Spanish Roof Bracket Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for spanish roof bracket

In an increasingly competitive global market, sourcing high-quality Spanish roof brackets can pose significant challenges for international B2B buyers. The complexity of diverse roofing materials and the varying climatic conditions across regions like Africa, South America, the Middle East, and Europe necessitate a comprehensive understanding of product specifications and supplier capabilities. This guide offers a detailed exploration of Spanish roof brackets, covering various types, applications, and critical considerations for supplier vetting, cost analysis, and logistics.

By delving into the nuances of Spanish roof brackets, this guide empowers buyers to make informed purchasing decisions. We will discuss the essential features of different bracket types, including their compatibility with specific roofing tiles and their role in enhancing structural integrity. Additionally, we will provide insights into the procurement process, helping you identify reliable suppliers who meet your quality standards while navigating potential challenges related to lead times and shipping logistics.

Whether you’re in Vietnam, Saudi Arabia, or any other region, understanding the market landscape for Spanish roof brackets is crucial for ensuring the success of your roofing projects. Equip yourself with the knowledge to optimize your sourcing strategy and secure high-quality products that meet your specific needs.

Understanding spanish roof bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bronze Snow Rail Bracket | Made from bronze, suitable for Spanish 13 tiles; 3-pipe system | Snow management on Spanish tile roofs | Pros: Durable, corrosion-resistant; Cons: Special order with long lead time. |

| Aluminum Mount Bracket | Lightweight, corrosion-resistant; fits various roof slopes | Solar panel mounting on Spanish tile roofs | Pros: Easy installation, cost-effective; Cons: May not support heavy loads as well as metal options. |

| Raised Roof Bracket | Designed for header beams; adjustable for different slopes | Structural support in patio and roof systems | Pros: Customizable; Cons: Limited to specific applications. |

| Tile Mount Hook | Adjustable height; compatible with various tile types | Solar installations on curved and Spanish tiles | Pros: Versatile and efficient installation; Cons: Requires precise alignment for optimal performance. |

| 3-Pipe Snow Rail System | Supports higher snow loads; spaced installation for stability | High-snow load areas with Spanish tile roofs | Pros: Enhanced snow load support; Cons: More complex installation process. |

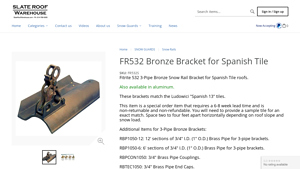

What are the Characteristics of the Bronze Snow Rail Bracket?

Bronze snow rail brackets are specifically designed for Spanish tile roofs, particularly compatible with Spanish 13 tiles. These brackets utilize a three-pipe system, which provides superior support against snow accumulation. When considering a purchase, B2B buyers should note the long lead time for special orders, as well as the need to provide a tile sample for exact matching. This type is ideal for regions with significant snowfall, ensuring safety and structural integrity.

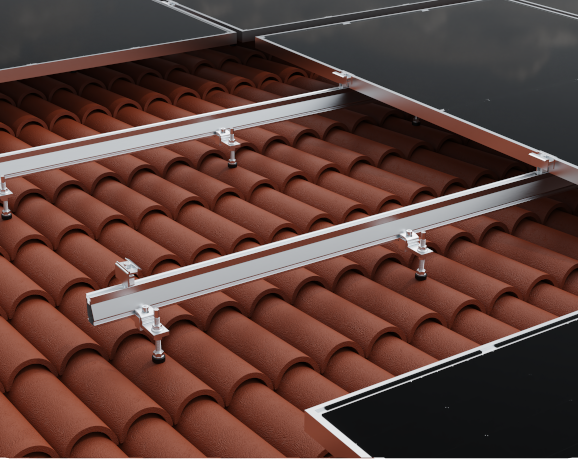

How Does the Aluminum Mount Bracket Function in B2B Applications?

The aluminum mount bracket is a lightweight and corrosion-resistant option that suits various roof slopes. It is particularly beneficial for solar panel installations on Spanish tile roofs, offering a cost-effective solution for businesses looking to integrate renewable energy sources. While easy to install, buyers should consider that aluminum may not bear as much weight as heavier metal brackets, making it essential to assess the specific application requirements.

What Makes the Raised Roof Bracket Unique for B2B Buyers?

Raised roof brackets are designed primarily for structural support, enabling the installation of header beams on roofs. These brackets can be customized for different slopes, providing flexibility for various construction projects. B2B buyers should be aware that while standard raised roof brackets can be returned if in new condition, custom orders are non-refundable. This aspect necessitates careful consideration of the project specifications before purchase.

Why Choose Tile Mount Hooks for Solar Installations?

Tile mount hooks are versatile and adjustable, designed to fit various curved tiles, including Spanish tiles. They are an excellent choice for solar panel installations, allowing for efficient and quick setups. B2B buyers should ensure precise alignment during installation to maximize performance, as improper fitting can lead to inefficiencies. The adaptability of these hooks makes them a valuable asset for businesses venturing into solar energy projects.

What are the Advantages of Using a 3-Pipe Snow Rail System?

The 3-pipe snow rail system is engineered for areas with high snow loads, providing enhanced support for Spanish tile roofs. This system’s installation requires careful spacing and configuration to ensure stability and effectiveness in snow management. While it offers superior snow load capabilities, the complexity of installation may deter some buyers. Thus, businesses should weigh the benefits of increased safety against the potential need for professional installation services.

Key Industrial Applications of spanish roof bracket

| Industry/Sector | Specific Application of Spanish Roof Bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Building | Installation of snow guards on tiled roofs | Enhances safety by preventing snow and ice avalanches from damaging property or injuring individuals | Ensure brackets are compatible with specific tile types and local building codes |

| Renewable Energy | Mounting solar panels on Spanish tile roofs | Facilitates efficient solar energy production while maintaining roof integrity | Consider durability, weather resistance, and ease of installation |

| Architectural Design | Supporting decorative roof elements | Allows for aesthetic enhancements while ensuring structural stability | Verify design specifications and load-bearing capacities |

| Roofing and Maintenance Services | Repair and retrofit of existing roofs | Extends roof lifespan and improves performance in adverse weather | Source brackets that are easy to install and maintain |

| Landscaping and Outdoor Structures | Supporting outdoor structures like pergolas or awnings | Provides stability and enhances outdoor living spaces | Look for customizable options to fit various design requirements |

How is the Spanish Roof Bracket Used in Construction and Building Projects?

In the construction sector, Spanish roof brackets are commonly used to install snow guards on tiled roofs. These brackets are strategically placed to prevent heavy snow loads from sliding off roofs, which can cause significant damage to property and pose safety risks. For international buyers, especially in regions with heavy snowfall, it is crucial to ensure that the brackets are compatible with specific tile types and adhere to local building codes to avoid compliance issues.

What Role Do Spanish Roof Brackets Play in Renewable Energy Installations?

Spanish roof brackets are integral in mounting solar panels on Spanish tile roofs, providing a secure and stable platform for solar energy systems. They facilitate the effective harnessing of solar energy while ensuring that the roof remains intact and watertight. Buyers from regions with high solar potential, such as Africa and the Middle East, should consider sourcing brackets that offer durability against harsh weather conditions and ease of installation to optimize their solar projects.

How Do Spanish Roof Brackets Enhance Architectural Design?

In architectural design, Spanish roof brackets support decorative elements, enabling the construction of visually appealing roofs without compromising structural integrity. They can be used to secure ornamental features or additional roofing layers, enhancing the overall aesthetic. For B2B buyers, it is essential to verify design specifications and load-bearing capacities to ensure that the chosen brackets meet both functional and design requirements.

What Benefits Do Spanish Roof Brackets Offer for Roofing and Maintenance Services?

For roofing and maintenance services, Spanish roof brackets are vital for repairing and retrofitting existing roofs. They help extend the lifespan of roofs by providing robust support and improving performance under various weather conditions. When sourcing these brackets, businesses should prioritize those that are easy to install and maintain, ensuring minimal disruption to ongoing roofing projects.

How Can Spanish Roof Brackets Support Landscaping and Outdoor Structures?

Spanish roof brackets can also be utilized to support outdoor structures such as pergolas or awnings, providing stability and enhancing outdoor living spaces. This application is particularly relevant for businesses involved in landscaping and outdoor design. Buyers should look for customizable options that can be tailored to fit various design requirements and enhance the functionality of outdoor areas.

3 Common User Pain Points for ‘spanish roof bracket’ & Their Solutions

Scenario 1: Delays in Receiving Custom Spanish Roof Brackets

The Problem:

For B2B buyers, especially those involved in construction or roofing projects, delays in receiving custom-made Spanish roof brackets can be a significant issue. Many suppliers require a lead time of 6-8 weeks for special orders, and these brackets are often non-returnable and non-refundable. This situation can lead to project delays, increased labor costs, and potential financial losses if the brackets are not received in time for scheduled installations. Additionally, if a mismatch occurs between the brackets and the tiles, the buyer may have to reorder, exacerbating the delay.

The Solution:

To mitigate these challenges, B2B buyers should establish clear communication with suppliers early in the procurement process. This includes providing a sample tile for accurate matching and confirming the lead time during the initial inquiry. Buyers should also explore options for stock brackets that may meet their needs without the lengthy custom order process. Additionally, it’s advisable to maintain a buffer in project schedules to accommodate potential delays. Implementing a robust inventory management system that tracks usage can also help anticipate needs and streamline orders before they become urgent.

Scenario 2: Compatibility Issues with Spanish Roof Brackets

The Problem:

A frequent pain point for buyers is the compatibility of Spanish roof brackets with various tile sizes and types. Many suppliers offer brackets that are designed for specific tile models, which can lead to confusion and mistakes during installation. For instance, if a buyer orders brackets for Spanish 13 tiles but mistakenly receives brackets for Spanish 18 tiles, this incompatibility can halt construction progress and require additional time and resources to rectify.

The Solution:

To avoid compatibility issues, buyers must conduct thorough research before placing orders. This involves understanding the exact specifications of the tiles being used, including dimensions and exposure levels. When ordering, it’s crucial to double-check compatibility with the supplier, possibly by requesting detailed product specifications or installation guidelines. Buyers should also consider creating a checklist of requirements to streamline the ordering process. Engaging with suppliers who provide comprehensive product documentation can further reduce the risk of errors.

Scenario 3: Installation Challenges with Spanish Roof Brackets

The Problem:

Installation challenges can be a significant hurdle for B2B buyers utilizing Spanish roof brackets. Factors such as roof slope, material variations, and adverse weather conditions can complicate the installation process. Inadequate installation can lead to structural issues or safety hazards, resulting in costly rework and liability concerns.

The Solution:

To ensure a successful installation, buyers should prioritize selecting brackets that are specifically designed for their roofing conditions. Detailed installation guides provided by manufacturers can be invaluable; these often include spacing recommendations based on roof pitch and snow load requirements. It’s advisable to invest in training for installation teams or hiring experienced contractors who are familiar with the specific requirements of Spanish tile roofs. Additionally, utilizing adjustable brackets can provide flexibility in accommodating various roof conditions, making the installation process more manageable. Lastly, incorporating a quality assurance step post-installation can help identify any potential issues early, ensuring long-term performance and safety.

Strategic Material Selection Guide for spanish roof bracket

What Are the Key Materials for Spanish Roof Brackets?

When selecting materials for Spanish roof brackets, it is essential to consider the properties, advantages, and limitations of each option. The choice of material can significantly influence the performance, durability, and cost-effectiveness of the brackets, particularly for international buyers in diverse climates and regulatory environments.

Which Material Options Are Commonly Used for Spanish Roof Brackets?

1. Bronze

Key Properties:

Bronze is known for its excellent corrosion resistance, especially in coastal environments, and can withstand high temperatures without losing structural integrity.

Pros & Cons:

Bronze brackets are highly durable and can last for decades with minimal maintenance. However, they are more expensive than other materials, which could be a limiting factor for budget-conscious buyers. Manufacturing complexity can also be higher due to the need for specialized casting processes.

Impact on Application:

Bronze is particularly suitable for applications in areas with high humidity or salt exposure, making it ideal for coastal regions in Africa and South America.

Considerations for International Buyers:

Buyers should ensure that bronze products comply with international standards such as ASTM B150. The higher cost may be justified by the longevity and reduced maintenance needs in harsh environments.

2. Aluminum

Key Properties:

Aluminum is lightweight and offers good corrosion resistance, especially when anodized. It has a lower temperature rating compared to bronze but is still suitable for most roofing applications.

Pros & Cons:

The primary advantage of aluminum is its lower cost and ease of manufacturing. However, it may not be as durable as bronze, particularly under heavy snow loads or extreme weather conditions.

Impact on Application:

Aluminum brackets are suitable for moderate climates and are often used in regions with less severe weather conditions.

Considerations for International Buyers:

Aluminum products should meet standards such as ASTM B221. The affordability of aluminum makes it appealing for projects in developing regions, but buyers should consider the potential need for additional support in heavy snow areas.

3. Stainless Steel

Key Properties:

Stainless steel offers exceptional strength and corrosion resistance. It can withstand high temperatures and is suitable for various environmental conditions.

Pros & Cons:

Stainless steel brackets are incredibly durable and require minimal maintenance. However, they tend to be more expensive than aluminum and can be heavier, which may complicate installation.

Impact on Application:

The high strength of stainless steel makes it ideal for applications in regions with heavy snow loads or extreme weather, such as parts of Europe and the Middle East.

Considerations for International Buyers:

Buyers should verify compliance with standards like ASTM A240. The investment in stainless steel may be worthwhile for projects requiring long-term durability.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight and resistant to corrosion and UV degradation. They can be engineered to mimic the appearance of traditional materials.

Pros & Cons:

These materials are cost-effective and easy to install. However, they may not offer the same level of structural integrity as metals, particularly under heavy loads.

Impact on Application:

Plastic composites are suitable for residential applications in mild climates but may not be appropriate for commercial projects requiring high load capacities.

Considerations for International Buyers:

Ensure compliance with local building codes and standards. The lower cost makes plastic composites attractive for budget-sensitive projects, particularly in emerging markets.

Summary Table of Material Options for Spanish Roof Brackets

| Material | Typical Use Case for Spanish Roof Bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Bronze | Coastal areas with high humidity | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Moderate climates with less severe weather | Lightweight and cost-effective | Less durable under heavy loads | Medium |

| Stainless Steel | Regions with heavy snow loads or extreme weather | Exceptional strength and durability | More expensive and heavier | High |

| Plastic Composites | Residential applications in mild climates | Cost-effective and easy to install | Limited structural integrity | Low |

By carefully evaluating these materials, international B2B buyers can make informed decisions that align with their specific project requirements and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for spanish roof bracket

What Are the Main Stages of Manufacturing Spanish Roof Brackets?

Manufacturing Spanish roof brackets involves several critical stages, each designed to ensure the final product meets both functional and aesthetic requirements. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with selecting high-quality materials, typically bronze, aluminum, or stainless steel. These materials are chosen for their durability and resistance to corrosion, which is essential for outdoor applications. Once the material is selected, it undergoes cutting and shaping to prepare it for the next stage. This includes the use of advanced cutting machines that ensure precision in dimensions, which is vital for the proper fitting of the brackets to Spanish tiles.

How Are Spanish Roof Brackets Formed?

The forming process is where the raw materials are transformed into the desired shape. Techniques such as stamping, casting, or machining are commonly employed.

- Stamping: This method is often used for producing brackets in bulk, as it allows for high-speed production with consistent results. The metal sheets are pressed into molds to create the basic shape of the brackets.

- Casting: For more intricate designs, casting may be utilized. This involves pouring molten metal into a mold, where it solidifies into the desired shape.

- Machining: Post-forming, machining may be required to achieve precise dimensions or to add features such as holes for screws or pipes.

These techniques ensure that the brackets are not only functional but also align perfectly with the specifications of the Spanish tiles they are designed to support.

What Is the Assembly Process for Spanish Roof Brackets?

After forming, the assembly process begins. This stage may include attaching various components such as pipes or additional support brackets. Depending on the design, the assembly might involve welding, riveting, or bolting parts together.

Quality control is vital during assembly to ensure that each bracket meets the specified standards. This may involve checking the fit of the components, ensuring that all connections are secure, and verifying that the brackets function as intended.

What Finishing Techniques Are Used for Spanish Roof Brackets?

Finishing is the final stage in the manufacturing process, focusing on aesthetics and protection. Various techniques can be applied, including:

- Powder Coating: This process involves applying a dry powder that is then cured under heat to create a hard finish. It provides excellent corrosion resistance and can be customized in various colors to match architectural designs.

- Anodizing: For aluminum brackets, anodizing enhances corrosion resistance while allowing for color options. This electrochemical process thickens the natural oxide layer on the surface, improving durability.

- Polishing: For bronze or stainless steel brackets, polishing may be employed to create a shiny, attractive surface.

These finishing touches not only improve the visual appeal of the brackets but also extend their lifespan, making them suitable for various environmental conditions.

What Quality Assurance Standards Are Relevant for Spanish Roof Brackets?

Quality assurance (QA) is crucial in the manufacturing of Spanish roof brackets to ensure that they meet international standards. Commonly referenced standards include:

- ISO 9001: This standard emphasizes a quality management system that helps organizations ensure they meet customer and regulatory requirements. Compliance with ISO 9001 indicates a commitment to quality processes throughout the manufacturing cycle.

- CE Marking: For products sold in the European market, CE marking signifies that the brackets meet EU safety, health, and environmental protection requirements.

- API Standards: While more common in the oil and gas industry, API standards can also apply to manufacturers producing metal components, ensuring they adhere to rigorous quality and performance benchmarks.

What Are the Key Quality Control Checkpoints in Spanish Roof Bracket Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and ensure product reliability. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to verify they meet specifications. Testing may include material composition analysis and dimensional checks.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production quality. This includes verifying that forming and assembly processes are executed correctly.

- Final Quality Control (FQC): Before shipping, a thorough inspection is performed on the finished product. This may include functional testing, dimensional verification, and surface finish evaluation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks and ensure product reliability. Here are several methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control practices, and overall facility conditions. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

- Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers understand their quality assurance processes. These reports should outline inspection results, testing methods, and compliance with relevant standards.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes. These agencies can conduct checks at various stages of production, ensuring adherence to specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality control and certification.

- Cultural Differences: Understanding cultural differences in business practices can influence communication and expectations regarding quality. Buyers should establish clear lines of communication and expectations with suppliers.

- Regulatory Compliance: Different regions may have varying regulatory requirements for construction materials. It’s important for buyers to be aware of local regulations to ensure that the products they purchase comply.

- Documentation Requirements: Proper documentation, including certificates of compliance and test reports, is crucial for international transactions. Buyers should request these documents to facilitate customs clearance and ensure that the products meet local standards.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing Spanish roof brackets, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spanish roof bracket’

In the competitive landscape of sourcing Spanish roof brackets, particularly for international B2B buyers, a systematic approach is essential. This guide provides a step-by-step checklist to help you navigate the procurement process effectively, ensuring you acquire high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Start by identifying the exact requirements for your Spanish roof brackets. Consider factors such as material type (bronze, aluminum, stainless steel), load capacity, and compatibility with specific tile types (e.g., Ludowici Spanish 13). Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products you source are fit for purpose.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies that specialize in roofing materials, particularly those with experience in your target markets (Africa, South America, the Middle East, and Europe). Pay attention to their market reputation and product offerings, ensuring they have the right expertise in Spanish roof brackets.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications and comply with international standards. This may include ISO certifications or specific industry approvals. Compliance ensures that the products meet quality benchmarks and can provide long-term reliability, which is crucial for roofing applications.

Step 4: Request Samples and Technical Data

Before making a bulk order, request samples of the Spanish roof brackets along with detailed technical data sheets. This step allows you to assess the quality and functionality of the products firsthand. Pay attention to the dimensions, weight, and finish to ensure they align with your project requirements.

Step 5: Assess Lead Times and Availability

Inquire about the lead times for production and delivery. Many Spanish roof brackets, especially custom orders, can have extended lead times of 6-8 weeks. Understanding the timeline is vital for project planning and can help you avoid delays that could impact your overall schedule.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms. Ensure that you understand the total cost, including shipping and any potential import duties. Look for suppliers who offer favorable payment terms, such as net payment options, which can assist with cash flow management.

Step 7: Review Warranty and Return Policies

Finally, carefully examine the warranty and return policies offered by the suppliers. Since many brackets may be non-returnable or have restocking fees, it’s crucial to understand your options should the product not meet your expectations. A solid warranty can also provide peace of mind regarding the durability and longevity of your investment.

By following this comprehensive sourcing checklist, you can streamline your procurement process for Spanish roof brackets, ensuring that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for spanish roof bracket Sourcing

What Are the Key Cost Components for Sourcing Spanish Roof Brackets?

When sourcing Spanish roof brackets, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials for Spanish roof brackets include aluminum, bronze, and stainless steel. The cost for these materials varies based on market demand and availability. For instance, high-quality stainless steel may be more expensive but offers superior durability and corrosion resistance.

-

Labor: Labor costs can fluctuate based on the region where the brackets are manufactured. Skilled labor is essential for high-quality production, and countries with higher wage standards may see increased labor costs. This is particularly relevant for custom brackets that require specialized skills.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and salaries of non-production staff. Manufacturers often calculate overhead on a per-unit basis, which can affect pricing based on the scale of production.

-

Tooling: Initial investment in tooling for custom or specialized brackets can be substantial. These costs are often amortized over the production volume, meaning that larger orders can reduce the cost per unit significantly.

-

Quality Control (QC): Ensuring that brackets meet industry standards and specifications is crucial, especially for international buyers who may require certifications. QC processes add to the overall cost but are essential for maintaining product integrity.

-

Logistics: Shipping costs can vary widely depending on the destination, volume, and chosen Incoterms. International shipping may involve additional tariffs and customs duties, which should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Affect the Cost of Spanish Roof Brackets?

Several factors can influence the pricing of Spanish roof brackets, making it crucial for buyers to understand these dynamics.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Suppliers often offer discounts for larger orders, allowing buyers to achieve better cost efficiency. Understanding the supplier’s pricing tiers based on volume can lead to substantial savings.

-

Specifications and Customization: Customized brackets that meet specific project requirements typically come at a premium. Buyers should evaluate whether the added cost of customization is justified based on their project needs.

-

Material Quality and Certifications: The quality of materials and any certifications (e.g., ISO standards) can affect pricing. High-quality materials and certifications often result in higher upfront costs but can lead to lower maintenance and replacement expenses over time.

-

Supplier Factors: The reputation and reliability of suppliers can impact price. Established suppliers with a track record of quality may charge higher prices but offer better service and product consistency.

-

Incoterms: The choice of Incoterms affects logistics and shipping costs. Understanding the responsibilities related to shipping, insurance, and tariffs can help buyers negotiate better terms with suppliers.

What Buyer Tips Can Enhance Cost-Efficiency in Spanish Roof Bracket Sourcing?

To optimize cost-efficiency in sourcing Spanish roof brackets, buyers can consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Many suppliers are open to negotiation, and demonstrating a long-term purchasing commitment can lead to better rates.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. This includes installation, maintenance, and potential replacement costs over the lifespan of the brackets.

-

Pricing Nuances for International Buyers: International buyers should be aware of fluctuating exchange rates, import duties, and shipping costs. Establishing clear communication with suppliers about these factors can help avoid unexpected expenses.

-

Research and Compare: Conduct thorough research to compare prices and services from multiple suppliers. Leveraging online resources and industry contacts can provide insights into competitive pricing and supplier reliability.

Disclaimer

The prices and cost structures mentioned are indicative and may vary based on market conditions, supplier policies, and specific buyer requirements. It is advisable to conduct a detailed analysis and obtain quotes tailored to individual project needs.

Alternatives Analysis: Comparing spanish roof bracket With Other Solutions

When considering roofing solutions, particularly for Spanish tile roofs, it’s essential to evaluate various options that can provide similar functionalities. The Spanish roof bracket, known for its durability and specific design to accommodate Spanish tiles, has several alternatives that might suit different project requirements and budgets. Below is a comparison of the Spanish roof bracket against two viable alternatives: raised roof brackets and solar panel mounting hooks designed for Spanish tiles.

| Comparison Aspect | Spanish Roof Bracket | Raised Roof Bracket | Solar Panel Mounting Hooks |

|---|---|---|---|

| Performance | Excellent snow load management; designed for specific tile types. | Suitable for header beams; less effective for snow management. | Good for solar installations; versatile for various tile types. |

| Cost | Higher initial investment (approx. $590). | More economical (approx. $150). | Moderate cost (varies, typically around $100-$200). |

| Ease of Implementation | Requires specific tile samples and has a lead time for orders. | Simple installation; customizable sizes available. | Pre-assembled for quick installation; adjustable features. |

| Maintenance | Low maintenance; durable materials. | Low maintenance; standard materials. | Minimal maintenance; stainless steel construction ensures longevity. |

| Best Use Case | Ideal for snow-prone regions with Spanish tiles. | Best for supporting header beams in various roofing projects. | Optimal for solar panel installations on Spanish tile roofs. |

What Are the Advantages and Disadvantages of Raised Roof Brackets?

Raised roof brackets are designed primarily for constructing header beams and providing structural support. They are often more cost-effective than Spanish roof brackets, making them an attractive option for budget-conscious projects. The simplicity of installation is another advantage, allowing for quicker project timelines. However, they do not offer the same level of snow load management as specialized snow rail systems, which may be a critical consideration in regions with heavy snowfall.

How Do Solar Panel Mounting Hooks Compare for Spanish Tile Roofs?

Solar panel mounting hooks specifically designed for Spanish tiles offer a versatile solution for integrating solar energy systems into roofing projects. These hooks are pre-assembled, which significantly reduces installation time and labor costs. Their adjustable features allow for compatibility with various roofing conditions, making them an excellent choice for solar panel installations. However, they are primarily focused on solar applications, so they may not be suitable for projects where snow load management is a concern. Additionally, the quality and durability of the materials can vary, which might impact long-term performance.

Conclusion: How Should B2B Buyers Choose the Right Roofing Solution?

When selecting the appropriate roofing solution, B2B buyers should consider several factors, including the specific requirements of their project, budget constraints, and environmental conditions. For projects involving Spanish tile roofs in areas with heavy snowfall, the Spanish roof bracket is likely the most effective option. However, for those looking to support solar panel installations or seeking a more economical solution, raised roof brackets or solar panel mounting hooks may be more suitable. Ultimately, the choice should align with the project’s functional needs, cost considerations, and long-term maintenance expectations to ensure a successful roofing solution.

Essential Technical Properties and Trade Terminology for spanish roof bracket

What Are the Key Technical Properties of Spanish Roof Brackets?

When selecting Spanish roof brackets, understanding their technical specifications is crucial for ensuring compatibility, durability, and performance. Here are some essential properties:

-

Material Grade

Spanish roof brackets are typically made from high-grade materials such as bronze, brass, and stainless steel. These materials provide excellent resistance to corrosion, especially in humid or coastal environments. For B2B buyers, choosing the right material ensures longevity and reduces maintenance costs over time. -

Load Capacity

The load capacity of a bracket indicates how much weight it can support. This specification is essential for regions with heavy snow loads or extreme weather conditions. Buyers must assess the expected load on the roof to select brackets that can withstand these conditions without failure. -

Spacing Tolerance

Spacing tolerance refers to the recommended distance between brackets during installation. For instance, brackets should be spaced 2 to 4 feet apart, depending on the roof slope and snow load. Proper spacing is critical to ensure that the system can effectively manage snow and ice, preventing damage to the roof and underlying structures. -

Installation Lead Time

Many specialized brackets, such as those for Spanish tiles, require custom orders that can take 6-8 weeks for delivery. Understanding lead times is vital for project planning and scheduling, especially for contractors working on tight deadlines. -

Dimensions and Compatibility

Brackets must be compatible with specific tile sizes, such as Ludowici Spanish 13 or Spanish 18 tiles. Providing accurate dimensions ensures that the brackets fit perfectly, which is crucial for maintaining the aesthetic and functional integrity of the roof. -

Coating and Finish

The surface treatment of brackets, such as powder coating or anodizing, enhances their durability and aesthetic appeal. A good finish protects against UV rays and environmental wear, making it a significant factor for buyers looking for long-lasting solutions.

What Are Common Trade Terms Associated with Spanish Roof Brackets?

Familiarity with industry jargon can facilitate smoother transactions and communications in the procurement process. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. For buyers, knowing whether a supplier is an OEM can ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, as it can affect the overall purchasing cost. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. For B2B buyers, issuing an RFQ helps in comparing prices and terms, allowing for informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for buyers to know who is responsible for shipping costs, insurance, and risks during transit. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the products. For B2B buyers, knowing lead times helps in planning inventory and project timelines effectively. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the lifespan and performance of the product. Understanding warranty terms can help buyers assess the risk associated with their investment in roof brackets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance project efficiency and ensure the successful installation of Spanish roof brackets.

Navigating Market Dynamics and Sourcing Trends in the spanish roof bracket Sector

What Are the Key Market Dynamics and Trends in the Spanish Roof Bracket Sector?

The Spanish roof bracket market is currently experiencing a surge driven by various global factors. An increasing demand for sustainable building materials, particularly in regions like Africa, South America, and the Middle East, is reshaping sourcing strategies. As construction projects expand in these areas, the need for reliable and durable roofing solutions has become paramount. This has led to a heightened interest in products such as snow guards and solar panel mounts designed specifically for Spanish tile roofs, which are popular in Mediterranean climates.

Technological advancements are also influencing sourcing trends. The rise of e-commerce platforms has made it easier for international B2B buyers to access a wider range of products and suppliers, facilitating more competitive pricing and streamlined procurement processes. Moreover, the integration of Building Information Modeling (BIM) technology in construction projects is enhancing the design and installation efficiency of roof brackets, enabling buyers to visualize their projects better before procurement.

Emerging markets are increasingly focusing on quality and compliance with international standards, which is essential for buyers from Europe and beyond. This has prompted suppliers to enhance their product offerings, focusing on durability and safety features, especially in regions with challenging weather conditions. Such dynamics are vital for B2B buyers looking to source high-quality Spanish roof brackets that can withstand various environmental stresses.

How Is Sustainability Influencing Sourcing Decisions for Spanish Roof Brackets?

Sustainability has become a critical consideration in the sourcing of Spanish roof brackets. With growing awareness of environmental impact, international buyers are prioritizing products that utilize eco-friendly materials and manufacturing processes. The construction industry is under pressure to reduce its carbon footprint, and sourcing brackets made from recycled or sustainably sourced materials is increasingly appealing.

Ethical sourcing is also gaining traction. Buyers are seeking suppliers who adhere to fair labor practices and demonstrate transparency in their supply chains. Certifications such as LEED (Leadership in Energy and Environmental Design) and other green certifications are becoming essential for suppliers to showcase their commitment to sustainability. This not only enhances brand reputation but also aligns with the values of socially conscious buyers.

In addition, the integration of renewable energy solutions, such as solar panels mounted on Spanish roofs, further emphasizes the trend towards sustainability. Products designed to facilitate the installation of solar energy systems are increasingly being favored, as they contribute to energy efficiency and reduced reliance on fossil fuels. For B2B buyers, aligning with suppliers that prioritize sustainability can lead to long-term benefits, including cost savings and improved market positioning.

What Is the Historical Context of the Spanish Roof Bracket Market?

The Spanish roof bracket market has evolved significantly over the past few decades. Traditionally, roofing systems in Mediterranean regions relied heavily on clay tiles, which posed challenges in terms of snow management and energy efficiency. The introduction of specialized brackets, such as snow guards and solar mounts, marked a pivotal shift towards addressing these challenges.

Historically, suppliers focused on functionality and durability, often using materials like bronze and aluminum to enhance the longevity of their products. As the market has matured, there has been a shift towards integrating modern technology and sustainable practices. This evolution has not only improved product performance but also expanded the market to include innovative solutions that cater to the growing demand for energy efficiency and environmental responsibility.

Today, international B2B buyers are presented with a diverse array of options, reflecting the market’s adaptation to changing customer needs and global trends. Understanding this historical context is crucial for buyers looking to make informed sourcing decisions in the Spanish roof bracket sector.

Frequently Asked Questions (FAQs) for B2B Buyers of spanish roof bracket

-

How do I ensure the right fit for Spanish roof brackets on my tiles?

To ensure a proper fit for Spanish roof brackets, it’s crucial to provide a sample of the tile you plan to use. This will help suppliers identify the appropriate bracket that matches the specific dimensions and profile of your tiles. Additionally, consider the spacing recommendations based on your roof’s slope and snow load requirements, typically spaced 2 to 4 feet apart. Engaging in clear communication with your supplier about your roof specifications will also facilitate a better fit. -

What is the best material for Spanish roof brackets?

The best materials for Spanish roof brackets are typically bronze, brass, and stainless steel, as they offer durability and corrosion resistance. Bronze and brass are particularly effective for snow guard applications on tile roofs due to their strength and weather resistance. When selecting materials, consider the local climate and environmental conditions to ensure longevity and performance. Always consult with your supplier to determine the most suitable material based on your specific project requirements. -

What customization options are available for Spanish roof brackets?

Customization options for Spanish roof brackets can vary by supplier but often include adjustments in size, color, and material. Some manufacturers may also offer custom designs to accommodate unique tile profiles or specific project needs. When discussing your requirements, be clear about your expectations and any unique challenges your project may present. Custom brackets may have longer lead times and typically are non-returnable, so ensure that all details are confirmed before placing an order. -

What is the minimum order quantity (MOQ) for Spanish roof brackets?

The minimum order quantity (MOQ) for Spanish roof brackets can differ significantly among suppliers. Many manufacturers set an MOQ to ensure cost-effectiveness in production and shipping. Typically, MOQs may range from 10 to 100 units, but this can be negotiated based on your specific needs, especially for larger projects. Always inquire about the MOQ upfront to avoid surprises during the ordering process. -

What are the payment terms typically offered for B2B transactions?

Payment terms for B2B transactions can vary widely, but common practices include upfront payment, partial deposits, or net payment terms (e.g., Net 30 or Net 60). Some suppliers may also accept letters of credit or financing options for larger orders. It’s essential to clarify payment terms before finalizing your order to ensure that they align with your cash flow and financial planning. -

How do I vet suppliers for Spanish roof brackets?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their industry reputation, customer reviews, and years in business. Request references from previous clients and verify their compliance with international quality standards. Additionally, consider visiting their manufacturing facility or requesting samples of their products to assess quality firsthand. Engaging with suppliers who have experience in your specific market region can also provide added reassurance. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have quality assurance (QA) processes in place, including product testing, inspections, and certifications. Inquire about their QA protocols and whether they adhere to international standards such as ISO certifications. Suppliers should also provide documentation or reports detailing their QA procedures. A strong QA program helps ensure that the brackets meet your specifications and will perform well under local conditions. -

What logistics options should I consider when importing Spanish roof brackets?

When importing Spanish roof brackets, consider logistics options such as shipping methods (air freight vs. sea freight), customs clearance, and delivery timelines. Work with suppliers who have experience in international shipping to navigate potential challenges. Additionally, consider partnering with a freight forwarder to streamline the process and ensure compliance with import regulations in your country. Understanding the total landed cost, including duties and taxes, will also help you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Spanish Roof Bracket Manufacturers & Suppliers List

1. Fitrite – 532 3-Pipe Bronze Snow Rail Bracket

Domain: slateroofwarehouse.com

Registered: 2010 (15 years)

Introduction: Fitrite 532 3-Pipe Bronze Snow Rail Bracket for Spanish Tile roofs. SKU: FR532S. Special order item with a 6-8 week lead time, non-returnable and non-refundable. Requires a sample tile for exact match. Recommended spacing: 2-4 feet apart horizontally depending on roof slope and snow load. Matches Ludowici “Spanish 13” tiles. Weight: 8 lbs. Price: $590.00. Snow rails prevent ice and snow avalanches…

2. Alumawood – Raised Roof Bracket

Domain: alumawoodproducts.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Raised Roof Bracket”, “sku”: “00076”, “price”: “$150.00”, “roof_slope_options”: [“6/12”, “5/12”, “4/12”, “3/12”, “custom (+$85.00)”], “description”: “Roof mount bracket is for building header beams on roofs. This bracket fits a 3\”x8\” Alumawood header beam.”, “refund_policy”: {“standard”: “can be refunded if returned in new condition, minus shipping cost.”, “custom”: “non-refund…

3. Solar Parts Components – Solar Spanish Tile Mounts

Domain: solarpartscomponents.com

Registered: 2018 (7 years)

Introduction: Product Name: Solar Spanish Tile Mounts (Model: SPC-IK-01)\nKey Features: \n1. Adjustable height (up to 2 cm) based on roofing conditions.\n2. 10-year warranty for curved tile roof mount systems.\n3. Made from first-grade SUS 304 stainless steel and AL6005-T5 extruded aluminum alloy for durability.\n4. Suitable for both framed and frameless solar panels.\n5. Compatible with portrait and landscape …

4. SunWatts – Tile Roof Mounts

Domain: sunwatts.com

Registered: 2018 (7 years)

Introduction: Tile Roof Mounts include various products such as: 1. IronRidge All Tile Hook – Universal tile mount compatible with most tile roofs (Flat, S- and W-tile). MSRP: $6.00. 2. UniRac QuickMount Tile Replacement Flashing S-Tile – Black finish, compatible with QM Tile Hook. MSRP: $10.00. 3. UniRac Tile Roof Hook – Flat Tile Side Mount with two #14 X 3.5 inches screws. MSRP: $10.00. 4. Everest Flat Tile …

5. Bird B Gone – Roof Tile Brackets 10 Pk

Domain: birdbgone.com

Registered: 1997 (28 years)

Introduction: {“name”: “Roof Tile Brackets 10 Pk”, “type”: “J-bracket”, “length”: “6 inches”, “description”: “Multi-use bracket commonly used for installing cable perimeters on roof tiles. Resembles Bird B Gone’s standard Multi-Purpose Cable bracket with an extended 6” base that allows it to slide under Spanish tiles or other roof tiles for support.”, “screw_hole_size”: “1/4 inch”, “cable_diameter_compatibility…

6. Benys Solar – Solar Roof Flat Tile Hook Mounting Pack of 8

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Solar roof flat tile hook mounting Pack of 8″,”Brand”:”Benys Solar”,”Condition”:”New”,”Price”:”$67.95/ea or Best Offer”,”Quantity Available”:”6 available”,”Bulk Savings”:”Buy 1 for $67.95 each, Buy 2 for $61.16 each, Buy 3 for $57.76 each, Buy 4 or more for $54.36 each”,”Shipping Cost”:”$6.00 USPS Priority Mail”,”Location”:”Tempe, Arizona, United States”,”Delivery Estimate”:”Betwe…

7. Best Materials – 2-Bar Tile Roof Snow Barricade Bracket

Domain: bestmaterials.com

Registered: 2003 (22 years)

Introduction: {“product_name”:”2-Bar Tile Roof Snow Barricade Bracket”,”material”:”Stainless Steel”,”finish”:”Painted Finish”,”sale_price”:”$130.95″,”regular_price”:”$170.00″,”savings”:”$39.05″,”shipping_time”:”Typically ships in 1-2 Business Days”,”order_options”:”Specify color before adding to cart”,”description”:”Curved base plate customizable for all Spanish & clay tile roofing systems, available in 1 inch …

8. Snogem – Custom Spanish & Clay Tile Deck Mount Bar Systems

Domain: snogem.com

Registered: 2002 (23 years)

Introduction: Spanish & Clay Tile Deck Mount Bar Systems for custom configured roof systems. Curved base plate customizable for all Spanish & clay tile roofing systems. Available in 1″ or 2″ retention bar, using single, double, or triple bar support. Specifications include options for 1″ and 2″ square and round bars. Accessories available for both 1″ and 2″ bars, including inserts, end caps, and barricade plate…

Strategic Sourcing Conclusion and Outlook for spanish roof bracket

In today’s competitive marketplace, strategic sourcing of Spanish roof brackets is essential for international buyers aiming to optimize their supply chains and meet diverse roofing needs. Key considerations include understanding product specifications, lead times, and the importance of matching brackets to specific tile types, such as Ludowici Spanish tiles. By leveraging quality materials like bronze and stainless steel, buyers can enhance durability and performance, especially in regions with varying weather conditions.

Furthermore, establishing relationships with reliable suppliers can facilitate access to custom solutions and prompt support, thereby reducing downtime during projects. This proactive approach not only ensures compliance with local building codes but also enhances the overall safety and functionality of roofing installations.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should actively engage with suppliers to explore innovative bracket solutions that align with evolving market trends. By prioritizing strategic sourcing, businesses can not only improve their operational efficiency but also position themselves as leaders in the roofing industry. Embrace this opportunity to enhance your offerings and drive growth in your respective markets.