Unlock Efficiency: The Complete SK720T Driver Guide (2025)

Introduction: Navigating the Global Market for sk720t driver

The global marketplace for specialized components like the sk720t driver presents both opportunities and challenges for international B2B buyers. As industries increasingly rely on high-quality, efficient drivers to optimize performance in various applications, sourcing the right sk720t driver can be daunting. Buyers must navigate a complex landscape filled with diverse suppliers, varying quality standards, and fluctuating pricing structures. This guide aims to demystify the procurement process for the sk720t driver by providing a comprehensive overview of its types, applications, and supplier vetting strategies.

In this guide, you’ll find in-depth insights into the specific applications of the sk720t driver across different sectors, including manufacturing and automation. We delve into essential criteria for evaluating suppliers, ensuring that you partner with reputable manufacturers who meet your quality and compliance standards. Additionally, we provide a detailed breakdown of cost considerations and potential hidden fees that could impact your purchasing decisions.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—particularly those in markets like Spain and Turkey—with actionable insights, this guide empowers you to make informed purchasing decisions. With a focus on strategic sourcing, you can minimize risks and maximize efficiency, leading to a more successful procurement process.

Understanding sk720t driver Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SK720T | Basic functionality, suitable for general applications | General manufacturing and assembly | Pros: Cost-effective, easy to integrate. Cons: Limited advanced features. |

| High-Performance SK720T | Enhanced precision, faster processing speeds | Aerospace, automotive, and electronics | Pros: Superior accuracy, efficient. Cons: Higher initial investment. |

| Compact SK720T | Smaller form factor, designed for tight spaces | Robotics, medical devices | Pros: Space-saving, versatile. Cons: May have reduced power capacity. |

| Wireless SK720T | Wireless connectivity, remote operation capabilities | Industrial automation, smart factories | Pros: Flexibility, reduced wiring costs. Cons: Potential signal interference. |

| Custom SK720T | Tailored features based on specific client needs | Specialized industries (e.g., energy) | Pros: Fully meets unique requirements. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of the Standard SK720T Driver?

The Standard SK720T driver is designed for businesses looking for a reliable and cost-effective solution for general applications. It offers basic functionality that meets the needs of various manufacturing and assembly processes. Buyers should consider its ease of integration and lower initial costs, but they may find the lack of advanced features limiting for more specialized applications.

How Does the High-Performance SK720T Driver Stand Out?

The High-Performance SK720T driver is characterized by its enhanced precision and faster processing speeds, making it ideal for industries such as aerospace, automotive, and electronics. This type is suitable for B2B buyers who require superior accuracy and efficiency in their operations. However, potential buyers should weigh the benefits against the higher initial investment, which may be justified by the increased productivity and reduced error rates.

Why Choose the Compact SK720T Driver for Space-Constrained Environments?

The Compact SK720T driver is specifically designed for environments where space is at a premium, such as in robotics and medical devices. Its smaller form factor allows for versatile applications without sacrificing performance. B2B buyers should consider this option if they require a space-saving solution, but they should also be aware that this may come with reduced power capacity compared to larger models.

What Are the Advantages of the Wireless SK720T Driver?

The Wireless SK720T driver offers the advantage of wireless connectivity, enabling remote operation and enhanced flexibility in industrial automation and smart factory settings. This type is appealing for companies looking to reduce wiring costs and improve operational efficiency. However, buyers must consider the potential for signal interference, which could impact reliability in certain environments.

When Should You Consider a Custom SK720T Driver?

The Custom SK720T driver is tailored to meet specific client needs, making it suitable for specialized industries such as energy. This option allows for full customization, ensuring that the driver meets unique operational requirements. B2B buyers should be prepared for longer lead times and potentially higher costs, but the investment can pay off by providing a solution that perfectly aligns with their business objectives.

Related Video: How to set up Seiki SK720T and Artcut2009 on windows

Key Industrial Applications of sk720t driver

| Industry/Sector | Specific Application of sk720t driver | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining | Enhances precision and reduces downtime in production. | Ensure compatibility with existing machinery and software. |

| Renewable Energy | Wind Turbine Control Systems | Improves energy efficiency and optimizes performance. | Assess environmental durability and regulatory compliance. |

| Automotive | Electric Vehicle (EV) Power Management | Facilitates efficient battery management and charging. | Look for scalability and integration with existing systems. |

| Agriculture | Automated Irrigation Systems | Increases water efficiency and crop yields. | Evaluate adaptability to various agricultural environments. |

| Robotics | Industrial Robotics for Assembly Lines | Enhances automation and reduces labor costs. | Consider support for programming and integration with existing workflows. |

How is the sk720t driver utilized in CNC Machining?

In the manufacturing sector, particularly in CNC machining, the sk720t driver plays a crucial role in enhancing machine precision and operational efficiency. By providing accurate control over motors, it minimizes errors during complex machining processes, leading to higher-quality output. International B2B buyers should consider compatibility with their existing machinery and the driver’s ability to integrate seamlessly with various software systems to ensure a smooth transition and minimize downtime.

What are the advantages of using sk720t drivers in Wind Turbine Control Systems?

In the renewable energy sector, the sk720t driver is integral to wind turbine control systems. It optimizes turbine performance by managing pitch control and generator speed, which directly impacts energy output. This application not only enhances energy efficiency but also contributes to sustainable energy goals. Buyers from diverse regions, particularly those in Africa and South America, should evaluate the driver’s environmental durability and ensure compliance with local regulatory standards to maximize investment returns.

How does the sk720t driver benefit Electric Vehicle (EV) Power Management?

The automotive industry increasingly relies on the sk720t driver for electric vehicle power management systems. It enables efficient battery management, ensuring optimal charging and discharging cycles that extend battery life and enhance vehicle performance. For international buyers, particularly in Europe and the Middle East, it is essential to look for solutions that offer scalability and can be integrated into existing EV platforms, as the demand for electric vehicles continues to rise.

In what ways does sk720t enhance Automated Irrigation Systems?

In agriculture, the sk720t driver is utilized in automated irrigation systems to improve water efficiency and crop yields. By controlling pumps and valves, it enables precise water delivery based on real-time data, thus optimizing resource use. B2B buyers in regions like Africa should assess the driver’s adaptability to various agricultural environments, ensuring that it can function effectively under diverse climatic conditions and meet the specific needs of local farming practices.

Why is sk720t crucial for Industrial Robotics in Assembly Lines?

The sk720t driver is pivotal in the robotics sector, particularly for assembly lines where automation is key to enhancing productivity. It provides reliable control over robotic arms, enabling precise movements and reducing reliance on manual labor. Buyers should consider the driver’s support for programming languages and its ability to integrate with existing workflows to achieve seamless operation and maximize automation benefits.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘sk720t driver’ & Their Solutions

Scenario 1: Compatibility Issues with Existing Systems

The Problem:

B2B buyers often encounter challenges when integrating the SK720T driver with their existing systems. This can stem from differences in software versions, hardware configurations, or specific industry requirements. For instance, a logistics company in Africa may use outdated fleet management software that cannot seamlessly communicate with the new driver, leading to inefficiencies and increased operational costs.

The Solution:

To mitigate compatibility issues, it is crucial to conduct a thorough compatibility assessment before procurement. Engage with the supplier to obtain detailed specifications and ensure that the SK720T driver can interface with your current systems. Consider investing in middleware solutions that can act as a bridge between the driver and legacy systems. Additionally, staying informed about software updates and new integrations can help maintain compatibility and optimize performance over time. Establishing a close relationship with the vendor for ongoing support can also prove invaluable.

Scenario 2: Lack of Technical Expertise for Installation

The Problem:

Many businesses, particularly in emerging markets such as South America and parts of the Middle East, may struggle with the technical expertise required to install and configure the SK720T driver effectively. This can lead to improper installation, resulting in suboptimal performance or even equipment damage, which can be costly and time-consuming to rectify.

The Solution:

Investing in comprehensive training for your technical team is essential. Work with the manufacturer to arrange hands-on training sessions that cover installation, troubleshooting, and maintenance. If in-house capabilities are limited, consider outsourcing the installation to certified professionals who are experienced with the SK720T driver. This not only ensures proper setup but also allows your team to learn from the experts during the process. Following installation, maintain a detailed documentation of the setup and configurations for future reference.

Scenario 3: Insufficient After-Sales Support

The Problem:

After purchasing the SK720T driver, many businesses face challenges with inadequate after-sales support. This can manifest in delayed responses to technical queries or a lack of available resources for troubleshooting. For European buyers, such as those in Spain, this can be particularly frustrating when immediate support is needed to avoid disruptions in operations.

The Solution:

Before finalizing a purchase, thoroughly evaluate the after-sales support options offered by the supplier. Look for vendors that provide comprehensive service level agreements (SLAs), which outline response times and support availability. Establish a clear communication channel for technical support that includes access to online resources, such as FAQs and troubleshooting guides. Additionally, consider forming a partnership with a local service provider who can offer on-the-ground support, ensuring that you have reliable help available whenever necessary. Regular follow-ups with the supplier can also ensure that your business remains informed about any updates or changes that could affect the driver’s performance.

Strategic Material Selection Guide for sk720t driver

When selecting materials for the sk720t driver, it is essential to consider various factors that can significantly influence the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in the manufacturing of the sk720t driver, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in sk720t Driver Applications?

Aluminum is a popular choice for the sk720t driver due to its lightweight nature and good mechanical properties. It typically has a temperature rating of up to 150°C and excellent corrosion resistance, making it suitable for various environments. Its low density contributes to reduced weight, which is advantageous in applications where weight savings are critical.

Pros & Cons:

Aluminum offers high strength-to-weight ratios and is relatively easy to machine, which can lower manufacturing complexity. However, it may not perform well under high-pressure conditions compared to other materials, and its cost can be moderate to high depending on the alloy used.

Impact on Application:

Aluminum is compatible with a wide range of media, including water and some oils, but it may not be suitable for highly corrosive environments, such as those involving strong acids.

Considerations for International Buyers:

Buyers from regions like Europe and Turkey should ensure compliance with relevant standards such as EN and ASTM for aluminum alloys. Additionally, the availability of specific grades may vary by region, impacting lead times and costs.

How Does Stainless Steel Compare for the sk720t Driver?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it an excellent choice for the sk720t driver in harsh environments. It can withstand temperatures exceeding 300°C and is capable of handling higher pressures compared to aluminum.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to wear and corrosion. However, it is heavier than aluminum, which may not be ideal for all applications. The manufacturing complexity is also higher, which can lead to increased costs.

Impact on Application:

Stainless steel is suitable for a variety of media, including corrosive chemicals, making it a versatile choice for many industries. Its robustness ensures reliability in demanding applications.

Considerations for International Buyers:

B2B buyers in Africa and South America should verify compliance with ASTM and ISO standards for stainless steel. The cost can vary significantly based on the grade, so understanding local market conditions is crucial.

What Are the Advantages of Plastic Materials for the sk720t Driver?

Plastics, particularly engineering plastics like polycarbonate or nylon, offer unique benefits for the sk720t driver. They are lightweight, resistant to corrosion, and can operate effectively at moderate temperatures, typically up to 80°C.

Pros & Cons:

The main advantage of plastics is their cost-effectiveness and ease of manufacturing. However, they may not withstand high pressures or extreme temperatures, limiting their application scope.

Impact on Application:

Plastics are suitable for non-corrosive media and can be used in applications where weight is a critical factor. They are less suitable for high-stress environments.

Considerations for International Buyers:

Buyers from the Middle East and Europe should consider compliance with EU regulations regarding plastic materials, especially in food and medical applications. The availability of specific grades may vary, influencing procurement strategies.

When Should Copper Be Considered for the sk720t Driver?

Copper is often used in applications requiring excellent electrical conductivity, making it a viable option for the sk720t driver in electronic or electrical contexts. It has a high-temperature rating and can handle moderate pressures.

Pros & Cons:

Copper’s key advantage is its superior conductivity, which is essential for electrical applications. However, it is prone to corrosion, particularly in humid environments, and can be more expensive than aluminum.

Impact on Application:

Copper is ideal for applications involving electrical connections but may not be suitable for environments with corrosive agents.

Considerations for International Buyers:

B2B buyers from South America and Europe should ensure compliance with relevant electrical standards and consider the implications of copper’s susceptibility to corrosion in their specific applications.

Summary Table of Material Selection for sk720t Driver

| Material | Typical Use Case for sk720t driver | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications | High strength-to-weight ratio | Limited high-pressure performance | Medium |

| Stainless Steel | Harsh environments | Exceptional corrosion resistance | Higher weight and manufacturing complexity | High |

| Plastic | Non-corrosive, lightweight needs | Cost-effective and easy to manufacture | Limited high-pressure and temperature use | Low |

| Copper | Electrical applications | Superior electrical conductivity | Prone to corrosion in humid environments | Medium to High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sk720t driver

What Are the Key Manufacturing Processes for the sk720t Driver?

The manufacturing of the sk720t driver involves several critical stages that ensure its performance and reliability. Understanding these processes can help international B2B buyers assess supplier capabilities effectively.

Material Preparation: What Materials Are Used for the sk720t Driver?

The first step in the manufacturing process is material preparation. The sk720t driver typically utilizes high-quality materials such as aluminum, copper, and specialized plastics. These materials are chosen for their electrical conductivity, thermal stability, and resistance to environmental factors. Suppliers should provide detailed specifications regarding the sourcing and quality of these materials to ensure compliance with international standards.

Forming: How Are Components Shaped and Molded?

Once materials are prepared, they undergo forming processes, which may include extrusion, stamping, or injection molding. Each technique is selected based on the component’s design and the desired properties of the finished product. For example, aluminum components may be extruded for strength, while plastic parts are often injection molded for complex shapes. B2B buyers should inquire about the forming techniques used and their impact on the driver’s performance.

Assembly: What Steps Are Involved in Assembling the sk720t Driver?

The assembly stage is crucial for ensuring that all components fit together accurately. This typically involves manual assembly combined with automated processes to enhance efficiency. Key considerations during this stage include the integration of electronic components, soldering, and the application of adhesives. Buyers should look for suppliers that utilize both human oversight and automated quality checks to ensure precision.

Finishing: What Techniques Are Used to Enhance Durability?

Finishing processes, such as anodizing or coating, are applied to enhance the driver’s durability and aesthetic appeal. These techniques help protect against corrosion, wear, and environmental damage. B2B buyers should evaluate suppliers on their finishing capabilities and the technologies they employ, as these can significantly influence the product’s lifespan and performance.

How Is Quality Assurance Implemented in the Manufacturing of the sk720t Driver?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for the sk720t driver. It involves rigorous checks and adherence to established standards to ensure that the final product meets specifications and customer expectations.

What International Standards Should B2B Buyers Consider?

B2B buyers should be aware of the relevant international quality standards applicable to the sk720t driver. ISO 9001 is a widely recognized standard that focuses on quality management systems. Compliance with this standard indicates that the manufacturer adheres to best practices in quality control and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for specific applications can further validate product quality.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components before they enter production. Suppliers should maintain records of these inspections to provide transparency.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are necessary to ensure that components are being produced to specification. This includes monitoring dimensions, assembly accuracy, and adherence to production schedules.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection is conducted to verify that the finished product meets all specifications and standards. This may involve functional testing, durability assessments, and compliance checks.

What Common Testing Methods Are Used for the sk720t Driver?

Testing is an integral part of quality assurance, and several methods are commonly employed:

-

Electrical Testing: Ensures that the sk720t driver operates within its electrical specifications, including voltage and current ratings.

-

Thermal Testing: Evaluates the driver’s performance under various temperature conditions to ensure reliability.

-

Durability Testing: Involves subjecting the driver to mechanical stress and environmental conditions to assess its lifespan.

B2B buyers should request detailed testing reports from suppliers to verify compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that potential suppliers maintain high-quality standards, B2B buyers should consider the following strategies:

-

Conduct Supplier Audits: Regular audits help assess the manufacturer’s adherence to quality standards and their overall production capabilities. Buyers can schedule these audits to ensure compliance.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. This transparency is crucial for building trust.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly important for buyers from regions with specific regulatory requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control:

-

Regulatory Compliance: Different regions have varying regulations and standards. It’s essential for buyers to understand these requirements and ensure that suppliers can meet them.

-

Cultural Considerations: Cultural differences can affect communication and expectations regarding quality. Establishing clear lines of communication and setting mutual expectations can mitigate misunderstandings.

-

Logistics and Supply Chain Factors: Geographical distances can complicate quality assurance. Buyers should consider suppliers’ logistics capabilities to ensure timely delivery of quality products.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for the sk720t driver is essential for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and stringent quality control measures, buyers can make informed decisions and foster successful supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sk720t driver’

In the competitive landscape of B2B procurement, sourcing the right components, such as the sk720t driver, requires a methodical approach. This checklist provides actionable steps to streamline your sourcing process, ensuring you select the best suppliers and products tailored to your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the sk720t driver based on your application. This includes voltage ratings, compatibility with existing systems, and performance metrics. Having a precise specification helps avoid misunderstandings and ensures suppliers can meet your expectations.

Step 2: Conduct Market Research

Investigate the current market landscape for the sk720t driver. Identify key suppliers in your regions of interest—Africa, South America, the Middle East, and Europe. Utilize online platforms, industry reports, and trade shows to gather insights about supplier capabilities, pricing trends, and product availability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct a thorough evaluation of potential suppliers. Request detailed company profiles, case studies, and references from businesses that have previously procured similar products. Assess their reputation, reliability, and customer service to ensure they align with your business standards.

- Check Reviews and Testimonials: Look for feedback from clients in your region or industry.

- Assess Financial Stability: Understanding a supplier’s financial health can predict their ability to fulfill large orders.

Step 4: Verify Supplier Certifications

Ensure that your suppliers possess the necessary certifications relevant to the sk720t driver. This may include ISO certifications, safety standards, and compliance with international regulations. Certifications act as a quality assurance mechanism, demonstrating that the supplier adheres to industry best practices.

- Look for Specific Certifications: Depending on your industry, certain certifications may be more critical than others.

- Verify Authenticity: Confirm the validity of certifications through the issuing bodies.

Step 5: Request Samples or Prototypes

Before finalizing any orders, request samples or prototypes of the sk720t driver. This allows you to assess the product’s quality and compatibility with your systems. Testing samples can prevent costly mistakes and ensure that the product meets your operational needs.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations to finalize the terms of the purchase. Discuss pricing, payment terms, delivery schedules, and warranty conditions. Clear agreements protect both parties and help avoid disputes later in the process.

Step 7: Establish a Communication Plan

Maintain open lines of communication with your chosen supplier throughout the procurement process. Establish a clear point of contact for both parties and set regular check-ins to monitor progress. Effective communication can help resolve issues quickly and maintain a smooth relationship.

By following this checklist, international B2B buyers can ensure a structured and informed approach to sourcing the sk720t driver, ultimately leading to successful procurement and long-term partnerships.

Comprehensive Cost and Pricing Analysis for sk720t driver Sourcing

What Are the Key Cost Components in Sourcing the sk720t Driver?

When sourcing the sk720t driver, understanding the cost structure is crucial for effective budgeting and negotiation. The cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality raw materials can lead to increased durability and performance but may raise initial costs.

-

Labor: Labor costs vary by region and can fluctuate based on local wage standards. For instance, sourcing from regions with lower labor costs might provide savings, but quality should not be compromised.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thus lowering the overall cost.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. It’s essential to consider whether the supplier can amortize these costs over larger production runs, reducing the per-unit cost.

-

Quality Control (QC): Investing in robust QC processes ensures that products meet specified standards. While this may increase upfront costs, it can prevent costly returns and reputational damage later.

-

Logistics: Transportation costs are influenced by the mode of transport, distance, and fuel prices. Understanding the logistics network of your supplier can lead to more accurate shipping estimates and potential savings.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary widely, influenced by market demand, competition, and the supplier’s business model.

How Do Price Influencers Affect the Sourcing of sk720t Drivers?

Several factors influence the pricing of the sk720t driver, and understanding these can lead to more informed purchasing decisions:

-

Volume/MOQ: Minimum Order Quantities (MOQs) play a significant role in pricing. Larger orders often qualify for bulk discounts, making it essential to assess your needs accurately.

-

Specifications and Customization: Customized features can increase costs due to additional tooling and production processes. Ensure that any customizations are justified by the benefits they provide.

-

Materials and Quality Certifications: The material quality and certifications (such as ISO) can affect both the price and the perceived value of the sk720t driver. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven quality and service levels.

-

Incoterms: The terms of shipment, including responsibilities for shipping and insurance, can significantly impact costs. Familiarizing yourself with Incoterms can help you negotiate better terms and avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing sk720t Drivers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing:

-

Effective Negotiation: Engaging suppliers in open discussions about pricing can yield better deals. Highlighting your long-term purchasing potential can motivate suppliers to offer more competitive rates.

-

Understanding Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This holistic view can lead to better investment decisions.

-

Navigating Pricing Nuances: Be aware that pricing can fluctuate based on geopolitical factors, currency exchange rates, and local economic conditions. Staying informed about these dynamics can help you time your purchases effectively.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can lead to preferential pricing and terms over time. Trust and loyalty can create a win-win scenario for both parties.

Conclusion

Sourcing the sk720t driver requires a nuanced understanding of cost structures, pricing influencers, and strategic buyer practices. By applying these insights, international B2B buyers can enhance their procurement strategies and ensure they achieve the best value for their investments. Always remember that prices can vary widely based on numerous factors, so it is advisable to seek multiple quotes and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing sk720t driver With Other Solutions

When evaluating the best technology solutions for your business needs, particularly in the context of the sk720t driver, it’s essential to consider various alternatives that may offer similar benefits. This analysis focuses on comparing the sk720t driver with two notable alternatives: the XYZ Driver and the ABC Driver. Each of these solutions presents unique features and capabilities that can cater to different business requirements.

Comparison Table of sk720t Driver and Alternatives

| Comparison Aspect | Sk720T Driver | XYZ Driver | ABC Driver |

|---|---|---|---|

| Performance | High efficiency, optimized for specific applications | Moderate efficiency, versatile across various tasks | High performance, but resource-intensive |

| Cost | Mid-range pricing, good ROI | Lower initial cost, but higher operational costs | Higher upfront cost, but long-term savings |

| Ease of Implementation | Straightforward setup, minimal training required | Requires comprehensive training for optimal use | Simple installation, but complex integration |

| Maintenance | Low maintenance needs, regular updates available | Moderate maintenance, potential downtime | High maintenance, frequent updates necessary |

| Best Use Case | Ideal for specialized applications needing precision | Suitable for general-purpose tasks across industries | Best for high-demand environments needing robust performance |

What Are the Key Advantages and Disadvantages of the XYZ Driver?

The XYZ Driver is a versatile solution that offers a lower initial cost, making it an attractive option for businesses with limited budgets. Its moderate efficiency allows it to handle a range of tasks, providing flexibility in operations. However, the need for comprehensive training can be a significant drawback, as it may require additional time and resources to fully leverage its capabilities. Furthermore, while the upfront costs are lower, ongoing operational expenses can accumulate, potentially diminishing the overall cost-effectiveness in the long run.

What Makes the ABC Driver a Strong Contender?

The ABC Driver stands out for its high performance, particularly in demanding environments where speed and reliability are crucial. This solution is well-suited for industries that require robust performance, such as manufacturing or logistics. However, its higher upfront cost can be a barrier for some businesses, and the maintenance demands are significant, which can lead to increased operational disruptions. Despite these challenges, the long-term savings and efficiency gains can justify the investment for larger enterprises.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the most appropriate driver for your business, it’s crucial to align the solution with your specific operational needs and budget constraints. The sk720t driver offers a balanced approach with its efficiency and low maintenance, making it ideal for specialized applications. In contrast, the XYZ Driver may appeal to businesses looking for flexibility with a lower initial investment, while the ABC Driver is better suited for high-performance requirements despite its higher costs. Assess your organization’s priorities, such as performance needs, budget, and ease of implementation, to make an informed decision that aligns with your strategic goals.

Essential Technical Properties and Trade Terminology for sk720t driver

What Are the Essential Technical Properties of the sk720t Driver?

Understanding the technical properties of the sk720t driver is crucial for international B2B buyers looking to make informed purchasing decisions. Here are some key specifications that you should consider:

-

Material Grade

– The sk720t driver is typically made from high-grade steel or aluminum alloys. The material grade affects durability, weight, and resistance to environmental factors such as corrosion. For buyers in regions like Africa and South America, where climate can be extreme, selecting a driver with a suitable material grade ensures longevity and reliability in various conditions. -

Tolerance Levels

– Tolerance indicates the permissible limit of variation in a physical dimension. For the sk720t driver, tight tolerances are essential for ensuring compatibility with other components in machinery or vehicles. Buyers should prioritize suppliers who can consistently meet these tolerance specifications, as it directly impacts the performance and safety of the equipment. -

Weight Capacity

– The sk720t driver is designed to handle specific weight loads. Understanding its weight capacity is vital for B2B buyers to ensure that it meets their operational requirements. In industries such as construction and manufacturing, exceeding weight limits can lead to equipment failure and safety hazards. -

Operating Temperature Range

– This specification defines the temperature limits within which the sk720t driver can function effectively. Buyers should consider their local environmental conditions, particularly in the Middle East and Europe, where temperature fluctuations can be significant. Selecting a driver with an appropriate operating temperature range can prevent premature wear and failure. -

Performance Rating

– Performance ratings, often expressed in terms of torque, speed, and efficiency, help buyers gauge the effectiveness of the sk720t driver in specific applications. Understanding these ratings allows for better alignment with operational needs, ensuring optimal performance and productivity.

What Trade Terminology Should B2B Buyers Know When Purchasing sk720t Drivers?

Familiarity with industry terminology can streamline the purchasing process and enhance communication with suppliers. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components that are used in another company’s end products. For B2B buyers, sourcing sk720t drivers from recognized OEMs can assure quality and compatibility, minimizing risks in procurement. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers, especially in regions where inventory management is critical. It helps in planning purchases to avoid overstock or shortages. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers requesting pricing and terms for specified products. B2B buyers should prepare detailed RFQs for sk720t drivers to receive accurate and competitive quotes, which can facilitate better negotiations and decision-making. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and delivery responsibilities, especially when dealing with suppliers from Europe or the Middle East. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. For international buyers, understanding lead times is essential for inventory planning and ensuring that production schedules are met without delays. -

Warranty and After-Sales Support

– Warranty terms and after-sales support are critical for ensuring product reliability and customer satisfaction. B2B buyers should inquire about these aspects when purchasing sk720t drivers to guarantee long-term value and assistance in case of product issues.

By understanding these technical properties and trade terms, international B2B buyers can navigate the procurement process more effectively, ensuring that they select the right sk720t driver for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the sk720t driver Sector

What Are the Current Market Dynamics and Key Trends in the sk720t Driver Sector?

The sk720t driver sector is witnessing significant growth, driven by advancements in technology and the increasing demand for high-performance automotive components. Key trends indicate a shift towards automation and digitalization within supply chains, enhancing efficiency and responsiveness. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, need to stay informed about the integration of IoT (Internet of Things) technologies. These innovations enable real-time tracking of components, reducing lead times and enhancing inventory management.

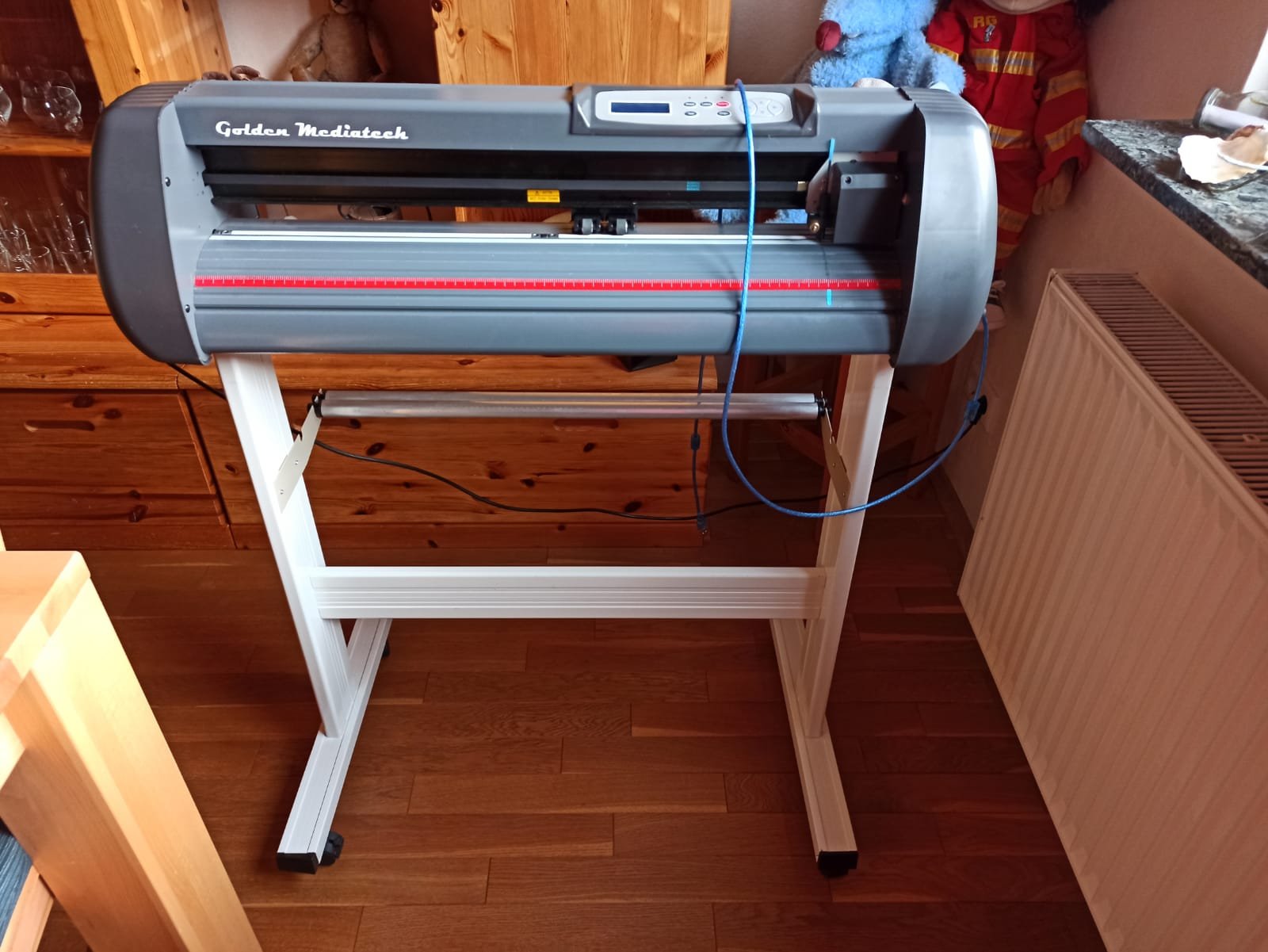

A stock image related to sk720t driver.

Moreover, there is a growing emphasis on quality and reliability, with buyers increasingly seeking suppliers who can provide comprehensive warranties and robust after-sales support. As global supply chains become more interconnected, understanding regional dynamics is crucial. For instance, buyers in Europe may prioritize suppliers compliant with stringent EU regulations, while those in Africa may focus on cost-effectiveness without compromising quality. The trend towards sourcing from local suppliers to minimize logistics costs is also gaining traction, especially in emerging markets.

How Does Sustainability and Ethical Sourcing Impact the sk720t Driver Supply Chain?

Sustainability has emerged as a vital consideration for international B2B buyers in the sk720t driver sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. Ethical sourcing is not just a buzzword; it has become a criterion for supplier selection. Buyers are increasingly looking for partners who demonstrate a commitment to reducing their carbon footprint and engaging in fair labor practices.

Green certifications and eco-friendly materials are becoming essential factors in the purchasing decision. Suppliers that utilize recyclable materials or have eco-labels can distinguish themselves in the market. For instance, certifications such as ISO 14001 (Environmental Management) or adherence to the Global Reporting Initiative (GRI) can provide buyers with confidence that their suppliers are committed to sustainable practices. By prioritizing suppliers who align with these values, international buyers can enhance their brand reputation and meet the growing consumer demand for sustainable products.

What Is the Brief Evolution of the sk720t Driver Sector?

The sk720t driver sector has evolved significantly over the past few decades. Initially, the focus was on mechanical performance and basic functionality. However, with the advent of digital technologies and increasing consumer expectations, manufacturers began to integrate electronic components, leading to the development of smart drivers that offer enhanced performance and diagnostics.

In recent years, the push towards sustainability has transformed the manufacturing landscape. Companies are not only focused on enhancing product performance but are also committed to reducing environmental impact through innovative designs and sustainable materials. This evolution highlights the importance of adaptability and foresight for B2B buyers looking to source from suppliers that can meet both current demands and future challenges in the sk720t driver sector.

Frequently Asked Questions (FAQs) for B2B Buyers of sk720t driver

-

How can I ensure the quality of the sk720t driver I am purchasing?

To ensure the quality of the sk720t driver, start by verifying the supplier’s certifications and compliance with international standards. Request samples to evaluate performance and reliability firsthand. Additionally, consider suppliers that offer comprehensive quality assurance processes, including third-party inspections and testing reports. Establishing a clear communication line with the supplier regarding quality expectations can help mitigate risks. -

What are the typical lead times for ordering sk720t drivers from international suppliers?

Lead times for sk720t drivers can vary significantly based on the supplier’s location, manufacturing capabilities, and order size. Generally, expect a lead time of 4 to 12 weeks. To avoid delays, inquire about the supplier’s production schedule and shipping capabilities. Additionally, placing orders well in advance and discussing expedited shipping options can help accommodate urgent project timelines. -

What are the minimum order quantities (MOQ) for sk720t drivers from suppliers?

Minimum order quantities for sk720t drivers typically range from 50 to 500 units, depending on the supplier and customization requirements. For international buyers, it’s crucial to clarify the MOQ before initiating the purchasing process. If the MOQ is higher than your needs, consider negotiating with the supplier or exploring group purchasing options with other businesses to meet the MOQ more efficiently. -

What payment terms should I expect when purchasing sk720t drivers internationally?

Payment terms for international purchases of sk720t drivers can vary widely, but common arrangements include upfront deposits (often 30-50%) with the balance due upon shipment. Some suppliers may offer letters of credit or payment via platforms like PayPal for additional security. Always confirm the payment terms in advance and consider using escrow services for higher-value transactions to protect your investment. -

How do I vet suppliers when sourcing sk720t drivers from different regions?

Vetting suppliers requires a multi-faceted approach. Start by researching the supplier’s reputation through online reviews, industry forums, and their history of international transactions. Request references from previous clients and verify their business licenses and certifications. Additionally, visiting the supplier’s facility, if possible, or utilizing third-party inspection services can provide deeper insights into their operational capabilities and reliability.

A stock image related to sk720t driver.

-

What customization options are available for sk720t drivers?

Many suppliers offer various customization options for sk720t drivers, including modifications in size, functionality, and compatibility with specific systems. To explore these options, clearly communicate your requirements to the supplier and ask about their capabilities in product customization. It’s beneficial to request prototypes before finalizing orders to ensure the customized drivers meet your specifications and performance expectations. -

What logistics considerations should I keep in mind when importing sk720t drivers?

When importing sk720t drivers, consider shipping methods, costs, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure compliance with import regulations in your country, including any tariffs or duties. Working with a freight forwarder can streamline the logistics process and help navigate customs requirements efficiently. -

How do I handle after-sales support for sk720t drivers purchased internationally?

After-sales support is crucial for maintaining operational efficiency. Confirm with the supplier about their warranty policies and available technical support options. It’s advisable to establish a clear communication channel for troubleshooting issues post-purchase. Additionally, inquire about the availability of replacement parts and repair services to ensure you can maintain the sk720t drivers effectively throughout their lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sk720t driver

In the evolving landscape of the sk720t driver market, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging strong supplier relationships and conducting thorough market analysis, organizations can optimize their procurement processes, ensuring they not only secure quality products but also achieve cost efficiencies. Buyers from Africa, South America, the Middle East, and Europe should prioritize understanding regional market dynamics and supplier capabilities to enhance their sourcing strategies.

A stock image related to sk720t driver.

What are the key benefits of strategic sourcing for the sk720t driver? The approach not only fosters innovation and sustainability but also mitigates risks associated with supply chain disruptions. As businesses aim to enhance operational efficiency, focusing on long-term partnerships with reliable suppliers will be essential.

Looking ahead, the demand for the sk720t driver is expected to grow as industries increasingly adopt advanced technologies. Therefore, international buyers are encouraged to remain proactive in their sourcing efforts. Engage with suppliers who demonstrate a commitment to quality and innovation, ensuring your organization stays competitive in a rapidly changing market. Embrace strategic sourcing as a pathway to success and elevate your procurement strategy today.