8.8 Cubic Feet Tank Of Helium Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for 8.8 cubic feet tank of helium

In today’s dynamic global market, sourcing an 8.8 cubic feet tank of helium presents unique challenges for international B2B buyers. The increasing demand for helium across various sectors—such as event planning, medical applications, and industrial uses—compels businesses to navigate a complex landscape of suppliers, pricing structures, and safety regulations. This guide is designed to equip decision-makers with the essential knowledge needed to make informed purchases, ensuring they secure the right helium tanks for their specific needs.

Throughout this comprehensive resource, we will explore the different types of helium tanks available, their diverse applications, and key considerations for supplier vetting. Additionally, we will provide insights into pricing, potential cost-saving strategies, and logistical considerations that may impact your sourcing decisions. By focusing on the unique requirements of international buyers from Africa, South America, the Middle East, and Europe—including critical markets like Germany and Vietnam—this guide aims to empower businesses to streamline their procurement processes.

Understanding the intricacies of sourcing helium tanks can significantly impact your operational efficiency and cost-effectiveness. With actionable insights and expert recommendations, this guide is your roadmap to successfully navigating the global helium market, enabling you to make strategic purchasing decisions that align with your business objectives.

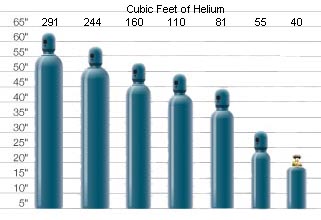

Understanding 8.8 cubic feet tank of helium Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Disposable Helium Tank | Non-refillable, lightweight, portable | Event planning, parties, small decorations | Pros: Easy to use, no return needed. Cons: Limited to one-time use, higher cost per cubic foot. |

| High Purity Helium Tank | Contains 99% pure helium, suitable for sensitive applications | Scientific research, medical applications | Pros: Longer balloon float time, ideal for precision work. Cons: More expensive, requires careful handling. |

| Refillable Helium Cylinder | Can be refilled, larger volume options available | Long-term rental businesses, large events | Pros: Cost-effective for high usage, sustainable. Cons: Requires return logistics, potential for maintenance issues. |

| Mini Helium Tank | Smaller capacity, designed for limited use | Small gatherings, DIY projects | Pros: Affordable, easy to store. Cons: Limited balloon capacity, may not suit larger events. |

| Industrial Helium Tank | High-capacity, designed for heavy-duty applications | Manufacturing, welding, scientific labs | Pros: Cost-effective for bulk use, durable. Cons: Requires specialized transport, handling expertise. |

What Are the Characteristics of Disposable Helium Tanks?

Disposable helium tanks are designed for one-time use and are highly portable, making them ideal for events where convenience is essential. They typically hold around 8.8 cubic feet of helium, sufficient for inflating a moderate number of balloons. These tanks are popular among event planners and party decorators due to their ease of use and the lack of need for return logistics. However, buyers should consider the higher cost per cubic foot compared to refillable options, especially if frequent use is anticipated.

How Does High Purity Helium Differ from Standard Tanks?

High purity helium tanks contain 99% pure helium, making them suitable for applications requiring high-quality gas, such as scientific research and medical uses. The purity level enhances balloon float time and is crucial in fields where gas quality is paramount. While these tanks are more expensive, their benefits often outweigh the costs for businesses needing reliable performance in sensitive environments. B2B buyers should prioritize supplier reliability and purity guarantees when selecting these tanks.

Why Choose Refillable Helium Cylinders?

Refillable helium cylinders offer a sustainable and cost-effective solution for businesses that require helium on a regular basis. These tanks can be refilled multiple times, making them ideal for companies involved in event planning or balloon decoration services. While they may require additional logistics for return and refilling, the overall savings and reduced environmental impact can be significant. Buyers should assess their helium consumption patterns to determine if this option aligns with their operational needs.

What Are the Benefits of Mini Helium Tanks?

Mini helium tanks are compact, lightweight, and designed for small-scale use, catering to DIY enthusiasts and small gatherings. With a lower helium capacity, they are more affordable and easy to store. However, they may not be suitable for larger events due to their limited output. Businesses targeting casual customers or those organizing low-key events will find these tanks beneficial. Buyers should consider their specific event size and balloon requirements before opting for this type.

When to Consider Industrial Helium Tanks?

Industrial helium tanks are built for heavy-duty applications and larger volumes, making them suitable for manufacturing, welding, and laboratory environments. These tanks typically have a higher capacity and are designed for frequent use, offering a cost-effective solution for businesses with substantial helium needs. However, they require specialized handling and transportation. B2B buyers should evaluate their operational capabilities and ensure compliance with safety regulations when selecting industrial tanks.

Key Industrial Applications of 8.8 cubic feet tank of helium

| Industry/Sector | Specific Application of 8.8 cubic feet tank of helium | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Event Management | Balloon decoration for corporate events and parties | Enhances visual appeal and engagement at events | Ensure compliance with local regulations and safety standards. Consider logistics for timely delivery. |

| Scientific Research | Use in laboratory experiments requiring inert gas | Provides a controlled environment for sensitive experiments | Verify the purity level of helium; inquire about certifications for laboratory use. |

| Healthcare | Application in MRI machines for cooling systems | Improves operational efficiency and equipment longevity | Source from reputable suppliers to ensure gas quality and reliability. |

| Manufacturing | Use in leak testing and quality assurance processes | Ensures product integrity and reduces waste | Confirm the tank’s compatibility with specific testing equipment. Consider bulk purchasing for cost efficiency. |

| Entertainment | Inflating large promotional balloons for marketing | Creates impactful advertising displays | Evaluate the tank’s portability and ease of use for on-site events. Assess supplier reliability for large orders. |

In the event management sector, an 8.8 cubic feet tank of helium is essential for creating eye-catching balloon decorations at corporate events, weddings, and parties. The use of helium balloons enhances the visual appeal and can significantly increase guest engagement. For international buyers, understanding local regulations regarding helium use and ensuring timely delivery to event sites is crucial to avoid last-minute complications.

In scientific research, helium is often required as an inert gas in various laboratory experiments. The 8.8 cubic feet tank can provide a controlled environment necessary for sensitive tests, such as those involving cryogenics or spectroscopy. Buyers in this sector must verify the purity of the helium, ensuring it meets the specific standards required for laboratory applications, as well as any necessary certifications.

The healthcare industry utilizes helium in MRI machines, where it serves as a cooling agent. The 8.8 cubic feet tank can help maintain the operational efficiency of these machines, thus extending their lifespan. B2B buyers in healthcare must prioritize sourcing helium from reputable suppliers to guarantee quality and reliability, as any contamination could affect medical imaging results.

In manufacturing, helium is used for leak testing and quality assurance processes. The 8.8 cubic feet tank allows for precise testing to ensure product integrity, ultimately reducing waste and costs. Buyers should confirm that the tank is compatible with their specific testing equipment and consider bulk purchasing options to achieve cost efficiency.

The entertainment sector often uses helium tanks to inflate large promotional balloons for marketing campaigns. The 8.8 cubic feet tank provides the necessary helium for creating impactful advertising displays that can draw attention at events and festivals. For international B2B buyers, evaluating the tank’s portability and ease of use is vital, especially for on-site events where logistics can be challenging. Additionally, assessing the reliability of suppliers for large orders can help ensure successful campaigns.

3 Common User Pain Points for ‘8.8 cubic feet tank of helium’ & Their Solutions

Scenario 1: Difficulty in Accurate Helium Calculations for Events

The Problem:

B2B buyers, especially event planners, often struggle with accurately estimating the amount of helium needed for various balloon arrangements. This miscalculation can lead to either excess helium, which is wasteful and costly, or insufficient helium, resulting in a disappointing event where balloons cannot be inflated as intended. This issue is particularly pressing for international buyers in regions with limited access to helium, making it crucial to optimize usage and minimize wastage.

The Solution:

To address this challenge, utilize an online helium balloon calculator tailored for event planning. These calculators allow buyers to input details such as balloon sizes, types, and the desired quantity to generate precise helium requirements. Additionally, consider sourcing an 8.8 cubic feet tank of helium from a reliable supplier that offers clear specifications and guidelines on how many balloons can be filled per tank. For example, an 8.8 cubic feet tank can typically fill around 30 to 40 standard 11-inch balloons. By using these tools and resources, buyers can streamline their planning process, ensuring they order the right amount of helium while avoiding unnecessary costs.

Scenario 2: Inadequate Understanding of Helium Tank Safety and Regulations

The Problem:

International buyers may encounter confusion regarding the safety and regulatory requirements for transporting and using helium tanks, especially when importing them across borders. Regulations can vary significantly between regions, and failure to comply can result in legal issues, fines, or even the inability to transport the tanks altogether. This is particularly concerning for businesses in Africa and the Middle East, where regulatory frameworks may not be as straightforward.

The Solution:

To mitigate these risks, conduct thorough research on the regulations governing helium tanks in both the country of origin and the destination. Engage with local authorities or import/export specialists who can provide insights into the necessary documentation and safety standards. Moreover, ensure that the 8.8 cubic feet helium tanks being purchased come with proper safety certifications and guidelines, such as CGA (Compressed Gas Association) compliance. Suppliers should provide essential safety equipment, such as cylinder caps and secure transport solutions. By being proactive in understanding and adhering to these regulations, buyers can facilitate smoother transactions and avoid potential pitfalls.

Scenario 3: Challenges in Efficient Helium Usage and Balloon Longevity

The Problem:

B2B buyers often face issues with helium balloon longevity, as balloons filled with helium can deflate quickly, leading to disappointing results for events and decorations. This is a significant concern for businesses that rely on helium-filled balloons as a primary decoration or promotional tool. The quick deflation can be particularly problematic in warmer climates or during outdoor events, where heat can accelerate helium loss.

The Solution:

To enhance the longevity of helium-filled balloons, consider using high-quality latex balloons and applying a helium balloon treatment such as Hi-Float, which helps to seal the helium inside the balloon and slows down the escape rate. Additionally, when purchasing an 8.8 cubic feet helium tank, ensure that it contains high purity helium (ideally above 99% purity) as this will contribute to better performance and longer-lasting balloons. Moreover, educate staff or event planners on best practices for balloon handling and storage, such as keeping balloons out of direct sunlight and in cooler environments prior to use. By implementing these strategies, businesses can maximize the effectiveness of their helium investments and ensure that their events are visually stunning and memorable.

Strategic Material Selection Guide for 8.8 cubic feet tank of helium

What Are the Key Materials for an 8.8 Cubic Feet Helium Tank?

When selecting materials for an 8.8 cubic feet helium tank, it’s essential to consider properties such as pressure rating, corrosion resistance, and overall durability. The choice of material can significantly influence the tank’s performance, safety, and compliance with international standards. Below is an analysis of several common materials used in helium tank construction.

Aluminum: A Lightweight and Corrosion-Resistant Option

Key Properties: Aluminum tanks are known for their lightweight nature and excellent corrosion resistance. They typically have a pressure rating of around 2,000 PSI, making them suitable for helium storage.

Pros & Cons: Aluminum is durable and resistant to rust, but it can be more expensive than steel. Manufacturing complexity is moderate, as aluminum requires specialized welding techniques. Its lightweight nature makes it easier to transport, but it may not withstand impact as well as steel.

Impact on Application: Aluminum tanks are compatible with helium and are often used in environments where weight is a critical factor, such as in event setups or portable applications.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum alloys is crucial. Buyers in regions like Europe and the Middle East should ensure that the tanks meet the relevant safety regulations.

Steel: The Traditional Heavy-Duty Choice

Key Properties: Steel tanks are typically heavier and have a higher pressure rating, often exceeding 2,500 PSI. They are known for their strength and durability.

Pros & Cons: Steel is less expensive than aluminum and offers superior impact resistance. However, it is prone to rust if not properly coated, and its weight can be a disadvantage for transport. Manufacturing steel tanks requires more energy and resources, leading to higher environmental impact.

Impact on Application: Steel tanks are suitable for stationary applications where weight is less of a concern, such as in industrial settings or large-scale helium distribution.

Considerations for International Buyers: Compliance with international standards such as DIN 24013 for steel tanks is essential. Buyers should also consider the availability of maintenance services to prevent corrosion.

Composite Materials: The Future of Helium Tanks?

Key Properties: Composite tanks, often made from carbon fiber or fiberglass, are lightweight and have a high pressure rating, sometimes exceeding 3,000 PSI.

Pros & Cons: The primary advantage of composite materials is their weight-to-strength ratio, which allows for easier handling and transport. However, they are generally more expensive to manufacture and may require specialized handling during production and use.

Impact on Application: Composite tanks are ideal for high-pressure applications and are increasingly used in aerospace and advanced medical applications.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ISO 11119 for composite gas cylinders. The availability of composite tanks may vary by region, impacting logistics and supply chain considerations.

Summary of Material Selection for Helium Tanks

| Material | Typical Use Case for 8.8 cubic feet tank of helium | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable helium tanks for events and parties | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Steel | Industrial helium storage and distribution | High strength and durability | Prone to rust without coating | Low |

| Composite | High-pressure applications in aerospace or medical | Excellent weight-to-strength ratio | Expensive and requires special handling | High |

In conclusion, the choice of material for an 8.8 cubic feet helium tank depends on specific application needs, budget constraints, and compliance with international standards. Understanding the properties and implications of each material can help international B2B buyers make informed decisions that align with their operational requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 8.8 cubic feet tank of helium

What Are the Key Stages in the Manufacturing Process of an 8.8 Cubic Feet Helium Tank?

Manufacturing an 8.8 cubic feet helium tank involves several critical stages that ensure the final product is both durable and safe for use. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the selection of high-quality raw materials, typically aluminum or steel, which are chosen for their strength-to-weight ratio and resistance to corrosion. The materials undergo rigorous testing to assess their physical properties, ensuring they meet industry standards. Pre-treatment processes such as cleaning and surface preparation are conducted to remove any contaminants that could affect the welding and coating processes.

Forming: In this stage, the prepared materials are shaped into the desired form. Techniques such as deep drawing or spinning are often employed to create the cylindrical body of the tank. This step requires precision to ensure uniform thickness and structural integrity. Advanced machinery, like CNC (Computer Numerical Control) equipment, is frequently used to achieve the required specifications.

Assembly: Following forming, the various components of the tank, including the neck and valve fittings, are assembled. This is often achieved through welding or other joining methods, ensuring that all connections are airtight. The assembly process is critical, as any flaws can lead to leaks, compromising the safety of the tank.

Finishing: The final stage involves surface treatment and inspection. Tanks may be coated with protective finishes to enhance corrosion resistance and durability. Additionally, aesthetic elements such as branding or labeling are applied. Rigorous inspections are conducted to verify that each tank meets the required specifications and quality standards.

How is Quality Assurance Implemented in Helium Tank Manufacturing?

Quality assurance is a fundamental aspect of helium tank manufacturing. It ensures that each tank produced is safe, reliable, and compliant with international standards.

Relevant International Standards: Compliance with standards such as ISO 9001 is crucial for manufacturers. This standard provides a framework for quality management systems, ensuring that processes are efficient and products meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking in Europe and API (American Petroleum Institute) standards are essential for indicating compliance with safety and performance benchmarks.

Quality Control Checkpoints: Quality control (QC) processes typically involve several checkpoints:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specified standards before they enter the production process.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections are performed to identify any deviations from quality standards. This helps catch issues early in the production cycle, reducing waste and rework.

– Final Quality Control (FQC): After finishing, each tank undergoes a final inspection to ensure it meets all specifications. This may include pressure testing, visual inspections, and functional tests of the valves and fittings.

What Common Testing Methods Are Used to Ensure Tank Quality?

Manufacturers utilize various testing methods to ensure the integrity and safety of helium tanks. Common testing procedures include:

-

Hydrostatic Testing: This method involves filling the tank with water and pressurizing it to check for leaks and structural integrity. The tank must withstand a specified pressure for a predetermined duration without any signs of deformation or leakage.

-

Visual Inspection: Trained inspectors conduct thorough visual checks for any surface defects, weld quality, and overall finish. This non-destructive method is crucial for identifying potential issues before the tank is shipped.

-

Ultrasonic Testing: This technique uses high-frequency sound waves to detect internal flaws in the material. It is particularly useful for identifying cracks or inclusions that may not be visible externally.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies to ensure supplier compliance:

-

Audits: Conducting on-site audits of the manufacturing facilities can provide invaluable insights into the supplier’s processes and quality management systems. This allows buyers to assess whether the supplier adheres to industry standards and best practices.

-

Quality Reports: Requesting detailed quality reports from the supplier can help buyers understand the specific tests conducted, results obtained, and any corrective actions taken in case of non-compliance.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control processes. These inspections often include comprehensive assessments of materials, manufacturing practices, and final product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific nuances in quality control when sourcing helium tanks. Different regions may have varying regulatory requirements, and understanding these can be crucial for compliance and safety.

-

Regulatory Compliance: Buyers should familiarize themselves with the regulations specific to their regions. For instance, CE marking is essential for products sold within the European Union, while other regions may require different certifications.

-

Cultural Considerations: Understanding cultural differences in business practices can impact quality assurance processes. Buyers should consider how these differences may affect communication and expectations regarding quality.

-

Logistics and Transportation: Quality assurance does not end at manufacturing; it extends to transportation and storage. Buyers must ensure that suppliers adhere to safety and handling protocols during shipping to prevent damage or degradation of the tanks.

In conclusion, understanding the manufacturing processes and quality assurance practices for helium tanks is critical for B2B buyers. By focusing on the stages of manufacturing, relevant quality standards, testing methods, and supplier verification strategies, buyers can make informed decisions that ensure the safety and reliability of their helium supply.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8.8 cubic feet tank of helium’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure an 8.8 cubic feet tank of helium. Helium is a critical resource for various applications, including event planning, medical uses, and scientific research. Ensuring you choose the right tank and supplier is essential for operational efficiency and safety.

Step 1: Define Your Technical Specifications

Clearly outline the required specifications for your helium tank. Understanding the exact volume, purity, and pressure specifications is critical to meet your specific needs. For instance, consider whether you require high-purity helium for scientific applications or standard helium for event decorations.

- Volume: Ensure the tank’s capacity matches your anticipated usage.

- Purity Level: Specify if you need high-purity helium (99% or above) for sensitive applications.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to create a list of potential suppliers. The reliability of your helium supply hinges on the credibility of your supplier. Look for companies with proven track records in your region, especially those familiar with the unique demands of your market.

- Local vs. International Suppliers: Consider local suppliers for reduced shipping costs and faster delivery times.

- Industry Reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that suppliers hold the necessary certifications and comply with local regulations. This step is crucial to ensure safety and quality standards are met, particularly in regions with strict gas handling regulations.

- ISO Certifications: Look for suppliers with ISO certifications to ensure quality management practices.

- Safety Standards: Confirm compliance with local safety regulations, particularly for gas handling and storage.

Step 4: Request Quotes and Compare Pricing

Gather detailed quotes from multiple suppliers for comparison. Pricing can vary significantly, so obtaining several quotes allows you to make an informed decision. Be sure to understand what each quote includes to avoid unexpected costs later.

- Inclusions: Check if the quote covers delivery, setup, and any additional equipment like regulators or valves.

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

Step 5: Assess Customer Support and After-Sales Services

Evaluate the level of customer support and after-sales services provided by the supplier. Good customer service can save time and ensure smooth operations, especially if issues arise post-purchase.

- Technical Support: Ensure the supplier offers assistance with installation and troubleshooting.

- Return and Exchange Policies: Understand their policies in case of defective products or incorrect orders.

Step 6: Confirm Delivery and Logistics Arrangements

Finalize the logistics for delivery to ensure timely receipt of your helium tank. Delays in delivery can disrupt your operations, so it’s essential to confirm the expected timeline and shipping methods.

- Lead Times: Ask about the estimated delivery time and any potential delays.

- Shipping Costs: Clarify who bears the shipping costs and any additional fees.

Step 7: Plan for Safe Usage and Storage

Develop a plan for the safe usage and storage of the helium tank. Proper handling and storage practices are vital to ensure safety and compliance with regulations.

- Training: Ensure that personnel are trained in safe handling procedures.

- Storage Requirements: Verify that storage facilities meet the necessary safety standards to prevent leaks and accidents.

By following this checklist, B2B buyers can make informed decisions when sourcing an 8.8 cubic feet tank of helium, ensuring they meet both operational needs and safety requirements.

Comprehensive Cost and Pricing Analysis for 8.8 cubic feet tank of helium Sourcing

What Are the Key Cost Components for Sourcing an 8.8 Cubic Feet Helium Tank?

When analyzing the cost structure for an 8.8 cubic feet helium tank, various components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The tank’s construction typically involves high-quality aluminum or steel, which can vary in price based on market fluctuations. High-purity helium gas is also a significant cost factor, particularly if sourced from reliable suppliers that ensure consistent quality.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality assurance, and administrative tasks. This varies by region, with labor rates typically lower in South America and Africa compared to Europe.

-

Manufacturing Overhead: This includes expenses related to the operation of the manufacturing facility, such as utilities and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are amortized over production runs, affecting the unit price.

-

Quality Control (QC): Ensuring the safety and reliability of helium tanks is critical. This requires investments in testing and certification, particularly for markets with stringent regulations like Germany.

-

Logistics: Transportation and handling costs are influenced by distance, shipping methods, and the chosen Incoterms. For international buyers, understanding these logistics can significantly affect overall pricing.

-

Margin: Suppliers typically add a profit margin to cover costs and ensure sustainability. This margin can vary widely based on market competition and demand.

How Do Price Influencers Impact the Cost of Helium Tanks?

Several factors can influence the pricing of helium tanks, particularly in international B2B transactions:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often results in lower per-unit costs. Suppliers may offer discounts for larger orders, which can be an attractive option for businesses planning events or needing regular supplies.

-

Specifications and Customization: Custom tanks designed for specific applications may incur additional costs. Buyers should assess whether standard tanks meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Tanks made from premium materials or those that meet specific certifications (like ISO standards) tend to be more expensive. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers with a track record of quality may command higher prices but offer better assurance of performance.

-

Incoterms: The choice of Incoterms affects cost and risk distribution in shipping. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate pricing analysis.

What Buyer Tips Can Help Optimize Costs?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize costs:

-

Negotiation: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Leverage competition among suppliers to negotiate better terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), not just the initial purchase price. Consider factors such as durability, maintenance, and potential recycling costs when assessing value.

-

Pricing Nuances for International Buyers: Understand the impact of currency fluctuations and import duties on the overall cost. Researching local market conditions can provide insights into fair pricing.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive offers.

-

Market Research: Stay informed about market trends and pricing shifts. Utilizing tools such as helium calculators can assist in accurately estimating needs and costs.

Disclaimer

The prices and cost structures provided herein are indicative and may vary based on current market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with multiple suppliers to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing 8.8 cubic feet tank of helium With Other Solutions

Exploring Viable Alternatives to the 8.8 Cubic Feet Tank of Helium

In the realm of helium solutions, buyers often seek alternatives that can fulfill similar needs for events, decorations, or industrial applications. Understanding these options is essential for making informed purchasing decisions. Below, we compare the 8.8 cubic feet tank of helium against two viable alternatives: a larger helium rental tank and high-purity helium tanks.

| Comparison Aspect | 8.8 Cubic Feet Tank Of Helium | Helium Rental Tank (242 CF) | High-Purity Helium Tank (99.99%) |

|---|---|---|---|

| Performance | Suitable for small to medium events, fills approx. 50-60 balloons | Suitable for large events, fills hundreds of balloons | Provides longer-lasting float time, ideal for specialized applications |

| Cost | Generally lower upfront cost, around $50-$70 | Higher upfront rental cost, typically $150-$300 | Higher cost, $55-$150, but offers better quality helium |

| Ease of Implementation | Easy to use, disposable after use | Requires transport and return logistics | Simple to use but may require specialized equipment for optimal performance |

| Maintenance | No maintenance required; disposable | Minimal maintenance, return at end of rental | No maintenance, but must be handled carefully to avoid leaks |

| Best Use Case | Small parties, DIY events | Large-scale events, commercial uses | Scientific applications, events requiring high-quality helium |

What Are the Benefits and Drawbacks of a Helium Rental Tank?

Helium rental tanks, such as those with a capacity of 242 cubic feet, are ideal for larger events where a significant volume of helium is required. They can fill hundreds of balloons, making them suitable for corporate events, weddings, or festivals. However, the upfront rental cost can be higher, and logistics for pickup and return may complicate the process. Additionally, users must ensure they adhere to safety guidelines during transport and operation.

How Does High-Purity Helium Compare?

High-purity helium tanks, typically containing 99.99% pure helium, are designed for specialized applications, including scientific research and industrial uses. These tanks offer the advantage of longer-lasting float times for balloons, which can be particularly beneficial for events that require decor to last for extended periods. However, they come at a higher price point and may require specific dispensing equipment to optimize usage. While they are not necessary for all events, they are invaluable in contexts where helium purity is critical.

Conclusion: How Should B2B Buyers Choose the Right Helium Solution?

When selecting the right helium solution, B2B buyers should consider their specific needs, including the scale of their event, budget constraints, and the desired performance of helium-filled products. For smaller events, the 8.8 cubic feet tank offers a cost-effective and convenient option. For larger gatherings, helium rental tanks can provide the necessary volume, albeit with higher costs and logistical considerations. In specialized applications where quality is paramount, high-purity helium tanks are the best choice despite their higher price. Evaluating these factors will ensure that buyers choose the most suitable helium solution for their unique requirements.

Essential Technical Properties and Trade Terminology for 8.8 cubic feet tank of helium

What Are the Essential Technical Properties of an 8.8 Cubic Feet Helium Tank?

When considering the procurement of an 8.8 cubic feet helium tank, several technical specifications are crucial for ensuring that the product meets operational needs. Here are some key properties:

-

Material Grade

– Helium tanks are typically constructed from aluminum or steel. Aluminum tanks are lighter and resistant to corrosion, making them suitable for portable applications. Steel tanks, while heavier, are often more durable and can withstand higher pressures. The choice of material affects both transportation costs and longevity, which is essential for businesses looking to maximize their investment. -

Pressure Rating

– The pressure rating indicates the maximum pressure the tank can safely hold, usually measured in PSI (pounds per square inch). For an 8.8 cubic feet helium tank, this can range from 1800 to 3000 PSI. Understanding the pressure rating is vital for ensuring compatibility with regulators and safe handling during filling and transportation. -

Capacity and Fill Volume

– The tank’s nominal capacity of 8.8 cubic feet must be understood in terms of the actual volume of helium it can deliver. This is particularly important for B2B buyers who need to calculate how many balloons or other helium-dependent products they can inflate. For example, a typical 9-inch latex balloon requires about 0.5 cubic feet of helium. -

Regulator Compatibility

– Tanks require regulators for safe gas release. Knowing the thread size (e.g., CGA 580 for most helium tanks) is crucial for ensuring that the regulator fits properly. This detail impacts operational efficiency and safety, as improper connections can lead to leaks or hazardous situations. -

Weight

– The weight of the tank, including the gas, affects transportation and handling. Lighter tanks are more suitable for events or locations where mobility is essential. Understanding the weight can also aid in logistics planning, especially for international shipping. -

Non-Refillable vs. Refillable

– It’s important to distinguish whether a tank is designed to be refillable or is a one-time-use disposable tank. Non-refillable tanks are often lighter and easier to handle, while refillable tanks can offer long-term cost savings for businesses that require helium regularly.

What Are Common Trade Terms Related to Helium Tanks?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of helium tanks, knowing the OEM can help buyers assess quality and reliability. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest amount of a product that a supplier is willing to sell. This term is significant for B2B buyers who may want to negotiate smaller orders or need to understand inventory commitments. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This is a critical step in the procurement process, allowing buyers to compare options and make informed decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is vital for managing logistics and costs effectively. -

Cylinder Safety Standards

– This refers to regulations that govern the manufacturing, transport, and storage of gas cylinders, including helium tanks. Compliance with these standards ensures safety and reliability, which is crucial for businesses that handle pressurized gases. -

Float Time

– Float time indicates how long a helium-filled balloon will remain inflated before it starts to sag. This term is particularly relevant for event planners and decorators who need to ensure their displays last throughout an event.

In summary, a thorough understanding of the technical properties and trade terminology related to an 8.8 cubic feet helium tank is essential for B2B buyers. This knowledge ensures informed purchasing decisions, optimizes operational efficiency, and enhances safety in handling and storage.

Navigating Market Dynamics and Sourcing Trends in the 8.8 cubic feet tank of helium Sector

What Are the Global Drivers and Key Trends in the 8.8 Cubic Feet Tank of Helium Market?

The global helium market is experiencing significant shifts driven by various factors. One of the primary drivers is the growing demand for helium in diverse industries such as medical, aerospace, and entertainment. In particular, event planning and balloon decoration sectors are increasingly relying on helium for creating visually appealing displays. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable sources, the need for 8.8 cubic feet helium tanks is rising due to their optimal size for small to medium events.

Emerging technologies are influencing sourcing trends, with a notable increase in online marketplaces facilitating easier access to helium products. Suppliers are leveraging digital platforms to enhance their visibility and streamline the procurement process for buyers. Furthermore, the advent of smart logistics solutions is improving supply chain efficiency, allowing for faster delivery times and better inventory management. The market dynamics are also being shaped by geopolitical factors, including trade policies and supply chain disruptions, which may affect the availability and pricing of helium tanks. Buyers should stay informed about these fluctuations to make strategic purchasing decisions.

How Does Sustainability Impact Sourcing in the Helium Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the helium sector. The environmental impact of helium extraction and transportation is prompting companies to seek more sustainable practices. Ethical sourcing is increasingly prioritized, with buyers favoring suppliers that demonstrate a commitment to minimizing carbon footprints. This includes opting for helium sourced from facilities that utilize environmentally friendly methods and technologies.

Additionally, the demand for ‘green’ certifications is on the rise. Suppliers who can provide evidence of sustainable practices—such as using renewable energy in production or implementing efficient recycling programs—are more likely to attract international buyers. The use of high-purity helium, which reduces the amount required for specific applications, is another trend gaining traction. By selecting suppliers with stringent quality standards, companies can not only improve their environmental impact but also enhance the performance of their helium applications.

What Is the Historical Context of the Helium Market’s Evolution?

The helium market has evolved significantly since its discovery in the late 19th century. Initially used for scientific research, helium gained prominence during World War I and II for its applications in military airships. Over the decades, its utility expanded into various sectors, including healthcare for MRI machines and the entertainment industry for balloons.

In recent years, the helium market has faced challenges due to supply constraints and rising demand. The depletion of natural gas reserves that contain helium has prompted a shift towards recycling and the development of new extraction technologies. This evolution is critical for B2B buyers, as understanding the historical context can inform their purchasing strategies and help them navigate the complexities of the current market landscape.

By staying attuned to these trends and historical insights, international B2B buyers can position themselves to make informed decisions in the 8.8 cubic feet tank of helium sector, ensuring they meet their operational needs while adhering to sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 8.8 cubic feet tank of helium

-

How can I determine the amount of helium needed for my event?

To estimate the helium required for your event, you can utilize online helium calculators, which provide guidance based on the size and type of balloons you plan to use. For example, a standard 9-inch latex balloon typically requires about 0.5 cubic feet of helium. Therefore, an 8.8 cubic feet tank can inflate approximately 17-18 such balloons. Always consider factors like balloon type, atmospheric conditions, and whether you’ll use any helium-saving techniques to optimize your usage. -

What is the best way to source an 8.8 cubic feet helium tank for international shipping?

When sourcing helium tanks for international shipping, prioritize suppliers with a proven track record in exporting gas products. Verify their compliance with international shipping regulations, including proper labeling and safety standards. It’s advisable to request samples or product specifications to ensure the tanks meet your quality requirements. Additionally, consider suppliers that offer competitive pricing and reliable logistics partnerships to ensure timely delivery. -

What quality assurance measures should I expect from helium tank suppliers?

Reputable helium tank suppliers should provide clear documentation of their quality assurance practices, including certifications like ISO 9001. They should conduct regular testing to ensure the purity of helium and the integrity of the tanks. Request information about their manufacturing processes, safety protocols, and any warranties or guarantees they offer. A strong quality assurance program can significantly reduce risks associated with product defects or non-compliance. -

Are there customization options available for helium tanks?

Many suppliers offer customization options for helium tanks, which may include branding, specific valve types, or tank colors. It’s essential to discuss your requirements upfront to understand the capabilities of the supplier. Customizations can enhance your product’s marketability and ensure it meets your specific operational needs. However, be aware that custom orders may have longer lead times and minimum order quantities (MOQs) that differ from standard products. -

What are the typical payment terms for purchasing helium tanks internationally?

Payment terms can vary by supplier and region but often include options such as advance payment, letter of credit, or net 30/60 days after delivery. When engaging with suppliers, ensure to clarify their preferred payment methods and any associated fees. Additionally, consider using escrow services for large transactions to protect your investment until the goods are received and verified. -

How do I vet potential helium tank suppliers?

To vet potential suppliers, start by researching their reputation within the industry through online reviews and testimonials. Check for their certifications, such as safety and quality standards relevant to gas products. It’s also beneficial to request references from previous clients to gauge their reliability. Conducting a site visit, if feasible, can provide further insights into their operational practices and inventory management. -

What should I consider regarding logistics and shipping for helium tanks?

When planning logistics for helium tank shipments, consider factors such as shipping regulations for hazardous materials, customs clearance processes, and the supplier’s shipping capabilities. Ensure that the supplier can provide adequate packaging to prevent damage during transit and that they have experience with international shipping. Additionally, evaluate their delivery timelines and costs to align with your project schedules. -

What are the safety considerations when handling helium tanks?

Safety is paramount when handling helium tanks. Always ensure that personnel are trained in proper handling techniques and understand the risks associated with compressed gases. Tanks should be stored upright in a secure area, away from heat sources and direct sunlight. Regular inspections for leaks, rust, or damage are crucial, and using protective gear when connecting or disconnecting hoses is recommended to prevent injuries.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 8.8 Cubic Feet Tank Of Helium Manufacturers & Suppliers List

1. Walmart – Helium Party Solution

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Helium Party Solution, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Creative Balloons Manufacturing – Helium Balloon Calculator

Domain: creativeballoonsmanufacturing.com

Registered: 2014 (11 years)

Introduction: Helium Balloon Chart and Calculator provides essential information for determining the amount of helium needed for various balloon sizes. It includes details on balloon dimensions, lift capacity, and recommendations for optimal usage.

3. Laballoons – Helium Tanks Collection

Domain: laballoons.com

Registered: 2002 (23 years)

Introduction: Helium and CO2 Tanks collection includes various sizes of helium tanks suitable for different events. Key products include: 27 CF Aluminum Helium Cylinder with Handle – $249.00 (6 available), 55 CF Aluminum Helium Cylinder with Handle – $299.00 (7 available), 110 CF Aluminum Helium Cylinder with Handle – $549.00 (8 available), 150 CF Aluminum Helium Cylinder with Handle – $650.00 (4 available), 21…

4. Target – 9.5 Medium Helium Balloon Kit

Domain: target.com

Registered: 1997 (28 years)

Introduction: 9.5″ Medium Helium Balloon Kit, Balloon Time Multicolor Steel Tank for All Occasions, 3.2 out of 5 stars with 3326 reviews, 58 Questions, Free & easy returns within 90 days for a full refund, WARNING: choking hazard – children under 8 can choke or suffocate on uninflated or broken balloons, Adult supervision required, Eligible for registries and wish lists.

5. Unique – Balloon Time EMPTY Helium Tank

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Balloon Time EMPTY Helium Tank 8.9 Cubic Ft. Project Tank PINK”,”condition”:”For parts or not working”,”price”:”$8.88 or Best Offer”,”shipping_cost”:”$42.40″,”estimated_delivery”:”Mon, Jul 28 – Sat, Aug 2″,”quantity_available”:1,”item_number”:”186614459639″,”brand”:”Unique”,”type”:”Party Blower”}

6. Airgas – Gas Purchasing Solutions

Domain: airgas.com

Registered: 1995 (30 years)

Introduction: This company, Airgas – Gas Purchasing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Shop BVV – High Purity Helium Tank 99.99%

Domain: shopbvv.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “High Purity Helium Tank 99.99%”, “purity”: “99.99% Pure”, “origin”: “Made in Italy”, “capacity”: “103 liters”, “continuous_output_duration”: “~31.5 Seconds at 80PSI”, “tank_thread”: “M11 x 1.0”, “regulator_thread”: “M11 x 1.0”, “regulator_output”: “1/4\” Brass Barb”, “valve_dispenser_output”: “1/4\” Brass Barb”, “valve_dispenser_thread”: “M11 x 1.0”, “non_refillable”: true, “recy…

Strategic Sourcing Conclusion and Outlook for 8.8 cubic feet tank of helium

In summary, strategic sourcing of an 8.8 cubic feet tank of helium is crucial for businesses seeking to optimize their supply chain, reduce costs, and enhance operational efficiency. By understanding the specific needs of your market—whether for events, decorations, or industrial applications—buyers can make informed decisions that align with their budgetary constraints and usage requirements.

Moreover, leveraging local suppliers and understanding regional pricing dynamics can lead to significant savings, especially in markets across Africa, South America, the Middle East, and Europe. It’s essential to assess the purity and pressure specifications of helium tanks to ensure that they meet your operational standards, particularly for high-demand applications.

As the demand for helium continues to grow, investing in reliable suppliers and establishing long-term partnerships will be key to maintaining competitive advantage. We encourage international B2B buyers to act now—explore partnerships with reputable suppliers to secure your helium needs, ensuring that your business is well-equipped for future growth and success.