shipments and increase costs. This complexity often leaves buyers feeling overwhelmed and uncertain about the best practices for a smooth import process.

The Solution: To navigate these challenges effectively, buyers should invest time in understanding the import regulations specific to their destination countries. This includes researching tariffs, required documentation, and any local standards applicable to fencing materials. Engaging a freight forwarder with expertise in importing materials into your target market can streamline the logistics process. They can provide guidance on documentation, help with customs clearance, and offer insights on the most efficient shipping routes. Furthermore, establishing a clear communication line with suppliers regarding shipping timelines and regulatory requirements will ensure everyone is aligned and prepared, reducing the likelihood of delays.

Strategic Material Selection Guide for precio de alambre malla ciclonica en honduras

When selecting the appropriate materials for “precio de alambre malla ciclonica en Honduras,” international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below is an analysis of common materials used in cyclone wire fencing, focusing on their key properties, advantages and disadvantages, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Galvanized Steel for Cyclone Wire Fencing?

Galvanized Steel is one of the most popular materials for cyclone wire fencing due to its excellent corrosion resistance and strength. The galvanization process involves coating the steel with zinc, which protects it from rust and extends its lifespan, particularly in humid or saline environments.

Pros & Cons: The primary advantage of galvanized steel is its durability and relatively low cost. However, it can be susceptible to scratches that expose the underlying metal, leading to corrosion over time. Additionally, while galvanized steel is easy to manufacture, its weight can complicate transportation and installation.

Impact on Application: Galvanized steel is well-suited for agricultural and residential fencing, providing a robust barrier against livestock and intruders. However, buyers must ensure compatibility with local environmental conditions to maximize performance.

Considerations for International Buyers: Compliance with international standards such as ASTM A123 for hot-dip galvanized coatings is crucial. Buyers from Europe and the Middle East should also consider local regulations regarding material specifications.

How Does PVC Coated Wire Compare for Cyclone Fencing Applications?

PVC Coated Wire offers an alternative to galvanized steel, featuring a plastic coating that enhances corrosion resistance and aesthetic appeal. This coating can also provide additional insulation, making it suitable for electrical applications.

Pros & Cons: The key advantage of PVC coated wire is its resistance to environmental degradation and its variety of color options, which can enhance the visual appeal of installations. However, it tends to be more expensive than galvanized options and may require specialized manufacturing processes.

Impact on Application: PVC coated wire is ideal for decorative fencing and areas where aesthetics are a priority, such as parks or residential areas. However, its performance in extreme temperatures may be limited compared to bare galvanized steel.

Considerations for International Buyers: Buyers should verify that the PVC coating meets standards like ASTM D2247 for weather resistance. Additionally, understanding the local market’s preferences for color and finish can influence purchasing decisions.

What Are the Benefits and Limitations of Stainless Steel Wire in Cyclone Fencing?

Stainless Steel Wire is known for its exceptional corrosion resistance and strength, making it an excellent choice for cyclone fencing in harsh environments. It is particularly beneficial in coastal areas where salt exposure can lead to rapid corrosion of other materials.

Pros & Cons: The primary advantage of stainless steel is its longevity and minimal maintenance requirements. However, it is significantly more expensive than both galvanized and PVC coated options, which may deter budget-conscious buyers.

Impact on Application: Stainless steel wire is suitable for high-security applications and environments where durability is paramount. Its resistance to corrosion makes it ideal for agricultural use in coastal regions.

Considerations for International Buyers: Buyers should ensure that the stainless steel used complies with standards such as ASTM A313 for wire and ASTM A240 for sheets. Understanding the cost implications and potential for long-term savings due to reduced maintenance can help justify the initial investment.

How Does Barbed Wire Enhance the Security of Cyclone Fencing?

Barbed Wire can be integrated with cyclone fencing to enhance security. It consists of sharp-edged wires that deter intruders and livestock from breaching the fence.

Pros & Cons: The main advantage of barbed wire is its cost-effectiveness and added security. However, it can pose safety risks and may not be suitable for all applications, particularly in residential areas where aesthetics are a concern.

Impact on Application: Barbed wire is commonly used in agricultural and industrial settings where security is a top priority. Its effectiveness can be diminished if not properly installed or maintained.

Considerations for International Buyers: Compliance with local safety regulations is essential, especially in urban areas. Buyers should also consider the cultural perceptions of barbed wire, as it may not be welcomed in all regions.

Summary Table of Material Selection for Cyclone Wire Fencing

| Material | Typical Use Case for precio de alambre malla ciclonica en honduras | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Agricultural and residential fencing | Excellent corrosion resistance | Susceptible to scratches | Low |

| PVC Coated Wire | Decorative and aesthetic fencing | Enhanced corrosion resistance | Higher manufacturing cost | Medium |

| Stainless Steel Wire | High-security and coastal applications | Exceptional durability | Significantly higher cost | High |

| Barbed Wire | Agricultural and industrial security | Cost-effective security enhancement | Safety risks and aesthetic concerns | Low |

This strategic material selection guide provides valuable insights for international B2B buyers considering cyclone wire fencing in Honduras. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for precio de alambre malla ciclonica en honduras

What Are the Key Stages in Manufacturing Cyclone Wire Mesh in Honduras?

The manufacturing of cyclone wire mesh, commonly referred to as “alambre malla ciclonica,” involves several critical stages that ensure the final product meets both quality and performance standards. For international B2B buyers, understanding these stages is vital for making informed purchasing decisions.

-

Material Preparation: The process begins with selecting high-quality steel wire, which is typically galvanized to prevent corrosion. Buyers should inquire about the wire gauge, as it affects both the strength and durability of the mesh. Suppliers often use either low-carbon steel or stainless steel, depending on the intended application. A thorough understanding of the materials used can help buyers determine the longevity and suitability of the mesh for their projects.

-

Forming: This stage involves bending and weaving the wire into the desired mesh configuration. Techniques such as welding or twisting are commonly employed to create the required mesh structure. Buyers should ensure that manufacturers use automated machinery for consistency, as manual processes can lead to variations in quality.

-

Assembly: After forming, the mesh is cut to size and assembled into panels or rolls. This stage may also include additional treatments such as powder coating or painting, which enhance the mesh’s aesthetic appeal and resistance to environmental factors. B2B buyers should inquire about customization options to meet specific project requirements.

-

Finishing: The final stage involves inspecting the mesh for defects and ensuring it meets specified dimensions. This may include additional processes like packaging for shipping. Buyers should verify that the supplier has stringent quality control measures in place during this stage to minimize defects in the final product.

How Is Quality Assurance Implemented in Cyclone Wire Mesh Manufacturing?

Quality assurance (QA) is essential in ensuring that the cyclone wire mesh produced in Honduras adheres to international standards and meets customer expectations. For B2B buyers, understanding the QA processes can significantly influence purchasing decisions.

-

International Standards Compliance: Manufacturers often adhere to standards like ISO 9001, which outlines requirements for a quality management system. Compliance ensures that the manufacturing processes are consistent and products are reliable. Buyers should request certification documents to verify compliance with these international standards.

-

Industry-Specific Certifications: Depending on the application, additional certifications such as CE marking or API standards may be relevant. These certifications indicate compliance with specific safety and quality regulations, which can be particularly important for buyers in the construction or industrial sectors.

-

Quality Control Checkpoints: Effective quality control includes several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

– Final Quality Control (FQC): The finished product undergoes rigorous testing and inspection before shipment. -

Common Testing Methods: Various testing methods are employed to ensure the quality of cyclone wire mesh, including tensile strength tests, corrosion resistance tests, and dimensional checks. B2B buyers should inquire about the specific tests conducted and request test reports for verification.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to mitigate risks and ensure product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes firsthand. During these audits, buyers can evaluate the supplier’s adherence to quality standards, inspect production lines, and review quality control documentation.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, including data on defect rates, testing results, and compliance with international standards. These documents provide insights into the supplier’s reliability and commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be particularly useful for buyers unfamiliar with the local manufacturing environment.

-

Understanding Quality Control Nuances for Different Markets: B2B buyers should be aware that quality expectations and regulations may vary significantly between regions. For instance, European buyers may have stricter compliance requirements compared to those in South America or Africa. Understanding these nuances will help buyers set appropriate quality expectations and negotiate terms effectively.

What Are the Challenges in Ensuring Quality Assurance in Honduras?

While many manufacturers in Honduras strive to meet international quality standards, several challenges can impact the consistency of quality assurance processes.

-

Supply Chain Issues: Disruptions in the supply chain can affect the availability of high-quality raw materials, which may compromise the final product. B2B buyers should evaluate the supplier’s sourcing strategies and alternative supply options.

-

Regulatory Compliance: Navigating the regulatory landscape can be complex, particularly for international standards. Manufacturers may face challenges in keeping up with evolving regulations, making it essential for buyers to verify compliance regularly.

-

Skilled Labor Shortages: A lack of skilled labor in the manufacturing sector can impact quality control processes. Buyers should assess the supplier’s workforce training programs to ensure they have the necessary expertise to maintain quality.

Conclusion

Understanding the manufacturing processes and quality assurance measures for cyclone wire mesh in Honduras is crucial for international B2B buyers. By focusing on material selection, production techniques, and quality control practices, buyers can make informed decisions that align with their project requirements. Verifying supplier quality through audits, reports, and third-party inspections further ensures that the products sourced meet the necessary standards for performance and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precio de alambre malla ciclonica en honduras’

In the fast-paced world of B2B procurement, especially for specialized products like precio de alambre malla ciclonica en Honduras, having a structured approach is essential. This guide offers a step-by-step checklist tailored for international buyers looking to source cyclone wire fencing effectively. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your specific requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the cyclone wire you require. This includes dimensions, material quality, and any specific coatings or treatments needed for durability.

– Why It Matters: Defining these specifications helps avoid misunderstandings with suppliers and ensures that the product meets your operational needs.

– What to Look For: Consider factors like gauge, tensile strength, and corrosion resistance, which can significantly impact performance.

Step 2: Research the Market Landscape

Understanding the market dynamics in Honduras is crucial for making informed decisions. Investigate local suppliers, pricing trends, and regional demand.

– Why It Matters: A comprehensive market analysis helps you identify competitive pricing and reliable suppliers while understanding potential import tariffs and regulations.

– What to Look For: Utilize online marketplaces, industry reports, and trade publications to gather data on current market conditions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Why It Matters: Supplier reliability is vital for maintaining your supply chain integrity. A thorough evaluation minimizes risks associated with poor-quality products or unreliable delivery.

– What to Look For: Check for certifications such as ISO, local business licenses, and testimonials from previous clients to assess their credibility.

Step 4: Request Samples for Quality Assurance

Once you have shortlisted potential suppliers, request samples of the cyclone wire to evaluate quality firsthand.

– Why It Matters: Samples allow you to assess the physical properties of the wire, ensuring it meets your specifications and performance standards.

– What to Look For: Examine the wire for consistency, finish, and overall craftsmanship. Consider testing it under conditions that reflect your usage.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure the best pricing and favorable terms.

– Why It Matters: Effective negotiation can lead to cost savings and better service conditions, enhancing your overall procurement strategy.

– What to Look For: Discuss bulk discounts, payment terms, and delivery timelines. Ensure that you understand all costs involved, including shipping and handling.

Step 6: Finalize Contracts and Agreements

Once negotiations are complete, draft clear contracts that outline all agreed-upon terms, including specifications, pricing, and delivery schedules.

– Why It Matters: A well-defined contract protects both parties and serves as a reference point in case of disputes.

– What to Look For: Ensure that the contract includes clauses for warranty, liability, and dispute resolution.

Step 7: Monitor Delivery and Quality Post-Purchase

After placing your order, closely monitor the delivery process and inspect the products upon arrival.

– Why It Matters: Proactive monitoring helps ensure that the product meets your specifications and that any issues are addressed promptly.

– What to Look For: Verify that the delivery matches your order and that the quality is consistent with the samples provided.

By following this checklist, B2B buyers can navigate the complexities of sourcing cyclone wire fencing in Honduras with confidence, ensuring that their procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for precio de alambre malla ciclonica en honduras Sourcing

What Are the Key Cost Components for Sourcing Alambre Malla Ciclonica in Honduras?

Understanding the cost structure of alambre malla ciclonica (chain link fencing) is crucial for international B2B buyers. The primary components that influence the pricing include:

-

Materials: The type of wire used, such as galvanized or vinyl-coated steel, significantly affects the cost. Galvanized wire is more durable and rust-resistant, but it typically comes at a higher price point.

-

Labor: Labor costs in Honduras are relatively low compared to many countries in Europe and North America. However, skilled labor for manufacturing high-quality fencing can add to the overall expenses.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs incurred by factories. Manufacturers with modern facilities may have higher overhead, which could be reflected in the pricing.

-

Tooling: The initial investment in machinery and tools for production can influence the per-unit cost. Manufacturers that have invested in advanced tooling may offer better quality and efficiency.

-

Quality Control (QC): Implementing rigorous quality control processes ensures the products meet international standards. This can increase the cost but is essential for ensuring reliability and safety.

-

Logistics: Shipping costs, including freight and insurance, can vary significantly based on destination and volume. Understanding Incoterms is critical for determining who bears these costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary widely based on supplier reputation, demand, and market conditions.

How Do Price Influencers Impact Alambre Malla Ciclonica Pricing?

Several factors can influence the final price of alambre malla ciclonica, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts, significantly lowering the unit price. Be sure to negotiate MOQs that suit your purchasing capabilities.

-

Specifications and Customization: Custom dimensions, coatings, or additional features can lead to increased costs. Discussing your specific requirements upfront can help avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) typically demand higher prices. However, investing in quality can reduce long-term maintenance costs.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge a premium but offer better reliability and service.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for determining who is responsible for various costs throughout the shipping process.

What Tips Can Help Buyers Negotiate Better Prices for Alambre Malla Ciclonica?

When sourcing alambre malla ciclonica, international B2B buyers can leverage various strategies to achieve cost efficiency:

-

Negotiate Terms: Always negotiate payment terms and delivery schedules. Flexible payment options can improve cash flow and reduce upfront costs.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but the total costs associated with the product over its lifecycle, including installation, maintenance, and replacement.

-

Research Market Prices: Conduct thorough market research to understand typical pricing structures and avoid overpaying. This knowledge can empower negotiations with suppliers.

-

Build Relationships with Suppliers: Establishing long-term relationships with manufacturers can lead to better pricing, priority service, and insights into market trends.

-

Consider Local Suppliers: Depending on your region, sourcing from local suppliers can reduce shipping costs and lead times, which may offset any higher product prices.

A stock image related to precio de alambre malla ciclonica en honduras.

Disclaimer on Indicative Prices

Prices for alambre malla ciclonica can fluctuate based on market conditions, currency exchange rates, and supplier negotiations. It is advisable to obtain multiple quotes and continuously monitor market trends to ensure competitive pricing.

Alternatives Analysis: Comparing precio de alambre malla ciclonica en honduras With Other Solutions

When considering the best fencing solutions for various applications, it’s essential to analyze alternatives to the “precio de alambre malla ciclonica en Honduras.” This analysis will help international B2B buyers identify the most cost-effective and efficient options suited to their specific needs. Below, we compare the cyclone wire fencing with two viable alternatives: welded wire fencing and electric fencing.

Comparison Table of Fencing Solutions

| Comparison Aspect | Precio De Alambre Malla Ciclonica En Honduras | Welded Wire Fencing | Electric Fencing |

|---|---|---|---|

| Performance | Durable, resistant to corrosion, good visibility | Strong, provides a solid barrier | Highly effective, deterrent |

| Cost | Moderate initial cost, low maintenance | Higher initial cost, moderate maintenance | Lower initial cost, higher maintenance |

| Ease of Implementation | Relatively easy to install | Requires more labor and tools | Moderate complexity, needs power source |

| Maintenance | Low maintenance, occasional inspections needed | Moderate maintenance, rust prevention required | High maintenance, regular checks needed |

| Best Use Case | Agricultural, residential, and commercial use | Security-focused environments | High-security installations |

What Are the Pros and Cons of Welded Wire Fencing?

Welded wire fencing is made from steel wires that are welded together at intersections. This type of fencing offers superior strength, making it ideal for environments that require robust security measures. The primary advantage of welded wire fencing is its durability, which can withstand significant pressure and impact. However, it comes with a higher initial cost and requires more labor for installation. Maintenance is also essential as it may be prone to rust without proper treatment.

How Does Electric Fencing Compare?

Electric fencing is another alternative that offers a different approach to security. It serves as a deterrent rather than a physical barrier, as it delivers a mild electric shock when touched. This type of fencing is often used in high-security areas, such as prisons or military installations. The advantages include lower initial costs compared to welded wire fencing and a highly effective deterrent effect. However, electric fencing requires a consistent power source and regular maintenance to ensure functionality, making it a more complex solution.

Conclusion: How to Choose the Right Fencing Solution for Your Needs

For international B2B buyers, the decision on which fencing solution to invest in should be guided by specific operational needs, budget constraints, and long-term goals. While “precio de alambre malla ciclonica en Honduras” provides a balanced option with moderate costs and low maintenance, buyers should consider the unique advantages of welded wire and electric fencing. Evaluating the performance, costs, and maintenance requirements will help in making an informed decision that aligns with both immediate and future fencing needs.

Essential Technical Properties and Trade Terminology for precio de alambre malla ciclonica en honduras

What are the Essential Technical Properties of Cyclone Wire in Honduras?

When evaluating the price of cyclone wire (alambre malla ciclonica) in Honduras, understanding its technical properties is crucial for international B2B buyers. Here are some key specifications that influence both quality and pricing:

-

Material Grade

Cyclone wire is typically made from low carbon steel or galvanized steel. The material grade affects its tensile strength, corrosion resistance, and overall durability. Buyers should look for wire conforming to international standards like ASTM A641 or BS 1722, ensuring reliable performance in various environmental conditions. -

Wire Diameter

The diameter of the wire is a critical factor affecting its strength and application. Common diameters range from 1.5 mm to 3.0 mm. Thicker wires offer greater strength and resistance to bending, making them suitable for high-security applications. Understanding the required wire diameter can help buyers make informed decisions based on their specific security needs. -

Mesh Size

The mesh size (spacing between wires) directly influences the wire’s ability to deter intruders. Typical mesh sizes range from 50 mm x 50 mm to 100 mm x 100 mm. A tighter mesh provides enhanced security, while a larger mesh may be more cost-effective for less critical applications. Buyers must align mesh size with their security objectives and budget. -

Coating Type

The type of coating, such as galvanization or PVC, plays a significant role in the wire’s longevity and resistance to weather elements. Galvanized wire offers excellent corrosion resistance, while PVC-coated wire provides additional protection and aesthetic appeal. Understanding coating options allows buyers to choose products that meet their environmental and aesthetic requirements. -

Tensile Strength

This property measures the maximum load the wire can bear without breaking. Cyclone wire typically has a tensile strength ranging from 350 to 600 MPa. High tensile strength is vital for applications requiring robust security measures, as it ensures the wire can withstand significant pressure and impacts. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. For cyclone wire, tolerances can affect both the installation process and the wire’s performance. A tighter tolerance generally indicates better manufacturing quality, which is crucial for buyers seeking reliability and consistency.

What are Common Trade Terms Related to Cyclone Wire Pricing?

Understanding trade terminology is equally important for B2B buyers to navigate the purchasing process effectively. Here are some commonly used terms in the industry:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then marketed under another company’s brand. In the context of cyclone wire, knowing whether a supplier is an OEM can help buyers assess product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is essential for buyers to understand the MOQ as it can impact their purchasing strategy and inventory management. Negotiating lower MOQs can help smaller businesses access essential materials without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For cyclone wire, submitting an RFQ allows buyers to compare prices, specifications, and lead times across different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for buyers from Africa, South America, the Middle East, and Europe, as they clarify who bears the costs and risks associated with shipping and delivery. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For international buyers, understanding lead times is essential for planning and inventory management, especially in regions with variable shipping durations.

By grasping these technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding cyclone wire in Honduras, ensuring they meet both their operational needs and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the precio de alambre malla ciclonica en honduras Sector

What Are the Current Market Dynamics for ‘precio de alambre malla ciclonica en honduras’?

The market for ‘precio de alambre malla ciclonica en Honduras’ is influenced by several global drivers, including increasing infrastructure development, urbanization, and agricultural expansion. As nations in Africa, South America, the Middle East, and Europe look to bolster their infrastructure, the demand for cyclone wire fencing is rising. This trend is particularly notable in sectors such as agriculture, construction, and security, where cyclone wire is essential for protecting crops, delineating property boundaries, and ensuring safety.

Emerging B2B technologies are reshaping sourcing strategies in this sector. Digital platforms for procurement and supply chain management are gaining traction, allowing international buyers to identify reliable suppliers in Honduras more efficiently. Additionally, the use of data analytics is helping businesses better understand pricing trends and market fluctuations, enabling them to make informed purchasing decisions.

International B2B buyers should also be aware of regional economic factors that impact the pricing of cyclone wire. Currency fluctuations, trade policies, and local manufacturing capabilities can significantly affect sourcing costs. Buyers from regions like Europe and the Middle East should stay updated on these factors to secure competitive pricing and favorable trade conditions.

How Can Sustainability and Ethical Sourcing Impact Your Procurement Decisions?

Sustainability has become a pivotal concern in the global marketplace, and the ‘precio de alambre malla ciclonica en Honduras’ sector is no exception. The environmental impact of producing cyclone wire—particularly in terms of resource consumption and waste generation—has led to increased scrutiny from consumers and regulatory bodies alike. B2B buyers are encouraged to prioritize suppliers who implement sustainable manufacturing practices, such as utilizing recycled materials and minimizing energy consumption.

Ethical sourcing is equally important, with businesses now facing pressure to ensure that their supply chains are free from exploitation and environmental harm. Buyers should seek suppliers who provide transparency about their sourcing practices and labor conditions. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, the demand for ‘green’ certifications is on the rise, as consumers and businesses alike prefer products that contribute to environmental sustainability. By selecting suppliers who adhere to these standards, B2B buyers can enhance their brand reputation and appeal to environmentally conscious clients.

What Is the Historical Context of Cyclone Wire in Honduras?

The use of cyclone wire in Honduras can be traced back several decades, primarily as a fencing solution for agricultural purposes. Initially adopted by local farmers to protect crops from livestock and intruders, the application of cyclone wire has expanded over time to include urban development and security installations. As Honduras has experienced significant economic growth, the construction and real estate sectors have increasingly utilized cyclone wire for perimeter security and property delineation.

This evolution reflects broader trends in the region, where the demand for reliable fencing solutions has risen alongside urbanization and agricultural intensification. For international B2B buyers, understanding this historical context can provide valuable insights into the reliability and adaptability of cyclone wire as a long-term investment in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of precio de alambre malla ciclonica en honduras

-

How can I determine the best suppliers for alambre malla ciclonica in Honduras?

To find reliable suppliers for alambre malla ciclonica in Honduras, start by researching industry directories and trade platforms such as Alibaba or Global Sources. Look for suppliers with strong ratings and verified business credentials. Additionally, consider reaching out to local trade associations or chambers of commerce in Honduras for recommendations. Conduct thorough due diligence, including checking references and customer reviews, to ensure the supplier’s reliability and product quality. -

What are the typical price ranges for alambre malla ciclonica in Honduras?

The price of alambre malla ciclonica in Honduras can vary significantly based on factors such as wire gauge, height, and roll size. Typically, prices range from $0.10 to $0.30 per linear meter, depending on these specifications. It’s essential to request quotes from multiple suppliers to compare pricing and ensure you’re getting a competitive deal. Also, factor in shipping costs and any potential import duties when calculating the total price. -

What minimum order quantities (MOQs) should I expect when sourcing alambre malla ciclonica?

Minimum order quantities for alambre malla ciclonica can vary by supplier, but they often range from 500 to 2,000 meters. Some suppliers may offer lower MOQs for first-time buyers or smaller businesses. Always inquire about MOQs during your initial discussions to avoid unexpected costs. Negotiating MOQs can also be beneficial, especially if you plan to establish a long-term relationship with the supplier. -

What payment terms are common for international purchases of alambre malla ciclonica?

Common payment terms for international purchases include a 30% deposit upfront with the balance due upon delivery or a letter of credit. Some suppliers may also accept full payment in advance, while others might offer net payment terms (e.g., net 30 or net 60). It’s crucial to clarify payment terms before finalizing any agreements, as this can significantly impact your cash flow and financial planning. -

How do I ensure quality assurance for alambre malla ciclonica sourced from Honduras?

To ensure quality assurance, request product certifications and compliance documentation from your supplier, such as ISO certifications or local quality standards. Consider conducting a factory audit or hiring a third-party inspection service to evaluate the manufacturing process and product quality before shipment. Additionally, ask for samples to assess the material and craftsmanship before placing a large order. -

What are the logistics considerations for importing alambre malla ciclonica from Honduras?

Logistics considerations include understanding shipping methods, transit times, and customs clearance processes. Choose between air freight for faster delivery or sea freight for cost-effectiveness. Verify that your supplier is familiar with international shipping regulations and can assist with necessary documentation. Additionally, factor in insurance and potential customs duties to ensure a smooth import process. -

How can I customize alambre malla ciclonica to meet specific project requirements?

Many suppliers offer customization options for alambre malla ciclonica, such as varying wire gauge, mesh size, and coating finishes. When discussing your needs with suppliers, provide detailed specifications and any relevant project requirements. Be prepared to discuss lead times for customized orders, as they may take longer to produce compared to standard products. -

What are the common challenges faced when sourcing alambre malla ciclonica internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. To mitigate these issues, establish clear communication channels with your supplier and consider hiring a local intermediary or translator if necessary. Additionally, be aware of potential delays caused by customs or logistical issues, and build a buffer into your project timelines to accommodate these factors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for precio de alambre malla ciclonica en honduras

In navigating the complexities of sourcing precio de alambre malla ciclonica en Honduras, international B2B buyers must prioritize strategic sourcing as a critical component of their procurement strategy. Understanding the price dynamics influenced by local supply chains, import tariffs, and market demand is essential for making informed purchasing decisions. Additionally, fostering relationships with local suppliers can lead to better pricing, enhanced reliability, and improved negotiation leverage.

What are the benefits of strategic sourcing for international buyers? Leveraging strategic sourcing not only mitigates risks associated with fluctuating prices but also opens avenues for cost savings and efficiency improvements. By aligning procurement strategies with the unique economic landscapes of Honduras, buyers can ensure that they are positioned competitively in their respective markets.

Looking ahead, the demand for cyclone wire mesh is expected to grow, driven by infrastructure development and security needs across various regions. Therefore, it is imperative for buyers from Africa, South America, the Middle East, and Europe to actively engage with suppliers, assess market trends, and adapt their strategies accordingly. By doing so, they can capitalize on emerging opportunities and secure a reliable supply chain for cyclone wire mesh that meets their operational needs.