Unlock Savings with HMS Photovoltaik: The Complete Guide (2025)

Introduction: Navigating the Global Market for hms photovoltaik

Navigating the global market for hms photovoltaik presents unique challenges for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. As the demand for renewable energy solutions grows, sourcing high-quality photovoltaic systems that meet diverse regional needs can be daunting. This guide aims to simplify that process by offering a comprehensive overview of hms photovoltaik, including the various types available, their applications across different sectors, and effective strategies for supplier vetting.

Understanding the intricacies of hms photovoltaik is crucial for making informed purchasing decisions. Buyers will gain insights into the latest technological advancements, optimal installation practices, and potential cost implications. Additionally, we will delve into the regulatory landscape affecting photovoltaic systems in various regions, ensuring that buyers are equipped with the knowledge to navigate compliance issues effectively.

This guide empowers B2B buyers by providing actionable insights that facilitate strategic sourcing decisions. By addressing key considerations such as supplier reliability, product certifications, and market trends, we aim to enhance buyers’ confidence in their procurement processes. Whether you are a small business in Italy looking to invest in solar energy or a large-scale operation in South Africa seeking sustainable solutions, this guide is designed to meet your specific needs and help you leverage the benefits of hms photovoltaik.

Understanding hms photovoltaik Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monocrystalline Panels | High efficiency, space-efficient, uniform appearance | Large-scale solar farms, commercial buildings | Pros: High efficiency, long lifespan. Cons: Higher cost compared to other types. |

| Polycrystalline Panels | Lower efficiency than monocrystalline, made from multiple crystals | Residential installations, small businesses | Pros: Lower cost, decent efficiency. Cons: Requires more space for the same output. |

| Thin-Film Technology | Lightweight, flexible, lower efficiency but adaptable | BIPV (Building-Integrated Photovoltaics), portable applications | Pros: Lightweight, versatile. Cons: Lower efficiency, shorter lifespan. |

| Bifacial Panels | Dual-sided energy capture, increased output potential | Utility-scale projects, rooftops | Pros: Higher energy yield, adaptable placement. Cons: Higher initial investment. |

| Building-Integrated PV | Integrated into building materials, aesthetically pleasing | Urban developments, architectural projects | Pros: Space-saving, attractive design. Cons: Potentially higher installation costs. |

What Are the Key Characteristics of Monocrystalline Panels?

Monocrystalline panels are recognized for their high efficiency and sleek design, making them a popular choice among B2B buyers focused on maximizing energy output in limited spaces. They are manufactured from a single crystal structure, which allows for greater efficiency rates, often exceeding 20%. Ideal for large-scale solar farms and commercial buildings, these panels are particularly suited for regions with high solar insolation. Buyers should consider the higher initial investment against long-term energy savings and durability.

How Do Polycrystalline Panels Compare in Efficiency and Cost?

Polycrystalline panels are created from multiple silicon crystals, which results in a lower efficiency rate, typically between 15-18%. These panels are generally more affordable than their monocrystalline counterparts, making them an attractive option for small businesses and residential installations. B2B buyers should weigh the cost savings against the need for larger installation spaces, as these panels require more area to generate equivalent power output.

What Makes Thin-Film Technology Unique for Specific Applications?

Thin-film technology stands out due to its lightweight and flexible nature, allowing for various applications, including portable solar solutions and building-integrated photovoltaics (BIPV). While they offer lower efficiency, typically around 10-12%, their versatility makes them suitable for unconventional installations where traditional panels may not fit. Buyers should consider the trade-off between flexibility and efficiency, especially in projects where aesthetics and weight are critical factors.

Why Are Bifacial Panels Gaining Popularity Among B2B Buyers?

Bifacial panels capture sunlight from both sides, significantly increasing energy output potential, especially in reflective environments. They are particularly beneficial for utility-scale projects and rooftops where space is at a premium. While their initial cost is higher, the potential for increased energy yield can lead to a better return on investment over time. B2B buyers should evaluate the site conditions and reflectivity to maximize the advantages of bifacial technology.

How Does Building-Integrated PV Enhance Urban Development?

Building-Integrated Photovoltaics (BIPV) are designed to blend seamlessly with building materials, offering an aesthetically pleasing alternative to traditional solar panels. This technology is particularly appealing for urban developments and architectural projects where space is limited, and design is paramount. Although installation costs can be higher, the dual benefit of energy generation and enhanced property value makes BIPV a compelling option for B2B buyers focused on innovative building solutions.

Key Industrial Applications of hms photovoltaik

| Industry/Sector | Specific Application of hms photovoltaik | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Solar Power Generation Systems | Reduces energy costs and carbon footprint, enhancing sustainability. | Reliability of components, local regulations, and certifications. |

| Agriculture | Solar-Powered Irrigation Systems | Enables efficient water management, leading to higher crop yields. | Compatibility with existing systems, durability in harsh conditions. |

| Telecommunications | Off-Grid Solar Solutions for Telecom Towers | Ensures uninterrupted service and reduces operational costs. | Energy storage solutions, geographical adaptability, and installation support. |

| Manufacturing | Solar Energy for Production Facilities | Lowers energy expenses and increases operational efficiency. | Scalability, integration with existing energy systems, and maintenance services. |

| Construction | Solar-Integrated Building Solutions | Enhances property value and meets green building standards. | Local building codes, design flexibility, and aesthetic compatibility. |

How is hms photovoltaik Used in Renewable Energy?

In the renewable energy sector, hms photovoltaik is primarily utilized in solar power generation systems. These systems convert sunlight into electricity, providing a sustainable energy source that significantly reduces operational costs and the carbon footprint of businesses. International buyers, especially in regions like Africa and South America, should consider the reliability of components and compliance with local regulations, which can impact installation and long-term performance.

What are the Applications in Agriculture?

For agriculture, hms photovoltaik powers solar irrigation systems, enhancing water management in farming operations. This application helps farmers efficiently use water resources, leading to increased crop yields and reduced dependency on traditional power sources. Buyers must evaluate the compatibility of these systems with existing infrastructure and the durability of components in harsh climates, particularly in the Middle East and Africa.

How Does hms photovoltaik Benefit Telecommunications?

Telecommunications companies leverage hms photovoltaik for off-grid solar solutions, particularly for remote telecom towers. This application ensures uninterrupted service and lowers operational costs associated with conventional power sources. B2B buyers in this sector should prioritize energy storage solutions and the adaptability of systems to different geographical conditions to maintain service reliability.

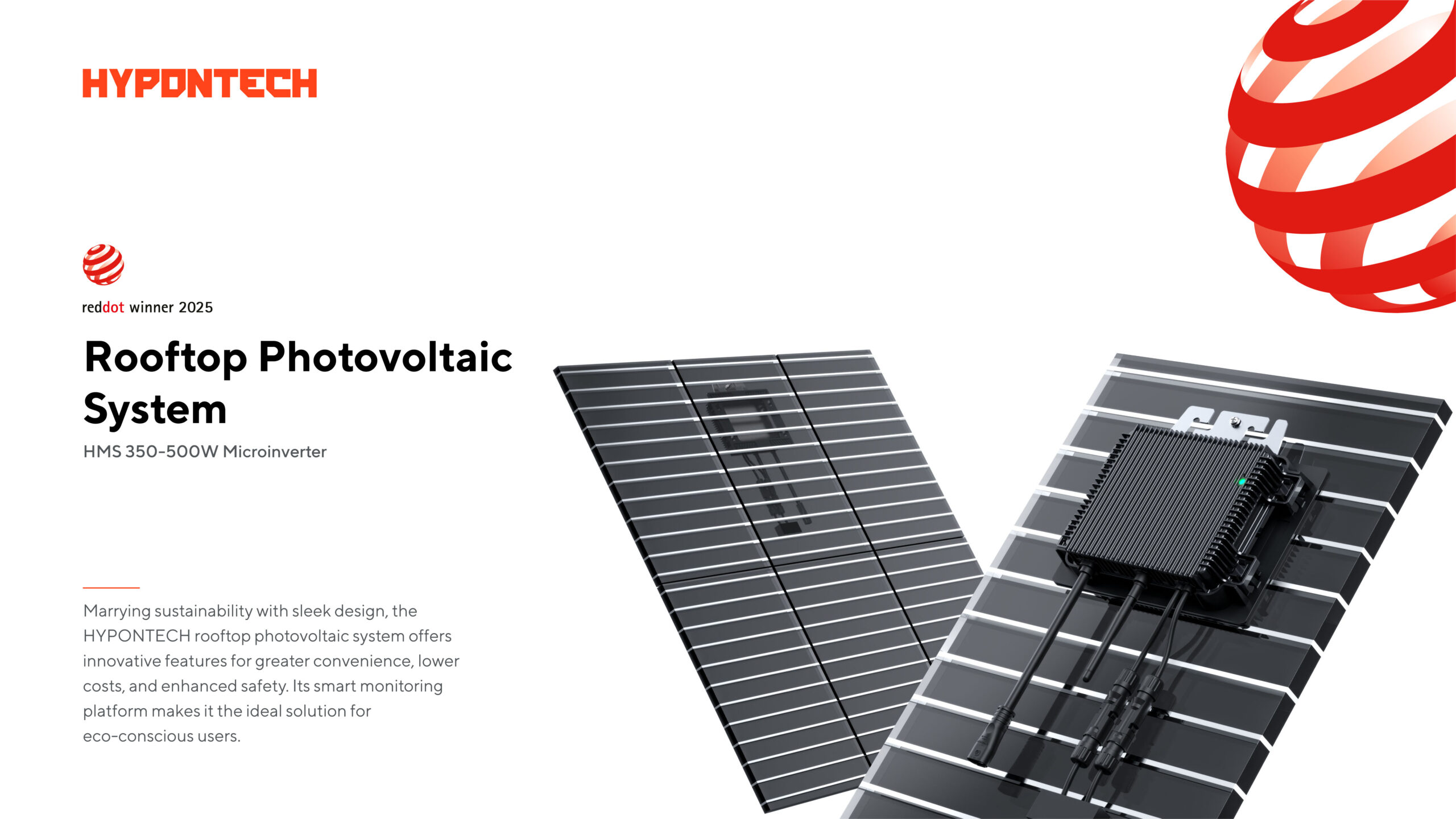

A stock image related to hms photovoltaik.

How is hms photovoltaik Applied in Manufacturing?

In manufacturing, hms photovoltaik is integrated into production facilities to provide solar energy, which can significantly lower energy expenses and enhance operational efficiency. This application is particularly valuable for businesses aiming to reduce their reliance on fossil fuels. Buyers should consider the scalability of solutions and their ability to integrate with existing energy systems for optimal performance.

What are the Construction Applications of hms photovoltaik?

The construction industry utilizes hms photovoltaik for solar-integrated building solutions, which enhance property value and help meet green building standards. This integration not only provides renewable energy but also contributes to aesthetic appeal. Buyers in Europe, particularly in countries like Italy and the UK, must be aware of local building codes and design flexibility to ensure compliance and maximize the benefits of solar integration.

Related Video: Electricity – Sources and Uses

3 Common User Pain Points for ‘hms photovoltaik’ & Their Solutions

Scenario 1: Overcoming High Initial Investment Costs in Photovoltaic Systems

The Problem: One of the primary pain points for B2B buyers, particularly in regions such as Africa and South America, is the high upfront cost associated with installing photovoltaic systems. Many businesses face tight budgets and are apprehensive about the significant investment needed for solar technology. This concern is compounded by the fear of not achieving a return on investment (ROI) within a reasonable timeframe, especially in emerging markets where economic conditions can be volatile.

The Solution: To mitigate these financial challenges, B2B buyers should explore financing options such as Power Purchase Agreements (PPAs) or leasing arrangements. These alternatives allow businesses to install photovoltaic systems with little to no upfront costs, paying instead for the energy generated over time. Additionally, buyers can leverage government incentives or subsidies specific to their region, which can significantly reduce the overall investment. It is crucial to conduct a thorough cost-benefit analysis that includes potential savings on energy bills and the environmental benefits of adopting sustainable practices. Engaging with reputable suppliers who can provide flexible financing plans tailored to local conditions will also enhance the feasibility of photovoltaic systems for businesses.

Scenario 2: Navigating Regulatory and Compliance Challenges

The Problem: International B2B buyers often encounter complex regulatory landscapes when considering the installation of photovoltaic systems. This is especially true in regions like the Middle East and Europe, where energy regulations and compliance requirements can vary widely. Businesses may struggle to understand local laws, permitting processes, and environmental standards, leading to potential delays and increased costs.

The Solution: To effectively navigate these regulatory challenges, B2B buyers should invest in local expertise. Engaging with local consultants or legal advisors who specialize in energy regulations can provide invaluable insights into the specific requirements for photovoltaic installations in their region. Additionally, buyers should ensure that their chosen suppliers are knowledgeable about compliance issues and can assist with the necessary permits and documentation. Building relationships with local regulatory bodies can also facilitate smoother processes. By staying informed about legislative changes and engaging in proactive communication with stakeholders, businesses can streamline their photovoltaic project timelines and avoid costly setbacks.

Scenario 3: Ensuring System Reliability and Performance

The Problem: Another common pain point for B2B buyers is the concern over the reliability and performance of photovoltaic systems. In regions with fluctuating weather conditions or limited technical support, businesses fear that their solar installations may not deliver consistent energy output. This uncertainty can deter companies from making the switch to solar, as they prioritize uninterrupted operations.

The Solution: To address these reliability concerns, businesses should prioritize selecting high-quality photovoltaic components from reputable manufacturers, such as hms photovoltaik. It is essential to conduct thorough research and engage in comparative analysis of products based on efficiency ratings and warranties. Buyers should also consider investing in advanced monitoring systems that allow real-time tracking of energy production and system performance. This proactive approach enables businesses to identify potential issues early and ensure optimal operation. Additionally, establishing a maintenance plan with a reliable service provider can further enhance system longevity and performance, providing peace of mind to businesses looking to integrate renewable energy sources into their operations.

Strategic Material Selection Guide for hms photovoltaik

What Are the Key Materials Used in hms photovoltaik?

When selecting materials for hms photovoltaik systems, it is crucial to consider their properties and how they align with the specific requirements of various applications. Below is an analysis of four common materials used in hms photovoltaik, focusing on their performance characteristics, advantages and disadvantages, and implications for international B2B buyers.

1. Silicon

Key Properties: Silicon is the most widely used semiconductor material in photovoltaic cells. It has excellent temperature stability, with a temperature rating of up to 125°C. Its corrosion resistance is moderate, making it suitable for various environmental conditions.

Pros & Cons: Silicon is durable and has a long lifespan, often exceeding 25 years. However, the manufacturing process can be complex and costly, particularly for high-purity silicon. Additionally, while silicon-based panels are highly efficient, they can be heavy, impacting installation logistics.

Impact on Application: Silicon is compatible with a wide range of media, including water and various gases, making it versatile for different applications. However, its performance can degrade in extreme temperatures, necessitating careful consideration in hotter climates.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, as silicon panels may need specific certifications to meet regional regulations. Understanding ASTM and JIS standards can help in selecting reliable suppliers.

2. Glass

Key Properties: Glass is primarily used as a protective layer for photovoltaic modules. It offers high transparency (over 90%) and excellent UV resistance, withstanding temperatures up to 200°C.

Pros & Cons: The main advantage of glass is its durability and ability to protect sensitive components from environmental damage. However, it can be brittle and may require additional support structures to prevent breakage during transport and installation.

Impact on Application: Glass is compatible with various cleaning agents and does not react with most chemicals, making it suitable for outdoor applications. However, its weight can be a limitation in certain installations, particularly in regions with stringent building codes.

Considerations for International Buyers: Buyers should focus on sourcing tempered or laminated glass, which meets international safety standards. Compliance with local building codes in Europe and South America is essential to avoid legal issues.

3. Aluminum

Key Properties: Aluminum is commonly used for frames and mounting structures in photovoltaic systems. It has a high strength-to-weight ratio and excellent corrosion resistance, withstanding harsh environmental conditions.

Pros & Cons: The lightweight nature of aluminum simplifies transportation and installation, making it a preferred choice for many projects. However, it can be more expensive than steel and may require additional coatings to enhance its lifespan in corrosive environments.

Impact on Application: Aluminum’s compatibility with various media, including saltwater, makes it suitable for coastal applications. However, its thermal expansion properties must be considered to avoid structural issues over time.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local standards for corrosion resistance, especially in humid or coastal regions. Familiarity with DIN and ASTM specifications can aid in selecting quality suppliers.

4. Polymeric Materials

Key Properties: Polymeric materials, such as ethylene-vinyl acetate (EVA), are often used as encapsulants in photovoltaic modules. They provide excellent adhesion and temperature resistance, typically rated up to 85°C.

Pros & Cons: These materials are lightweight and cost-effective, enhancing the overall efficiency of photovoltaic systems. However, they may degrade under UV exposure over time, which can impact long-term performance.

Impact on Application: Polymeric materials are compatible with most environmental conditions, but their longevity can be a concern in regions with high UV exposure, such as Africa and the Middle East.

Considerations for International Buyers: Buyers should prioritize suppliers that offer UV-stabilized polymeric materials to ensure durability. Understanding local regulations regarding material safety and performance standards is crucial for compliance.

Summary Table of Material Selection for hms photovoltaik

| Material | Typical Use Case for hms photovoltaik | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | Photovoltaic cells | High efficiency and durability | Complex and costly manufacturing process | High |

| Glass | Protective layer | Excellent durability and UV resistance | Brittle and heavy | Medium |

| Aluminum | Frames and mounting structures | Lightweight and corrosion resistant | More expensive than steel | Medium |

| Polymeric Materials | Encapsulants | Cost-effective and lightweight | Potential UV degradation over time | Low |

This guide should assist international B2B buyers in making informed decisions regarding material selection for hms photovoltaik systems, ensuring compatibility with regional standards and performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hms photovoltaik

What are the Main Stages of Manufacturing Processes for HMS Photovoltaik?

The manufacturing of HMS photovoltaik, a key player in the solar energy sector, involves several critical stages, ensuring high efficiency and reliability in solar panel production. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Ensuring Quality from the Start

Material preparation is a foundational step where raw materials such as silicon wafers, glass, and metals are sourced and pre-processed. High-purity silicon is essential for achieving optimal photovoltaic performance. Suppliers should be vetted for the quality of their materials, as impurities can significantly affect the efficiency of solar cells. B2B buyers should inquire about supplier certifications and material provenance to ensure compliance with international standards.

Forming: Shaping Components with Precision

In the forming stage, silicon wafers are cut and shaped into the required dimensions. Techniques such as laser cutting and chemical etching are commonly employed to create precise shapes and surface textures that enhance light absorption. Buyers should look for manufacturers that utilize advanced technology and automation, which can lead to better consistency and lower defect rates.

Assembly: Integrating Components for Optimal Performance

The assembly process involves integrating various components, including solar cells, back sheets, and junction boxes. This stage requires careful handling to avoid contamination. Automated assembly lines equipped with robotics help minimize human error and increase efficiency. B2B buyers should assess the assembly capabilities of suppliers, focusing on their technological investments and production capacity to meet demand.

Finishing: Quality Control and Final Touches

Finishing is the final stage of manufacturing, where the assembled solar panels undergo testing and quality assurance. This includes applying protective coatings and ensuring that all components are securely bonded. Buyers should verify that manufacturers adhere to stringent finishing processes, as this directly impacts the longevity and performance of the solar panels.

How is Quality Assurance Implemented in HMS Photovoltaik Manufacturing?

Quality assurance (QA) is crucial in the production of HMS photovoltaik to ensure that products meet both international and industry-specific standards. Understanding these QA processes helps B2B buyers make informed purchasing decisions.

What International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the quality of photovoltaic products. ISO 9001, which focuses on quality management systems, is one of the most recognized certifications. Compliance with this standard demonstrates that a manufacturer has effective processes in place for continuous improvement.

In addition to ISO 9001, specific industry standards such as CE marking (Conformité Européenne) and IEC 61215 (which certifies the design and durability of solar modules) are critical. These certifications ensure that products are safe and reliable for use in different markets, including Europe, where compliance is mandatory.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with key checkpoints including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications. Suppliers should provide certification documents for the materials used.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor production quality. Techniques such as statistical process control (SPC) can be beneficial in identifying deviations early.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted. This includes electrical testing, visual inspections, and performance evaluations to ensure the products meet established standards.

B2B buyers should request QC reports and documentation from manufacturers, which can provide insights into their quality management practices.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of suppliers is critical for B2B buyers, especially when sourcing from regions like Africa, South America, and the Middle East, where standards may vary. Here are several strategies to ensure quality assurance:

What Types of Audits Can Be Conducted?

Conducting audits is an effective way to assess a supplier’s quality management systems. Buyers can perform:

-

Supplier Audits: These on-site evaluations allow buyers to observe production processes, QC measures, and compliance with standards. Audits should focus on both documentation and actual practices.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality processes. This is particularly useful for international buyers who may not have the resources for extensive in-house audits.

How to Utilize QC Reports Effectively?

Requesting detailed QC reports from suppliers is vital for understanding their quality assurance processes. These reports should include:

-

Testing Methods Used: Information on how products are tested, including any certifications obtained during testing.

-

Defect Rates: Historical data on product defects can indicate the reliability of a supplier.

-

Corrective Actions Taken: Understanding how a supplier addresses quality issues can provide insights into their commitment to continuous improvement.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, especially in regions like Europe, Africa, and South America, buyers must be aware of specific nuances in quality control:

-

Cultural Differences: Different regions may have varying approaches to quality assurance and compliance. Understanding local practices can help navigate potential issues.

-

Regulatory Compliance: Ensure that suppliers are up-to-date with local regulations and international standards, as non-compliance can lead to significant delays and additional costs.

-

Communication: Establishing clear communication channels is essential for addressing quality concerns promptly. Regular updates and feedback can help maintain quality standards throughout the supply chain.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make more informed decisions when sourcing HMS photovoltaik products, ultimately ensuring they receive high-quality, reliable solar panels that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hms photovoltaik’

To successfully procure HMS Photovoltaik systems, international B2B buyers must navigate a series of critical steps that ensure the selection of reliable suppliers and high-quality products. This checklist serves as a practical guide to streamline your sourcing process and minimize potential risks.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes understanding the energy output you need, the type of photovoltaic technology (e.g., monocrystalline, polycrystalline), and any specific certifications required for your market.

– Why it Matters: Having precise specifications helps narrow down potential suppliers and ensures you receive products that meet your operational needs.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers of HMS Photovoltaik systems. Look for manufacturers with a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe.

– Key Considerations:

– Review industry reports and market trends.

– Utilize online platforms and industry trade shows to gather information about suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to conduct a comprehensive evaluation. Request company profiles, case studies, and references from other buyers in your industry or region.

– What to Look For:

– Supplier’s experience in the photovoltaic sector.

– Positive feedback from previous clients and successful project completions.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers have the necessary certifications and comply with international standards, such as ISO and IEC. This step is vital to guarantee product quality and safety.

– Important Certifications:

– Look for certifications relevant to your region’s regulations (e.g., CE marking in Europe).

– Assess the supplier’s commitment to sustainability and environmental standards.

Step 5: Request Product Samples

Before making a bulk purchase, request samples of the HMS Photovoltaik products. Testing samples in real-world conditions can help you evaluate their performance and compatibility with your systems.

– Why This Matters: Testing samples ensures that the products meet your expectations and helps identify any potential issues before a larger investment.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate the terms and conditions of the purchase. This includes pricing, payment terms, delivery schedules, and after-sales support.

– Key Points to Discuss:

– Warranty periods and service agreements.

– Clear communication channels for any future inquiries or issues.

Step 7: Establish a Relationship for Future Collaboration

Building a strong relationship with your supplier can lead to better pricing, priority support, and access to new technologies. Maintain open lines of communication to discuss future projects and opportunities.

– Benefits of a Strong Partnership:

– Improved reliability and trust.

– Potential for collaborative innovations in photovoltaic technology.

By following this step-by-step checklist, international B2B buyers can effectively navigate the procurement process for HMS Photovoltaik systems, ensuring that they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for hms photovoltaik Sourcing

What Are the Key Cost Components for Sourcing hms photovoltaik?

When sourcing hms photovoltaik, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of solar cells, glass, and frames can significantly impact costs. High-efficiency materials may incur higher upfront costs but lead to better performance and energy generation over time.

-

Labor: Labor costs can vary significantly based on the region and the skill level of the workforce. Countries with lower labor costs might offer competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes expenses related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce these costs, benefiting buyers.

-

Tooling: The initial investment in tooling for custom designs can be substantial. Buyers should consider how this cost will be amortized over the volume of products ordered.

-

Quality Control (QC): Ensuring the quality of hms photovoltaik products is paramount. Investing in rigorous QC processes can prevent costly defects and returns.

-

Logistics: Shipping costs, including freight and insurance, are critical in the total cost of ownership. Buyers must evaluate the most efficient shipping methods, considering lead times and costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the typical margins in the industry can aid in negotiations.

How Do Price Influencers Affect the Cost of hms photovoltaik?

Several factors can influence the pricing of hms photovoltaik. Understanding these can help buyers optimize their purchasing strategies:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts. Buyers should assess their purchasing needs and consider consolidating orders to achieve better pricing.

-

Specifications and Customization: Custom designs or specific technical specifications can lead to higher prices. Buyers should weigh the benefits of customization against the costs.

-

Materials: The choice of materials directly impacts pricing. Buyers should evaluate different material options and their long-term benefits to determine the best value.

-

Quality and Certifications: Products that meet international quality standards or have specific certifications (e.g., ISO, IEC) may command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer higher prices due to their quality assurance but can also provide peace of mind.

-

Incoterms: The chosen Incoterms can influence overall costs. For instance, FOB (Free on Board) pricing requires buyers to manage shipping costs, while DDP (Delivered Duty Paid) includes all shipping expenses, which could be more convenient.

What Tips Can Help Buyers Negotiate Better Pricing?

To secure favorable pricing for hms photovoltaik, international B2B buyers should consider the following strategies:

-

Negotiation Skills: Develop strong negotiation skills to discuss pricing, terms, and conditions effectively. Understanding market rates and being prepared to walk away can strengthen your position.

-

Cost-Efficiency: Look beyond the initial price. Analyze the total cost of ownership, including installation, maintenance, and potential savings on energy bills.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Trust and reliability can foster collaboration and negotiation flexibility.

-

Market Research: Stay informed about market trends, competitor pricing, and new technologies. This knowledge can help in discussions with suppliers and in making informed purchasing decisions.

-

Timing of Orders: Timing can significantly impact pricing. Consider placing orders during off-peak seasons when suppliers may offer discounts to boost sales.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing offers from multiple suppliers can reveal competitive pricing and better terms.

Conclusion

While sourcing hms photovoltaik, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies is vital for international B2B buyers. By focusing on these elements, buyers can make informed decisions that align with their business objectives and enhance their purchasing efficiency. Always remember that pricing can vary widely based on numerous factors, so conducting thorough research and maintaining flexibility can lead to better outcomes.

Alternatives Analysis: Comparing hms photovoltaik With Other Solutions

Understanding Alternatives for hms photovoltaik Solutions

When considering energy solutions for businesses, it is essential to analyze various alternatives to hms photovoltaik to ensure the best fit for specific operational needs. This analysis will focus on comparing hms photovoltaik with two viable alternatives: traditional solar panels and solar thermal systems. Each option has unique advantages and drawbacks, making it crucial for B2B buyers to evaluate them thoroughly.

Comparison Table of Energy Solutions

| Comparison Aspect | hms photovoltaik | Traditional Solar Panels | Solar Thermal Systems |

|---|---|---|---|

| Performance | High efficiency, scalable | Moderate efficiency, site-dependent | High efficiency for heating |

| Cost | Moderate initial investment, lower long-term costs | Lower initial investment, variable ROI | Higher upfront costs, but long-term savings |

| Ease of Implementation | Requires specialized installation | Standard installation process | Complex installation, needs plumbing |

| Maintenance | Low maintenance needs, regular checks | Low maintenance, occasional cleaning | Moderate maintenance, system checks required |

| Best Use Case | Commercial and industrial applications | Residential and commercial use | Industrial heating applications |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Traditional Solar Panels?

Traditional solar panels convert sunlight into electricity through photovoltaic cells. They have a lower initial investment compared to hms photovoltaik, making them an attractive option for many businesses, especially in regions with abundant sunlight. However, their efficiency can be site-dependent, meaning that geographical location and local weather conditions can significantly impact performance. Additionally, while they require minimal maintenance, they may not be as scalable as hms photovoltaik solutions, limiting growth potential for expanding businesses.

How Do Solar Thermal Systems Compare to hms photovoltaik?

Solar thermal systems focus on harnessing solar energy for heating purposes, making them ideal for industries needing hot water or steam. While they generally have higher upfront costs, they can offer significant long-term savings on energy bills, especially in sectors like manufacturing and hospitality. However, the installation process is often more complex, requiring plumbing and specialized knowledge. This can lead to higher initial labor costs and a longer return on investment compared to hms photovoltaik, which tends to be more straightforward in terms of installation and scalability.

Making the Right Choice for Your Business Needs

In conclusion, selecting the right energy solution involves understanding the specific requirements of your business. For companies in need of scalable, high-efficiency energy solutions, hms photovoltaik stands out as a strong option. However, traditional solar panels may be more suitable for smaller operations or those looking for lower upfront costs. Conversely, solar thermal systems are excellent for industries focused on heating applications but may require a more significant investment and complex installation. B2B buyers should assess their energy needs, budget constraints, and long-term goals to choose the most effective solution.

Essential Technical Properties and Trade Terminology for hms photovoltaik

What are the Key Technical Properties of HMS Photovoltaik?

A stock image related to hms photovoltaik.

When evaluating HMS photovoltaik (high-performance solar photovoltaic modules), international B2B buyers should focus on several critical technical specifications that can directly impact project success. Below are some essential properties to consider:

-

Material Grade

The material grade of photovoltaic cells, typically silicon-based, is crucial for determining efficiency and durability. Higher-grade materials often yield better energy conversion rates and longer lifespans, which can reduce long-term operational costs. For buyers, understanding material grades helps in selecting products that align with their project requirements and budget constraints. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in the dimensions and electrical characteristics of solar panels. For example, a tolerance of ±3% in power output means that a panel rated at 300W could produce between 291W and 309W. Tight tolerances ensure consistent performance, which is vital for large-scale deployments where uniformity affects overall system efficiency. -

Temperature Coefficient

This specification indicates how much a solar panel’s output decreases with rising temperatures. A lower temperature coefficient signifies better performance in hot climates, which is particularly relevant for buyers in regions like Africa and the Middle East. Understanding this property enables buyers to make informed decisions about the suitability of panels for their local climate conditions. -

Efficiency Rating

The efficiency rating measures the percentage of sunlight converted into usable electricity. Higher efficiency panels may have a higher upfront cost but offer more power generation per square meter, making them ideal for space-constrained installations. Buyers should assess efficiency ratings to optimize energy output relative to their installation area. -

Warranty and Lifespan

Warranties typically cover performance and product defects, with many manufacturers offering 25-year warranties. A robust warranty often indicates confidence in product durability and performance. Buyers should evaluate warranty terms as part of their risk management strategy, especially in regions with harsh environmental conditions.

What are Common Trade Terms in HMS Photovoltaik Procurement?

Understanding industry jargon is essential for navigating the procurement process effectively. Here are some key terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. For buyers, sourcing from reputable OEMs can ensure quality and reliability in solar modules. This term is crucial when discussing specifications and customization options with suppliers. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQs is vital for budget planning and inventory management. Buyers should negotiate MOQs that align with their project scale to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. Including detailed specifications and quantities in an RFQ can help buyers receive accurate pricing and lead times, facilitating better decision-making in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers understand their liabilities and rights in international trade, which is especially important for cross-border transactions. -

Lead Time

Lead time is the period from placing an order to receiving the products. Shorter lead times can enhance project timelines, making it critical for buyers to inquire about production and shipping schedules during the procurement process.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance project outcomes and streamline procurement processes.

Navigating Market Dynamics and Sourcing Trends in the hms photovoltaik Sector

What Are the Key Market Dynamics and Trends in the HMS Photovoltaik Sector?

The HMS photovoltaik sector is experiencing a significant transformation driven by various global factors. The demand for renewable energy sources, particularly solar power, has surged due to climate change concerns and the need for energy independence. This trend is particularly pronounced in regions such as Africa and South America, where energy access remains a critical challenge. Innovations in photovoltaic technology, such as bifacial solar panels and improved energy efficiency, are becoming more prevalent, influencing procurement strategies among B2B buyers.

Emerging technologies like artificial intelligence (AI) and the Internet of Things (IoT) are reshaping how businesses approach sourcing in the HMS photovoltaik market. AI-driven analytics enable firms to optimize their supply chains and predict demand fluctuations more accurately. Moreover, the shift towards decentralized energy systems is pushing B2B buyers to seek flexible and adaptable solutions that can cater to local needs, especially in developing regions.

In Europe, particularly in the UK and Italy, regulatory frameworks are increasingly favoring green energy solutions, creating a competitive landscape for international suppliers. Buyers are advised to stay abreast of policy changes, as they can significantly affect sourcing strategies and operational costs. Collaboration with local suppliers can also enhance market entry and reduce logistical challenges, offering a strategic advantage in these dynamic markets.

How Can Sustainability and Ethical Sourcing Impact B2B in the HMS Photovoltaik Sector?

Sustainability is no longer just a buzzword; it is a critical factor influencing purchasing decisions in the HMS photovoltaik sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices and ethical sourcing. The environmental impact of sourcing photovoltaic materials, such as silicon and metals, necessitates a thorough evaluation of supply chains. Buyers should consider suppliers who employ sustainable extraction methods and have robust waste management protocols.

Furthermore, certifications such as ISO 14001 (Environmental Management) and the Responsible Business Alliance (RBA) certification are becoming essential indicators of a supplier’s commitment to ethical practices. Companies that can provide transparency regarding their sourcing processes and environmental impact are more likely to attract discerning B2B buyers.

The importance of ‘green’ certifications extends beyond compliance; it can enhance brand reputation and customer loyalty. In markets like Europe and the Middle East, where consumers are increasingly eco-conscious, aligning with sustainable suppliers can provide a competitive edge. By integrating sustainability into their sourcing strategies, B2B buyers can not only reduce their environmental footprint but also contribute positively to their corporate social responsibility (CSR) goals.

What Is the Historical Context of the HMS Photovoltaik Sector’s Development?

The HMS photovoltaik sector has undergone significant evolution since the introduction of solar technologies in the mid-20th century. Initially dominated by government-funded projects and research initiatives, the market began to gain traction in the 1970s with the oil crisis highlighting the need for alternative energy sources. Over the decades, advancements in technology, coupled with decreasing costs, have made solar energy more accessible.

In the early 2000s, the rise of global awareness regarding climate change catalyzed investment in renewable energy, leading to a boom in solar photovoltaic installations. This growth has been particularly evident in Europe, which has been at the forefront of solar adoption, and in emerging markets across Africa and South America, where solar offers a viable solution to energy scarcity.

Today, the HMS photovoltaik sector continues to evolve, shaped by innovations in technology, changing regulatory landscapes, and increasing consumer demand for sustainable energy solutions. Understanding this historical context is crucial for B2B buyers as it provides insights into market trends and future directions, enabling informed sourcing decisions in a rapidly changing environment.

Frequently Asked Questions (FAQs) for B2B Buyers of hms photovoltaik

-

How do I solve issues related to low solar energy efficiency in my HMS photovoltaik systems?

To address low solar energy efficiency, first ensure that the solar panels are clean and free from debris, as dirt can significantly affect performance. Regular maintenance checks should be scheduled to inspect the inverter, wiring, and connections for any faults. Additionally, consider conducting a performance analysis to identify any systemic issues, and if necessary, consult with the manufacturer or a local expert for tailored solutions. Upgrading to higher-efficiency panels may also be an option if you need to enhance overall performance. -

What is the best HMS photovoltaik solution for commercial applications?

The best HMS photovoltaik solution for commercial applications typically involves high-efficiency solar panels combined with robust inverters and energy storage systems. Look for products that offer scalability to accommodate future energy needs and have proven reliability in similar climates. Additionally, consider the warranty and support services offered by the supplier, as these can be crucial for long-term performance. Evaluate case studies or testimonials from similar businesses to help inform your decision. -

How can I vet suppliers for HMS photovoltaik systems effectively?

When vetting suppliers for HMS photovoltaik systems, check their reputation through online reviews and industry references. Request documentation of their certifications and compliance with international standards. Conduct background checks on their financial stability and experience in the market. Additionally, consider visiting their facilities or previous project sites to assess quality firsthand. Engaging in direct discussions can also reveal insights into their customer service and responsiveness. -

What customization options are available for HMS photovoltaik products?

Customization options for HMS photovoltaik products often include panel size, power output, and specific mounting solutions tailored to your project needs. Many suppliers also offer bespoke energy management systems to optimize efficiency based on your energy consumption patterns. When discussing customization, ensure to communicate your project specifications clearly and ask about the implications on lead times and costs. -

What is the minimum order quantity (MOQ) for HMS photovoltaik systems?

Minimum order quantities (MOQs) for HMS photovoltaik systems can vary significantly based on the supplier and product type. Typically, larger suppliers may have higher MOQs due to manufacturing efficiencies, while smaller suppliers may be more flexible. It is advisable to inquire directly with potential suppliers about their MOQ policies, as this can influence your purchasing strategy, especially for smaller projects or pilot installations. -

What payment terms should I expect when purchasing HMS photovoltaik systems?

Payment terms for purchasing HMS photovoltaik systems generally range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your negotiation power. Some suppliers might offer financing options or installment payments for larger orders. It’s crucial to clarify these terms before finalizing the deal, as well as to understand any penalties for late payments or discounts for early settlements. -

How do I ensure quality assurance (QA) for HMS photovoltaik products?

To ensure quality assurance (QA) for HMS photovoltaik products, demand certification documents that prove compliance with international quality standards such as ISO 9001. Implement a comprehensive inspection process upon delivery, including visual checks and performance testing of solar panels and inverters. Establish a clear agreement with the supplier regarding warranty terms and after-sales support, which can help mitigate risks associated with product quality. -

What logistics considerations should I keep in mind when sourcing HMS photovoltaik systems internationally?

When sourcing HMS photovoltaik systems internationally, consider shipping methods, customs regulations, and potential delays in transit. It is essential to work with suppliers who have experience in exporting to your region to ensure compliance with local laws and standards. Additionally, factor in costs related to shipping, insurance, and any import duties. Developing a detailed logistics plan that includes timelines and contingency measures can help streamline the process and avoid disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hms photovoltaik

In the evolving landscape of solar energy, strategic sourcing for hms photovoltaik is not merely an operational necessity but a pathway to sustainable growth. International B2B buyers from Africa, South America, the Middle East, and Europe can leverage the insights gained from this guide to enhance their procurement processes. By focusing on value-driven partnerships, buyers can secure high-quality products that meet their unique regional demands while fostering innovation and efficiency.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in strategic sourcing allows companies to optimize their supply chains, reduce costs, and improve the overall quality of their solar solutions. By understanding local market dynamics and aligning with reputable suppliers, businesses can navigate regulatory challenges and capitalize on incentives aimed at promoting renewable energy.

A stock image related to hms photovoltaik.

What Is the Future Outlook for Solar Energy in Global Markets?

The future of photovoltaik technology is bright, driven by advancements in efficiency and a growing emphasis on sustainability. As countries ramp up their renewable energy commitments, the demand for reliable solar solutions will continue to rise. Now is the time for international B2B buyers to act—embrace strategic sourcing practices that not only fulfill immediate needs but also position your business at the forefront of the green energy revolution. Engage with suppliers who share your vision and values to ensure a resilient and sustainable future.