Ag13 Battery Equivalent Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for ag13 battery equivalent

As global demand for compact power solutions continues to rise, navigating the market for AG13 battery equivalents presents a significant challenge for international B2B buyers. Sourcing reliable AG13 battery alternatives can be complicated by varying specifications, quality standards, and regional availability, making it essential to understand the nuances of these small yet powerful energy sources. This guide offers a comprehensive overview of the AG13 battery equivalents, including alternative models such as LR44, SR44, and A76, while detailing their applications across diverse industries—from consumer electronics to medical devices.

In the following sections, we will delve into critical aspects such as supplier vetting processes, cost considerations, and best practices for ensuring quality and compatibility. We recognize that buyers from regions like Africa, South America, the Middle East, and Europe—such as Vietnam and Brazil—face unique challenges when it comes to sourcing these batteries. Therefore, this guide is designed to empower you with actionable insights and strategic recommendations that will facilitate informed purchasing decisions. By understanding the specifications, environmental impacts, and market trends associated with AG13 battery equivalents, you can streamline your procurement processes and enhance your product offerings, ensuring both reliability and sustainability in your supply chain.

Understanding ag13 battery equivalent Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LR44 | Alkaline, 1.5V, similar dimensions to AG13 | Watches, calculators, toys | Pros: Cost-effective, widely available. Cons: Shorter lifespan compared to silver oxide options. |

| SR44 | Silver oxide chemistry, higher capacity | Medical devices, high-drain gadgets | Pros: Longer lifespan, stable discharge. Cons: Higher cost than alkaline alternatives. |

| A76 | Alkaline, equivalent dimensions to LR44 | Remote controls, electronic toys | Pros: Economical, good performance. Cons: May leak more than silver oxide batteries. |

| 357A | Silver oxide, designed for precision devices | Watches, laser pointers | Pros: Superior conductivity, longer shelf life. Cons: Typically more expensive than alkaline batteries. |

| 76A | Alkaline, similar performance to LR44 | Key fobs, small electronics | Pros: Affordable, readily available. Cons: Not as reliable in high-drain applications. |

What are the Characteristics of LR44 Batteries and Their Suitability for B2B Purchases?

LR44 batteries are alkaline button cells that operate at 1.5 volts, making them a versatile choice for various applications, including watches and calculators. Their compact size and cost-effectiveness appeal to businesses looking for bulk purchasing options. However, while they are widely available, their shorter lifespan compared to silver oxide batteries may be a drawback in high-use scenarios. B2B buyers should consider the balance between cost and longevity when selecting LR44 batteries for their devices.

How Do SR44 Batteries Differ from Other AG13 Equivalents?

SR44 batteries utilize silver oxide chemistry, providing a higher capacity and more stable voltage output than their alkaline counterparts. This makes them particularly suitable for medical devices and high-drain gadgets where reliability is critical. While SR44 batteries come at a higher price point, their longer lifespan and superior performance justify the investment for businesses that prioritize quality and performance. B2B buyers should evaluate their specific needs to determine if the benefits of SR44 batteries align with their operational requirements.

What Makes A76 Batteries a Popular Choice in the Market?

A76 batteries are another alkaline option that shares dimensions and voltage with the LR44. They are commonly used in remote controls and electronic toys, making them a practical choice for businesses in the consumer electronics sector. A76 batteries are typically more economical than silver oxide variants, although they may have a higher tendency to leak. B2B purchasers should weigh the cost savings against potential reliability issues when considering A76 batteries for their applications.

Why are 357A Batteries Preferred for Precision Devices?

The 357A battery is a silver oxide variant known for its precision and reliability, making it ideal for applications like watches and laser pointers. With superior conductivity and a longer shelf life, these batteries are often favored in industries that require consistent performance. While they are usually more expensive than alkaline options, the investment can lead to reduced maintenance costs and fewer replacements, which is crucial for B2B buyers focused on operational efficiency.

How Do 76A Batteries Compare in Terms of Performance and Cost?

76A batteries are alkaline cells that offer performance comparable to LR44 batteries, making them suitable for key fobs and other small electronics. Their affordability and availability make them an attractive option for businesses looking to keep costs down. However, like other alkaline batteries, they may not perform as well in high-drain applications. B2B buyers should consider the specific requirements of their devices to ensure that 76A batteries will meet their performance expectations.

Key Industrial Applications of ag13 battery equivalent

| Industry/Sector | Specific Application of ag13 battery equivalent | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Remote controls for TVs and audio devices | Ensures reliable operation of devices, enhancing user experience | Consistent quality and performance; bulk purchasing options |

| Medical Equipment | Surgical instruments and diagnostic devices | Provides critical power for life-saving equipment, ensuring reliability | Compliance with medical standards; long shelf life; safety certifications |

| Automotive | Key fobs and remote entry systems | Enhances convenience and security for vehicles, improving customer satisfaction | Compatibility with various vehicle models; volume discounts for bulk orders |

| Home Appliances | Toys and small appliances | Delivers consistent performance in high-demand applications, increasing product reliability | Eco-friendly options; supplier reliability and support for bulk orders |

| Industrial Equipment | Measurement tools and sensors | Ensures accurate readings and reliability in industrial operations, minimizing downtime | Temperature tolerance; storage conditions; compatibility with existing equipment |

How is the AG13 Battery Equivalent Used in Consumer Electronics?

In consumer electronics, AG13 battery equivalents are predominantly utilized in remote controls for TVs and audio devices. These batteries ensure the devices operate reliably, enhancing user experience by providing consistent power. For international buyers, particularly in Africa and South America, sourcing high-quality batteries is crucial to avoid frequent replacements and ensure device longevity. Buyers should prioritize suppliers that offer bulk purchasing options and guarantee performance consistency to meet consumer demands.

What Role Do AG13 Battery Equivalents Play in Medical Equipment?

AG13 battery equivalents are essential in medical equipment, such as surgical instruments and diagnostic devices. These batteries provide critical power, ensuring the reliability of life-saving equipment. For businesses in the medical sector, compliance with stringent medical standards is paramount, necessitating sourcing from certified manufacturers. Long shelf life and safety certifications are key considerations for buyers to ensure that equipment remains functional when needed most.

How are AG13 Battery Equivalents Integrated into Automotive Applications?

In the automotive sector, AG13 battery equivalents are commonly found in key fobs and remote entry systems. They enhance vehicle convenience and security, significantly improving customer satisfaction. For B2B buyers in Europe and the Middle East, it is important to ensure compatibility with various vehicle models. Suppliers offering volume discounts for bulk orders can provide substantial cost savings, making it beneficial for businesses to maintain a steady supply.

What Benefits Do AG13 Battery Equivalents Offer for Home Appliances?

AG13 battery equivalents power toys and small appliances, delivering consistent performance even under high demand. This reliability is crucial for manufacturers aiming to enhance product quality and customer satisfaction. International buyers should consider eco-friendly battery options and evaluate supplier reliability when sourcing these batteries. Support for bulk orders can also streamline inventory management and reduce overall costs.

How Are AG13 Battery Equivalents Utilized in Industrial Equipment?

In industrial settings, AG13 battery equivalents are utilized in measurement tools and sensors, ensuring accurate readings and reliability in operations. This is vital for minimizing downtime and maintaining productivity. Buyers in diverse regions, including Africa and South America, should pay attention to temperature tolerance and storage conditions when sourcing these batteries. Compatibility with existing equipment is also essential to ensure seamless integration and operational efficiency.

3 Common User Pain Points for ‘ag13 battery equivalent’ & Their Solutions

Scenario 1: Difficulty in Identifying Compatible AG13 Battery Equivalents

The Problem: B2B buyers often face challenges in identifying the correct AG13 battery equivalents for their devices. This issue is compounded by the existence of multiple names and models that can replace the AG13, such as LR44, A76, and 357. Misidentifying the correct battery can lead to operational disruptions in devices like watches, medical equipment, and remote controls, causing inconvenience and potential losses in productivity.

The Solution: To effectively navigate this compatibility issue, B2B buyers should implement a systematic approach to battery selection. Start by maintaining a comprehensive inventory of devices that utilize AG13 batteries, along with their specific battery requirements. When sourcing replacements, prioritize suppliers that provide detailed specifications for each battery type, including voltage, size, and chemical composition. Leveraging technology, consider using QR codes or apps that can provide instant compatibility checks for various battery models. This proactive strategy not only ensures the right battery is sourced but also minimizes the risk of device malfunction due to incorrect replacements.

Scenario 2: Concerns Over Battery Lifespan and Performance

The Problem: Many B2B buyers are concerned about the lifespan and performance of AG13 battery equivalents, particularly when it comes to bulk purchasing. Batteries that fail prematurely can result in unexpected costs, device downtime, and diminished trust from end-users, especially in sensitive applications like medical devices or high-demand electronic gadgets.

The Solution: To address concerns regarding battery lifespan and performance, it is essential for buyers to conduct thorough supplier evaluations. Request documentation that includes performance metrics, such as average discharge rates and shelf life, to ensure the batteries meet the necessary standards. Additionally, prioritize suppliers who offer a quality guarantee and have a proven track record in the industry. Implementing a rotation system for battery usage can also help optimize performance; ensure that older stock is used first while maintaining a controlled environment for storage to prolong battery life. By investing time in supplier selection and management, buyers can enhance reliability and operational efficiency.

Scenario 3: Environmental Compliance and Disposal Challenges

The Problem: With increasing regulations surrounding the disposal of batteries, B2B buyers are often faced with the challenge of ensuring that AG13 battery equivalents are disposed of in an environmentally friendly manner. This is particularly crucial in regions like Africa and South America, where improper disposal can lead to legal repercussions and negative environmental impacts.

The Solution: B2B buyers should establish a comprehensive battery disposal policy that aligns with local regulations and environmental standards. Partnering with certified recycling programs can facilitate proper disposal and ensure compliance with environmental laws. Buyers can also consider sourcing AG13 equivalents from manufacturers who prioritize eco-friendly practices, such as using sustainable materials or offering recycling programs for used batteries. Educating staff on the importance of responsible disposal and providing accessible recycling options can further enhance compliance efforts. By taking proactive steps in environmental management, businesses can mitigate risks and contribute positively to sustainability efforts.

Strategic Material Selection Guide for ag13 battery equivalent

What Materials Are Commonly Used in AG13 Battery Equivalents?

When selecting materials for AG13 battery equivalents, it is essential to consider the properties and performance characteristics of the materials used in their construction. The most common materials for AG13 equivalents include alkaline, silver oxide, zinc, and nickel. Each material has distinct advantages and limitations that can influence the performance and suitability of the batteries for various applications.

1. Alkaline

Key Properties: Alkaline batteries typically operate at a voltage of 1.5 volts and have a good energy density, which allows for a longer lifespan in devices with moderate power consumption. They are also known for their stable discharge characteristics.

Pros & Cons: Alkaline batteries are cost-effective and widely available. However, they may not perform as well in high-drain applications compared to silver oxide batteries. Their manufacturing process is relatively simple, which contributes to lower costs.

Impact on Application: Alkaline batteries are suitable for devices that require moderate energy, such as remote controls and toys. However, they may not be ideal for devices that demand high energy output, like digital cameras.

Considerations for International Buyers: Compliance with international standards like ASTM and JIS is crucial. Alkaline batteries are generally accepted globally, but buyers should verify local regulations regarding battery disposal and recycling.

2. Silver Oxide

Key Properties: Silver oxide batteries provide a nominal voltage of 1.55 volts, which is slightly higher than alkaline batteries. They offer excellent energy density and stable voltage output over their lifespan.

Pros & Cons: The primary advantage of silver oxide batteries is their superior performance in high-drain applications, making them ideal for watches and medical devices. However, they are more expensive to produce due to the cost of silver, which can limit their use in price-sensitive markets.

Impact on Application: Silver oxide batteries are particularly well-suited for precision devices that require consistent voltage, such as watches and hearing aids. Their higher cost may be justified in applications where reliability is paramount.

Considerations for International Buyers: Buyers should be aware of the environmental impact of silver mining and the importance of proper disposal. Compliance with environmental regulations is critical, especially in regions with strict battery disposal laws.

3. Zinc

Key Properties: Zinc is often used as the anode material in batteries, providing good conductivity and a stable discharge profile. Zinc-based batteries typically operate at 1.5 volts.

Pros & Cons: Zinc batteries are less expensive and have a lower environmental impact compared to silver oxide batteries. However, they may have a shorter shelf life and can be less efficient in high-drain applications.

Impact on Application: Zinc batteries are suitable for low-drain devices, such as calculators and remote controls. Their cost-effectiveness makes them appealing for bulk purchases in emerging markets.

Considerations for International Buyers: Buyers should consider the availability of zinc batteries in their region and the potential for local sourcing. Understanding local market preferences and compliance with international standards can facilitate smoother procurement processes.

4. Nickel

Key Properties: Nickel-based batteries, such as nickel-metal hydride (NiMH), can provide higher energy density and are rechargeable, operating at a nominal voltage of 1.2 volts.

Pros & Cons: The ability to recharge nickel batteries makes them an eco-friendly option, reducing waste. However, they typically have a lower voltage than alkaline and silver oxide batteries, which may limit their use in certain applications.

Impact on Application: Nickel batteries are ideal for applications where frequent recharging is possible, such as in electronic toys and portable devices. Their lower voltage may restrict their use in devices requiring a consistent 1.5 volts.

Considerations for International Buyers: Buyers should evaluate the local infrastructure for battery recycling and the availability of charging solutions. Compliance with international standards for rechargeable batteries is also essential.

Summary Table of Materials for AG13 Battery Equivalents

| Material | Typical Use Case for AG13 Battery Equivalent | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alkaline | Remote controls, toys | Cost-effective and widely available | Performance may drop in high-drain devices | Low |

| Silver Oxide | Watches, medical devices | Superior performance in high-drain apps | Higher production cost due to silver | High |

| Zinc | Calculators, low-drain devices | Cost-effective with lower environmental impact | Shorter shelf life and efficiency issues | Low |

| Nickel | Rechargeable devices, electronic toys | Eco-friendly and rechargeable | Lower voltage may limit application | Medium |

This guide provides a comprehensive overview of the materials used in AG13 battery equivalents, highlighting their properties, advantages, limitations, and considerations for international B2B buyers. Understanding these factors will help businesses make informed decisions when sourcing batteries for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for ag13 battery equivalent

What Are the Main Stages in the Manufacturing Process of AG13 Battery Equivalents?

The manufacturing of AG13 battery equivalents involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Are Materials Prepared for AG13 Battery Production?

Material preparation is the foundational step in battery manufacturing. This involves sourcing high-purity raw materials, such as zinc, silver oxide, and electrolytes. Manufacturers often rely on established suppliers who can provide materials that meet international quality standards. Rigorous testing of incoming materials (Incoming Quality Control, IQC) is essential to confirm their compliance with specifications. This process may involve chemical composition analysis and physical property evaluations.

What Techniques Are Used in Forming AG13 Battery Components?

The forming stage entails the transformation of raw materials into battery components. Key techniques employed during this phase include:

- Mixing: Raw materials are blended to create the active materials for the anode and cathode.

- Pressing: The mixed materials are compacted into the desired shapes using hydraulic or mechanical presses. This step is crucial for ensuring uniform density and performance characteristics.

- Sintering: For some manufacturers, sintering may be applied to enhance the mechanical integrity and electrochemical properties of the components.

Each of these techniques must be carefully controlled to maintain product consistency and reliability.

How Is the Assembly Process Conducted for AG13 Battery Equivalents?

Once individual components are formed, they are assembled into complete batteries. The assembly process typically involves several key steps:

- Component Alignment: Precise alignment of the positive and negative electrodes is essential for optimal performance.

- Electrolyte Filling: The electrolyte is injected into the cell, ensuring it adequately saturates the active materials.

- Sealing: The battery is sealed using advanced techniques to prevent leakage and ensure longevity. This can involve crimping or laser welding, depending on the design.

The assembly phase is critical, as any misalignment or contamination can lead to performance issues.

What Are the Finishing Processes for AG13 Battery Equivalents?

Finishing processes are the final touchpoints in battery manufacturing. These steps include:

- Labeling and Packaging: Batteries are labeled according to international standards and packaged in a manner that protects them during transportation and storage.

- Testing: Finished batteries undergo rigorous testing to confirm they meet specified voltage and current outputs, as well as to check for any defects.

The finishing stage ensures that the product not only functions correctly but also complies with market regulations.

What Quality Control Standards Are Relevant for AG13 Battery Production?

Quality assurance is paramount in battery manufacturing, especially for AG13 equivalents. Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems. This certification demonstrates a commitment to consistent quality and continuous improvement.

Which Industry-Specific Certifications Should B2B Buyers Be Aware Of?

In addition to ISO certifications, specific industry standards such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain applications may apply. These certifications ensure that the batteries meet safety and performance requirements.

What Are the Key Quality Control Checkpoints in Battery Manufacturing?

Quality control is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival.

- In-Process Quality Control (IPQC): Ongoing monitoring during manufacturing to identify and correct issues as they arise.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet all specifications.

These checkpoints are crucial for maintaining high standards and preventing defects.

What Common Testing Methods Are Used for AG13 Battery Quality Assurance?

Various testing methods are employed to ensure battery performance and safety. Common tests include:

- Voltage and Current Testing: Measuring output to confirm it meets specifications.

- Leakage Testing: Ensuring that the battery is properly sealed and does not leak.

- Temperature Cycling: Assessing performance under varying temperatures to ensure reliability in diverse environments.

These tests help identify any potential failures before the batteries reach the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into their quality control practices and compliance with international standards.

- Request Quality Reports: Buyers should ask for documentation, including IQC, IPQC, and FQC reports, to understand the quality metrics the supplier adheres to.

- Third-Party Inspections: Engaging third-party inspectors can offer an unbiased evaluation of the supplier’s manufacturing and quality assurance processes.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Different regions may have varying requirements for certifications and compliance, which can affect market access. Buyers should:

- Understand Regional Regulations: Familiarize themselves with local regulations concerning battery imports, such as environmental guidelines and safety standards.

- Engage Local Experts: Collaborating with local experts can help navigate the complexities of international trade and certification requirements.

By thoroughly understanding the manufacturing processes and quality assurance measures of AG13 battery equivalents, B2B buyers can make informed decisions that align with their operational needs and market standards. This knowledge not only enhances product reliability but also fosters stronger supplier relationships and market competitiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ag13 battery equivalent’

Introduction

This practical sourcing guide provides a comprehensive checklist for B2B buyers interested in procuring AG13 battery equivalents. Given the widespread applications of these batteries in various electronic devices, it’s essential to approach sourcing strategically. This guide will help you navigate the complexities of selecting the right battery equivalent, ensuring quality, compliance, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the AG13 battery equivalents you need. Consider factors such as voltage, dimensions, and chemical composition. Understanding these specifications will help you identify suitable products and avoid compatibility issues with your devices.

- Voltage: Ensure the battery maintains a nominal voltage of 1.5 volts.

- Size: Confirm that the diameter (approximately 11.4 mm) and thickness (around 5.8 mm) meet your device’s requirements.

- Chemical Composition: Decide whether you prefer alkaline or silver oxide options based on performance needs.

Step 2: Research Potential Suppliers

Begin your sourcing process by identifying potential suppliers. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors specializing in AG13 battery equivalents.

- Reputation: Look for suppliers with a strong market presence and positive reviews.

- Experience: Prioritize suppliers with a track record in your industry or related fields.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant certifications. This is crucial for ensuring compliance with international standards and regulations.

- Quality Assurance: Check for ISO certifications and other quality management systems.

- Environmental Compliance: Ensure suppliers adhere to environmental regulations, particularly regarding battery disposal and recycling.

Step 4: Request Product Samples

To assess the quality and performance of the AG13 battery equivalents, request samples from shortlisted suppliers. Testing these samples in your applications is critical to ensure they meet your expectations.

- Performance Testing: Evaluate the battery’s discharge rate and longevity under load conditions.

- Physical Inspection: Check for any manufacturing defects or inconsistencies in size and weight.

Step 5: Compare Pricing and Terms

Once you have assessed product samples, compare pricing and purchasing terms among your shortlisted suppliers. This step is essential for optimizing your procurement budget while ensuring quality.

- Bulk Discounts: Inquire about volume pricing options, especially if you plan to make large purchases.

- Shipping Costs: Consider shipping terms and costs, as these can significantly impact your overall expenditure.

Step 6: Assess After-Sales Support

Evaluate the level of customer support offered by suppliers. Reliable after-sales service can make a significant difference in your sourcing experience.

- Warranty and Returns: Understand the warranty terms and return policies for defective products.

- Technical Support: Ensure that suppliers provide technical assistance for any issues that may arise during the battery’s lifecycle.

Step 7: Finalize and Place Order

After thorough evaluation and comparison, finalize your choice of supplier. Place your order and ensure all terms are clearly documented to avoid misunderstandings.

- Contract Clarity: Include all agreed-upon terms in a formal contract.

- Order Confirmation: Obtain written confirmation of your order details, including delivery timelines and payment terms.

By following this checklist, you will be better positioned to successfully source AG13 battery equivalents that meet your operational needs while ensuring quality and compliance.

Comprehensive Cost and Pricing Analysis for ag13 battery equivalent Sourcing

What Are the Key Cost Components in Sourcing AG13 Battery Equivalents?

When sourcing AG13 battery equivalents, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The chemical composition of AG13 batteries typically involves silver oxide, zinc, and other materials, which can fluctuate in price due to market demand and availability. Buyers should consider the quality of these materials, as higher-grade components can lead to better performance and longevity.

-

Labor: Labor costs are influenced by the manufacturing location. Countries with lower wage standards may offer cost advantages, but this should be balanced against the potential for quality discrepancies.

-

Manufacturing Overhead: This includes expenses related to the production facility, machinery maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, thereby lowering overall production costs.

-

Tooling: The initial investment in tooling for battery production can be significant. Buyers should consider whether a supplier has the necessary tooling capabilities to produce the required battery volumes without incurring excessive costs.

-

Quality Control: Rigorous QC processes ensure that the batteries meet safety and performance standards. While this may add to the cost, it is essential for minimizing returns and maintaining customer satisfaction.

-

Logistics: Shipping costs can vary significantly based on the supplier’s location and the buyer’s region. Incoterms also play a crucial role in defining who bears the cost and risk during transportation.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on the supplier’s pricing strategy and market positioning. Understanding the competitive landscape can provide leverage in negotiations.

How Do Price Influencers Affect AG13 Battery Equivalent Costs?

Several factors influence the pricing of AG13 battery equivalents, including volume requirements, specifications, materials, quality certifications, and supplier-related factors.

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to optimize pricing.

-

Specifications and Customization: Customized batteries or those with specific performance characteristics may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Batteries that meet international standards or have specific certifications (like RoHS or CE) may come at a premium. It is crucial to assess whether these certifications are necessary for your market.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better quality assurance but at a higher price point. Conversely, newer suppliers might provide competitive pricing but with increased risk.

-

Incoterms: Understanding shipping terms is vital for total cost calculations. Different Incoterms dictate who is responsible for shipping costs, insurance, and risks, which can significantly affect the total landed cost.

What Are the Best Tips for Negotiating and Achieving Cost-Efficiency in AG13 Battery Purchases?

B2B buyers can adopt several strategies to enhance cost-efficiency and negotiate effectively when sourcing AG13 battery equivalents.

-

Negotiate on Volume: Leverage bulk purchasing to negotiate better pricing. Suppliers are often willing to offer discounts for larger orders.

-

Consider Total Cost of Ownership (TCO): TCO encompasses not just the purchase price but also the costs of logistics, storage, and disposal. Selecting higher-quality batteries may yield lower TCO in the long run due to reduced failure rates and longer lifespans.

-

Stay Informed on Market Trends: Keeping abreast of market trends regarding material costs, labor rates, and technological advancements can provide valuable insights during negotiations.

-

Evaluate International Pricing Nuances: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional supply chain dynamics that can affect pricing.

-

Conduct Supplier Audits: Prioritize suppliers that demonstrate robust quality control measures. This not only ensures better product quality but can also reduce the overall costs associated with returns and replacements.

In summary, a comprehensive understanding of the cost structure and pricing influencers, along with strategic negotiation tactics, can empower B2B buyers to make informed decisions when sourcing AG13 battery equivalents. As prices can vary widely based on multiple factors, it’s advisable to obtain indicative pricing from multiple suppliers to establish a competitive benchmark.

Alternatives Analysis: Comparing ag13 battery equivalent With Other Solutions

Exploring Alternative Battery Solutions to AG13 Battery Equivalent

In a competitive B2B landscape, selecting the right power source is crucial for maintaining device performance and ensuring operational efficiency. The AG13 battery equivalent is widely recognized for its reliability in powering small electronic devices. However, various alternatives exist that may offer unique advantages depending on specific application requirements. This analysis compares the AG13 battery equivalent against two viable alternatives: the SR44 silver oxide battery and the LR44 alkaline battery.

| Comparison Aspect | AG13 Battery Equivalent | SR44 Silver Oxide Battery | LR44 Alkaline Battery |

|---|---|---|---|

| Performance | 1.5V, good for low-drain devices | 1.5V, higher energy density and longevity | 1.5V, reliable but shorter lifespan |

| Cost | Low-cost, typically $0.11 – $1.50 | Moderate cost, typically $0.85 – $1.50 | Very low cost, typically $0.05 – $0.85 |

| Ease of Implementation | Widely available, easy to replace | Requires careful handling due to sensitivity | Simple installation, readily available |

| Maintenance | Low maintenance, disposable | Low maintenance, but recycling recommended | Low maintenance, but prone to leakage |

| Best Use Case | Watches, calculators, toys | Medical devices, high-performance electronics | General-purpose electronics, remote controls |

Analyzing the Alternatives

What Are the Advantages and Disadvantages of the SR44 Silver Oxide Battery?

The SR44 battery is often considered a superior alternative to the AG13 due to its higher energy density and longer lifespan. It is especially beneficial in applications requiring consistent voltage over extended periods, such as in medical devices and precision instruments. However, the SR44 is generally more expensive and may not be as widely available as the AG13. Its sensitivity to temperature fluctuations also requires careful handling, which may be a concern for some users.

How Does the LR44 Alkaline Battery Compare to the AG13?

The LR44 battery is another common alternative that offers similar voltage and size specifications to the AG13. It is particularly popular for everyday devices like remote controls and toys. The LR44 is generally less expensive, making it a cost-effective choice for bulk purchases. However, it typically has a shorter lifespan compared to the AG13 and SR44, and there is a risk of leakage, which can damage devices. Thus, while it is a practical option for non-critical applications, it may not be ideal for high-performance needs.

Conclusion: Making an Informed Battery Choice for Your Business

When selecting a battery solution for your devices, it is essential to consider factors such as performance requirements, budget constraints, and the specific environment in which the battery will be used. For businesses in Africa, South America, the Middle East, and Europe, understanding the nuances of each option can lead to more informed purchasing decisions. The AG13 battery equivalent offers a reliable choice for low-drain applications, while the SR44 excels in high-performance scenarios. Meanwhile, the LR44 presents a budget-friendly option for general use. By assessing the particular needs of your devices and operations, you can choose the most suitable battery solution that aligns with your business goals.

Essential Technical Properties and Trade Terminology for ag13 battery equivalent

What Are the Key Technical Properties of AG13 Battery Equivalents?

Understanding the technical specifications of AG13 battery equivalents is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties:

1. Nominal Voltage

The AG13 battery typically operates at a nominal voltage of 1.5 volts. This standard voltage is critical as it ensures compatibility with a wide range of devices, including watches, calculators, and medical equipment. For B2B buyers, matching the voltage with device requirements helps avoid operational failures and customer dissatisfaction.

2. Current Capacity

AG13 batteries generally have a maximum continuous current rating of about 20 milliamperes (mA). This specification is vital for devices that require a consistent power supply. Understanding the current capacity helps buyers select batteries that can maintain device performance without premature depletion, which is especially important in high-demand applications.

3. Operating Temperature Range

The operational temperature range for AG13 batteries is typically between -20°C and 60°C. This property is essential for ensuring reliable performance in various environments, from extreme cold to heat. Buyers operating in diverse climates must consider this range to guarantee that batteries will function correctly under local conditions.

4. Dimensions

AG13 batteries have specific dimensions, approximately 11.4 mm in diameter and 5.8 mm in thickness. Proper sizing is crucial for compatibility with devices. Buyers should verify these measurements to prevent issues related to fitment, which can lead to increased costs due to returns or replacements.

5. Chemical Composition

AG13 batteries often use silver oxide (Ag2O) for the positive electrode and zinc (Zn) for the negative electrode, with an electrolyte composed of silver chloride (AgCl) and sodium hydroxide (NaOH). The choice of materials affects the battery’s lifespan and environmental impact. Buyers should consider the chemical makeup to ensure compliance with local regulations and sustainability initiatives.

6. Shelf Life

AG13 batteries can be stored for several years without significant performance loss, given proper conditions. This property is important for inventory management, allowing businesses to stock up without worrying about rapid degradation. Understanding shelf life helps buyers optimize their supply chain and reduce waste.

What Are Common Trade Terms Related to AG13 Battery Equivalents?

Familiarity with industry terminology can greatly enhance communication and negotiation processes. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the battery industry, OEMs often provide batteries that meet specific performance standards. B2B buyers should look for OEMs to ensure product reliability and compatibility with their devices.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their orders and manage inventory effectively. This term helps in negotiating bulk purchases, which can lead to cost savings.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Utilizing RFQs enables businesses to compare options and make informed purchasing decisions, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping and delivery terms. Familiarity with Incoterms helps buyers understand their obligations and rights during transactions, reducing the risk of misunderstandings and disputes.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for inventory management and ensuring that production schedules are met. Buyers should factor in lead times when planning orders to avoid disruptions.

6. Battery Recycling Programs

This term refers to initiatives aimed at the proper disposal and recycling of batteries to minimize environmental impact. B2B buyers should be aware of these programs to ensure compliance with environmental regulations and corporate social responsibility goals.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making processes when sourcing AG13 battery equivalents, ultimately leading to more successful and sustainable business operations.

Navigating Market Dynamics and Sourcing Trends in the ag13 battery equivalent Sector

What Are the Key Market Dynamics and Trends Affecting AG13 Battery Equivalent Sourcing?

The AG13 battery equivalent sector is experiencing significant growth driven by the increasing demand for portable electronic devices and the rising popularity of wearable technology. Global markets, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in consumption of button cell batteries due to the proliferation of gadgets such as smartwatches, calculators, and medical devices. Key trends influencing this market include the adoption of e-commerce platforms for battery procurement, which facilitates easier access to various brands and models, and the shift towards bulk purchasing to optimize cost efficiencies.

Moreover, the competitive landscape is evolving with an influx of both established manufacturers and new entrants, leading to a wider variety of products and price points. Buyers are increasingly looking for high-quality, reliable batteries, which has prompted manufacturers to invest in research and development. This focus on innovation includes enhancing battery performance, extending shelf life, and reducing production costs. Additionally, as the market expands, international B2B buyers must navigate complex supply chains, ensuring timely delivery and compliance with regional regulations, particularly when sourcing from countries like Vietnam and Brazil, which are emerging as manufacturing hubs.

How Important Is Sustainability and Ethical Sourcing in the AG13 Battery Equivalent Market?

Sustainability and ethical sourcing have become paramount considerations for international B2B buyers in the AG13 battery equivalent sector. As environmental awareness grows, companies are increasingly held accountable for their supply chain practices. The AG13 batteries contain heavy metals and chemicals that can pose environmental risks if not disposed of properly. Therefore, sourcing from manufacturers that adhere to stringent environmental regulations is crucial for maintaining corporate responsibility and brand reputation.

Buyers are encouraged to seek suppliers who offer “green” certifications and materials, indicating a commitment to environmentally friendly practices. This includes manufacturers that utilize sustainable production processes, minimize waste, and implement recycling programs for used batteries. Additionally, the rising trend of eco-friendly batteries, such as those that are rechargeable or made from less harmful materials, is appealing to environmentally conscious consumers and businesses alike. By prioritizing sustainability in their procurement processes, B2B buyers can contribute to reducing the environmental impact associated with battery production and disposal.

What Is the Brief Evolution of AG13 Battery Equivalents?

The AG13 battery equivalent has evolved significantly since its inception, adapting to the changing landscape of electronic devices. Originally introduced as a compact power source for watches and calculators, the AG13 battery has expanded its applications to include a diverse range of consumer electronics. Over the years, manufacturers have refined the chemistry and design of these batteries, enhancing their performance and reliability.

The introduction of alternative models, such as LR44, SR44, and A76, has further improved options for consumers, offering interchangeable solutions that cater to various device requirements. As technology continues to advance, the AG13 battery sector is poised to embrace innovations in battery technology, such as increased energy density and the potential for greener alternatives. This evolution not only reflects the demands of modern electronics but also highlights the importance of adaptability in the global battery market.

Frequently Asked Questions (FAQs) for B2B Buyers of ag13 battery equivalent

-

How do I determine the best AG13 battery equivalent for my devices?

To select the ideal AG13 battery equivalent, first identify the voltage and dimensions required by your device. Common replacements include LR44, A76, and SR44 batteries, which share similar specifications. Consult your device’s manual or specifications to ensure compatibility. Additionally, consider the chemical composition; for instance, SR44 batteries often provide longer lifespans due to their silver oxide composition. Finally, check for manufacturer recommendations to avoid any operational issues. -

What factors should I consider when sourcing AG13 battery equivalents internationally?

When sourcing AG13 battery equivalents, consider the supplier’s reputation, product certifications, and quality assurance processes. Verify the manufacturer’s compliance with international safety standards and regulations, especially regarding hazardous materials. Evaluate shipping options, delivery times, and costs to ensure they meet your business timeline. Additionally, assess the supplier’s ability to provide bulk orders and their willingness to accommodate customization requests for specific packaging or branding. -

What is the typical minimum order quantity (MOQ) for AG13 battery equivalents?

The MOQ for AG13 battery equivalents can vary widely among suppliers, typically ranging from 100 to 1,000 units. Factors influencing MOQ include the manufacturer’s production capacity, the type of battery, and the terms of the sales agreement. For larger orders, you may negotiate better pricing or lower MOQs. Always communicate your requirements upfront to ensure the supplier can meet your needs without compromising quality or service. -

What payment terms are commonly offered by suppliers of AG13 battery equivalents?

Common payment terms for AG13 battery equivalents include options like net 30, net 60, or payment in advance. Some suppliers may offer discounts for upfront payments or bulk purchases. It’s crucial to clarify these terms before finalizing your order to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services for higher-value transactions to mitigate financial risks. -

How can I ensure the quality of AG13 battery equivalents from my supplier?

To ensure quality, request product samples before placing a bulk order. Verify that the batteries meet international safety and performance standards, such as ISO certification. Inquire about the supplier’s quality control processes, including testing for capacity, voltage, and leakage. It’s also beneficial to read reviews or seek references from other businesses that have sourced from the same supplier to gauge reliability and product performance. -

What logistics considerations should I be aware of when importing AG13 batteries?

When importing AG13 batteries, consider shipping methods, lead times, and customs regulations in your country. Ensure that the supplier provides necessary documentation, such as safety data sheets and certificates of origin, to facilitate smoother customs clearance. Additionally, be mindful of potential import duties and taxes that may apply. Collaborate with a logistics partner experienced in battery transportation to navigate any special requirements related to hazardous materials. -

Are there eco-friendly alternatives to traditional AG13 battery equivalents?

Yes, there are eco-friendly alternatives to traditional AG13 battery equivalents, including rechargeable lithium-ion batteries and nickel-metal hydride (NiMH) batteries. These options reduce waste and can be more cost-effective in the long run. However, ensure that the alternative battery meets the specific voltage and size requirements of your devices. As environmental awareness grows, many manufacturers are focusing on developing sustainable battery technologies, which could also be a selling point for your business. -

What should I do if I encounter issues with AG13 battery performance?

If you experience performance issues with AG13 batteries, first check that they are correctly installed and compatible with your device. Ensure that the batteries are within their expiration date and have been stored properly. If problems persist, reach out to your supplier for support, as they may offer troubleshooting advice or replacement options. Document any issues for warranty claims and consider evaluating alternative suppliers if the performance does not meet expectations consistently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Ag13 Battery Equivalent Manufacturers & Suppliers List

1. Batteries and Butter – AG13 Alkaline Watch Batteries

Domain: batteriesandbutter.com

Registered: 2003 (22 years)

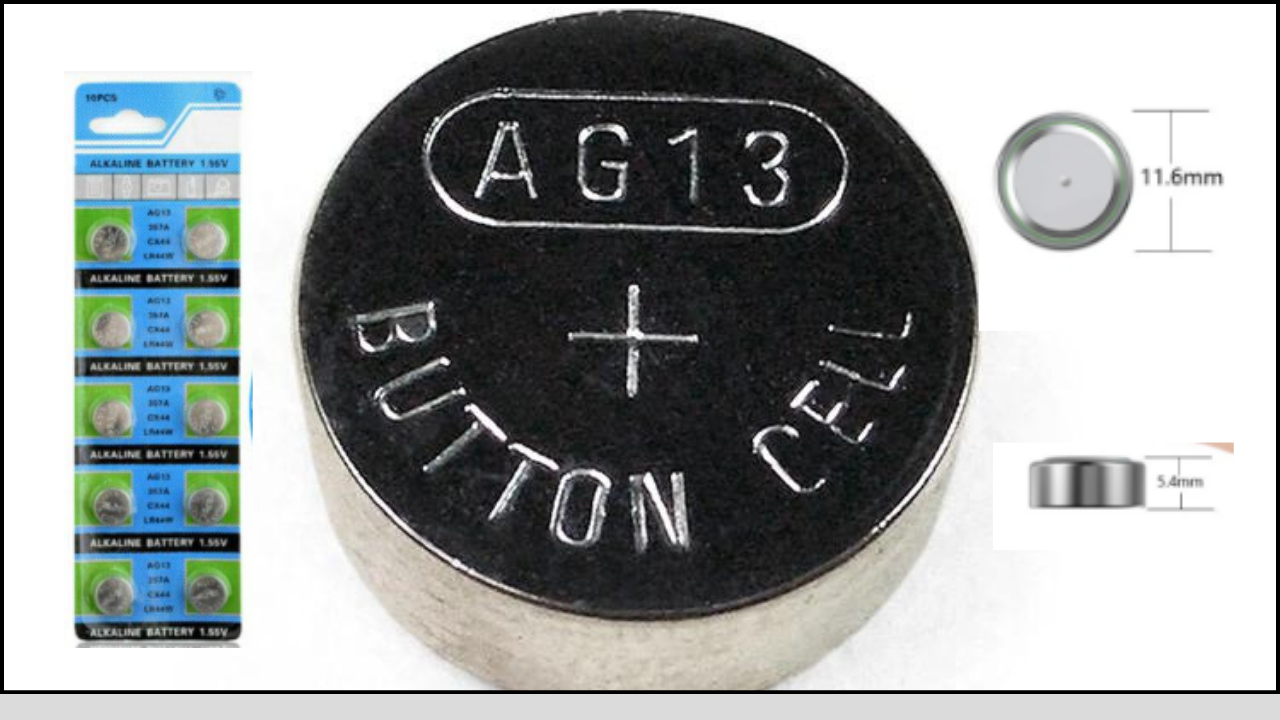

Introduction: AG13 Alkaline Watch Batteries are also known as LR44, 157, A74, or LR1154. They are equivalent in size and voltage to SR44 (357) Silver Oxide batteries. Key specifications include:

– Standard voltage: 1.5 volts

– Termination voltage: 0.9 volts

– Capacity: 130mAh

– Cell size: 11.6 x 5.4mm

– Operating temperature: -10C to +60C

– Recommended storage temperature: below 25C

Available brands inc…

2. Reddit – AG13 Button Batteries

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: AG13 batteries (1.5 V button batteries) are also known as LR44, 157, A76, and LR1154. They are slightly smaller than a thumbnail and were mentioned to possibly be made with ‘silver’ (AG) like some watch batteries.

3. Medic Batteries – AG13 Button Cell Batteries

Domain: medicbatteries.com

Registered: 2005 (20 years)

Introduction: AG13 Button Battery, AG13 Button Cell Batteries, AG13 Equivalent, Energizer 357 – AG13 Equivalent, used in watches, medical equipment, laser pointers, low prices, volume discounts, free shipping, bulk packaging, 100% guaranteed, 4 year minimum shelf life.

4. Walmart – AG13/LR44 Alkaline Button Watch Battery

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – AG13/LR44 Alkaline Button Watch Battery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. G&T’s – Battery Size Charts & Duracell Alkaline Packs

Domain: gts-shop.co.uk

Registered: 2019 (6 years)

Introduction: Battery Equivalent Size Charts – G&T’s Original Warehouse. Common Household Batteries: Duracell Simply Alkaline AA Batteries – Pack of 6 £3.99 (£0.67 / 1 pc), Duracell Simply Alkaline AAA Batteries – Pack of 6 £3.99 (£0.67 / 1 pc), Duracell Simply Alkaline AA Batteries – Pack of 12 £7.49 (£0.62 / 1 pc), Duracell Simply Alkaline AAA Batteries – Pack of 12 £7.49 (£0.62 / 1 pc), JCB Ultra Alkaline AA…

6. Battery Equivalents – Essential Battery Types

Domain: batteryequivalents.com

Registered: 2018 (7 years)

Introduction: Battery Types: LR44, AG13, SG13, LR1154, SR44, SR44SW, 303, 357, A76

Common Applications: Wrist watches, small flashlights, calculators, remote control devices, thermometers, laser pointers, small electronic units.

Battery Chemistry: Alkaline (LR44/LR1154) and Silver-Oxide (SR44/SR1154).

Dimensions: 11.6 mm diameter, 5.4 mm height.

Nominal Voltage: Alkaline – 1.5V, Silver-Oxide – 1.55V.

End-Point …

7. Batteries in a Flash – Watch Battery Cross Reference Chart

Domain: batteriesinaflash.com

Registered: 2003 (22 years)

Introduction: Watch Battery Cross Reference Chart – Find Equivalent Watch Batteries. The chart includes various brands and their corresponding battery models, dimensions (in mm and inches), and equivalent batteries. Examples include:

– Maxell SR626SW equivalent to 377

– Energizer 303 equivalent to SR44SW

– Dimensions provided for each battery type. The chart is designed for easy navigation to find the right bat…

8. BuyABattery – LR44 Battery Equivalent

Domain: buyabattery.co.uk

Registered: 2005 (20 years)

Introduction: 10 x LR44 Battery Equivalent G13 G13A G13-A AG13 V13GA A76 GPA76 1.5V

Strategic Sourcing Conclusion and Outlook for ag13 battery equivalent

In the competitive landscape of battery sourcing, particularly for AG13 equivalents, strategic sourcing emerges as a crucial element for B2B buyers. By focusing on reliable manufacturers such as Duracell, Energizer, and Panasonic, companies can ensure consistent quality and performance, which is vital for applications ranging from watches to medical devices. Understanding the interchangeable nature of AG13 with batteries like LR44 and SR44 allows buyers to optimize inventory management and reduce costs through bulk purchasing strategies.

Moreover, environmental considerations are increasingly influencing procurement decisions. As manufacturers pivot towards eco-friendly alternatives, sourcing from companies committed to sustainability not only enhances corporate responsibility but also aligns with global regulatory trends.

As we look to the future, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to leverage these insights for informed sourcing decisions. By prioritizing quality, compatibility, and sustainability, you can position your business for success in a rapidly evolving market. Take action now to secure the best AG13 battery equivalents and drive your operational efficiency forward.