Improve Your Supply Chain: The Complete AV Tubing Guide (2025)

Introduction: Navigating the Global Market for av tubing

In today’s dynamic global market, sourcing high-quality AV tubing poses a significant challenge for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The demand for reliable and durable tubing solutions is on the rise, driven by various industries including construction, telecommunications, and manufacturing. This guide aims to demystify the complexities surrounding AV tubing by providing a comprehensive analysis of its various types, applications, and the essential considerations for supplier vetting.

Understanding the nuances of AV tubing is crucial for making informed purchasing decisions. Buyers will benefit from insights into the specific properties of different tubing materials, such as flexibility, durability, and resistance to environmental factors. Additionally, this guide will explore cost implications, helping businesses budget effectively while ensuring they do not compromise on quality.

By equipping B2B buyers with actionable insights and practical strategies, this guide empowers them to navigate the global market confidently. Whether you are a buyer in Egypt seeking reliable suppliers or a company in Brazil looking for innovative tubing solutions, the information contained herein is designed to enhance your procurement processes and ensure successful partnerships in the AV tubing sector.

Understanding av tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible PVC Tubing | Highly flexible, lightweight, and resistant to chemicals | Food and beverage processing, chemical handling | Pros: Cost-effective, easy to install. Cons: Limited temperature range. |

| Silicone Tubing | High-temperature resistance and flexibility | Medical devices, food processing | Pros: Biocompatible, durable. Cons: More expensive than PVC. |

| Polyurethane Tubing | Excellent abrasion resistance and flexibility | Pneumatic applications, robotics | Pros: Strong and durable. Cons: Can be more costly than PVC. |

| Rubber Tubing | High elasticity and resistance to wear | Automotive, industrial machinery | Pros: Excellent sealing properties. Cons: Heavier and less flexible than PVC. |

| Stainless Steel Tubing | Corrosion-resistant and strong | Oil and gas, pharmaceutical | Pros: Long-lasting, withstands extreme conditions. Cons: Higher initial cost. |

What are the characteristics of Flexible PVC Tubing?

Flexible PVC tubing is characterized by its lightweight nature and high flexibility, making it an ideal choice for applications that require bending and twisting. Its resistance to a variety of chemicals makes it suitable for food and beverage processing as well as chemical handling. When purchasing, buyers should consider the tubing’s temperature limitations, as it may not perform well in extreme heat or cold.

Why is Silicone Tubing suitable for medical applications?

Silicone tubing is known for its high-temperature resistance and flexibility, making it an excellent choice for medical devices and food processing industries. Its biocompatibility ensures that it can be safely used in applications that involve human contact. Buyers should weigh the benefits of durability and safety against the higher cost compared to alternatives like PVC.

What makes Polyurethane Tubing advantageous in robotics?

Polyurethane tubing offers excellent abrasion resistance and flexibility, which are critical in pneumatic applications and robotics. Its strength allows it to withstand wear and tear in demanding environments. Buyers should consider the cost implications, as polyurethane can be more expensive than PVC, but the longevity may justify the investment.

How does Rubber Tubing perform in industrial settings?

Rubber tubing is known for its high elasticity and resistance to wear, making it a reliable choice for automotive and industrial machinery applications. Its excellent sealing properties enhance its performance in various industrial settings. However, buyers should note that rubber tubing tends to be heavier and less flexible than PVC, which may affect installation and handling.

In what situations is Stainless Steel Tubing preferred?

Stainless steel tubing is favored for its corrosion resistance and strength, making it ideal for oil and gas applications, as well as pharmaceutical industries. Its ability to withstand extreme conditions ensures longevity and reliability. However, the higher initial cost may be a consideration for buyers, who should evaluate the long-term benefits of investing in durable materials.

Key Industrial Applications of av tubing

| Industry/Sector | Specific Application of av tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Fuel and hydraulic systems | Enhanced safety and performance in critical systems | Compliance with aviation standards and certifications |

| Automotive | Brake and fuel lines | Improved durability and resistance to high pressure | Material quality, temperature resistance, and certifications |

| Construction | Plumbing and HVAC systems | Efficient fluid transport and energy savings | Local regulations, material compatibility, and installation ease |

| Medical | Medical device manufacturing | Precise control of fluids in diagnostic and therapeutic equipment | Biocompatibility, sterilization, and regulatory compliance |

| Food and Beverage | Processing and packaging systems | Hygiene and safety in food handling | Compliance with food safety standards and material certifications |

How Is AV Tubing Used in Aerospace Applications?

In the aerospace industry, av tubing is critical for fuel and hydraulic systems. It is engineered to withstand extreme temperatures and pressures, ensuring reliable operation in flight-critical applications. International B2B buyers in this sector must prioritize suppliers who comply with stringent aviation standards and certifications, ensuring both safety and performance. Additionally, sourcing high-quality materials that meet specific aerospace requirements can significantly reduce the risk of failure during operation.

What Are the Benefits of AV Tubing in Automotive Applications?

In the automotive sector, av tubing is commonly used for brake and fuel lines. Its ability to resist high pressure and environmental factors translates into enhanced durability and reliability, essential for vehicle safety. Buyers from regions like South America and Africa should focus on sourcing tubing that meets local and international automotive standards, ensuring compatibility with existing systems. Understanding the material properties and potential for temperature fluctuations is also crucial for optimal performance.

How Is AV Tubing Applied in Construction?

AV tubing plays a vital role in plumbing and HVAC systems within the construction industry. Its design facilitates efficient fluid transport, contributing to energy savings in heating and cooling systems. B2B buyers in the Middle East and Europe should consider local regulations regarding plumbing materials and ensure that the tubing is compatible with other construction materials. Ease of installation and long-term durability are key factors that influence sourcing decisions.

Why Is AV Tubing Important in Medical Device Manufacturing?

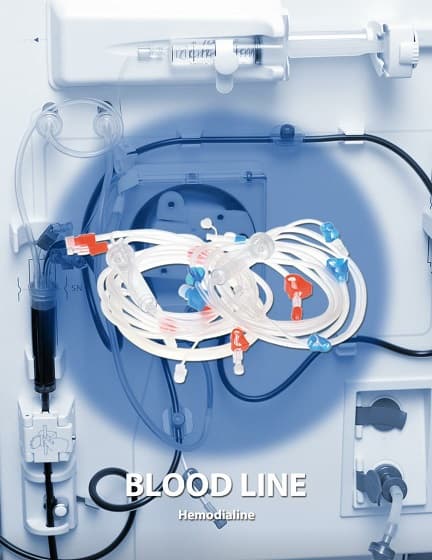

In medical device manufacturing, av tubing is essential for the precise control of fluids in diagnostic and therapeutic equipment. The tubing must be biocompatible and capable of withstanding sterilization processes to ensure patient safety. Buyers in this sector should prioritize suppliers who can provide documentation of compliance with medical regulations and standards. This focus not only enhances product safety but also builds trust with healthcare providers and patients alike.

How Does AV Tubing Benefit the Food and Beverage Industry?

In the food and beverage industry, av tubing is used in processing and packaging systems to ensure hygiene and safety during food handling. The material must meet stringent food safety standards, making it critical for B2B buyers to source tubing that is certified for food contact. Additionally, understanding the requirements for easy cleaning and sterilization is essential for maintaining compliance with health regulations, thereby safeguarding the brand’s reputation and consumer trust.

Related Video: Uses of Radioisotope in Industry | Nuclear Energy | Science

3 Common User Pain Points for ‘av tubing’ & Their Solutions

Scenario 1: Ensuring Durability and Reliability in Harsh Environments

The Problem: B2B buyers often encounter significant challenges when sourcing AV tubing suitable for harsh environments, such as extreme temperatures or exposure to chemicals. For instance, a manufacturer in Egypt might require AV tubing for a production line that operates in a hot climate, which can lead to premature degradation or failure of standard tubing materials. This not only affects operational efficiency but can also lead to costly downtime and repairs.

The Solution: To overcome this issue, buyers should seek out AV tubing specifically designed for high-performance applications. Materials like polyvinyl chloride (PVC) or reinforced thermoplastic elastomers (TPE) can offer enhanced resistance to heat and chemicals. Buyers should also consider sourcing from suppliers that provide detailed product specifications, including temperature ratings and chemical compatibility charts. Engaging with manufacturers who offer custom solutions can lead to tailored products that meet specific environmental requirements. Additionally, conducting a thorough evaluation of potential suppliers’ track records in similar industries can help ensure reliability and durability.

Scenario 2: Navigating Complex Compliance Regulations

The Problem: International B2B buyers must navigate a labyrinth of compliance regulations regarding materials used in AV tubing, especially when dealing with exports to Europe and North America. A buyer in Brazil, for example, might struggle to ensure that their AV tubing meets stringent EU standards for safety and environmental impact. Failure to comply can result in significant fines, loss of contracts, or halted shipments.

The Solution: To effectively address compliance concerns, it is vital for buyers to partner with suppliers who are well-versed in international standards and certifications. Buyers should request documentation demonstrating compliance with relevant regulations, such as RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). Establishing a close relationship with suppliers can facilitate regular updates on regulatory changes and help buyers stay informed. Furthermore, participating in industry workshops or webinars can enhance a buyer’s understanding of compliance issues, ensuring they make informed purchasing decisions.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Supply chain disruptions can severely impact B2B buyers’ operations, particularly when sourcing AV tubing from international suppliers. A company in the Middle East, for example, might face unexpected delays due to geopolitical tensions or global shipping challenges, leading to production holdups and financial losses.

The Solution: To mitigate the risk of supply chain disruptions, buyers should diversify their supplier base by identifying multiple vendors across different regions. This strategy not only reduces dependency on a single source but also enhances flexibility in meeting demand. Implementing just-in-time inventory practices can also help in managing stock levels more effectively, reducing the risk of overstock or stockouts. Additionally, leveraging technology such as supply chain management software can provide real-time visibility into inventory levels and supplier performance. Regular communication with suppliers to discuss potential risks and collaboratively develop contingency plans can further strengthen resilience against disruptions.

Strategic Material Selection Guide for av tubing

What Are the Common Materials Used for AV Tubing?

When selecting materials for AV tubing, international B2B buyers must consider various factors, including performance, compatibility, and regulatory compliance. Here, we analyze four common materials used in AV tubing, focusing on their properties, advantages, disadvantages, and implications for buyers in different regions.

How Does Polyvinyl Chloride (PVC) Perform in AV Tubing Applications?

Key Properties: PVC is known for its excellent chemical resistance and low moisture absorption. It typically operates at temperatures up to 60°C and can withstand moderate pressure levels.

Pros & Cons: PVC is lightweight and cost-effective, making it a popular choice for many applications. However, it has limitations in high-temperature environments and can become brittle over time when exposed to UV light.

Impact on Application: PVC is suitable for transporting water, chemicals, and gases in moderate conditions. However, it is not recommended for applications involving high-pressure or extreme temperature fluctuations.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM D1784. PVC’s availability and cost-effectiveness make it a preferred choice in many developing markets.

What Advantages Does Polyethylene (PE) Offer for AV Tubing?

Key Properties: PE has a high resistance to impact and is flexible, with a temperature rating of up to 80°C. It is also resistant to corrosion and chemicals.

Pros & Cons: The flexibility of PE allows for easy installation and adaptability in various environments. However, it can be more expensive than PVC and may not be suitable for high-pressure applications.

Impact on Application: PE is ideal for transporting potable water and chemicals, making it suitable for agricultural and industrial applications. Its flexibility allows it to be used in various terrains, particularly beneficial in regions with challenging landscapes.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider compliance with standards such as DIN 8074. The material’s environmental impact and recyclability can also be pivotal in regions prioritizing sustainability.

How Does Stainless Steel Compare in AV Tubing Applications?

Key Properties: Stainless steel is renowned for its high strength and durability, with excellent resistance to corrosion and extreme temperatures (up to 300°C).

Pros & Cons: While stainless steel offers superior longevity and reliability, it is significantly more expensive than plastic alternatives and can be challenging to fabricate and install.

Impact on Application: This material is ideal for high-pressure applications and environments where hygiene is critical, such as food and pharmaceutical industries. Its robustness makes it suitable for long-term installations.

Considerations for International Buyers: Buyers from the Middle East and Europe should ensure compliance with standards such as ASTM A312 for stainless steel tubing. The higher initial investment may be offset by lower maintenance costs over time.

What Role Does Copper Play in AV Tubing?

Key Properties: Copper tubing is known for its excellent thermal conductivity and corrosion resistance. It can handle high temperatures (up to 200°C) and pressures effectively.

Pros & Cons: Copper is durable and has antimicrobial properties, making it suitable for plumbing and HVAC applications. However, it is more expensive than plastic materials and may require specialized installation techniques.

Impact on Application: Copper is widely used in water supply lines, refrigeration, and heating systems due to its thermal properties. Its longevity makes it a reliable choice for critical applications.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the varying regulations regarding copper usage. Compliance with standards such as ASTM B88 is essential, and the fluctuating copper market can impact pricing.

Summary Table of Material Selection for AV Tubing

| Material | Typical Use Case for AV Tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Water and chemical transport | Cost-effective and lightweight | Limited temperature resistance | Low |

| Polyethylene (PE) | Potable water and agricultural use | Flexible and impact-resistant | Higher cost and pressure limits | Medium |

| Stainless Steel | High-pressure and hygienic applications | Superior durability and strength | High cost and fabrication complexity | High |

| Copper | Plumbing and HVAC systems | Excellent thermal conductivity | Expensive and requires specialized installation | High |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in AV tubing. Understanding these factors will help in making informed purchasing decisions tailored to specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for av tubing

What Are the Key Stages in the Manufacturing Process of AV Tubing?

The manufacturing of AV tubing involves several critical stages, each designed to ensure the final product meets stringent quality standards and performance specifications. Understanding these stages will help B2B buyers evaluate suppliers effectively.

1. Material Preparation: How Is the Right Material Chosen?

The first step in the manufacturing process involves selecting high-quality raw materials. AV tubing is typically made from various metals, including aluminum, copper, or specialized alloys, depending on the intended application. Suppliers should provide detailed information about the source of their materials, ensuring they meet international standards such as ASTM or ISO certifications. This transparency is crucial for B2B buyers looking to avoid subpar products.

2. Forming: What Techniques Are Used to Shape AV Tubing?

Once materials are prepared, they undergo forming processes, which can include extrusion, bending, or hydroforming. Extrusion is particularly common for producing consistent shapes and diameters. In this process, heated material is forced through a die, resulting in long sections of tubing. Bending and hydroforming techniques allow for more complex shapes, which can be essential for specific applications.

A stock image related to av tubing.

B2B buyers should inquire about the forming techniques used by suppliers, as these can significantly impact the integrity and performance of the tubing. Advanced forming techniques can lead to better material properties and reduced defects.

3. Assembly: How Is AV Tubing Assembled for Final Products?

In the assembly stage, various components are joined together. This might involve welding, soldering, or mechanical fastening. The choice of assembly method impacts the tubing’s durability and performance, especially under high-stress conditions.

Buyers should ask suppliers about their assembly techniques and the qualifications of their personnel. Certifications in welding or assembly processes can provide additional assurance of quality.

4. Finishing: What Final Treatments Enhance AV Tubing Quality?

The finishing stage includes processes such as surface treatment, coating, and polishing, which improve the tubing’s resistance to corrosion and wear. Common methods include anodizing for aluminum tubing or applying protective coatings to enhance longevity.

B2B buyers should consider the finishing techniques employed by suppliers, as these can influence the tubing’s performance in specific environments. It’s beneficial to request samples or specifications for the finishing processes used.

What Are the Quality Assurance Standards Relevant to AV Tubing Manufacturing?

Quality assurance (QA) is a critical component of AV tubing manufacturing, ensuring that products meet both international and industry-specific standards. Familiarity with these standards helps B2B buyers make informed purchasing decisions.

International Standards: Why Is ISO 9001 Important?

A stock image related to av tubing.

ISO 9001 is a globally recognized standard for quality management systems (QMS). Manufacturers certified under ISO 9001 demonstrate a commitment to consistent quality and continuous improvement. B2B buyers should prioritize suppliers with this certification, as it indicates adherence to established quality protocols.

Industry-Specific Certifications: What Are CE and API Standards?

For AV tubing used in specific applications, additional certifications may be required. The CE mark indicates compliance with European health, safety, and environmental protection standards. For tubing used in the oil and gas sector, the American Petroleum Institute (API) certification is critical, as it ensures the product meets stringent industry requirements.

When sourcing AV tubing, B2B buyers should verify that suppliers hold relevant industry certifications, as this can significantly impact the reliability and safety of their products.

What Quality Control Checkpoints Are Common in AV Tubing Manufacturing?

Effective quality control (QC) is vital throughout the AV tubing manufacturing process. Key checkpoints include:

1. Incoming Quality Control (IQC): How Are Raw Materials Inspected?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that only materials meeting specified standards are used in production. B2B buyers should inquire about the IQC procedures their suppliers follow, including testing methods and documentation.

2. In-Process Quality Control (IPQC): What Checks Are Conducted During Manufacturing?

IPQC includes monitoring processes during manufacturing to identify defects early. This may involve regular inspections of forming and assembly stages. Buyers should look for suppliers that implement rigorous IPQC measures, as these can prevent issues from escalating into significant problems.

3. Final Quality Control (FQC): What Testing Is Done Before Shipment?

FQC is the final step before products are shipped to customers. This phase typically involves comprehensive testing, including pressure tests, dimensional checks, and visual inspections. Suppliers should provide detailed reports of FQC results to assure buyers of product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should take proactive steps to verify their QC practices:

1. Conduct Supplier Audits: What Should Buyers Look For?

Conducting on-site audits can provide valuable insights into a supplier’s manufacturing and QC processes. During an audit, buyers should assess the facility’s cleanliness, equipment maintenance, and adherence to safety protocols.

2. Request QC Reports: How Can Documentation Support Quality Claims?

Suppliers should provide documentation that outlines their QC processes, including results from IQC, IPQC, and FQC checks. Buyers can use this information to evaluate the reliability of the supplier’s quality assurance measures.

3. Engage Third-Party Inspectors: Why Are Independent Assessments Beneficial?

Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can conduct thorough evaluations of the manufacturing process and final products, ensuring compliance with international standards.

What Nuances Should International B2B Buyers Be Aware Of Regarding QC?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating QC practices:

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can influence supplier interactions. Buyers should approach negotiations with sensitivity to these differences.

-

Regulatory Compliance: Different regions have varying regulations regarding quality standards. Buyers must ensure that suppliers comply with local and international regulations relevant to their market.

-

Supply Chain Logistics: International shipping can introduce additional risks to product quality. Buyers should discuss logistics with suppliers to ensure that products maintain integrity throughout transit.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions that enhance their supply chain effectiveness and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘av tubing’

Introduction

Sourcing AV tubing can be a complex process, especially for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. This guide aims to simplify your procurement journey by providing a practical checklist that ensures you consider all critical factors, from technical specifications to supplier evaluations. By following these steps, you can make informed decisions that align with your operational needs and business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define your technical requirements for AV tubing. Consider factors such as material type, diameter, flexibility, and any specific industry standards that must be met. Why is this important? Well-defined specifications help you communicate effectively with suppliers and ensure that the products meet your operational requirements.

- Material Considerations: Determine if you need PVC, rubber, or another material based on your application.

- Compliance Standards: Identify any regional compliance standards, such as ISO or ASTM, that the tubing must meet.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in AV tubing. Utilize online directories, industry trade shows, and networking events to gather information. What should you focus on? Look for suppliers with a solid reputation and experience in your industry.

- Industry Experience: Prefer suppliers with a track record in supplying AV tubing for your specific application.

- Geographic Presence: Consider suppliers with distribution centers in your region to minimize shipping costs and delays.

Step 3: Evaluate Supplier Certifications

It’s essential to verify the certifications of potential suppliers to ensure product quality and compliance. Request documentation such as ISO certifications or product quality assurance certificates. Why does this matter? Certifications demonstrate a supplier’s commitment to quality and can mitigate risks associated with non-compliance.

- Quality Assurance: Ensure the supplier has a robust quality management system in place.

- Safety Standards: Confirm adherence to safety regulations relevant to your industry.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the AV tubing. This allows you to assess the quality and suitability of the product for your specific needs. What should you evaluate? Test the samples under your operational conditions to ensure they perform as expected.

- Performance Testing: Check for flexibility, durability, and resistance to environmental factors.

- Compatibility Checks: Ensure the tubing is compatible with existing equipment or systems.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a potential supplier, enter into negotiations to discuss pricing, payment terms, and delivery schedules. What’s crucial here? Establishing clear terms can prevent misunderstandings and ensure a smooth procurement process.

- Volume Discounts: Inquire about discounts for larger orders.

- Payment Flexibility: Discuss payment options that align with your cash flow needs.

Step 6: Assess After-Sales Support

After securing a supplier, evaluate their after-sales support services. Reliable after-sales support can be a game-changer, especially in troubleshooting and product maintenance. Why is this critical? Strong support can minimize downtime and ensure your operations run smoothly.

- Technical Assistance: Check if the supplier offers technical support or training for your staff.

- Return Policies: Understand the return policies in case of defective products.

Step 7: Monitor Supplier Performance

After the procurement process, continuously monitor the supplier’s performance. Establish key performance indicators (KPIs) to evaluate delivery times, product quality, and customer service. What should you focus on? Regular assessments can help you maintain a reliable supply chain and make adjustments if necessary.

- Feedback Mechanisms: Implement feedback systems to communicate any issues promptly.

- Long-Term Relationships: Foster relationships with suppliers who consistently meet or exceed expectations.

By following this structured checklist, you can streamline your sourcing of AV tubing and enhance your procurement strategy, ultimately leading to better operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for av tubing Sourcing

What are the Key Cost Components in AV Tubing Sourcing?

When sourcing AV tubing, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality and type of materials used in AV tubing significantly affect the price. Common materials include various grades of aluminum and PVC, with higher quality materials typically leading to increased costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing AV tubing. Regions with higher labor costs may drive up the overall price, while countries with lower labor costs might offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment depreciation. Manufacturers often distribute these overhead costs across all products, influencing the final price of AV tubing.

-

Tooling: The creation of specialized tools for production can be a significant upfront investment. These costs are amortized over the production volume, meaning higher volume orders can lead to lower per-unit tooling costs.

-

Quality Control (QC): Ensuring that AV tubing meets quality standards involves testing and inspection processes. The more rigorous the QC processes, the higher the associated costs, impacting the final pricing.

-

Logistics: Transportation costs, including shipping and handling, can vary widely based on distance, mode of transport, and logistics provider. Buyers should consider these costs as part of their overall sourcing strategy.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on their market position, brand reputation, and the competitive landscape.

How Do Price Influencers Affect AV Tubing Costs?

Several factors can influence the pricing of AV tubing, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating favorable terms regarding MOQs can lead to significant savings.

-

Specifications and Customization: Customized AV tubing designed to meet specific requirements can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: High-quality materials and additional certifications (e.g., ISO) may drive up costs but can enhance product reliability and performance. Buyers should weigh the benefits against the additional expense.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all impact pricing. Established suppliers may charge more due to their perceived reliability and quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for pricing negotiations. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for AV Tubing?

International B2B buyers can leverage several strategies to improve their sourcing outcomes:

-

Negotiation: Effective negotiation is key to securing favorable pricing. Buyers should be prepared to discuss volume commitments, payment terms, and delivery schedules to achieve better terms.

-

Cost-Efficiency: Assessing the total cost of ownership (TCO) rather than just the purchase price can lead to more informed decisions. Consider maintenance, operational costs, and potential downtime when evaluating suppliers.

-

Understanding Pricing Nuances: Be aware of regional pricing variations. For example, suppliers in Africa or South America may have different pricing structures compared to those in Europe or the Middle East, influenced by local economic conditions.

-

Research and Benchmarking: Conducting market research and benchmarking against competitors can provide insights into fair pricing and help buyers justify their negotiation positions.

Disclaimer on Indicative Prices

Prices for AV tubing can fluctuate based on market conditions, material availability, and other external factors. Buyers are encouraged to seek quotes from multiple suppliers and conduct thorough due diligence to ensure they are receiving competitive pricing aligned with their specific needs.

Alternatives Analysis: Comparing av tubing With Other Solutions

When evaluating solutions for fluid delivery and management, international B2B buyers often encounter a variety of options. Among these, AV tubing stands out for its specific applications, but it’s crucial to consider alternatives that may better suit certain operational needs. This section provides a comparative analysis of AV tubing against other viable solutions, enabling buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions.

| Comparison Aspect | ‘Av Tubing’ | Alternative 1: Flexible PVC Tubing | Alternative 2: Metal Piping |

|---|---|---|---|

| Performance | High flexibility, suitable for various applications | Moderate flexibility, good for low-pressure systems | Excellent durability, high pressure handling |

| Cost | Moderate | Low | High |

| Ease of Implementation | Easy to install | Very easy to install, lightweight | Requires skilled labor for installation |

| Maintenance | Low maintenance | Moderate, may require periodic checks | Low, but repairs can be costly |

| Best Use Case | Medical and laboratory applications | General fluid transfer in non-critical systems | Industrial applications requiring high durability |

How Does Flexible PVC Tubing Compare to AV Tubing?

Flexible PVC tubing is a popular alternative due to its affordability and ease of installation. It is lightweight, making it simple to transport and handle. However, its performance is limited to low-pressure systems, which may not be suitable for all applications. While it offers a lower upfront cost, buyers should consider the potential need for replacements and repairs over time, which could offset initial savings.

What are the Advantages of Metal Piping Over AV Tubing?

Metal piping, typically made from materials like copper or stainless steel, provides exceptional durability and the ability to handle high-pressure applications. It is ideal for industrial settings where robustness is required. However, the initial investment is significantly higher compared to AV tubing and flexible PVC tubing. Installation can also be more complex, necessitating skilled labor, which adds to overall project costs. Maintenance is generally low, but any repairs can be expensive, making it crucial for buyers to evaluate their long-term operational needs.

Conclusion: How Should International B2B Buyers Choose the Right Solution?

Selecting the appropriate fluid delivery solution requires careful consideration of specific operational requirements and constraints. B2B buyers should assess their application needs, budget, and maintenance capabilities when comparing AV tubing to alternatives such as flexible PVC tubing and metal piping. By analyzing performance, costs, and installation requirements, companies can make informed decisions that optimize efficiency and cost-effectiveness in their operations. Ultimately, the right choice will depend on balancing immediate needs with long-term operational goals.

Essential Technical Properties and Trade Terminology for av tubing

What Are the Key Technical Properties of AV Tubing?

When sourcing AV tubing, understanding its technical properties is crucial for making informed purchasing decisions. Here are several critical specifications:

1. Material Grade

The material grade of AV tubing typically refers to the quality and type of raw materials used in manufacturing. Common materials include aluminum, copper, and various polymers. The choice of material impacts durability, weight, and thermal conductivity. For example, aluminum is lightweight and resistant to corrosion, making it suitable for applications requiring mobility and longevity. B2B buyers should consider the material grade to ensure compatibility with their specific applications, especially in industries such as electronics or automotive.

2. Diameter and Wall Thickness

The diameter and wall thickness of AV tubing are essential specifications that determine the tubing’s flow capacity and strength. A larger diameter allows for greater fluid flow, while the wall thickness affects the structural integrity and pressure resistance of the tubing. Buyers must match these specifications to their operational requirements to avoid potential failures or inefficiencies in their systems.

3. Tolerance

Tolerance refers to the acceptable limits of variation in the dimensions of the AV tubing. High precision is often required in applications such as medical devices or aerospace components. Understanding the tolerance specifications ensures that the tubing will fit correctly within the intended assemblies, reducing the risk of assembly issues or operational failures.

4. Operating Temperature Range

The operating temperature range indicates the extremes within which the AV tubing can function effectively without degrading. This property is critical for applications in environments with high heat or cold, such as manufacturing processes or outdoor installations. Buyers should verify that the tubing can withstand the specific temperature conditions of their applications to maintain performance and safety.

5. Pressure Rating

The pressure rating specifies the maximum pressure the AV tubing can safely handle. This is particularly important in hydraulic and pneumatic systems where pressure fluctuations can occur. Selecting tubing with an appropriate pressure rating is essential to prevent leaks, bursts, or other failures that could lead to costly downtimes or accidents.

What Are Common Trade Terms Used in AV Tubing Procurement?

Understanding trade terminology is equally important when dealing with AV tubing. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of AV tubing, buyers often engage with OEMs to source customized tubing solutions that fit their specific needs. This relationship can enhance product quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum amount of product that a supplier is willing to sell. It can significantly impact purchasing decisions, particularly for smaller businesses or startups. Understanding the MOQ helps buyers plan their inventory and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of tubing along with any relevant terms and conditions. This process allows buyers to compare prices and negotiate terms, ensuring they receive the best deal possible.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to manage shipping costs, responsibilities, and risks associated with the transportation of AV tubing.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the goods. Knowing the lead time is essential for inventory management and planning production schedules. Buyers should factor this into their procurement strategy to ensure timely availability of AV tubing for their operations.

In conclusion, a comprehensive understanding of the technical properties and trade terminology associated with AV tubing empowers international B2B buyers to make more informed decisions, ultimately leading to enhanced operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the av tubing Sector

What Are the Current Market Dynamics and Key Trends in the AV Tubing Sector?

The AV tubing sector is experiencing significant growth, driven by advancements in technology and increasing demand for lightweight, durable materials across various industries. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must stay informed about these global drivers to make strategic sourcing decisions. The integration of Industry 4.0 technologies, including IoT and smart manufacturing, is shaping how AV tubing is produced and distributed. This shift not only enhances efficiency but also allows for real-time monitoring of supply chains, ensuring that businesses can respond promptly to market changes.

Emerging trends such as the rise of additive manufacturing (3D printing) are revolutionizing the AV tubing landscape. This technology enables customized production, reducing waste and inventory costs, which is particularly beneficial for companies operating in regions with limited access to traditional manufacturing resources. Additionally, the focus on reducing lead times and enhancing supply chain resilience is prompting buyers to consider local suppliers and nearshoring options, especially in response to global disruptions caused by events like the COVID-19 pandemic.

Furthermore, international buyers should be aware of the increasing importance of compliance with international standards and regulations, particularly in Europe, where stringent environmental and safety standards are enforced. Understanding these market dynamics is crucial for buyers looking to leverage opportunities and mitigate risks in their sourcing strategies.

How Are Sustainability and Ethical Sourcing Influencing the AV Tubing Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the AV tubing sector. As environmental concerns escalate, B2B buyers are prioritizing suppliers that demonstrate a commitment to sustainable practices. The environmental impact of tubing production, including energy consumption and waste generation, has become a key consideration for international buyers. Companies are increasingly seeking materials that are recyclable or made from recycled sources, which not only reduces their carbon footprint but also enhances their brand reputation.

Ethical sourcing is equally important, as buyers are becoming more aware of the social implications of their procurement decisions. Ensuring that suppliers maintain fair labor practices and adhere to ethical standards is essential for building a responsible supply chain. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. For buyers in regions like Africa and South America, where local supply chains can be less regulated, it is crucial to conduct thorough due diligence to avoid potential reputational risks.

Incorporating sustainable materials and practices into sourcing strategies not only meets consumer demand for environmentally friendly products but also positions companies favorably in a competitive marketplace. As sustainability continues to shape the AV tubing sector, B2B buyers must adapt their sourcing strategies to align with these evolving expectations.

What Is the Historical Context of AV Tubing Development Relevant to B2B Buyers?

The AV tubing sector has evolved significantly over the last few decades, transitioning from traditional manufacturing methods to more advanced production techniques. Initially, AV tubing was predominantly made from metal, which offered durability but lacked flexibility and adaptability. The introduction of synthetic materials revolutionized the industry, allowing for the production of lighter, more versatile tubing options.

In the 1990s, the rise of composite materials further transformed the AV tubing landscape, providing enhanced strength-to-weight ratios and resistance to corrosion. This evolution has been crucial for industries such as automotive, aerospace, and construction, where the demand for lightweight yet durable materials is paramount. Understanding this historical context helps international B2B buyers appreciate the technological advancements that have shaped the current market and informs their decision-making when selecting suppliers and materials. As the sector continues to innovate, staying abreast of these changes will be vital for maximizing competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of av tubing

-

How do I determine the right specifications for av tubing?

To choose the right specifications for av tubing, consider the application and environment where it will be used. Key factors include diameter, wall thickness, material (like PVC or rubber), and operating temperature. Additionally, evaluate the tubing’s flexibility and durability requirements based on the intended use. Consulting with suppliers or industry standards can provide guidance on selecting the appropriate specifications tailored to your needs. -

What is the best material for av tubing in different climates?

The best material for av tubing varies by climate. For humid conditions, PVC is often preferred due to its moisture resistance, while rubber tubing may perform better in colder climates due to its flexibility at low temperatures. For hot environments, look for materials that can withstand high temperatures without degrading. Always check supplier specifications to ensure the tubing will meet your environmental challenges. -

How can I vet suppliers for av tubing in international markets?

Vetting suppliers for av tubing involves checking their reputation, certifications, and quality control processes. Start by researching their business history, customer reviews, and any industry-specific certifications. It’s also beneficial to request samples and conduct factory visits if possible. Utilizing third-party auditing services can provide an additional layer of assurance regarding their production capabilities and compliance with international standards. -

What are common payment terms for international av tubing purchases?

Common payment terms for international av tubing purchases include letter of credit, advance payment, or payment on delivery. Negotiating terms may depend on the supplier’s policies and your relationship. Ensure to clarify payment methods, currency, and any associated fees upfront to avoid misunderstandings. Establishing a clear contract that outlines these terms can help protect both parties. -

What is the minimum order quantity (MOQ) for av tubing?

Minimum order quantities (MOQs) for av tubing can vary widely based on the supplier and specific product. Generally, MOQs can range from a few hundred meters to several thousand, depending on manufacturing capabilities and material costs. It’s essential to discuss your requirements with the supplier to see if they can accommodate smaller orders or if they offer tiered pricing for larger quantities. -

How do I ensure quality assurance for av tubing?

To ensure quality assurance for av tubing, request detailed product specifications and quality control documentation from suppliers. It’s important to inquire about their testing methods, compliance with international standards, and warranty policies. Conducting independent inspections or certifications can further validate the quality of the tubing before shipment. Establishing a quality agreement with the supplier can also clarify expectations. -

What are the logistics considerations for importing av tubing?

When importing av tubing, consider logistics factors such as shipping methods, customs regulations, and lead times. Select a reliable freight forwarder familiar with your destination country to handle documentation and customs clearance. Additionally, factor in storage solutions upon arrival, as av tubing can be bulky. Be aware of any tariffs or taxes that may apply to your shipment to avoid unexpected costs. -

Can av tubing be customized for specific applications?

Yes, av tubing can often be customized to meet specific applications. Many suppliers offer customization options such as varying lengths, diameters, colors, and materials. When discussing customization, clearly communicate your requirements and any industry standards that must be met. Additionally, inquire about lead times for customized orders, as they may differ from standard products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for av tubing

As the global demand for AV tubing continues to rise, strategic sourcing emerges as a critical factor for international B2B buyers. By prioritizing suppliers that offer high-quality materials, competitive pricing, and reliable delivery timelines, businesses can significantly enhance their operational efficiency and product offerings. Engaging with manufacturers from diverse regions, such as Africa, South America, the Middle East, and Europe, not only fosters innovation but also mitigates risks associated with supply chain disruptions.

A stock image related to av tubing.

What are the next steps for B2B buyers in the AV tubing market? It is essential to conduct thorough market research and leverage data analytics to identify trends and opportunities that align with your business goals. Establishing robust relationships with suppliers can lead to better negotiation outcomes and improved service levels.

Looking ahead, the AV tubing market presents immense potential for growth and collaboration. Buyers are encouraged to stay informed about technological advancements and shifts in consumer preferences that could impact product specifications. Embracing a proactive approach to strategic sourcing will position your business to thrive in this dynamic landscape. Connect with trusted suppliers today to ensure your competitive edge in the evolving market of AV tubing.