Roto Turn Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for roto turn

In the dynamic landscape of global construction and architecture, sourcing high-quality roto turn systems presents a unique challenge for international B2B buyers. With the increasing demand for innovative window and door solutions that balance functionality, aesthetics, and security, understanding the intricacies of the roto turn market is essential. This guide is designed to demystify the complexities of sourcing roto turn hardware, covering various types, applications, and key considerations for selecting suppliers.

From the versatile Roto NX systems that accommodate diverse design needs to the sleek concealed options of the Roto AL Designo, buyers will gain insights into the latest product offerings that meet rigorous performance standards. Additionally, we delve into supplier vetting processes, cost considerations, and the critical factors influencing purchasing decisions, ensuring that buyers from Africa, South America, the Middle East, and Europe—such as Saudi Arabia and Germany—are equipped with the knowledge to make informed choices.

By navigating this comprehensive guide, B2B buyers will not only streamline their procurement processes but also enhance the quality and security of their construction projects, ultimately leading to greater customer satisfaction and competitive advantage in their respective markets.

Understanding roto turn Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tilt & Turn | Dual-functionality; allows both tilting and turning of the sash. | Residential and commercial window systems | Pros: Versatile, good ventilation, space-saving. Cons: More complex installation. |

| Tilt-Only | Allows only for tilting of the sash. | High-rise buildings, where ventilation is key. | Pros: Simpler installation, enhanced security. Cons: Limited functionality. |

| Turn-Only | Enables only the turning action of the sash. | Suitable for areas needing full opening. | Pros: Easy access, straightforward operation. Cons: Less ventilation control. |

| Roto AL Designo | Concealed hardware design; supports heavy sashes. | High-end residential and architectural projects | Pros: Aesthetic appeal, robust performance. Cons: Higher cost, may require specialized installation. |

| Roto NX | Modular design; accommodates various sash sizes and weights. | Versatile applications in diverse environments | Pros: Flexible integration, high durability. Cons: Complexity may increase production time. |

What Are the Key Characteristics of Tilt & Turn Systems?

Tilt & Turn systems are characterized by their ability to function in two modes: tilting for ventilation and turning for full opening. This versatility makes them ideal for both residential and commercial applications. B2B buyers should consider the ease of operation and the potential for enhanced airflow, especially in climates that require effective ventilation solutions. However, the complexity of installation can be a drawback, requiring skilled labor to ensure proper functionality.

How Does the Tilt-Only Variation Benefit Buyers?

The Tilt-Only variation is designed for situations where ventilation is the primary concern. It allows the sash to tilt open while remaining secure, making it a popular choice for high-rise buildings. This type is particularly beneficial in environments where security is paramount, as it minimizes the risk of unauthorized access. Buyers should weigh the simplicity of installation and enhanced security against the limited functionality compared to other systems.

What Advantages Does the Turn-Only System Offer?

Turn-Only systems provide straightforward operation, allowing for full opening of the window without the tilt feature. This makes them suitable for areas where maximum access is needed, such as kitchens and patios. The ease of use is a significant advantage for B2B buyers, particularly in commercial settings where frequent window operation is necessary. However, the lack of ventilation control can be a disadvantage in warmer climates.

Why Choose the Roto AL Designo System?

The Roto AL Designo system features concealed hardware, providing a sleek aesthetic while supporting heavy sash weights. This makes it an excellent choice for high-end residential projects or architectural applications where design and functionality are both priorities. B2B buyers should consider the durability and performance benefits, but also be prepared for potentially higher costs and the need for specialized installation.

What Makes Roto NX a Versatile Option?

Roto NX is known for its modular design, allowing for the accommodation of various sash sizes and weights. This flexibility makes it suitable for a wide range of applications, from residential to commercial environments. Buyers should appreciate the robustness and durability of this system, which can withstand demanding conditions. However, the complexity of its integration into existing production processes may lead to longer lead times, which should be factored into project planning.

Key Industrial Applications of roto turn

| Industry/Sector | Specific Application of roto turn | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | High-rise residential buildings | Enhanced aesthetics and functionality in window design | Compliance with local building codes and regulations |

| Hospitality & Tourism | Hotels and resorts | Improved guest experience with secure, accessible windows | Durability and maintenance requirements for high-traffic areas |

| Commercial Real Estate | Office buildings and commercial spaces | Energy efficiency through superior sealing and ventilation | Customization options for various window sizes and types |

| Manufacturing | Industrial facilities | Increased safety and security for operational environments | Heavy-duty options for larger sashes and robust performance |

| Residential | Single-family homes | Versatile opening options for enhanced airflow and light | Compatibility with different frame materials (wood, PVC, aluminum) |

How is ‘roto turn’ utilized in construction and architecture for high-rise buildings?

In high-rise residential buildings, roto turn systems are integral for creating windows that are both functional and visually appealing. These systems allow for versatile opening mechanisms, including tilt and turn options, which enhance ventilation while maintaining security. International buyers, especially from regions like Europe and the Middle East, must ensure that the hardware meets stringent building regulations and aesthetic standards. The ability to customize hardware to fit various frame types adds significant value to architects and builders.

What role does ‘roto turn’ play in enhancing guest experiences in the hospitality sector?

In hotels and resorts, the roto turn mechanism provides a balance of security and ease of use, allowing guests to enjoy fresh air without compromising safety. The tilt function enables effective ventilation in guest rooms, contributing to comfort and satisfaction. For hotel operators, sourcing durable and low-maintenance hardware is crucial to withstand the demands of high occupancy rates. Additionally, ensuring that the systems align with the overall design aesthetic of the property can elevate the guest experience.

How does ‘roto turn’ improve energy efficiency in commercial real estate?

In commercial buildings, roto turn systems contribute to energy efficiency through superior sealing capabilities that prevent air leaks. This is particularly beneficial in office environments, where maintaining a comfortable temperature is essential for productivity. Buyers in this sector should consider the thermal performance ratings of the hardware and its compatibility with various window formats. Customization options allow for integration into existing architectural designs, maximizing both functionality and energy savings.

Why is ‘roto turn’ essential for safety in manufacturing facilities?

In manufacturing environments, roto turn systems enhance safety and security by providing robust locking mechanisms and reliable operation. These systems can accommodate larger, heavier windows, ensuring that operational areas remain secure while allowing for necessary ventilation. For international buyers, it’s important to evaluate the load capacities and durability of the hardware, especially in regions with varying climate conditions. The ability to source heavy-duty options tailored to specific manufacturing needs is a key consideration.

How does ‘roto turn’ add value to residential properties?

For single-family homes, roto turn systems offer homeowners versatile opening options that enhance natural light and airflow. The ease of operation and aesthetic appeal of these systems can significantly increase property value. Buyers should prioritize compatibility with different frame materials, as well as the availability of various security features. Ensuring that the chosen hardware meets local building codes and provides long-term durability will also be critical for residential applications.

3 Common User Pain Points for ‘roto turn’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Hardware for Diverse Projects

The Problem: B2B buyers, especially architects and construction firms, often face challenges when sourcing ‘roto turn’ hardware that is compatible with a variety of window and door designs. With the market being flooded with different manufacturers and hardware specifications, it can become overwhelming to ensure that the chosen components will meet project requirements while adhering to local regulations and design aesthetics. This inconsistency can lead to delays in project timelines and increased costs due to rework or modifications.

The Solution: To effectively source compatible ‘roto turn’ hardware, buyers should start by conducting a thorough needs assessment of their specific project requirements. This includes understanding the weight capacities, materials, and desired aesthetic finishes. Engaging with reputable suppliers like Roto Frank or Roto North America can provide access to a comprehensive range of products that meet international standards. Furthermore, utilizing online tools and software for rod calculations and ordering can streamline the procurement process. These resources ensure that all components align with both functional and design specifications, thereby reducing the risk of compatibility issues.

Scenario 2: Installation Complexities Leading to Increased Labor Costs

The Problem: Many buyers experience frustrations with the installation process of ‘roto turn’ systems, which can be intricate and labor-intensive. This complexity often results in longer installation times, requiring skilled labor that may not be readily available, thus inflating project budgets. Misunderstandings during the installation process can also lead to functional inefficiencies, compromising the performance and security features of the windows and doors.

The Solution: To mitigate installation challenges, B2B buyers should prioritize selecting ‘roto turn’ systems that offer straightforward installation features, such as modular designs or pre-assembled components. For instance, systems like Roto AL Designo include features that simplify the installation process, like clampable frame components and minimal preparation requirements. Additionally, investing in comprehensive training for installation teams through supplier workshops can significantly enhance their skills and efficiency. Access to detailed installation manuals and technical support from manufacturers can also provide clarity and confidence during the installation phase, ultimately leading to reduced labor costs and increased project efficiency.

Scenario 3: Ensuring Security and Compliance with International Standards

The Problem: In regions such as Africa, South America, the Middle East, and Europe, B2B buyers often grapple with ensuring that ‘roto turn’ hardware meets stringent security and compliance standards. Security features are paramount in preventing unauthorized access, especially in commercial buildings. Buyers may find it challenging to navigate the various compliance regulations across different countries, which can lead to legal repercussions and compromised safety.

The Solution: To address security concerns, buyers should prioritize hardware options that provide high-security features, such as the PAS24 certification available in Roto’s product lines. Understanding local regulations and compliance standards is crucial; thus, consulting with local experts or regulatory bodies can provide valuable insights. Implementing a thorough vetting process when selecting suppliers ensures that the ‘roto turn’ systems not only meet international security standards but also adhere to local codes. Additionally, leveraging integrated security solutions, such as the Roto NX TiltSafe system that allows for burglary inhibition even in tilt mode, can enhance overall safety while ensuring compliance with the required standards. Regular training and updates on security technologies can further empower buyers to make informed decisions that protect their investments.

Strategic Material Selection Guide for roto turn

What Are the Key Materials Used in Roto Turn Systems?

When selecting materials for roto turn systems, it is essential to consider properties that directly impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of roto turn hardware, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

How Does Aluminum Perform in Roto Turn Applications?

Aluminum is a widely used material in roto turn systems due to its lightweight nature and excellent corrosion resistance. Key properties include a high strength-to-weight ratio and the ability to withstand varying temperatures without significant deformation.

Pros: Aluminum is durable, resistant to rust, and offers a modern aesthetic, making it suitable for architectural applications. It is also relatively easy to manufacture and can be extruded into complex shapes.

Cons: The primary drawback of aluminum is its cost compared to other materials like steel or PVC. Additionally, while it is corrosion-resistant, it can still suffer from oxidation over time if not properly treated.

Impact on Application: Aluminum is compatible with various media, including air and water, making it ideal for window and door applications.

Considerations for International Buyers: Buyers in regions such as Europe and the Middle East should ensure compliance with standards like DIN EN 573 for aluminum alloys and consider the local climate’s impact on material performance.

What Role Does Steel Play in Roto Turn Systems?

Steel, particularly stainless steel, is another common choice for roto turn hardware due to its exceptional strength and durability. It offers high corrosion resistance, especially when treated or coated.

Pros: Steel is robust and can handle heavier loads, making it suitable for larger windows and doors. Its longevity and resistance to wear make it a preferred choice for high-traffic applications.

Cons: The main disadvantage is its weight, which can complicate installation and increase manufacturing costs. Additionally, while stainless steel resists corrosion, it can be more expensive than aluminum.

Impact on Application: Steel is suitable for environments where strength is paramount, such as commercial buildings. It is compatible with various media, including chemicals, provided the right grade is selected.

Considerations for International Buyers: Buyers should be aware of ASTM A240 standards for stainless steel and ensure that the selected grade meets local building codes.

How Does PVC Compare in Roto Turn Systems?

Polyvinyl chloride (PVC) is often utilized in roto turn systems for its excellent thermal insulation properties and cost-effectiveness.

Pros: PVC is lightweight, resistant to moisture, and does not require painting or finishing. It is also an economical option for manufacturers and end-users.

Cons: However, PVC may not be as strong as aluminum or steel, limiting its use in larger applications. It can also become brittle over time when exposed to UV light unless treated.

Impact on Application: PVC is best suited for residential applications where thermal efficiency is prioritized. It is compatible with air and water but may struggle in extreme temperature conditions.

Considerations for International Buyers: Buyers should check compliance with local standards such as EN 12608 for PVC profiles, especially in regions with high UV exposure.

What About Composite Materials in Roto Turn Systems?

Composite materials, which combine various materials like wood and plastic, are gaining traction in roto turn systems due to their unique properties.

Pros: Composites offer the aesthetic appeal of wood with the durability of synthetic materials. They provide excellent thermal insulation and are resistant to warping and cracking.

Cons: The main limitation is the higher cost associated with composite materials compared to traditional options. Additionally, the manufacturing process can be more complex.

Impact on Application: Composites are suitable for residential and commercial applications where aesthetics and performance are equally important. They are compatible with a variety of environmental conditions.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards for durability and environmental impact, particularly in regions with stringent building codes.

Summary Table of Material Selection for Roto Turn Systems

| Material | Typical Use Case for roto turn | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Windows and doors in residential/commercial settings | Lightweight and corrosion-resistant | Higher cost compared to PVC | Medium |

| Steel | Heavy-duty applications, commercial buildings | Exceptional strength and durability | Heavier, complicates installation | High |

| PVC | Residential windows and doors | Cost-effective and moisture-resistant | Less strength, can become brittle | Low |

| Composite | Aesthetic residential/commercial applications | Combines aesthetics with durability | Higher cost, complex manufacturing | High |

This material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for roto turn

What Are the Main Stages of Manufacturing Roto Turn Systems?

The manufacturing process for roto turn systems is meticulously structured to ensure high performance and durability, crucial for B2B buyers in construction and window manufacturing. The main stages of this process include material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with sourcing high-quality materials, typically aluminum, steel, or PVC. These materials must meet stringent specifications for strength, corrosion resistance, and aesthetic appeal. Suppliers often provide certificates of compliance, which verify that materials adhere to relevant international standards.

-

Forming: This stage involves shaping the materials using advanced machining techniques such as CNC milling and stamping. For instance, aluminum frames undergo extrusion to create profiles that are both lightweight and strong. Precision is paramount here, as any deviation can affect the functionality of the final product.

-

Assembly: After forming, components are assembled into complete roto turn systems. This process often utilizes automated assembly lines to enhance efficiency and accuracy. Key components such as hinges, locking mechanisms, and handles are integrated at this stage, ensuring that they work seamlessly together.

-

Finishing: The final stage includes surface treatments such as anodizing or powder coating, which not only enhance aesthetics but also provide additional corrosion resistance. Quality control checks are conducted to ensure that the finish meets specified standards and that there are no defects.

How Is Quality Assurance Implemented in Roto Turn Manufacturing?

Quality assurance (QA) is integral to the manufacturing of roto turn systems, ensuring that every product meets both industry standards and customer expectations. The QA process typically adheres to international standards, including ISO 9001, which focuses on quality management systems.

-

International Standards: Compliance with ISO 9001 ensures that the manufacturing process is consistently monitored and improved. Additionally, industry-specific certifications such as CE marking in Europe signify that products meet safety and performance standards.

-

Quality Checkpoints: The QA process involves several critical checkpoints:

– Incoming Quality Control (IQC): This initial inspection verifies that materials and components received from suppliers meet quality standards before they enter the production line.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process, where operators check for defects and ensure that machinery operates within specified tolerances.

– Final Quality Control (FQC): Once assembly is complete, a final inspection assesses the functionality and aesthetics of the finished product. -

Common Testing Methods: Various testing methods are employed to ensure product integrity. For example, mechanical testing might include load testing of hinges and locks to verify their performance under stress. Corrosion resistance tests, such as salt spray testing, assess the durability of finishes under adverse conditions.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure the reliability of roto turn systems. Here are some best practices:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities provide insights into the supplier’s processes and adherence to quality standards. Buyers should look for documented procedures that align with ISO standards and industry best practices.

-

Request Quality Control Reports: Suppliers should provide detailed reports outlining their quality control processes, including results from IQC, IPQC, and FQC stages. These documents serve as evidence of compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can add an additional layer of assurance. These inspectors can conduct random checks on products and processes, ensuring that the supplier adheres to agreed-upon specifications.

What Are the Quality Control and Certification Nuances for International Buyers?

When engaging with suppliers across different regions, B2B buyers must be aware of specific quality control and certification nuances.

-

Regional Certification Requirements: Different markets have varying certification requirements. For example, products sold in Europe must meet CE marking requirements, while Middle Eastern markets may require compliance with local standards. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Cultural Considerations: Understanding cultural differences in manufacturing and quality control practices can enhance communication with suppliers. For instance, some regions may prioritize efficiency over extensive documentation, which could affect how quality is reported and verified.

-

Long-Term Partnerships: Building long-term relationships with suppliers can lead to improved transparency and trust. Buyers should engage in open dialogue regarding quality expectations and collaborate on continuous improvement initiatives.

How Can B2B Buyers Leverage Quality Assurance for Competitive Advantage?

Investing time and resources into understanding the manufacturing processes and quality assurance of roto turn systems can yield significant competitive advantages for B2B buyers. By selecting suppliers with robust QA practices, buyers can:

- Enhance Product Reliability: High-quality products reduce the likelihood of failures, leading to greater customer satisfaction and lower warranty claims.

- Improve Brand Reputation: Consistently delivering reliable products helps build a brand reputation for quality, which is essential in competitive markets.

- Foster Innovation: Collaborating with suppliers who prioritize quality can lead to innovative solutions and improved product offerings, ultimately benefiting end-users.

By prioritizing these aspects, B2B buyers can ensure that they are not only purchasing high-quality roto turn systems but also establishing a foundation for long-term success in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roto turn’

Introduction

This guide serves as a practical checklist for international B2B buyers seeking to procure ‘roto turn’ systems for windows and doors. Understanding the nuances of sourcing this hardware is essential for ensuring quality, functionality, and compliance with regional standards. By following these steps, buyers can streamline their procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your ‘roto turn’ systems. This includes understanding the dimensions, weight capacities, and types of materials required (e.g., aluminum, wood, or vinyl).

– Consider functionality: Decide if you need tilt-only, turn-only, or tilt-and-turn options based on your project needs.

– Aesthetic preferences: Specify if you require concealed hardware for a sleek look or if traditional visible hardware is acceptable.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in ‘roto turn’ technology. This can help you identify features that enhance security, durability, and energy efficiency.

– Emerging technologies: Look for systems that integrate smart technology for added convenience and security.

– Sustainability: Consider eco-friendly options that comply with green building standards, particularly if you’re targeting markets in Europe or North America.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they can meet your needs. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Check credentials: Ensure suppliers have necessary certifications, such as ISO standards or local compliance marks.

– Assess experience: Look for suppliers with a proven track record in your target market, particularly those familiar with regional regulations.

Step 4: Verify Product Quality and Compliance

Quality assurance is critical in procurement. Ensure that the products meet international and local standards relevant to your region.

– Test reports and certifications: Ask for documentation that proves the product’s performance and safety standards, like PAS24 for security or BS EN1670 for corrosion resistance.

– Warranty and support: Inquire about the warranty terms and the availability of technical support for installation and maintenance.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures. Look beyond the initial cost to understand total ownership costs, including shipping, taxes, and duties.

– Negotiate terms: Discuss payment terms that suit both parties, considering options like deposits, payment on delivery, or financing.

– Evaluate value: Assess the overall value, including product quality, service support, and delivery timelines, rather than focusing solely on price.

Step 6: Plan for Logistics and Delivery

Coordinate logistics early in the procurement process to avoid delays. Determine the best shipping methods and timelines based on your project deadlines.

– Customs and import regulations: Be aware of import regulations in your country to prevent unexpected delays or additional costs.

– Delivery tracking: Establish a system for tracking shipments to stay informed about the status of your order.

Step 7: Establish After-Sales Support and Maintenance Plans

Ensure that your supplier provides adequate after-sales support. This includes installation guidance, maintenance plans, and troubleshooting assistance.

– Training: Consider asking for training sessions for your team on how to install and maintain the systems effectively.

– Long-term relationship: Building a strong relationship with your supplier can lead to better support and potential discounts on future orders.

By adhering to this checklist, B2B buyers can effectively navigate the complexities of sourcing ‘roto turn’ systems, ensuring they select the best products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for roto turn Sourcing

What Are the Key Cost Components in Roto Turn Sourcing?

When sourcing Roto Turn systems, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. High-quality aluminum or specialized alloys for corrosion resistance can elevate the price, but they also enhance durability and performance. For instance, the Roto AL Designo system utilizes robust materials that support sash weights of up to 180 kg.

-

Labor: Labor costs vary based on the region and the complexity of the assembly process. Skilled labor is often required for the installation of tilt and turn systems, especially for customized solutions.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and maintenance of production facilities. Efficient manufacturing processes, including automation, can help reduce these overheads.

-

Tooling: The investment in specialized tooling for custom designs can be substantial. However, these costs can be amortized over larger production runs, making them more manageable for high-volume orders.

-

Quality Control (QC): Ensuring that products meet specific standards necessitates a robust QC process, which incurs additional costs. Certifications such as PAS24 for security and BS EN1670 for corrosion resistance can also influence pricing.

-

Logistics: Transportation and handling costs can vary widely depending on the sourcing location and the destination market. International shipping may involve tariffs and customs duties, particularly relevant for buyers in regions like Africa and South America.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary based on market demand and competition.

How Do Price Influencers Affect Roto Turn Sourcing?

Several factors can influence the pricing of Roto Turn systems:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs. Negotiating favorable terms for bulk purchases can yield significant savings.

-

Specifications/Customization: Custom features tailored to specific architectural requirements can add to costs. Buyers should weigh the need for customization against standard options that may be more cost-effective.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly influence the price. Premium materials may come with a higher upfront cost but can reduce long-term maintenance expenses.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can impact total costs, including shipping and insurance.

What Are the Best Buyer Tips for Cost-Efficiency in Roto Turn Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Engage in negotiations to secure better pricing, especially for larger orders. Suppliers may offer discounts or favorable payment terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs associated with maintenance, energy efficiency, and durability. Higher-quality products may lead to lower TCO.

-

Understand Pricing Nuances: Pricing can vary significantly based on local market conditions and import regulations. Stay informed about regional trends and potential tariffs that could affect costs.

-

Build Strong Supplier Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service over time. Suppliers may be more willing to negotiate terms with trusted partners.

-

Evaluate Local vs. International Suppliers: While international suppliers might offer competitive pricing, local suppliers can reduce shipping costs and lead times. Assess the trade-offs between cost and convenience.

Conclusion

Navigating the cost and pricing landscape for Roto Turn systems requires a keen understanding of various components and influencers. By strategically considering these factors, B2B buyers can optimize their sourcing strategies, ensuring both quality and cost-effectiveness in their procurement processes. While indicative prices can provide a starting point, a thorough analysis of the total cost structure and negotiation strategies will yield the best outcomes for international buyers.

Alternatives Analysis: Comparing roto turn With Other Solutions

When evaluating window and door hardware solutions, understanding the available alternatives to the Roto Turn system is essential for B2B buyers. The right choice can significantly impact performance, cost-effectiveness, and long-term satisfaction. Below, we compare Roto Turn with two viable alternatives: Casement Windows and Sliding Door Systems.

| Comparison Aspect | Roto Turn | Casement Windows | Sliding Door Systems |

|---|---|---|---|

| Performance | High functionality with tilt and turn features, suitable for various sash weights. | Excellent ventilation and energy efficiency. | Smooth operation with large openings for accessibility. |

| Cost | Moderate to high, depending on customization and materials. | Generally lower upfront costs, but may require more maintenance. | Can be cost-effective for large openings, but hardware can be expensive. |

| Ease of Implementation | Moderate; requires skilled labor for installation. | Generally easier to install, especially in standard sizes. | Installation can be complex, especially for larger systems. |

| Maintenance | Low; durable with minimal upkeep. | Moderate; hinges may require regular lubrication. | Higher maintenance due to tracks and rollers needing regular cleaning. |

| Best Use Case | Ideal for spaces requiring both ventilation and security. | Best for smaller openings where airflow is a priority. | Perfect for patios or large openings needing seamless transitions. |

What are the Advantages and Disadvantages of Casement Windows Compared to Roto Turn?

Casement windows are hinged at the side and open outward, offering excellent ventilation and unobstructed views. They typically come at a lower initial cost and are easier to install in standard configurations. However, they may require more maintenance over time, especially concerning the hinges. While they excel in airflow, casement windows do not provide the same level of security and flexibility in operation as the Roto Turn system, which offers a dual-functionality feature.

How Do Sliding Door Systems Compare to Roto Turn in Terms of Efficiency?

Sliding door systems allow for expansive openings and are ideal for connecting indoor and outdoor spaces. They provide smooth operation and are often considered more accessible for high-traffic areas. However, they can be more expensive due to the complexity of their tracks and hardware, which require regular maintenance to ensure smooth function. While sliding doors excel in aesthetics and access, they do not offer the same ventilation options as the Roto Turn system, which can tilt for airflow while remaining secure.

How Should B2B Buyers Decide Between Roto Turn and Its Alternatives?

Choosing the right window and door hardware solution depends on specific needs and circumstances. Buyers should consider factors such as the desired functionality, budget constraints, and maintenance capabilities. For instance, if security and dual-functionality are paramount, Roto Turn is an excellent choice. Conversely, if the focus is on cost-effectiveness and ease of installation, casement windows may be preferable. Sliding door systems are ideal for those seeking large openings and seamless transitions but require a willingness to invest in maintenance.

In conclusion, a thorough analysis of each option, aligned with project requirements and environmental considerations, will guide B2B buyers in selecting the most suitable solution for their needs.

Essential Technical Properties and Trade Terminology for roto turn

What Are the Key Technical Properties of Roto Turn Systems?

When considering roto turn systems for windows and doors, understanding their technical properties is crucial for making informed purchasing decisions. Below are some critical specifications that buyers should be aware of:

-

Material Grade

The material used in roto turn hardware, such as aluminum or high-strength steel, determines its durability and resistance to environmental factors. High-grade materials can enhance corrosion resistance and overall longevity, which is particularly important in regions with extreme weather conditions. Choosing the right material can significantly reduce maintenance costs over time. -

Sash Weight Capacity

Roto turn systems are designed to accommodate specific sash weights, typically ranging from 100 kg to 180 kg, depending on the model. Understanding this capacity is vital for ensuring that the chosen system can support the intended window or door design without compromising safety or performance. Exceeding the weight limits may lead to mechanical failure, which can be costly and hazardous. -

Corrosion Resistance Rating

Systems often come with a corrosion resistance rating, such as BS EN1670 Grade 5, which indicates the hardware’s ability to withstand various environmental conditions. A higher grade means longer-lasting performance in moist or saline environments, making this a critical specification for international buyers in humid climates or coastal regions. -

Resistance Class

The resistance class (e.g., RC 2 and RC 3) indicates the security level of the hardware. These classifications are essential for buyers focused on enhancing security features in residential or commercial buildings. Systems with higher resistance classes can deter break-ins and offer peace of mind to end-users. -

Ease of Installation

Features that facilitate quick installation, such as Torx drive screws and clampable components, can significantly reduce labor costs and project timelines. Buyers should look for systems that provide straightforward assembly and require minimal preparation, which is especially beneficial for contractors managing multiple projects. -

Adjustability Features

The ability to adjust locking points and compression settings is crucial for achieving optimal performance. Adjustable features can compensate for settling structures over time, ensuring that windows and doors maintain their functionality and energy efficiency.

What Are Common Trade Terms Related to Roto Turn Systems?

Navigating the B2B landscape requires familiarity with industry-specific terminology. Here are some key terms relevant to roto turn systems:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help ensure quality and compatibility when sourcing components for roto turn systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for companies looking to maintain a lean supply chain. -

RFQ (Request for Quotation)

An RFQ is a formal process used to solicit price quotes from suppliers. This is particularly useful for buyers looking to compare prices and specifications across multiple vendors for roto turn systems. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs and risk management. Familiarity with these terms helps buyers understand their obligations and rights when importing roto turn systems. -

Lead Time

Lead time refers to the time between placing an order and receiving the goods. Understanding lead times is crucial for project planning and ensuring that materials arrive when needed to avoid project delays. -

Certification Standards

These are industry-specific standards that products must meet to ensure safety and performance, such as CE marking in Europe. Knowing the relevant certification standards for roto turn systems helps buyers ensure compliance with regional regulations and quality expectations.

By understanding these technical properties and trade terms, international B2B buyers can make well-informed decisions when sourcing roto turn systems, ultimately leading to improved project outcomes and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the roto turn Sector

What Are the Current Market Dynamics and Key Trends in the Roto Turn Sector?

The roto turn sector is experiencing significant shifts driven by technological advancements, changing consumer preferences, and regional market dynamics. Globally, there is a growing demand for energy-efficient window and door solutions, particularly in regions like Europe and North America, where stringent building regulations are pushing the adoption of high-performance systems. In emerging markets such as Africa and South America, urbanization and increased construction activities are propelling the demand for innovative window solutions.

Key trends include the integration of smart technologies into window systems, allowing for enhanced security and energy management. The Roto NX range, for instance, offers burglary inhibition features integrated into the tilt position, catering to the rising demand for both functionality and safety. Additionally, the trend towards minimalist design is influencing product development, as seen in concealed hardware systems that combine aesthetics with performance. International buyers are also gravitating towards modular designs that facilitate easy installation and customization, allowing for greater flexibility in manufacturing processes.

Furthermore, sustainability is becoming a non-negotiable factor in sourcing decisions. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials and manufacturing processes, responding to both regulatory pressures and consumer demand for greener products.

How Are Sustainability and Ethical Sourcing Influencing the Roto Turn Sector?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the roto turn sector. The environmental impact of window and door hardware manufacturing can be substantial, making it essential for suppliers to adopt sustainable practices. This includes using recycled materials, reducing waste in production, and ensuring that manufacturing processes minimize carbon footprints.

Buyers should prioritize suppliers that hold certifications for sustainability, such as ISO 14001, which demonstrates a commitment to environmental management systems. Additionally, sourcing from companies that use green materials not only supports environmental goals but can also enhance a brand’s reputation in the marketplace. For instance, products that comply with high corrosion resistance standards, such as BS EN1670 Grade 5, not only ensure durability but also contribute to a longer lifecycle for windows and doors, reducing the need for replacements.

Moreover, ethical supply chains are gaining importance, especially in regions where labor practices may vary. Buyers should conduct due diligence to ensure that suppliers adhere to fair labor practices and contribute positively to their local economies. This not only aligns with corporate social responsibility goals but also mitigates risks associated with unethical sourcing.

What Is the Evolution of the Roto Turn Sector and Its Relevance to B2B Buyers?

The roto turn sector has evolved significantly over the past few decades, transitioning from basic mechanical systems to sophisticated hardware solutions that combine functionality with advanced security features. Initially, the focus was primarily on operational efficiency and ease of use. However, as architectural designs became more complex and aesthetic demands increased, manufacturers began to innovate, leading to the development of concealed hardware systems that offer both elegance and high performance.

The introduction of modular designs has also played a crucial role in this evolution, allowing manufacturers to adapt to different market needs quickly. This flexibility is particularly beneficial for international B2B buyers who require solutions that can be tailored to various construction styles and regulatory environments.

Today, the roto turn sector is at a crossroads, driven by technological advancements and a growing emphasis on sustainability. For B2B buyers, understanding this evolution is essential for making informed sourcing decisions that align with current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of roto turn

-

How do I ensure the quality of roto turn hardware before purchasing?

To ensure quality, request detailed product specifications and certifications from potential suppliers. Look for compliance with international standards such as BS EN1670 for corrosion resistance and PAS24 for security. Conduct factory audits or inspections if possible, or rely on third-party quality assurance services. Reviewing product samples before placing large orders can also help assess the quality and functionality of the hardware. -

What are the key features to look for in tilt and turn hardware?

When sourcing tilt and turn hardware, prioritize features such as weight capacity, corrosion resistance, and ease of installation. Look for systems that offer concealed hinges for aesthetic appeal, as well as secure locking mechanisms to enhance safety. Additionally, ensure that the hardware is compatible with the materials you plan to use, whether it’s wood, aluminum, or vinyl, to guarantee optimal performance. -

What is the best roto turn system for high-security applications?

For high-security applications, consider the Roto AL Designo or Roto NX systems, both of which offer options for enhanced security features. Look for hardware with multiple locking points, high corrosion resistance ratings, and options for burglary inhibition in tilt positions. These systems can meet resistance classes RC 2 and RC 3, making them suitable for projects requiring stringent security measures. -

How can I customize roto turn hardware for my specific project needs?

Most suppliers offer customization options for roto turn hardware. Discuss your project requirements, including specific dimensions, load capacities, and aesthetic preferences with potential suppliers. Many manufacturers provide modular systems that can be tailored to fit unique architectural designs. Be sure to ask about available finishes, colors, and additional features that can enhance functionality and appearance. -

What are the minimum order quantities (MOQs) for roto turn hardware?

Minimum order quantities can vary significantly between suppliers and regions. Typically, MOQs may range from 50 to 500 units, depending on the specific hardware and supplier policies. When negotiating, discuss your project volume and potential future orders, as some suppliers may offer flexible MOQs for long-term partnerships or larger contracts. -

What payment terms should I expect when sourcing roto turn hardware internationally?

Payment terms can differ based on the supplier and the nature of the transaction. Common practices include advance payment, payment upon delivery, or net 30/60/90 days after receipt of goods. It’s advisable to negotiate terms that protect both parties, such as using escrow services or letters of credit for larger transactions. Always clarify the payment schedule in your contractual agreement to avoid misunderstandings. -

How do I handle logistics and shipping for international orders of roto turn hardware?

Logistics for international orders can be complex, involving customs regulations, tariffs, and shipping costs. Work closely with your supplier to understand their shipping capabilities and recommended logistics partners. Consider using freight forwarders who specialize in international shipping to handle documentation and customs clearance. Be aware of lead times and plan accordingly to ensure timely delivery to your project site. -

What should I include in my supplier vetting process for sourcing roto turn hardware?

When vetting suppliers, focus on their industry experience, reputation, and product range. Request references from previous clients and review case studies to gauge their reliability. Verify certifications and compliance with international standards relevant to your market. Additionally, assess their communication responsiveness and willingness to provide after-sales support, as these factors are critical for long-term business relationships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Roto Turn Manufacturers & Suppliers List

1. Roto – Universal Hardware Systems for Windows and Doors

Domain: ftt.roto-frank.com

Registered: 1996 (29 years)

Introduction: Roto NX: The universal hardware system for modern windows and balcony doors. Roto AL: The universal hardware for aluminium windows and balcony doors. Roto AL Designo: Concealed hardware for aesthetic aluminium windows and balcony doors. Roto AL 300: Economically efficient hardware for aluminium windows and balcony doors.

2. Titon – Roto AL Designo Tilt Turn System

Domain: products.titon.com

Registered: 1996 (29 years)

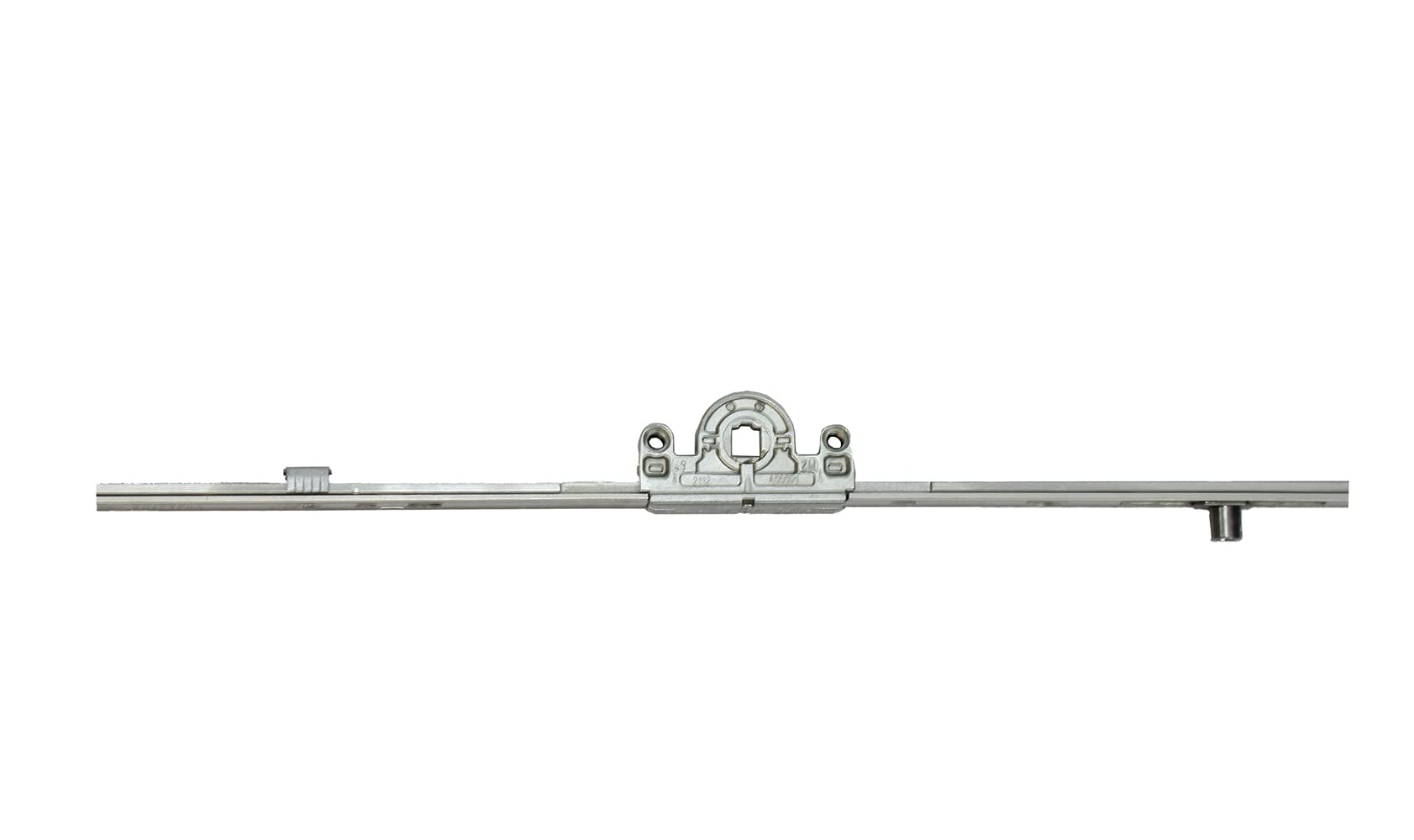

Introduction: {“product_name”: “Roto AL Designo Tilt Turn System”, “manufacturer”: “Titon”, “hardware_type”: “Concealed hardware for aluminium windows and balcony doors”, “sash_weight_capacity”: {“standard”: “80kg”, “maximum”: “180kg with additional load transfer kit”}, “maximum_sash_size”: {“width”: “1600mm”, “height”: “3000mm”}, “features”: [“Tilt before Turn Gear”, “Tilt Only and Turn Only options available”…

3. Roto – Roto Tilt Turn 40r-494389

Domain: goldenlocksinc.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Roto Tilt Turn 40r-494389”, “Brand”: “Roto”, “Product Type”: “Automatic Door Bottoms and Accessories”, “Price”: “$39.57”, “Model”: “40r-494389”, “Minimum Order”: “6”, “Special Order”: “Yes”}

4. Roto – Key Tilt & Turn Components

Domain: dgsupplyline.co.uk

Registered: 2003 (22 years)

Introduction: Roto Tilt & Turn Systems include various components and full gearing sets. Key products include: Roto RS500 Forked Handle (£102.55 – £152.75), Roto NT ‘R’ Hinge (Concealed), Roto NT ‘K’ Hinge (Face Fixed), Roto NT ‘A’ Hinge (Face Fixed), Roto AL Designo Concealed Tilt & Turn Gearing (£170.03 – £245.38), Roto ALU500 (Face-Fixed) (£250.20 – £347.45), Roto ALU500 Corner Drive (£34.95), Roto ALU T540 …

5. Roto – Solid Turn Restrictor

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Roto Solid turn restrictor gently slows doors to an individually set opening width without visible obstacles. It features simple adjustment for optimum damping, protecting walls and furniture.

6. Kubota – Roto Tiller

Domain: orangetractortalks.com

Registered: 2008 (17 years)

Introduction: Roto tiller, used with Kubota tractors, requires lifting before turning to avoid damage. Recommended for tilling large areas, but small turns are acceptable. Manufacturer’s guidelines suggest avoiding backing up with the tiller in the ground.

7. Forde Hall Supplies – Roto 260277 Corner Drive

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Roto 260277 Corner Drive”, “Suitable For”: “Aluminium & Timber TBT Tilt & Turn Windows”, “Condition”: “New”, “Price”: “GBP 13.99 (Approximately US $19.00)”, “Shipping Cost”: “GBP 13.31 (approx US $18.08)”, “Seller”: “Forde Hall Supplies”, “Seller Rating”: “99.4% positive”, “Quantity Available”: “More than 10 available”, “Returns”: “30 days returns, buyer pays for return shipping”…

Strategic Sourcing Conclusion and Outlook for roto turn

How Can Strategic Sourcing Enhance Your Roto Turn Solutions?

In today’s competitive market, strategic sourcing is crucial for international B2B buyers seeking high-quality roto turn hardware. By prioritizing suppliers that offer advanced technology, durable materials, and innovative designs, businesses can ensure they meet diverse client needs across various regions, including Africa, South America, the Middle East, and Europe. The integration of systems like Roto NX and Roto AL Designo not only enhances functionality but also elevates the aesthetic appeal of projects, aligning with modern architectural trends.

Moreover, understanding the technical specifications and security features of roto turn systems can lead to better procurement decisions. Buyers should focus on suppliers who provide comprehensive support, including installation resources and warranty guarantees, to streamline their sourcing process.

As you consider your next sourcing strategy, remember that investing in quality hardware is not just about immediate savings; it’s about long-term value creation and customer satisfaction. We encourage you to explore partnerships with trusted manufacturers and leverage their expertise to drive innovation in your projects. Embrace the future of window and door solutions with confidence, ensuring that your offerings stand out in the global marketplace.