Rolls Of Acetate Plastic Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for rolls of acetate plastic

Navigating the global market for rolls of acetate plastic presents a unique challenge for international B2B buyers. With diverse applications ranging from packaging to graphic arts, sourcing the right acetate rolls can be complex, especially when considering factors such as quality, price, and supplier reliability. This comprehensive guide aims to empower buyers by exploring various types of acetate rolls, their specific applications, and essential criteria for supplier vetting.

In addition to examining cost structures and market trends, we will delve into the environmental aspects of acetate production, highlighting options that are biodegradable and sustainable. With a focus on regions including Africa, South America, the Middle East, and Europe, this guide provides targeted insights for buyers from countries such as Saudi Arabia and Brazil. By addressing key challenges in the acetate sourcing process, we equip you with the knowledge to make informed purchasing decisions that align with your business goals and operational needs.

Whether you’re a seasoned professional or new to the market, understanding the nuances of acetate plastic can significantly enhance your procurement strategy, ensuring you select the best materials for your projects. Join us as we navigate the intricacies of this vital market, and discover how to leverage acetate rolls to elevate your business offerings.

Understanding rolls of acetate plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Acetate Rolls | High transparency, glossy finish | Graphic arts, overlays, packaging | Pros: Excellent clarity; versatile use. Cons: Prone to scratching. |

| Matte Acetate Rolls | Non-reflective surface, reduced glare | Printing, artistic applications | Pros: Ideal for photography; less glare. Cons: May show fingerprints. |

| Colored Acetate Rolls | Available in various colors, opaque options | Crafts, educational materials | Pros: Enhances visual appeal; creative uses. Cons: Limited applications in printing. |

| Biodegradable Acetate | Made from renewable resources, compostable | Eco-friendly packaging, art supplies | Pros: Sustainable choice; eco-conscious branding. Cons: May be less durable. |

| Heavyweight Acetate | Thicker gauge, more rigid | Industrial applications, signage | Pros: Durable and sturdy; ideal for heavy-duty use. Cons: More expensive. |

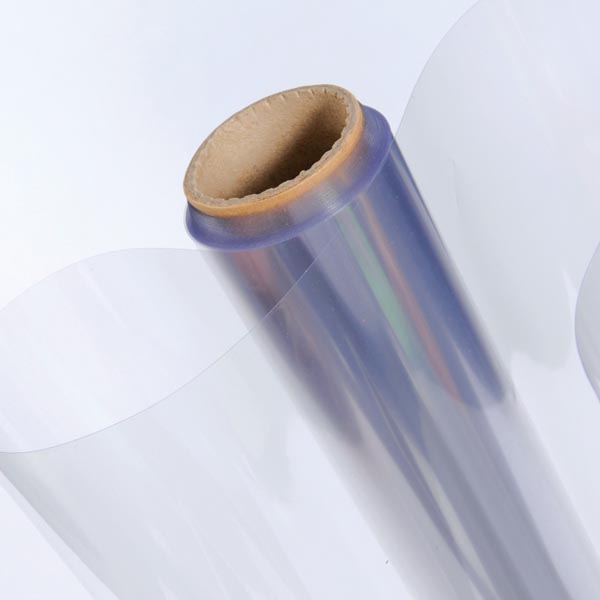

What Are the Characteristics of Clear Acetate Rolls?

Clear acetate rolls are characterized by their high transparency and glossy finish, making them ideal for a wide range of applications in graphic arts and packaging. They are commonly used for overlays, protective covers, and creating transparencies. When purchasing clear acetate, businesses should consider the thickness, as it affects both the durability and clarity of the final product. While these rolls offer excellent visual clarity, they are susceptible to scratching, which can be a concern for long-term use.

How Do Matte Acetate Rolls Differ from Clear Variants?

Matte acetate rolls feature a non-reflective surface that reduces glare, making them particularly suitable for printing and artistic applications. They are often preferred in photography and display settings where glare can obscure details. Buyers should evaluate the specific matte finish required for their projects, as some matte rolls may attract fingerprints more readily than their glossy counterparts. Overall, matte acetate provides a professional finish that enhances the presentation of printed materials.

What Are the Advantages of Colored Acetate Rolls?

Colored acetate rolls come in a variety of hues and can be opaque or semi-transparent. They are popular in crafts, educational projects, and creative applications where color enhances visual appeal. When sourcing colored acetate, businesses should consider the intended use, as some colors may not be suitable for printing. The versatility of colored acetate can add significant value to promotional materials, but buyers should be mindful of the limitations in professional printing contexts.

Why Choose Biodegradable Acetate for Your Business?

Biodegradable acetate is an environmentally friendly option made from renewable resources, making it an attractive choice for companies focused on sustainability. This type of acetate can be composted or recycled, appealing to eco-conscious consumers. When selecting biodegradable acetate, businesses should assess the balance between sustainability and durability, as these materials may not withstand heavy-duty applications as well as traditional acetate. This option is ideal for businesses that want to enhance their green branding.

In What Situations Are Heavyweight Acetate Rolls Preferred?

Heavyweight acetate rolls are thicker and more rigid, providing exceptional durability for industrial applications such as signage and displays. They are designed to withstand wear and tear in demanding environments, making them a reliable choice for businesses that require long-lasting materials. Buyers should consider the price point, as heavyweight acetate is generally more expensive than standard options. However, the investment can be justified by the increased longevity and performance in professional settings.

Key Industrial Applications of rolls of acetate plastic

| Industry/Sector | Specific Application of rolls of acetate plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Graphic Arts | Overlays and transparencies for printing and design | High clarity and versatility, enhancing visual presentations | Ensure thickness and clarity meet project specifications |

| Packaging and Labels | Packaging films for food and consumer goods | FDA-approved for food contact, ensuring safety and compliance | Verify certifications and material properties for safety |

| Education and Training | Educational materials and projector films | Durable, easy to handle, and reusable, reducing costs | Consider bulk purchasing options for cost-efficiency |

| Arts and Crafts | Stencils and templates for artists | Easy to cut and shape, fostering creativity and efficiency | Look for biodegradable options to appeal to eco-conscious markets |

| Industrial Manufacturing | Protective covers and component shields | Protects products during shipping and handling | Check for UV resistance and durability under specific conditions |

How Are Rolls of Acetate Plastic Used in the Graphic Arts Industry?

In the graphic arts sector, rolls of acetate plastic are predominantly utilized for creating overlays and transparencies. These materials provide exceptional clarity, making them ideal for presentations and design applications. The ability to print on acetate allows for intricate designs to be showcased effectively. For international buyers, especially in regions like Europe and the Middle East, it is crucial to ensure that the thickness and clarity of the acetate meet specific project requirements to avoid any production delays.

What Are the Benefits of Using Acetate in Packaging and Labels?

In the packaging industry, rolls of acetate plastic serve as protective films for food and consumer goods. Acetate is FDA-approved for food contact, ensuring that products are safe for consumer use. This application not only enhances product visibility but also provides a barrier against moisture and contaminants. Buyers from Africa and South America should prioritize sourcing acetate with verified certifications to ensure compliance with local regulations and international safety standards.

How Is Acetate Utilized in Educational Materials?

Acetate rolls are widely used in educational settings for creating materials such as projector films and reusable worksheets. Their durability and ease of handling make them cost-effective for schools and training institutions. The ability to write on and wipe clean acetate allows for repeated use, saving resources over time. Buyers should consider bulk purchasing to maximize cost-efficiency, particularly in regions with budget constraints.

What Role Does Acetate Play in Arts and Crafts?

In the arts and crafts industry, acetate rolls are frequently employed to create stencils and templates. The material’s easy cut and shape properties allow artists to design intricate patterns and shapes with minimal effort. Additionally, the glossy finish enhances the visual appeal of art projects. For B2B buyers, sourcing biodegradable acetate options can cater to environmentally conscious consumers, particularly in European markets.

How Is Acetate Used in Industrial Manufacturing?

Rolls of acetate plastic are utilized in industrial manufacturing as protective covers and component shields during shipping and handling. This application safeguards products from scratches, dust, and moisture, ensuring they reach their destination in optimal condition. Buyers should check for UV resistance and durability to ensure that the acetate can withstand various environmental conditions during transit, particularly in regions with extreme climates.

3 Common User Pain Points for ‘rolls of acetate plastic’ & Their Solutions

Scenario 1: Sourcing Quality Acetate Rolls for Diverse Applications

The Problem: Many B2B buyers encounter significant challenges when sourcing acetate plastic rolls that meet specific industry standards. This can lead to frustration when the products received do not match the specifications required for their applications, whether for packaging, printing, or crafting. For instance, a company in the graphic arts sector may receive rolls that are either too thin or lack the clarity needed for high-quality overlays, resulting in wasted materials and increased costs. In regions with limited access to quality suppliers, this issue can exacerbate, forcing buyers to settle for subpar products.

The Solution: To mitigate these challenges, buyers should prioritize working with reputable suppliers who provide detailed product specifications, including thickness, clarity, and material composition. Conduct thorough research to identify suppliers with positive reviews and a proven track record in the industry. Additionally, requesting samples before making bulk orders can help ensure that the acetate rolls meet the required standards. When placing an order, specify the intended use of the acetate (e.g., food-safe packaging, graphic overlays) to ensure the supplier provides the most suitable product. Utilizing a checklist for product specifications can streamline the ordering process and minimize the risk of receiving inadequate materials.

Scenario 2: Managing Inventory and Supply Chain Issues

The Problem: In the dynamic landscape of international trade, B2B buyers often face issues related to inventory management and supply chain disruptions. Fluctuations in demand, geopolitical factors, and shipping delays can lead to shortages of acetate rolls, hampering production schedules and resulting in lost revenue. For instance, a packaging company might find itself unable to fulfill orders due to a sudden increase in demand for acetate-based products, only to realize that their supplier cannot deliver additional stock in a timely manner.

The Solution: To effectively manage inventory and mitigate supply chain risks, buyers should adopt a proactive approach by establishing long-term relationships with multiple suppliers across different regions. This diversification allows for greater flexibility and ensures that alternative sources are available in case of disruptions. Implementing just-in-time (JIT) inventory practices can also help maintain optimal stock levels without overcommitting resources. Additionally, utilizing inventory management software can provide real-time insights into stock levels and forecast demand more accurately, enabling buyers to make informed purchasing decisions.

Scenario 3: Ensuring Compliance with Environmental Regulations

The Problem: As global awareness of environmental sustainability grows, many businesses must navigate complex regulations regarding the materials they use, including acetate plastic. B2B buyers in regions like Europe and North America face pressure to comply with stringent environmental standards, including sourcing biodegradable or recyclable materials. Failure to meet these requirements can result in fines, reputational damage, and loss of business opportunities.

The Solution: Buyers should prioritize sourcing acetate rolls that are certified biodegradable and compliant with relevant environmental regulations. Conducting due diligence on suppliers to verify their environmental certifications is essential. Engage with suppliers who can provide transparency regarding the sourcing and production processes of their acetate films. Furthermore, consider incorporating sustainability into product specifications by opting for materials that are both functional and environmentally friendly. Educating staff about compliance requirements and establishing a clear sustainability policy can further enhance a company’s reputation and operational practices in the marketplace.

Strategic Material Selection Guide for rolls of acetate plastic

What Are the Key Properties of Common Materials for Rolls of Acetate Plastic?

When selecting rolls of acetate plastic, understanding the various materials available is crucial for ensuring optimal performance in specific applications. Below, we analyze four common materials used in acetate rolls, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Cellulose Di-Acetate

Key Properties:

Cellulose di-acetate is a biodegradable thermoplastic that exhibits excellent clarity and transparency. It has a moderate temperature resistance, typically up to 60°C, making it suitable for various applications, including packaging and graphic arts.

Pros & Cons:

The primary advantage of cellulose di-acetate is its eco-friendliness, as it is derived from renewable resources and is fully biodegradable. However, its lower thermal stability compared to other plastics can limit its use in high-temperature environments. Additionally, it may be more expensive due to its production process.

Impact on Application:

This material is ideal for applications requiring high clarity, such as overlays in printing and packaging. Its biodegradable nature aligns with increasing global sustainability demands.

Considerations for International Buyers:

Buyers in regions like Europe and South America may prioritize eco-friendly materials due to stringent environmental regulations. Compliance with standards such as ASTM D6400 for biodegradable plastics is essential.

2. PETG (Polyethylene Terephthalate Glycol)

Key Properties:

PETG is a clear thermoplastic that offers high impact resistance and excellent chemical stability. It can withstand temperatures up to 70°C and is known for its durability.

Pros & Cons:

The key advantage of PETG is its robustness, making it suitable for applications requiring high durability, such as signage and protective covers. However, it is less biodegradable than cellulose di-acetate, which could be a drawback for environmentally conscious buyers.

Impact on Application:

PETG is compatible with various printing techniques and is often used for packaging that requires both clarity and strength.

Considerations for International Buyers:

Buyers from the Middle East and Africa should be aware of local recycling capabilities, as PETG is recyclable but not biodegradable. Compliance with local standards for food safety and packaging materials is also crucial.

3. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a versatile plastic known for its excellent chemical resistance and durability. It can handle temperatures up to 60°C and is available in both rigid and flexible forms.

Pros & Cons:

PVC is cost-effective and widely available, making it a popular choice for various applications. However, its environmental impact is significant, as it is not biodegradable and can release harmful chemicals during production and disposal.

Impact on Application:

PVC is often used in signage, packaging, and construction materials. Its durability makes it suitable for long-term applications, but its environmental concerns may deter some buyers.

Considerations for International Buyers:

Buyers in Europe may face stricter regulations regarding PVC use due to environmental concerns. Compliance with standards like REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is necessary.

4. Polypropylene (PP)

Key Properties:

Polypropylene is a lightweight thermoplastic with good chemical resistance and a melting point of around 160°C. It is known for its flexibility and toughness.

Pros & Cons:

The flexibility of polypropylene makes it suitable for various applications, including packaging and automotive parts. However, it may not offer the same clarity as acetate, which could limit its use in applications where transparency is essential.

Impact on Application:

PP is often used for packaging materials that require flexibility and durability, such as bags and containers.

Considerations for International Buyers:

Buyers in regions with high recycling rates, like Europe, may prefer polypropylene for its recyclability. Compliance with local recycling standards and certifications is important.

Summary Table of Material Selection for Rolls of Acetate Plastic

| Material | Typical Use Case for rolls of acetate plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cellulose Di-Acetate | Overlays, packaging | Eco-friendly and biodegradable | Lower thermal stability | Medium |

| PETG | Signage, protective covers | High impact resistance | Less biodegradable | Medium |

| PVC | Signage, construction materials | Cost-effective and durable | Significant environmental impact | Low |

| Polypropylene (PP) | Flexible packaging, automotive parts | Lightweight and tough | Lower clarity compared to acetate | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling them to make informed decisions based on application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rolls of acetate plastic

What Are the Key Stages in the Manufacturing Process of Acetate Plastic Rolls?

The manufacturing of acetate plastic rolls involves several critical stages, each designed to ensure the final product meets the high standards required by various industries. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality cellulose acetate, which is derived from wood pulp. This raw material undergoes purification to remove impurities, ensuring clarity and consistency. The cellulose acetate is then mixed with plasticizers to enhance flexibility and durability. This mixture is crucial for achieving the desired properties of the acetate rolls.

-

Forming: The prepared material is then subjected to a casting process, where it is spread into thin sheets or films. This can be done using techniques such as extrusion or calendering. In extrusion, the acetate mixture is forced through a die to form a continuous sheet, while calendering involves passing the material through a series of rollers to achieve the desired thickness. These techniques ensure uniform thickness and surface quality, which are vital for applications ranging from packaging to graphic arts.

-

Assembly: After the forming stage, the acetate sheets are wound onto rolls. This is done carefully to avoid any creases or defects that could affect the usability of the product. The rolls are then cut to various sizes based on customer specifications. This flexibility in size is essential for B2B buyers who require specific dimensions for their applications.

-

Finishing: The final stage involves additional treatments to enhance the properties of the acetate rolls. This can include coating for UV protection, anti-static treatments, or surface texturing. These finishing processes are crucial for ensuring that the acetate rolls meet the specific needs of different industries, such as graphic arts, printing, and packaging.

How Is Quality Assurance Implemented in Acetate Plastic Roll Production?

Quality assurance (QA) is integral to the manufacturing of acetate plastic rolls, ensuring that the final products are free from defects and meet international standards. Key components of a robust QA system include adherence to international standards, various quality checkpoints, and testing methodologies.

-

International Standards and Certifications: Manufacturers of acetate plastic rolls often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This certification ensures that manufacturers have established processes for consistent quality. Additionally, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and FDA approvals (for food contact safety) are also critical for B2B buyers, especially those in regulated markets.

-

Quality Control Checkpoints: The QA process includes several checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production line. It ensures that only high-quality cellulose acetate is used.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and detect any deviations from the standard. This can include checking the thickness, clarity, and flexibility of the acetate sheets.

– Final Quality Control (FQC): After the acetate rolls are completed, they undergo final inspections to ensure they meet specifications. This includes testing for defects, measuring dimensions, and assessing surface quality. -

Common Testing Methods: Various testing methods are employed to ensure the quality of acetate rolls. These may include:

– Mechanical Testing: Assessing the tensile strength, elongation, and tear resistance of the acetate film.

– Optical Testing: Checking clarity, haze, and light transmission properties to ensure the acetate meets visual standards for applications like packaging and overhead transparencies.

– Chemical Testing: Verifying that the material is free from harmful substances and complies with safety regulations.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is crucial to ensure they receive high-quality products. Here are several strategies to effectively assess supplier quality:

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should request to visit manufacturing facilities to observe operations, inspect quality control processes, and review documentation.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their quality control processes, testing methods, and compliance with international standards. These reports can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. These services can conduct on-site inspections and testing to verify that the products meet the required specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of certain nuances related to quality control:

-

Understanding Regional Standards: Different regions may have varying standards and regulations regarding acetate products. Buyers should familiarize themselves with these regulations to ensure compliance and avoid issues with importation.

-

Language and Communication Barriers: When conducting audits or inspections, language barriers can pose challenges. It is advisable to have bilingual representatives or interpreters to facilitate clear communication regarding quality expectations.

-

Cultural Differences in Quality Perception: Cultural perceptions of quality may vary. Buyers should engage in thorough discussions with suppliers to align on quality expectations and standards to avoid misunderstandings.

In conclusion, the manufacturing processes and quality assurance measures for acetate plastic rolls are crucial for ensuring that B2B buyers receive high-quality products that meet their specific needs. By understanding these processes and implementing effective verification strategies, buyers can establish reliable partnerships with suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rolls of acetate plastic’

This guide is designed to assist B2B buyers in the procurement of rolls of acetate plastic. It outlines essential steps and considerations to ensure that your sourcing process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before starting your search, it’s critical to identify the specific requirements for the acetate rolls you need. Consider factors such as thickness, size, transparency, and whether the acetate is biodegradable. This clarity helps streamline your discussions with suppliers and ensures that you receive products that meet your exact needs.

- Thickness Options: Common thicknesses include 0.003, 0.005, and 0.010 inches.

- Size Variability: Rolls can come in various dimensions, such as 25″ x 12ft or 50″ x 100ft.

Step 2: Research Potential Suppliers

Conduct thorough research to create a shortlist of potential suppliers. Utilize online platforms, industry directories, and trade shows to identify manufacturers and distributors who specialize in acetate plastic.

- Check Online Reviews: Look for feedback from other B2B buyers to gauge supplier reliability.

- Industry Reputation: Focus on suppliers with a solid track record in your specific industry.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications and compliance with industry standards. This step is vital for ensuring product quality and safety.

- ISO Certifications: Suppliers with ISO 9001 certification demonstrate a commitment to quality management systems.

- Environmental Certifications: Consider suppliers with certifications like FSC or SFI if sustainability is a priority for your business.

Step 4: Request Samples

Once you have identified a few potential suppliers, request samples of their acetate rolls. This allows you to assess the quality, clarity, and suitability of the product for your intended applications.

- Quality Assessment: Evaluate the sample’s clarity, flexibility, and ease of handling.

- Compatibility Check: Ensure the material works well with your existing equipment and processes.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your shortlisted suppliers to negotiate pricing, payment terms, and delivery schedules. This step is crucial for maximizing your budget and securing favorable conditions.

- Bulk Discounts: Inquire about discounts for larger orders to reduce overall costs.

- Payment Flexibility: Establish clear terms regarding payment schedules to manage cash flow effectively.

Step 6: Confirm Shipping and Logistics

Finalize the logistics of your order by discussing shipping options and timelines. Clear communication regarding logistics is vital to avoid delays in production.

- Shipping Methods: Evaluate options such as air freight for urgent needs or sea freight for cost-effective solutions.

- Customs Clearance: Ensure that suppliers can assist with customs documentation if shipping internationally.

Step 7: Establish a Long-term Relationship

Once you have successfully sourced your acetate rolls, focus on building a long-term relationship with your supplier. This can lead to better pricing, priority service, and tailored solutions as your business evolves.

- Regular Communication: Keep in touch with your supplier for updates on new products and innovations.

- Feedback Loop: Provide feedback on product performance to help your supplier improve their offerings.

By following this checklist, B2B buyers can effectively navigate the sourcing process for rolls of acetate plastic, ensuring they obtain high-quality products that meet their business requirements.

Comprehensive Cost and Pricing Analysis for rolls of acetate plastic Sourcing

Analyzing the cost structure and pricing of rolls of acetate plastic is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. Understanding these components can facilitate better sourcing decisions and enhance negotiation strategies.

What are the Main Cost Components for Rolls of Acetate Plastic?

The cost structure for rolls of acetate plastic typically includes several key components:

-

Materials: The primary cost driver is the raw material, cellulose acetate, which is derived from wood pulp. Prices can fluctuate based on global supply chain dynamics and the availability of sustainable sources.

-

Labor: Manufacturing labor costs vary by region. Countries with lower labor costs can provide a competitive advantage, but quality and expertise must also be considered.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, maintenance, and administrative expenses. Efficient production methods can help minimize these costs.

-

Tooling: Specific tooling is required to create acetate rolls of different sizes and specifications. Investment in high-quality tooling can lead to better precision and lower scrap rates.

-

Quality Control (QC): Ensuring product quality is essential, particularly for applications involving food contact or artistic uses. Implementing stringent QC processes incurs additional costs but is crucial for maintaining customer trust.

-

Logistics: Transportation costs can significantly impact pricing, particularly for international shipments. Factors such as distance, shipping method, and customs duties should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to cover costs and generate revenue. This can vary widely based on market competition and the value-added services provided.

What Influences the Pricing of Acetate Rolls?

Several factors can influence the pricing of acetate rolls:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts. Suppliers may set a MOQ, which impacts pricing flexibility.

-

Specifications and Customization: Customized products, such as specific thicknesses or finishes, may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality acetate or certifications (e.g., FDA approval for food contact) can lead to higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and service levels can affect pricing. Long-term relationships with trusted suppliers may lead to better pricing and terms.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is vital for determining who bears the costs and risks at different stages of the shipping process. This can influence the final price paid by the buyer.

What Tips Can Help Buyers Negotiate Better Prices?

International buyers should consider the following strategies to enhance their sourcing efficiency:

-

Engage in Negotiation: Establishing a strong rapport with suppliers can lead to more favorable terms. Consider negotiating not just on price but also on payment terms and delivery schedules.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate the long-term costs associated with the product, including shipping, storage, and potential waste from lower-quality materials.

-

Leverage Pricing Nuances: Be aware of seasonal pricing trends and market fluctuations. Timing your purchases can yield significant savings, especially in regions where demand spikes during specific seasons.

-

Research and Compare Suppliers: Take the time to research multiple suppliers. Comparing offers can reveal hidden costs and highlight which suppliers provide the best overall value.

Disclaimer for Indicative Prices

It’s important to note that pricing for rolls of acetate plastic can vary widely based on the factors discussed above. Prices should be viewed as indicative and subject to change based on market conditions and supplier negotiations. Always request formal quotes from suppliers to ensure accurate pricing for your specific needs.

Alternatives Analysis: Comparing rolls of acetate plastic With Other Solutions

Understanding Alternative Solutions to Rolls of Acetate Plastic

In the world of packaging, graphic arts, and various industrial applications, acetate plastic rolls are widely utilized due to their versatility and performance. However, businesses often seek alternative materials or methods that can meet their specific needs more effectively or economically. This analysis compares rolls of acetate plastic with two viable alternatives: polyester films and polypropylene films, allowing B2B buyers to make informed decisions.

Comparison Table

| Comparison Aspect | Rolls of Acetate Plastic | Polyester Films | Polypropylene Films |

|---|---|---|---|

| Performance | High clarity and flexibility | Excellent durability and strength | Good clarity, but less flexible |

| Cost | Moderate cost (e.g., $30 for 40″x12′) | Generally higher (e.g., $138.50 for similar size) | Lower cost (e.g., $20 for 50″x100′) |

| Ease of Implementation | Easy to cut and shape | Requires specialized cutting tools | User-friendly, can be cut with standard tools |

| Maintenance | Low maintenance, biodegradable | Moderate maintenance, recycling required | Low maintenance, recyclable |

| Best Use Case | Artwork protection, overlays | High-stress applications, packaging | Cost-effective packaging solutions |

Detailed Breakdown of Alternatives

Polyester Films

Polyester films are known for their superior strength and durability, making them ideal for applications where robustness is critical. They can withstand higher temperatures and are less prone to tearing compared to acetate. However, the cost of polyester films tends to be higher, which may not be suitable for budget-sensitive projects. Additionally, while cutting polyester requires specific tools for precision, its performance in demanding environments makes it a preferred choice in sectors such as electronics and automotive.

Polypropylene Films

Polypropylene films offer a cost-effective solution with decent clarity and good moisture resistance. They are less flexible than acetate, which may limit their use in applications requiring intricate shapes or designs. However, polypropylene is often more affordable, making it a popular choice for general packaging needs. This material is also easy to work with, as standard cutting tools suffice, and it provides a low-maintenance option for businesses focused on operational efficiency.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your business applications, consider factors such as performance requirements, budget constraints, and specific use cases. Rolls of acetate plastic excel in artistic and overlay applications where clarity and flexibility are paramount. In contrast, polyester films cater to high-durability needs, while polypropylene films serve as a budget-friendly alternative for basic packaging. By evaluating these aspects, B2B buyers can make informed choices that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for rolls of acetate plastic

What Are the Key Technical Properties of Rolls of Acetate Plastic?

Understanding the technical properties of acetate plastic rolls is crucial for B2B buyers to make informed purchasing decisions. Here are some essential specifications that define the quality and applicability of acetate rolls:

-

Material Grade: Acetate rolls are typically made from cellulose diacetate, a biodegradable plastic derived from wood pulp. The grade of the material can affect its clarity, flexibility, and durability. Higher grades are often preferred for applications that require superior transparency and strength, such as packaging and display products.

-

Thickness: Thickness is a critical specification that can range from 0.003 inches to 0.005 inches or more. The thickness impacts the film’s stiffness and ability to hold its shape, which is essential for applications like overlays and transparencies. Buyers should consider the intended use to determine the appropriate thickness, as thicker films may provide better durability but could be less flexible.

-

Clarity and Transparency: Clarity is a vital property, particularly in graphic arts and packaging. Acetate films are renowned for their exceptional clarity, which is important for visual applications. This property ensures that colors and images appear vibrant and undistorted, crucial for marketing materials and artistic displays.

-

Biodegradability: Many acetate films are certified biodegradable, making them an environmentally friendly choice. This is increasingly important for businesses looking to enhance their sustainability practices. Understanding the biodegradability of the product can influence purchasing decisions, especially in regions where environmental regulations are stringent.

-

FDA Compliance: For applications involving food contact, it is essential to ensure that the acetate film is FDA approved. This compliance guarantees that the material is safe for use in packaging food products, thus protecting both the consumer and the business from potential liabilities.

What Are Common Trade Terms Related to Acetate Plastic Rolls?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of acetate rolls, OEMs might be involved in producing specialized films for specific applications, such as custom packaging solutions.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest order size that a supplier is willing to accept. This is critical for buyers to consider, as it affects inventory management and cash flow. Understanding MOQ helps businesses plan their purchasing strategy, especially when entering new markets or testing new products.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For acetate rolls, an RFQ can help buyers obtain competitive pricing and terms from multiple suppliers, allowing for better negotiation and cost management.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs, risks, and liabilities. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which dictate who bears the responsibility during transportation.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for supply chain management, particularly for businesses that rely on just-in-time inventory systems.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right acetate products for their specific applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the rolls of acetate plastic Sector

What Are the Key Market Dynamics and Trends in the Rolls of Acetate Plastic Sector?

The global market for rolls of acetate plastic is experiencing significant growth, driven by various factors including increasing demand in the packaging, graphic arts, and printing industries. Acetate plastic, known for its clarity, durability, and versatility, is becoming a preferred choice for businesses seeking high-quality materials. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers are increasingly leveraging digital platforms for sourcing, reflecting a broader trend towards e-commerce and online procurement. This shift not only enhances accessibility but also enables buyers to compare prices and quality more effectively.

Emerging technologies are reshaping how acetate products are manufactured and sourced. Innovations such as advanced manufacturing techniques and automated supply chain management tools are streamlining operations, reducing lead times, and improving product consistency. Furthermore, the rise of smart manufacturing is influencing the production of acetate films, with real-time data analytics helping companies optimize their processes and inventory management.

B2B buyers in these regions must remain vigilant to fluctuations in raw material availability and pricing, which can be affected by global supply chain disruptions. Understanding regional market dynamics, including trade regulations and local demand trends, is crucial for buyers to make informed purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact B2B Sourcing Decisions for Rolls of Acetate Plastic?

Sustainability is becoming a central concern for businesses across the globe, and the rolls of acetate plastic sector is no exception. As environmental regulations tighten and consumer awareness grows, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. Acetate films, particularly those made from biodegradable materials, are gaining traction as they align with eco-friendly business models.

Buyers should look for suppliers that offer certified biodegradable acetate products and adhere to ethical sourcing practices. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 can serve as indicators of a supplier’s commitment to sustainability. Moreover, sourcing from manufacturers that engage in responsible waste management and energy-efficient production methods can enhance a company’s sustainability profile.

Incorporating sustainability into sourcing strategies not only helps reduce environmental impact but can also lead to cost savings in the long run. For instance, using recycled acetate can lower material costs while appealing to environmentally conscious consumers. By focusing on sustainable and ethical sourcing, B2B buyers can align their purchasing decisions with broader corporate social responsibility goals, thereby enhancing brand reputation and customer loyalty.

What Is the Historical Context of Rolls of Acetate Plastic in B2B Markets?

The evolution of acetate plastic dates back to the early 20th century when it was first developed as a substitute for cellulose nitrate. Initially used in the photographic and film industries, acetate soon found applications in various sectors due to its excellent clarity and flexibility. Over the decades, advancements in manufacturing processes have significantly enhanced the quality and versatility of acetate films, making them suitable for a broader range of applications, including packaging, arts, and crafts.

By the late 20th century, the rise of environmental awareness initiated a shift towards more sustainable materials, leading to the development of biodegradable acetate options. This evolution reflects the ongoing demand for innovative, high-performance materials that meet both functional and environmental criteria in B2B markets. Today, acetate plastic continues to play a crucial role in numerous industries, with an increasing focus on sustainability and ethical sourcing shaping its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of rolls of acetate plastic

-

How do I choose the right acetate roll for my business needs?

Selecting the appropriate acetate roll involves considering several factors such as thickness, clarity, and intended application. Acetate rolls come in various thicknesses, typically ranging from 0.003 to 0.005 inches, and offer options like clear, matte, or colored finishes. Assess your specific requirements—whether for packaging, graphic overlays, or printing—before making a decision. Additionally, inquire about certifications, such as FDA approval for food contact, which may be essential depending on your industry. -

What are the common applications of acetate rolls in various industries?

Acetate rolls are versatile and widely used across multiple sectors, including graphic arts, packaging, printing, and education. They are commonly employed for making overhead transparencies, artwork protection, and as overlays in presentations. In packaging, acetate provides a clear view of the product while maintaining durability. Understanding these applications can help you identify the right product for your business needs and market opportunities. -

What minimum order quantities (MOQ) should I expect when sourcing acetate rolls?

Minimum order quantities for acetate rolls can vary significantly based on the supplier and the specific product. Generally, MOQs can range from a few rolls to several hundred, especially for custom orders. When negotiating with suppliers, clarify your requirements and express your interest in bulk purchasing to explore potential discounts or flexibility in MOQs. This can help optimize your inventory management and reduce costs. -

How can I vet suppliers of acetate rolls for quality and reliability?

To ensure you partner with a reliable supplier, conduct thorough research by checking their certifications, customer reviews, and industry reputation. Request samples to evaluate the quality of their acetate rolls before committing to a larger order. Additionally, inquire about their production processes, quality assurance measures, and adherence to international standards. Establishing clear communication about your expectations and timelines can further gauge their reliability. -

What payment terms should I negotiate with acetate roll suppliers?

Payment terms can vary widely among suppliers, but it is essential to negotiate favorable conditions that align with your cash flow and business model. Common arrangements include upfront payments, net 30 or 60 days, or letters of credit for larger transactions. Discuss potential discounts for early payments or bulk orders to maximize savings. Always ensure that the payment terms are documented in the purchase agreement to avoid misunderstandings. -

What are the logistics considerations when importing acetate rolls internationally?

When importing acetate rolls, consider factors such as shipping methods, customs clearance, and local regulations. Choose a shipping method that balances cost and speed, while also being aware of potential import duties and taxes. Collaborate with a reliable freight forwarder who understands the nuances of international shipping. Additionally, ensure that the supplier provides the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. -

How can I customize acetate rolls to fit my specific needs?

Customization options for acetate rolls may include variations in thickness, width, color, and finishes. Many suppliers offer tailored solutions to meet specific business requirements. When seeking customization, provide detailed specifications and discuss your intended application to ensure the product meets your needs. Be aware that custom orders may have higher MOQs and longer lead times, so plan accordingly to avoid disruptions in your supply chain. -

What quality assurance measures should I expect from acetate roll suppliers?

Reputable suppliers should have robust quality assurance processes in place to ensure their acetate rolls meet industry standards. This may include regular testing for clarity, thickness, and durability. Inquire about their quality control protocols, including inspections during production and before shipment. Request documentation or certifications that verify compliance with international quality standards, which can provide peace of mind regarding the integrity of your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Rolls Of Acetate Plastic Manufacturers & Suppliers List

1. Tap Plastics – Acetate Rolls Clear

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acetate Rolls Clear, available in various sizes, ideal for crafts, displays, and protective coverings. Offers clarity and flexibility, resistant to moisture and UV light. Suitable for both indoor and outdoor use.

2. Renaissance Graphics – Acetate Clear Roll

Domain: renaissancegraphics.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Acetate Clear Roll”, “dimensions”: “40\”x12ft”, “thickness”: “.003”, “price”: “$30.00”, “SKU”: “9090”, “category”: “Films & Acetates”}

3. Martellato – Clear Plastic Acetate Roll

Domain: pastrychefsboutique.com

Registered: 2015 (10 years)

Introduction: [{‘name’: ‘Clear Plastic Acetate Roll – 80µm thickness – 305 mt – h 45mm’, ‘price’: ‘$49.01’, ‘manufacturer’: ‘Martellato’, ‘category’: ‘Acetate Rolls & Sheets’, ‘link’: ‘https://www.pastrychefsboutique.com/Pastry/baking-mats-and-liners/Acetate-Rolls-Sheets/martellato-nsa-h-45-clear-plastic-acetate-roll-80um-thickness-305-mt-h-45mm-acetate-rolls-sheets’}, {‘name’: ‘Clear Plastic Acetate Roll – 80µ…

4. Fine Art Store – Clear Acetate Rolls

Domain: fineartstore.com

Registered: 1997 (28 years)

Introduction: This company, Fine Art Store – Clear Acetate Rolls, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Jerry’s Artist Outlet – Clear Acetate Sheets & Rolls

Domain: jerrysartistoutlet.com

Registered: 2005 (20 years)

Introduction: Clear acetate sheets and rolls are versatile materials used for various applications, including arts and crafts, packaging, and displays. They offer clarity, durability, and flexibility, making them suitable for both professional and personal projects. Available in different sizes and thicknesses, these acetate products can be easily cut, folded, and manipulated to fit specific needs.

6. Grafix – Clear Acetate Rolls

Domain: dickblick.com

Registered: 1995 (30 years)

Introduction: Product Name: Grafix Clear Acetate Rolls

Brand: Grafix

Rating: 4.7 out of 5 stars (30 Reviews)

Material: Cellulose Acetate

Features: Glossy on both sides, 100% biodegradable

Uses: Protecting artwork, making overhead transparencies and overlays

Available Sizes:

– 25″ × 12 ft (63.5 cm × 3.7 m)

– 25″ × 25 ft (63.5 cm × 7.6 m)

– 25″ × 50 ft (63.5 cm × 15.2 m)

– 25″ × 100 ft (63.5 cm × 30.5 m)

– 50″ ×…

7. Jerry’s Artarama – Grafix Acetate Film

Domain: jerrysartarama.com

Registered: 1999 (26 years)

Introduction: This company, Jerry’s Artarama – Grafix Acetate Film, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Chef Rubber – Acetate & Guitar Sheets

Domain: shop.chefrubber.com

Registered: 2003 (22 years)

Introduction: Acetate Sheets: Handy for handling chocolate and ganache, creating chocolate cutouts and decorations, cake/pastry rings, and ribbons. Slightly more rigid than plastic sheets. Each sheet is separated with tissue paper. Item#: 707-ACE. Guitar Sheets: High quality for chocolate production applications, size 17in x 24in (432mm x 609mm). Item#: GUITARSHEETS. Plastic Sheet: 18in x 26in, 6mil thickness, …

Strategic Sourcing Conclusion and Outlook for rolls of acetate plastic

In navigating the complexities of sourcing rolls of acetate plastic, international B2B buyers must recognize the strategic advantages that come with informed purchasing decisions. Acetate plastic is not only versatile and biodegradable, making it suitable for a wide array of applications, from packaging to graphic arts, but it also offers superior clarity and durability. Key considerations for buyers include understanding the specifications that best meet their operational needs, such as thickness, size, and compliance with industry standards.

Strategic sourcing is essential for optimizing supply chains, reducing costs, and ensuring quality. By building strong relationships with reliable suppliers, buyers can secure favorable terms and access innovative products that enhance their competitive edge. Moreover, as global markets continue to evolve, staying abreast of trends and shifts in demand will empower businesses to adapt proactively.

As we look to the future, the potential for growth in the acetate plastic market remains robust. Buyers from regions such as Africa, South America, the Middle East, and Europe should seize this opportunity to refine their sourcing strategies. Engaging with suppliers who prioritize sustainability and innovation will not only fulfill immediate needs but also position businesses for long-term success in an increasingly conscientious market.