240 Centigrade As Fahrenheit Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for 240 centigrade as fahrenheit

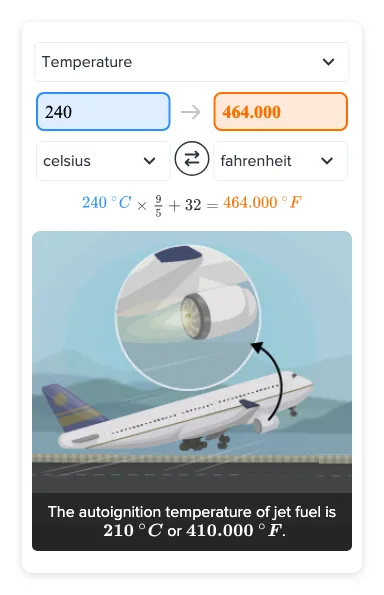

In today’s global market, accurately converting temperatures such as 240 degrees Celsius to Fahrenheit (464°F) is crucial for B2B buyers across various industries, including food processing, manufacturing, and logistics. The challenge lies not only in the conversion itself but also in understanding how these temperature metrics impact product quality, compliance, and safety standards. This guide delves into the intricacies of temperature conversion, providing insights into the applications of 240°C in diverse sectors, from cooking and baking to industrial processes.

Our comprehensive resource covers essential aspects such as the types of equipment that operate at this temperature, supplier vetting processes, and cost considerations. By navigating through these elements, international buyers from regions like Africa, South America, the Middle East, and Europe—especially countries like Vietnam and Brazil—can make informed purchasing decisions. This guide empowers you to assess suppliers effectively, ensuring that they meet both local and international standards for temperature-sensitive products.

With actionable insights and expert recommendations, you will be equipped to enhance operational efficiency and maintain product integrity. Understanding the significance of temperature conversion in your sourcing strategies not only mitigates risks but also positions your business for competitive advantage in the ever-evolving global landscape.

Understanding 240 centigrade as fahrenheit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Conversion | Direct conversion from Celsius to Fahrenheit. | Food processing, chemical industries. | Pros: Easy to calculate, universally understood. Cons: Limited to basic temperature applications. |

| Industrial Heating Equipment | Equipment rated for high temperatures (240°C). | Manufacturing, metalworking. | Pros: Designed for efficiency at high temps. Cons: High initial investment, maintenance costs. |

| Culinary Applications | Specific to baking and cooking temperatures. | Restaurants, catering services. | Pros: Essential for precise cooking. Cons: Requires knowledge of conversions for international recipes. |

| Laboratory Equipment | Precision instruments for research and testing. | Scientific research, quality control. | Pros: Highly accurate measurements. Cons: Costly and requires specialized training. |

| Environmental Controls | Systems that manage temperature for climate control. | HVAC, greenhouse management. | Pros: Essential for maintaining optimal conditions. Cons: Complex setup and ongoing operational costs. |

What are the Key Features of Standard Conversion for 240°C to Fahrenheit?

Standard conversion is the most basic method for translating temperature values between Celsius and Fahrenheit. It utilizes the straightforward formula where 240°C equates to 464°F. This method is primarily applicable in industries such as food processing and chemical manufacturing, where temperature monitoring is crucial. The simplicity of this conversion makes it universally understood, but it may not suffice for specialized applications requiring advanced precision.

How Does Industrial Heating Equipment Utilize 240°C?

Industrial heating equipment, rated for high temperatures like 240°C, is essential in sectors such as manufacturing and metalworking. These systems are designed to operate efficiently at elevated temperatures, ensuring productivity and safety. While they provide significant advantages in terms of performance, the initial investment and maintenance costs can be substantial, making it vital for businesses to assess their long-term needs and budget.

Why are Culinary Applications Significant for 240°C?

In culinary contexts, 240°C is a common temperature for baking and roasting, particularly in commercial kitchens and catering services. Understanding this conversion is crucial for chefs and food service professionals who may work with international recipes. While precise temperature management enhances culinary outcomes, it also necessitates a solid grasp of conversions, which can be challenging for some in the industry.

What Role Does Laboratory Equipment Play in Temperature Accuracy?

Laboratory equipment designed for high-temperature applications ensures precision in scientific research and quality control processes. Such instruments often require rigorous calibration and are essential in fields ranging from pharmaceuticals to environmental testing. While they offer unmatched accuracy, the associated costs and the need for specialized training can be barriers for some organizations.

How Do Environmental Controls Benefit from Understanding 240°C?

Environmental control systems that maintain temperatures around 240°C are vital in HVAC and greenhouse management. These systems ensure optimal conditions for various processes and living organisms. However, setting up these systems can be complex and may involve significant operational costs, making it essential for businesses to evaluate their specific requirements and budget constraints before implementation.

Key Industrial Applications of 240 centigrade as fahrenheit

| Industry/Sector | Specific Application of 240 centigrade as fahrenheit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Baking and roasting in industrial ovens | Ensures optimal cooking conditions for food safety and quality | Equipment must withstand high temperatures; energy efficiency is crucial. |

| Chemical Manufacturing | Polymerization processes | Facilitates the production of high-performance materials | Requires temperature control systems; compliance with safety regulations is essential. |

| Textile Production | Dyeing and finishing processes | Enhances colorfastness and fabric quality | Sourcing sustainable chemicals and equipment that can handle high temps is vital. |

| Metal Fabrication | Heat treatment of metals | Increases material strength and durability | Need for specialized furnaces and adherence to metallurgical standards. |

| Pharmaceutical Industry | Sterilization of equipment and products | Ensures product safety and compliance with health regulations | Must meet stringent safety and quality standards; sourcing certified sterilization equipment is key. |

How is 240 Degrees Celsius (464 Degrees Fahrenheit) Used in Food Processing?

In the food processing industry, 240 degrees Celsius is commonly utilized for baking and roasting in industrial ovens. This high temperature is crucial for achieving the desired texture and flavor in baked goods, ensuring that products are cooked thoroughly and safely. For international buyers, particularly in regions like Africa and South America, sourcing high-quality industrial ovens that can maintain this temperature consistently is essential. Additionally, equipment energy efficiency and durability are significant considerations to reduce operational costs and enhance productivity.

What Role Does 240 Degrees Celsius Play in Chemical Manufacturing?

In the chemical manufacturing sector, 240 degrees Celsius is often employed in polymerization processes, which are essential for creating high-performance materials such as plastics and resins. This temperature allows for the efficient reaction of monomers, leading to improved material properties. Buyers from the Middle East and Europe must prioritize sourcing reliable temperature control systems and ensure compliance with safety regulations to mitigate risks associated with high-temperature operations. The selection of suppliers with a proven track record in providing high-quality equipment is also critical.

How is 240 Degrees Celsius Applied in Textile Production?

The textile industry utilizes 240 degrees Celsius in dyeing and finishing processes to enhance the colorfastness and overall quality of fabrics. This temperature allows dyes to bond effectively with textile fibers, ensuring vibrant and durable colors. For B2B buyers, particularly in emerging markets like Vietnam and Brazil, sourcing sustainable chemicals and machinery capable of withstanding high temperatures is vital. Furthermore, understanding local environmental regulations and opting for eco-friendly solutions can provide a competitive advantage in the market.

Why is 240 Degrees Celsius Important in Metal Fabrication?

In metal fabrication, heat treatment processes often require temperatures around 240 degrees Celsius to improve the strength and durability of metals. This application is crucial for industries such as automotive and aerospace, where material performance is paramount. Buyers should consider sourcing specialized furnaces that can achieve and maintain this temperature while adhering to metallurgical standards. Ensuring that suppliers offer equipment capable of precise temperature control and monitoring is essential for maintaining product integrity.

How Does 240 Degrees Celsius Facilitate Sterilization in the Pharmaceutical Industry?

In the pharmaceutical sector, 240 degrees Celsius is employed for sterilizing equipment and products, ensuring compliance with stringent health regulations. This high temperature effectively eliminates pathogens, safeguarding product safety. International buyers must prioritize sourcing certified sterilization equipment that meets industry standards. Additionally, understanding the specific sterilization requirements for different products and ensuring suppliers provide comprehensive support and training can enhance operational efficiency and compliance.

3 Common User Pain Points for ‘240 centigrade as fahrenheit’ & Their Solutions

Scenario 1: Miscalculating Temperature Conversions in Industrial Processes

The Problem: In manufacturing environments, precision is paramount. A B2B buyer responsible for equipment that operates at high temperatures may encounter significant challenges if they mistakenly convert 240 degrees Celsius to Fahrenheit. For instance, if a supplier specifies a temperature of 240°C (464°F) for a heat treatment process, an incorrect conversion could lead to improper settings on machinery, resulting in product defects or even equipment damage. This miscalculation can cause delays in production and increase costs, ultimately impacting the company’s bottom line.

The Solution: To mitigate these risks, it’s essential to implement a robust temperature conversion protocol. Buyers should invest in reliable temperature conversion tools or software that accurately convert Celsius to Fahrenheit and vice versa. Additionally, providing training to staff on the importance of precise temperature readings and conversions can enhance overall operational accuracy. Regular audits of equipment settings and conversion processes can further ensure that all temperatures are correctly understood and applied in the manufacturing process. By fostering a culture of accuracy and accountability, companies can significantly reduce the risks associated with temperature miscalculations.

Scenario 2: Navigating International Standards and Compliance

The Problem: International B2B buyers often face the challenge of differing temperature standards across regions. For example, a buyer in Brazil may need to ensure that products requiring processing at 240°C are compliant with local regulations, which might reference temperatures in Fahrenheit. This discrepancy can lead to confusion and potential compliance issues, especially when dealing with exports to countries where Fahrenheit is the standard. Non-compliance can result in fines, product recalls, and reputational damage.

The Solution: To navigate these international standards effectively, it is crucial for buyers to familiarize themselves with the temperature regulations specific to their target markets. Collaborating with local experts or regulatory consultants can provide valuable insights into compliance requirements. Additionally, creating a comprehensive temperature conversion guide that includes both Celsius and Fahrenheit values can serve as a quick reference for all stakeholders involved. Regularly updating this guide to reflect any changes in regulations ensures that compliance is consistently met. Furthermore, investing in training programs that educate staff on international standards will promote a more informed workforce, capable of addressing compliance challenges proactively.

Scenario 3: Difficulty in Communicating Temperature Requirements with Suppliers

The Problem: Effective communication with suppliers is critical in B2B transactions. When a buyer specifies that a product needs to be treated at 240°C, but the supplier interprets this in Fahrenheit, it can lead to misunderstandings that compromise product quality. Such communication barriers often stem from differences in the measurement systems used across regions. This issue can delay shipments, increase costs, and lead to dissatisfaction on both sides.

The Solution: To enhance communication and reduce misunderstandings, buyers should adopt a standardized temperature specification format that includes both Celsius and Fahrenheit values. For instance, when placing an order, specifying “240°C (464°F)” can eliminate ambiguity. Additionally, establishing clear communication protocols with suppliers that emphasize the importance of temperature accuracy is essential. Utilizing digital platforms that facilitate real-time communication and documentation can also streamline the ordering process. Regular meetings with suppliers to review specifications and ensure clarity on technical requirements will further strengthen relationships and minimize the risk of errors in future transactions. By fostering transparent communication channels, B2B buyers can ensure that their temperature requirements are understood and met consistently.

Strategic Material Selection Guide for 240 centigrade as fahrenheit

What Materials Are Suitable for Applications at 240°C (464°F)?

When selecting materials that can withstand temperatures of 240°C (464°F), it is essential to consider their thermal properties, mechanical strength, and compatibility with the intended media. Below is an analysis of four commonly used materials in high-temperature applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel exhibits excellent mechanical strength and corrosion resistance at elevated temperatures. It typically has a temperature rating well above 240°C, making it suitable for various applications.

Pros & Cons:

Stainless steel is highly durable and resistant to oxidation, which is crucial in high-temperature environments. However, it can be relatively expensive compared to other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive chemicals and steam. Its robustness makes it a preferred choice for components in the food and beverage industry, as well as in chemical processing.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4401. Additionally, sourcing from reputable suppliers who adhere to quality certifications is crucial, especially in regions like Africa and South America, where material quality can vary.

2. Inconel

Key Properties:

Inconel is a high-performance nickel-chromium alloy known for its ability to withstand extreme temperatures and pressures. It maintains its mechanical properties even at elevated temperatures.

Pros & Cons:

The key advantage of Inconel is its superior resistance to oxidation and corrosion, making it ideal for harsh environments. However, it is one of the more expensive materials, and its machining can be complex, requiring specialized tools.

Impact on Application:

Inconel is commonly used in aerospace and chemical processing applications where high-temperature stability is critical. It is particularly effective in environments where exposure to corrosive gases is a concern.

Considerations for International Buyers:

Compliance with specifications such as ASTM B168 is essential. Buyers from the Middle East and Europe should also consider the supply chain logistics associated with sourcing Inconel, as it may not be as readily available in some regions.

3. PTFE (Polytetrafluoroethylene)

Key Properties:

PTFE is a fluoropolymer that remains stable at high temperatures, with a continuous service temperature of about 260°C (500°F). It exhibits excellent chemical resistance.

Pros & Cons:

PTFE is lightweight and has low friction properties, making it ideal for seals and gaskets. However, it can be prone to deformation under mechanical stress and is not as durable as metals.

Impact on Application:

PTFE is widely used in applications requiring chemical resistance, such as in the pharmaceutical and food industries. Its non-stick properties make it suitable for various cooking and processing equipment.

Considerations for International Buyers:

Ensure that the PTFE meets international standards such as ASTM D4894. Buyers should also verify the supplier’s ability to provide consistent quality, especially in regions where manufacturing standards may vary.

4. Ceramic Materials

Key Properties:

Ceramics can withstand high temperatures and exhibit excellent thermal stability. They are often used in applications where thermal insulation is necessary.

Pros & Cons:

The main advantage of ceramics is their ability to withstand extreme temperatures without deformation. However, they are brittle and can fracture under mechanical stress, limiting their use in load-bearing applications.

Impact on Application:

Ceramics are often used in thermal barriers, insulators, and components in high-temperature furnaces. They are particularly effective in environments where chemical resistance is also required.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ISO 13006 for ceramic tiles or ASTM C373 for ceramic materials. It’s crucial to assess the local availability of high-quality ceramics, especially in developing markets.

Summary Table

| Material | Typical Use Case for 240 centigrade as fahrenheit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing equipment, chemical tanks | Excellent corrosion resistance | Higher cost and manufacturing complexity | Medium |

| Inconel | Aerospace components, chemical reactors | Superior oxidation resistance | High cost and complex machining | High |

| PTFE | Seals, gaskets in chemical applications | Lightweight and low friction | Prone to deformation under stress | Medium |

| Ceramic | Thermal barriers, insulators | High-temperature stability | Brittle and prone to fracture | Medium |

This guide provides insights into material selection for applications at 240°C (464°F), emphasizing the importance of understanding the properties and implications of each material for international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for 240 centigrade as fahrenheit

What Are the Main Manufacturing Processes Involved in Achieving 240 Degrees Celsius as Fahrenheit?

When discussing the conversion of 240 degrees Celsius to Fahrenheit, which is equivalent to 464 degrees Fahrenheit, it’s essential to consider the manufacturing processes that might require such high-temperature applications. Industries such as food processing, ceramics, and certain metalworks often operate at these temperatures. Understanding the main stages of manufacturing—material preparation, forming, assembly, and finishing—helps B2B buyers make informed purchasing decisions.

How Is Material Prepared for High-Temperature Applications?

Material preparation is the first step in the manufacturing process. It involves selecting the right materials that can withstand high temperatures without compromising their structural integrity. Common materials include heat-resistant alloys, specialized ceramics, and certain polymers designed for thermal stability.

During this stage, suppliers typically conduct thorough inspections of raw materials to ensure they meet specific chemical and physical properties. This is crucial for international buyers, especially those from regions such as Africa and South America, where sourcing high-quality materials can sometimes be challenging. B2B buyers should request material certification documents, including tensile strength and thermal properties, to validate the material’s appropriateness for high-temperature applications.

What Techniques Are Used in the Forming Process?

The forming process involves shaping the prepared materials into desired configurations. Techniques such as casting, forging, and extrusion are commonly employed for materials that need to endure high temperatures.

- Casting is often used for metals and involves pouring molten material into molds. This technique is advantageous for creating complex shapes.

- Forging involves shaping materials through compressive forces, often providing enhanced strength and durability.

- Extrusion is useful for creating long, uniform shapes and can be applied to both metals and polymers.

Each of these techniques requires specialized equipment that can maintain the necessary temperature and pressure. B2B buyers should inquire about the specific techniques employed by suppliers to ensure they align with their product requirements.

How Is Assembly Managed for High-Temperature Components?

Assembly is the stage where individual components are brought together to form a complete product. For products that operate at 240 degrees Celsius, it’s vital to use assembly techniques that ensure durability and thermal resistance.

Welding, brazing, and mechanical fastening are common methods used in high-temperature assemblies. Each method has its pros and cons, particularly concerning thermal expansion and contraction during temperature fluctuations. B2B buyers should ensure that suppliers use appropriate techniques for the specific materials being assembled and ask for documentation that outlines the assembly process.

What Finishing Techniques Are Used to Ensure Quality?

Finishing processes enhance the surface quality and performance of the manufactured products. Techniques such as heat treatment, surface hardening, and protective coatings are often applied to improve durability and resistance to oxidation at high temperatures.

- Heat treatment alters the microstructure of materials to enhance properties such as hardness and strength.

- Surface hardening increases wear resistance, which is crucial for components exposed to high temperatures.

- Protective coatings may be applied to prevent corrosion and oxidation, especially in humid environments or when the products will be exposed to various chemicals.

B2B buyers should verify that the finishing techniques used align with industry standards and are suitable for the operational environment of the product.

What Quality Assurance Measures Should Be Considered?

Quality assurance (QA) is critical in ensuring that manufactured products meet both international and industry-specific standards. For high-temperature applications, adherence to quality standards such as ISO 9001 is essential, as it provides a framework for consistent quality management practices.

Which International Standards Are Relevant for High-Temperature Manufacturing?

ISO 9001 focuses on quality management systems and is applicable across various industries. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for the oil and gas sector may be relevant. B2B buyers should request evidence of compliance with these standards from suppliers to ensure product safety and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical in the manufacturing process to ensure that every stage meets the required specifications. Common checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to confirm they meet specifications.

- In-Process Quality Control (IPQC): Monitors production processes to identify any deviations from standards during manufacturing.

- Final Quality Control (FQC): Conducts comprehensive testing on finished products to ensure they meet all specifications before shipment.

B2B buyers should inquire about the QC procedures employed by suppliers and request access to inspection reports to verify compliance with required standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the reliability of suppliers, B2B buyers can conduct audits and inspections. These can be third-party evaluations or buyer-conducted audits to verify compliance with quality standards. Additionally, requesting detailed QC reports and certifications can provide insights into the supplier’s quality practices.

Buyers should also consider the nuances of QC and certification requirements that may vary across regions. For instance, suppliers in Europe may need different certifications than those in Africa or South America. Understanding these differences is crucial for international B2B transactions.

Conclusion: Ensuring Quality in High-Temperature Manufacturing

Understanding the manufacturing processes and quality assurance measures for products operating at 240 degrees Celsius (464 degrees Fahrenheit) is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, and ensuring compliance with international standards, buyers can significantly enhance their procurement decisions. Prioritizing thorough supplier evaluations and maintaining a robust quality assurance process will help mitigate risks and ensure the reliability of high-temperature applications across diverse industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘240 centigrade as fahrenheit’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source products or services that require an understanding of temperature conversions, specifically from 240 degrees Celsius to Fahrenheit (464°F). Understanding these conversions is vital in various industries, including food processing, manufacturing, and scientific research, where precise temperature specifications are crucial.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the temperature specifications in your procurement process. This includes understanding the operational needs that necessitate the 240°C (464°F) standard.

- Importance: Defining these specifications ensures that suppliers can meet your needs effectively.

- Look for: Specific applications, such as cooking, sterilization, or material processing, that require this temperature.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers who can provide the products or services relevant to your temperature requirements. Look for companies specializing in temperature-sensitive materials or equipment.

- Importance: Identifying specialized suppliers will increase the likelihood of receiving products that meet your quality standards.

- Look for: Supplier experience in your industry and reviews from previous clients.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses in similar sectors.

- Importance: A comprehensive evaluation helps mitigate risks associated with supplier reliability and product quality.

- Look for: Supplier certifications and adherence to international quality standards.

Step 4: Verify Product Specifications and Compliance

Ensure that the products you are considering meet the necessary temperature specifications and comply with relevant industry regulations.

- Importance: Compliance with standards is critical for safety and operational efficiency.

- Look for: Documentation that certifies the product’s ability to perform at 240°C, including safety data sheets and technical data sheets.

Step 5: Request Samples for Testing

Before finalizing any purchase, ask for samples of the products or materials to test their performance under the specified temperature conditions.

- Importance: Testing samples helps verify that the products meet your operational requirements and withstand the required temperatures.

- Look for: Consistency in performance during testing, ensuring that products can reliably operate at 240°C.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms.

- Importance: Clear agreements help prevent misunderstandings and ensure that both parties are aligned on expectations.

- Look for: Flexibility in payment terms and the ability to meet your delivery schedule.

Step 7: Establish a Quality Assurance Protocol

After procurement, implement a quality assurance protocol to monitor the performance of the sourced products over time.

- Importance: Continuous monitoring helps maintain product integrity and operational efficiency.

- Look for: Mechanisms for feedback and corrective actions if the products do not meet the expected standards during use.

By following this checklist, B2B buyers can effectively source products and services that require precise temperature specifications, ensuring operational success and compliance with industry standards.

Comprehensive Cost and Pricing Analysis for 240 centigrade as fahrenheit Sourcing

When considering the conversion of 240 degrees Celsius to Fahrenheit, which translates to 464 degrees Fahrenheit, it is essential for B2B buyers to understand the underlying cost structure and pricing factors associated with sourcing materials or products that require such temperature specifications. Here’s a breakdown of cost components, price influencers, and strategic buyer tips for international markets, particularly in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing at 240 Degrees Celsius?

Materials: The choice of materials that can withstand high temperatures significantly impacts costs. For example, materials such as high-grade metals, ceramics, or specialized composites can be more expensive than standard materials. Ensure that the selected materials comply with the necessary safety and performance standards.

Labor: Labor costs vary by region and are influenced by the complexity of the manufacturing process. Skilled labor may be required for precision engineering and assembly, which can increase labor costs. Understanding local labor markets can provide insights into potential cost-saving opportunities.

Manufacturing Overhead: This includes expenses related to factory operations that are not directly tied to the production of specific goods. Overhead costs can include utilities, facility maintenance, and administrative expenses, which should be factored into the total cost of production.

Tooling: The cost of tooling, such as molds or dies required for high-temperature applications, can be significant. Buyers should consider the initial investment in tooling and its impact on per-unit costs, especially when ordering in bulk.

Quality Control (QC): Implementing robust QC measures is crucial for products designed for high-temperature applications. The costs associated with testing and certification can vary, but they are essential for ensuring product reliability and safety.

Logistics: Shipping costs can vary widely based on the destination and the weight or volume of the products being sourced. Additionally, the choice of Incoterms can affect overall logistics costs and responsibilities.

Margin: Suppliers will typically include a margin that reflects their operational costs and desired profit level. Understanding the typical margins within your industry can aid in negotiations.

What Price Influencers Should Buyers Be Aware Of?

Volume/MOQ: Minimum order quantities (MOQ) often play a significant role in pricing. Larger volumes may lead to bulk discounts, while smaller orders could incur higher per-unit costs.

Specifications and Customization: Customized solutions that meet specific performance criteria can drive up costs. Buyers should carefully evaluate whether customization is necessary or if standard options suffice.

Materials and Quality Certifications: The quality of materials can significantly influence pricing. Products that require certifications for safety or performance are generally more expensive due to the additional testing and compliance processes.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven track record, while new entrants may offer lower prices to gain market share.

Incoterms: Understanding the implications of different Incoterms is crucial for managing logistics costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can lead to variations in pricing based on the responsibilities assigned to buyers and sellers.

How Can Buyers Negotiate for Better Pricing?

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with sourcing, including maintenance, durability, and potential downtimes. A higher upfront cost may be justified by lower TCO.

Leverage Volume Discounts: If feasible, consolidate orders to meet MOQ thresholds and negotiate better pricing based on larger volumes.

Explore Alternative Suppliers: Conduct market research to identify multiple suppliers that can meet the specifications for products operating at 240 degrees Celsius. This can provide leverage in negotiations and alternative options in case of supply chain disruptions.

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing agreements and priority service, which is particularly beneficial in fluctuating markets.

Disclaimer on Indicative Prices

Prices for materials and products that withstand 240 degrees Celsius can vary significantly based on market conditions, supplier negotiations, and regional economic factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and optimal sourcing strategies.

Alternatives Analysis: Comparing 240 centigrade as fahrenheit With Other Solutions

In a global market where precision in temperature measurement is vital across various industries, understanding the conversion of temperatures like 240 degrees Celsius to Fahrenheit (464 degrees Fahrenheit) is essential. This section explores viable alternatives to the traditional Celsius-to-Fahrenheit conversion, allowing B2B buyers to make informed decisions based on their operational needs.

| Comparison Aspect | 240 Centigrade As Fahrenheit | Digital Temperature Converters | Mobile Apps for Temperature Conversion |

|---|---|---|---|

| Performance | Accurate conversion (464°F) | Highly accurate, real-time data | Quick conversion, varying accuracy based on app |

| Cost | Free (manual calculation) | Medium (initial purchase) | Low to free (app download) |

| Ease of Implementation | Simple mathematical formula | Requires setup and calibration | Easy to download and use |

| Maintenance | No maintenance required | Regular calibration needed | Minimal maintenance (software updates) |

| Best Use Case | Quick reference for manual conversions | Industrial applications requiring precision | Everyday use, casual conversions |

What Are the Pros and Cons of Using Digital Temperature Converters?

Digital temperature converters provide a high level of accuracy and efficiency, making them suitable for industrial applications where precision is critical. They often feature advanced capabilities such as data logging and integration with other systems. However, they come with a medium cost and require proper setup and calibration to ensure accuracy. Regular maintenance is also necessary to keep the device functioning correctly, which can add to operational overhead.

How Do Mobile Apps for Temperature Conversion Compare?

Mobile apps for temperature conversion are an increasingly popular choice due to their accessibility and ease of use. Most apps are either free or available at a low cost, making them attractive for businesses that need quick, casual conversions. However, the accuracy can vary significantly between different applications, and they may not be suitable for high-stakes environments requiring precise measurements. Maintenance is minimal, primarily involving software updates, but users should ensure they choose reputable apps to avoid inaccuracies.

Conclusion: How Should B2B Buyers Choose the Right Temperature Conversion Solution?

When selecting a temperature conversion solution, B2B buyers should consider their specific operational needs. For those requiring high precision and integration into complex systems, digital temperature converters may be the best choice despite the initial investment and maintenance requirements. Conversely, businesses that need simple, quick conversions for everyday use might find mobile apps to be more efficient and cost-effective. Ultimately, understanding the unique demands of your operations will guide you in selecting the most appropriate solution for converting 240 degrees Celsius to Fahrenheit and beyond.

Essential Technical Properties and Trade Terminology for 240 centigrade as fahrenheit

What Are the Key Technical Properties of 240°C in Fahrenheit?

When discussing the conversion of 240°C to Fahrenheit (464°F), it is crucial for B2B buyers to understand several technical properties and specifications that may affect their operations, particularly in manufacturing, food processing, and industrial applications. Here are some essential properties to consider:

1. Temperature Tolerance

Temperature tolerance refers to the acceptable range of temperature variation for materials and processes. In industries such as food production or chemical manufacturing, maintaining precise temperatures is vital for product quality and safety. Understanding the temperature tolerance for equipment operating at 240°C can help ensure compliance with industry standards and reduce the risk of product failure.

2. Material Grade

Different materials respond differently at high temperatures. For instance, stainless steel, often used in manufacturing equipment, has specific grades (like 304 or 316) that determine its heat resistance. When operating at or near 240°C, selecting the appropriate material grade is essential to prevent deformation or failure during operations, which could lead to costly downtime or safety hazards.

3. Thermal Conductivity

Thermal conductivity is a measure of how well a material conducts heat. In processes where 240°C is a critical operating temperature, selecting materials with the right thermal conductivity ensures efficient heat transfer, preventing overheating and ensuring energy efficiency. This property is particularly important in industries like food processing, where maintaining specific temperatures can impact food safety and quality.

4. Heat Capacity

Heat capacity is the amount of heat energy required to raise the temperature of a substance. In practical terms, understanding the heat capacity of materials used at 240°C helps in determining the energy requirements for heating or cooling processes. This information is crucial for energy management and optimizing operational costs in manufacturing processes.

5. Durability Under Heat Stress

Materials and components used at high temperatures must be durable and resistant to thermal stress. This includes evaluating how materials expand, contract, or change properties at elevated temperatures. For B2B buyers, selecting components that can withstand the thermal stresses associated with 240°C operations is vital for long-term reliability and reduced maintenance costs.

What Are Common Trade Terms Related to Temperature Conversions?

Understanding industry jargon is essential for effective communication in B2B transactions. Here are some common terms related to temperature conversions and their significance:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of temperature-sensitive applications, OEMs must ensure their products can withstand specific temperatures, such as 240°C, which may influence their design and material selection.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For industries dealing with specialized materials that can operate at high temperatures, understanding MOQs helps businesses manage inventory and procurement costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. When dealing with temperature-sensitive materials or equipment, detailing the required specifications, including temperature ranges, can help suppliers provide accurate quotations and ensure compliance with industry standards.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the delivery of goods. Understanding Incoterms is crucial for B2B buyers engaged in international trade, particularly for temperature-sensitive goods, as they dictate who is responsible for costs and risks at various points in the shipping process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For industries that operate at high temperatures, such as food processing or manufacturing, understanding lead times is critical for planning and maintaining operational efficiency.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance with industry standards, particularly in environments where precise temperature control is crucial.

Navigating Market Dynamics and Sourcing Trends in the 240 centigrade as fahrenheit Sector

What are the Global Drivers Influencing the 240 Degrees Celsius to Fahrenheit Market?

The conversion of 240 degrees Celsius to Fahrenheit, translating to 464 degrees Fahrenheit, is critical in various industries, notably in manufacturing, food processing, and materials testing. As globalization continues to influence sourcing decisions, international B2B buyers must understand the implications of temperature measurements in different regions. This is especially relevant for industries requiring precise temperature control, such as pharmaceuticals and food production, where adherence to safety and quality standards is paramount.

Recent trends show a growing demand for advanced temperature monitoring technologies that ensure accuracy and reliability in processes involving high-temperature applications. Innovations such as IoT-enabled sensors and real-time data analytics are enhancing operational efficiency and driving down costs. Furthermore, the rise of automation in manufacturing processes is pushing companies to adopt sophisticated temperature control systems to maintain product integrity.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should also consider the impact of local regulations and standards that govern temperature management. Understanding these dynamics allows businesses to source compliant equipment and technologies that meet both regional and international requirements, ensuring competitiveness in the global market.

How is Sustainability Shaping Sourcing Practices for High-Temperature Applications?

In today’s environmentally-conscious marketplace, sustainability and ethical sourcing are becoming increasingly critical for B2B buyers, especially those involved with processes that operate at or exceed 240 degrees Celsius. High-temperature applications can have significant environmental impacts, from energy consumption to waste generation. Thus, companies are urged to adopt sustainable practices that mitigate these effects.

One important aspect is the procurement of ‘green’ materials and technologies that can withstand high temperatures without compromising performance. Buyers should seek suppliers who prioritize environmentally friendly manufacturing processes and materials certified by recognized organizations. Certifications such as ISO 14001 (Environmental Management) and Energy Star are indicators of a supplier’s commitment to sustainability.

Additionally, the focus on ethical supply chains is essential. Buyers must ensure that their suppliers adhere to fair labor practices and environmental standards, contributing to a more sustainable and responsible global economy. By aligning sourcing strategies with sustainability goals, B2B buyers can enhance their brand reputation, meet consumer demand for ethical products, and comply with increasingly stringent regulations.

What is the Historical Context of Temperature Measurement Systems?

The temperature measurement systems we rely on today have evolved significantly over the centuries. The Celsius scale, originally known as centigrade, was developed in the 18th century by Swedish astronomer Anders Celsius. This scale was designed to simplify temperature conversion and align with the metric system, establishing the freezing point of water at 0 degrees Celsius and the boiling point at 100 degrees Celsius.

On the other hand, the Fahrenheit scale, created by German physicist Daniel Gabriel Fahrenheit in the early 1700s, established a different baseline for temperature measurement, with water freezing at 32 degrees Fahrenheit and boiling at 212 degrees Fahrenheit. The divergence of these systems has necessitated the development of conversion methods, particularly for industries operating globally. Understanding this historical context is crucial for B2B buyers as they navigate the complexities of sourcing materials and technologies across different measurement systems, ensuring consistency and compliance in their operations.

In summary, the dynamics of the market for 240 degrees Celsius to Fahrenheit conversions are shaped by technological advancements, sustainability imperatives, and a deep understanding of historical measurement practices. By staying informed and proactive, international B2B buyers can make strategic decisions that enhance their operational efficiency and align with contemporary market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of 240 centigrade as fahrenheit

-

How do I convert 240 degrees Celsius to Fahrenheit?

To convert 240 degrees Celsius (°C) to Fahrenheit (°F), you can use the formula: °F = (°C × 1.8) + 32. Plugging in the values, you calculate: (240 × 1.8) + 32 = 464°F. This conversion is essential for B2B transactions, especially when dealing with suppliers in regions that utilize different temperature scales. Understanding these conversions ensures accurate communication regarding product specifications that involve temperature-sensitive materials or processes. -

What industries commonly require the conversion of 240°C to Fahrenheit?

Industries such as food processing, manufacturing, and pharmaceuticals often deal with high-temperature processes that require precise temperature control. For instance, in food processing, baking temperatures may be specified in Celsius but need to be communicated to partners in regions using Fahrenheit. Understanding conversions is crucial for compliance with safety standards and ensuring product quality during production and shipping. -

How can I ensure my suppliers accurately understand temperature requirements?

To ensure your suppliers understand your temperature requirements, provide clear specifications in both Celsius and Fahrenheit. Include temperature ranges in your purchase orders and contracts. Additionally, consider using temperature conversion charts or tools as part of your documentation. Regular communication and clarification can prevent misunderstandings that may affect product quality or compliance with industry standards. -

What should I consider when sourcing products that require specific temperature handling?

When sourcing products requiring specific temperature handling, consider the supplier’s experience with temperature-sensitive materials. Evaluate their quality assurance processes, including how they monitor and control temperatures during production and shipping. Additionally, inquire about their logistics capabilities to ensure products remain within required temperature ranges throughout the supply chain. -

What are the minimum order quantities (MOQs) for temperature-sensitive products?

MOQs for temperature-sensitive products can vary significantly by supplier and industry. Factors influencing MOQs include the nature of the product, production capacity, and the supplier’s inventory management practices. It’s advisable to negotiate MOQs that align with your needs, especially if you require customized products or specific temperature handling. Understanding these details upfront can help you manage costs and inventory effectively. -

How do I vet suppliers for compliance with temperature handling standards?

To vet suppliers for compliance with temperature handling standards, request documentation of their certifications and quality assurance processes. Conduct site visits if possible to observe their facilities and practices firsthand. Additionally, seek references from other clients who have similar temperature handling requirements. This due diligence will help ensure that your supplier can consistently meet your temperature specifications. -

What payment terms should I negotiate for sourcing temperature-sensitive products?

When negotiating payment terms for temperature-sensitive products, consider terms that provide flexibility and security. Options may include partial payments upfront with the remainder due upon delivery or after successful quality inspection. Also, explore using escrow services to protect both parties. Clear payment terms can help mitigate risks associated with product quality and delivery timelines. -

What logistics considerations are essential for transporting products requiring specific temperatures?

When transporting products requiring specific temperatures, consider the mode of transportation, packaging materials, and monitoring systems. Ensure that the logistics provider has experience with temperature-controlled shipping and can maintain the required temperature throughout the journey. Also, inquire about contingency plans in case of temperature deviations, as this is crucial for safeguarding the integrity of your products during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 240 Centigrade As Fahrenheit Manufacturers & Suppliers List

1. Vacations.info – Celsius to Fahrenheit Converter

Domain: vacations.info

Registered: 2002 (23 years)

Introduction: 240 Degrees Celsius to Fahrenheit conversion: 240°C = 464°F. The calculator allows users to convert Celsius to Fahrenheit, with automatic updates for various decimal values of Celsius (e.g., 240.01°C = 464.02°F, 240.02°C = 464.04°F, etc.).

2. Thinkster – Temperature Conversion Tool

Domain: hellothinkster.com

Registered: 2016 (9 years)

Introduction: This company, Thinkster – Temperature Conversion Tool, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Calculat.io – Celsius to Fahrenheit Converter

Domain: calculat.io

Registered: 2018 (7 years)

Introduction: 240 degrees Celsius is equal to 464 degrees Fahrenheit. Conversion formula: °F = (°C × 9/5) + 32. To convert 240°C to °F: ((240 × 9) ÷ 5) + 32 = 464°F. The calculator allows users to convert degrees Celsius to degrees Fahrenheit by entering a Celsius value and hitting the ‘Convert’ button.

4. DigiKey – Temperature Converter

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, DigiKey – Temperature Converter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. CtoF Converter – Temperature Conversion Tool

Domain: ctof.randomdecider.com

Registered: 2023 (2 years)

Introduction: 240 °C is equal to 464 °F. Conversion formula: °F = (°C × 9/5) + 32. Steps: 1. Substitute 240°C into the formula. 2. Multiply 240 by 1.8 to get 432. 3. Add 32 to get the final result of 464°F.

6. CalculateMe – Temperature Conversion

Domain: calculateme.com

Registered: 2005 (20 years)

Introduction: 240 Celsius is equal to 464 Fahrenheit. Celsius is a temperature scale used globally, where water freezes at 0° and boils at 100°. The Fahrenheit scale is commonly used in the United States. The conversion formula from Celsius to Fahrenheit is °F = 9 * °C + 32.

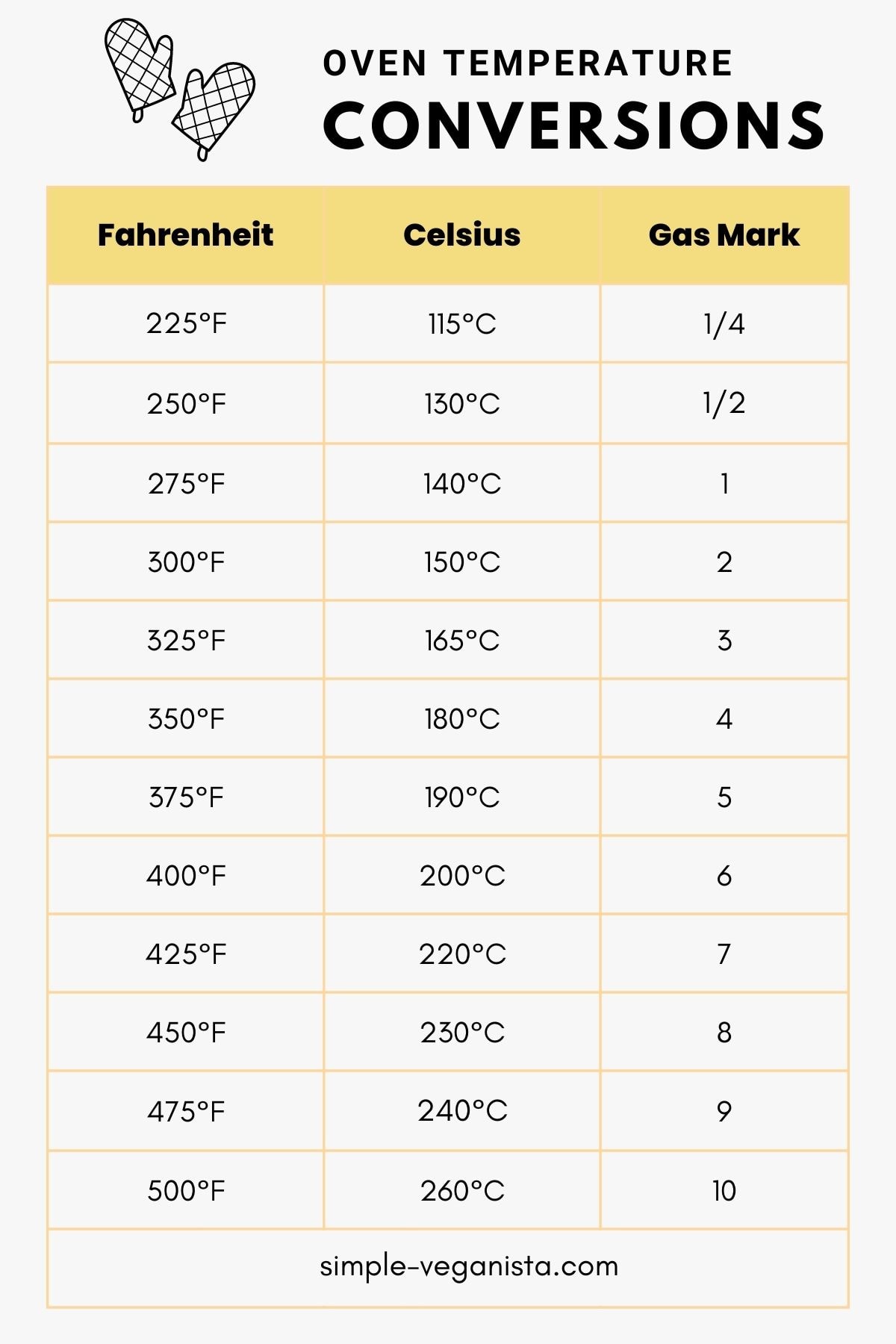

7. Simple Veganista – Oven Temperature Conversion Guide

Domain: simple-veganista.com

Registered: 2015 (10 years)

Introduction: Celsius to Fahrenheit conversion guide for kitchen use, including temperature scales (Celsius, Fahrenheit, Gas Mark), descriptions of each scale, and a detailed oven temperature conversion chart with common temperatures and their equivalents in Celsius and Gas Mark.

8. Converter.net – Temperature Conversion Tool

Domain: converter.net

Registered: 2005 (20 years)

Introduction: Convert 240 degrees Celsius to degrees Fahrenheit using Converter.net. The site allows users to convert various units of temperature and other measurements easily by selecting units and entering values.

Strategic Sourcing Conclusion and Outlook for 240 centigrade as fahrenheit

In the context of international trade and industry, understanding temperature conversions like 240 degrees Celsius to Fahrenheit (464°F) is crucial for B2B buyers across various sectors, including manufacturing, food processing, and chemical production. Accurate conversions ensure that products meet safety and quality standards, ultimately enhancing operational efficiency and compliance.

Strategic sourcing plays a vital role in optimizing supply chains, reducing costs, and fostering sustainable business practices. By leveraging reliable temperature data, companies can make informed decisions regarding equipment specifications, processing conditions, and product quality. This not only minimizes waste but also enhances customer satisfaction through consistent product performance.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of global sourcing, it is essential to prioritize partnerships with suppliers who understand the importance of precise temperature management. Moving forward, businesses should consider investing in advanced technologies and training to streamline their sourcing processes. Embrace the power of strategic sourcing to not only meet current market demands but also anticipate future trends, ensuring long-term success in a competitive landscape.