Fruit Juice Packing Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Fruit Juice Packing Machine

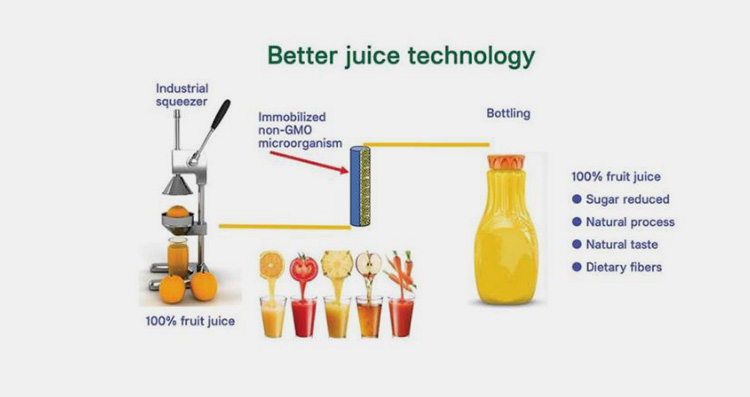

In the competitive beverage industry, efficient fruit juice packing machines are essential for manufacturers aiming to maintain product freshness, comply with stringent regulations, and scale operations across global markets. With rising consumer demand for sustainable and hygienic packaging, businesses in the USA and Europe face challenges like fluctuating raw material costs, evolving food safety standards (e.g., FDA and EU directives), and the need for automation to reduce labor expenses and waste.

This guide equips B2B decision-makers with actionable insights to select, implement, and optimize juice packing solutions. Drawing from industry leaders like Landpack, we’ll explore specialized machines such as spout pouch fillers, vertical form-fill-seal (VFFS) lines, and doypack packers tailored for liquid products.

Key Sections in This Guide

- Market Trends and Demand Drivers: Analysis of global growth in juice consumption, emphasizing eco-friendly materials and smart packaging technologies.

- Machine Types and Features: Detailed overview of options like rotary premade pouch packers and liquid filling lines, including specifications for juice-specific applications.

- Regulatory Compliance and Standards: Navigating certifications (e.g., HACCP, ISO) for USA and European markets.

- Selection Criteria and Best Practices: Factors such as throughput, customization, and integration with existing production lines.

- Case Studies and ROI Insights: Real-world examples from juice manufacturers, highlighting cost savings and efficiency gains.

By the end, you’ll have a clear roadmap to navigate the complexities of the fruit juice packing machine market, ensuring your business stays ahead in a rapidly evolving landscape. (248 words)

Top 10 Fruit Juice Packing Machine Manufacturers & Suppliers List

1. Top 10 Packing Machine Manufacturers in the world – Landpack

Domain: landpack.com

Registered: 2009 (16 years)

Introduction: Table of Contents · 1. Landpack-China · 2. Tetra Pak- Switzerland · 3. Krones-Germany · 4. KHS GmbH-Germany · 5. Sidel-France · 6. Syntegon-Germany · 7 ……

2. Top 10 Liquid Filling Machine Manufacturers – HonorPack

Domain: honorpack.com

Registered: 2009 (16 years)

Introduction: Accutek Packaging Equipment has become a top liquid filling company. This is a USA-based manufacturer that was established in 1989. They create machines for ……

Illustrative Image (Source: Google Search)

3. Top 20 Juice Filling Machine Manufacturers in 2025

Domain: finbolink.com

Registered: 2023 (2 years)

Introduction: Zhangjiagang Mic Machinery is widely recognized among juice filling machine manufacturers, providing efficient, hygienic, and customizable equipment for juice ……

4. Top Quality Juice Beverage Filling Machine for Efficient Production

Domain: lilanpackage.com

Registered: 2024 (1 years)

Introduction: Introducing the Juice Beverage Filling Machine from Shanghai Lilan Packaging Technology Co., Ltd., a leading manufacturer, supplier, and factory based in China….

5. Bottling & Filling Equipment Manufacturer | E-PAK Machinery

Domain: epakmachinery.com

Registered: 2001 (24 years)

Introduction: E-PAK Machinery manufactures quality liquid filling machines, including cappers and labelers, for the bottling industry. Buy equipment and parts online….

6. Fruit Processing & Juice Production Machinery | ProFruit

Domain: pro-fruit.com

Registered: 2019 (6 years)

Introduction: Processing machinery – from fruit washers and crushers to belt presses and bag-in-box fillers. Efficient juice and purée production from fresh produce….

Illustrative Image (Source: Google Search)

7. Fruit juice packaging machine – Micmachinery

Domain: micmachine.com

Registered: 2016 (9 years)

Introduction: Mic Machinery’s juice bottle filling machines offer tailored solutions for varied packaging requirements. Whether you prefer sleek individual bottles or larger ……

Understanding fruit juice packing machine Types and Variations

Understanding Fruit Juice Packing Machine Types and Variations

Based on industry standards and equipment commonly used for fruit juice packaging in B2B applications, we identify five key types of fruit juice packing machines. These variations cater to different production scales, package formats, and operational needs, ensuring efficient handling of liquid products like fruit juices. The following table summarizes the types, their features, applications, and pros/cons.

Illustrative Image (Source: Google Search)

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Vertical Form Fill Seal (VFFS) Machines | Forms pouches from roll stock, fills with juice, seals them vertically. Includes options for multi-lane operation, nitrogen flushing for freshness, and integration with weighers. | Ideal for high-volume production of pouches for retail and bulk juice packaging. | Pros: High speed (up to 100+ packs/min), flexible pouch sizes, cost-effective for large runs. Cons: Limited to flexible pouches, higher initial setup costs. |

| Premade Pouch Packing Machines (e.g., Doypack, Spout Pouch) | Uses pre-made pouches (stand-up, zipper, spout) loaded into the machine for filling and sealing. Supports spout insertion for easy pouring. | Suitable for premium juice brands requiring resealable or portable pouches for consumer markets. | Pros: Handles diverse pouch shapes, easy product changeovers, extends shelf life. Cons: Requires pre-made pouches, potentially higher material costs. |

| Sachet/Stick Pack Machines | Fills and seals small, single-serve sachets or sticks from roll stock, often with heat sealing. | Best for portion-controlled juice packs, such as travel or sampling sizes in foodservice and retail. | Pros: Compact design, low material waste, suitable for low-volume or specialty production. Cons: Lower speed (up to 50 packs/min), limited to small formats. |

| Liquid Filling and Capping Lines | Automated lines for filling bottles or jars with juice, followed by capping/labeling. Includes rotary fillers for precision and aseptic options. | Used in bottling operations for juices in glass/plastic bottles, common in beverage manufacturing. | Pros: Versatile for various container types, high accuracy, scalable for medium to large plants. Cons: Higher energy use, requires bottle sterilization for extended shelf life. |

| Flow Wrap Machines | Wraps juice products (e.g., in bottles or pouches) in flexible film using horizontal flow. Includes feeding systems and sealing. | Applied for wrapping multi-packs of juice bottles or pouches for distribution and retail. | Pros: Efficient for bundling, reduces packaging waste, handles irregular shapes. Cons: Slower for liquids, best for secondary packaging. |

Vertical Form Fill Seal (VFFS) Machines

VFFS machines are a cornerstone in fruit juice packaging for their ability to produce sealed pouches on-demand. They form pouches from flat roll stock, fill them with juice via nozzles, and seal them vertically in a continuous process. Key features include multi-head weighing for accurate portioning, gas flushing to preserve juice freshness, and compatibility with various films (e.g., laminated for barrier properties). These machines excel in high-volume environments, achieving speeds of 60-120 packs per minute, and can be integrated into automated lines for end-to-end production. In B2B contexts, they are favored by juice manufacturers in the USA and Europe for cost-effective, flexible packaging that meets retail demands for pouches.

Premade Pouch Packing Machines (e.g., Doypack, Spout Pouch)

Premade pouch machines, such as Doypack or spout pouch fillers, utilize pre-formed pouches that are loaded into the machine for filling and sealing. For fruit juices, spout pouches allow for easy dispensing without spillage, while zipper versions enable resealability. Features often include vacuum or gas filling to maintain product quality, touch-screen controls for precision, and options for printing dates or branding. These machines support production rates of 20-60 pouches per minute, making them ideal for premium or specialty juices. In Europe and the USA, they are commonly used by brands targeting consumer convenience, such as organic or functional juices, where shelf appeal and portability are priorities.

Sachet/Stick Pack Machines

Sachet or stick pack machines are designed for small-format packaging, filling and sealing individual portions of fruit juice into flat or stick-shaped packs. They use roll-fed material, heat-sealing technology, and precise dosing pumps to handle viscous liquids like juices. Features include compact footprints for space-constrained facilities, easy cleaning for hygiene, and customization for tear notches or perforations. Production speeds typically range from 30-50 packs per minute, with options for multi-lane setups. These are popular in B2B applications for juice sampling, travel packs, or portion-controlled products, especially in European markets emphasizing sustainability and single-serve formats.

Liquid Filling and Capping Lines

Liquid filling and capping lines are automated systems for bottling fruit juices into rigid containers like glass or PET bottles. They incorporate rotary fillers for volumetric or weight-based dosing, followed by capping, labeling, and sometimes palletizing. Aseptic versions ensure contamination-free filling for extended shelf life, with features like CIP (clean-in-place) systems for efficiency. Speeds can reach 100-300 bottles per minute, depending on configuration. In the USA and Europe, these lines are essential for large-scale juice production, supporting regulatory compliance (e.g., FDA or EU standards) and integration with downstream equipment for complete beverage lines.

Illustrative Image (Source: Google Search)

Flow Wrap Machines

Flow wrap machines provide secondary packaging by enclosing fruit juice products, such as pre-filled bottles or pouches, in a continuous film wrap. They feature horizontal wrapping with end seals, automatic feeding, and options for shrink-wrapping for stability. Key attributes include high-speed operation (up to 200 wraps per minute) and versatility for bundling multiple units. These machines are used in distribution for multi-packs, reducing individual handling and enhancing transport efficiency. In B2B scenarios across the USA and Europe, they are valued for their ability to minimize waste and improve supply chain logistics for juice products.

Key Industrial Applications of fruit juice packing machine

Key Industrial Applications of Fruit Juice Packing Machine

Fruit juice packing machines are essential for automating the packaging of liquid beverages, ensuring hygiene, efficiency, and product integrity in high-volume operations. Below is a table outlining key industrial applications, along with detailed benefits tailored for B2B audiences in the USA and Europe.

| Industry/Application | Detailed Benefits |

|---|---|

| Beverage Production and Bottling | Automates filling and sealing of bottles or pouches, reducing labor costs by up to 50% and minimizing contamination risks. Supports compliance with FDA and EU food safety standards (e.g., HACCP), enabling high-speed production (up to 10,000 units/hour) for brands like Tropicana or Innocent. Enhances shelf life through aseptic packaging, reducing waste and improving ROI in competitive markets. |

| Fruit Juice Processing and Manufacturing | Integrates seamlessly into processing lines for raw fruit to packaged juice, optimizing workflow with features like volumetric filling and tamper-evident seals. Lowers operational downtime via quick-changeover designs, supporting diverse SKUs. Benefits include energy efficiency (reducing utility costs by 20%) and precise dosing, ideal for manufacturers meeting EU GMP and US FSMA regulations. |

| Retail and Distribution Packaging | Enables flexible pouch or bottle formats for retail distribution, improving supply chain efficiency with lightweight, stackable designs that cut shipping costs by 30%. Enhances product visibility through customizable labeling, boosting brand recognition in North American and European supermarkets. Reduces spoilage with vacuum or nitrogen flushing options, extending product freshness and minimizing returns. |

| Export and Global Trade Logistics | Facilitates international shipping with robust, leak-proof packaging that withstands long-distance transport. Supports compliance with global standards like Codex Alimentarius, enabling seamless export to EU and US markets. Benefits include modular scalability for varying batch sizes, reducing inventory holding costs and accelerating time-to-market for exporters dealing with seasonal fruit supplies. |

| Dairy and Juice Blend Operations | Handles mixed products like fruit-juice blends or fortified beverages, with hygienic stainless-steel components preventing cross-contamination. Improves yield through precise filling accuracy (±1%), supporting premium positioning in health-focused segments. Offers ROI through automation that scales with demand, aligning with sustainability goals in Europe (e.g., reduced plastic use via recyclable pouches). |

| Food Service and Institutional Supply | Produces portion-controlled pouches or bottles for catering and hospitality, ensuring consistent quality and ease of use. Reduces manual handling with automated capping and labeling, cutting preparation time in large-scale operations. Benefits include extended shelf life without refrigeration in some models, lowering storage costs for B2B buyers like restaurant chains or schools. |

3 Common User Pain Points for ‘fruit juice packing machine’ & Their Solutions

3 Common User Pain Points for Fruit Juice Packing Machines & Their Solutions

Fruit juice manufacturers in the USA and Europe often encounter operational challenges that impact efficiency, compliance, and profitability. Below, we outline three common pain points, structured by scenario, problem, and solution, based on industry insights from juice packing equipment providers.

1. Inefficient Filling and High Product Waste

- Scenario: A mid-sized juice producer in the USA scales up production during peak seasons, using automated juice packing machines to fill pouches with various fruit blends.

- Problem: Inconsistent filling speeds and imprecise dosing lead to overfilling, underfilling, or spillage, resulting in 5-10% product waste, increased costs, and regulatory non-compliance with weight standards (e.g., FDA or EU labeling rules).

- Solution: Invest in advanced rotary premade pouch packing machines with integrated multihead weighers for accurate dosing and real-time monitoring. These systems reduce waste by up to 15% through precise controls and automated adjustments, ensuring compliance and cost savings.

2. Frequent Downtime Due to Maintenance Issues

- Scenario: A European juice bottling facility operates 24/7, relying on vertical form-fill-seal (VFFS) machines for high-volume aseptic packaging of organic juices.

- Problem: Mechanical wear from acidic fruit juices causes seals to fail, nozzles to clog, and motors to overheat, leading to unplanned downtime of 10-20 hours per week, disrupting supply chains and increasing labor costs.

- Solution: Opt for corrosion-resistant machines with self-cleaning features and predictive maintenance software. Regular upgrades, such as stainless-steel components and IoT-enabled diagnostics, minimize breakdowns and extend machine lifespan, improving uptime by 20-30%.

3. Hygiene and Contamination Risks in Production

- Scenario: A B2B juice supplier in Europe exports to the USA, using spout pouch filling machines for ready-to-drink beverages in a shared facility with other food lines.

- Problem: Cross-contamination from residues or microbial buildup violates hygiene standards like HACCP or FSMA, risking product recalls, fines, and reputational damage, especially with allergens in fruit juices.

- Solution: Implement retort pouch packaging machines with integrated sanitization systems, including UV sterilization and CIP (clean-in-place) protocols. These ensure aseptic environments, reduce contamination risks by 90%, and facilitate easier compliance audits for international markets.

Strategic Material Selection Guide for fruit juice packing machine

Strategic Material Selection Guide for Fruit Juice Packing Machines

Overview

Fruit juice packing machines require careful material selection to ensure compliance with food safety standards (e.g., FDA in the USA and EU regulations such as Regulation (EU) No. 10/2011 for food contact materials), operational efficiency, product integrity, and sustainability. This guide analyzes key materials for machine construction and packaging, drawing from industry practices in juice packaging equipment like those offered by Landpack (e.g., Juice Packing Machine, Doypack Packaging Machine, and Spout Pouch Filling Machine). Selection prioritizes hygiene, corrosion resistance, durability, and cost-effectiveness.

Materials for Machine Construction

Packing machines for fruit juice must handle acidic, corrosive liquids while maintaining hygiene to prevent contamination. Common materials include:

- Stainless Steel (e.g., 304 or 316 Grade): Primary choice for frames, hoppers, pumps, and conveyor systems. Offers excellent corrosion resistance against acidic juices, easy sanitization, and compliance with food-grade standards. Ideal for high-volume lines like Landpack’s Vertical Form Fill Seal Machine (VFFS) or Rotary Premade Pouch Packing Machine. Drawbacks: Higher initial cost compared to alternatives.

- Food-Grade Plastics (e.g., Polyethylene or Nylon): Used in components like belts, guides, and seals for flexibility and lightweight design. Provides good chemical resistance but may wear faster in high-acid environments. Suitable for budget-conscious setups in smaller machines like Mini Doypack Packing Machine.

- Aluminum Alloys: Employed in lightweight structural parts for portability. Resistant to corrosion but less durable than stainless steel for heavy-duty juice lines. Best for auxiliary roles in machines like Flow Wrap Machine.

Materials for Packaging Components

Packaging materials must preserve juice freshness, extend shelf life, and align with consumer preferences for portability and sustainability. Based on Landpack’s product range (e.g., Stand Up Pouch Packing Machine, Retort Pouch Packaging Machine), options include:

- Plastic Films and Laminates (e.g., PET/Aluminum Foil/PE): Used in pouches for machines like Doypack Packaging Machine or Spout Pouch Filling Machine. Provides barrier properties against oxygen and light, ensuring extended shelf life. Lightweight and recyclable, but concerns include plastic waste in Europe (per EU directives) and potential flavor migration.

- Glass: Ideal for premium juice bottles in high-end lines. Offers superior barrier properties and recyclability, with no chemical leaching. However, heavier and more fragile, increasing shipping costs and breakage risks in automated machines.

- Carton or Paper-Based Materials (e.g., Aseptic Cartons): Used in form-fill-seal systems like Vertical Form Fill Seal Machine. Cost-effective, sustainable, and provides good light/oxygen barriers. Suitable for ambient storage but may require specialized sealing for acidic juices to prevent delamination.

Factors Influencing Material Selection

- Hygiene and Safety: Prioritize materials certified for food contact (e.g., FDA-approved or EU-compliant). Stainless steel and glass minimize contamination risks in acidic environments.

- Durability and Maintenance: Stainless steel withstands high-volume production (e.g., in Landpack’s Granular Packing Machine adapted for liquids). Plastics may need frequent replacement.

- Cost and Scalability: Glass is premium but expensive; plastic films offer lower costs for mass production.

- Sustainability: In Europe and the USA, favor recyclable options like cartons or bio-based plastics to meet regulations like the EU’s Packaging Directive.

- Application Fit: For ready-to-drink juices, select materials that support pasteurization or retorting (e.g., retort pouches).

Comparison Table: Packaging Material Options

| Material Type | Pros | Cons | Suitability for Fruit Juice Packing Machines (e.g., Landpack Models) | Cost Range (USD per Unit) | Regulatory Compliance (USA/EU) |

|---|---|---|---|---|---|

| Plastic Films/Laminates (e.g., PET/Al Foil/PE) | Excellent barrier against oxygen/light; lightweight; flexible for pouches | Potential plastic waste; flavor absorption in high-acid juices | High (Doypack, Spout Pouch Machines) | $0.05–$0.20 | FDA/EU compliant with testing |

| Glass | Superior barrier; fully recyclable; no leaching | Heavy; fragile; high breakage risk in automation | Medium (Bottle Filling Lines) | $0.50–$2.00 | FDA/EU standard |

| Carton/Paper-Based | Sustainable; cost-effective; good for aseptic packaging | May delaminate in acidic conditions; limited barrier for long shelf life | High (VFFS Machines) | $0.10–$0.30 | EU recycling directives; FDA approval |

In-depth Look: Manufacturing Processes and Quality Assurance for fruit juice packing machine

In-depth Look: Manufacturing Processes and Quality Assurance for Fruit Juice Packing Machines

Manufacturing Processes

Fruit juice packing machines, such as those used for pouch filling and sealing, undergo a structured manufacturing process to ensure durability, precision, and compliance with industry standards. Drawing from manufacturers like Landpack, the process typically involves four key stages: preparation, forming, assembly, and quality control (QC). These steps leverage advanced machinery and materials to produce machines capable of handling high-volume liquid packaging, including aseptic filling for fruit juices.

Preparation (Prep)

This initial stage focuses on sourcing and preparing raw materials and components to meet the machine’s specifications for liquid packaging, such as stainless steel for corrosion resistance and food-grade plastics for hygienic operation.

– Material Sourcing: Procure high-grade stainless steel (e.g., 316L for juice contact parts), aluminum alloys, and polymers compliant with FDA and EU food safety standards.

– Component Inventory: Gather sub-assemblies like pumps, valves, sensors, and control systems from certified suppliers.

– Design Validation: Use CAD software to finalize blueprints, ensuring compatibility with juice viscosity and pouch types (e.g., doypack or spout pouches).

– Tooling Setup: Prepare jigs, fixtures, and molds for precise fabrication, minimizing waste in high-volume production.

Illustrative Image (Source: Google Search)

Forming

Forming shapes the core structural elements of the machine, such as frames, hoppers, and conveyor systems, to handle the dynamic requirements of juice filling lines.

– Metal Fabrication: Cut, bend, and weld stainless steel sheets into frames and enclosures using CNC machines for accuracy.

– Casting and Molding: Produce plastic components like hoppers and seals via injection molding, ensuring resistance to acidic fruit juices.

– Electrical and Mechanical Subassemblies: Assemble motors, drives, and PLC systems, integrating sensors for automated filling accuracy (e.g., weighing up to 500ml per pouch).

– Integration of Packaging Elements: Form pouch-handling mechanisms, such as grippers for premade pouches, optimized for vertical form-fill-seal (VFFS) processes common in juice packaging.

Assembly

Assembly brings together all formed components into a functional unit, with a focus on seamless integration for efficient juice packing operations.

– Structural Assembly: Mount frames and conveyor systems, ensuring alignment for smooth pouch transport at speeds up to 60 packs per minute.

– Mechanical Integration: Install filling nozzles, sealing jaws, and capping mechanisms, calibrated for liquid flow rates and aseptic conditions.

– Electrical and Control Setup: Connect wiring, PLCs, and HMI interfaces for automated control, including touchscreens for real-time monitoring.

– Testing Integration: Perform initial power-up tests to verify basic functionality, such as pump priming and seal integrity.

Quality Control (QC)

QC is embedded throughout manufacturing to detect defects and ensure reliability, particularly for machines handling perishable products like fruit juices.

– In-Process Inspections: Use visual checks and dimensional measurements to verify component tolerances (e.g., ±0.1mm for sealing accuracy).

– Functional Testing: Run simulated juice filling cycles to assess performance metrics like fill volume precision (within 1% error) and leak rates.

– Calibration and Adjustment: Fine-tune sensors and actuators using calibrated tools to meet OEM specifications.

– Final Validation: Conduct endurance tests under load (e.g., 24-hour continuous operation) and document results for traceability.

Quality Assurance

Quality assurance for fruit juice packing machines emphasizes adherence to global standards to guarantee safety, efficiency, and regulatory compliance in markets like the USA and Europe. Manufacturers such as Landpack prioritize certifications that align with food processing requirements, focusing on risk management and continuous improvement.

Key Quality Standards

| Standard | Description | Relevance to Fruit Juice Packing Machines |

|---|---|---|

| ISO 9001 | Quality Management Systems – Requirements for organizations to demonstrate consistent product quality and customer satisfaction. | Ensures systematic processes for machine design, production, and post-sales support, reducing defects in juice packaging lines. |

| ISO 22000 | Food Safety Management Systems – Focuses on hazard analysis and critical control points (HACCP) for food-related equipment. | Critical for aseptic filling machines to prevent contamination in fruit juice production, addressing allergens and microbial risks. |

| CE Marking (EU) | Indicates conformity with health, safety, and environmental protection standards for machinery in the European market. | Required for machines sold in Europe, verifying electromagnetic compatibility and safety guards for operators handling liquid filling. |

| FDA Compliance (USA) | Adherence to U.S. Food and Drug Administration guidelines for food contact materials and equipment. | Ensures components like seals and nozzles are food-grade, preventing adulteration in juice packing processes. |

| ISO 14001 | Environmental Management Systems – Promotes sustainable manufacturing practices. | Guides eco-friendly material selection and waste reduction in machine assembly, appealing to B2B buyers in sustainability-focused markets. |

Implementation Practices

- Audit and Certification: Machines undergo third-party audits by bodies like TÜV or NSF to validate ISO compliance, with certificates displayed on product datasheets.

- Traceability Systems: Implement lot tracking and serial numbering for components, enabling recall management if issues arise in field operations.

- Continuous Improvement: Use feedback loops from user data to refine designs, such as enhancing energy efficiency in high-speed juice lines to meet ISO 50001 energy management standards.

- Documentation: Provide comprehensive manuals and compliance reports, detailing QC protocols to build trust with B2B clients in the beverage industry.

This structured approach ensures fruit juice packing machines deliver reliable performance, meeting the demands of high-stakes operations in the USA and European markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fruit juice packing machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Fruit Juice Packing Machines

This checklist provides a structured approach to sourcing fruit juice packing machines for B2B operations in the USA and Europe. It ensures compliance with regional standards (e.g., FDA in the USA, CE marking in Europe) and focuses on efficiency, cost-effectiveness, and reliability. Use it to systematically evaluate suppliers like Landpack, which specializes in juice pouch and packaging machines.

Step 1: Define Your Requirements

- Specify production needs: Daily output capacity (e.g., 1,000–10,000 liters/hour), juice types (e.g., organic, pasteurized), and packaging formats (e.g., pouches, bottles, cartons).

- Identify machine features: Automation level, filling accuracy, hygiene standards (e.g., stainless steel construction for easy cleaning), and integration with existing lines.

- Consider regulatory compliance: Ensure machines meet FDA requirements in the USA (e.g., for food safety) and CE marking in Europe (e.g., for machinery safety).

- Budget outline: Set a rough range including purchase, installation, and maintenance costs.

Step 2: Research Suppliers and Market Options

- Identify reputable manufacturers: Search for B2B suppliers specializing in liquid packaging, such as Landpack (offering juice pouch packing machines, spout pouch fillers, and rotary premade pouch machines).

- Review product catalogs: Evaluate options like vertical form-fill-seal (VFFS) machines for pouches or inline fillers for bottles, ensuring they handle viscous fruit juices.

- Check industry certifications: Prioritize suppliers with ISO 9001, HACCP, and GMP certifications for quality assurance.

- Explore regional distributors: For USA and Europe, consider local agents to minimize import duties and logistics costs.

Step 3: Request and Compare Quotes

- Contact shortlisted suppliers: Provide detailed specs from Step 1 and request formal quotations, including pricing, delivery timelines, and warranty terms.

- Compare offerings: Use a table to evaluate key factors (see example below).

| Supplier | Machine Type | Capacity (L/hour) | Price Range | Delivery Time | Key Features | Compliance Notes |

|---|---|---|---|---|---|---|

| Landpack | Juice Pouch Packing Machine | 2,000–5,000 | $50,000–$150,000 | 8–12 weeks | Aseptic filling, customizable pouches | CE/FDA compliant |

| Competitor A | Inline Filler | 1,000–3,000 | $40,000–$120,000 | 6–10 weeks | High-speed capping | ISO certified |

| Competitor B | VFFS Machine | 3,000–8,000 | $60,000–$200,000 | 10–14 weeks | Multi-format support | HACCP approved |

- Factor in total cost of ownership: Include energy consumption, spare parts availability, and training costs.

Step 4: Verify Supplier Credibility and Compliance

- Assess track record: Review case studies, client testimonials, and references from similar B2B juice producers.

- Confirm certifications: Request proof of FDA/EU compliance, including material safety data sheets (MSDS) for machine components.

- Evaluate after-sales support: Inquire about on-site training, maintenance contracts, and 24/7 technical support availability in USA/Europe.

Step 5: Conduct Due Diligence and Testing

- Request demos or trials: Arrange virtual or in-person demonstrations to test machine performance with sample fruit juices.

- Perform site visits: If possible, inspect the supplier’s factory for quality control processes.

- Review terms: Analyze contracts for payment schedules, intellectual property, and liability clauses.

Step 6: Finalize Purchase and Implementation

- Negotiate terms: Discuss discounts, customizations, and financing options based on volume commitments.

- Secure logistics: Plan for shipping, customs clearance (e.g., via Incoterms for USA/Europe trade), and installation by certified technicians.

- Implement and train: Schedule staff training post-delivery to ensure smooth integration with production lines.

- Monitor ROI: Track metrics like output efficiency and downtime reduction within the first 3–6 months.

By following this checklist, you can streamline the sourcing process, mitigate risks, and select a fruit juice packing machine that aligns with your operational goals and regional standards. For tailored advice, consult industry experts or suppliers like Landpack.

Comprehensive Cost and Pricing Analysis for fruit juice packing machine Sourcing

Comprehensive Cost and Pricing Analysis for Fruit Juice Packing Machine Sourcing

Sourcing fruit juice packing machines, such as those offered by manufacturers like Landpack, involves evaluating multiple cost components to ensure budget alignment and operational efficiency. This analysis breaks down key expenses based on typical industry benchmarks for B2B buyers in the USA and Europe, drawing from standard procurement practices for equipment like juice pouch packing machines, vertical form-fill-seal (VFFS) lines, and liquid filling systems. Prices can vary by machine type (e.g., rotary premade pouch vs. spout pouch filling), capacity (e.g., 1,000-10,000 pouches/hour), and customization.

Illustrative Image (Source: Google Search)

Key Cost Factors

Costs are influenced by factors such as machine specifications, vendor location (e.g., China-based suppliers like Landpack), import regulations, and scale. Below is a breakdown into primary categories: materials, labor, and logistics. Estimates are in USD, based on mid-2023 data for a mid-range juice packing line (e.g., a 5,000-pouch/hour VFFS machine with filling capabilities).

1. Materials

This includes the machine purchase price, spare parts, and consumables. Juice packing machines from Landpack range from $10,000 for basic sachet machines to $200,000+ for fully automated lines.

| Cost Component | Estimated Range (USD) | Description |

|---|---|---|

| Base Machine Cost | $50,000 – $150,000 | Core equipment like juice pouch filling machines or rotary premade pouch packers. Includes standard features for liquid handling. |

| Customization/Upgrades | $10,000 – $50,000 | Additions like spout pouches, zipper closures, or retort capabilities for shelf-stable juice. |

| Spare Parts (Initial) | $5,000 – $15,000 | Pumps, seals, and nozzles; essential for juice-specific operations. |

| Consumables (Annual) | $2,000 – $10,000 | Packaging materials like pouches, films, and labels; varies by production volume. |

| Total Materials Estimate | $67,000 – $225,000 | Excludes ongoing consumables; bulk purchases can reduce this by 10-20%. |

2. Labor

Labor encompasses installation, training, and ongoing operation. Skilled technicians are often required for setup, especially for complex lines like automated vacuum packing or multihead weigher systems.

| Cost Component | Estimated Range (USD) | Description |

|---|---|---|

| Installation and Commissioning | $5,000 – $20,000 | Professional setup by vendor or third-party engineers; includes site visits for juice-specific calibrations. |

| Training and Onboarding | $2,000 – $10,000 | Staff training on machine operation, maintenance, and safety; typically 1-2 weeks per team. |

| Ongoing Operational Labor | $20,000 – $50,000 (Annual) | Salaries for operators and maintenance staff; assumes a 2-shift operation for juice production lines. |

| Maintenance/Repairs | $5,000 – $15,000 (Annual) | Costs for routine servicing and parts; downtime can add indirect labor costs. |

| Total Labor Estimate | $32,000 – $95,000 (Initial + Annual) | Labor rates are higher in Europe (e.g., €50-100/hour) vs. USA ($30-60/hour); remote training can cut costs by 30%. |

3. Logistics

Logistics covers transportation, import duties, and storage, critical for international sourcing from Asia to the USA or Europe.

Illustrative Image (Source: Google Search)

| Cost Component | Estimated Range (USD) | Description |

|---|---|---|

| Shipping and Freight | $2,000 – $10,000 | Sea freight for large machines; air freight for urgent parts. Landpack’s China-based shipping adds 2-4 weeks transit. |

| Import Duties and Tariffs | $5,000 – $20,000 | USA: 2-5% on machinery; Europe: 0-10% under EU tariffs, plus VAT (20% in UK). Juice machines may qualify for exemptions if classified as food processing equipment. |

| Insurance and Handling | $1,000 – $5,000 | Coverage for damage during transit; includes customs clearance fees. |

| Storage and Installation Prep | $2,000 – $10,000 | On-site warehousing and facility modifications for lines like granular or liquid packing machines. |

| Total Logistics Estimate | $10,000 – $45,000 | Costs rise with machine size; group shipments or local EU/USA distributors (e.g., via Landpack partners) can reduce this by 15-25%. |

Overall Total Cost Estimate: $109,000 – $365,000 for initial setup, plus 10-20% annual ongoing expenses. These figures exclude financing costs; financing can spread payments over 1-5 years at 5-10% interest.

Tips to Save Costs

To optimize sourcing for fruit juice packing machines, consider these strategies tailored for USA and European buyers:

- Negotiate Bulk or Long-Term Contracts: Request volume discounts from suppliers like Landpack for multiple units or service agreements, potentially saving 10-15% on base prices.

- Opt for Modular Designs: Choose scalable machines (e.g., VFFS lines) to avoid over-specification; start with basic juice pouch packers and upgrade later to cut initial materials costs by 20-30%.

- Leverage Local Distributors: Partner with USA/EU-based agents for Landpack equipment to reduce shipping and tariffs; this can lower logistics by 25% through reduced import duties.

- Invest in Energy-Efficient Models: Select machines with lower power consumption to minimize long-term operational labor and energy costs; qualify for incentives like USA’s EPA rebates or EU’s energy efficiency grants.

- Conduct Competitive Bidding: Solicit quotes from multiple vendors (e.g., compare Landpack with European alternatives) and factor in total cost of ownership, including warranties for spare parts.

- Plan for Scalability: Assess production needs to avoid overcapacity; a mini doypack machine for small juice operations can halve upfront costs compared to full lines.

By focusing on these breakdowns and tips, B2B buyers can make informed decisions, ensuring cost-effective sourcing that aligns with production goals in juice packaging.

Alternatives Analysis: Comparing fruit juice packing machine With Other Solutions

Alternatives Analysis: Comparing Fruit Juice Packing Machine with Other Solutions

In the fruit juice packaging sector, businesses often evaluate the Landpack Fruit Juice Packing Machine against alternatives to ensure alignment with production needs, cost structures, and scalability. Below, we compare it with two common alternatives: Manual Filling and Packing Lines, and Vertical Form Fill Seal (VFFS) Machines adapted for liquids. The comparison focuses on key criteria such as efficiency, cost, scalability, customization, and maintenance, drawing from industry standards for B2B operations in the USA and Europe.

Illustrative Image (Source: Google Search)

Comparison Table

| Criteria | Fruit Juice Packing Machine (Landpack) | Manual Filling and Packing Lines | Vertical Form Fill Seal (VFFS) Machines for Liquids |

|---|---|---|---|

| Efficiency | High; automated pouch filling, sealing, and labeling at speeds up to 50-100 pouches/min, reducing labor needs. | Low; labor-intensive, prone to inconsistencies, suitable for small batches only. | Moderate to high; forms, fills, and seals pouches in one process at 30-80 pouches/min, but requires product-specific adjustments. |

| Cost | Initial investment $50,000-$200,000; long-term savings via reduced waste and labor. | Low upfront ($10,000-$50,000); high ongoing labor costs and potential for errors. | Medium ($100,000-$300,000); efficient for high-volume runs, but higher energy and material costs. |

| Scalability | Excellent; modular design supports 1-8 lanes, easy upgrades for increased production. | Poor; limited to small-scale operations, hard to scale without significant rework. | Good; expandable for larger outputs, ideal for mid-to-large facilities. |

| Customization | Strong; supports various pouch types (e.g., spout, zipper, stand-up) and flavors via integrated fillers. | Limited; basic setups with manual adjustments, not ideal for diverse juice variants. | Moderate; flexible pouch shapes but may need custom feeders for viscous juices. |

| Maintenance | Low; automated systems with scheduled servicing; complies with FDA/EU standards. | High; frequent human intervention increases downtime and contamination risks. | Medium; requires regular cleaning and part replacements; robust for continuous use. |

Analysis

The Landpack Fruit Juice Packing Machine stands out for its automation and efficiency, making it a superior choice for medium to large juice producers in the USA and Europe seeking to minimize operational costs and maximize output. Compared to manual filling and packing lines, it eliminates inconsistencies and labor dependencies, which are critical in regions with stringent food safety regulations like the EU’s HACCP standards. While manual methods offer lower initial costs, their inefficiency in scaling for commercial volumes—common in North American juice markets—renders them unsuitable for growth-oriented businesses.

Against VFFS machines, the Fruit Juice Packing Machine provides better customization for liquid products, such as handling varying juice viscosities without extensive modifications. VFFS is effective for dry goods or simpler liquids but may incur higher maintenance for acidic juices, potentially leading to seal failures. For European operations emphasizing sustainability, the modular design of the Landpack machine reduces material waste, aligning with EU eco-label requirements. Overall, businesses should prioritize the Fruit Juice Packing Machine for high-volume, customized juice packaging to achieve competitive advantages in B2B supply chains.

Essential Technical Properties and Trade Terminology for fruit juice packing machine

Essential Technical Properties for Fruit Juice Packing Machines

Fruit juice packing machines are specialized equipment designed for efficient, hygienic filling and packaging of liquid products like fruit juices, often in pouches, bottles, or cartons. Below are key technical properties commonly associated with these machines, based on industry standards for B2B applications in the USA and Europe. These ensure compliance with food safety regulations (e.g., FDA in the US, EU Food Hygiene Directive) and optimize production for high-volume operations.

Key Technical Specifications

| Property | Description | Typical Range/Examples |

|---|---|---|

| Filling Capacity | Volume of juice per pack; ensures precise dosing to minimize waste. | 100ml to 5L per cycle |

| Production Speed | Packs per minute (PPM); critical for scalability in commercial settings. | 30-200 PPM, depending on model |

| Filling Accuracy | Precision in volume measurement to maintain product consistency. | ±0.5% to ±1% tolerance |

| Packaging Types | Supported formats for juices, often aseptic to preserve freshness. | Pouches (spout, zipper), bottles, cartons |

| Material Compatibility | Handles viscous liquids; must be food-grade and corrosion-resistant. | Stainless steel (SS304/316), FDA-approved polymers |

| Power Requirements | Electrical and mechanical specs for installation in industrial facilities. | 1-10 kW, 220-480V, 50/60 Hz |

| Dimensions & Weight | Footprint for space planning in warehouses or production lines. | 2-5m length, 1-3m width, 500-2000kg |

| Automation Level | Degree of integration with sensors and controls for efficiency. | Semi-automatic to fully automated (PLC-controlled) |

| Maintenance Intervals | Downtime for cleaning and servicing to comply with hygiene standards. | Daily sanitization; quarterly servicing |

These properties vary by machine type (e.g., rotary premade pouch machines for juices from the reference source). Always verify with suppliers like Landpack for model-specific details.

Trade Terminology for Fruit Juice Packing Machines

In B2B transactions for fruit juice packing machines, understanding trade terms is essential for negotiating contracts, logistics, and compliance in USA and European markets. These terms facilitate smooth procurement, especially for OEM/ODM customizations.

Key Trade Terms

- MOQ (Minimum Order Quantity): The smallest quantity a supplier requires per order; e.g., 1-5 units for machines, reducing costs for bulk buyers.

- OEM (Original Equipment Manufacturer): Custom manufacturing under your brand; common for tailored juice lines.

- ODM (Original Design Manufacturer): Supplier designs and produces based on your specs; useful for innovative pouch formats.

- FOB (Free on Board): Seller handles costs until the goods are loaded; buyer manages shipping from port (e.g., common in US exports).

- CIF (Cost, Insurance, Freight): Seller covers costs, insurance, and freight to the buyer’s port; standard for European imports.

- DDP (Delivered Duty Paid): Seller handles all logistics, including duties; ideal for hassle-free delivery in the EU.

- LC (Letter of Credit): Bank-guaranteed payment method; preferred for high-value machinery to mitigate risks.

- TT (Telegraphic Transfer): Direct bank payment; faster for smaller orders but less secure.

- Warranty: Typically 1-2 years on parts; includes on-site support for installation and training.

- Certifications: Compliance markers like CE (EU safety), FDA (US food contact), ISO 9001 (quality management).

For specific terms, consult suppliers such as those listed in the reference (e.g., Landpack’s juice pouch machines) and align with regional regulations like USDA organic or EU traceability standards.

Navigating Market Dynamics and Sourcing Trends in the fruit juice packing machine Sector

Navigating Market Dynamics and Sourcing Trends in the Fruit Juice Packing Machine Sector

Market Dynamics

The fruit juice packing machine sector is influenced by evolving consumer preferences, regulatory pressures, and technological advancements. Key dynamics include:

- Rising Demand for Automation: With increasing emphasis on efficiency and precision, automated machines like rotary premade pouch packing machines and vertical form fill seal (VFFS) lines are gaining traction. These systems minimize human error and enhance production speed, crucial for high-volume juice manufacturers in the USA and Europe.

- Shift Toward Flexible Packaging: Stand-up pouches, spout pouches, and retort pouches are preferred for their portability and shelf stability. This trend reflects growing consumer demand for convenient, on-the-go products, driving investments in multi-functional machines capable of handling various pouch formats.

- Regulatory Compliance: In Europe, adherence to EU food safety standards (e.g., HACCP) and in the USA, FDA regulations necessitate machines with advanced sterilization features, such as those used in retort pouch packaging to ensure product integrity and extend shelf life.

- Global Supply Chain Pressures: Fluctuations in raw material costs (e.g., plastics and metals) and logistics disruptions post-pandemic are pushing manufacturers to adopt modular, energy-efficient machines that reduce operational costs.

| Market Trend | Impact on Fruit Juice Sector | Example Machines |

|---|---|---|

| Automation and AI Integration | Improves accuracy and reduces waste in juice filling | Rotary Premade Pouch Packing Machine |

| Sustainable Materials | Addresses eco-labeling requirements | Spout Pouch Filling Machine |

| Customization for Small Batches | Supports artisanal juice producers | Mini Doypack Packing Machine |

Sourcing Trends

Sourcing fruit juice packing machines requires evaluating suppliers based on reliability, customization, and global reach. Trends indicate a preference for integrated solutions from specialized manufacturers:

Illustrative Image (Source: Google Search)

- Direct from OEMs: Businesses are increasingly sourcing from original equipment manufacturers (OEMs) like Landpack, which offer end-to-end solutions including juice pouch packing machines and liquid filling lines. This reduces intermediaries and ensures alignment with sector-specific needs.

- Regional Partnerships: In the USA and Europe, partnerships with local distributors provide faster delivery and after-sales support, while international sourcing leverages cost efficiencies from Asia-based suppliers.

- Digital Procurement Platforms: Adoption of online marketplaces for machine procurement is rising, enabling comparison of specifications, pricing, and certifications (e.g., CE for Europe and UL for the USA).

- Focus on Scalability: Suppliers are trending toward offering modular systems that scale with production needs, such as VFFS packing lines that integrate with existing juice processing equipment.

- Post-Purchase Services: Emphasis on comprehensive support, including training, maintenance, and upgrades, is a key sourcing criterion, with providers like Landpack offering factory tours and client references.

Key sourcing considerations:

– Verify certifications (e.g., ISO 9001 for quality management).

– Assess energy efficiency ratings to align with sustainability goals.

– Negotiate for customization, such as machines tailored for aseptic filling of fruit juices.

Sustainability in Fruit Juice Packing

Sustainability is a core driver in the sector, with machines evolving to minimize environmental impact:

- Eco-Friendly Materials: Transition to biodegradable or recyclable pouches (e.g., retort pouches using plant-based films) reduces plastic waste. Machines like stand-up pouch packing systems are designed to handle these materials efficiently.

- Energy-Efficient Operations: Modern machines incorporate variable frequency drives and low-power components, cutting energy consumption by up to 30% compared to older models.

- Waste Reduction: Automated systems with multihead weighers and inline fillers minimize overfilling and material spillage, aligning with circular economy principles in Europe and the USA.

- Lifecycle Assessment: Suppliers are providing data on machine longevity and recyclability, encouraging buyers to choose systems with a lower carbon footprint.

Historical Overview

The evolution of fruit juice packing machines traces back to the early 20th century, when manual canning dominated. Post-World War II, the rise of bottled juices spurred the development of semi-automatic fillers in the 1950s. The 1980s introduced VFFS technology, revolutionizing pouch packaging for juices by enabling high-speed production. In the 2000s, advancements in aseptic processing addressed shelf-life challenges, while the 2010s focused on sustainability amid global environmental awareness. Today, with AI and IoT integrations, machines like those from Landpack represent the latest in smart, efficient packaging solutions for the fruit juice industry.

Frequently Asked Questions (FAQs) for B2B Buyers of fruit juice packing machine

Frequently Asked Questions for B2B Buyers of Fruit Juice Packing Machines

1. What types of fruit juice packing machines are available from Landpack?

Landpack offers a range of juice packing machines tailored for liquid packaging, including rotary premade pouch packing machines, spout pouch filling machines, vertical form fill seal (VFFS) machines, and liquid filling lines. These are designed for efficient, hygienic packaging of fruit juices in formats like pouches, bottles, and cartons, with options for automated operations to meet B2B production demands in the USA and Europe.

Illustrative Image (Source: Google Search)

2. How do these machines ensure product safety and hygiene for fruit juice packaging?

Fruit juice packing machines from Landpack incorporate stainless steel construction, food-grade materials, and CIP (Clean-In-Place) systems to maintain hygiene. They feature automatic sanitization processes, compliance with FDA and EU standards (e.g., HACCP), and UV sterilization options to prevent contamination, ensuring safe packaging for perishable liquids like fruit juices.

3. What key features should B2B buyers look for in a fruit juice packing machine?

Key features include high-speed filling accuracy (up to 50-100 packs per minute depending on the model), multi-head weighing for precise dosing, touch-screen controls for easy operation, and integration with existing production lines. Look for energy-efficient designs, anti-drip nozzles, and compatibility with various juice viscosities to optimize B2B efficiency and reduce waste.

4. Can Landpack’s machines handle different packaging formats for fruit juices?

Yes, these machines support multiple formats such as stand-up pouches, zippered pouches, retort pouches, and bottles. They can accommodate sizes from mini sachets (5-50ml) to larger packs (up to 5L), with customizable sealing options like M-shape or spout attachments, making them versatile for B2B juice producers targeting retail and wholesale markets in the USA and Europe.

5. What is the typical production capacity of these fruit juice packing machines?

Production capacity varies by model: rotary premade pouch machines handle 30-80 pouches per minute, VFFS lines can process 20-60 packs per minute, and inline fillers achieve 50-120 bottles per minute. High-capacity lines are available for scaling B2B operations, with options for 24/7 automated runs to meet demand for fruit juice packaging.

Illustrative Image (Source: Google Search)

6. Are there customization options for specific types of fruit juices?

Landpack provides customization for juice types, including viscosity adjustments for pulpy or clear juices, temperature controls for cold-filled products, and anti-foaming mechanisms. B2B buyers can opt for specialized modules for organic or fortified juices, ensuring compatibility with ingredients like vitamins or preservatives, tailored to USA and European market requirements.

7. What are the maintenance requirements for fruit juice packing machines?

Maintenance involves regular cleaning with food-safe detergents, lubrication of moving parts, and filter replacements every 3-6 months. Landpack recommends annual inspections and software updates for optimal performance. B2B users should train staff on preventive maintenance to minimize downtime, with remote diagnostics available for efficient support.

8. How do these machines ensure compliance with food safety regulations in the USA and Europe?

Machines comply with standards like FDA 21 CFR Part 117 (USA) and EU Regulation 1935/2004 by using traceable materials and integrated quality checks. They include data logging for traceability, allergen detection, and export certifications. Landpack offers documentation and audits to help B2B buyers achieve certifications such as SQF or ISO 22000, facilitating cross-border juice packaging operations.

Strategic Sourcing Conclusion and Outlook for fruit juice packing machine

Strategic Sourcing Conclusion and Outlook for Fruit Juice Packing Machine

Strategic sourcing for fruit juice packing machines delivers substantial value by optimizing procurement processes, ensuring alignment with business objectives in the USA and Europe. By focusing on supplier selection, cost management, and supply chain resilience, organizations achieve cost reductions of 10-20% through bulk purchasing and long-term contracts, while maintaining high-quality standards compliant with regional regulations like FDA and EU food safety directives.

Illustrative Image (Source: Google Search)

Key value drivers include:

- Efficiency Gains: Automation in machines such as rotary premade pouch packers reduces labor costs and minimizes downtime, enhancing production scalability.

- Quality Assurance: Sourcing from certified providers like Landpack ensures equipment reliability, reducing defects and waste in juice packaging lines.

- Sustainability Focus: Eco-friendly options, such as retort pouch machines, support green initiatives, aligning with Europe’s circular economy goals and US environmental standards.

- Innovation Access: Partnerships unlock advanced features like spout pouch filling, driving product differentiation in competitive markets.

Looking ahead, the outlook is promising with emerging trends in AI-driven automation and sustainable materials. By leveraging global sourcing strategies, B2B buyers can anticipate 15-25% efficiency improvements through digital twins and IoT integration. Proactive engagement with suppliers will be key to navigating supply chain disruptions and capitalizing on growth in premium juice segments. Total word count: 198.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.