Cut Costs with a Dry Ice Machine: The Ultimate Buying Guide (2025)

Introduction: Navigating the Global Market for dry ice machine

In the fast-evolving landscape of global trade, sourcing a reliable dry ice machine presents unique challenges for international B2B buyers. Companies across Africa, South America, the Middle East, and Europe face increasing demands for efficient cooling solutions, particularly in industries such as food preservation, pharmaceuticals, and transportation. Understanding the intricacies of the dry ice machine market, from machine types to applications, is essential for making informed purchasing decisions that can significantly impact operational efficiency and cost management.

This comprehensive guide delves into various aspects of the dry ice machine sector, including the different types of machines available, their specific applications, and critical factors for supplier vetting. We explore the cost implications associated with different machine models and the long-term benefits they provide. By equipping buyers with actionable insights, this guide aims to empower businesses to navigate the complexities of sourcing dry ice machines effectively.

International B2B buyers, particularly those from regions like Argentina and Poland, will find valuable information tailored to their unique market dynamics and procurement needs. With this guide, you will be better positioned to select the right dry ice machine that meets your operational requirements while optimizing costs and ensuring compliance with local regulations. Whether you are looking to enhance your supply chain or improve product quality, the insights offered here will support you in making strategic purchasing decisions.

Understanding dry ice machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dry Ice Pelletizer | Produces small pellets; compact design | Food processing, medical transport | Pros: Efficient, easy to transport; Cons: Limited output for large operations. |

| Dry Ice Block Maker | Creates larger blocks for extended cooling | Shipping, cold storage, industrial uses | Pros: Longer cooling duration; Cons: Requires more space. |

| Dry Ice Blaster | Utilizes dry ice for cleaning; often portable | Industrial cleaning, surface preparation | Pros: Eco-friendly, reduces waste; Cons: Higher initial investment. |

| Dry Ice Fog Machine | Generates fog effect using dry ice; specialized design | Entertainment, special effects | Pros: Unique visual effects; Cons: Limited use outside entertainment. |

| Dry Ice Transport Cooler | Insulated containers designed for safe transport | Logistics, pharmaceuticals, perishable goods | Pros: Maintains temperature; Cons: Bulkier than standard coolers. |

What are the Characteristics and Suitability of Dry Ice Pelletizers?

Dry ice pelletizers are designed to create small, uniform pellets of dry ice, which are ideal for applications requiring precise cooling or freezing. These machines are compact and can be integrated easily into existing production lines, making them suitable for food processing and medical transport sectors. When considering a pelletizer, B2B buyers should evaluate the machine’s output capacity and compatibility with their specific cooling needs. This type of machine is particularly advantageous for operations that require frequent and consistent dry ice production.

How Do Dry Ice Block Makers Differ in Functionality and Application?

Dry ice block makers produce larger blocks of dry ice, which are particularly effective for long-term cooling solutions. Industries such as shipping, cold storage, and industrial applications benefit from these machines due to their ability to provide sustained cooling over extended periods. Buyers should assess the block maker’s production speed and the size of blocks it can produce to match their logistical requirements. While block makers are less portable than pelletizers, their efficiency in maintaining low temperatures makes them a preferred choice for bulk shipping of perishables.

What Advantages Do Dry Ice Blasters Offer for Industrial Cleaning?

Dry ice blasters use dry ice pellets as a cleaning medium, making them a unique solution for surface preparation and industrial cleaning. This method is eco-friendly, as it eliminates the need for harmful chemicals and reduces waste. B2B buyers looking for effective cleaning solutions should consider the initial investment cost against the long-term savings from reduced labor and material costs. Additionally, the portability of many dry ice blasters allows for versatile applications across different sites, making them suitable for various industries.

Why Choose a Dry Ice Fog Machine for Entertainment Purposes?

Dry ice fog machines are specialized equipment that creates dramatic fog effects, commonly used in the entertainment industry. These machines utilize dry ice to produce low-lying fog, enhancing visual presentations at events, concerts, and theatrical productions. For B2B buyers in the entertainment sector, the unique capabilities of dry ice fog machines can elevate their offerings. However, it’s important to note that their application is limited primarily to entertainment, and buyers should consider the frequency of use before investing.

What Are the Key Considerations for Dry Ice Transport Coolers?

Dry ice transport coolers are insulated containers specifically designed to maintain low temperatures during the transportation of temperature-sensitive goods. They are essential for logistics companies, pharmaceutical distributors, and businesses dealing with perishable products. Buyers should evaluate the cooler’s insulation efficiency and capacity to ensure it meets their shipping needs. While these coolers provide excellent temperature control, their bulkiness may be a consideration for companies with limited storage space.

Related Video: H-D6000 DMX Dry Ice Machine / Review with DMX Low Dry Ice Machine

Key Industrial Applications of dry ice machine

| Industry/Sector | Specific Application of dry ice machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Food preservation and transportation | Extends shelf life of products, reducing waste | Compliance with food safety regulations; reliable supply chain |

| Pharmaceuticals | Cold chain logistics for vaccines | Ensures efficacy of temperature-sensitive products | Temperature monitoring; adherence to international shipping standards |

| Manufacturing | Cleaning of machinery and equipment | Enhances equipment longevity and performance | Availability of various dry ice sizes; safety training for staff |

| Events & Entertainment | Special effects for events and performances | Creates visually appealing effects, enhancing experience | Customization options; reliable delivery schedules |

| Research & Development | Cooling in laboratory settings | Facilitates experiments requiring low temperatures | Quality assurance for purity of dry ice; bulk purchasing options |

How is Dry Ice Used in the Food & Beverage Industry?

In the food and beverage sector, dry ice machines are pivotal for food preservation and transportation. By maintaining low temperatures during transit, businesses can significantly extend the shelf life of perishable goods, minimizing spoilage and waste. International buyers, particularly from regions like Africa and South America, must consider compliance with local food safety regulations and ensure their supply chain can consistently deliver dry ice without interruption.

What Role Does Dry Ice Play in Pharmaceuticals?

The pharmaceutical industry relies heavily on dry ice machines for cold chain logistics, particularly for sensitive products like vaccines. Maintaining the required temperature during transport is critical to ensure the efficacy of these products. Buyers from Europe and the Middle East should focus on suppliers who provide temperature monitoring solutions and adhere to international shipping standards, ensuring that their products arrive safely and effectively.

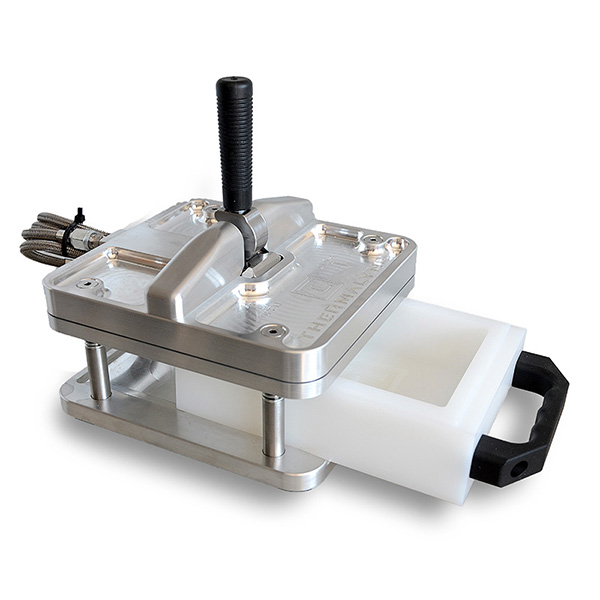

A stock image related to dry ice machine.

Why is Dry Ice Important for Manufacturing?

In manufacturing, dry ice machines are used for cleaning machinery and equipment through dry ice blasting. This method is effective in removing contaminants without damaging the underlying surfaces, thereby enhancing the longevity and performance of equipment. B2B buyers should consider the availability of various dry ice sizes and ensure that their staff receive proper safety training to mitigate risks associated with dry ice handling.

How is Dry Ice Utilized in Events & Entertainment?

The events and entertainment industry leverages dry ice machines to create stunning special effects, such as fog and smoke, which enhance the visual appeal of performances and events. Businesses in this sector should seek suppliers who offer customization options for different effects and maintain reliable delivery schedules to meet event timelines. This ensures that the desired atmosphere is created without delays.

What Are the Applications of Dry Ice in Research & Development?

In research and development, dry ice is essential for cooling in laboratory settings, particularly for experiments requiring low temperatures. Its ability to maintain consistent cooling makes it invaluable for sensitive research. International buyers should prioritize suppliers who guarantee the purity of dry ice and offer bulk purchasing options, which can lead to cost savings and ensure a steady supply for ongoing research projects.

Related Video: Industrial Cleaning Applications for Dry Ice Blasting

3 Common User Pain Points for ‘dry ice machine’ & Their Solutions

Scenario 1: Inconsistent Dry Ice Quality Impacts Operations

The Problem: Many B2B buyers face the challenge of inconsistent quality in the dry ice produced by their machines. This inconsistency can lead to significant operational issues, particularly in industries like pharmaceuticals and food transportation, where precise temperature control is critical. For example, a company in Argentina relying on dry ice for transporting vaccines may find that variations in dry ice quality result in temperature fluctuations, compromising the efficacy of their products. Such situations not only cause financial losses but can also damage reputations and client trust.

The Solution: To ensure high-quality dry ice production, businesses should prioritize sourcing machines from reputable manufacturers known for their quality control processes. When selecting a dry ice machine, look for features such as precise temperature regulation and materials that enhance insulation. Regular maintenance and calibration of the machine are also essential. Implementing a routine quality check of the dry ice produced will help identify any inconsistencies early. Training staff on best practices for handling and storing dry ice can further mitigate quality issues, ensuring that the dry ice remains effective throughout its use.

Scenario 2: High Operating Costs Deter Investment in Dry Ice Machines

The Problem: A common concern for international B2B buyers, especially in regions like the Middle East, is the high operating costs associated with dry ice machines. These costs can include electricity consumption, maintenance, and the price of raw materials. Businesses may hesitate to invest in these machines due to fears that the operational expenses will outweigh the benefits, leading to missed opportunities in markets that require reliable cold chain solutions.

The Solution: To address the issue of high operating costs, buyers should conduct a comprehensive cost-benefit analysis before purchasing a dry ice machine. Look for energy-efficient models that offer lower electricity consumption and consider the total cost of ownership, which includes initial purchase price, maintenance, and operating costs over time. Additionally, establishing a partnership with local suppliers for dry ice production can reduce transportation costs and improve supply chain efficiency. Exploring financing options or leasing arrangements may also make acquiring a dry ice machine more financially feasible, allowing businesses to take advantage of the benefits without incurring prohibitive costs upfront.

Scenario 3: Difficulty in Sourcing Replacement Parts and Support

The Problem: A significant pain point for B2B buyers is the challenge of sourcing replacement parts and technical support for dry ice machines. This issue can be particularly pronounced for companies in South America, where access to specialized equipment and service providers may be limited. When machines break down, businesses face downtime, which can disrupt operations and lead to financial losses.

The Solution: To mitigate difficulties in obtaining replacement parts and support, B2B buyers should choose dry ice machines from manufacturers with a strong global presence and a reliable network of local distributors. Before purchasing, inquire about the availability of spare parts and the manufacturer’s commitment to after-sales support. Establishing a maintenance contract with the supplier can also provide peace of mind and ensure timely assistance when issues arise. Additionally, creating a stock of commonly needed spare parts can minimize downtime, allowing businesses to maintain operational continuity and avoid costly interruptions.

Strategic Material Selection Guide for dry ice machine

When selecting materials for dry ice machines, international B2B buyers must consider a variety of factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in the construction of dry ice machines, focusing on their properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Dry Ice Machines?

Stainless steel is widely used in dry ice machines due to its excellent corrosion resistance and strength. It typically has a high-temperature rating, making it suitable for environments where thermal stability is crucial. The most common grades used are 304 and 316, with 316 offering better resistance to chlorides, which is beneficial in coastal regions.

Pros: Stainless steel is durable and can withstand the rigors of industrial use. It is also easy to clean, which is essential for maintaining hygiene in applications like food processing.

Cons: The primary downside is the cost, as stainless steel can be more expensive than alternative materials. Additionally, its manufacturing complexity can lead to longer lead times.

Impact on Application: Stainless steel is compatible with various media, including food and pharmaceuticals, making it a versatile choice for multiple applications.

Considerations for Buyers: Buyers from regions like Europe should ensure compliance with EU regulations regarding food safety, while those in Africa may need to consider local availability and sourcing options to keep costs manageable.

How Does Aluminum Compare as a Material for Dry Ice Machines?

Aluminum is another popular choice for dry ice machines, particularly due to its lightweight nature and good thermal conductivity. It is often used in components that require rapid cooling and heat dissipation.

Pros: Aluminum is generally less expensive than stainless steel and offers a good balance between weight and strength. Its excellent thermal properties make it ideal for applications requiring efficient heat transfer.

Cons: Aluminum is less durable than stainless steel and can corrode if not properly coated or treated. It also has a lower temperature rating, which may limit its use in high-pressure environments.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable dry ice machines.

Considerations for Buyers: In South America, where aluminum is widely available, buyers should focus on ensuring that the material meets local standards, such as INMETRO in Brazil.

What Role Does Plastic Play in Dry Ice Machine Construction?

Certain high-performance plastics, such as polycarbonate and polyethylene, are used in dry ice machines for components that require insulation and impact resistance. These materials are particularly useful in areas where weight reduction is essential.

Pros: Plastics are generally less expensive and easier to mold into complex shapes. They also provide excellent insulation properties, which can enhance energy efficiency.

Cons: The main limitation is that plastics may not withstand extreme temperatures as well as metals, which can lead to deformation or failure in high-stress environments.

Impact on Application: Plastic components are often used in non-structural parts, such as housings and insulation layers, where weight and insulation are priorities.

Considerations for Buyers: Buyers in the Middle East should ensure that the plastics used are compliant with local environmental regulations, as some plastics may have restrictions based on their recyclability.

How Does Carbon Steel Fit into the Material Selection for Dry Ice Machines?

Carbon steel is occasionally used in dry ice machines, particularly for structural components. It offers a good balance of strength and cost-effectiveness.

Pros: Carbon steel is strong and can be treated to enhance its corrosion resistance. It is also relatively inexpensive compared to stainless steel.

Cons: However, it is more prone to rusting and may require additional coatings or treatments to prevent corrosion, especially in humid environments.

Impact on Application: Carbon steel is suitable for internal components that do not come into direct contact with dry ice or other corrosive materials.

Considerations for Buyers: European buyers should be aware of the relevant standards, such as EN 10025, to ensure that the carbon steel used meets quality requirements.

Summary Table of Material Selection for Dry Ice Machines

| Material | Typical Use Case for dry ice machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food-grade applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable machines, heat exchangers | Lightweight and good thermal conductivity | Lower durability and corrosion risk | Medium |

| Plastic | Insulation and housing components | Cost-effective and good insulation | Limited temperature tolerance | Low |

| Carbon Steel | Non-contact structural components | Cost-effective and strong | Prone to rust without treatment | Low |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing dry ice machines, ensuring compliance and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for dry ice machine

What are the Main Stages in the Manufacturing Process of Dry Ice Machines?

The manufacturing process of dry ice machines involves several critical stages that ensure efficiency and quality in production.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically stainless steel and specialized alloys. These materials are chosen for their durability and resistance to low temperatures. Suppliers should provide certifications for the materials used, ensuring they meet specific standards.

-

Forming: In this stage, the raw materials are shaped into the required components using techniques such as stamping, bending, and machining. Advanced CNC (Computer Numerical Control) machines are often employed to ensure precision. This stage is crucial because any inaccuracies can lead to inefficiencies or failures in the final product.

-

Assembly: The individual components are then assembled into the dry ice machine. This process may involve both manual and automated techniques, depending on the complexity of the machine. Skilled labor is essential here to ensure that all parts fit together correctly and function as intended.

-

Finishing: Finally, the machines undergo finishing processes, including surface treatment to prevent corrosion and enhance aesthetics. Techniques such as powder coating or anodizing are common. This stage is vital for the long-term performance of the machine, particularly in harsh environments.

How is Quality Assurance Implemented in Dry Ice Machine Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process for dry ice machines, ensuring that each unit meets industry standards and customer expectations.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 play a significant role in the QA process. ISO 9001 focuses on quality management systems and is crucial for maintaining consistent quality in manufacturing. Other relevant certifications may include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Certification: Particularly important in industrial applications, this certification ensures the equipment meets stringent performance standards.

These certifications not only signify quality but also facilitate smoother international trade, especially for buyers in regions like Africa, South America, the Middle East, and Europe.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. The typical checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, continuous checks are made to monitor production quality. This can include measuring dimensions, testing mechanical properties, and verifying assembly integrity.

- Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing. This may involve functional testing, safety checks, and performance evaluations to ensure the machine operates correctly and efficiently.

What Common Testing Methods are Used in Quality Assurance?

Several testing methods are commonly employed to ensure the reliability of dry ice machines:

- Pressure Testing: Ensures that the machine can withstand operational pressures without leaks.

- Temperature Testing: Verifies that the machine can maintain the required low temperatures during operation.

- Performance Testing: Assesses the machine’s efficiency in producing dry ice, measuring output rates and energy consumption.

These tests are essential for B2B buyers to confirm the machine’s capabilities and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s QC processes is crucial. Here are actionable steps to ensure quality:

-

Conduct Supplier Audits: Regular audits can provide insights into the supplier’s manufacturing processes and quality control measures. This can be done by the buyer or a third-party auditor.

-

Request Quality Reports: Suppliers should be willing to share their quality control reports, including details of any tests conducted and their results. Look for consistency in results over time.

-

Third-Party Inspections: Engage third-party inspection services to evaluate the manufacturing facilities and processes. This adds an additional layer of assurance regarding quality.

What are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers need to be aware of specific nuances regarding quality control and certification.

-

Regional Compliance: Different regions may have varying regulations. For instance, CE marking is essential for machines sold in Europe but may not be recognized in other markets. Buyers should ensure that their suppliers comply with the relevant standards in their operational regions.

-

Documentation and Traceability: It is essential to maintain comprehensive documentation of all QC processes and certifications. This is particularly important for buyers from regions with strict import regulations, such as the EU.

-

Cultural Differences: Understanding cultural differences in business practices can aid in better communication with suppliers, especially in regions like Africa and the Middle East, where relationship-building is often key to successful negotiations.

Conclusion

A stock image related to dry ice machine.

Understanding the manufacturing processes and quality assurance measures for dry ice machines is essential for B2B buyers looking to make informed purchasing decisions. By focusing on the main stages of manufacturing, relevant international standards, key QC checkpoints, and effective verification methods, buyers can ensure they are investing in reliable and efficient machinery that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dry ice machine’

Introduction

When sourcing a dry ice machine, it’s essential to follow a structured approach to ensure you make informed decisions that align with your operational needs. This guide provides an actionable checklist designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. By adhering to these steps, you can streamline the procurement process and mitigate risks associated with sourcing equipment.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of a successful procurement process. Identify the production capacity, size, and type of dry ice machine that suits your operational requirements. Consider factors such as the frequency of use, the volume of dry ice needed, and the environment in which the machine will operate.

- Capacity Requirements: Determine how much dry ice you need daily.

- Type of Machine: Decide between batch or continuous production based on your needs.

Step 2: Conduct Market Research

Before selecting a supplier, conduct thorough market research to understand the landscape of available products. Investigate different manufacturers and models, and compare features, prices, and after-sales services. This step helps in identifying trends and potential suppliers that meet your requirements.

- Explore Reviews and Testimonials: Look for feedback from other businesses in your industry.

- Analyze Competitor Choices: See what machines similar companies are using.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures that you partner with a reliable supplier who can meet your needs effectively.

- Check Supplier Experience: Look for suppliers with a proven track record in your industry.

- Request Product Demos: If possible, see the machine in action to assess its performance.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you consider hold the necessary certifications and comply with international standards. Certifications can indicate quality assurance and adherence to safety regulations, which are particularly important for equipment like dry ice machines.

- ISO Certifications: Look for ISO 9001 or similar quality management standards.

- Safety Compliance: Ensure compliance with local and international safety regulations.

Step 5: Assess After-Sales Support and Warranty

After-sales support is vital to ensure the longevity and efficiency of your dry ice machine. Investigate what kind of technical support, training, and maintenance services are offered by the supplier. Additionally, review warranty terms to understand what is covered and for how long.

- Technical Support Availability: Confirm if support is available 24/7 or during business hours.

- Warranty Coverage: Understand the specifics of what the warranty covers, including parts and labor.

Step 6: Negotiate Pricing and Payment Terms

Once you have shortlisted potential suppliers, engage in negotiations to secure favorable pricing and payment terms. Consider bulk purchase discounts or extended payment plans, especially if your initial order is significant.

- Request Detailed Quotes: Ensure that quotes include all costs, such as shipping and installation.

- Discuss Payment Flexibility: Explore options for payment plans that suit your cash flow.

Step 7: Finalize Purchase and Plan for Installation

After selecting the supplier and agreeing on terms, finalize the purchase. Plan for the installation of the dry ice machine, considering any logistical challenges that may arise. Make sure to communicate with the supplier about installation requirements and timelines.

- Coordinate Installation: Schedule the installation to minimize disruption to your operations.

- Train Staff: Ensure that your team is adequately trained to operate and maintain the machine effectively.

By following these steps, B2B buyers can navigate the complexities of sourcing a dry ice machine with confidence, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for dry ice machine Sourcing

What Are the Key Cost Components for Sourcing a Dry Ice Machine?

When evaluating the total cost structure of sourcing a dry ice machine, several key components come into play. Understanding these can help international B2B buyers make informed decisions and optimize their procurement strategies.

-

Materials: The type of materials used in manufacturing dry ice machines significantly influences the overall cost. High-grade steel and specialized insulation materials may incur higher initial costs but provide durability and efficiency over time.

-

Labor: Labor costs can vary widely based on geographic location. Countries with lower labor costs might offer a competitive edge, but it’s essential to consider the skill level and expertise of the workforce, which can impact the quality of the machine.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and indirect labor. Depending on the supplier’s operational efficiency, these costs can affect the final pricing of the dry ice machine.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for machines with unique specifications. Buyers should inquire about the tooling costs and whether they can be amortized over larger orders.

-

Quality Control (QC): A robust QC process ensures that the machines meet required specifications and standards, which can add to the overall cost. However, investing in quality control can prevent costly defects and enhance long-term reliability.

-

Logistics: Shipping and handling are critical cost factors, especially for international buyers. Incoterms, shipping distances, and transportation modes will influence logistics costs and should be factored into the total cost analysis.

-

Margin: Supplier profit margins vary based on market conditions, brand reputation, and exclusivity. Understanding the market landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect the Sourcing of Dry Ice Machines?

Several factors can influence the pricing of dry ice machines beyond the basic cost components. Recognizing these can provide buyers with leverage in negotiations.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should evaluate their needs and consider consolidating purchases to achieve better pricing.

-

Specifications and Customization: Customized machines tailored to specific operational needs may come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Materials and Quality Certifications: Machines made with higher quality materials and those that meet international standards (like ISO certifications) might command higher prices. However, these investments can lead to long-term savings through increased efficiency and reduced maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers may charge more but provide assurances regarding quality and service, which can be critical for international operations.

-

Incoterms: The agreed-upon Incoterms can impact the total landed cost. Understanding whether costs for shipping, insurance, and duties are included in the quoted price is crucial for accurate budgeting.

What Tips Can Help International Buyers Optimize Their Dry Ice Machine Sourcing Costs?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective sourcing strategies can lead to substantial cost savings.

-

Negotiate Terms: Leverage your purchasing power by negotiating terms with suppliers. This could include price breaks for larger orders or favorable payment terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the operational costs, including energy consumption, maintenance, and potential downtime. A lower initial cost may lead to higher operational expenses over time.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends and market conditions. This knowledge can aid in negotiations and help identify competitive suppliers.

-

Research Local Suppliers: Explore local manufacturing options to reduce shipping costs and improve lead times. Local suppliers may also offer more flexible payment terms.

-

Stay Informed on Regulatory Standards: Ensure that the machine complies with local regulations and standards, which can prevent unexpected costs related to compliance.

By considering these aspects, international B2B buyers can make more informed decisions and enhance their sourcing strategies for dry ice machines.

Disclaimer: Prices are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always consult with multiple suppliers for accurate pricing tailored to your needs.

Alternatives Analysis: Comparing dry ice machine With Other Solutions

Understanding the Importance of Alternatives in Dry Ice Solutions

When considering the use of a dry ice machine, it’s essential to evaluate alternative solutions that may meet your business needs effectively. Different industries have unique requirements for cooling and freezing applications, and understanding the strengths and weaknesses of various options can lead to more informed purchasing decisions. This analysis compares dry ice machines with two viable alternatives: liquid nitrogen systems and gel packs, providing insights tailored for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

Comparison Table of Dry Ice Machine vs Alternatives

| Comparison Aspect | Dry Ice Machine | Liquid Nitrogen System | Gel Packs |

|---|---|---|---|

| Performance | High cooling capacity | Extremely high cooling | Moderate cooling |

| Cost | Moderate initial cost | High operational cost | Low initial cost |

| Ease of Implementation | Requires training | Requires specialized handling | Very easy to use |

| Maintenance | Low maintenance | Regular maintenance needed | Minimal maintenance |

| Best Use Case | Shipping perishables | Cryogenic applications | Short-term cooling |

What Are the Pros and Cons of Liquid Nitrogen Systems?

Liquid nitrogen systems are known for their extremely high cooling capacity, making them ideal for applications that require rapid temperature drops, such as cryogenic preservation. However, the operational costs can be significant, especially when factoring in the need for specialized equipment and safety protocols. Implementing a liquid nitrogen system often requires trained personnel to handle the substance safely, which can complicate the logistics for businesses in regions with limited access to trained staff. Therefore, while they are suitable for specific high-tech applications, the complexity and cost may be prohibitive for many B2B buyers.

How Do Gel Packs Compare as a Cooling Solution?

Gel packs are a popular alternative for businesses seeking a low-cost, easy-to-use cooling solution. They are widely available, require no specialized training, and involve minimal maintenance. However, gel packs offer only moderate cooling capacity, which may not be sufficient for shipping perishables over long distances or for high-volume applications. They are best suited for short-term cooling needs, such as transporting small food items or pharmaceuticals. For companies looking for an economical solution for lighter applications, gel packs can be a viable option, but they may not meet the demands of more extensive shipping operations.

A stock image related to dry ice machine.

Conclusion: How to Choose the Right Cooling Solution for Your Business

Selecting the appropriate cooling solution depends on various factors, including your specific application, budget constraints, and operational capabilities. A dry ice machine is an excellent choice for businesses focused on shipping perishables and needing a reliable, high-capacity cooling method. In contrast, liquid nitrogen systems may cater to industries requiring extreme cooling but come with higher costs and complexities. Gel packs serve as a practical solution for short-term cooling needs but may lack the performance for more demanding applications. By carefully evaluating these alternatives, international B2B buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for dry ice machine

What Are the Key Technical Properties of a Dry Ice Machine?

When evaluating dry ice machines, understanding their technical specifications is crucial for ensuring optimal performance and reliability in your operations. Here are some essential properties to consider:

1. Material Grade

The construction material of a dry ice machine significantly impacts its durability and performance. High-grade stainless steel is commonly used for components that come into contact with dry ice, as it resists corrosion and withstands low temperatures. B2B buyers should prioritize machines made from materials that ensure longevity and reduce maintenance costs.

2. Production Capacity

This specification indicates the amount of dry ice a machine can produce within a given time frame, typically measured in kilograms per hour. For businesses with high-volume needs, selecting a machine with a suitable production capacity is essential to maintain supply without interruptions. Understanding your operational requirements will help you select the right capacity.

3. Tolerance Levels

Tolerance refers to the acceptable limits of variation in the dimensions of the machine’s components. High tolerance levels ensure that parts fit together accurately, which is vital for the machine’s efficiency and safety. Inaccurate tolerances can lead to inefficiencies, increased wear, and potential hazards, making it a critical factor for B2B buyers.

4. Energy Efficiency Rating

Energy efficiency is becoming increasingly important in manufacturing processes due to rising operational costs and environmental concerns. A dry ice machine with a high energy efficiency rating can significantly reduce electricity consumption and costs. Buyers should inquire about energy ratings and certifications to make informed decisions that align with their sustainability goals.

5. Cooling Technology

Different dry ice machines utilize various cooling technologies, such as vapor compression or thermoelectric systems. The choice of cooling technology can affect the machine’s efficiency, maintenance requirements, and operational costs. Understanding the advantages and disadvantages of each type will enable buyers to select a machine that best fits their operational needs.

What Are Common Trade Terms Related to Dry Ice Machines?

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some commonly used terms in the industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When purchasing a dry ice machine, understanding whether the supplier is an OEM can affect warranty terms and service support. B2B buyers should ensure they are dealing with reputable OEMs to guarantee quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for bulk purchases of dry ice machines or associated components. Buyers should negotiate MOQs to ensure they align with their purchasing capabilities and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should prepare comprehensive RFQs that outline their requirements clearly to receive accurate and competitive quotes from multiple suppliers, aiding in informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms can help B2B buyers clarify shipping responsibilities, costs, and risks associated with importing dry ice machines. Familiarity with Incoterms can prevent misunderstandings and disputes during the purchasing process.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. This term is crucial for B2B buyers who rely on timely deliveries to maintain their operations. Understanding lead times can help in planning and ensuring that production schedules remain uninterrupted.

By familiarizing yourself with these essential technical properties and trade terms, you can make more informed purchasing decisions regarding dry ice machines, ultimately enhancing your operational efficiency and effectiveness in your respective market.

Navigating Market Dynamics and Sourcing Trends in the dry ice machine Sector

What Are the Key Market Drivers for Dry Ice Machines?

The dry ice machine market is currently experiencing significant growth, driven by several global factors. The increasing demand for dry ice across various industries, particularly food and beverage, healthcare, and logistics, is a primary driver. As international trade expands, the need for reliable refrigeration solutions has surged, particularly in regions like Africa and South America, where infrastructure is rapidly developing. The rise in e-commerce and the distribution of temperature-sensitive products have also propelled the need for efficient dry ice production technologies.

Moreover, advancements in B2B technology are reshaping sourcing trends. Automation and smart technologies are being integrated into dry ice machines, enhancing efficiency and reducing operational costs. Buyers are increasingly looking for machines that offer real-time monitoring and predictive maintenance capabilities, which can significantly minimize downtime and improve supply chain efficiency. Additionally, the ongoing digital transformation has led to a rise in online platforms for sourcing machinery, making it easier for international buyers from regions such as the Middle East and Europe to access a broader range of suppliers and competitive pricing.

How Can Sustainability Influence Your Sourcing Decisions for Dry Ice Machines?

Sustainability is becoming a critical factor for B2B buyers in the dry ice machine sector. The environmental impact of production processes is under scrutiny, and companies are increasingly pressured to adopt ethical sourcing practices. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and processes. For instance, sourcing machines that utilize renewable energy for operations can significantly reduce a company’s carbon footprint.

Moreover, certifications such as ISO 14001 for environmental management systems can serve as a benchmark for assessing a supplier’s commitment to sustainable practices. By choosing suppliers with green certifications, buyers can not only enhance their brand image but also align with regulatory requirements that are becoming more stringent across various regions, including Europe and parts of South America.

Investing in sustainable dry ice machine technologies can also yield long-term cost savings by reducing energy consumption and waste. As consumers and businesses alike become more environmentally conscious, aligning with sustainable practices can also open doors to new market opportunities.

What is the Historical Context of Dry Ice Machines in B2B Markets?

The evolution of dry ice machines dates back to the early 20th century when dry ice was first produced as a cooling agent. Initially, its use was limited to industrial applications due to the lack of advanced production technologies. However, as the food and beverage sector began to recognize the benefits of dry ice for preserving perishables during transportation, the demand for dry ice machines started to grow.

Over the decades, technological advancements have led to the development of more efficient and compact machines, making dry ice production accessible to a broader range of businesses. The introduction of automated systems and smart technologies in recent years has further transformed the sector, allowing for enhanced operational efficiency and lower production costs. Today, as B2B buyers navigate an increasingly competitive market, understanding the historical context of dry ice machines can provide valuable insights into the evolution of sourcing trends and the potential for future innovations.

In summary, international B2B buyers must stay informed about market dynamics, prioritize sustainability, and leverage technological advancements when sourcing dry ice machines to remain competitive in a rapidly evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of dry ice machine

-

How do I choose the right dry ice machine for my business needs?

Choosing the right dry ice machine involves assessing your production capacity, the scale of your operations, and the specific applications of dry ice in your business. Consider factors like the machine’s output rate, size, and energy consumption. Additionally, evaluate the support and maintenance services offered by suppliers. It’s advisable to request demonstrations or trials, if possible, to ensure the machine meets your operational requirements. -

What are the key features to look for in a dry ice machine?

When selecting a dry ice machine, look for features such as automation capabilities, safety mechanisms, ease of operation, and maintenance requirements. A good machine should have a reliable cooling system, efficient dry ice production rate, and compatibility with various applications like food preservation or shipping. Additionally, consider the machine’s energy efficiency, which can significantly affect operational costs over time. -

What is the typical lead time for ordering a dry ice machine from international suppliers?

Lead times can vary significantly based on the supplier’s location, production capacity, and shipping method. Typically, you can expect a lead time ranging from 4 to 12 weeks. It’s crucial to communicate clearly with suppliers about your timeline and needs. Always factor in additional time for customs clearance and local regulations, especially when importing machines into regions like Africa or South America. -

What are the common payment terms for purchasing a dry ice machine?

Payment terms can differ among suppliers, but common practices include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. For larger transactions, consider negotiating payment terms that allow for secure escrow arrangements or letters of credit. Always clarify these terms in your contract to avoid any misunderstandings. -

How can I verify the credibility of a dry ice machine supplier?

To vet suppliers, conduct thorough research using industry directories, customer reviews, and testimonials. Request references from previous clients and check their track record for on-time delivery and product quality. Participating in trade shows or industry conferences can also provide opportunities to meet suppliers in person and assess their capabilities directly. -

What are the minimum order quantities (MOQ) for dry ice machines?

Minimum order quantities can vary based on the manufacturer and the specific model of the dry ice machine. Some suppliers may have an MOQ of one unit, while others might require bulk orders for better pricing. When negotiating, clarify the MOQ and consider discussing flexible options if you’re testing the market or starting small. -

What logistics considerations should I keep in mind when importing a dry ice machine?

When importing a dry ice machine, consider shipping costs, customs duties, and local regulations regarding equipment importation. Work with logistics providers experienced in international trade to ensure compliance and timely delivery. Additionally, factor in installation and training costs for your team to effectively operate the machine upon arrival. -

What quality assurance measures should I expect from dry ice machine suppliers?

Reputable suppliers should provide quality assurance certifications, such as ISO or CE markings, indicating compliance with international safety and quality standards. Inquire about their testing procedures, warranty terms, and after-sales support. It’s beneficial to request a detailed service agreement to ensure you receive adequate support for maintenance and repairs throughout the machine’s lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dry ice machine

In the realm of B2B procurement, strategic sourcing of dry ice machines stands as a pivotal factor for enhancing operational efficiency and reducing costs. Buyers from Africa, South America, the Middle East, and Europe must prioritize thorough market research and supplier evaluations to identify the most reliable manufacturers. Understanding regional regulations, logistical considerations, and supplier capabilities can significantly influence purchasing decisions.

Investing in high-quality dry ice machines not only ensures consistent performance but also supports sustainability initiatives through reduced waste and energy consumption. By leveraging strategic partnerships, businesses can enhance their supply chain resilience and respond more adeptly to market fluctuations.

Looking ahead, the dry ice machine market is expected to witness innovation and growth driven by increased demand across various sectors, including food preservation, pharmaceuticals, and logistics. International B2B buyers should remain proactive in exploring technological advancements and emerging market trends to stay competitive.

Now is the time to refine your sourcing strategies and engage with reputable suppliers who can meet your specific needs. Embrace this opportunity to elevate your business operations and secure a sustainable future in the global marketplace.