Fruit Juice Filling Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Fruit Juice Filling Machines

In the competitive landscape of the beverage industry, securing a reliable fruit juice filling machine is paramount for manufacturers aiming to optimize production efficiency and meet consumer demands. As global markets in the USA and Europe expand, businesses face mounting pressures from fluctuating supply chains, stringent food safety regulations, and the need for scalable, versatile solutions that handle diverse liquids like juices, purees, and concentrates.

The challenge lies in selecting equipment that not only ensures hygiene and precision but also adapts to varying production scales—from small-batch operations to high-volume lines—while minimizing downtime and operational costs. Outdated or mismatched machinery can lead to product waste, compliance risks, and lost market share in a sector where innovation drives profitability.

This guide equips B2B decision-makers with essential insights to navigate this dynamic market. We’ll explore:

- Market Overview: Key trends, regional regulations in the USA and Europe, and emerging technologies shaping the industry.

- Types of Machines: A breakdown of semi-automatic (e.g., tabletop fillers like MINIFLOW) and automatic options (e.g., MAXIFLOW for high-capacity filling at ~2000 l/h), including Bag In Box and Stand Up Pouch systems suitable for juices and beyond.

- Key Considerations: Factors like capacity, user-friendliness, customization, and integration with pasteurizers for thermal processing.

- Selection and Best Practices: Tips for evaluating vendors, cost-benefit analysis, and real-world case studies from manufacturers leveraging advanced fillers for efficient, disturbance-free operations.

By the end, you’ll have a clear roadmap to invest in fruit juice filling machines that enhance productivity and sustain growth in global markets.

Top 10 Fruit Juice Filling Machine Manufacturers & Suppliers List

1. Top 10 Liquid Filling Machine Manufacturers – HonorPack

Domain: honorpack.com

Registered: 2009 (16 years)

Introduction: KHS GmbH is one of the leading liquid-filling machine manufacturers in Germany. Their headquarters is situated in Dortmund and has 5,400 employees. With ……

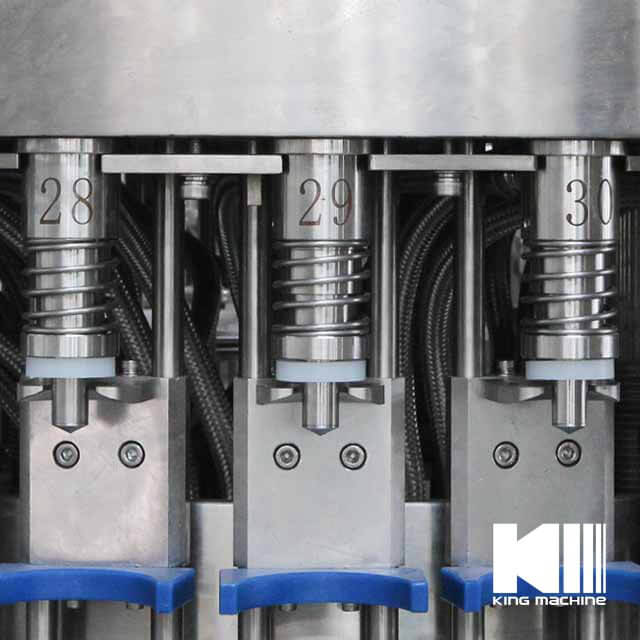

2. Juice Filling Machine | Hot Juice Bottling Machines for Sale

Domain: king-machine.com

Registered: 2008 (17 years)

Introduction: As one of the leading beverage-packing machine manufacturers, we provide quality liquid filler and amazing service to many of our customers worldwide….

3. Bottling & Filling Equipment Manufacturer | E-PAK Machinery

Domain: epakmachinery.com

Registered: 2001 (24 years)

Introduction: E-PAK Machinery manufactures quality liquid filling machines, including cappers and labelers, for the bottling industry. Buy equipment and parts online….

Illustrative Image (Source: Google Search)

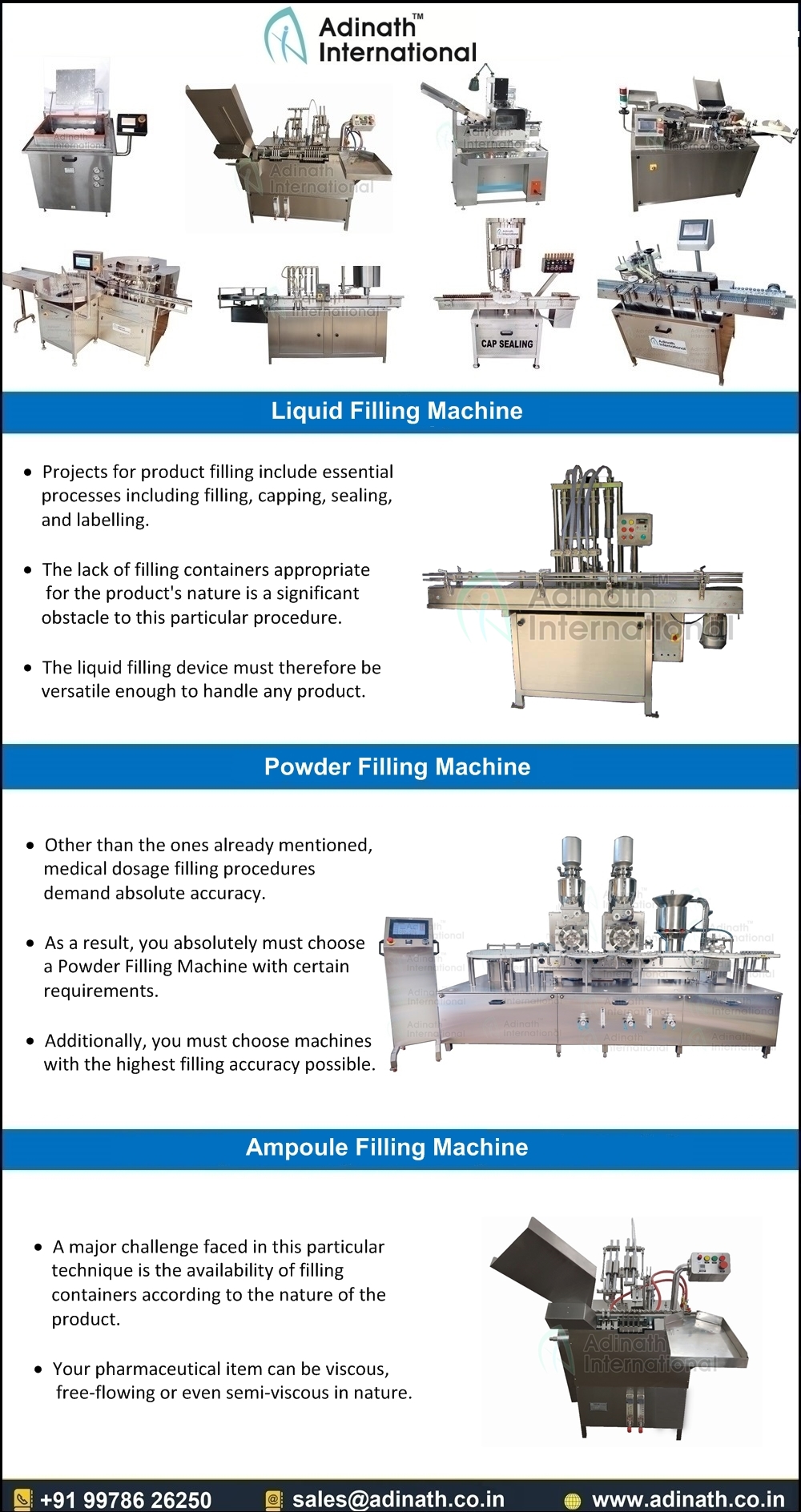

Understanding fruit juice filling machine Types and Variations

Understanding Fruit Juice Filling Machine Types and Variations

Fruit juice filling machines vary based on automation level, capacity, and integration with other processes like pasteurization. Below, we outline 5 key types, drawing from industry solutions like those offered by ProFruit, which cater to B2B manufacturers in the USA and Europe seeking efficient packaging for liquids such as juice, puree, and related products.

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Tabletop Semi-Automatic Fillers | Compact, table-mounted design; manual operation with some automation; suitable for small-scale operations; handles Bag in Box and Stand up Pouch packages (0.75L-5L). | Ideal for small to medium juice producers; fills hot and cold liquids like juice, milk, and wine. | Pros: Low cost, ease of use, portability. Cons: Lower speed (e.g., <2000L/h), requires manual intervention, limited for high-volume production. |

| Semi-Automatic Fillers | User-friendly interfaces; semi-automated filling process; adjustable for different pouch sizes; often includes modifications for height adjustment. | Suited for medium-scale juice and beverage manufacturers; handles diverse liquids including oil, alcohol, and chemicals in flexible packaging. | Pros: Balances automation and control, efficient for varied products, user-friendly design. Cons: Still involves some manual steps, moderate capacity, not ideal for fully automated lines. |

| Automatic Single-Head Fillers | Fully automated single filling head; high precision; capacity up to ~2000L/h; supports Bag in Box and Stand up Pouch for webbed or separate bags. | Best for mid-to-large juice bottling operations; fills liquids like juice and puree seamlessly. | Pros: High efficiency, minimal labor, consistent quality. Cons: Higher upfront cost, requires maintenance, less flexible for multi-product lines. |

| Automatic Multi-Head Fillers | Dual or more filling heads; designed for high-capacity operations; smooth handling of different products; fully automatic. | Targeted at large-scale juice and beverage producers; ideal for high-volume filling of juice, wine, and milk into flexible packaging. | Pros: Scalable capacity, handles complex products efficiently. Cons: Complex setup, higher energy use, potential downtime for repairs. |

| Integrated Pasteurizer-Filler Systems | Combines thermal pasteurization (diesel/gas-powered) with filling; compact design; capacities vary (e.g., 500L or 1000L systems); integrated with semi-automatic fillers like MINIFLOW. | Optimized for juice manufacturers needing pasteurization; processes hot and cold liquids for small to medium production. | Pros: All-in-one solution for hygiene and efficiency, reduces space needs. Cons: Higher energy consumption, specialized for thermal processes, may not suit non-pasteurized products. |

Tabletop Semi-Automatic Fillers

These machines, such as the MINIFLOW, feature a compact table-mounted design for easy integration into limited spaces. They support semi-automated filling of Bag in Box and Stand up Pouch packages ranging from 0.75L to 5L, with manual placement of pouches and automated dispensing. Key features include adjustable settings for different liquid viscosities and user-friendly controls. In B2B juice production, they are applied for small-scale operations in the USA and Europe, where flexibility for artisanal juices or small batches is essential. They handle products like fruit juice, puree, and wine, ensuring minimal waste through precise filling. Pros include affordability and simplicity, making them suitable for startups; cons are lower throughput and the need for operator involvement, which may not scale for high-volume lines.

Semi-Automatic Fillers

Exemplified by models like SEMIFLOW, these fillers offer a semi-automated process with intuitive interfaces and options for height adjustments to accommodate various pouch sizes. They are designed for disturbance-free operation, filling hot and cold liquids into flexible packaging. Features often include ergonomic designs for clean filling and compatibility with diverse liquids such as juice, oil, and broth. Applications focus on medium-scale juice manufacturers in Europe and the USA, where efficiency is balanced with customization. Pros encompass user-friendliness and versatility for multi-product facilities; cons include partial reliance on manual labor and moderate speeds, potentially limiting them for fully automated production environments.

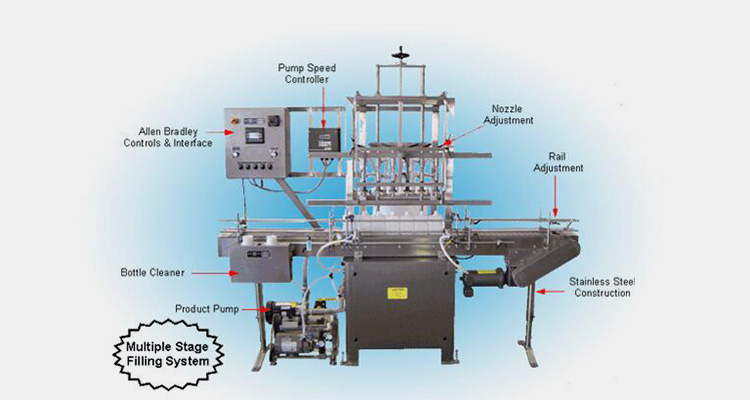

Automatic Single-Head Fillers

Automatic fillers like MAXIFLOW utilize a single filling head for fully automated operation, achieving capacities up to approximately 2000L/h. They feature precision controls for webbed or separate Bag in Box bags and Stand up Pouches, with capabilities for hot and cold liquid filling. This type is ideal for mid-sized juice bottling operations in the USA and Europe, ensuring consistent quality for products like fruit juice and puree. Pros include high efficiency and reduced labor costs; cons are the initial investment and need for regular maintenance, which may not suit highly variable production needs.

Illustrative Image (Source: Google Search)

Automatic Multi-Head Fillers

With dual or multiple heads, such as the DOUBLE FLOW, these machines enable high-capacity, smooth filling of various products into Bag in Box and Stand up Pouch packaging. Features include automated processes for diverse liquids, high throughput, and robust designs for industrial settings. They are applied in large-scale juice and beverage manufacturing across the USA and Europe, where volume is key for products like wine and milk. Pros include scalability and efficiency for complex operations; cons involve higher complexity, energy demands, and potential repair challenges in continuous-use scenarios.

Integrated Pasteurizer-Filler Systems

These systems, like HEAT 500 or HEAT 1000 combined with MINIFLOW, integrate diesel or gas-powered pasteurization with semi-automatic filling for a streamlined process. They offer compact solutions for thermal heating and precise filling, with capacities tailored to small to medium production. Suitable for juice producers requiring hygiene assurance, they handle hot and cold liquids in flexible packaging. In B2B contexts in the USA and Europe, they are used for efficient, space-saving setups for fruit juice and similar products. Pros include integrated functionality and energy efficiency for pasteurization needs; cons are higher operational costs and specificity to thermal processes, limiting use for non-pasteurized items.

Key Industrial Applications of fruit juice filling machine

Key Industrial Applications of Fruit Juice Filling Machine

Fruit juice filling machines, such as those designed for Bag in Box and Stand up Pouch packaging, are versatile for B2B operations in the USA and European beverage sectors. Below is a Markdown table outlining key industrial applications, informed by advanced filling technologies that handle liquids like juice and puree with capacities up to 2,000 liters per hour. Each application includes detailed benefits, emphasizing efficiency, scalability, and product integrity.

| Industry/Application | Detailed Benefits |

|---|---|

| Fruit Juice and Puree Production |

|

| Beverage Industry (Wine and Alcohol) |

|

| Dairy and Milk Products |

|

| Food and Broth Processing |

|

| Oil and Chemical Liquids |

|

3 Common User Pain Points for ‘fruit juice filling machine’ & Their Solutions

3 Common User Pain Points for Fruit Juice Filling Machines & Their Solutions

Pain Point 1: Inefficient Handling of Varying Package Sizes and Types

Scenario: B2B manufacturers producing fruit juices in diverse packaging formats, such as Bag in Box (BIB) and Stand Up Pouches, often struggle with fillers that lack adaptability, leading to inconsistent fills, spills, or downtime when switching between sizes like 0.75L to 5L.

Problem: Traditional machines may not support seamless adjustments, resulting in operational inefficiencies and product waste.

Solution: Opt for versatile fillers like the ProFruit MINIFLOW or SEMIFLOW, which feature adjustable table heights and compatibility with multiple package types, ensuring clean and precise filling across sizes for improved productivity.

Illustrative Image (Source: Google Search)

Pain Point 2: Challenges in Managing Temperature Variations During Filling

Scenario: Juice producers dealing with both hot (pasteurized) and cold liquids face difficulties in maintaining product integrity, as standard fillers may not handle thermal changes effectively, causing contamination risks or equipment strain.

Problem: Inadequate temperature control can lead to inconsistent quality, safety issues, or reduced machine lifespan in high-volume operations.

Solution: Integrate systems like the ProFruit HEAT 500 or HEAT 1000 pasteurizers combined with MINIFLOW fillers, designed for efficient thermal processing and filling of hot and cold liquids, ensuring disturbance-free operation and compliance with hygiene standards.

Pain Point 3: Limited Scalability for Production Capacity

Scenario: Small to medium-scale juice manufacturers expanding output encounter bottlenecks when their semi-automatic fillers cannot match increasing demand, forcing manual interventions or equipment upgrades that disrupt workflows.

Problem: Capacity constraints, such as low throughput (e.g., below 2000L/h), hinder growth and increase labor costs in competitive markets like the USA and Europe.

Solution: Upgrade to automatic options like the ProFruit MAXIFLOW or DOUBLE FLOW, which offer high-capacity filling (up to 2000L/h) for BIB and pouches, enabling smooth scaling without compromising efficiency or user-friendliness.

Strategic Material Selection Guide for fruit juice filling machine

Strategic Material Selection Guide for Fruit Juice Filling Machines

Key Considerations for Material Selection

When selecting materials for fruit juice filling machines, focus on compatibility with acidic, perishable liquids like fruit juices to ensure product safety, shelf life, and operational efficiency. Materials must resist corrosion, maintain hygiene, and comply with regulations in the USA (e.g., FDA standards) and Europe (e.g., EU food contact materials directives). Key factors include:

- Chemical Compatibility: Materials must withstand fruit juice’s acidity (pH typically 3-4) to prevent degradation or contamination.

- Barrier Properties: Essential for preventing oxygen ingress, which can oxidize juices and reduce quality.

- Durability and Flexibility: Suitable for high-volume filling into Bag in Box (BIB) and Stand up Pouch (SUP) formats, as used in machines like ProFruit’s MINIFLOW, MAXIFLOW, and AUTOFLOW.

- Cost-Effectiveness: Balance initial costs with long-term efficiency for small to medium-scale operations.

- Sustainability: Increasing demand for recyclable or eco-friendly options in B2B markets.

Analysis of Common Materials Used

Fruit juice filling machines, such as those from ProFruit, often incorporate flexible packaging materials designed for liquids like juices, purees, and wines. The primary materials for packaging are layered films and laminates, while machine components (e.g., filling heads, nozzles) typically use stainless steel or food-grade plastics for contact parts.

Illustrative Image (Source: Google Search)

- Polyethylene (PE): Commonly used as an inner layer in BIB and SUP bags for its flexibility and sealing properties. It provides good moisture resistance but limited oxygen barrier, making it suitable for short-shelf-life juices. Cost-effective for high-volume production.

- Polyethylene Terephthalate (PET): Offers superior strength and clarity, often laminated with other materials for improved barrier. Ideal for premium juices requiring extended shelf life; widely compliant with FDA and EU standards.

- Aluminum Foil Laminates: Integrated into multi-layer films for exceptional oxygen and light barriers, preventing oxidation in fruit juices. Used in specialized BIB packages; higher cost but essential for sensitive products like citrus juices.

- Polyamide (PA) or Nylon: Provides mechanical strength and puncture resistance, often combined with PE for durable SUP pouches. Suitable for larger sizes (e.g., 0.75L to 5L) as seen in ProFruit’s fillers.

- Stainless Steel (for Machine Components): 304 or 316 grade for filling heads and tanks in machines like the HEAT 500/1000 pasteurizers. Corrosion-resistant against acidic juices, ensuring hygiene and longevity.

These materials align with ProFruit’s equipment, which handles a wide range of liquids including juices, with fillers designed for seamless integration into BIB and SUP packaging.

Comparison Table of Packaging Materials

| Material | Barrier Properties (Oxygen/Water Vapor) | Suitability for Fruit Juice | Cost (Relative Scale) | Durability | Regulatory Compliance | Common Applications in Filling Machines |

|---|---|---|---|---|---|---|

| PE | Moderate (Good for water vapor, poor for oxygen) | High for short-term storage | Low | Good for flexibility | FDA/EU approved | Inner layers in BIB bags (e.g., MINIFLOW) |

| PET | High (Excellent for oxygen and moisture) | High for extended shelf life | Medium | Excellent strength | FDA/EU approved | Laminated films in SUP pouches (e.g., AUTOFLOW) |

| Aluminum Foil Laminates | Very High (Superior barrier) | High for sensitive juices | High | Very durable | FDA/EU approved | Multi-layer BIB for premium products (e.g., MAXIFLOW) |

| PA/Nylon | Moderate to High (Strong mechanical) | High for puncture resistance | Medium to High | Very durable | FDA/EU approved | Outer layers in SUP (e.g., DOUBLE FLOW) |

In-depth Look: Manufacturing Processes and Quality Assurance for fruit juice filling machine

In-depth Look: Manufacturing Processes and Quality Assurance for Fruit Juice Filling Machines

Fruit juice filling machines, such as those for bag-in-box and stand-up pouch formats, undergo rigorous manufacturing processes to ensure reliability, efficiency, and compliance with global standards. Drawing from industry expertise, like ProFruit’s over 20 years of experience in producing fillers for liquids including juice, these processes emphasize precision engineering for seamless operation across various production scales.

Manufacturing Processes

The manufacturing of fruit juice filling machines follows a structured sequence to integrate components into high-performance systems capable of handling hot and cold liquids with minimal disturbance. This is informed by specialized designs for flexible packaging and user-friendly interfaces.

Preparation

- Material Selection: Sourcing high-grade stainless steel, durable polymers, and electronic components to withstand corrosive liquids like juice and chemicals, ensuring longevity and hygiene.

- Design Validation: Utilizing CAD software to simulate machine operations, incorporating features like adjustable filling tables for package sizes (e.g., 0.75L to 5L) based on user feedback and technological advancements.

- Component Procurement: Acquiring specialized parts, such as filling heads and pasteurization units, from certified suppliers to align with semi-automatic and automatic filler requirements.

Forming

- Fabrication of Key Parts: Precision machining of frames, nozzles, and conveyor systems to enable smooth liquid flow and minimize contamination risks in juice processing.

- Integration of Automation: Assembling sensors and controls for automated functions, such as in models like MAXIFLOW, which supports capacities up to 2,000L/h for efficient bag-in-box filling.

- Thermal and Mechanical Shaping: Forming components for heat-resistant features, including pasteurizers like HEAT 500 and HEAT 1000, designed for diesel/gas-powered thermal processing.

Assembly

- Module Integration: Combining sub-assemblies, such as filling heads and pouch-up systems, into cohesive units like the 2-head DOUBLE FLOW or AUTOFLOW fillers for versatile liquid handling.

- Electrical and Hydraulic Setup: Installing wiring, pumps, and valves to facilitate disturbance-free operation, tailored for products ranging from juice to wine and oils.

- Customization for Packaging: Adapting machines for bag-in-box and stand-up pouch formats, with modifications for height-adjustable tables to ensure clean filling across package sizes.

Quality Control (QC)

- In-Process Inspections: Testing each stage for alignment, leak-proofing, and operational efficiency, using metrics like flow rate accuracy and user interface responsiveness.

- Functional Testing: Running full-cycle simulations with sample liquids to verify performance, such as in SEMIFLOW and MINIFLOW models for semi-automatic and automatic filling.

- Final Validation: Conducting endurance tests to confirm durability, ensuring machines meet specifications for small to medium-scale juice production.

Quality Assurance

Quality assurance for fruit juice filling machines adheres to international standards to guarantee product reliability, safety, and market compliance in USA and Europe. ProFruit’s emphasis on innovative, user-friendly designs aligns with these frameworks.

Illustrative Image (Source: Google Search)

- ISO 9001 Compliance: Manufacturers implement ISO 9001 for quality management systems, ensuring consistent production processes, risk mitigation, and continuous improvement. This standard verifies traceability, from material sourcing to final assembly, reducing defects in juice fillers.

- Additional Certifications: Integration of ISO 22000 for food safety (critical for juice handling) and CE marking for European conformity, focusing on hygiene, electrical safety, and environmental impact.

- Performance Metrics: Regular audits measure key indicators, such as operational uptime and maintenance ease, supported by over a decade of field data from diverse filling technologies.

| Aspect | ISO Standard | Key Benefit for Juice Fillers |

|---|---|---|

| Quality Management | ISO 9001 | Ensures repeatable, high-quality assembly for efficient juice production. |

| Food Safety | ISO 22000 | Minimizes contamination risks in liquid handling, aligning with FDA and EU regulations. |

| Conformity | CE Marking | Facilitates market entry in Europe with verified safety for automated systems. |

These processes and standards result in machines that deliver smooth, efficient filling for fruit juices, enhancing productivity for B2B clients in the beverage industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fruit juice filling machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Fruit Juice Filling Machines

This checklist provides a structured approach to sourcing a fruit juice filling machine, tailored for B2B buyers in the USA and Europe. It draws on industry standards for food processing equipment, emphasizing compliance with FDA regulations in the USA and EU hygiene and safety directives (e.g., 1935/2004/EC, Machinery Directive 2006/42/EC). Use this as a reference to ensure efficient, compliant procurement.

Step 1: Define Requirements

Assess your operational needs to match the machine with your production scale and product specifications.

– [ ] Determine production capacity (e.g., liters per hour: 500–2,000 L/h for semi-automatic to automatic models).

– [ ] Specify liquid types (e.g., fruit juices, purees; ensure compatibility with pasteurization if needed).

– [ ] Choose packaging format (e.g., Bag-in-Box, Stand-up Pouches in sizes 0.75–5 L).

– [ ] Select automation level (e.g., semi-automatic like MINIFLOW for small-scale; automatic like MAXIFLOW or AUTOFLOW for high-capacity).

– [ ] Evaluate space and integration (e.g., tabletop models for compact setups; multi-head for efficiency).

– [ ] Review additional features (e.g., pasteurization integration with HEAT 500/1000 for thermal processing).

Step 2: Research Suppliers

Identify reputable manufacturers and distributors to compare options.

– [ ] Search for suppliers specializing in food-grade filling machinery (e.g., those with 20+ years in liquid filling, including juices and wines).

– [ ] Focus on B2B platforms, trade shows (e.g., ProFruit, or equivalents), and directories (e.g., ThomasNet in USA, Europages in Europe).

– [ ] Prioritize vendors with expertise in flexible packaging and user-friendly designs (e.g., adjustable tables for pouch sizes).

– [ ] Verify supplier locations and shipping logistics to USA or Europe markets.

– [ ] Check for case studies or references from similar fruit juice producers.

Step 3: Evaluate Options and Compliance

Compare machines against your requirements and regulatory standards.

– [ ] Request detailed specifications (e.g., capacity, compatibility with liquids like juice, oil, or chemicals; disturbance-free operation).

– [ ] Confirm certifications (e.g., CE marking for EU; NSF/ANSI 29 or FDA compliance for USA food contact).

– [ ] Assess hygiene and safety features (e.g., smooth operation for clean filling; compliance with EU 1935/2004/EC for materials).

– [ ] Review energy efficiency and environmental impact (e.g., compact designs for reduced footprint).

– [ ] Compare warranties, maintenance needs, and scalability for future production growth.

Step 4: Budget and Cost Analysis

Calculate total costs to ensure financial viability.

– [ ] Obtain quotes from multiple suppliers, including base price, installation, and customization.

– [ ] Factor in ongoing expenses (e.g., power for pasteurizers, consumables like bags).

– [ ] Evaluate ROI based on efficiency gains (e.g., automated filling reducing labor costs).

– [ ] Account for import duties, taxes, and shipping for USA/Europe delivery.

– [ ] Consider financing options or leasing for capital-intensive purchases.

Step 5: Request Demonstrations and Trials

Test machines before purchase to validate performance.

– [ ] Schedule on-site demos or virtual tours to assess ease of use and integration.

– [ ] Test with your specific juice types (e.g., hot/cold filling capabilities in models like SEMIFLOW or AUTOFLOW).

– [ ] Evaluate user-friendliness (e.g., simple operation without advanced training).

– [ ] Gather feedback from your team on ergonomics and maintenance.

Step 6: Negotiate and Finalize Purchase

Secure the best terms and prepare for delivery.

– [ ] Negotiate contracts including delivery timelines, payment terms, and penalties.

– [ ] Ensure inclusion of training and support (e.g., on-site setup for Bag-in-Box systems).

– [ ] Verify after-sales service (e.g., parts availability, technical support).

– [ ] Document all agreements, including compliance with local regulations.

Illustrative Image (Source: Google Search)

Step 7: Post-Purchase Implementation

Plan for installation and ongoing use.

– [ ] Coordinate installation with supplier, ensuring site readiness (e.g., power, space for multi-head fillers).

– [ ] Conduct operator training to maximize efficiency.

– [ ] Monitor initial production runs and schedule maintenance.

– [ ] Track performance metrics (e.g., output vs. capacity) and adjust as needed.

Use this checklist iteratively, marking off completed items. For USA buyers, consult FDA guidelines; for Europe, reference EU standards. If sourcing from international suppliers like those with ProFruit expertise, prioritize those with global shipping and multilingual support.

Comprehensive Cost and Pricing Analysis for fruit juice filling machine Sourcing

Comprehensive Cost and Pricing Analysis for Fruit Juice Filling Machine Sourcing

Sourcing a fruit juice filling machine involves evaluating multiple cost factors to ensure alignment with production needs, budget, and regulatory requirements in the USA and Europe. Based on industry data from manufacturers like ProFruit, which offers Bag In Box and Stand Up Pouch fillers ranging from semi-automatic tabletop models to high-capacity automatic systems (e.g., capacities up to 2000 liters per hour), pricing typically varies based on automation level, capacity, and customization. Below, we break down key cost components and provide actionable tips for cost optimization.

Key Pricing Factors

Fruit juice filling machine prices are influenced by specifications such as automation (semi-automatic vs. fully automatic), filling capacity, material compatibility (e.g., for juices, purees, or pastes), and additional features like pasteurization integration. Entry-level semi-automatic models (e.g., ProFruit’s MINIFLOW) start at approximately $5,000–$15,000 USD, while advanced automatic systems (e.g., AUTOFLOW or DOUBLE FLOW) can range from $20,000–$50,000 USD or higher, depending on custom modifications. In Europe, expect similar ranges in EUR, with potential surcharges for EU-compliant certifications (e.g., CE marking). Always request quotes from multiple suppliers for precise figures, as bulk orders or long-term contracts may offer discounts.

Cost Breakdown

The total cost of ownership for a fruit juice filling machine extends beyond the initial purchase price, incorporating materials, labor, and logistics. The table below outlines estimated breakdowns for a mid-range semi-automatic or automatic Bag In Box filler (e.g., ProFruit models), based on typical USA/Europe sourcing scenarios. These are approximate and can fluctuate by 20–30% due to market conditions, supplier negotiations, and location-specific taxes.

| Cost Component | Description | Estimated Percentage of Total Cost | Example Breakdown (for a $30,000 USD Machine) |

|---|---|---|---|

| Materials | Machine hardware, including frames, pumps, seals, and packaging components (e.g., Bag In Box pouches). Costs include raw materials like stainless steel for durability and FDA/EU-compliant parts. | 40–50% | $12,000–$15,000 (includes base unit and consumables like seals or filters). |

| Labor | Installation, training, and ongoing operation. This covers skilled technicians for setup (often 1–3 days), operator training, and maintenance. In the USA/Europe, labor rates average $50–$100/hour. | 20–30% | $6,000–$9,000 (e.g., $2,000 for installation, $4,000 for initial training, plus annual maintenance at 5–10% of machine value). |

| Logistics | Shipping, customs, import duties, and insurance. For transatlantic sourcing (e.g., from Europe to USA), factor in freight costs, tariffs (5–15% in the USA for machinery), and potential delays. EU intra-trade is often duty-free. | 15–25% | $4,500–$7,500 (e.g., $3,000 shipping, $1,500 duties, $1,000 insurance). |

| Other (e.g., Software, Warranties) | Integration software, extended warranties, and after-sales support. | 5–10% | $1,500–$3,000 (e.g., $1,000 for automation software, $500 for 1-year warranty). |

Total estimated cost of ownership over 5 years (including depreciation and operational expenses) could reach 150–200% of the initial purchase price, driven by energy consumption (e.g., for pasteurizers like ProFruit’s HEAT 1000) and parts replacement.

Tips to Save Costs

To optimize sourcing and reduce expenses without compromising quality or compliance, consider these evidence-based strategies tailored for USA and Europe markets:

- Opt for Semi-Automatic Models: Choose semi-automatic fillers like ProFruit’s MINIFLOW or SEMIFLOW for lower initial costs ($5,000–$15,000) if production volumes are moderate (under 1,000 liters/hour). These reduce labor needs compared to fully automatic systems, saving 20–30% on total ownership.

- Negotiate Bulk or Custom Packages: Request quotes for bundled purchases, including pasteurizers (e.g., HEAT 500 or 1000 with fillers), which can lower per-unit costs by 10–15%. In Europe, leverage EU procurement frameworks for volume discounts.

- Prioritize Local Sourcing: Source from USA-based or European suppliers (e.g., ProFruit in Europe) to minimize logistics expenses, avoiding 10–20% in shipping and duties. For USA buyers, check for free trade agreements to reduce tariffs.

- Focus on Energy-Efficient Features: Select models with integrated pasteurization and adjustable heights (e.g., ProFruit’s table modifications for 0.75L–5L pouches) to cut energy costs by 15–25% over time, especially in high-capacity setups.

- Plan for Maintenance and Upgrades: Factor in preventive maintenance to extend lifespan, potentially saving 10% annually on repairs. Avoid over-customization; stick to standard sizes to keep material costs down.

- Leverage Financing and Incentives: Explore leasing options or government incentives (e.g., USDA grants in the USA for food processing equipment) to defer upfront costs by 20–30%. In Europe, utilize EU funding for sustainable manufacturing.

By conducting a thorough cost analysis and applying these tips, B2B buyers in the USA and Europe can source fruit juice filling machines that balance efficiency with fiscal responsibility. Consult suppliers like ProFruit for detailed quotes and ensure all machines meet local safety standards (e.g., FDA in the USA, EHEDG in Europe).

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing fruit juice filling machine With Other Solutions

Alternatives Analysis: Comparing Fruit Juice Filling Machine With Other Solutions

This section compares Bag In Box (BIB) filling machines, as exemplified by ProFruit’s solutions for fruit juice, with two alternative filling technologies: traditional bottle filling machines and carton-based aseptic filling systems (e.g., Tetra Pak-style). The comparison focuses on key factors relevant to B2B operations in the USA and Europe, including efficiency, cost, packaging flexibility, and suitability for fruit juice production. Data is informed by industry standards and ProFruit’s product specifications.

Comparison Table

| Factor | Bag In Box (BIB) Filling Machines (e.g., ProFruit MINIFLOW/MAXIFLOW) | Traditional Bottle Filling Machines | Carton-Based Aseptic Filling Systems (e.g., Tetra Pak) |

|---|---|---|---|

| Packaging Type | Flexible pouches/bags (BIB, Stand Up Pouch) in sizes 0.75L–5L | Glass/plastic bottles (various sizes) | Cartons (aseptic bricks, Tetra Brik) in 0.25L–2L |

| Capacity (L/h) | 200–2,000+ (semi-automatic to automatic models) | 1,000–10,000+ (high-speed lines) | 5,000–20,000+ (integrated lines) |

| Suitability for Fruit Juice | Excellent for fresh, pure, or pasteurized juices; handles hot/cold liquids | Good for pasteurized juices; requires stable formulations | Ideal for long-shelf-life juices; aseptic for extended preservation |

| Efficiency & Automation | Semi-automatic (e.g., MINIFLOW) to fully automatic (e.g., MAXIFLOW); easy operation, minimal downtime | High-speed automated lines; requires conveyor integration | Fully automated; high throughput but complex setup |

| Cost (Initial Investment) | Low to medium ($10K–$50K for semi-automatic; higher for automatic) | Medium to high ($50K–$200K+ for lines) | High ($100K–$500K+ for aseptic systems) |

| Operational Costs | Low (energy-efficient, minimal waste; suitable for small/medium operations) | Medium (bottle recycling/storage needed) | High (sterilization/maintenance intensive) |

| Flexibility & Versatility | High (fills juices, wines, milks, oils; adaptable to multiple products) | Medium (bottle-specific; less versatile for non-juices) | Low (carton-specific; optimized for aseptic products) |

| Shelf Life & Preservation | Good with pasteurization integration (e.g., HEAT series); disturbance-free filling | Variable (depends on sealing/pasteurization) | Excellent (aseptic extends shelf life up to 12 months) |

| Environmental Impact | Positive (lightweight, recyclable bags; reduces plastic waste) | Variable (recyclable bottles but higher transport emissions) | Positive (lightweight cartons; efficient material use) |

| Target Scale | Small to medium enterprises (e.g., 200–2,000 L/h) | Medium to large (high-volume bottling) | Large-scale production (5,000+ L/h) |

Analysis

-

Strengths of BIB Filling Machines: ProFruit’s BIB solutions excel in flexibility and cost-effectiveness for mid-tier fruit juice producers in the USA and Europe. They support a wide range of liquid types, including juices, with seamless integration for pasteurization (e.g., HEAT 500/1000 models). Lower initial and operational costs make them ideal for businesses seeking efficient, user-friendly systems without the complexity of high-speed lines. Environmentally, BIB reduces waste through lightweight packaging, aligning with EU sustainability regulations.

-

Comparison to Bottle Filling Machines: BIB offers superior versatility and lower costs compared to traditional bottles, which are better suited for larger operations requiring high throughput. Bottles incur higher transport and storage expenses due to weight and fragility, whereas BIB’s flexible bags simplify logistics. For fruit juice, BIB’s disturbance-free filling preserves quality, outperforming bottles in non-aseptic scenarios.

-

Comparison to Carton-Based Aseptic Systems: While cartons provide superior shelf life and scalability for large-scale juice processing, they demand significantly higher investments and are less adaptable to diverse products. BIB systems from ProFruit are more accessible for SMEs, with comparable environmental benefits but greater ease of operation. For producers prioritizing cost over ultra-long preservation, BIB is preferable.

Illustrative Image (Source: Google Search)

In summary, BIB filling machines provide a balanced alternative for fruit juice operations, particularly in cost-sensitive or versatile environments, versus the scale-focused efficiency of bottles or the preservation-driven complexity of cartons.

Essential Technical Properties and Trade Terminology for fruit juice filling machine

Essential Technical Properties

Fruit juice filling machines, particularly Bag-In-Box (BIB) and Stand-Up Pouch fillers, are designed for efficient liquid packaging in B2B production environments. Key technical properties include:

- Filling Capacity: Ranges from semi-automatic tabletop models (e.g., MINIFLOW) handling small batches to automatic systems like MAXIFLOW at ~2000 liters/hour or DOUBLE FLOW with dual heads for high-volume operations.

- Product Suitability: Compatible with various liquids including fruit juice, puree, wine, milk, oil, alcohol, broth, and chemicals; supports both hot and cold filling to maintain product integrity.

- Packaging Types and Sizes: Handles BIB and Stand-Up Pouch formats; adjustable for sizes from 0.75L to 5L with height-modifiable tables for clean, efficient filling.

- Automation Level: Options from semi-automatic (manual loading) to fully automatic (e.g., AUTOFLOW for seamless hot/cold liquid filling).

- Operational Features: Engineered for disturbance-free operation; includes pasteurization integration (e.g., HEAT 500/1000 models) for thermal processing; user-friendly interfaces for ease of use and efficiency.

- Power and Compactness: Diesel/gas-powered pasteurizers available; compact designs suitable for small to medium-scale facilities.

These properties ensure scalability, reliability, and compliance with industry standards for juice production.

Trade Terminology

In B2B transactions for fruit juice filling machines, understanding key trade terms is essential for negotiations, logistics, and customization. Common terms include:

Illustrative Image (Source: Google Search)

- MOQ (Minimum Order Quantity): The smallest quantity of machines or parts a supplier requires for an order, often set to ensure production efficiency (e.g., 1-5 units for fillers like MINIFLOW).

- OEM (Original Equipment Manufacturer): Refers to custom manufacturing where a supplier produces machines or components to a buyer’s specifications, such as modifying fillers for specific juice types or capacities.

- FOB (Free on Board): A shipping term indicating the seller covers costs and risks until goods are loaded onto the vessel at the specified port, common for exporting machines from Europe to the USA.

- CIF (Cost, Insurance, and Freight): Includes costs for shipping, insurance, and freight to the destination port, useful for international procurement to clarify total pricing.

- Incoterms: Standardized rules (e.g., FOB, CIF) defining responsibilities for sellers and buyers in global trade, ensuring clear agreements on delivery for machinery imports.

- Lead Time: The period from order confirmation to delivery, typically 4-12 weeks for customized BIB fillers, affecting production planning.

- Warranty and After-Sales Support: Often 1-2 years coverage on equipment, with terms specifying parts replacement or on-site service for maintenance in juice processing lines.

Navigating Market Dynamics and Sourcing Trends in the fruit juice filling machine Sector

Navigating Market Dynamics and Sourcing Trends in the Fruit Juice Filling Machine Sector

Historical Evolution of Fruit Juice Filling Machines

The fruit juice filling machine sector has evolved significantly since the early 20th century, driven by advancements in food processing technology and rising demand for packaged beverages. Initially, manual filling methods dominated, but the post-World War II era saw the introduction of semi-automatic systems to improve efficiency and hygiene. By the 1980s, fully automatic machines emerged, incorporating pasteurization and aseptic filling to extend shelf life. In recent decades, innovations like Bag in Box (BIB) and Stand Up Pouch fillers have revolutionized the industry, enabling versatile packaging for liquids such as juice, puree, and wine. Companies like ProFruit, with over 20 years of manufacturing expertise, have played a key role in this progression, offering solutions that blend thermal processing with compact filling for small to large-scale operations in regions like the USA and Europe.

Current Market Dynamics and Trends

The global fruit juice filling machine market is projected to grow at a compound annual growth rate (CAGR) of approximately 5-7% through 2030, fueled by increasing consumer demand for convenient, healthy beverages and the expansion of the beverage industry. Key dynamics include:

- Shift to Flexible Packaging: BIB and pouch systems are gaining traction over traditional glass or rigid plastic due to lower shipping costs, reduced waste, and extended product freshness. In the USA and Europe, where sustainability regulations are stringent, these formats align with eco-friendly initiatives.

- Automation and Efficiency: High-capacity automatic fillers, such as those handling 2,000 liters per hour, are in demand for medium to large producers. Semi-automatic options cater to smaller operations, with innovations in user-friendly interfaces reducing labor costs and downtime.

- Regional Variations: In Europe, stricter EU food safety standards (e.g., HACCP compliance) drive adoption of pasteurizers integrated with fillers. In the USA, focus on high-volume production for supermarkets and export markets emphasizes scalability and customization for diverse liquids like juice and milk.

- Economic Factors: Fluctuations in raw material prices and supply chain disruptions post-2020 have pushed companies toward resilient sourcing, with trends favoring local suppliers to minimize risks.

| Trend | Key Drivers | Impact on Sector |

|---|---|---|

| Sustainable Packaging | Environmental regulations (e.g., EU’s Circular Economy Action Plan) | Increased adoption of recyclable BIB and pouches, reducing carbon footprint by 20-30%. |

| Digital Integration | IoT and smart sensors | Enhances predictive maintenance, lowering operational costs by 15%. |

| Customization | Varied product portfolios (e.g., juice with additives) | Boosts market share for versatile fillers like ProFruit’s AUTOFLOW. |

Sourcing Trends and Sustainability Considerations

Sourcing in the fruit juice filling machine sector is increasingly focused on sustainability, with suppliers prioritizing eco-friendly materials and ethical supply chains. Key trends include:

- Material Innovation: Shift from single-use plastics to biodegradable films for BIB and pouches, complying with regulations like the USA’s Food Packaging Modernization Act and Europe’s REACH directives. This reduces waste and appeals to environmentally conscious buyers.

- Supply Chain Resilience: Post-pandemic, manufacturers are sourcing components locally or regionally to mitigate global disruptions. For instance, European producers emphasize EU-sourced parts for fillers, while US firms integrate domestic suppliers for faster turnaround.

- Energy-Efficient Designs: Integration of diesel/gas pasteurizers with fillers, as seen in ProFruit’s HEAT series, optimizes energy use, cutting consumption by up to 25% compared to traditional systems.

- Circular Economy Practices: Emphasis on recyclable and reusable packaging, with fillers designed for multi-product use (e.g., juice to chemicals), promoting longevity and reducing disposal costs.

To navigate these trends, B2B buyers should prioritize suppliers with proven sustainability credentials, such as those offering customizable, eco-compliant solutions for capacities ranging from 0.75L to 5L pouches.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of fruit juice filling machine

Frequently Asked Questions for B2B Buyers of Fruit Juice Filling Machines

1. What types of fruit juice filling machines are available?

ProFruit offers a range of Bag In Box and Stand Up Pouch filling machines, including semi-automatic models like the MINIFLOW tabletop filler and fully automatic options such as the MAXIFLOW and AUTOFLOW. These are designed for efficient filling of liquids, with capacities up to 2,000 liters per hour for high-volume operations.

2. Can these machines handle pasteurization for fruit juice?

Yes, integrated systems like the Diesel/Gas Pasteurizer HEAT 500 and HEAT 1000 combine thermal heating with filling capabilities. These provide compact, efficient solutions for pasteurizing and filling fruit juice, puree, and other liquids in small to medium-scale production.

3. What packaging formats do these filling machines support?

The machines are versatile, supporting Bag In Box packages and Stand Up Pouch (Pouch-up) formats in sizes ranging from 0.75 liters to 5 liters. They can fill both webbed and separate bags, making them suitable for various flexible packaging needs in the fruit juice industry.

4. Are these machines suitable for other liquids besides fruit juice?

Absolutely. The filling machinery is engineered to handle a wide variety of liquids, including juice, puree, wine, milk, oil, alcohol, broth, and chemicals, ensuring adaptability for diverse B2B applications.

Illustrative Image (Source: Google Search)

5. What is the capacity range for these fruit juice filling machines?

Capacities vary by model: semi-automatic fillers like MINIFLOW are ideal for lower-volume needs, while automatic models such as MAXIFLOW and DOUBLE FLOW can process up to 2,000 liters per hour, supporting scalable production from small to high-capacity operations.

6. How user-friendly are these machines for B2B operations?

ProFruit’s machines prioritize ease of use with intuitive controls and features like adjustable filling tables for different pouch sizes. They are designed for efficient, disturbance-free operation, reducing training time and enhancing productivity in manufacturing environments.

7. What maintenance and support options are available?

With over 20 years of manufacturing experience, ProFruit provides robust support including hands-on use with various technologies. Maintenance involves standard procedures for cleaning and calibration, and the company offers specialized modifications and user experience optimizations to ensure long-term reliability.

8. How do these machines improve efficiency in fruit juice production?

These fillers enable smooth, automated filling of hot and cold liquids into flexible packaging, minimizing downtime and enhancing convenience. Models like the SEMIFLOW and AUTOFLOW are optimized for high-efficiency workflows, helping B2B buyers streamline production and reduce operational costs.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for fruit juice filling machine

Strategic Sourcing Conclusion and Outlook for Fruit Juice Filling Machines

Strategic sourcing of fruit juice filling machines is essential for manufacturers seeking efficiency, scalability, and cost-effectiveness in packaging operations. By prioritizing vendors like ProFruit, businesses in the USA and Europe can access advanced Bag In Box (BIB) and Stand Up Pouch (SUP) fillers that cater to diverse liquid products, including juices, wines, and purees.

Key Value Summary

The value lies in innovative, user-friendly solutions that enhance productivity:

– Versatility and Capacity: Machines like MAXIFLOW and AUTOFLOW handle 2,000 liters/hour, accommodating various package sizes (0.75L to 5L) for seamless hot and cold filling.

– Efficiency and Innovation: Semi-automatic (e.g., MINIFLOW) and automatic options reduce labor while integrating pasteurization for small to high-volume production.

– Customization and Reliability: Over 20 years of expertise ensure disturbance-free operations, with modifications for optimal packaging convenience.

Outlook

As demand for sustainable, flexible packaging grows, investing in these technologies will drive competitive advantage. Future trends point to IoT-enabled fillers for real-time monitoring. Manufacturers should evaluate vendors based on ROI, compliance with EU/USA standards, and after-sales support to future-proof operations.

In conclusion, strategic partnerships with specialized suppliers like ProFruit empower businesses to optimize sourcing, minimize waste, and scale profitably. (198 words)

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.