Maximize Quality: The Ultimate Ricoma Embroidery Machine Guide (2025)

Introduction: Navigating the Global Market for ricoma embroidery machine

Navigating the complexities of sourcing a Ricoma embroidery machine can be a daunting challenge for international B2B buyers, especially when considering the diverse market landscapes across Africa, South America, the Middle East, and Europe. This guide aims to demystify the procurement process by providing a comprehensive overview of the various types of Ricoma machines, their applications, and the critical factors to consider when evaluating suppliers. By understanding the nuances of machine specifications and supplier reliability, businesses can make informed purchasing decisions that align with their operational needs and budget constraints.

With the embroidery market experiencing significant growth, driven by the increasing demand for customized textile products, it is essential for buyers to stay informed about the latest advancements in embroidery technology. This guide will delve into key aspects such as cost analysis, maintenance requirements, and value-added services that suppliers offer. Furthermore, we will explore how to effectively vet potential suppliers to ensure quality and reliability in your investments.

Empowering international buyers with actionable insights, this guide serves as a vital resource for those looking to enhance their production capabilities through strategic sourcing of Ricoma embroidery machines. Whether you are a seasoned buyer or new to the embroidery industry, the information provided here will equip you with the tools necessary to navigate the global market confidently.

Understanding ricoma embroidery machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Head Embroidery Machine | Compact design, suitable for small businesses; one needle | Custom logos, small batch production | Pros: Cost-effective, easy to use. Cons: Limited production speed. |

| Multi-Head Embroidery Machine | Multiple heads for simultaneous embroidery; higher output | Large scale manufacturing, promotional items | Pros: High efficiency, reduced labor costs. Cons: Higher initial investment. |

| Flatbed Embroidery Machine | Large flat surface for bulk items; versatile for different fabrics | Apparel, bags, and home textiles | Pros: Suitable for large designs, adaptable. Cons: Requires more floor space. |

| Cap Embroidery Machine | Specialized for caps and hats; curved sewing capabilities | Sportswear, promotional caps | Pros: High-quality cap designs, tailored for headgear. Cons: Limited to cap production. |

| Industrial Embroidery Machine | Heavy-duty, high-speed operation; designed for long runs | Mass production in factories | Pros: Extremely durable, high volume output. Cons: Complex setup, maintenance costs. |

What Are the Key Characteristics of Single-Head Embroidery Machines?

Single-head embroidery machines are designed for small businesses or individual entrepreneurs focusing on custom embroidery. They typically feature one needle and a compact design, making them ideal for small batch productions and personalized items like logos on clothing. When considering a purchase, buyers should evaluate their production needs and budget, as these machines are generally more affordable but may not keep up with high-volume demands.

How Do Multi-Head Embroidery Machines Enhance Production Efficiency?

Multi-head embroidery machines significantly boost productivity by allowing multiple designs to be embroidered simultaneously. These machines are ideal for businesses that require large quantities of embroidered items, such as promotional products or uniforms. Buyers should consider the initial investment and the potential for reduced labor costs, as the increased output can lead to higher profit margins over time.

Why Choose Flatbed Embroidery Machines for Versatile Applications?

Flatbed embroidery machines provide a large flat surface, making them suitable for various applications, including apparel and home textiles. Their versatility allows businesses to work with different fabric types and sizes, accommodating larger designs. Buyers should assess their workspace requirements and the range of products they intend to produce, as these machines can take up more floor space compared to other models.

What Advantages Do Cap Embroidery Machines Offer for Niche Markets?

Cap embroidery machines are specialized for creating intricate designs on caps and hats, featuring curved sewing capabilities. They are perfect for businesses in the sportswear and promotional merchandise sectors. Buyers should consider their target market and production volume, as these machines excel in producing high-quality headgear but may limit the types of products that can be embroidered.

How Do Industrial Embroidery Machines Support Mass Production?

Industrial embroidery machines are built for high-speed operations and long production runs, making them ideal for factories and large-scale manufacturers. These heavy-duty machines can handle substantial workloads and are designed for durability. However, potential buyers should consider the complexity of setup and maintenance costs, as these machines require a more significant investment and technical expertise to operate efficiently.

Related Video: How I Use My Ricoma Embroidery Machine

Key Industrial Applications of ricoma embroidery machine

| Industry/Sector | Specific Application of ricoma embroidery machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Custom logo embroidery on clothing | Enhances brand visibility and personalization | Ensure machine supports diverse fabrics and intricate designs |

| Promotional Products | Embroidered promotional merchandise | Increases product appeal and customer engagement | Look for high-speed production capabilities |

| Home Textiles | Decorative embroidery on cushions and curtains | Adds aesthetic value and differentiation | Consider color variety and thread durability |

| Sportswear | Performance apparel with embroidered designs | Combines functionality with brand identity | Verify moisture-wicking capabilities and fabric compatibility |

| Corporate Gifts | Personalized embroidered gifts for clients | Strengthens client relationships and loyalty | Assess options for bulk production and customization |

How is the Ricoma Embroidery Machine Used in Apparel Manufacturing?

In the apparel manufacturing sector, the Ricoma embroidery machine is utilized for creating custom logos and designs on garments. This application is essential for enhancing brand visibility and personalization. Manufacturers can produce high-quality embroidered clothing, which not only attracts customers but also fosters brand loyalty. International buyers should consider sourcing machines that can handle various fabric types, ensuring versatility in their production lines.

What Role Does the Ricoma Embroidery Machine Play in Promotional Products?

For businesses focused on promotional products, the Ricoma embroidery machine serves as a critical tool for producing embroidered merchandise, such as caps, bags, and t-shirts. This application increases product appeal, allowing companies to engage customers through unique branding opportunities. B2B buyers should prioritize machines with high-speed production capabilities to meet the demands of large orders and quick turnarounds, especially in competitive markets.

How is the Ricoma Embroidery Machine Beneficial for Home Textiles?

In the home textiles industry, the Ricoma embroidery machine is employed to create decorative elements on items like cushions and curtains. This application adds aesthetic value and differentiation in a crowded market. Buyers from Africa, South America, the Middle East, and Europe should consider machines that offer a wide range of thread colors and durability, ensuring that the final products can withstand consumer use while maintaining visual appeal.

How Does the Ricoma Embroidery Machine Enhance Sportswear Production?

The sportswear sector leverages the Ricoma embroidery machine for adding embroidered designs to performance apparel, merging functionality with brand identity. This application is crucial for creating visually appealing sportswear that resonates with consumers. When sourcing, it is essential for buyers to verify the machine’s compatibility with moisture-wicking fabrics and other technical materials to ensure optimal performance in activewear.

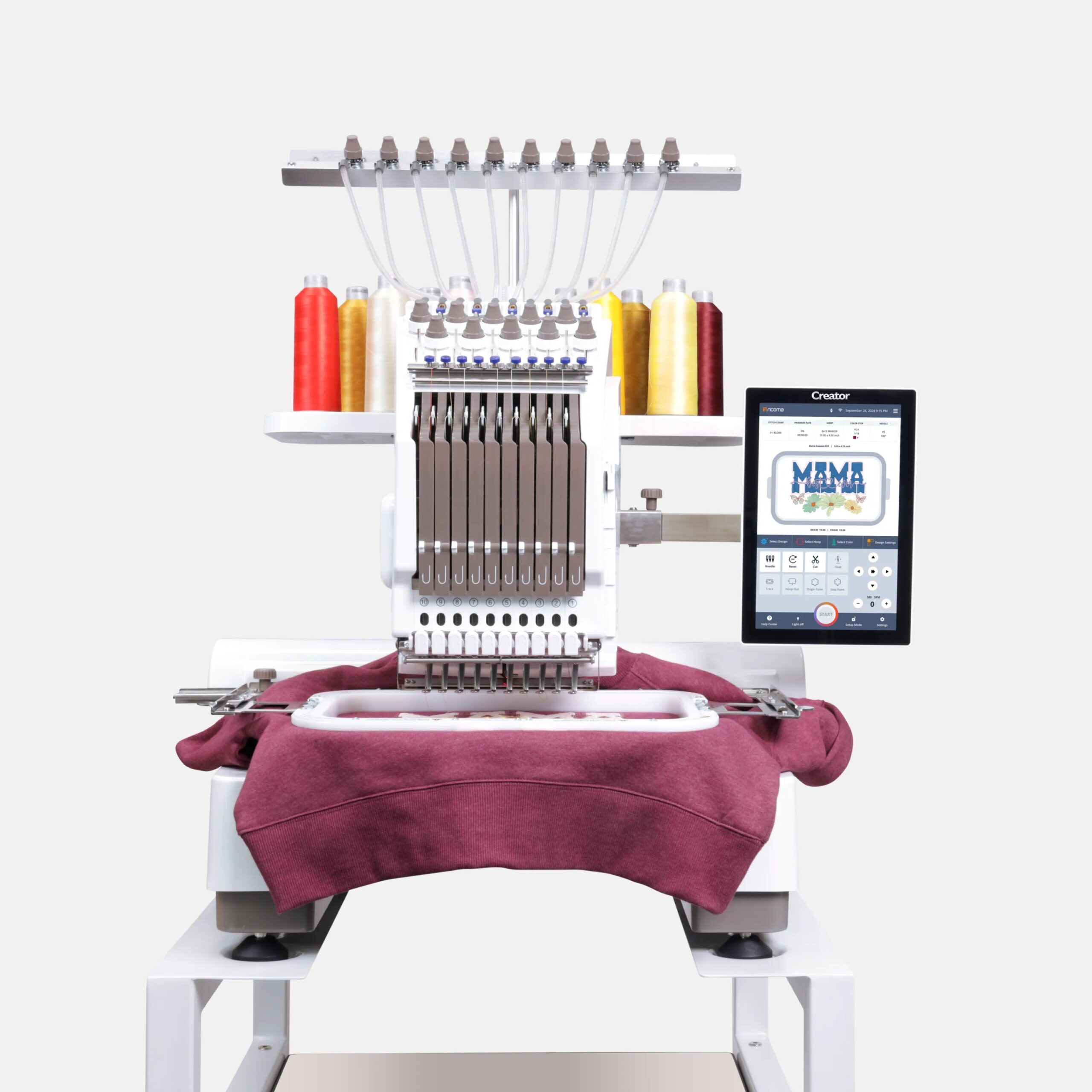

A stock image related to ricoma embroidery machine.

What are the Advantages of Using the Ricoma Embroidery Machine for Corporate Gifts?

In the realm of corporate gifts, the Ricoma embroidery machine is used to create personalized embroidered items for clients, such as towels, bags, and apparel. This application strengthens client relationships and enhances loyalty by providing thoughtful, branded gifts. B2B buyers should assess machines that offer options for bulk production and customization, allowing businesses to efficiently meet client demands while maintaining quality.

Related Video: Patch Embroidery From Start to Finish (Digitizing, Embroidery, Clean up) | Ricoma Embroidery Machine

3 Common User Pain Points for ‘ricoma embroidery machine’ & Their Solutions

Scenario 1: Managing Production Downtime Effectively with Ricoma Embroidery Machines

The Problem:

B2B buyers often encounter significant challenges with production downtime when using Ricoma embroidery machines. This downtime can stem from technical malfunctions, improper setup, or software issues, leading to delays in fulfilling customer orders. In industries such as fashion, promotional products, or custom textile production, these delays can not only affect revenue but also damage client relationships. Buyers in regions like Africa and South America may face additional hurdles due to limited access to immediate technical support and parts, exacerbating the situation.

The Solution:

To mitigate production downtime, it is crucial for buyers to implement a robust maintenance schedule for their Ricoma embroidery machines. This involves regular cleaning, lubrication, and inspection of key components such as the needle, thread tension, and bobbin. Additionally, buyers should invest in comprehensive training for their operators, ensuring they are well-versed in troubleshooting common issues.

Sourcing local technical support or establishing a service agreement with the machine supplier can provide faster response times for repairs. For buyers in remote areas, consider stocking essential spare parts to minimize delays. Utilizing the machine’s built-in diagnostic tools can also help preemptively identify issues before they escalate into significant problems.

Scenario 2: Customizing Designs Without Compromising Efficiency

The Problem:

A common pain point for B2B buyers utilizing Ricoma embroidery machines is the challenge of customizing designs while maintaining production efficiency. Many businesses require quick turnarounds on custom orders, but the complexity of digitizing new designs can slow down the production process. This becomes particularly problematic for businesses in Europe and the Middle East, where customer expectations for rapid delivery are high, and competition is fierce.

The Solution:

To streamline the design customization process, buyers should invest in advanced digitizing software that integrates seamlessly with Ricoma machines. This software should offer user-friendly features that allow operators to modify existing designs quickly, reducing the time spent on new digitization.

Additionally, consider creating a library of pre-digitized templates that can be quickly adjusted to meet specific customer needs. Training staff on efficient design workflows and leveraging automation features of the Ricoma machines can further enhance productivity. Collaborating with experienced digitizers or outsourcing complex designs to specialists can also help balance customization with efficiency, ensuring that orders are fulfilled on time without sacrificing quality.

Scenario 3: Addressing Quality Control Issues in Embroidery Production

The Problem:

Quality control is a significant concern for B2B buyers, especially when producing high-volume orders with Ricoma embroidery machines. Variations in thread tension, needle selection, and fabric types can lead to inconsistent results, resulting in rework and wasted materials. Buyers from South America and Africa, in particular, may face challenges related to sourcing high-quality materials that meet their production standards, further complicating quality assurance.

The Solution:

Implementing a stringent quality control process is essential to maintain high standards in embroidery production. Buyers should establish clear quality benchmarks and train their staff to recognize common quality issues, such as thread breaks or misalignments.

Investing in high-quality threads and fabrics that are compatible with Ricoma machines can also help minimize inconsistencies. Regularly calibrating the machine settings for different materials and conducting test runs before full production runs can ensure that quality remains consistent.

Additionally, integrating a feedback loop where operators can report issues and suggest improvements will foster a culture of quality awareness. Engaging with suppliers for better material options and exploring local partnerships can also provide access to superior resources, enhancing the overall quality of the finished products.

Strategic Material Selection Guide for ricoma embroidery machine

What Are the Key Materials for Ricoma Embroidery Machines?

When selecting materials for Ricoma embroidery machines, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and ensuring compatibility with various applications. Below, we analyze four common materials used in embroidery machine components, focusing on their key properties, pros and cons, and considerations for international B2B buyers.

Which Fabrics Are Commonly Used in Ricoma Embroidery Machines?

1. Polyester Fabric

Key Properties: Polyester fabric is known for its excellent durability, resistance to shrinking and stretching, and quick-drying capabilities. It can withstand a wide temperature range, making it suitable for various embroidery processes.

Pros & Cons: The main advantage of polyester is its strength and resistance to wrinkles and mildew. However, it can be more expensive than cotton and may not be as breathable, which can affect comfort in certain applications.

Impact on Application: Polyester is highly compatible with most embroidery threads and stabilizers, making it a popular choice for both commercial and custom designs.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the polyester meets local textile standards, such as ASTM or ISO certifications, to guarantee quality and performance.

How Does Cotton Compare as an Embroidery Material?

2. Cotton Fabric

Key Properties: Cotton is a natural fiber known for its softness, breathability, and hypoallergenic properties. It performs well under various conditions but has a lower resistance to heat compared to synthetic fabrics.

Pros & Cons: Cotton is generally more affordable and provides a comfortable feel, making it suitable for clothing. However, it is less durable than polyester and can shrink or fade over time, particularly when exposed to high temperatures.

Impact on Application: Cotton works well with most embroidery techniques, but its tendency to absorb moisture can lead to issues with thread tension and stability.

Considerations for International Buyers: Buyers in Europe may prefer organic cotton options due to increasing demand for sustainable materials. Compliance with EU regulations on textile labeling and safety is also essential.

What Role Does Nylon Play in Embroidery Machine Applications?

3. Nylon Fabric

Key Properties: Nylon is known for its high tensile strength, elasticity, and resistance to abrasion. It also has a low moisture absorption rate, making it suitable for outdoor applications.

Pros & Cons: The key advantage of nylon is its durability and resistance to wear and tear. However, it can be more challenging to embroider due to its slippery nature, which may require specialized techniques or stabilizers.

Impact on Application: Nylon is ideal for items that require high durability, such as outdoor gear or sportswear. Its compatibility with various threads makes it a versatile choice.

Considerations for International Buyers: Buyers from the Middle East should consider the high UV resistance of nylon, which is beneficial in hot climates. Compliance with local textile regulations is necessary to ensure product safety and quality.

How Does Rayon Fabric Enhance Embroidery Quality?

4. Rayon Fabric

Key Properties: Rayon is a semi-synthetic fiber that mimics the softness and drape of natural fibers. It has excellent dye-ability, resulting in vibrant colors, and offers good moisture absorption.

Pros & Cons: Rayon provides a luxurious finish and is often used for high-end embroidery projects. However, it is less durable than polyester and can be prone to fading and shrinking.

Impact on Application: Rayon is particularly suitable for decorative embroidery on garments and home textiles, where aesthetics are paramount.

Considerations for International Buyers: Buyers in Europe should be aware of the environmental impact of rayon production and may prefer sustainably sourced options. Compliance with local environmental regulations is also critical.

Summary Table of Material Selection for Ricoma Embroidery Machines

| Material | Typical Use Case for Ricoma Embroidery Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Commercial and custom designs | Excellent durability and quick-drying | More expensive than cotton | Medium |

| Cotton | Apparel and home textiles | Softness and breathability | Less durable, prone to shrinking | Low |

| Nylon | Outdoor gear and sportswear | High tensile strength and abrasion resistance | Difficult to embroider | Medium |

| Rayon | High-end decorative embroidery | Luxurious finish and vibrant colors | Less durable, prone to fading | Medium |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their specific needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ricoma embroidery machine

What Are the Main Stages of Manufacturing for Ricoma Embroidery Machines?

The manufacturing process for Ricoma embroidery machines involves several critical stages that ensure the production of high-quality, durable products. Understanding these stages is essential for B2B buyers to make informed purchasing decisions.

-

Material Preparation

– The first step involves sourcing high-quality raw materials, including metals, plastics, and electronic components. Suppliers should be vetted for their material quality, as this directly impacts the machine’s performance and longevity.

– Rigorous testing of incoming materials (Incoming Quality Control, or IQC) is crucial. This ensures that only materials meeting specified standards are used in production. -

Forming

– Forming processes, such as CNC machining and stamping, are employed to create the machine’s structural components. This stage requires precision to ensure that parts fit together correctly, which is critical for the machine’s overall functionality.

– Advanced technologies, such as laser cutting and robotic welding, may be utilized to enhance accuracy and efficiency during this phase. -

Assembly

– The assembly stage is where the machine components come together. Skilled technicians follow detailed assembly protocols to ensure that each machine is built to specifications.

– During this phase, In-Process Quality Control (IPQC) checkpoints are established to monitor the assembly process. Regular inspections are conducted to catch any defects early. -

Finishing

– After assembly, machines undergo finishing processes, including painting, coating, and final adjustments. This not only improves aesthetics but also protects against wear and corrosion.

– Final checks, including Full Quality Control (FQC), are performed to ensure that the machine operates as intended before it is packaged and shipped.

How Is Quality Assurance Implemented in Ricoma Embroidery Machines?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for Ricoma embroidery machines. It involves adhering to international standards and implementing robust QC protocols.

-

What International Quality Standards Are Relevant?

– Ricoma embroidery machines typically comply with international standards such as ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer adheres to strict quality assurance processes.

– Additionally, industry-specific certifications, such as CE marking (indicating compliance with European safety standards) and other relevant certifications (like API for certain components), are crucial for B2B buyers to consider. -

What Are the Key Quality Control Checkpoints?

– Incoming Quality Control (IQC): This initial checkpoint ensures that all materials meet quality standards before they enter the production line.

– In-Process Quality Control (IPQC): Conducted during the assembly phase, this checkpoint monitors the assembly processes and identifies any defects in real-time.

– Final Quality Control (FQC): This comprehensive assessment occurs after the machines are fully assembled and undergoes rigorous testing to ensure they meet all operational specifications. -

What Common Testing Methods Are Used?

– Various testing methods are employed to ensure quality, including functional testing, durability testing, and safety assessments. These tests help verify that the machines can handle the rigors of daily use in commercial environments.

– Performance metrics, such as stitching accuracy and speed, are also evaluated during testing to ensure that the machines operate at optimal levels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

-

Conducting Audits

– Buyers should request to conduct audits of the manufacturing facilities. This allows them to assess the quality management systems in place and ensure compliance with international standards.

– During an audit, buyers can evaluate the factory’s processes, check documentation, and observe production practices firsthand. -

Reviewing Quality Reports

– Suppliers should provide quality control reports that detail the results of IQC, IPQC, and FQC assessments. These documents should highlight any issues encountered during production and the corrective actions taken.

– Regular updates on quality metrics can also provide insights into the supplier’s ongoing commitment to maintaining high standards. -

Utilizing Third-Party Inspection Services

– Engaging third-party inspection agencies can provide an objective assessment of the supplier’s quality control processes. These agencies can perform inspections at various stages of the manufacturing process and provide unbiased reports to buyers.

– Third-party inspections can be particularly beneficial for buyers located far from the manufacturing site, as they ensure that quality standards are upheld without the need for frequent onsite visits.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the quality control landscape can be challenging for international B2B buyers. Understanding regional regulations and cultural nuances is essential for successful procurement.

-

Regional Compliance Requirements

– Different regions may have specific compliance requirements that must be met. For example, the EU has stringent regulations regarding machinery safety and environmental standards.

– Buyers should familiarize themselves with these regulations to ensure that the machines they purchase comply with local laws and standards. -

Cultural Considerations in Quality Assurance

– Cultural differences can impact quality perceptions and practices. Buyers from different regions may have varying expectations regarding quality and reliability.

– Building strong relationships with suppliers can facilitate better communication about quality expectations and help align practices with buyer requirements. -

Establishing Clear Quality Expectations

– It is crucial for buyers to communicate their quality expectations clearly from the outset. This includes specifying desired certifications, testing methods, and quality benchmarks.

– Clear contractual agreements regarding quality standards can help mitigate risks and ensure that both parties are aligned on expectations.

By understanding the manufacturing processes and quality assurance measures in place for Ricoma embroidery machines, international B2B buyers can make more informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ricoma embroidery machine’

Introduction: How to Effectively Source a Ricoma Embroidery Machine

Sourcing a Ricoma embroidery machine requires a strategic approach to ensure that the investment aligns with your business needs and operational goals. This checklist serves as a practical guide for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. By following these steps, you can navigate the procurement process with confidence and clarity.

Step 1: Define Your Technical Specifications

Identifying the technical specifications for the Ricoma embroidery machine you require is critical. Consider factors such as the type of embroidery (e.g., flat, cap, or 3D), the size of the embroidery field, and the number of needles. This clarity will help you filter suppliers that offer machines tailored to your needs.

- Consider your production volume: Evaluate how many garments you plan to produce to determine the machine’s capacity.

- Assess compatibility: Ensure the machine can handle the materials you intend to use.

Step 2: Conduct Market Research for Suppliers

Before making any commitments, perform thorough market research to identify reputable suppliers of Ricoma embroidery machines. Investigate their market presence, customer reviews, and service offerings.

- Utilize online platforms: Websites like Alibaba or industry-specific directories can provide insights into various suppliers.

- Check for local distributors: In regions like Africa or South America, local distributors can offer better support and service.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Ask for testimonials: Genuine reviews from existing customers can provide insights into reliability and service quality.

- Visit facilities if possible: A site visit can help assess the supplier’s operational capabilities and quality control processes.

Step 4: Verify Supplier Certifications

Ensure that your potential suppliers have the necessary certifications and comply with international standards. This step is vital for guaranteeing product quality and safety.

- Look for ISO certifications: These indicate adherence to quality management standards.

- Check for compliance with local regulations: Different regions may have specific requirements for machinery.

Step 5: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline the costs, payment terms, and warranty options. This will allow you to compare the offers accurately.

- Breakdown of costs: Ensure the quote includes all costs, such as shipping and installation.

- Warranty and support: Understanding warranty coverage and post-sale support is essential for long-term satisfaction.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to secure the best terms that fit your business model. Discuss payment terms, delivery schedules, and after-sales support to ensure clarity.

- Be clear about expectations: Define service levels and timelines to prevent misunderstandings.

- Consider long-term partnerships: Building a relationship with your supplier can lead to better terms in the future.

Step 7: Finalize the Purchase and Plan for Installation

Once terms are agreed upon, finalize the purchase by signing a contract that clearly states all terms and conditions. Plan for the installation process to ensure a smooth transition.

- Prepare your workspace: Ensure that your facility is ready to accommodate the new machine.

- Schedule training for staff: Proper training can maximize the machine’s capabilities and improve productivity.

By following these steps, you can confidently source a Ricoma embroidery machine that meets your business needs while ensuring a successful procurement process.

Comprehensive Cost and Pricing Analysis for ricoma embroidery machine Sourcing

What are the Key Cost Components in Sourcing Ricoma Embroidery Machines?

When sourcing Ricoma embroidery machines, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of raw materials, such as metal and electronic components, can significantly influence the overall price of the machine. High-quality materials may incur higher costs but can improve durability and performance.

-

Labor: Labor costs vary by region and can impact the final price. In countries with lower labor costs, such as Vietnam, the manufacturing cost might be reduced, allowing for competitive pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling for specific embroidery designs or machine specifications can add to the initial costs. Buyers should consider whether they require specialized tooling and how it affects the overall pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that machines meet high standards, but it can also increase costs. Buyers should evaluate the supplier’s QC practices and how they align with their quality expectations.

-

Logistics: Shipping and handling fees can vary widely based on the distance from the supplier, mode of transport, and shipping terms. International buyers should be aware of potential customs duties and taxes that may apply.

-

Margin: Suppliers will add a margin to cover their costs and make a profit. Understanding typical margins in the industry can help buyers assess whether they are getting a fair deal.

How Do Price Influencers Affect Ricoma Embroidery Machine Sourcing?

Several factors can influence the pricing of Ricoma embroidery machines:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Buyers should evaluate their production needs to determine optimal order sizes.

-

Specifications and Customization: Customized machines tailored to specific requirements may incur additional costs. Buyers should clarify their needs upfront to avoid unexpected expenses later.

-

Materials Quality and Certifications: Machines made from premium materials and those that meet international certifications may have higher prices but often provide better performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a track record of quality and service might charge more but offer better assurance of performance.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Buyers should select terms that align with their logistical capabilities and cost preferences.

What Are Essential Buyer Tips for Sourcing Ricoma Embroidery Machines?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance the sourcing process:

-

Negotiate Wisely: Engage in negotiations with suppliers to explore discounts or payment terms that can improve overall cost efficiency. Understanding market rates can bolster your negotiating position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operating costs, and potential downtime. A cheaper machine may lead to higher TCO if it requires frequent repairs.

-

Be Aware of Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and local market conditions can impact pricing. Buyers should factor these elements into their total cost calculations.

-

Conduct Supplier Audits: Before finalizing a purchase, conduct audits or request references to ensure the supplier’s capabilities align with your quality and delivery expectations.

-

Stay Informed About Market Trends: Keep abreast of trends in the embroidery machine market, including technological advancements and shifts in supplier dynamics, to make informed purchasing decisions.

Disclaimer on Indicative Prices

A stock image related to ricoma embroidery machine.

Prices for Ricoma embroidery machines can fluctuate based on various factors including market conditions, supplier changes, and international trade dynamics. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they are making well-informed purchasing decisions.

Alternatives Analysis: Comparing ricoma embroidery machine With Other Solutions

When considering the purchase of an embroidery machine, it’s crucial to explore various alternatives that might meet your specific business needs. The Ricoma embroidery machine is a well-known option in the market, but several other solutions can offer comparable performance and features. This section will provide a detailed analysis of the Ricoma machine against two viable alternatives: the Brother PR Series and the Janome Memory Craft Series.

Comparison Table of Embroidery Machines

| Comparison Aspect | Ricoma Embroidery Machine | Brother PR Series | Janome Memory Craft Series |

|---|---|---|---|

| Performance | High-speed, multi-needle | Versatile, strong for commercial use | User-friendly, good for home and small business |

| Cost | Moderate ($5,000 – $10,000) | Higher ($7,000 – $15,000) | Lower ($2,500 – $5,000) |

| Ease of Implementation | Requires training for optimal use | Moderate; user-friendly interface | Easy setup, intuitive controls |

| Maintenance | Regular upkeep needed; parts readily available | Low to moderate; reliable brand support | Low; less frequent servicing |

| Best Use Case | Large-scale commercial applications | Ideal for diverse commercial projects | Great for hobbyists and small businesses |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of the Brother PR Series?

The Brother PR Series is designed for commercial use, offering a range of features that cater to businesses looking for versatility. It includes advanced technology for embroidery, such as a large color touch screen and automatic needle threading, which streamlines the process. However, its higher price point may deter smaller businesses or startups. Additionally, while it performs exceptionally well for various embroidery tasks, the initial learning curve may be steep for operators unfamiliar with advanced settings.

How Does the Janome Memory Craft Series Compare?

The Janome Memory Craft Series is an excellent option for those prioritizing user-friendliness and affordability. Its intuitive controls make it accessible for hobbyists and small businesses looking to produce high-quality embroidery without significant investment. While it may not match the Ricoma or Brother machines in terms of speed and commercial capabilities, it excels in its ease of use and lower maintenance requirements. The downside is that it may lack some advanced features that larger operations might require, limiting its scalability.

Conclusion: How Should B2B Buyers Choose the Right Embroidery Machine?

Selecting the right embroidery machine ultimately depends on your specific business needs and budget. If your focus is on large-scale production and versatility, the Ricoma or Brother PR Series might be the best fit despite their higher costs. Conversely, for smaller operations or hobbyists, the Janome Memory Craft Series offers a compelling balance of performance and affordability. Assess your operational scale, the types of projects you plan to undertake, and your budget constraints to make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for ricoma embroidery machine

What Are the Key Technical Properties of Ricoma Embroidery Machines?

When evaluating Ricoma embroidery machines, understanding their technical specifications is crucial for international B2B buyers. Here are some essential properties to consider:

-

Stitching Speed (Stitches Per Minute)

This specification indicates how quickly a machine can produce embroidery. Higher speeds can significantly boost production efficiency, allowing businesses to meet tight deadlines. For instance, a machine with a stitching speed of 1000 SPM can complete tasks in less time, enhancing overall output. -

Needle Count

The number of needles on an embroidery machine directly influences the complexity of designs it can create. Machines with higher needle counts (e.g., 6 to 15 needles) allow for multi-color embroidery without manual thread changes, which is essential for businesses aiming to offer diverse products. -

Hoop Size

The hoop size determines the maximum dimensions of the embroidery design that can be executed. Businesses must select machines with appropriate hoop sizes for their specific applications, as this affects versatility in product offerings, especially in custom orders. -

Material Compatibility

Ricoma machines are designed to work with a variety of fabrics, including cotton, polyester, and specialty materials like denim or leather. Understanding material compatibility is crucial for B2B buyers who plan to diversify their product lines and cater to different market segments. -

User Interface and Software Integration

A user-friendly interface and compatibility with design software can streamline operations. Machines that support advanced design software allow businesses to create intricate patterns easily, reducing training time and improving workflow efficiency. -

Durability and Warranty

The grade of materials used in the construction of the machine impacts its longevity. A robust machine not only reduces maintenance costs but also enhances productivity. Warranties and service agreements can provide additional security for buyers, ensuring support in case of operational issues.

What Are Common Trade Terms Associated with Ricoma Embroidery Machines?

Familiarizing yourself with industry terminology can enhance communication and negotiation in the B2B landscape. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce components or products that are sold under another brand’s name. Understanding OEM relationships can help buyers assess the quality and reliability of the machines they are purchasing. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs to ensure they can meet the supplier’s requirements without overcommitting their resources. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products. This is a critical step in the procurement process, allowing businesses to compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risk management, and delivery obligations. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for inventory management and ensuring that production schedules are met. -

Tolerances

In manufacturing, tolerances indicate the allowable deviation from a specified dimension. Knowing the tolerances for embroidery machines ensures that buyers receive products that meet their quality standards, which is vital for maintaining brand reputation.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing Ricoma embroidery machines, ultimately enhancing their operational capabilities and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the ricoma embroidery machine Sector

What Are the Current Market Dynamics and Key Trends Affecting Ricoma Embroidery Machines?

A stock image related to ricoma embroidery machine.

The market for Ricoma embroidery machines is witnessing significant growth driven by several global factors. The rise of personalized and customized products is leading businesses to adopt advanced embroidery solutions that offer flexibility and high-quality output. The increasing demand for automation in production processes is another key trend, as businesses seek to enhance operational efficiency and reduce labor costs. Moreover, the proliferation of e-commerce platforms has made it essential for B2B buyers to leverage technologies that can quickly adapt to changing market demands.

Emerging technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) are transforming the embroidery landscape. These technologies enable real-time monitoring and predictive maintenance, ensuring minimal downtime and increased productivity. Buyers from Africa, South America, the Middle East, and Europe should be aware of the importance of integrating these technologies into their operations to remain competitive. Additionally, sourcing trends are shifting towards suppliers who can offer comprehensive support and training, not just equipment, fostering a more collaborative partnership.

How Can Sustainability and Ethical Sourcing Impact the Ricoma Embroidery Machine Sector?

Sustainability has become a critical consideration for B2B buyers in the Ricoma embroidery machine market. The environmental impact of production processes and the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who prioritize sustainable practices, such as reducing energy consumption and minimizing waste. This shift is not only beneficial for the environment but also enhances brand reputation, appealing to a growing consumer base that values sustainability.

Ethical sourcing is also gaining traction, with companies expected to provide transparency in their supply chains. Certifications such as ISO 14001 for environmental management and Oeko-Tex for textiles can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers who adhere to these standards, B2B buyers can ensure that their sourcing aligns with global sustainability goals. Furthermore, using eco-friendly materials in the production of Ricoma embroidery machines can help mitigate the environmental impact and fulfill consumer demand for greener products.

What Is the Evolution of the Ricoma Embroidery Machine Sector?

The Ricoma embroidery machine sector has evolved considerably over the past few decades. Initially, embroidery was a manual craft, but technological advancements have transformed it into an automated process, significantly increasing production capabilities. Ricoma, founded in 1996, has played a pivotal role in this evolution by offering innovative solutions that cater to both small businesses and large enterprises.

Over the years, Ricoma has introduced various models equipped with advanced features such as multi-needle capabilities, user-friendly software, and high-speed operation, making it easier for businesses to enter the embroidery market. This evolution reflects a broader trend in the industry towards automation and efficiency, enabling companies to produce high-quality embroidered products quickly and cost-effectively. Understanding this historical context is crucial for B2B buyers looking to invest in embroidery technology that meets modern demands.

Frequently Asked Questions (FAQs) for B2B Buyers of ricoma embroidery machine

-

How do I choose the right Ricoma embroidery machine for my business?

Choosing the right Ricoma embroidery machine involves assessing your specific needs such as production volume, types of fabrics, and design complexity. Evaluate the features of various models, including the number of needles, hoop sizes, and software compatibility. Additionally, consider your budget and the potential return on investment. Engaging with a sales representative who understands your market can provide insights tailored to your business. -

What are the customization options available for Ricoma embroidery machines?

Ricoma offers various customization options, including different hoop sizes, needle configurations, and specialized software. You can also request specific features that cater to your niche, such as additional attachments for unique stitching techniques. When discussing customization with suppliers, ensure they can accommodate your requests without significantly delaying delivery times. -

What is the minimum order quantity (MOQ) for Ricoma embroidery machines?

The minimum order quantity for Ricoma embroidery machines can vary based on the model and the supplier’s policies. Generally, you may find that MOQs range from one machine to a batch of several units, especially for bulk purchases. It is advisable to negotiate with suppliers to understand their MOQ and explore potential discounts for larger orders. -

What payment terms should I expect when purchasing a Ricoma embroidery machine?

Payment terms can differ significantly among suppliers. Common arrangements include a 30% upfront deposit with the balance due before shipment, or payment in full upon order confirmation. Always clarify payment methods accepted (e.g., bank transfers, letters of credit) and inquire about any financing options available to help manage cash flow. -

How can I ensure the quality of Ricoma embroidery machines before purchasing?

To ensure the quality of Ricoma embroidery machines, consider requesting samples of their work, visiting their production facility, or reviewing customer testimonials. Additionally, verify that the machines comply with international quality standards. Engaging a third-party inspection service can also provide an unbiased assessment before finalizing your purchase. -

What logistics considerations should I keep in mind when importing Ricoma embroidery machines?

When importing Ricoma embroidery machines, consider shipping costs, customs duties, and delivery timelines. Research the most efficient shipping methods based on your location, and ensure that the supplier provides all necessary documentation for customs clearance. It’s beneficial to work with a logistics partner who has experience with international shipments to navigate any potential challenges. -

How do I vet suppliers of Ricoma embroidery machines effectively?

Vetting suppliers requires thorough research. Start by checking their business credentials, industry experience, and customer reviews. Request references from other clients and assess their after-sales support, warranty policies, and service capabilities. Engaging in direct communication can provide insights into their responsiveness and reliability. -

What kind of after-sales support can I expect with Ricoma embroidery machines?

Ricoma typically offers robust after-sales support, including installation assistance, training, and ongoing technical support. Ensure that your supplier outlines their warranty terms and what is covered, as well as the availability of spare parts and service technicians. It’s essential to clarify these details upfront to avoid unexpected issues after purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ricoma embroidery machine

As international B2B buyers consider the acquisition of Ricoma embroidery machines, strategic sourcing emerges as a critical factor in maximizing value. By aligning purchasing decisions with business objectives, companies can enhance operational efficiency and ensure quality output. Key takeaways include the importance of evaluating suppliers based on their technological capabilities, after-sales support, and alignment with local market needs.

Moreover, understanding the total cost of ownership—including maintenance, training, and potential downtime—can lead to more informed purchasing decisions. For buyers in Africa, South America, the Middle East, and Europe, establishing strong relationships with manufacturers and distributors can facilitate better negotiation terms and access to localized support.

Looking ahead, the embroidery industry is poised for growth, driven by advancements in automation and customization. B2B buyers are encouraged to stay abreast of emerging trends and innovations in the Ricoma product line, which can provide a competitive edge. Embrace this opportunity to enhance your production capabilities and explore the possibilities that strategic sourcing offers for your business’s success.