Discover the Benefits of a Pattern Sewer: Your Guide (2025)

Introduction: Navigating the Global Market for pattern sewer

As the global market for pattern sewing continues to expand, B2B buyers face the critical challenge of identifying reliable suppliers and high-quality materials that meet their specific needs. Whether you are sourcing intricate patterns for fashion design or durable textiles for industrial applications, understanding the nuances of pattern sewing is vital. This guide provides a comprehensive overview of the market, covering essential topics such as types of patterns, various applications, effective supplier vetting strategies, and cost considerations.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe—countries such as Egypt and the UK—making informed purchasing decisions can significantly impact business outcomes. This guide empowers buyers by equipping them with actionable insights and practical tools to navigate the complexities of sourcing.

By exploring critical factors such as quality control, production timelines, and ethical sourcing practices, you will be better positioned to negotiate favorable terms and establish long-lasting partnerships with suppliers. Ultimately, this resource aims to facilitate a smoother procurement process, ensuring that you can confidently invest in the right pattern sewing solutions tailored to your business needs.

Understanding pattern sewer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Pattern Sewers | Operated by hand, allows for high customization. | Small-scale fashion production, bespoke tailoring. | Pros: Customization; Cons: Labor-intensive, slower production rates. |

| Computerized Pattern Sewers | Automated systems that enhance precision and speed. | Mass production, industrial garment manufacturing. | Pros: High efficiency; Cons: High initial investment. |

| Overlock Pattern Sewers | Specializes in finishing edges to prevent fraying. | Apparel manufacturing, knitwear production. | Pros: Durable seams; Cons: Limited to specific types of fabrics. |

| Flatlock Pattern Sewers | Creates flat seams for a smooth finish, often used in activewear. | Sportswear and activewear production. | Pros: Comfort; Cons: Requires skilled operators. |

| Chain Stitch Pattern Sewers | Utilizes a chain stitch for flexibility and stretch. | Denim production, heavy-duty fabrics. | Pros: Stretchable seams; Cons: Less durable than other stitches. |

What Are the Key Characteristics of Manual Pattern Sewers?

Manual pattern sewers are characterized by their hands-on operation, allowing for a high degree of customization and flexibility. They are particularly suitable for small-scale fashion production or bespoke tailoring, where unique designs are crucial. B2B buyers should consider the labor intensity and slower production rates, which may not be ideal for high-volume needs but are perfect for niche markets.

How Do Computerized Pattern Sewers Enhance Production?

Computerized pattern sewers utilize advanced technology to automate the sewing process, significantly increasing precision and speed. These machines are ideal for mass production in industrial garment manufacturing, making them a popular choice among larger apparel brands. While the efficiency and accuracy are major advantages, buyers must weigh the high initial investment against potential long-term savings in labor and material costs.

What Are the Benefits of Overlock Pattern Sewers?

Overlock pattern sewers are designed to finish fabric edges, preventing fraying and enhancing durability. They find primary applications in apparel manufacturing and knitwear production, where fabric integrity is critical. Buyers should note that while overlock machines provide strong seams, they are limited to specific fabric types, which may restrict their versatility in diverse production settings.

Why Choose Flatlock Pattern Sewers for Activewear?

Flatlock pattern sewers are known for creating smooth seams, making them ideal for sportswear and activewear production. Their design allows for comfort and flexibility, which is essential in athletic clothing. However, they require skilled operators to achieve the desired quality, which can be a consideration for B2B buyers focused on maintaining production standards while managing labor costs.

What Makes Chain Stitch Pattern Sewers Suitable for Denim?

Chain stitch pattern sewers employ a unique stitching method that provides flexibility and stretch, making them particularly well-suited for denim production and heavy-duty fabrics. This type of sewing machine is favored for its ability to create seams that can withstand significant wear and tear. Buyers should consider the balance between the benefits of stretchability and the potential trade-offs in durability compared to other stitching methods.

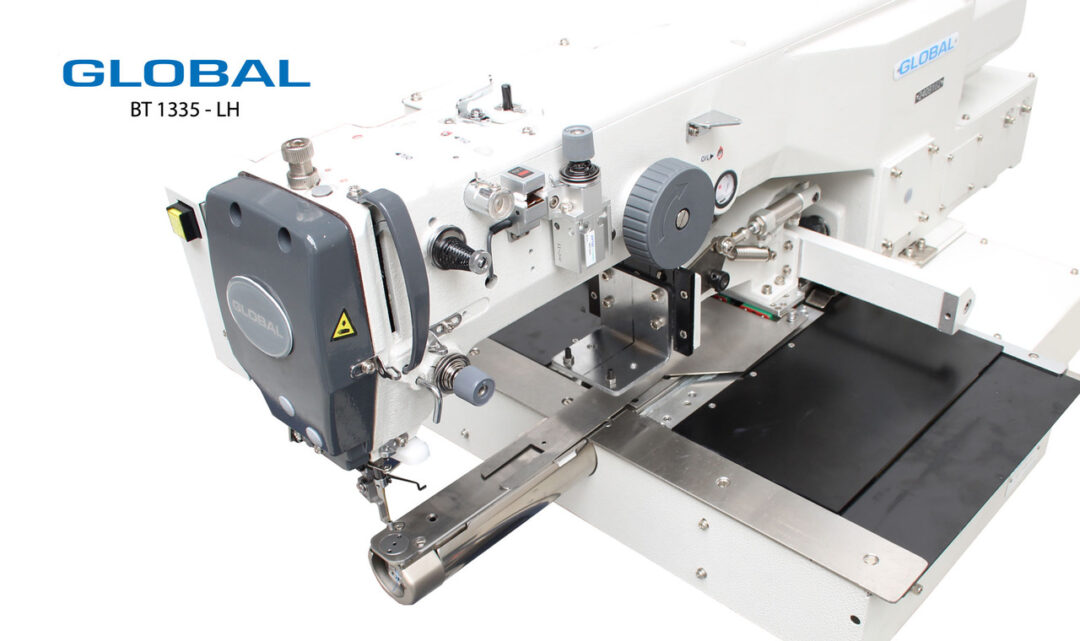

Related Video: How to use BAS-326G Programmable electronic pattern sewer

Key Industrial Applications of pattern sewer

| Industry/Sector | Specific Application of Pattern Sewer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Production of intricate fabric patterns | Enhances product differentiation and aesthetic appeal | Quality of materials, precision in pattern design, and lead times |

| Fashion Design | Custom garment creation | Enables unique fashion statements and market adaptability | Trend alignment, sustainable sourcing, and flexibility in orders |

| Interior Design | Upholstery and drapery pattern design | Improves interior aesthetics and customer satisfaction | Material durability, colorfastness, and compliance with local standards |

| Automotive Industry | Upholstery patterns for vehicle interiors | Enhances comfort and luxury perception in vehicles | Compliance with safety standards, durability, and comfort features |

| Home Décor | Custom patterns for curtains and furnishings | Adds personalization and style to living spaces | Fabric quality, design versatility, and alignment with market trends |

How is Pattern Sewer Used in Textile Manufacturing?

In the textile manufacturing sector, pattern sewers are crucial for creating intricate designs on fabrics. This application allows manufacturers to produce unique patterns that differentiate their products in a saturated market. For international buyers, especially from regions like Africa and South America, sourcing high-quality materials and ensuring precision in pattern design are essential. Buyers should also consider lead times to meet seasonal demands.

What Role Does Pattern Sewer Play in Fashion Design?

In fashion design, pattern sewers are utilized for custom garment creation, allowing designers to bring their creative visions to life. This capability not only fosters unique fashion statements but also enables brands to adapt swiftly to changing market trends. B2B buyers in Europe, particularly in the UK, should prioritize trend alignment and sustainable sourcing when engaging with pattern sewer suppliers to enhance brand reputation and customer appeal.

How is Pattern Sewer Utilized in Interior Design?

Interior designers leverage pattern sewers to create bespoke upholstery and drapery patterns that enhance the aesthetic appeal of spaces. This application directly contributes to customer satisfaction and the overall ambiance of a room. For buyers in the Middle East, understanding material durability and colorfastness is vital, as these factors impact the longevity and maintenance of interior designs.

What is the Importance of Pattern Sewer in the Automotive Industry?

In the automotive sector, pattern sewers are employed to produce upholstery patterns for vehicle interiors, significantly enhancing comfort and luxury perceptions. This application is increasingly important as consumers seek vehicles that offer both functionality and style. International buyers should focus on compliance with safety standards and the durability of materials when sourcing pattern sewers for automotive applications.

How Does Pattern Sewer Enhance Home Décor?

Pattern sewers are essential in the home décor industry for creating custom patterns for curtains and furnishings, adding a personal touch to living spaces. This capability allows businesses to cater to diverse customer tastes and preferences. Buyers from South America should consider fabric quality and design versatility to ensure their offerings align with market demands and consumer expectations.

Related Video: LABORATORY APPARATUS AND THEIR USES

3 Common User Pain Points for ‘pattern sewer’ & Their Solutions

Scenario 1: Inconsistent Stitching Quality in Production

The Problem: B2B buyers often encounter challenges with the quality of stitching when using pattern sewers. This inconsistency can lead to product defects, requiring costly rework or even resulting in wasted materials. For companies that depend on high-quality outputs, especially in the fashion and textile industries, this can severely impact brand reputation and customer satisfaction. Buyers may also face difficulties in assessing the skill level of operators, leading to further complications in quality assurance.

The Solution: To mitigate these issues, buyers should invest in comprehensive training programs for their sewing operators. This training should cover the intricacies of pattern sewing, including machine maintenance, fabric handling, and quality control measures. Additionally, implementing a rigorous quality assurance process is crucial. This could involve regular audits of the sewing process, setting clear quality standards, and using sample checks to ensure consistency. Sourcing pattern sewers from reputable manufacturers that provide training and support can also enhance the overall production quality. By prioritizing operator training and quality checks, businesses can ensure that they maintain high standards in their products.

Scenario 2: Difficulty in Finding the Right Pattern Designs

The Problem: Another significant pain point for B2B buyers is the struggle to find the right pattern designs that meet their specific needs. This can be particularly challenging for companies targeting niche markets or those looking to differentiate their products in a competitive landscape. Without access to a diverse range of patterns, businesses risk producing uninspired or generic products that fail to resonate with consumers.

The Solution: To overcome this hurdle, buyers should establish partnerships with specialized pattern designers or pattern libraries that focus on their target market. Engaging with freelance designers or using platforms that connect businesses with creative professionals can yield unique and tailored designs. Moreover, investing in software that allows for digital pattern creation and customization can provide flexibility in design processes. Encouraging collaboration between design and production teams will ensure that the patterns chosen are not only aesthetically pleasing but also feasible for production, thus streamlining the entire process from conception to finished product.

Scenario 3: High Production Costs Due to Inefficient Processes

The Problem: High production costs can significantly strain the budgets of B2B buyers, particularly in regions where labor and material costs fluctuate. Inefficient sewing processes, whether due to outdated machinery or poorly designed workflows, can lead to increased labor hours and material waste. This inefficiency not only affects profitability but can also lead to delayed delivery times, negatively impacting customer relationships.

The Solution: Buyers can tackle this issue by conducting a thorough analysis of their current sewing processes. Implementing lean manufacturing principles can help identify wasteful practices and streamline operations. Investing in modern sewing technology, such as automated pattern sewing machines, can significantly enhance efficiency and reduce labor costs. Additionally, optimizing the layout of the sewing floor to promote better workflow can minimize movement and increase productivity. Regular training sessions that focus on efficient sewing techniques can also empower workers to perform at their best, ultimately driving down production costs while maintaining quality standards.

Strategic Material Selection Guide for pattern sewer

When selecting materials for pattern sewers, international B2B buyers must consider various factors that influence product performance, manufacturing complexity, and regulatory compliance. Below is an analysis of four common materials used in pattern sewing, focusing on their properties, advantages, disadvantages, and considerations for international markets, particularly in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Cotton in Pattern Sewing?

Cotton is a widely used natural fiber in pattern sewing due to its softness and breathability. It typically has a temperature rating that allows for comfortable wear in various climates. Cotton is also biodegradable and relatively inexpensive, making it a popular choice for eco-conscious brands.

Pros:

– Excellent moisture absorption and breathability.

– Soft texture, suitable for skin contact.

– Biodegradable and environmentally friendly.

Cons:

– Prone to shrinkage and wrinkling.

– Limited durability compared to synthetic fibers.

– Requires careful washing to maintain appearance.

Impact on Application:

Cotton is compatible with a variety of media, including dyes and prints, making it versatile for different designs. However, its tendency to shrink may affect pattern accuracy over time.

Considerations for International Buyers:

Buyers should ensure compliance with local textile regulations, such as the OEKO-TEX certification, which guarantees that the fabric is free from harmful substances. In regions like Europe, adherence to such standards is often mandatory.

How Does Polyester Compare as a Material for Pattern Sewing?

Polyester is a synthetic fiber known for its durability and resistance to shrinking and stretching. It performs well under varying temperature and pressure conditions, making it suitable for a wide range of applications.

Pros:

– High durability and resistance to wear.

– Excellent moisture-wicking properties.

– Quick-drying, making it ideal for activewear.

Cons:

– Less breathable than natural fibers, which may lead to discomfort in hot climates.

– Environmental concerns regarding its production and disposal.

– Can be more expensive than cotton.

Impact on Application:

Polyester is compatible with various printing techniques, including sublimation, which allows for vibrant designs. However, its lower breathability may limit its use in certain climates.

Considerations for International Buyers:

Buyers should be aware of sustainability certifications, such as Global Recycled Standard (GRS), especially in regions like Europe, where eco-friendly products are increasingly preferred.

What Are the Benefits and Limitations of Nylon in Pattern Sewing?

Nylon is another synthetic fiber known for its strength and elasticity. It has a high resistance to abrasion and is often used in applications requiring durability and flexibility.

A stock image related to pattern sewer.

Pros:

– Exceptional strength-to-weight ratio.

– Resistant to mildew and abrasion.

– Good elasticity, maintaining shape over time.

Cons:

– Can be less breathable than cotton and polyester.

– May require special care to avoid damage.

– Higher cost compared to natural fibers.

Impact on Application:

Nylon is suitable for outdoor and activewear patterns due to its durability. However, its lower breathability may not be ideal for all applications.

Considerations for International Buyers:

Compliance with international standards like ASTM and DIN is crucial, particularly for buyers in the Middle East and Europe, where product safety and performance are heavily regulated.

How Does Spandex Enhance Pattern Sewing Applications?

A stock image related to pattern sewer.

Spandex, also known as elastane, is often blended with other fibers to provide stretchability. Its key property is its ability to return to its original shape after stretching, which is essential for form-fitting garments.

Pros:

– Provides excellent stretch and recovery.

– Enhances comfort and fit in garments.

– Durable and resistant to wear.

Cons:

– Can degrade with exposure to heat and sunlight.

– Limited breathability when used in high percentages.

– Higher manufacturing complexity due to blending requirements.

Impact on Application:

Spandex is ideal for activewear and fitted garments, enhancing the overall performance of the fabric. However, its inclusion may complicate the manufacturing process.

Considerations for International Buyers:

Buyers should ensure that spandex meets local regulations regarding chemical safety, particularly in markets like Europe, where stringent guidelines exist.

Summary Table of Material Selection for Pattern Sewing

| Material | Typical Use Case for Pattern Sewer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual wear, home textiles | Soft, breathable, eco-friendly | Prone to shrinkage and wrinkles | Low |

| Polyester | Activewear, outdoor clothing | Durable, quick-drying | Less breathable | Medium |

| Nylon | Outdoor gear, activewear | Strong, abrasion-resistant | Less breathable | High |

| Spandex | Fitted garments, activewear | Excellent stretch and recovery | Degrades with heat exposure | Medium |

This guide provides essential insights for international B2B buyers, enabling informed decisions regarding material selection for pattern sewing, ensuring compliance, and meeting market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for pattern sewer

What Are the Main Stages of Manufacturing for Pattern Sewers?

The manufacturing process for pattern sewers typically involves several key stages that ensure the final product meets both functional and aesthetic requirements. Understanding these stages is crucial for international B2B buyers looking to ensure quality and efficiency in their supply chains.

Material Preparation: How Is Fabric Sourced and Prepared?

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality fabrics that align with the specific needs of pattern sewing. Key considerations include:

- Fabric Types: Buyers should be aware of the different types of fabrics suitable for pattern sewing, such as cotton, polyester, and blends. Each fabric type has unique properties that affect the final product.

- Pre-Treatment: Fabrics often undergo pre-treatment processes such as washing, bleaching, or dyeing to remove impurities and prepare them for sewing. This step is essential to ensure that the fabric behaves as expected during the sewing process.

By collaborating closely with suppliers who have established relationships with reputable fabric mills, B2B buyers can ensure that they receive high-quality materials.

Forming: What Techniques Are Used in Pattern Sewing?

Once the materials are prepared, the next step is forming, where the fabric is cut and shaped according to the required patterns. Techniques commonly used include:

- Pattern Drafting: This involves creating templates based on design specifications. Accurate drafting is essential to avoid discrepancies in size and fit.

- Cutting Methods: Different cutting methods, such as manual cutting or automated cutting machines, can be used. Automated cutting offers precision and speed, which is particularly beneficial for large production runs.

B2B buyers should evaluate suppliers based on their cutting technologies and the skill level of their workforce to ensure precision in the forming stage.

Assembly: How Are Patterns Sewn Together?

The assembly stage is where the actual sewing occurs. Key techniques include:

- Sewing Techniques: Various sewing techniques are employed depending on the fabric and design, including straight stitching, zigzag stitching, and overlocking. The choice of technique impacts the durability and finish of the final product.

- Quality of Sewing Equipment: The type of sewing machines used (industrial vs. domestic) can influence efficiency and quality. Industrial machines are preferred for large-scale production due to their speed and durability.

B2B buyers should ensure that their suppliers use advanced sewing technologies and skilled labor to maintain high-quality standards during assembly.

Finishing: What Processes Enhance the Final Product?

The final stage in manufacturing is finishing, which enhances the product’s appearance and prepares it for delivery. This includes:

- Trimming and Pressing: Excess threads are trimmed, and the product is pressed to ensure a polished look.

- Quality Checks: Final quality inspections are conducted to ensure that the product meets design specifications and quality standards.

Buyers should inquire about the finishing processes used by suppliers to ensure that their products are presented professionally.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is crucial in the manufacturing process to ensure that the final products meet international standards and buyer expectations. Understanding these QA measures will help buyers make informed decisions when selecting suppliers.

Which International Standards Should Suppliers Adhere To?

International quality standards, such as ISO 9001, serve as benchmarks for manufacturing and quality assurance. These standards ensure that suppliers maintain consistent quality in their processes. Additionally, industry-specific standards, such as CE marking for products sold in Europe or API standards for specific sectors, should also be considered.

B2B buyers should verify that their suppliers are certified under these standards, as it reflects their commitment to quality and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic checks at various points in the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): This includes monitoring production processes to identify and rectify any issues during manufacturing.

- Final Quality Control (FQC): This is a comprehensive inspection of the finished product before it is shipped to ensure it meets all specifications.

B2B buyers should engage with suppliers who implement rigorous QC processes at each checkpoint.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

What Audit Processes Should Be Implemented?

Regular audits are an effective way to assess a supplier’s quality control measures. These can be conducted by:

- Internal Audits: Suppliers should perform regular internal audits to ensure compliance with their own quality standards.

- Third-Party Audits: Engaging third-party auditors can provide an objective assessment of a supplier’s quality assurance processes.

Buyers should request audit reports and findings to understand the supplier’s commitment to quality.

What Testing Methods Are Commonly Used?

Common testing methods for quality assurance in pattern sewing include:

- Fabric Testing: Assessing fabric properties such as tensile strength, colorfastness, and shrinkage.

- Product Testing: Evaluating the finished product for durability, fit, and overall quality.

By understanding the testing methods employed by suppliers, B2B buyers can gauge the reliability of their products.

What Are the Nuances of Quality Control for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are additional nuances to consider in quality control:

- Regulatory Compliance: Different regions may have specific regulations regarding textile products. Understanding these regulations is crucial for compliance and market entry.

- Cultural Expectations: Quality perceptions may vary across cultures. Buyers should communicate their quality expectations clearly to avoid misunderstandings.

By being aware of these nuances, international B2B buyers can better navigate the complexities of global sourcing and manufacturing.

In conclusion, understanding the manufacturing processes and quality assurance measures for pattern sewing is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control practices, buyers can ensure they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pattern sewer’

Introduction

Sourcing a reliable pattern sewer is a critical step for businesses in the fashion and textile industry, particularly for international B2B buyers from Africa, South America, the Middle East, and Europe. This guide provides a practical checklist to help you navigate the procurement process effectively, ensuring you find a supplier that meets your technical and quality requirements while also aligning with your business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for communicating your needs to potential suppliers. Outline the types of patterns you require, the materials to be used, and any specific design elements that must be incorporated. This will not only streamline the sourcing process but also minimize misunderstandings later on.

- Material Requirements: Specify the fabric types and any eco-friendly options if sustainability is a priority for your brand.

- Pattern Complexity: Determine whether you need basic patterns or more intricate designs, as this will influence the skill level required from the supplier.

Step 2: Conduct Market Research on Suppliers

Researching the market is crucial to identify potential suppliers who specialize in pattern sewing. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. This step is vital to ensure you have a diverse range of options to consider.

- Industry Reputation: Look for suppliers with positive reviews and testimonials from other businesses in your sector.

- Local vs. International Suppliers: Consider the advantages of sourcing locally, such as reduced shipping costs and shorter lead times, versus the potential for lower prices from international suppliers.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence is critical to mitigate risks associated with supplier reliability.

- Quality Assurance Processes: Inquire about their quality control measures and how they handle defects or production issues.

- Previous Work Samples: Ask for samples of their previous work to assess the quality of their sewing and pattern-making skills.

Step 4: Verify Supplier Certifications

Certifications can provide additional assurance about a supplier’s capabilities and adherence to industry standards. Verify any relevant certifications they may hold, such as ISO certifications or compliance with local labor laws. This step is important for ensuring ethical practices and quality assurance.

- Sustainability Certifications: If your brand emphasizes sustainability, check for certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX.

- Safety Standards: Ensure that the supplier meets necessary safety and quality standards relevant to your target market.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms and conditions. This includes pricing, payment terms, lead times, and any penalties for non-compliance. Clear agreements help to establish mutual expectations and can prevent disputes later on.

- Payment Options: Discuss upfront payments versus payment upon delivery to find a balance that works for both parties.

- Lead Time Guarantees: Ensure that the supplier can commit to your required timelines, especially for seasonal or time-sensitive projects.

Step 6: Establish a Communication Protocol

Effective communication is key to a successful partnership. Establish a protocol that outlines how you will communicate with your supplier, including preferred methods (email, phone, video calls) and frequency of updates. This step is essential to keep projects on track and address any issues promptly.

- Regular Check-ins: Schedule periodic meetings to review progress and make adjustments as needed.

- Point of Contact: Designate a specific person on both sides to streamline communication and decision-making.

A stock image related to pattern sewer.

Step 7: Plan for Quality Control and Feedback

Implement a quality control process to ensure that the final products meet your specifications. Plan for regular feedback sessions with your supplier to discuss any issues and areas for improvement. This ongoing dialogue is vital for building a productive long-term relationship.

- Inspection Procedures: Set guidelines for inspecting samples before full-scale production begins.

- Feedback Mechanism: Establish a clear method for providing constructive feedback to encourage continuous improvement.

By following these steps, international B2B buyers can effectively source a reliable pattern sewer that meets their business needs and quality standards.

Comprehensive Cost and Pricing Analysis for pattern sewer Sourcing

What Are the Key Cost Components in Sourcing Pattern Sewers?

When sourcing pattern sewers, understanding the cost structure is crucial for effective budgeting and negotiations. The primary cost components include:

-

Materials: The choice of fabrics and threads significantly impacts cost. High-quality materials may lead to higher initial expenses but can improve durability and customer satisfaction.

-

Labor: Skilled labor is essential for quality pattern sewing. Labor costs can vary greatly based on geographic location and the skill level of the workers. For instance, sourcing from regions with lower wage standards, such as parts of Africa or South America, may reduce costs.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses associated with running the sewing facility. Efficient manufacturing practices can help minimize these costs.

-

Tooling: The cost of specialized tools and machinery needed for pattern sewing can be significant. Investing in the right tools can enhance productivity and quality.

-

Quality Control (QC): Implementing a robust QC process ensures that the finished products meet required specifications. While this adds to the cost, it can prevent costly returns and rework.

-

Logistics: Shipping costs, including freight and insurance, should be factored into the overall cost structure. These can vary based on distance, shipping method, and the chosen Incoterms.

-

Margin: Suppliers will include a profit margin that can vary based on competition, demand, and their operational costs.

How Do Price Influencers Affect Pattern Sewer Sourcing?

Several factors can influence the pricing of pattern sewing services:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, reducing the per-unit cost. Negotiating MOQs can lead to better pricing arrangements.

-

Specifications and Customization: Custom designs typically incur additional costs. Clearly defining specifications can help control costs and avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials affects both the price and the quality of the finished product. Certifications can also add to costs but may be necessary for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium but offer better quality assurance.

-

Incoterms: Understanding Incoterms is vital for determining who is responsible for shipping costs and risks. This can significantly impact the overall cost of sourcing.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers can adopt several strategies to enhance their sourcing effectiveness:

-

Negotiate Terms: Always negotiate the price and terms with suppliers. Consider discussing discounts for larger orders or long-term contracts.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial price. This includes considering quality, durability, and potential returns.

-

Understand Pricing Nuances: Pricing for pattern sewing can fluctuate based on market demand, seasonal trends, and geopolitical factors. Staying informed can give buyers leverage in negotiations.

-

Research Local Markets: For buyers from Africa, South America, the Middle East, and Europe, understanding regional supply chains can uncover local suppliers who may offer more competitive pricing.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Frequent communication and feedback can foster trust and cooperation.

Conclusion

While sourcing pattern sewing services involves multiple cost components and pricing influencers, buyers can effectively navigate these complexities by leveraging negotiation strategies and understanding their supply chains. By focusing on total cost rather than just initial pricing, international buyers can enhance their sourcing decisions and ensure long-term profitability.

Alternatives Analysis: Comparing pattern sewer With Other Solutions

When evaluating solutions for sewing patterns, it’s essential to consider various alternatives that cater to different needs and operational environments. This analysis will compare the ‘pattern sewer’ with two viable alternatives: digital pattern-making software and traditional hand-drawing methods. Each of these options has its unique strengths and weaknesses, making it crucial for B2B buyers to understand their implications.

| Comparison Aspect | Pattern Sewer | Digital Pattern-Making Software | Traditional Hand-Drawing Methods |

|---|---|---|---|

| Performance | High precision and efficiency | Very high precision; quick adjustments | Moderate precision; time-consuming |

| Cost | Moderate initial investment | High upfront cost, subscription fees | Low cost; minimal tools needed |

| Ease of Implementation | Easy to set up and operate | Requires training; can be complex | Simple; requires skill and practice |

| Maintenance | Low maintenance required | Regular software updates needed | Minimal maintenance; tools last long |

| Best Use Case | Ideal for mass production | Best for custom designs and rapid prototyping | Suitable for small-scale or artisanal work |

What Are the Pros and Cons of Digital Pattern-Making Software?

Digital pattern-making software offers significant advantages, such as high precision and the ability to make rapid adjustments to designs. This software often integrates with other design tools, streamlining the workflow for designers and manufacturers alike. However, the initial investment can be substantial, with many solutions requiring ongoing subscription fees. Additionally, staff may need training to utilize the software effectively, which can introduce a learning curve and additional costs.

How Do Traditional Hand-Drawing Methods Compare?

Traditional hand-drawing methods are the most cost-effective option, requiring only basic tools like paper and pencils. This method allows for a high degree of artistic expression and customization, making it suitable for small-scale, artisanal projects. However, it can be time-consuming and may lack the precision that digital solutions offer. Moreover, as production scales, hand-drawn patterns may become inefficient, leading to longer turnaround times.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right solution for pattern sewing largely depends on the specific needs and operational context of the business. For companies focused on mass production, the ‘pattern sewer’ offers efficiency and reliability. Conversely, businesses that prioritize customization and rapid prototyping may benefit more from digital pattern-making software, despite its higher cost. Finally, for artisans or small-scale operations, traditional hand-drawing methods can provide a low-cost, creative alternative. By carefully assessing performance, cost, ease of implementation, maintenance, and the best use case, international B2B buyers can make informed decisions tailored to their specific requirements.

Essential Technical Properties and Trade Terminology for pattern sewer

What Are the Key Technical Properties of a Pattern Sewer?

Understanding the essential technical properties of a pattern sewer is crucial for international B2B buyers. These specifications can significantly impact production quality, efficiency, and overall project success. Here are some critical properties to consider:

1. Material Grade

The material grade refers to the type and quality of the fabric used in the production of patterns. High-quality materials ensure durability, longevity, and performance. For B2B buyers, selecting the right material grade is vital as it directly affects the final product’s quality and customer satisfaction. For instance, choosing a high-grade cotton for fashion apparel can enhance the garment’s comfort and appeal.

2. Tolerance

Tolerance denotes the permissible limit of variation in dimensions during the manufacturing process. In pattern sewing, maintaining tight tolerances is essential for ensuring that finished products fit correctly. This aspect is particularly crucial for industries like fashion and automotive, where precision can affect functionality and aesthetics. B2B buyers must ensure that suppliers can meet specified tolerances to avoid costly reworks or returns.

3. Stitch Type and Density

Stitch type refers to the specific stitching method used in the sewing process, such as straight, zigzag, or overlock. Stitch density, measured in stitches per inch (SPI), determines the strength and durability of the seams. For international buyers, understanding the required stitch type and density helps in selecting manufacturers that can produce high-quality and resilient products suited for their target markets.

4. Production Capacity

Production capacity indicates the volume of output a pattern sewer can handle within a specific timeframe. It is essential for B2B buyers to assess the production capacity of their suppliers to ensure they can meet market demand without compromising quality. Understanding a supplier’s capacity can aid in planning and logistics, especially when entering new markets or scaling operations.

5. Lead Time

Lead time is the duration from the placement of an order to the delivery of the finished goods. For international B2B transactions, lead time is critical for managing inventory and meeting customer expectations. Buyers should negotiate lead times with suppliers to align with their supply chain processes and market needs.

What Common Trade Terms Should B2B Buyers Know?

Navigating the world of pattern sewing requires familiarity with specific industry terminology. Here are some common trade terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products or components that are sold under another company’s brand. For buyers, working with OEMs can provide access to high-quality products tailored to specific needs, often at lower costs due to economies of scale.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects purchasing decisions and inventory management. Buyers should negotiate MOQs to align with their market demand and financial capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products or services. For B2B buyers, issuing RFQs helps in comparing supplier offers, ensuring competitive pricing and terms before making purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers as they clarify the logistics and cost responsibilities involved in cross-border transactions.

5. Customization

Customization refers to tailoring products to meet specific customer requirements. In the context of pattern sewing, this could involve adjusting designs, materials, or sizes. Understanding customization options allows B2B buyers to better cater to their target markets and differentiate their offerings.

By grasping these technical properties and trade terminologies, B2B buyers from regions like Africa, South America, the Middle East, and Europe can make informed decisions, enhancing their sourcing strategies and operational efficiency in the pattern sewing industry.

Navigating Market Dynamics and Sourcing Trends in the pattern sewer Sector

What Are the Key Market Dynamics and Trends in the Pattern Sewer Sector?

The pattern sewer sector is experiencing transformative changes driven by global demand for customized textile products and the rise of digital technologies. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide tailored solutions that meet specific market needs. Key drivers include the growing trend of personalization in fashion, heightened consumer expectations for quality, and the rapid adoption of technology in production processes. Advanced software for pattern design and automated sewing technologies are reshaping sourcing dynamics, enabling faster turnaround times and reduced costs.

Emerging sourcing trends highlight a shift towards localized production to mitigate risks associated with global supply chains. This is particularly relevant for buyers in regions like Egypt and the UK, where understanding local market nuances can enhance competitive advantage. The integration of artificial intelligence (AI) in pattern making and sewing processes is also on the rise, offering significant efficiency gains and allowing businesses to respond quickly to changing consumer demands. Furthermore, the demand for sustainable practices is compelling suppliers to innovate, leading to increased interest in eco-friendly materials and processes.

How Is Sustainability and Ethical Sourcing Shaping the Pattern Sewer Industry?

The environmental impact of the textile industry has never been more scrutinized, pushing B2B buyers to prioritize sustainability in their sourcing decisions. Ethical supply chains are crucial for mitigating environmental damage and enhancing brand reputation. Buyers from all regions are increasingly seeking suppliers who can demonstrate a commitment to sustainability through transparency in their production processes.

In the pattern sewer sector, the adoption of “green” certifications and materials is gaining traction. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® assure buyers that materials are sourced responsibly and produced with minimal environmental impact. Moreover, the use of sustainable fabrics, such as organic cotton and recycled polyester, is becoming a significant factor in procurement strategies. For international buyers, aligning with suppliers who emphasize ethical practices not only meets consumer expectations but also positions their brands favorably in competitive markets.

What Is the Historical Context of the Pattern Sewer Sector?

The evolution of the pattern sewer sector reflects broader shifts in the textile industry, transitioning from traditional manual sewing techniques to modern automated processes. Historically, pattern sewing was predominantly manual, relying on skilled artisans to produce garments. However, the advent of industrialization in the 19th century marked a significant turning point, as mechanized sewing machines began to dominate the industry.

In recent decades, technological advancements have further revolutionized the sector, with digital pattern-making software and automated sewing machines becoming commonplace. This evolution has allowed for greater precision, reduced waste, and faster production cycles, catering to the growing demand for customized and ethically sourced products. Understanding this historical context is essential for international B2B buyers, as it provides insight into the capabilities and innovations that suppliers can offer today.

Frequently Asked Questions (FAQs) for B2B Buyers of pattern sewer

-

How do I ensure the quality of pattern sewer products when sourcing internationally?

To ensure quality, conduct thorough supplier vetting by requesting samples and certifications. It’s essential to verify the supplier’s manufacturing processes and quality control measures. Consider engaging third-party inspection services to assess the products before shipment. Additionally, review testimonials and ratings from other international buyers to gauge reliability. Establish clear quality expectations in your contracts to mitigate risks. -

What is the best way to negotiate payment terms with pattern sewer suppliers?

When negotiating payment terms, aim for flexibility that suits both parties. Common terms include a deposit upfront (usually 30%) and the balance upon delivery. Consider using letters of credit or escrow services to protect your investment. It’s also wise to discuss the possibility of discounts for early payments or larger orders. Clear communication about payment timelines can foster a strong business relationship. -

What are the minimum order quantities (MOQs) typically required by pattern sewer suppliers?

MOQs can vary significantly based on the supplier and the complexity of the patterns. Some suppliers may have an MOQ as low as 50 units, while others may require 500 or more for custom designs. It’s crucial to discuss your specific needs upfront and explore options for lower MOQs, especially if you’re testing a new market. Look for suppliers who are willing to accommodate smaller orders as part of a long-term partnership. -

How can I customize patterns for my brand when working with pattern sewer suppliers?

To customize patterns, start by providing your design specifications and any relevant branding guidelines. Many suppliers offer design services or can collaborate with your design team to create unique patterns. Ensure you communicate your expectations regarding color, texture, and materials clearly. It’s also beneficial to review and approve prototypes before full production to align with your brand vision. -

What logistics considerations should I keep in mind when sourcing pattern sewer products?

Logistics plays a critical role in international sourcing. Consider factors such as shipping methods, lead times, and customs regulations in your target markets. Partner with reliable freight forwarders who understand the complexities of international shipping. Discuss shipping terms (like FOB or CIF) with your supplier to clarify responsibilities. Additionally, ensure you have contingency plans for potential delays or issues that may arise during transit. -

What quality assurance practices should I implement when importing pattern sewer products?

Implementing a robust quality assurance (QA) process is vital. Start by defining your quality standards and communicating them to your supplier. Conduct regular audits and inspections at different production stages. Utilizing third-party QA services can provide an unbiased assessment of product quality before shipment. Additionally, establish a returns policy to address any defects or discrepancies after receiving your order. -

How do international trade regulations affect sourcing pattern sewer products?

International trade regulations can impact tariffs, import duties, and compliance with safety standards. It’s essential to familiarize yourself with the regulations in your country as well as those in the supplier’s country. Engage with trade experts or legal advisors to ensure compliance and to avoid unexpected costs. Stay updated on trade agreements that may benefit your sourcing strategy and reduce costs. -

What are the common challenges faced by B2B buyers when sourcing pattern sewer products internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Time zone differences can also complicate communication and project timelines. To mitigate these issues, establish clear communication channels and consider hiring a local representative or translator. Building a strong relationship with your supplier can also help navigate these challenges and foster smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pattern sewer

What Are the Key Takeaways for B2B Buyers in Strategic Sourcing of Pattern Sewers?

In conclusion, the strategic sourcing of pattern sewers is pivotal for international B2B buyers looking to enhance their product offerings, particularly in the dynamic markets of Africa, South America, the Middle East, and Europe. Key takeaways include the importance of understanding local market trends and consumer preferences to effectively tailor products. Establishing strong partnerships with reliable suppliers can lead to improved quality, reduced lead times, and cost efficiencies.

How Can Strategic Sourcing Create Competitive Advantages?

By leveraging strategic sourcing, businesses can gain a competitive edge through innovation and responsiveness to market demands. This approach not only streamlines operations but also fosters sustainability and ethical sourcing practices, which are increasingly valued by consumers globally. For buyers in regions like Egypt and the UK, aligning sourcing strategies with local regulations and cultural nuances is essential for success.

What Should International B2B Buyers Do Next?

As you navigate the complexities of sourcing pattern sewers, consider investing in supplier relationship management tools and conducting thorough market research to inform your decisions. Embrace the opportunity to collaborate with suppliers who share your vision for quality and innovation. By doing so, you position your business for sustainable growth and success in an ever-evolving marketplace. Your journey in strategic sourcing begins now—take the next step to transform your sourcing strategy and drive your business forward.