Discover Cost-Saving Solutions with Handrail Brackets (2025)

Introduction: Navigating the Global Market for handrail brackets

In the ever-evolving global market, sourcing handrail brackets can present significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the nuances of various types of handrail brackets, including their materials and applications, is crucial for making informed purchasing decisions. This comprehensive guide aims to demystify the complexities surrounding handrail brackets by exploring a wide array of options, their specific uses in both residential and commercial settings, and the importance of regulatory compliance.

International buyers often face obstacles such as inconsistent quality, varying standards, and fluctuating costs. This guide addresses these concerns by providing actionable insights on supplier vetting processes, cost analysis, and tips for negotiating favorable terms. By equipping B2B buyers with the knowledge needed to navigate supplier relationships and market dynamics, we empower them to make strategic choices that enhance safety and design in their projects. Whether you’re a contractor in Brazil seeking durable solutions or a distributor in the Middle East looking for competitive pricing, this guide serves as an essential resource to streamline your procurement process and elevate your product offerings.

Understanding handrail brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall-Mounted Brackets | Attached directly to walls; space-saving design | Residential and commercial staircases | Pros: Space-efficient, versatile; Cons: Limited load capacity compared to others. |

| Adjustable Brackets | Can be modified for various angles and heights | Custom stair designs, ramps | Pros: Flexible for different projects; Cons: More complex installation. |

| Post-Mounted Brackets | Fixed to newel posts; provides strong support | High-traffic areas, public buildings | Pros: High load-bearing capacity; Cons: Requires more space for installation. |

| Decorative Brackets | Aesthetic designs that enhance visual appeal | Retail spaces, upscale residential projects | Pros: Enhances design elements; Cons: May not be suitable for all applications. |

| Heavy-Duty Brackets | Made from robust materials for maximum strength | Industrial applications, outdoor settings | Pros: Exceptional durability and strength; Cons: Heavier and may require professional installation. |

What Are Wall-Mounted Brackets and Their Uses?

Wall-mounted brackets are a popular choice for both residential and commercial staircases. They attach directly to the wall, allowing for a clean and minimalist look. This type is particularly suitable for narrow spaces where traditional balusters may be impractical. When purchasing wall-mounted brackets, buyers should consider the weight they need to support, as these brackets typically have a lower load capacity compared to other types. Additionally, the choice of material and finish can impact both aesthetics and durability.

How Do Adjustable Brackets Benefit B2B Buyers?

Adjustable brackets are designed for flexibility, allowing for modifications in height and angle. This makes them ideal for custom stair designs or ramps that require specific configurations. B2B buyers should note that while these brackets offer versatility, they may require a more complex installation process. It’s crucial to ensure that the installation team has the necessary skills and tools to adjust the brackets correctly. Considerations like material quality and the expected weight load are also essential when selecting adjustable brackets.

Why Choose Post-Mounted Brackets for High-Traffic Areas?

Post-mounted brackets are affixed to newel posts, providing robust support for handrails in high-traffic areas. They are commonly used in public buildings and commercial spaces where safety and durability are paramount. These brackets can bear significant weight, making them suitable for environments with heavy use. Buyers should evaluate the space available for installation, as these brackets require more room than wall-mounted options. Additionally, the choice of materials can influence the overall strength and longevity of the installation.

What Are the Advantages of Decorative Brackets?

Decorative brackets serve both functional and aesthetic purposes, enhancing the visual appeal of staircases in retail and upscale residential settings. They come in various designs, allowing buyers to match the brackets with the overall decor of the space. While they add an attractive element, buyers should ensure that the chosen decorative brackets can also meet safety and load requirements. It’s important to balance aesthetics with functionality, particularly in commercial environments where foot traffic is high.

When to Use Heavy-Duty Brackets?

Heavy-duty brackets are constructed from robust materials to withstand significant stress and weight, making them ideal for industrial applications and outdoor settings. These brackets are designed for durability and can support larger handrails in environments where safety is critical. Buyers should consider the installation requirements, as heavy-duty brackets may necessitate professional installation due to their weight and complexity. Additionally, understanding the specific load requirements of the installation site is essential to ensure safety and compliance with local regulations.

Related Video: How to install Handrail Brackets? | L003

Key Industrial Applications of handrail brackets

| Industry/Sector | Specific Application of Handrail Brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Support for staircases in commercial buildings | Enhances safety and compliance with building codes | Material durability, load-bearing capacity, and design |

| Healthcare | Handrails in hospitals and clinics | Improves patient safety and ease of mobility | Compliance with health regulations and ease of cleaning |

| Transportation | Railings in public transport stations | Increases passenger safety and accessibility | Corrosion resistance, weatherproofing, and maintenance ease |

| Hospitality | Handrails in hotels and resorts | Enhances guest experience and safety | Aesthetic design, material choice, and installation support |

| Residential | Handrails for private homes and apartments | Provides safety and adds value to properties | Customization options and compliance with local regulations |

How Are Handrail Brackets Used in Construction Projects?

In the construction industry, handrail brackets are essential for supporting staircases in commercial buildings. They provide a secure attachment point for handrails, enhancing the safety of stairways, which are often high-traffic areas. By ensuring compliance with local building codes, these brackets help prevent accidents and liabilities. International buyers, particularly from regions like Africa and South America, should prioritize sourcing durable materials that can withstand various environmental conditions while ensuring the brackets meet the required load-bearing specifications.

What Role Do Handrail Brackets Play in Healthcare Facilities?

In healthcare settings, handrail brackets are vital for installing handrails in hospitals and clinics. They facilitate patient movement and provide necessary support, thereby reducing the risk of falls. The brackets must comply with health regulations to ensure safety and ease of use for patients with limited mobility. Buyers in the Middle East and Europe should consider sourcing brackets that are easy to clean and resistant to various disinfectants, ensuring hygiene standards are maintained while also being durable enough for high usage.

How Are Handrail Brackets Applied in Transportation Infrastructure?

Handrail brackets are commonly used in public transport stations to secure railings that enhance passenger safety. These installations must withstand heavy use and exposure to the elements, making the choice of corrosion-resistant materials crucial. For international buyers in regions with diverse climates, such as Africa and South America, it is important to focus on sourcing brackets that not only meet safety regulations but also require minimal maintenance over time, ensuring long-term functionality and safety.

Why Are Handrail Brackets Important in the Hospitality Sector?

In the hospitality industry, handrail brackets are used in hotels and resorts to support handrails in staircases and other areas. These installations contribute to guest safety and comfort, enhancing the overall experience. Buyers from Europe and the Middle East should look for brackets that offer aesthetic appeal, as they often become a part of the interior design. Additionally, ease of installation and the ability to customize designs can significantly influence purchasing decisions.

How Do Handrail Brackets Benefit Residential Properties?

For residential applications, handrail brackets are crucial for ensuring the safety of staircases in private homes and apartments. They not only provide necessary support but also add value to properties by enhancing their safety features. Buyers in South America and Africa should consider local building codes and aesthetic preferences when sourcing handrail brackets. Customization options that align with home designs can improve marketability and satisfy homeowner expectations.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘handrail brackets’ & Their Solutions

Scenario 1: Sourcing Durable Handrail Brackets for Varied Environments

The Problem:

B2B buyers in regions like Africa or South America often face the challenge of sourcing handrail brackets that are durable enough to withstand harsh environmental conditions. For instance, businesses operating in coastal areas must consider corrosion resistance due to high humidity and salt exposure. Similarly, construction companies in arid regions need brackets that can endure extreme temperatures without degrading. This scenario can lead to significant delays in projects if the wrong materials are chosen or if the products fail to meet local environmental standards.

The Solution:

To effectively source handrail brackets for these varied environments, buyers should prioritize suppliers that offer a range of materials specifically designed for durability. Stainless steel and galvanized steel brackets are excellent choices for coastal regions due to their corrosion-resistant properties. Additionally, buyers should verify that the products meet international quality standards, such as ISO certifications, which ensure reliability across different climates. Engaging with suppliers who provide extensive product information, including environmental ratings and testing results, can also help in making informed decisions. Conducting thorough research into local regulations regarding construction materials will further ensure compliance and longevity of the handrail systems.

Scenario 2: Ensuring Proper Installation and Compliance with Safety Regulations

The Problem:

In the Middle East, where safety regulations are strictly enforced, B2B buyers often struggle with ensuring that handrail brackets are installed correctly to meet local building codes. Misunderstanding the compliance requirements can lead to costly fines and project delays, especially for contractors who are unfamiliar with the specific regulations in their region. Additionally, the complexity of certain installations can lead to improper mounting, resulting in safety hazards.

The Solution:

To navigate compliance challenges, buyers should invest in comprehensive training programs for their installation teams. This training should cover local safety regulations and best practices for handrail bracket installation. Furthermore, working closely with manufacturers who provide detailed installation guides and support can ensure that all steps are followed accurately. Utilizing technology such as augmented reality (AR) can also assist in visualizing the correct installation process. Additionally, consider conducting periodic safety audits to ensure ongoing compliance and to identify areas for improvement in installation practices.

Scenario 3: Customizing Handrail Brackets for Unique Architectural Designs

The Problem:

In European markets, architectural diversity means that standard handrail brackets often do not fit unique or custom designs, leading to dissatisfaction among architects and contractors. Buyers may find themselves constrained by limited options that do not align with their project specifications, resulting in increased lead times and project costs. This mismatch can also compromise the aesthetic appeal of the final installation, impacting the overall value of the property.

The Solution:

To overcome customization challenges, B2B buyers should seek suppliers that offer bespoke solutions and a wide variety of designs. Engaging with manufacturers who have the capability to produce custom handrail brackets based on specific architectural requirements can greatly enhance project outcomes. Buyers should also consider collaborating with local designers to create prototypes that reflect both functionality and aesthetic appeal. Investing in advanced manufacturing technologies, such as 3D printing, can expedite the prototyping process, allowing for rapid adjustments based on feedback. Additionally, maintaining an open line of communication with architects during the design phase ensures that all elements, including handrail brackets, integrate seamlessly into the final structure.

Strategic Material Selection Guide for handrail brackets

When selecting materials for handrail brackets, international B2B buyers must consider various factors that influence performance, durability, and compliance with local regulations. Below, we analyze four common materials used in the manufacturing of handrail brackets, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel for Handrail Brackets?

Stainless steel is a popular choice for handrail brackets due to its excellent corrosion resistance and strength. Key properties include a high tensile strength, which allows it to withstand significant loads, and a temperature rating that makes it suitable for both indoor and outdoor applications. Stainless steel is also non-reactive, ensuring that it maintains its aesthetic appeal over time.

Pros & Cons: The primary advantages of stainless steel include its durability and low maintenance requirements. However, it can be more expensive than other materials, which may be a consideration for budget-conscious buyers. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is ideal for environments exposed to moisture, such as coastal areas, where corrosion resistance is crucial. Buyers should also consider local standards such as ASTM A276 for stainless steel specifications.

How Does Aluminum Compare as a Material for Handrail Brackets?

Aluminum is lightweight and offers good corrosion resistance, making it another viable option for handrail brackets. Its properties include a lower density than stainless steel, which can facilitate easier installation and reduce shipping costs. Aluminum can also be anodized for enhanced durability and aesthetic appeal.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which simplifies handling and installation. However, it may not offer the same load-bearing capacity as stainless steel, making it less suitable for high-traffic areas. Additionally, while generally less expensive, aluminum can be prone to denting and scratching.

Impact on Application: Aluminum brackets are often used in residential applications and light commercial settings. Compliance with local standards such as EN 755 for aluminum extrusions should be verified by buyers.

What Are the Benefits of Plastic for Handrail Brackets?

Plastic, particularly high-density polyethylene (HDPE) or polyvinyl chloride (PVC), is increasingly used for handrail brackets due to its resistance to moisture and chemicals. Key properties include lightweight construction and ease of fabrication, making it suitable for a variety of applications.

Pros & Cons: The main advantage of plastic is its cost-effectiveness and resistance to corrosion. However, plastic may not provide the same structural integrity as metal options, which can limit its use in high-load applications. Additionally, UV exposure can lead to degradation over time.

Impact on Application: Plastic brackets are often used in indoor settings or environments where exposure to harsh conditions is minimal. Buyers should ensure compliance with relevant standards, such as ASTM D638 for tensile properties of plastics.

Why Choose Wood for Handrail Brackets?

Wood is a traditional material that offers aesthetic appeal and can be easily customized. Key properties include natural insulation and a variety of finishes that can enhance the overall design of a space. However, wood is susceptible to moisture and pest damage, which can affect its longevity.

Pros & Cons: The primary advantage of wood is its warmth and visual appeal, making it a favorite in residential applications. On the downside, wood requires regular maintenance and may not be suitable for outdoor use without proper treatment.

Impact on Application: Wood brackets are often used in upscale residential projects. Buyers should be aware of local building codes regarding wood treatment and fire safety, such as compliance with the European standard EN 335 for durability.

Summary Table of Material Selection for Handrail Brackets

| Material | Typical Use Case for handrail brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-traffic areas, outdoor settings | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Residential and light commercial | Lightweight and easy to install | Lower load-bearing capacity | Medium |

| Plastic | Indoor settings, low-traffic areas | Cost-effective and corrosion-resistant | Limited structural integrity | Low |

| Wood | Residential, upscale projects | Aesthetic appeal and customization | Susceptible to moisture and pests | Medium |

This guide provides a comprehensive overview of material options for handrail brackets, helping international B2B buyers make informed decisions that align with their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for handrail brackets

What Are the Key Stages in the Manufacturing Process of Handrail Brackets?

The manufacturing of handrail brackets involves several critical stages, each designed to ensure that the final product is robust, reliable, and compliant with international standards. Understanding these stages can help B2B buyers make informed decisions when sourcing products.

Material Preparation: How Is Raw Material Selected and Processed?

The first stage of manufacturing handrail brackets is material preparation. Typically, manufacturers use high-quality metals such as stainless steel, aluminum, or wrought iron due to their strength and corrosion resistance.

- Material Selection: B2B buyers should look for suppliers that source materials compliant with industry standards, ensuring durability and safety.

- Cutting and Shaping: Raw materials are cut into specific dimensions using precision cutting tools. This may include laser cutting for intricate designs or shearing for simpler shapes.

Selecting suppliers that maintain strict quality control during material preparation is crucial. This can be verified through supplier audits and certifications.

What Forming Techniques Are Commonly Used for Handrail Brackets?

Once the material is prepared, the next phase is forming, which shapes the raw materials into the desired bracket configuration.

- Forging: This technique involves shaping the metal using compressive forces, resulting in a strong and durable product. It’s often used for high-stress applications.

- Casting: Molten metal is poured into molds to create complex shapes. This method is useful for producing intricate designs that would be challenging to forge.

- Stamping: Sheet metal is stamped into shape using dies, allowing for high-volume production with consistent quality.

For international buyers, understanding the forming techniques used can impact the performance of the handrail brackets in their specific applications.

How Are Handrail Brackets Assembled and Finished?

The assembly and finishing processes are crucial for ensuring the functionality and aesthetic appeal of handrail brackets.

- Assembly: Components such as brackets, screws, and fittings are assembled using either manual labor or automated processes. Ensuring that all parts fit correctly is essential for structural integrity.

- Finishing: This stage may involve powder coating, galvanizing, or painting to enhance corrosion resistance and appearance. Finishing not only improves aesthetic value but also prolongs the lifespan of the brackets.

Buyers should inquire about the finishing options available, as these can significantly affect maintenance and longevity.

What Quality Assurance Measures Are in Place During Manufacturing?

Quality assurance (QA) is critical to ensuring that handrail brackets meet safety and performance standards. B2B buyers should be aware of the following QA measures:

Which International Standards Should Buyers Be Aware Of?

Compliance with international standards is essential for ensuring product quality. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization.

- CE Marking: Indicates compliance with EU safety, health, and environmental requirements.

- API Standards: Relevant for brackets used in oil and gas applications, ensuring they meet industry-specific requirements.

Understanding these standards can help buyers assess the credibility of their suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) should be integrated at various stages of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products before shipment, ensuring they meet all specifications.

Buyers can request documentation of these QC processes to ensure compliance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verification of a supplier’s QC processes is crucial for B2B buyers, especially when sourcing from different regions such as Africa, South America, the Middle East, and Europe.

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing capabilities and QC practices.

- Quality Reports: Requesting regular quality reports can help track the supplier’s performance over time.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes.

This due diligence helps mitigate risks associated with sourcing from international suppliers.

What Are the Common Testing Methods for Handrail Brackets?

Testing methods ensure that the handrail brackets perform under expected conditions. Common methods include:

- Load Testing: Evaluating the strength and stability of brackets under various loads to ensure safety.

- Corrosion Resistance Testing: Exposing brackets to corrosive environments to assess their durability.

- Dimensional Inspection: Verifying that the dimensions of finished products adhere to specifications.

Understanding these testing methods allows buyers to ensure they are purchasing reliable and safe products.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from different regions face unique challenges regarding quality control. Here are some considerations:

- Regulatory Compliance: Different regions may have specific regulations regarding safety and quality. Buyers should be aware of these and ensure their suppliers comply.

- Cultural Differences: Understanding cultural attitudes towards quality and compliance can help facilitate better communication and expectations with suppliers.

- Logistical Considerations: Shipping and handling can impact product quality. Buyers should ensure suppliers have robust logistics practices to protect products during transport.

By considering these nuances, international buyers can better navigate the complexities of sourcing handrail brackets and ensure they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘handrail brackets’

In today’s global marketplace, sourcing handrail brackets requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This checklist will guide international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, through the essential steps of procuring handrail brackets that meet their project specifications and regulatory requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the handrail brackets you need. This includes materials (e.g., stainless steel, aluminum, or plastic), load-bearing capacity, and compliance with local building codes. By specifying these details upfront, you can streamline the sourcing process and avoid compatibility issues during installation.

Step 2: Conduct Market Research for Suppliers

Research potential suppliers who specialize in handrail brackets. Look for manufacturers with a strong reputation in your region and check their online presence, customer reviews, and product range. Understanding market trends and supplier capabilities can help you identify the best options that align with your specifications.

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with any supplier, verify their certifications and compliance with international standards. Look for ISO certifications and adherence to local safety regulations. This step is vital to ensure that the handrail brackets you purchase are safe, reliable, and suitable for your project’s requirements.

Step 4: Request Samples and Technical Data Sheets

Always request samples of the handrail brackets you are considering. This allows you to assess the quality and finish of the product firsthand. Additionally, obtain technical data sheets that provide detailed information on material properties, installation guidelines, and maintenance requirements.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing. Be sure to evaluate what is included in the pricing, such as shipping costs, bulk discounts, and warranty options. Understanding the payment terms is equally important; negotiate terms that are favorable for your cash flow and project timeline.

Step 6: Assess Logistics and Delivery Capabilities

Consider the logistics involved in sourcing handrail brackets. Assess the supplier’s ability to deliver on time, particularly if you have tight project deadlines. Check if they offer flexible shipping options and whether they can handle customs clearance efficiently if sourcing from abroad.

Step 7: Establish a Communication Plan

Maintain clear and consistent communication with your chosen supplier throughout the sourcing process. Set expectations regarding timelines, quality checks, and updates on production status. Effective communication can help preempt potential issues and foster a strong working relationship.

By following this checklist, international B2B buyers can ensure a smooth and successful sourcing experience for handrail brackets, ultimately leading to safer and more aesthetically pleasing installations.

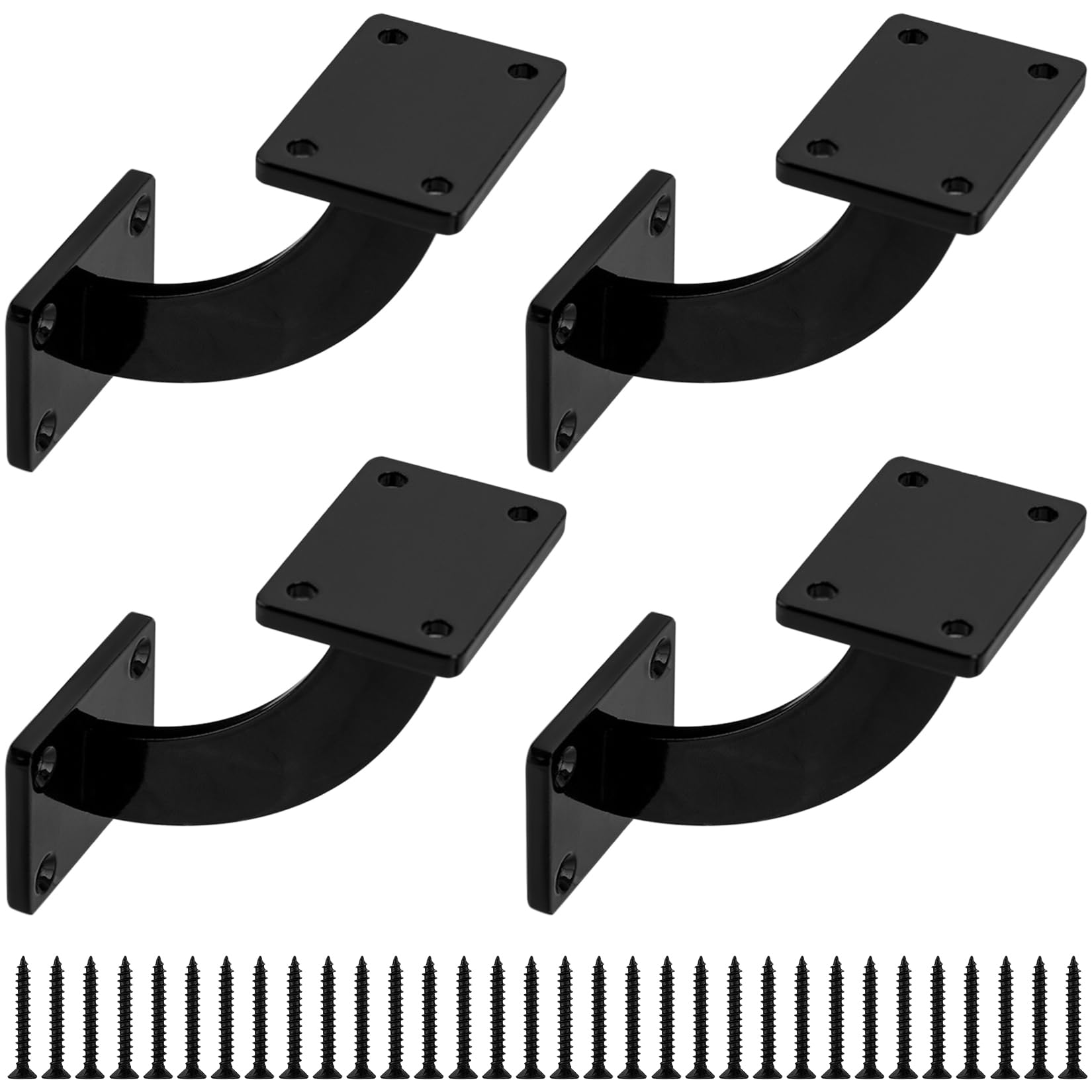

A stock image related to handrail brackets.

Comprehensive Cost and Pricing Analysis for handrail brackets Sourcing

What Are the Key Cost Components in Handrail Bracket Sourcing?

When sourcing handrail brackets, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials for handrail brackets include stainless steel, aluminum, and various types of plastics. Stainless steel, while durable and resistant to corrosion, tends to be the most expensive option. Conversely, plastic brackets may be more affordable but offer less durability.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. In regions with higher wages, such as parts of Europe, labor costs can be substantial. In contrast, countries in Africa or South America may have lower labor costs, potentially reducing the overall expenditure.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and salaries for administrative staff. Efficient manufacturing processes can help minimize overhead costs, affecting the final pricing of handrail brackets.

-

Tooling: Initial tooling costs can be significant, especially for custom or specialized brackets. This cost is typically amortized over production runs, making it crucial to consider the volume of brackets ordered.

-

Quality Control (QC): Investing in quality assurance processes ensures that the brackets meet safety and aesthetic standards. While this may increase upfront costs, it can prevent costly returns and reputational damage in the long run.

A stock image related to handrail brackets.

-

Logistics: Shipping and handling costs are vital components of the total cost. Factors such as distance, weight, and shipping method (air vs. sea) can significantly influence logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers assess whether a quote is competitive.

How Do Price Influencers Impact Handrail Bracket Costs?

Several factors can influence the pricing of handrail brackets:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate favorable MOQs that align with their needs.

-

Specifications and Customization: Customized brackets tailored to specific project requirements can increase costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Materials and Quality Certifications: Brackets made from high-grade materials or those that meet specific industry certifications (e.g., ISO, CE) may command higher prices but offer better durability and compliance with safety standards.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can also affect pricing. Established suppliers may charge a premium but often provide better quality and service.

-

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) can impact the overall cost. Buyers should be aware of how these terms affect their logistics and pricing.

What Tips Can Help Buyers Optimize Costs When Sourcing Handrail Brackets?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Strategically: Always engage in negotiations with suppliers. Presenting competitive offers from other vendors can leverage better pricing or terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with installation, maintenance, and potential replacements. Investing in higher-quality brackets may yield savings over time.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing standards due to local economic conditions, tariffs, and import duties. Understanding these nuances helps in making informed purchasing decisions.

-

Request Samples: Before making large orders, requesting samples can help assess quality and fit for specific applications, reducing the risk of costly errors.

Disclaimer on Indicative Prices

Prices for handrail brackets can fluctuate based on market conditions, material availability, and supplier pricing strategies. Always consult multiple suppliers and seek updated quotes to ensure you are receiving competitive and fair pricing.

Alternatives Analysis: Comparing handrail brackets With Other Solutions

When evaluating options for securing handrails, it’s essential to consider alternatives to traditional handrail brackets. Each solution presents unique advantages and drawbacks that can influence your decision based on specific project requirements, budget constraints, and aesthetic preferences. Below, we explore several alternatives to handrail brackets, providing a clear comparison to aid international B2B buyers in making informed choices.

Comparison Table

| Comparison Aspect | Handrail Brackets | Welded Handrails | Wall-Mounted Handrails |

|---|---|---|---|

| Performance | High stability and support | Very high stability, permanent | Good stability, may vary with wall material |

| Cost | Moderate cost | Higher initial investment | Generally lower cost |

| Ease of Implementation | Easy to install with tools | Requires welding skills and equipment | Simple installation, often DIY-friendly |

| Maintenance | Low maintenance | Minimal maintenance, long-lasting | Moderate maintenance, check wall integrity |

| Best Use Case | Residential and commercial settings | Industrial applications, permanent installations | Space-saving, residential and commercial |

What Are the Benefits and Drawbacks of Welded Handrails?

Welded handrails provide an exceptionally robust solution, ideal for high-traffic areas or environments where safety is paramount. The main advantage is their superior strength and permanence; once installed, they will not shift or require adjustment. However, the downside is the higher cost and the need for specialized skills and equipment for installation. This option is best suited for industrial applications or permanent installations where long-term durability is critical.

How Do Wall-Mounted Handrails Compare?

Wall-mounted handrails are an excellent alternative for spaces with limited floor area or where traditional handrails are impractical. They are often easier and cheaper to install, making them a popular choice for residential projects. However, their stability can be influenced by the wall material and condition, which might require additional reinforcement. Wall-mounted solutions are ideal for stairways or hallways where space-saving designs are essential but may not provide the same level of support as brackets or welded options.

Conclusion: How to Choose the Right Solution for Your Needs?

Selecting the right solution for handrail installation depends on your specific project requirements, including safety standards, budget, and aesthetic preferences. Handrail brackets offer a good balance of cost and performance for many applications, while welded handrails excel in strength for demanding environments. Wall-mounted handrails provide flexibility and space efficiency, making them suitable for residential settings. Consider your project’s unique context, and weigh the pros and cons of each option to determine the best fit for your needs.

Essential Technical Properties and Trade Terminology for handrail brackets

What Are the Key Technical Properties of Handrail Brackets?

When selecting handrail brackets for international projects, understanding their technical properties is crucial. Here are some essential specifications to consider:

1. Material Grade

Handrail brackets are typically made from materials such as stainless steel, aluminum, or wrought iron. The grade of material affects durability, corrosion resistance, and overall strength. For instance, stainless steel grades like 304 or 316 are ideal for outdoor applications in coastal areas due to their superior corrosion resistance. B2B buyers should prioritize material grades based on environmental conditions and expected load requirements.

2. Load Capacity

The load capacity of handrail brackets determines how much weight they can support without failure. This specification is vital for ensuring safety and compliance with building codes. It varies based on the bracket’s design and material. For commercial projects, consulting the manufacturer’s load ratings ensures that the selected brackets will withstand the anticipated usage.

3. Tolerance

Tolerance refers to the permissible limit of variation in the bracket’s dimensions. Accurate tolerances are essential for proper installation and ensuring that handrails fit securely. A tight tolerance may be necessary for aesthetic projects, while a more relaxed tolerance could be acceptable in industrial applications. Understanding tolerance helps in minimizing installation issues and ensuring a seamless fit.

4. Finish

The finish of handrail brackets can impact both aesthetics and durability. Options range from powder coating to galvanization, each providing different levels of protection against wear and corrosion. For example, a powder-coated finish offers a broad color palette and enhanced resistance to scratches and fading. Buyers should consider the visual aspects and environmental exposure when choosing a finish.

5. Size and Compatibility

Handrail brackets come in various sizes, which must match the dimensions of the handrail and the mounting surface. Compatibility with standard handrails and fittings is essential for ease of installation. Buyers should verify that the selected brackets align with the design specifications of their projects to prevent costly modifications.

What Are Common Trade Terms Related to Handrail Brackets?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication with suppliers and manufacturers. Here are some common trade terms relevant to handrail brackets:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of handrail brackets, an OEM might supply custom-designed brackets to a construction company. Understanding OEM relationships is crucial for buyers looking for bespoke solutions or specific design requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers, as it affects purchasing decisions and inventory management. Understanding MOQ helps in budgeting and planning for large-scale projects, especially in regions like Africa and South America where import costs can be significant.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. For handrail brackets, issuing an RFQ can help buyers compare prices and services from different manufacturers. This process is essential for making informed purchasing decisions and securing the best possible terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers engaged in international transactions, as they help mitigate risks and ensure clarity in logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving it. This term is critical in project planning, especially for B2B buyers who need to coordinate schedules and ensure timely delivery of materials. Awareness of lead times helps in managing expectations and maintaining project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing handrail brackets, ensuring safety, compliance, and aesthetic appeal in their projects.

Navigating Market Dynamics and Sourcing Trends in the handrail brackets Sector

What Are the Key Trends Impacting the Handrail Brackets Market?

A stock image related to handrail brackets.

The global handrail brackets market is experiencing significant growth, driven by increasing construction activities and the rising emphasis on safety in residential and commercial buildings. In regions such as Africa, South America, the Middle East, and Europe, buyers are witnessing an uptick in infrastructure development, spurred by urbanization and government initiatives aimed at enhancing public safety. This demand has led to innovative sourcing trends, particularly the integration of advanced manufacturing technologies such as automation and 3D printing, which enable the production of customized handrail brackets tailored to specific architectural needs.

Moreover, the growing influence of e-commerce is reshaping procurement processes for B2B buyers. Online platforms facilitate easier access to a broader range of products, allowing buyers to compare prices, quality, and suppliers quickly. Additionally, buyers are increasingly prioritizing suppliers that offer transparency in their sourcing practices, particularly those that can demonstrate compliance with international quality standards. This shift is essential for ensuring product reliability and safety, especially in regions where regulatory frameworks are evolving.

How Important Is Sustainability and Ethical Sourcing in the Handrail Brackets Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the handrail brackets sector. The environmental impact of manufacturing processes, particularly in metal and plastic production, has prompted buyers to seek suppliers who prioritize eco-friendly practices. Sustainable sourcing not only reduces carbon footprints but also helps in mitigating waste and resource depletion.

Buyers are increasingly looking for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management, and materials that are recyclable or sourced sustainably, like responsibly harvested wood or recycled metals. Ethical sourcing practices also ensure that suppliers adhere to fair labor practices and maintain transparency in their supply chains. This focus not only enhances brand reputation but also aligns with the growing consumer preference for environmentally responsible products.

How Has the Handrail Brackets Market Evolved Over Time?

The evolution of the handrail brackets market reflects broader trends in construction and design. Historically, handrail brackets were primarily utilitarian, focusing on safety and structural support. However, as architectural styles have evolved, so too have the materials and designs of handrail brackets. The introduction of diverse materials such as stainless steel, aluminum, and engineered wood has expanded aesthetic options, allowing for greater customization in both residential and commercial projects.

In recent decades, advancements in manufacturing technology have allowed for more intricate designs and improved durability. The adoption of CAD (Computer-Aided Design) tools has enabled manufacturers to innovate rapidly, responding to changing market demands with speed. This evolution underscores the importance of staying abreast of trends and technological advancements for B2B buyers seeking to source high-quality handrail brackets that meet contemporary design and safety standards.

Frequently Asked Questions (FAQs) for B2B Buyers of handrail brackets

-

How do I choose the right handrail brackets for my project?

Choosing the right handrail brackets involves considering several factors. First, assess the material and weight of the handrail to ensure the brackets can support it adequately. Additionally, look at the aesthetic style—brackets come in various designs, from traditional to contemporary. Ensure the bracket dimensions match the handrail profile for a secure fit. Also, consider the installation method; some brackets require specific tools or skills. Lastly, check for compliance with local building codes, as this can impact safety and liability. -

What is the best material for handrail brackets?

The best material for handrail brackets largely depends on the application and environmental conditions. Stainless steel is highly recommended for outdoor use due to its corrosion resistance and durability. For indoor projects, wrought iron offers a classic look and strength, while aluminum provides a lightweight, rust-resistant option. Wood brackets can offer aesthetic warmth but may require more maintenance. Ensure the selected material aligns with the design vision while also meeting strength and longevity requirements. -

How can I ensure the quality of handrail brackets when sourcing internationally?

To ensure quality when sourcing handrail brackets internationally, it’s essential to vet suppliers thoroughly. Request samples to evaluate material quality and construction. Check for certifications that demonstrate compliance with industry standards and safety regulations. Establish clear quality assurance (QA) protocols, including inspection processes during production and before shipment. Additionally, consider using third-party inspection services to verify quality before the products leave the factory, providing an extra layer of assurance. -

What are the common minimum order quantities (MOQs) for handrail brackets?

Minimum order quantities (MOQs) for handrail brackets can vary significantly between suppliers. Typically, MOQs range from 50 to 500 pieces, depending on the manufacturer and the type of bracket. For customized brackets, the MOQ may be higher due to the costs associated with design and production. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your project requirements and budget. -

What payment terms should I expect when purchasing handrail brackets?

Payment terms for purchasing handrail brackets can vary widely among suppliers. Common terms include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within 30, 60, or 90 days after receiving the goods. Always clarify payment methods accepted, such as bank transfers, letters of credit, or PayPal, and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

How do I handle logistics and shipping for international purchases of handrail brackets?

Handling logistics for international purchases of handrail brackets involves several key steps. First, confirm the shipping terms (Incoterms) with your supplier, which define responsibilities for shipping, insurance, and tariffs. Choose a reliable freight forwarder who can manage customs clearance and transportation. Be prepared to provide necessary documentation for customs, including invoices and packing lists. Finally, factor in delivery timelines and costs, as these can significantly affect your project schedule and budget. -

Can I customize handrail brackets to fit my specific design needs?

Yes, many suppliers offer customization options for handrail brackets to meet specific design requirements. Customization can include size, material, color, and finish to match your project’s aesthetic. When considering customization, provide detailed specifications and drawings to the supplier. Keep in mind that custom orders may involve higher costs and longer lead times, so plan accordingly to ensure timely delivery for your project. -

What safety regulations should I be aware of when sourcing handrail brackets?

When sourcing handrail brackets, it’s crucial to be aware of safety regulations that apply in your region. Regulations can vary significantly between countries and even local jurisdictions. Familiarize yourself with building codes that dictate handrail height, spacing, and load-bearing requirements. Ensure that your suppliers comply with these regulations, as non-compliance can lead to safety hazards and legal issues. It may be beneficial to consult with local authorities or industry experts to ensure full compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for handrail brackets

In the competitive landscape of handrail brackets, strategic sourcing emerges as a critical factor for B2B buyers looking to optimize their purchasing processes. By prioritizing quality, compliance with local regulations, and aesthetic appeal, businesses can enhance their offerings and build lasting relationships with clients. Sourcing from reputable manufacturers ensures that the materials used meet durability standards, which is essential for both safety and customer satisfaction.

Additionally, leveraging technology and data analytics in sourcing can lead to significant cost savings and improved supply chain efficiency. Buyers from regions such as Africa, South America, the Middle East, and Europe should focus on building partnerships with suppliers who understand the unique market dynamics and compliance requirements of their regions.

As we look to the future, the demand for innovative handrail solutions will continue to grow, driven by trends in safety, design, and sustainability. Now is the time for international B2B buyers to engage in strategic sourcing practices that not only fulfill current needs but also position them for future success in a rapidly evolving market. Consider exploring partnerships that align with your business goals to stay ahead in the handrail bracket industry.