Bronze Wheels Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for bronze wheels

In today’s competitive landscape, sourcing bronze wheels presents unique challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for stylish yet durable bronze wheels is on the rise, but navigating the complexities of supplier selection, product specifications, and market trends can be daunting. This guide aims to demystify the process by providing a thorough overview of the different types of bronze wheels available, their various applications across industries, and the essential criteria for vetting suppliers.

From understanding the nuances of wheel construction to assessing cost implications and shipping logistics, this comprehensive resource equips buyers with actionable insights for making informed purchasing decisions. Whether you are sourcing for automotive applications, industrial machinery, or specialty vehicles, our guide covers critical factors such as load ratings, bolt patterns, and finish options that influence performance and aesthetics.

By addressing key considerations and emerging trends, this guide empowers B2B buyers to confidently navigate the global market for bronze wheels. With an emphasis on practical solutions and strategic sourcing, you’ll be well-prepared to enhance your procurement strategies and capitalize on the growing demand for bronze wheels in your target market.

Understanding bronze wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hyper Bronze | Bright, reflective finish with a vibrant sheen | Off-road vehicles, racing cars | Pros: Eye-catching appearance, enhances vehicle aesthetics. Cons: May show scratches easily. |

| Matte Bronze | Non-reflective, subdued finish | Luxury vehicles, daily drivers | Pros: Elegant look, hides dirt and scratches well. Cons: Less shiny appeal, potential color fading over time. |

| Bronze Chrome | Combination of bronze with chrome accents | Custom builds, show cars | Pros: Unique visual appeal, blends classic and modern styles. Cons: Higher maintenance, prone to corrosion. |

| Black with Bronze Lip | Black base with bronze highlights | Performance vehicles, tuners | Pros: Striking contrast, stylish and sporty appearance. Cons: Can be more expensive, requires careful cleaning. |

| Forged Bronze | Lightweight, high-strength construction | Racing, performance applications | Pros: Superior durability, reduced weight for better performance. Cons: Higher cost, limited availability. |

Hyper Bronze wheels are characterized by their bright, reflective finish, making them ideal for off-road vehicles and racing cars. Their striking appearance can significantly enhance the aesthetics of any vehicle. However, buyers should consider that while they are visually appealing, they are prone to showing scratches, which may require more upkeep.

Matte Bronze wheels offer a more understated elegance with their non-reflective finish. This type is commonly used in luxury vehicles and daily drivers, appealing to those who prefer a sophisticated look. While they effectively hide dirt and scratches, buyers should be aware that the matte finish may fade over time, requiring periodic refinishing.

Bronze Chrome wheels combine the richness of bronze with chrome accents, making them a popular choice for custom builds and show cars. Their unique visual appeal can create a striking contrast, but they may require higher maintenance and are more susceptible to corrosion, which is an important consideration for buyers in humid or coastal regions.

Black with Bronze Lip wheels present a sporty and stylish option, often favored by performance vehicles and tuners. The contrast between the black base and bronze highlights makes for an eye-catching design. However, this type can be more expensive and requires careful cleaning to maintain its appearance.

Forged Bronze wheels stand out for their lightweight and high-strength construction, making them suitable for racing and performance applications. These wheels provide superior durability and improved performance due to their reduced weight. However, they come at a higher cost and may have limited availability, making them a consideration for specialized buyers focused on high-performance needs.

Key Industrial Applications of bronze wheels

| Industry/Sector | Specific Application of Bronze Wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom wheels for high-performance vehicles | Enhanced aesthetics and performance, attracting buyers | Durability, weight specifications, and compliance with local regulations |

| Off-Road and Adventure Sports | Wheels for off-road trucks and SUVs | Improved traction and durability in rugged conditions | Load ratings, corrosion resistance, and fitment options |

| Construction and Heavy Machinery | Wheels for construction vehicles | Increased productivity and reduced downtime | Compatibility with machinery specifications and safety standards |

| Aerospace and Aviation | Specialty wheels for aircraft ground support | Lightweight design improves fuel efficiency | Compliance with aviation regulations and material certifications |

| Marine Industry | Wheels for boats and marine vehicles | Resistance to corrosion and harsh environmental conditions | Material quality and performance under marine conditions |

How Are Bronze Wheels Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, bronze wheels are often employed as custom wheels for high-performance vehicles. These wheels not only enhance the vehicle’s aesthetic appeal but also contribute to improved performance by reducing weight and optimizing traction. For international buyers, particularly in regions like Europe and South America, it is crucial to ensure that the wheels meet local safety and regulatory standards, while also considering the specific durability requirements that may vary based on climate and road conditions.

What Role Do Bronze Wheels Play in Off-Road and Adventure Sports?

In the off-road and adventure sports industry, bronze wheels are specifically designed for trucks and SUVs that navigate rugged terrains. These wheels provide superior traction and durability, essential for vehicles operating in challenging environments. B2B buyers in Africa and the Middle East should prioritize sourcing wheels with high load ratings and corrosion-resistant finishes to ensure longevity and reliability under extreme conditions. Additionally, fitment options must be verified to ensure compatibility with various vehicle models.

Why Are Bronze Wheels Important for Construction and Heavy Machinery?

For construction and heavy machinery, bronze wheels are utilized for various vehicles, enhancing productivity and minimizing downtime. The robustness of bronze wheels enables them to withstand the heavy loads and harsh conditions typical in construction sites. Buyers in this sector should focus on compatibility with specific machinery models and adherence to safety standards. Sourcing wheels that meet these requirements can lead to improved operational efficiency and reduced maintenance costs.

How Do Bronze Wheels Benefit the Aerospace and Aviation Sector?

In the aerospace and aviation sector, specialty bronze wheels are utilized for aircraft ground support equipment. Their lightweight design contributes to improved fuel efficiency, which is a critical factor in this industry. International buyers must ensure that the wheels comply with stringent aviation regulations and possess the necessary material certifications. This compliance not only guarantees safety but also enhances the overall operational performance of ground support vehicles.

In What Ways Are Bronze Wheels Used in the Marine Industry?

The marine industry often employs bronze wheels for boats and marine vehicles due to their excellent resistance to corrosion and ability to withstand harsh environmental conditions. This characteristic is vital for ensuring the longevity and reliability of marine equipment. B2B buyers should consider the quality of materials and performance specifications when sourcing bronze wheels for marine applications, ensuring that they meet the specific demands of saltwater environments and varying weather conditions.

3 Common User Pain Points for ‘bronze wheels’ & Their Solutions

Scenario 1: Sourcing Quality Bronze Wheels That Meet Compliance Standards

The Problem: B2B buyers often face challenges in sourcing bronze wheels that not only meet their aesthetic requirements but also comply with local regulations and quality standards. For buyers in regions like Africa and the Middle East, where import regulations can be strict, ensuring that the wheels adhere to specific certifications is critical. This can lead to delays in procurement, increased costs, and potential liability issues if non-compliant products are used.

The Solution: To mitigate these challenges, buyers should establish relationships with reputable suppliers that specialize in bronze wheels and possess the necessary certifications. It’s essential to request comprehensive product specifications and compliance documents before finalizing any orders. Additionally, conducting thorough research on suppliers’ reputations, including reviews from other B2B customers and checking their compliance history, can provide further assurance. Utilizing a fitment guide to verify compatibility with specific vehicle models will also help ensure that the wheels meet both performance and aesthetic needs.

Scenario 2: Understanding the Durability and Maintenance Needs of Bronze Wheels

The Problem: One of the most common pain points for B2B buyers is the concern about the durability and maintenance of bronze wheels, especially in harsh environments. Buyers operating in regions with extreme weather conditions or rough terrains may worry about how bronze wheels will hold up over time. They often encounter issues like corrosion, discoloration, and wear, which can lead to additional replacement costs and operational downtime.

The Solution: To address these concerns, buyers should prioritize sourcing bronze wheels that are treated with protective coatings specifically designed to enhance durability. When selecting wheels, consider those with finishes that are resistant to corrosion and fading, such as clear protective coatings or anodized finishes. Additionally, implementing a regular maintenance schedule that includes cleaning and inspecting the wheels can significantly extend their lifespan. Providing training for staff on proper cleaning techniques and periodic inspections will further help in maintaining the wheels’ appearance and functionality.

Scenario 3: Navigating the Aesthetic Appeal Versus Performance Trade-offs

The Problem: B2B buyers often struggle with the decision-making process between choosing bronze wheels for their aesthetic appeal versus prioritizing performance features. This dilemma can be particularly acute in industries where visual branding is essential, but operational efficiency cannot be compromised. Buyers may find themselves torn between trendy designs and specifications that enhance vehicle performance, leading to indecision and potential losses in procurement time.

The Solution: To overcome this issue, buyers should conduct a thorough analysis of their operational needs and branding goals. Engaging in discussions with suppliers can provide insights into how specific bronze wheel designs impact performance metrics like weight, load capacity, and handling. A tailored approach may involve selecting a bronze wheel that offers a balance between style and performance, such as choosing lightweight alloys that retain the desired visual appeal while enhancing vehicle dynamics. Furthermore, creating a prototype or conducting test runs with selected wheels can provide concrete data on their performance, helping buyers make informed decisions that align with both aesthetic and operational objectives.

Strategic Material Selection Guide for bronze wheels

What Are the Key Materials Used in Bronze Wheels?

When selecting bronze wheels for various applications, understanding the materials involved is crucial for ensuring optimal performance and durability. The following analysis covers four common materials used in the manufacturing of bronze wheels, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Alloy Impact Bronze Wheel Performance?

Aluminum alloys are often combined with bronze to enhance the wheel’s strength and reduce weight. Key properties of aluminum alloys include a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. These properties make aluminum alloys suitable for high-performance applications where weight savings are critical.

Pros: Aluminum alloys offer high durability and resistance to corrosion, making them ideal for off-road and heavy-duty applications. They are also relatively easy to manufacture, allowing for complex designs.

Cons: The primary disadvantage is cost; aluminum alloys can be more expensive than other materials. Additionally, they may not perform as well under extreme temperatures compared to other metals.

Impact on Application: Aluminum alloys are compatible with various media and environments, making them versatile for different vehicle types. However, international buyers should ensure compliance with local standards such as ASTM or DIN for quality assurance.

What Role Does Steel Play in Bronze Wheel Manufacturing?

Steel, particularly high-carbon steel, can also be used in the production of bronze wheels. Steel is known for its exceptional strength and resilience, making it suitable for heavy-duty applications.

Pros: The main advantage of steel is its durability and cost-effectiveness. Steel wheels can withstand high stress and impact, making them ideal for rugged terrains.

Cons: However, steel is heavier than aluminum, which can negatively affect vehicle performance. Additionally, steel is prone to rust if not properly coated, which can lead to corrosion over time.

Impact on Application: Steel wheels are often preferred in regions with rough terrains, such as parts of Africa and South America. Buyers should consider local environmental conditions and the need for protective coatings to prevent rust.

How Do Composite Materials Enhance Bronze Wheel Design?

Composite materials, such as carbon fiber reinforced polymers, are increasingly being used in the production of bronze wheels. These materials offer unique properties, including high strength, low weight, and excellent fatigue resistance.

Pros: Composites are lightweight, which can improve vehicle performance and fuel efficiency. They also provide excellent resistance to corrosion and environmental degradation.

Cons: The manufacturing process for composites can be complex and costly, limiting their use in mass production. Additionally, they may not be as widely accepted in traditional markets, which could affect resale value.

Impact on Application: Composites are particularly appealing to performance-oriented markets in Europe and the Middle East, where innovation is highly valued. B2B buyers should ensure compliance with international standards to facilitate market entry.

What Are the Benefits of Using Magnesium Alloys in Bronze Wheels?

Magnesium alloys are another option for bronze wheels, known for their lightweight and high strength. They are often used in high-performance automotive applications.

Pros: Magnesium alloys offer the best strength-to-weight ratio among metals, which can significantly enhance vehicle performance. They also have good corrosion resistance when treated properly.

Cons: However, magnesium alloys can be more expensive and are less commonly used than aluminum or steel. They also require careful handling during manufacturing due to their flammability.

Impact on Application: Magnesium alloys are particularly attractive in high-performance automotive markets in Europe and the Middle East. Buyers should be aware of the specific handling and compliance requirements associated with these materials.

Summary Table of Material Selection for Bronze Wheels

| Material | Typical Use Case for bronze wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | High-performance vehicles | High strength-to-weight ratio | Higher cost compared to other metals | Medium |

| Steel | Heavy-duty applications | Exceptional durability | Heavier and prone to rust | Low |

| Composite | Performance-oriented vehicles | Lightweight and corrosion-resistant | Complex manufacturing process | High |

| Magnesium Alloy | High-performance automotive | Best strength-to-weight ratio | Higher cost and handling complexity | High |

This guide provides a comprehensive overview of the materials commonly used in bronze wheels, helping international B2B buyers make informed decisions based on performance, cost, and application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for bronze wheels

What Are the Key Stages in the Manufacturing Process of Bronze Wheels?

The manufacturing process of bronze wheels is intricate, involving several critical stages that ensure high quality and performance. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Bronze Wheel Production?

The first step involves selecting high-quality bronze alloy, typically a combination of copper, tin, and other elements to enhance strength and corrosion resistance. The raw materials undergo rigorous testing to ensure they meet specified chemical compositions. This step is crucial as the properties of the alloy directly affect the durability and performance of the wheels.

Once the materials are confirmed, they are processed into appropriate forms, such as sheets or billets, which will be used in subsequent stages. The preparation phase may also include heat treatment processes to enhance material properties, making them suitable for forming.

What Techniques Are Used in Forming Bronze Wheels?

Forming is a critical stage where the prepared materials are shaped into wheels. This can be achieved through various techniques, including casting, forging, and machining.

-

Casting: In this method, molten bronze is poured into molds to create the desired wheel shape. This technique allows for intricate designs but requires careful temperature control to avoid defects.

-

Forging: This process involves shaping the bronze under high pressure, which improves the strength of the material. Forged wheels are often lighter and more durable, making them a popular choice in high-performance applications.

-

Machining: After forming, the wheels may undergo precision machining to achieve exact specifications for dimensions and finish. This ensures that all wheels meet the required tolerances for fitment.

How Are Bronze Wheels Assembled and Finished?

Once the individual components are formed, they are assembled. This may involve attaching the wheel rim to the hub, ensuring that all parts fit securely and align correctly.

Finishing is the final step in the manufacturing process, which includes surface treatments to enhance aesthetics and protect against environmental factors. Common finishing techniques for bronze wheels include anodizing and powder coating, which can provide both color options and additional corrosion resistance.

What Quality Assurance Practices Are Essential for Bronze Wheels?

Quality assurance (QA) is paramount in the manufacturing of bronze wheels. Adhering to international standards ensures that the products meet safety and performance requirements.

Which International Standards Should B2B Buyers Be Aware Of?

Most reputable manufacturers comply with ISO 9001, a standard that focuses on quality management systems. This certification indicates that the manufacturer has established processes to ensure consistent quality. Additionally, other industry-specific certifications like CE marking for compliance with European safety standards and API standards for performance in certain applications can be crucial for B2B buyers.

What Are the Key Quality Control Checkpoints in Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase ensures that raw materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After production, finished wheels undergo thorough testing to verify dimensions, finish, and performance characteristics. This may include load testing, visual inspections, and surface quality assessments.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure reliability in their supply chain, B2B buyers should adopt several strategies to verify supplier QC:

-

Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance measures in place. This can include reviewing documentation and observing production practices.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QA processes, including statistics on defect rates and corrective actions taken.

-

Third-Party Inspections: Utilizing independent third-party inspection services can add an additional layer of assurance. These organizations can perform unbiased evaluations of the manufacturing processes and finished products.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial, especially when dealing with suppliers from diverse regions such as Africa, South America, the Middle East, and Europe.

-

Cultural Differences: Different regions may have varying standards of quality and practices. Buyers should be aware of local manufacturing norms and how they may impact product quality.

-

Compliance with Local Regulations: Ensuring that products comply with local regulations in the buyer’s region is essential. This may involve additional certifications or testing that are not required in the supplier’s country.

-

Lead Times and Communication: Time zone differences and cultural communication styles can impact the efficiency of quality control processes. Establishing clear channels of communication and regular updates can help mitigate potential issues.

Conclusion: Ensuring Quality in Bronze Wheel Manufacturing

Manufacturing bronze wheels involves a complex interplay of material selection, forming techniques, assembly, and finishing processes. For B2B buyers, understanding these processes and the associated quality assurance practices is critical to ensuring that they receive high-quality products that meet their specifications. By leveraging international standards and effective verification methods, businesses can secure reliable suppliers and maintain confidence in their sourcing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bronze wheels’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure bronze wheels. Sourcing bronze wheels involves evaluating technical specifications, understanding market trends, and verifying supplier reliability. Following this checklist will ensure that you make informed purchasing decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the bronze wheels you intend to purchase. This includes determining the required diameter, width, bolt pattern, offset, and load rating. Understanding these specifications is vital to ensure the wheels fit your vehicles or machinery correctly, avoiding costly returns or modifications.

- Key Specifications to Consider:

- Wheel diameter (e.g., 15″, 17″, 18″)

- Bolt pattern (e.g., 5×100, 5×114.3)

- Load rating to meet operational requirements

Step 2: Research Market Trends

Stay updated on market trends related to bronze wheels to identify popular styles and finishes. Trends like matte bronze or hyper bronze can influence your choice based on consumer preferences or regional aesthetics. Understanding these trends can help you select products that will appeal to your target market, enhancing your competitive edge.

- Areas to Explore:

- Color variations (e.g., Matte Bronze, Bronze Chrome)

- Popular wheel styles among your competitors

- Seasonal variations in demand

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product catalogs, and case studies. This step is crucial to ensure that the supplier can meet your specific requirements and has a track record of reliability.

- Key Evaluation Criteria:

- Supplier certifications and industry standards

- Customer testimonials and reviews

- Production capacity and lead times

Step 4: Verify Quality Assurance Processes

Quality assurance is paramount when sourcing bronze wheels. Ensure that your chosen supplier implements rigorous quality control measures throughout their production processes. This will minimize defects and enhance the durability of the wheels, which is critical for maintaining safety and performance.

- What to Look For:

- Quality control certifications (e.g., ISO 9001)

- Inspection processes for raw materials and finished products

- Warranty policies that reflect product confidence

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among potential suppliers while considering the quality of the products offered. Additionally, negotiate payment terms that suit your cash flow requirements, such as payment upon delivery or installment plans. A clear understanding of pricing will help you manage budgets effectively.

- Important Considerations:

- Bulk order discounts or promotional offers

- Shipping costs and logistics

- Payment flexibility and credit terms

Step 6: Review Shipping and Delivery Options

Examine the shipping methods and delivery timelines provided by your suppliers. Timely delivery is crucial for maintaining your inventory and fulfilling customer orders. Understanding shipping options allows you to plan accordingly and avoid disruptions in your supply chain.

- Shipping Factors to Assess:

- Domestic vs. international shipping capabilities

- Delivery times based on location

- Tracking and insurance options for high-value orders

Step 7: Establish a Long-term Relationship

Once you find a reliable supplier, aim to establish a long-term partnership. A strong relationship can lead to better pricing, priority service, and access to new products as they become available. Regular communication and feedback will foster trust and ensure that your supplier understands your evolving needs.

- Strategies for Partnership:

- Schedule regular check-ins to discuss performance

- Share market insights to align on future trends

- Collaborate on promotional initiatives to drive sales

Comprehensive Cost and Pricing Analysis for bronze wheels Sourcing

What Are the Key Cost Components in Sourcing Bronze Wheels?

When sourcing bronze wheels, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The quality of materials used significantly impacts the cost. Bronze alloys vary in composition, affecting both durability and price. Higher-grade materials may increase upfront costs but can lead to lower maintenance expenses and longer lifespan.

-

Labor: Manufacturing bronze wheels involves skilled labor, particularly for processes like casting and machining. Labor costs can differ based on the region, with countries in Asia typically offering lower labor costs compared to Europe or North America.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can reduce overhead, benefiting overall pricing.

-

Tooling: Initial investment in tooling for production can be substantial, especially for custom designs. This cost is often amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs) when negotiating prices.

-

Quality Control (QC): Ensuring product quality is vital for maintaining standards. QC processes add to the cost but are necessary to minimize defects and returns, which can adversely impact profitability.

-

Logistics: Transportation costs, including shipping and handling, significantly influence the total cost. Factors like distance, shipping method, and Incoterms can add complexity and variability to logistics expenses.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the market dynamics and competitive landscape can help buyers negotiate better margins.

What Influences the Pricing of Bronze Wheels?

Several factors can affect the pricing of bronze wheels, including:

-

Volume/MOQ: Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better terms and reduce per-unit costs.

-

Specifications and Customization: Custom designs or specific specifications may increase costs. Buyers should clearly outline their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or certifications (like ISO or ASTM) may lead to increased costs but can enhance product reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived quality and reliability, whereas emerging manufacturers may offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect logistics and pricing. Buyers should understand the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) on their total costs.

What Are Some Effective Buyer Tips for Sourcing Bronze Wheels?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Leverage market research to justify requests for discounts or better terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, logistics, and potential resale value. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can impact the final cost of bronze wheels. These factors can vary significantly based on the buyer’s location.

-

Supplier Diversification: Consider sourcing from multiple suppliers to avoid dependency and to leverage competitive pricing. This approach can also mitigate risks associated with supply chain disruptions.

Disclaimer

Prices for bronze wheels can vary widely based on the factors discussed. The figures mentioned in this analysis are indicative and should be verified with suppliers for accurate pricing. Always conduct thorough research and due diligence before finalizing any purchase.

Alternatives Analysis: Comparing bronze wheels With Other Solutions

Exploring Alternatives to Bronze Wheels: A Comprehensive Comparison

In the ever-evolving landscape of vehicle wheels, bronze wheels have gained popularity for their aesthetic appeal and durability. However, various alternatives offer distinct advantages depending on specific requirements and applications. This analysis will compare bronze wheels with two viable alternatives: aluminum alloy wheels and steel wheels, focusing on key aspects relevant to B2B buyers.

| Comparison Aspect | Bronze Wheels | Aluminum Alloy Wheels | Steel Wheels |

|---|---|---|---|

| Performance | Good strength-to-weight ratio; suitable for off-road and performance vehicles | Excellent weight reduction; enhances fuel efficiency and handling | Durable but heavier, leading to reduced performance |

| Cost | Mid-range pricing; generally more expensive than steel | Varies widely; can be cost-effective or premium | Generally the most affordable option |

| Ease of Implementation | Requires precise fitment; may need specialized installation | Easy to install; widely compatible with many vehicles | Straightforward installation; commonly used |

| Maintenance | Low maintenance; resistant to corrosion | Requires periodic cleaning; susceptible to damage | Low maintenance; can rust without proper care |

| Best Use Case | Off-road vehicles, custom builds, and aesthetics | Performance vehicles, everyday cars, and racing | Commercial vehicles, budget builds, and winter use |

Detailed Breakdown of Alternatives

Aluminum Alloy Wheels

Aluminum alloy wheels are a popular choice in the automotive industry due to their lightweight characteristics. They improve vehicle performance by enhancing acceleration and fuel efficiency. Additionally, they are often designed with stylish finishes that can appeal to a wide range of consumers. However, they can be more susceptible to damage from road hazards and may require more frequent cleaning to maintain their appearance. Overall, they are ideal for performance-oriented applications but may not be as durable as bronze wheels in rugged conditions.

Steel Wheels

Steel wheels are known for their robustness and cost-effectiveness. They are typically heavier than both bronze and aluminum options, which can negatively impact performance, particularly in high-speed or off-road scenarios. Nevertheless, their strength makes them an excellent choice for commercial vehicles and applications where durability is paramount. Steel wheels are also less prone to cosmetic damage, making them suitable for harsh environments. However, they can rust if not properly maintained, and their heavier weight can reduce overall vehicle efficiency.

Conclusion: How to Choose the Right Wheel Solution for Your Needs

When selecting the right wheel solution, B2B buyers should consider their specific requirements, including performance, budget, and maintenance capabilities. Bronze wheels offer a compelling combination of style and durability, making them suitable for off-road and custom applications. In contrast, aluminum alloy wheels excel in performance and aesthetics but may require more upkeep. Steel wheels provide the best value in terms of cost and durability, particularly for commercial use. By carefully weighing these factors, buyers can make informed decisions that align with their operational needs and vehicle specifications.

Essential Technical Properties and Trade Terminology for bronze wheels

What Are the Key Technical Properties of Bronze Wheels That B2B Buyers Should Know?

When sourcing bronze wheels for commercial applications, understanding their technical specifications is crucial for ensuring compatibility and performance. Below are essential properties that buyers should consider:

1. Material Composition

Bronze wheels are typically made from an alloy that combines copper and tin, providing excellent strength and corrosion resistance. The specific material grade can affect the wheel’s performance characteristics, including weight, durability, and resistance to wear and tear. Buyers should verify the alloy composition to ensure it meets their specific application requirements, especially in harsh environments.

2. Wheel Diameter and Width

The diameter and width of a wheel are critical for fitment and performance. Common sizes range from 15 inches to 18 inches in diameter, with widths varying between 8 inches and 10.5 inches. The right dimensions ensure that the wheel fits the vehicle’s specifications, affecting handling, stability, and overall driving experience. Buyers should consult vehicle fitment guides or manufacturers to determine the appropriate size for their needs.

3. Bolt Pattern and Offset

The bolt pattern (measured in millimeters) and offset are vital for ensuring the wheel aligns correctly with the vehicle hub. For instance, a bolt pattern of 5×114.3 means there are five bolt holes spaced 114.3mm apart. Offset, which can be positive, negative, or zero, determines how far the wheel sits in relation to the vehicle’s suspension. Proper alignment minimizes wear on suspension components and enhances safety.

4. Load Rating

The load rating indicates the maximum weight a wheel can support without failing. Common ratings for bronze wheels can range from 2,200 lbs to 3,000 lbs. This specification is particularly important for commercial vehicles that carry heavy loads, ensuring that the wheels can withstand operational demands without compromising safety.

5. Hub Bore Size

The hub bore size is the diameter of the center hole on the wheel, which must fit snugly onto the vehicle’s hub. A mismatch can lead to vibrations and poor handling. Typical hub bore sizes for bronze wheels are around 71.5mm. Buyers should confirm the hub bore size to prevent installation issues.

What Common Trade Terms Should B2B Buyers Understand When Purchasing Bronze Wheels?

Familiarity with industry terminology can streamline the procurement process and facilitate better communication with suppliers. Here are some common terms relevant to bronze wheels:

1. OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle or its parts. When sourcing bronze wheels, buyers may prefer OEM products for guaranteed compatibility and quality assurance. Understanding OEM specifications helps in identifying the right products that meet original standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it can affect inventory levels and purchasing decisions. Buyers should inquire about the MOQ for bronze wheels to ensure it aligns with their purchasing capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of bronze wheels, an RFQ helps buyers gather multiple offers and compare them based on price, delivery time, and other terms. This process is essential for making informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade transactions. These terms clarify who bears the risk and cost of transportation, insurance, and duties. Familiarity with Incoterms is vital for B2B buyers to negotiate contracts effectively and understand their obligations.

5. Backspacing

Backspacing refers to the distance from the mounting surface of the wheel to the back edge of the wheel. This measurement is crucial for ensuring that the wheel fits within the vehicle’s fender wells without causing rubbing or clearance issues. Understanding backspacing helps buyers select wheels that are not only aesthetically pleasing but also functionally appropriate for their vehicles.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when procuring bronze wheels, ensuring they meet their operational needs and vehicle specifications.

Navigating Market Dynamics and Sourcing Trends in the bronze wheels Sector

What Are the Current Market Dynamics and Key Trends in the Bronze Wheels Sector?

The global bronze wheels market is experiencing significant growth, driven by increasing consumer demand for aesthetically appealing and high-performance automotive accessories. Factors such as the rising popularity of off-road and performance vehicles, particularly in regions like Africa and South America, are contributing to this trend. B2B buyers are increasingly seeking bronze wheels due to their unique visual appeal, which sets vehicles apart in a competitive market. This demand is further fueled by the growing trend of customization among vehicle owners, who prefer non-standard finishes to enhance the look of their vehicles.

Emerging technologies in manufacturing, such as advanced alloy compositions and innovative finishing techniques, are also transforming the bronze wheels sector. These advancements not only improve the durability and performance of the wheels but also allow for a wider range of designs and sizes. For international B2B buyers, understanding local market preferences and trends is crucial. For instance, buyers in Europe may favor a more refined aesthetic, while those in the Middle East may lean towards bold, eye-catching designs.

Sourcing trends are shifting towards online platforms that offer extensive catalogs and customization options. E-commerce solutions are becoming vital for international buyers, enabling them to easily compare products, access detailed specifications, and streamline the ordering process. Moreover, strategic partnerships with local distributors can enhance market penetration and customer service, making it essential for B2B buyers to cultivate these relationships.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions in the Bronze Wheels Market?

Sustainability is becoming a focal point in the bronze wheels sector, influencing purchasing decisions among B2B buyers. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or energy-efficient manufacturing methods.

Ethical sourcing is also crucial for maintaining brand reputation and meeting regulatory standards. B2B buyers should seek suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and without exploiting labor. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Incorporating ‘green’ materials in the production of bronze wheels not only reduces environmental impact but can also appeal to a growing segment of eco-conscious consumers. For instance, manufacturers utilizing low-emission processes or offering wheels made from recycled aluminum alloys can differentiate themselves in a crowded market. B2B buyers can leverage these aspects to enhance their value proposition, aligning their offerings with the values of their target customers.

What Is the Historical Context Behind the Popularity of Bronze Wheels?

The evolution of bronze wheels can be traced back to the early days of automotive customization, where aesthetics began to play a pivotal role in vehicle modifications. Traditionally, silver and chrome finishes dominated the market; however, as consumer preferences shifted towards more personalized and unique styles, bronze emerged as a popular alternative. Its warm tone and classic appeal provided a fresh take on wheel aesthetics, allowing vehicle owners to express individuality.

In the past two decades, the rise of the aftermarket automotive scene has accelerated the acceptance of non-traditional finishes like bronze. This shift has been driven by a growing community of automotive enthusiasts who value customization as a form of self-expression. Manufacturers began to recognize this trend and responded by offering an expanding range of bronze wheel options, from matte finishes to intricate designs.

Today, bronze wheels not only symbolize a distinct style but also reflect the evolving tastes of consumers who seek both performance and aesthetics. For B2B buyers, understanding this historical context can provide insights into current market trends and help identify opportunities for product differentiation in their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of bronze wheels

-

How can I determine the right specifications for bronze wheels for my vehicles?

To select the appropriate bronze wheels, begin by considering the vehicle’s specifications, including bolt pattern, offset, and diameter. Consult your vehicle’s manual or existing wheel specifications for accurate measurements. Additionally, utilize online fitment guides provided by suppliers to cross-reference wheel dimensions. This ensures compatibility and optimal performance. Engaging with a knowledgeable supplier can also facilitate finding the best options based on your specific requirements. -

What are the key factors to consider when sourcing bronze wheels from international suppliers?

When sourcing bronze wheels internationally, prioritize supplier reputation, product quality, and compliance with industry standards. Verify their certifications and ask for references from previous clients. Evaluate their manufacturing processes and quality assurance measures to ensure they meet your expectations. Additionally, consider their ability to provide timely delivery and after-sales support, as these factors are crucial for maintaining operational efficiency in your business. -

What are the minimum order quantities (MOQ) for bronze wheels?

MOQs for bronze wheels can vary significantly based on the manufacturer and the specific product line. Typically, MOQs range from 50 to 100 units, but some suppliers may offer flexibility for smaller orders or initial samples. It’s advisable to discuss your needs directly with potential suppliers to understand their terms and negotiate MOQs that align with your purchasing strategy. This flexibility can be crucial for new businesses or those testing market demand. -

How can I customize bronze wheels to meet specific design requirements?

Customization options for bronze wheels often include size, finish, and design elements such as spoke patterns and colors. Many suppliers offer bespoke services that allow you to specify your requirements. It’s essential to communicate your vision clearly and provide detailed specifications, including any design files if necessary. Request samples or prototypes to assess the final product before committing to a larger order, ensuring that the customization aligns with your brand’s aesthetic. -

What payment terms should I expect when sourcing bronze wheels internationally?

Payment terms can vary by supplier, but common practices include a deposit (typically 30-50%) upfront and the balance upon delivery or before shipping. Some suppliers may offer credit terms for established businesses or bulk orders. It’s vital to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Always ensure that the payment terms are documented in your purchase agreement to avoid misunderstandings. -

How do I ensure quality assurance for the bronze wheels I import?

To guarantee quality assurance, establish clear quality control standards with your supplier before placing an order. Request samples to evaluate material quality and craftsmanship. Additionally, consider third-party inspections during production and before shipment to verify compliance with your specifications. Ensure that the supplier provides warranties or guarantees that protect your investment and offer recourse in the event of defects. -

What logistics considerations should I keep in mind when importing bronze wheels?

Logistics play a crucial role in the importation of bronze wheels. Evaluate shipping methods, costs, and delivery timelines to ensure they align with your operational needs. Consider customs regulations and import duties in your country, which can impact overall costs. Partnering with a reliable freight forwarder can streamline the process and help navigate any complexities related to international shipping, ensuring your order arrives on time and in good condition. -

How can I stay updated on market trends for bronze wheels?

To stay informed about market trends for bronze wheels, regularly engage with industry publications, online forums, and trade shows focused on automotive parts. Networking with other B2B buyers and suppliers can provide valuable insights into emerging styles and technologies. Additionally, subscribing to newsletters from key manufacturers and following industry influencers on social media can keep you abreast of the latest innovations and consumer preferences in the bronze wheels market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Bronze Wheels Manufacturers & Suppliers List

1. Method Race Wheels – Bronze Wheels for Trucks, Jeeps, and SUVs

Domain: methodracewheels.com

Registered: 2009 (16 years)

Introduction: This company, Method Race Wheels – Bronze Wheels for Trucks, Jeeps, and SUVs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Cosmis USA – Bronze Wheels

Domain: cosmisusa.com

Registered: 2012 (13 years)

Introduction: This company, Cosmis USA – Bronze Wheels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Discounted Wheel Warehouse – Custom Wheels for Trucks and Cars

Domain: discountedwheelwarehouse.com

Registered: 2002 (23 years)

Introduction: Bronze custom wheels available for trucks and cars; options for lightweight performance or durable wheels; brands include Fuel, KMC, and American Racing; various sizes and widths available; over 1 million wheels and tires sold; options to filter by wheel diameter (14″ to 26″), width (6.5″ to 12″), and brand.

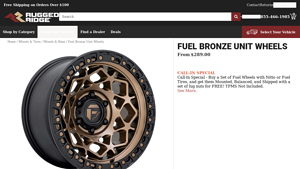

4. Rugged Ridge – Fuel Bronze Unit Wheels

Domain: ruggedridge.com

Registered: 2000 (25 years)

Introduction: {“name”: “Fuel Bronze Unit Wheels”, “price”: “From $289.00”, “features”: [“Matte bronze finish with black ring”, “Mesh-like design”, “Concave face”, “Simulated beadlock ring”, “Spot milled ring accents”, “Fuel center cap”], “warranty”: {“structural”: “Lifetime”, “finish”: “1 Year”}, “material”: “Durable cast aluminum”, “construction”: “1 piece”, “style”: “Race/baja style”, “call_in_special”: “Buy …

5. Reddit – Bronze Wheels for Ford Mustangs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bronze wheels for Ford Mustangs; users discuss their long-term satisfaction and compatibility with various car colors.

6. Element Wheels – Premium Wheel Selection

Domain: elementwheels.com

Registered: 2004 (21 years)

Introduction: This company, Element Wheels – Premium Wheel Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Anovia Wheels – 18 Inch Bronze Rims

Domain: maperformance.com

Registered: 2004 (21 years)

Introduction: 18 Inch Wheels & Rims | MAPerformance – Tagged “Bronze”. Vendor restrictions prevent sales in Australia, the UK, and California. Shipping is limited to the United States. Contact customer service for inquiries. Available brands include Anovia Wheels, AodHan Wheels, Enkei, ESR Wheels, Stage Wheels, Volk Racing, and XXR Wheels. In stock items: 29; out of stock items: 6. Price range: From $ to $1,102…

8. Lock Off Road Wheels – Lunatic Matte Bronze

Domain: lockoffroadwheels.com

Registered: 2022 (3 years)

Introduction: {“product_name”:”Lunatic Matte Bronze”,”wheel_size”:”20×9″,”offset”:”-12″,”bolt_pattern”:”6×139.7″,”finish”:”Matte Bronze”,”material”:”Aluminum”,”load_rating”:”2500 lbs”,”features”:”Lightweight, Durable, Off-road ready”}

9. Wheel Pros – Key Product

Domain: wheelpros.com

Registered: 1998 (27 years)

Introduction: Key product details include a variety of wheels categorized by brand, type, and specifications. Brands featured include American Racing, Black Rhino, Fuel Off-Road, KMC Wheels, Rotiform, and more. The wheels are available in different materials such as cast aluminum and flow formed aluminum. The product range includes options for UTVs and off-road vehicles. Various specifications are provided, inc…

Strategic Sourcing Conclusion and Outlook for bronze wheels

How Can Strategic Sourcing Enhance Your Procurement of Bronze Wheels?

In summary, strategic sourcing for bronze wheels presents a unique opportunity for international B2B buyers to leverage the growing popularity of these stylish and high-performance products. With their aesthetic appeal and diverse range of styles, bronze wheels can enhance the value proposition of any vehicle, catering to the preferences of markets in Africa, South America, the Middle East, and Europe.

By focusing on quality suppliers and understanding regional demands, businesses can ensure they are offering competitive products that resonate with local consumers. Additionally, the importance of fitment guides, load ratings, and wheel specifications cannot be overstated; these factors play a crucial role in meeting the performance expectations of end-users.

As the market evolves, it’s vital to stay ahead of trends, recognizing that consumer preferences are shifting towards distinctive, non-traditional colors like bronze. Now is the time to act—strengthen your procurement strategy by establishing partnerships with reputable manufacturers and distributors who can provide the latest designs and innovations in bronze wheels. Embrace this trend, and position your business for success in a rapidly changing marketplace.