Above Ground Septic Tank Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for above ground septic tank

As global industries evolve, the demand for efficient waste management solutions, such as above ground septic tanks, is on the rise. International B2B buyers face the critical challenge of sourcing reliable and cost-effective septic systems that meet diverse regulatory standards and environmental considerations. This guide serves as a comprehensive resource, providing insights into various types of above ground septic tanks, their applications across different sectors, and essential supplier vetting processes.

In this guide, we delve into key factors that influence purchasing decisions, including the specifications of different tank models, storage capacities, and materials used in construction. We also examine regional compliance requirements, helping buyers navigate the complexities of international regulations, particularly in emerging markets across Africa, South America, the Middle East, and Europe—such as Germany and Brazil.

By equipping B2B buyers with actionable insights on cost considerations, maintenance practices, and supplier evaluation, this guide empowers informed purchasing decisions. Whether you are looking to invest in portable sanitation solutions for construction sites or seeking permanent waste management systems for residential or commercial use, this resource aims to streamline your procurement process, ensuring you secure the best solutions for your specific needs.

Understanding above ground septic tank Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Holding Tanks | Lightweight, designed for easy mobility, available in various capacities | Construction sites, events, and temporary sanitation needs | Pros: Easy to transport, quick setup. Cons: Limited capacity for long-term use. |

| Job Shack Holding Tanks | Low-profile design, can fit under trailers, connectable for increased capacity | Portable sanitation for construction and outdoor events | Pros: Space-saving, customizable capacity. Cons: May require frequent emptying. |

| Above Ground Wastewater Tanks | Larger capacity, permanent installations, various materials available | Residential and commercial wastewater management | Pros: Durable, long-term solution. Cons: More expensive, requires installation. |

| Septic Holding Tanks | Made from robust materials, designed for both grey and black water | Wastewater storage in areas without plumbing | Pros: Versatile use, easy maintenance. Cons: Requires regular pumping. |

| Polyethylene Septic Tanks | Lightweight, corrosion-resistant, and available in multiple sizes | Ideal for temporary and permanent wastewater solutions | Pros: Cost-effective, resistant to environmental factors. Cons: Limited lifespan compared to concrete. |

What Are the Characteristics of Portable Holding Tanks?

Portable holding tanks are designed for temporary waste storage, making them ideal for construction sites and outdoor events. Their lightweight nature allows for easy transport and setup. Typically available in capacities ranging from 100 to 500 gallons, these tanks are suitable for short-term applications where traditional plumbing is unavailable. Buyers should consider the frequency of waste disposal and the tank’s capacity to ensure it meets their specific needs.

How Do Job Shack Holding Tanks Stand Out?

Job shack holding tanks feature a low-profile design that allows them to fit under trailers and mobile units, making them an excellent choice for construction sites. They can be connected in series to increase holding capacity, providing flexibility for various project sizes. While they are easy to access for maintenance, buyers should be aware of their limited storage capacity and plan for regular waste removal to avoid overflow.

What Advantages Do Above Ground Wastewater Tanks Offer?

Above ground wastewater tanks are permanent installations that provide a robust solution for managing residential and commercial wastewater. These tanks come in various sizes and materials, including polyethylene and fiberglass, offering durability and long-term usability. Their installation requires more investment and planning compared to portable options, but they are ideal for businesses that need a reliable, long-lasting wastewater management system.

Why Choose Septic Holding Tanks for Wastewater Storage?

Septic holding tanks are versatile solutions designed to store both grey and black water, making them suitable for locations lacking plumbing infrastructure. These tanks are constructed from durable materials and are designed for easy maintenance, typically requiring regular pumping to prevent overflow. Buyers should consider their specific waste management needs and the tank’s location when selecting a septic holding tank to ensure compliance with local regulations.

What Makes Polyethylene Septic Tanks a Cost-Effective Choice?

Polyethylene septic tanks are lightweight and resistant to corrosion, making them a popular choice for both temporary and permanent wastewater solutions. Available in various sizes, these tanks are easy to transport and install, appealing to businesses looking for flexibility and cost-effectiveness. However, buyers should be mindful of their lifespan, as polyethylene tanks may not last as long as traditional concrete tanks, necessitating future replacements.

Key Industrial Applications of above ground septic tank

| Industry/Sector | Specific Application of Above Ground Septic Tank | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary waste management at construction sites | Efficient waste disposal minimizes site disruption and enhances productivity | Ensure compliance with local regulations; consider tank capacity and material durability |

| Event Management | Sanitation solutions for outdoor events and festivals | Provides essential sanitation, improving attendee experience and safety | Look for portable options with easy transport and maintenance features |

| Agriculture | Waste management for temporary agricultural setups | Supports hygiene in remote locations, aiding in productivity and compliance | Assess tank capacity for seasonal needs and compatibility with local waste disposal systems |

| Mining | Waste holding for remote mining operations | Prevents environmental contamination and maintains site compliance | Evaluate tank mobility and resistance to harsh conditions; consider local regulations |

| Disaster Relief | Emergency sanitation solutions in disaster-stricken areas | Quick deployment helps maintain hygiene and prevent disease outbreaks | Prioritize ease of transport and rapid setup; ensure tanks meet health standards |

How Are Above Ground Septic Tanks Used in Construction?

In the construction industry, above ground septic tanks are often deployed for temporary waste management. These tanks are essential for managing waste at sites lacking permanent plumbing systems. By providing a reliable solution for black and gray water disposal, they help maintain hygiene and operational efficiency. Buyers in this sector should prioritize tanks that comply with local regulations, considering factors such as capacity and the material’s resistance to environmental conditions.

What Role Do Above Ground Septic Tanks Play in Event Management?

Above ground septic tanks serve as crucial sanitation solutions for outdoor events, such as festivals and concerts. They offer a practical way to manage waste in areas without existing plumbing, ensuring that attendees have access to sanitary facilities. This not only enhances the overall experience but also mitigates health risks. Event organizers should seek portable tanks that are easy to transport and maintain, with a focus on those that can handle varying attendee volumes.

How Are Above Ground Septic Tanks Beneficial in Agriculture?

In agriculture, especially for temporary setups like mobile farms or seasonal harvests, above ground septic tanks provide a hygienic waste management solution. They ensure that waste is contained and disposed of properly, which is critical for compliance with health regulations. Buyers should consider the tank’s capacity based on seasonal needs and ensure compatibility with local waste disposal practices to avoid penalties.

Why Are Above Ground Septic Tanks Important in Mining Operations?

For mining operations in remote locations, above ground septic tanks are vital for effective waste management. These tanks prevent environmental contamination by securely holding waste until it can be properly disposed of. The mobility and durability of these tanks are key considerations for buyers, as they must withstand harsh conditions while ensuring compliance with environmental regulations.

How Can Above Ground Septic Tanks Aid in Disaster Relief Efforts?

Above ground septic tanks are invaluable in disaster relief scenarios, where rapid deployment of sanitation solutions is critical. These tanks can be quickly set up to provide essential waste management in areas affected by natural disasters, helping to maintain hygiene and prevent disease outbreaks. Buyers should focus on tanks that are easy to transport and set up, ensuring they meet health standards for emergency situations.

3 Common User Pain Points for ‘above ground septic tank’ & Their Solutions

Scenario 1: Managing Limited Space on Construction Sites

The Problem: Construction companies often face the challenge of limited space on job sites, making it difficult to install traditional underground septic systems. In many urban areas or tight environments, the need for sanitation solutions must be balanced with site logistics. This can lead to operational inefficiencies and increased costs if waste management isn’t handled properly. B2B buyers, particularly those in the construction and portable sanitation sectors, find themselves in a bind when they need a robust solution that doesn’t compromise the available space or hinder project timelines.

The Solution: Above ground septic tanks provide an ideal solution for these scenarios. Their low-profile design allows them to fit into tight spaces, such as under trailers or in small areas where traditional tanks cannot go. When sourcing these tanks, buyers should prioritize models that are specifically designed for portable applications, such as those offered by Quadel Industries or PolyJohn. Additionally, opting for tanks that can be connected in series can enhance waste storage capacity without requiring more ground space. Buyers should also consider integrating these tanks with portable toilets to create a seamless sanitation solution for construction sites, ensuring that waste is managed efficiently while adhering to health regulations.

Scenario 2: Overcoming Regulatory Compliance Challenges

The Problem: Navigating the regulatory landscape can be daunting for businesses operating in regions with strict environmental and health regulations. B2B buyers often struggle to ensure that their above ground septic solutions comply with local laws, which can vary significantly between countries and even within regions. Non-compliance can lead to hefty fines, project delays, and damage to a company’s reputation.

The Solution: To mitigate these risks, buyers should invest in above ground septic tanks that are ANSI/NSF 61 approved, as these certifications indicate compliance with recognized safety and health standards. It’s essential to conduct thorough research on local regulations before making a purchase. Engaging with local environmental agencies can provide valuable insights into specific compliance requirements. Additionally, working with suppliers who have a proven track record in the region can help ensure that the tanks meet necessary standards. Buyers should also consider the long-term implications of their tank choice, opting for durable materials like polyethylene, which can withstand harsh conditions while maintaining compliance.

Scenario 3: Ensuring Easy Maintenance and Accessibility

The Problem: Maintenance of septic systems can be labor-intensive and costly, particularly for above ground solutions that may not be easily accessible. B2B buyers often express concerns about the operational efficiency of their sanitation solutions, particularly when it comes to routine maintenance and emergency repairs. If a septic tank is difficult to access, it can lead to increased downtime and higher operational costs.

The Solution: Selecting above ground septic tanks specifically designed for easy access can significantly reduce maintenance challenges. Tanks that feature top access ports are ideal, as they allow for quick inspections and servicing without extensive labor. Buyers should prioritize models that offer clear maintenance guidelines and ensure that their team is trained in proper maintenance practices. Additionally, establishing a regular maintenance schedule with a trusted service provider can help prevent issues before they arise. When negotiating with suppliers, inquire about the availability of service plans or warranties that include maintenance support, as this can further alleviate potential accessibility issues.

Strategic Material Selection Guide for above ground septic tank

What are the Key Materials for Above Ground Septic Tanks?

When selecting materials for above ground septic tanks, it is crucial to consider factors such as durability, cost, and suitability for specific applications. Below, we analyze four common materials used in the construction of these tanks, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

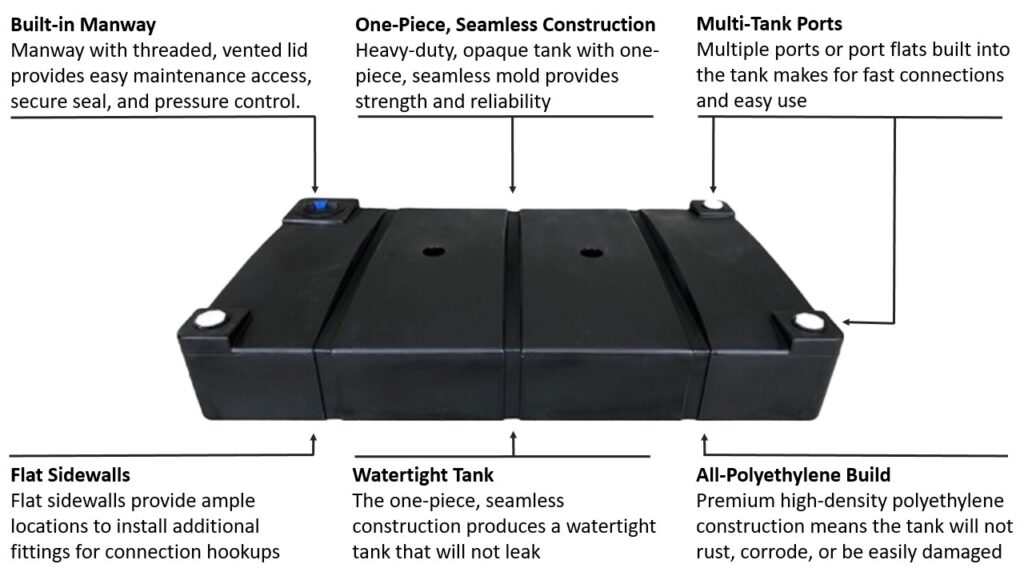

How Does Polyethylene Perform in Above Ground Septic Tanks?

Polyethylene is a widely used plastic material known for its excellent resistance to corrosion and chemicals, making it suitable for septic applications. It typically has a temperature tolerance ranging from -40°F to 120°F, which is adequate for most environments. Polyethylene tanks are lightweight, facilitating easier transport and installation.

Pros: They are cost-effective, durable, and resistant to UV degradation. Their flexibility allows for easy installation in various terrains, and they can be manufactured in various sizes to meet specific needs.

Cons: While they are generally robust, polyethylene tanks can be susceptible to punctures and may not perform well under extreme temperature fluctuations. Additionally, they may not be as structurally strong as some alternatives, leading to potential deformation over time.

Impact on Application: Polyethylene tanks are compatible with a wide range of waste types, including grey and black water, making them versatile for different applications.

Considerations for Buyers: Compliance with local regulations is essential, as some regions may require specific certifications. Buyers from Africa and South America should ensure that the tanks meet local environmental standards.

What Role Does Fiberglass Play in Septic Tank Construction?

Fiberglass reinforced plastic (FRP) is another popular choice for septic tanks due to its strength and durability. It can withstand high pressures and has a temperature rating of up to 200°F, making it suitable for hot climates.

Pros: Fiberglass tanks are resistant to corrosion and chemical damage, providing longevity. They are also lightweight and can be molded into various shapes, allowing for customized designs.

Cons: The manufacturing process is more complex and can result in higher costs. Additionally, fiberglass tanks may require additional support structures in certain applications due to their flexibility.

Impact on Application: FRP tanks are particularly effective in environments with high chemical exposure, such as industrial sites. However, they may not be suitable for all types of waste, particularly those with high solid content.

Considerations for Buyers: Buyers in Europe, especially in countries like Germany, should ensure that the tanks comply with DIN standards for environmental safety.

How Does Steel Compare as a Material for Septic Tanks?

Steel is often used for above ground septic tanks due to its strength and durability. It can withstand high pressures and is resistant to physical damage.

Pros: Steel tanks are robust and can handle heavy loads, making them suitable for high-traffic areas. They also have a long lifespan when properly maintained and coated.

Cons: Steel is prone to corrosion if not adequately treated, which can lead to leaks and structural failure. Additionally, they are heavier than plastic alternatives, making installation more labor-intensive.

Impact on Application: Steel tanks are ideal for heavy-duty applications but may require additional maintenance to prevent rust and corrosion.

Considerations for Buyers: Buyers from the Middle East should be aware of the need for anti-corrosive coatings due to high humidity and saline conditions.

What Advantages Does Concrete Offer for Septic Tank Applications?

Concrete is a traditional material for septic tanks, known for its durability and strength. It can withstand significant weight and has a high resistance to environmental factors.

Pros: Concrete tanks are highly durable and can last for decades with proper maintenance. They are also fire-resistant and provide excellent insulation.

Cons: The initial cost of concrete tanks is typically higher than plastic alternatives. They are also heavy, making installation more challenging and requiring more extensive groundwork.

Impact on Application: Concrete tanks are suitable for high-volume applications and can handle a variety of waste types, including industrial waste.

Considerations for Buyers: Buyers in regions with stringent regulations, such as Europe, should ensure that concrete tanks meet local building codes and environmental standards.

Summary Table of Material Selection for Above Ground Septic Tanks

| Material | Typical Use Case for Above Ground Septic Tank | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Residential and light commercial applications | Cost-effective and lightweight | Susceptible to punctures | Low |

| Fiberglass | Industrial and high-temperature environments | Corrosion-resistant and durable | Higher manufacturing costs | Medium |

| Steel | Heavy-duty commercial applications | Robust and strong | Prone to corrosion | Medium |

| Concrete | High-volume and industrial applications | Extremely durable and fire-resistant | Higher initial cost and heavy | High |

This strategic material selection guide provides essential insights for B2B buyers considering above ground septic tanks. Understanding the properties, advantages, and limitations of each material can assist in making informed purchasing decisions tailored to specific applications and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for above ground septic tank

What Are the Key Stages in the Manufacturing Process of Above Ground Septic Tanks?

The manufacturing process of above ground septic tanks typically involves several key stages, each crucial to ensuring the final product’s functionality and durability.

Material Preparation

The first step is selecting the right materials, usually high-density polyethylene (HDPE) or fiberglass, due to their excellent resistance to corrosion and environmental factors. Material preparation includes sourcing, inspecting, and processing these raw materials. Suppliers should ensure that the materials meet the necessary specifications and comply with international standards like ANSI/NSF 61 for drinking water systems.

Forming Techniques

Once the materials are prepared, the forming stage begins. This often involves advanced techniques like rotational molding or blow molding. In rotational molding, the raw material is placed in a mold that is heated and rotated, allowing the material to evenly coat the interior surface. This process results in a seamless tank, enhancing its structural integrity. Blow molding, on the other hand, involves inflating heated plastic within a mold to create hollow shapes. Both methods ensure uniform wall thickness and optimal strength for the tank.

Assembly Process

After forming, the components are assembled. This stage may involve welding or adhesive bonding to connect different parts, such as the tank body and fittings. Manufacturers must ensure that all connections are watertight to prevent leaks, which could compromise the tank’s functionality. The assembly process also includes integrating features such as access ports and overflow outlets, which are vital for maintenance and operational efficiency.

Finishing Touches

The finishing stage includes surface treatments, such as UV stabilization, to enhance the tank’s resistance to sunlight and extend its lifespan. Manufacturers may also apply coatings that provide additional protection against environmental factors. Quality checks are essential during this stage to ensure that every tank meets the specified requirements before leaving the factory.

How Is Quality Assurance Implemented in the Production of Above Ground Septic Tanks?

Quality assurance (QA) is integral to the manufacturing of above ground septic tanks, ensuring that each unit meets safety and performance standards.

What International Standards Should Be Considered?

International standards like ISO 9001 play a significant role in manufacturing quality. ISO 9001 outlines requirements for a quality management system (QMS) that helps organizations ensure they meet customer and regulatory requirements. Other relevant standards include CE marking for products sold in Europe, which demonstrates compliance with EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This initial check helps prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the production process. This includes checking the consistency of the forming techniques and ensuring that assembly methods yield watertight connections.

-

Final Quality Control (FQC): After assembly, each tank undergoes a thorough inspection. This includes pressure testing to ensure that there are no leaks and that the tank can withstand expected operating conditions.

What Testing Methods Are Commonly Used?

Common testing methods for above ground septic tanks include:

- Hydrostatic Testing: Tanks are filled with water to check for leaks and structural integrity.

- Impact Testing: This assesses the tank’s resistance to physical impacts and ensures durability.

- UV Resistance Testing: Tanks are exposed to UV light to determine their ability to withstand sunlight exposure over time.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to ensure that their suppliers adhere to stringent quality control measures:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. This includes reviewing their certifications and compliance with international standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of various tests conducted on the tanks. This documentation can help verify the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing capabilities and quality control measures. This is particularly important for international buyers, as it ensures that products meet local regulations and standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances when it comes to quality control and certification:

-

Regional Regulations: Each region may have distinct regulations regarding septic tank installation and operation. Buyers should ensure that the tanks comply with local regulations, which may include environmental standards and health codes.

-

Certification Recognition: Certifications like CE in Europe or ANSI/NSF in North America may not have the same recognition in other regions. Buyers should verify whether the certifications held by the supplier are acknowledged in their target market.

-

Logistical Considerations: Buyers should consider the implications of shipping and logistics on quality assurance. Tanks should be packaged adequately to prevent damage during transit, and buyers should inspect the tanks upon arrival to ensure they meet the agreed-upon specifications.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing above ground septic tanks, ensuring they choose reliable suppliers that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘above ground septic tank’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of above-ground septic tanks. Given the unique requirements and regulations in different regions, this checklist will ensure that you make informed decisions, optimize your purchasing process, and select the best solutions for your sanitation needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your above-ground septic tank. Consider factors such as capacity, material (e.g., polyethylene), and the specific gravity of the tank. Understanding these parameters will help you narrow down your options and ensure the selected tank meets your operational needs.

Step 2: Research Local Regulations

Each country or region may have specific regulations regarding septic systems. Research the local laws in your target market, focusing on compliance requirements for septic tanks. This knowledge is crucial to avoid legal issues and ensure that the tanks you procure are approved for use in your desired location.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is an essential step in the sourcing process. Request company profiles, product certifications, and references from previous buyers. Look for suppliers with a proven track record in your region, as local suppliers may better understand the market dynamics and regulatory landscape.

- Considerations:

- Assess their experience with above-ground septic tanks.

- Verify their ability to meet your technical specifications.

Step 4: Check Product Certifications

Ensure that the above-ground septic tanks you are considering have relevant certifications, such as ANSI/NSF approvals. Certification indicates that the product meets specific safety and quality standards, which is vital for maintaining compliance and ensuring the longevity of your investment.

Step 5: Analyze Pricing and Payment Terms

Gather detailed quotations from multiple suppliers to compare pricing structures. Look beyond the initial costs and consider the total cost of ownership, including shipping, installation, and maintenance. Also, negotiate payment terms to ensure favorable conditions that align with your cash flow needs.

Step 6: Assess Delivery and Support Services

Evaluate the supplier’s delivery options and after-sales support. Timely delivery is crucial to avoid project delays, so confirm lead times and logistics capabilities. Additionally, inquire about the availability of technical support and maintenance services post-purchase.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement with clear terms and conditions. Ensure that the contract outlines specifications, delivery schedules, warranties, and any service commitments. A well-defined agreement protects your interests and sets clear expectations for both parties.

By following this step-by-step checklist, you can streamline the sourcing process for above-ground septic tanks, ensuring that you select the best products that meet your operational and regulatory needs.

Comprehensive Cost and Pricing Analysis for above ground septic tank Sourcing

What Are the Key Cost Components in Sourcing Above Ground Septic Tanks?

When evaluating the cost structure for above ground septic tanks, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of material significantly impacts the overall cost. Most above ground septic tanks are made from polyethylene, which is durable and resistant to corrosion, but prices can vary based on the quality and specifications. For example, tanks with higher specific gravity ratings may require more expensive raw materials.

Labor and Manufacturing Overhead: Labor costs can vary widely depending on the region and complexity of the manufacturing process. Overhead costs, including utilities and facility maintenance, also contribute to the final price. Manufacturers often optimize these costs through lean production techniques, which can influence pricing.

Tooling and QC: Tooling costs are associated with the initial setup for production, including molds and machinery. Quality control is critical for ensuring compliance with local regulations and certifications, which can add to the cost but is essential for maintaining product integrity.

Logistics and Margin: The logistics of transporting tanks can be complex, especially when shipping internationally. Costs include shipping fees, customs duties, and potential tariffs, which can significantly affect the final price. Suppliers typically include a margin that reflects their operational costs and desired profit.

How Do Price Influencers Affect the Cost of Above Ground Septic Tanks?

Several factors can influence the pricing of above ground septic tanks, particularly for international B2B buyers.

Volume and Minimum Order Quantity (MOQ): Larger orders often come with discounted pricing. Understanding the MOQ is crucial for buyers looking to maximize their investment.

Specifications and Customization: Custom tanks designed for specific applications or with unique features can lead to higher costs. Buyers should clearly communicate their requirements to avoid unexpected pricing.

Materials and Certifications: Higher quality materials and certifications (e.g., ANSI/NSF approvals) can elevate the price. Buyers should weigh the benefits of certifications against their project requirements and budget.

Supplier Factors: The reputation, reliability, and geographical location of the supplier can impact pricing. Suppliers closer to the buyer may offer lower logistics costs, while established suppliers may charge a premium for their proven track record.

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. These terms dictate the responsibilities of buyers and sellers, affecting the total cost of ownership.

What Buyer Tips Can Help in Negotiating Costs for Above Ground Septic Tanks?

When sourcing above ground septic tanks, particularly in international markets, buyers can employ several strategies to enhance cost-efficiency.

Negotiation: Engage in open discussions with suppliers regarding pricing. Highlighting competitive quotes from other manufacturers can provide leverage in negotiations.

Total Cost of Ownership (TCO): Consider the total cost of ownership, which includes not only the purchase price but also installation, maintenance, and disposal costs. Assessing TCO can lead to better long-term investment decisions.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local taxes, and shipping costs, which can impact the overall price. Establishing payment terms that mitigate currency risk may also be beneficial.

Research and References: Conduct thorough research on suppliers and request references. Understanding the market landscape can provide insights into fair pricing and reputable manufacturers.

Disclaimer on Indicative Prices

Prices for above ground septic tanks can vary significantly based on the aforementioned factors. The prices listed by different manufacturers, such as those from Tank Depot or PolyJohn, should be considered as indicative. Buyers should obtain detailed quotes and conduct due diligence to ensure the best possible deal tailored to their specific needs.

Alternatives Analysis: Comparing above ground septic tank With Other Solutions

Introduction to Alternative Solutions for Waste Management

When it comes to waste management, particularly in contexts where traditional underground systems are impractical, above ground septic tanks present a viable solution. However, various alternatives exist that may better suit specific operational needs, budget constraints, or site conditions. Understanding these alternatives enables B2B buyers to make informed decisions tailored to their unique requirements.

Comparison Table of Above Ground Septic Tanks and Alternatives

| Comparison Aspect | Above Ground Septic Tank | Portable Holding Tank | Aerobic Treatment Unit |

|---|---|---|---|

| Performance | Effective for waste storage and treatment | Suitable for temporary waste storage | High-performance treatment with faster breakdown of waste |

| Cost | Moderate initial investment; ongoing maintenance costs | Lower initial cost but may require frequent emptying | Higher upfront cost; potential savings on maintenance |

| Ease of Implementation | Requires space and proper setup | Easy to deploy and relocate | Complex installation requiring professional assistance |

| Maintenance | Regular maintenance needed; accessible for servicing | Requires frequent pumping to prevent overflow | Requires periodic maintenance but less frequent than septic tanks |

| Best Use Case | Long-term waste management in residential/commercial applications | Temporary setups like construction sites or events | Areas with high wastewater generation and limited space |

Exploring the Alternatives in Detail

What Are the Benefits and Drawbacks of Portable Holding Tanks?

Portable holding tanks are designed for temporary waste storage, making them ideal for construction sites, events, or situations where plumbing is unavailable. Their primary advantage lies in their lower initial costs and ease of relocation. However, they require regular pumping to prevent overflow, which can lead to ongoing costs and logistical challenges. These tanks do not treat waste but merely hold it, necessitating a reliable service schedule to ensure sanitary conditions.

How Do Aerobic Treatment Units Compare?

Aerobic Treatment Units (ATUs) utilize oxygen to break down waste more efficiently than traditional systems. This results in a higher quality effluent, making ATUs suitable for areas with strict discharge regulations or limited space for traditional systems. While they offer superior performance and can minimize environmental impact, their higher upfront costs and complex installation requirements can be a barrier for some buyers. Regular maintenance is also necessary, but it is typically less frequent than that of conventional septic systems.

Conclusion: Choosing the Right Waste Management Solution

Selecting the most appropriate waste management solution requires careful consideration of specific operational needs, site conditions, and budget constraints. Above ground septic tanks are robust solutions for long-term waste management, while portable holding tanks offer flexibility for temporary needs. Aerobic treatment units present a technologically advanced option for efficient waste treatment but come with higher costs and installation complexity. By evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and regulatory requirements, ultimately enhancing their waste management strategies.

Essential Technical Properties and Trade Terminology for above ground septic tank

What Are the Key Technical Properties of Above Ground Septic Tanks?

Understanding the technical specifications of above ground septic tanks is crucial for B2B buyers seeking reliable waste management solutions. Here are some of the critical properties:

-

Material Composition

– Above ground septic tanks are typically made from polyethylene or fiberglass. Polyethylene tanks are lightweight, corrosion-resistant, and offer durability against harsh environmental conditions. Fiberglass tanks, while heavier, provide superior strength and UV resistance. Selecting the right material can enhance longevity and reduce maintenance costs, essential factors for businesses operating in diverse climates. -

Capacity

– The capacity of above ground septic tanks generally ranges from 100 to over 500 gallons. Selecting the appropriate size is vital for ensuring effective waste management. A tank that is too small may lead to frequent emptying, while an oversized tank can result in unnecessary costs. Understanding the specific needs of your application—whether for construction sites or permanent installations—is essential for optimizing operational efficiency. -

Specific Gravity

– This measurement indicates the tank’s ability to hold different types of waste materials. Common specific gravities for septic tanks range from 1.5 to 1.9. Higher specific gravity ratings generally allow for handling more diverse waste types. For B2B buyers, knowing the specific gravity helps ensure compliance with local regulations and operational efficiency. -

Certification and Compliance

– Many above ground septic tanks are ANSI/NSF 61 certified, which indicates they meet strict health and safety standards. Certifications provide assurance of product quality and regulatory compliance, which is especially important for businesses operating in heavily regulated environments. Choosing certified products can mitigate risks associated with legal liabilities and enhance brand reputation. -

Portability and Design

– The low-profile design of above ground septic tanks allows for easy installation in tight spaces, such as under construction trailers. This portability is crucial for businesses that require flexibility in waste management solutions. Tanks can often be connected in series to increase capacity, providing scalability for growing operations.

What Common Trade Terms Should B2B Buyers Understand?

Familiarity with industry terminology can facilitate smoother transactions and better decision-making in the B2B marketplace. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the source of quality and reliability in septic tank production. -

MOQ (Minimum Order Quantity)

– This is the smallest amount of a product a supplier is willing to sell. Knowing the MOQ is important for budget planning and inventory management, especially when sourcing above ground septic tanks for large-scale projects. -

RFQ (Request for Quotation)

– An RFQ is a standard business process to invite suppliers to bid on the procurement of products or services. Crafting a precise RFQ can streamline negotiations and ensure that suppliers provide the best possible pricing and terms. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms helps businesses clarify shipping costs, risk responsibilities, and delivery timelines, which is crucial for international transactions. -

Lead Time

– This refers to the time taken from placing an order to the product’s delivery. Knowing the lead time for septic tanks is essential for project planning and can affect overall timelines for construction or installation projects.

By understanding these properties and terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the above ground septic tank Sector

What Are the Current Market Dynamics and Key Trends in the Above Ground Septic Tank Sector?

The global above ground septic tank market is driven by several key factors, including urbanization, population growth, and increasing environmental regulations. In regions such as Africa, South America, and the Middle East, rapid urban development often leads to inadequate sewage infrastructure, heightening the demand for effective waste management solutions like above ground septic tanks. In Europe, particularly in countries like Germany, stringent environmental regulations are pushing the construction and sanitation sectors to adopt more sustainable practices, further boosting the market for above ground solutions.

Emerging technologies such as smart tank monitoring systems are transforming the way businesses manage septic tanks. These systems offer real-time data on tank levels, enabling proactive maintenance and reducing operational costs. Moreover, the trend towards modular and portable solutions is gaining traction, particularly in construction and event management sectors. Buyers are increasingly looking for customizable tanks that can be easily transported and adapted to various site conditions.

International B2B buyers are also influenced by global supply chain dynamics, with a shift towards local sourcing to mitigate risks associated with long-distance logistics. This trend is particularly relevant in regions like Africa and South America, where local suppliers are emerging to meet demand with competitive pricing and shorter delivery times. Understanding these market dynamics can empower buyers to make informed sourcing decisions that align with their operational needs and sustainability goals.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy for Above Ground Septic Tanks?

Sustainability is becoming a cornerstone of procurement strategies in the above ground septic tank sector. The environmental impact of waste management solutions is under scrutiny, prompting businesses to seek out eco-friendly alternatives. Above ground septic tanks made from recycled materials or those that utilize energy-efficient manufacturing processes are gaining popularity among environmentally conscious buyers.

Ethical sourcing is equally important, as B2B buyers are increasingly concerned about the social and environmental practices of their suppliers. Ensuring that suppliers adhere to ethical labor practices and have transparent supply chains can enhance brand reputation and foster long-term partnerships. Certifications such as ANSI/NSF standards not only ensure product safety but also signal to buyers a commitment to quality and sustainability.

Investing in ‘green’ certifications and materials can provide a competitive edge in the marketplace, particularly in regions where consumers and businesses are prioritizing sustainability. As global awareness of environmental issues continues to grow, companies that adopt ethical sourcing practices will likely see increased demand for their products, positioning them favorably in the eyes of international buyers.

What Has Been the Evolution of Above Ground Septic Tanks in the B2B Market?

The above ground septic tank sector has evolved significantly over the past few decades. Initially viewed as a temporary solution for waste management, these tanks have gained acceptance as a viable long-term alternative, especially in areas with challenging terrain or limited access to conventional sewage systems.

Technological advancements have played a crucial role in this evolution, with the introduction of materials such as high-density polyethylene that offer durability and resistance to corrosion. Additionally, the integration of smart technologies for monitoring and maintenance has enhanced the efficiency and reliability of above ground septic tanks.

Today, these tanks are widely recognized for their flexibility, ease of installation, and minimal environmental disruption, making them an attractive choice for both residential and commercial applications. As global market demands shift toward more sustainable and adaptable waste management solutions, the evolution of above ground septic tanks continues to reflect the changing needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of above ground septic tank

-

How do I choose the right above ground septic tank for my project?

When selecting an above ground septic tank, consider factors such as capacity, material, and specific gravity. Evaluate the anticipated volume of wastewater to determine the appropriate tank size, which typically ranges from 101 to over 500 gallons. Polyethylene tanks are popular due to their durability and resistance to corrosion. Additionally, ensure that the tank meets local regulatory requirements and is ANSI/NSF approved for safe wastewater handling. Consult with suppliers about the tank’s features and compatibility with your project’s needs. -

What are the advantages of using above ground septic tanks compared to underground systems?

Above ground septic tanks offer several benefits, including easier access for maintenance and repairs. They are typically lighter and can be relocated with less effort, making them ideal for temporary installations or sites with limited space. Moreover, their installation is often quicker, reducing labor costs and project timelines. In regions with high water tables, above ground systems can be more effective as they avoid the complications associated with groundwater interference. -

What should I consider when vetting suppliers for above ground septic tanks?

When vetting suppliers, assess their industry experience and reputation. Look for suppliers who have a track record of delivering quality products and excellent customer service. Verify certifications, such as ANSI/NSF approvals, which indicate compliance with safety and quality standards. Request references from previous clients and check online reviews. Additionally, inquire about the supplier’s ability to provide support regarding installation and maintenance, as well as their responsiveness to inquiries. -

Can I customize the design or capacity of an above ground septic tank?

Many manufacturers offer customization options for above ground septic tanks, allowing you to specify dimensions, capacity, and features tailored to your project’s requirements. Discuss your needs with potential suppliers to explore available options, such as fittings and additional functionalities. Customization may also include branding opportunities for B2B buyers looking to enhance their product offerings. Be sure to confirm any additional costs or lead times associated with custom orders. -

What are the minimum order quantities (MOQs) for purchasing above ground septic tanks?

Minimum order quantities can vary significantly among suppliers. Some manufacturers may have an MOQ of one tank, while others may require larger orders to optimize production and shipping costs. For international buyers, it’s essential to discuss MOQs upfront to understand the implications for pricing and logistics. Consider negotiating terms that allow for smaller trial orders, especially when establishing a new supplier relationship or entering a new market. -

What payment terms should I expect when sourcing above ground septic tanks internationally?

Payment terms for international transactions can vary widely. Common options include advance payment, letter of credit, or payment upon delivery. Be sure to clarify terms regarding deposits, balance payments, and any potential financing options. It’s advisable to negotiate terms that protect both parties, especially considering currency fluctuations and trade tariffs. Additionally, ensure that payment methods are secure and provide clear documentation for your financial records. -

How can I ensure quality assurance (QA) for above ground septic tanks?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Engage in quality checks during manufacturing, if possible, and consider third-party inspections to verify compliance with international standards. Additionally, establish a clear return policy and warranty terms before finalizing your order. Regular communication with the supplier regarding production timelines and quality checks will help maintain accountability and reduce the risk of receiving subpar products. -

What logistics considerations should I keep in mind when importing above ground septic tanks?

When importing above ground septic tanks, consider the logistics of shipping, including freight options, customs clearance, and potential tariffs. Engage a reliable freight forwarder to handle transportation and ensure compliance with local regulations. Factor in the shipping time, as larger tanks may require specialized handling. Additionally, confirm the supplier’s ability to provide necessary documentation, such as bills of lading and customs invoices, to facilitate a smooth import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Above Ground Septic Tank Manufacturers & Suppliers List

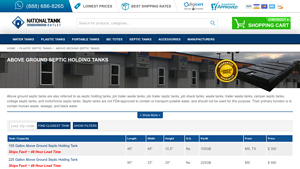

1. Tank and Barrel – Above Ground Septic Holding Tanks

Domain: tankandbarrel.com

Registered: 2015 (10 years)

Introduction: Above Ground Septic Holding Tanks

2. Reddit – Above Ground Septic Tanks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Above ground septic tanks ranging from 250 to 1000 gallons; considerations for installation include soil drainage and local regulations; potential need for regular pumping and access for service; alternatives to traditional septic systems may be necessary due to soil conditions.

3. NTO Tank – Above Ground Septic Tanks

Domain: ntotank.com

Registered: 2006 (19 years)

Introduction: Above Ground Septic Tanks are also known as septic holding tanks, job trailer waste tanks, camper septic tanks, and motorhome septic tanks. They are designed for use in mobile or raised structures, primarily to contain human waste, sewage, and black water. These tanks are made from high-density virgin polyethylene resin, are seamless, impact-resistant, and durable, with UV inhibitors to prevent su…

4. PolyJohn – Above Ground Portable Septic Holding Tank

Domain: tankretailer.com

Registered: 2022 (3 years)

Introduction: PolyJohn Above Ground Portable Septic Holding Tank, designed for temporary waste storage, features a durable construction, easy installation, and is suitable for various applications. Ideal for construction sites, outdoor events, and more. Holds up to 1,000 gallons, ensuring ample capacity for waste management needs.

5. Lion Home Service – Above-Ground Septic Tanks

Domain: lionhomeservice.com

Registered: 2017 (8 years)

Introduction: Above-ground septic tanks, also known as holding tanks, are large polyethylene containers designed to carry wastewater, typically storing 250-350 gallons. They are primarily for temporary use and are illegal in Northern Colorado due to sanitation and safety concerns. Above-ground tanks require a leach field for proper function and can become clogged, leading to costly maintenance. They are exposed…

6. Groundstone – Above Ground Septic Systems

Domain: groundstone.ca

Registered: 2017 (8 years)

Introduction: Above Ground Septic System, also known as a sand mound septic system, is used for on-site sewage treatment when conventional systems are unsuitable. It addresses issues like soil permeability, restricted layers, and high water tables that can lead to septic system failure. The system consists of a septic tank that directs wastewater to a pumping tank, which then pumps it to a sand mound above grou…

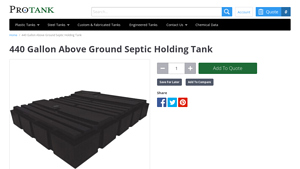

7. ProTank – Above Ground Holding Tank

Domain: protank.com

Registered: 1999 (26 years)

Introduction: {“Product Type”:”Above Ground Holding Tank”,”Part #”:”440GB”,”Specific Gravity”:1.5,”Weight (lbs)”:137,”Ship Freight Class”:250,”UV Inhibitors”:”Yes”,”Color”:”Black”,”Material”:”Polyethylene”,”Translucent”:”No”,”Gallon Indicators”:”No”,”Manufacturer Warranty”:”3 Year Warranty”,”Dimensions”:”91\” Length x 72\” Width x 16\” Height”,”Capacity (Gallons)”:440,”Liquid Access”:”2 Ports”,”Max Temp Allowed…

8. Watertanks.com – 250 Gal Sewage Holding Tank

Domain: watertanks.com

Registered: 1998 (27 years)

Introduction: [{‘part_number’: ‘0280-005’, ‘product_description’: ‘250 Gal Sewage Holding Tank-AG’, ‘capacity_gallons’: 250, ‘dimensions’: {‘length’: ’84’, ‘width’: ’40’, ‘height’: ’17’}, ‘fittings’: ‘(7) 3″ Spin-Ons w/Plugs’, ‘list_price’: 652.28}, {‘part_number’: ‘0280-010’, ‘product_description’: ‘350 Gal Sewage Holding Tank-AG’, ‘capacity_gallons’: 350, ‘dimensions’: {‘length’: ’89’, ‘width’: ’44’, ‘height’…

Strategic Sourcing Conclusion and Outlook for above ground septic tank

In today’s rapidly evolving market for above ground septic tanks, strategic sourcing plays a crucial role in ensuring that international B2B buyers secure the best solutions tailored to their specific needs. By understanding the diverse product offerings, including varying capacities, materials, and configurations, businesses can make informed decisions that enhance operational efficiency and compliance with regional regulations. The lightweight and easily accessible design of these tanks not only simplifies maintenance but also allows for flexibility in deployment, making them an ideal choice for diverse applications, from construction sites to temporary sanitation solutions.

As buyers from Africa, South America, the Middle East, and Europe navigate their purchasing decisions, prioritizing suppliers with robust certifications and proven track records will be vital. Engaging with manufacturers who adhere to international standards can mitigate risks and ensure quality.

Looking ahead, the demand for above ground septic tanks is expected to grow, driven by increasing urbanization and the need for sustainable waste management solutions. Now is the time to leverage strategic sourcing to position your business competitively. Explore your options, connect with trusted suppliers, and secure the best solutions for your operational needs today.