Discover Cost-Saving Benefits of Cup 120ml Sourcing (2025)

Introduction: Navigating the Global Market for cup 120ml

Navigating the complexities of sourcing the right cup 120ml for your business can be a daunting task. With a myriad of options available globally, international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in identifying high-quality suppliers that meet their specific needs. This guide aims to simplify the process by providing a comprehensive overview of the various types of 120ml cups available in the market, their applications across different industries, and essential factors to consider during the supplier vetting process.

As you delve into this resource, you will discover actionable insights on evaluating supplier credentials, understanding cost dynamics, and recognizing potential pitfalls in international transactions. By equipping yourself with the right knowledge, you will be empowered to make informed purchasing decisions that align with your business objectives. This guide not only addresses the nuances of sourcing cup 120ml but also emphasizes the importance of building strong relationships with suppliers to ensure sustainable procurement practices.

Whether you are looking for disposable options for the food and beverage industry or reusable cups for promotional events, this guide will serve as your roadmap to successfully navigate the global market. It is designed to enhance your understanding and confidence in making decisions that drive your business forward.

Understanding cup 120ml Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Cup | Lightweight, durable, and often disposable | Catering, events, and food service | Pros: Cost-effective, versatile. Cons: Less environmentally friendly. |

| Glass Cup | Elegant design, reusable, and offers a premium feel | Restaurants, cafes, and upscale events | Pros: Durable, enhances presentation. Cons: Heavier, potential breakage risk. |

| Paper Cup | Biodegradable, customizable prints, and lightweight | Coffee shops, takeout, and events | Pros: Eco-friendly, disposable. Cons: Not suitable for hot liquids without a lining. |

| Stainless Steel Cup | Insulated, durable, and reusable | Outdoor events, sports, and promotions | Pros: Long-lasting, maintains temperature. Cons: Higher initial cost. |

| Ceramic Cup | Classic design, often available in various colors | Specialty coffee shops, gifts | Pros: Aesthetic appeal, good heat retention. Cons: Fragile, can be heavier. |

What Are the Key Characteristics of Plastic Cups?

Plastic cups are a staple in the B2B market due to their lightweight and durable nature, making them ideal for high-volume events like catering and festivals. Their disposability offers convenience, allowing businesses to maintain cleanliness without extensive washing. However, potential buyers should consider the environmental impact of plastic waste, as many consumers are increasingly favoring sustainable options.

How Do Glass Cups Differ in Suitability for B2B Use?

Glass cups provide an elegant and premium feel, making them a preferred choice in restaurants and upscale events. Their ability to be reused enhances their appeal for businesses focused on sustainability and customer experience. While they offer durability and aesthetic value, buyers must account for the risk of breakage and the additional weight they add to shipping and handling.

Why Choose Paper Cups for Your B2B Needs?

Paper cups are increasingly popular in the food and beverage industry, especially among coffee shops and takeout services. Their biodegradable nature aligns with the growing demand for eco-friendly products. Customizable prints on paper cups allow businesses to enhance brand visibility. However, buyers should be mindful that standard paper cups may not hold hot liquids without a protective lining, which could limit their application.

What Advantages Do Stainless Steel Cups Offer?

Stainless steel cups are ideal for outdoor events and promotional uses, thanks to their insulating properties that keep beverages hot or cold for extended periods. Their durability and reusability make them a long-term investment for businesses looking to reduce waste. While the upfront cost is higher compared to disposable options, the longevity and quality can justify the investment for many buyers.

What Makes Ceramic Cups a Unique Choice?

Ceramic cups are often favored in specialty coffee shops and as gift items due to their classic design and wide range of colors. They provide excellent heat retention, enhancing the drinking experience. However, the fragility of ceramic cups can pose challenges, particularly in high-volume environments where breakage may lead to increased costs. Buyers should weigh these factors carefully when considering ceramic options for their B2B needs.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

Key Industrial Applications of cup 120ml

| Industry/Sector | Specific Application of cup 120ml | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Portion control for sauces and dressings | Ensures consistent serving sizes, reduces waste, and improves customer satisfaction | Quality of materials, compliance with food safety standards, customization options |

| Healthcare | Sample collection for laboratory testing | Facilitates accurate testing, enhances patient care | Sterility, regulatory compliance, and volume requirements |

| Hospitality & Catering | Individual servings for desserts or beverages | Enhances presentation, promotes portion control | Aesthetic design, durability, and eco-friendly options |

| Cosmetics & Personal Care | Packaging for creams and serums | Protects product integrity, enhances brand image | Material compatibility, sealing options, and branding potential |

| Education & Training | Use in training settings for practical demonstrations | Provides hands-on experience, promotes learning engagement | Durability, safety features, and ease of cleaning |

How is the cup 120ml utilized in the Food & Beverage industry?

In the food and beverage sector, the 120ml cup is often used for portion control of sauces, dressings, and beverages. This application ensures that customers receive consistent serving sizes, which not only enhances the dining experience but also minimizes waste. International buyers, particularly from Africa and South America, should consider sourcing cups that comply with local food safety regulations and are made from high-quality materials to maintain product integrity.

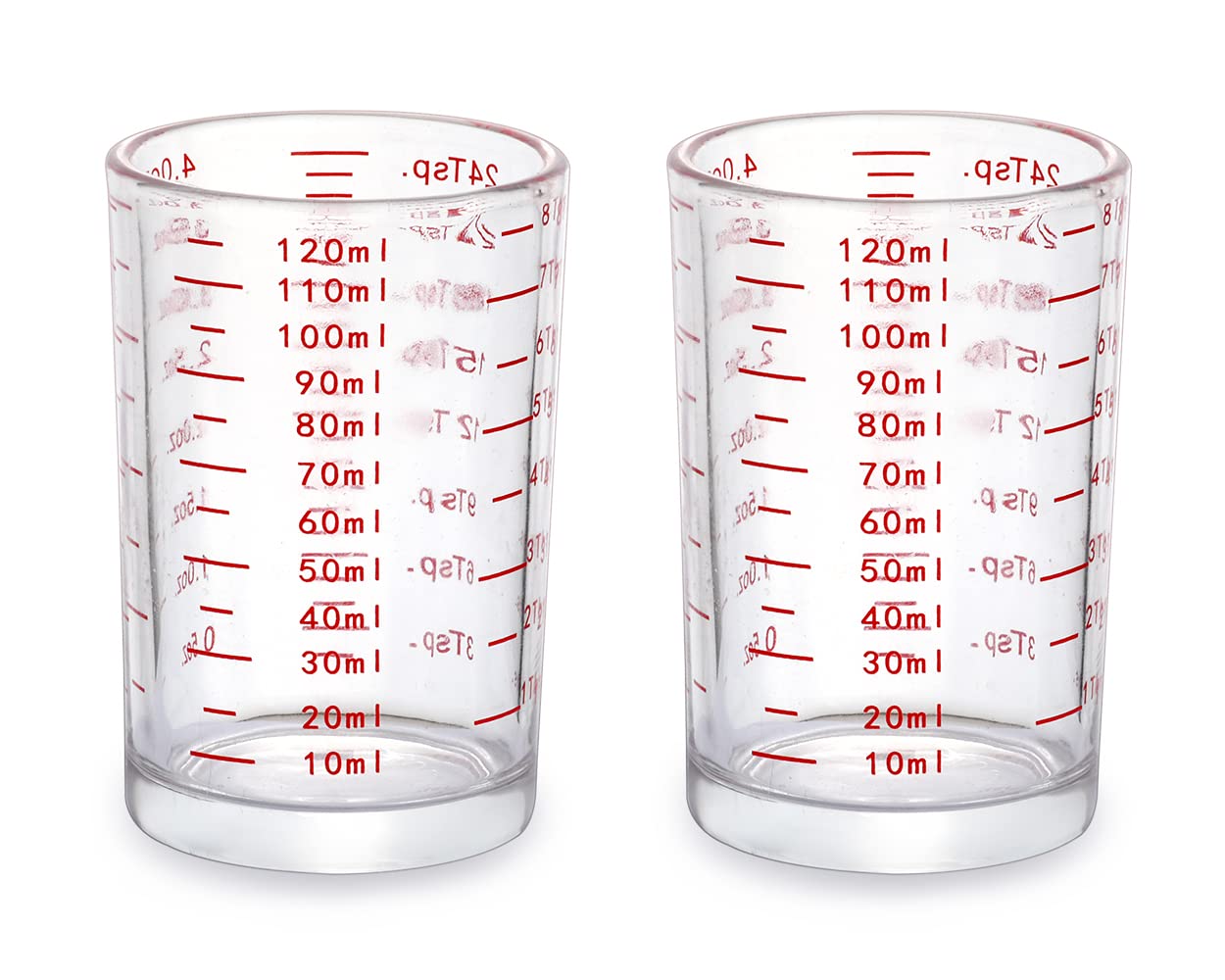

A stock image related to cup 120ml.

What role does the cup 120ml play in Healthcare?

In healthcare, the 120ml cup is frequently employed for sample collection in laboratory settings. This application is crucial for accurate testing and diagnosis, thereby enhancing patient care. For international B2B buyers in the Middle East and Europe, sourcing sterile cups that meet regulatory compliance is essential. Additionally, buyers should focus on the cups’ volume specifications to ensure they meet laboratory requirements.

How does the Hospitality & Catering industry benefit from the cup 120ml?

The hospitality and catering industries utilize the 120ml cup for serving individual portions of desserts, beverages, or condiments. This application not only improves the aesthetic presentation of dishes but also promotes portion control, which can lead to cost savings. Buyers from Europe and Africa should prioritize sourcing cups that are durable and visually appealing, as well as eco-friendly options that align with sustainability initiatives.

What advantages does the cup 120ml offer in Cosmetics & Personal Care?

In the cosmetics and personal care sector, the 120ml cup is used for packaging creams, serums, and other liquid products. This application protects the integrity of the products while enhancing the brand’s image through effective packaging. B2B buyers, particularly from South America and the Middle East, should consider sourcing cups that are compatible with various materials and offer sealing options to prevent leakage, along with customization for branding purposes.

How is the cup 120ml effective in Education & Training?

In educational settings, the 120ml cup is used for practical demonstrations, allowing students to engage in hands-on learning experiences. This application is particularly beneficial in science and culinary training, where practical skills are essential. International buyers should focus on sourcing durable cups that are safe for use and easy to clean, ensuring they can withstand repeated handling in training environments.

Related Video: Uses of Aluminium | Environmental Chemistry | Chemistry | FuseSchool

3 Common User Pain Points for ‘cup 120ml’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality ‘Cup 120ml’ for Diverse Markets

The Problem: B2B buyers, especially those in regions like Africa and South America, often struggle to find reliable suppliers of ‘cup 120ml’ that meet both quality and regulatory standards. This challenge can lead to delays in product launches, customer dissatisfaction, and increased costs due to poor-quality products that require replacement or reordering. The lack of established local suppliers means buyers may resort to international vendors, which can complicate logistics and raise import costs.

The Solution: To overcome sourcing challenges, buyers should conduct thorough market research to identify reputable suppliers. Platforms like Alibaba, Global Sources, or local trade fairs can be invaluable in locating manufacturers with a proven track record. When selecting a supplier, prioritize those that offer samples and have quality certifications such as ISO or other relevant standards. Establishing a solid communication line with potential suppliers can also help clarify product specifications and quality expectations. Engaging in small trial orders can mitigate risks, allowing buyers to assess the quality before committing to larger purchases.

Scenario 2: Navigating Compliance and Regulations for ‘Cup 120ml’

The Problem: International buyers face complex regulatory landscapes when importing ‘cup 120ml’. Different countries have varying regulations concerning food safety, materials used, and labeling requirements. This can be particularly daunting for businesses in the Middle East and Europe, where stringent compliance is mandatory. Non-compliance can lead to fines, shipment delays, or even product recalls, impacting the business’s bottom line.

The Solution: To effectively navigate compliance, B2B buyers should invest time in understanding the specific regulations applicable to their target markets. Consulting with local regulatory bodies or hiring compliance experts can provide clarity on the necessary certifications and documentation needed for ‘cup 120ml’. Additionally, working with suppliers who are well-versed in these regulations can streamline the process. Buyers should request documentation that proves compliance, such as material safety data sheets (MSDS) and certificates of conformity. Staying informed about changes in regulations through industry newsletters or trade associations can also keep businesses ahead of potential compliance issues.

Scenario 3: Ensuring Cost-Effectiveness in Bulk Purchasing of ‘Cup 120ml’

The Problem: Many B2B buyers face the challenge of balancing cost and quality when purchasing ‘cup 120ml’ in bulk. While bulk purchasing can lower unit costs, buyers often find that cheaper products compromise quality, leading to customer complaints and increased return rates. This is particularly problematic for businesses that rely on these cups for food service or retail, where customer satisfaction is crucial.

The Solution: To ensure cost-effectiveness without sacrificing quality, buyers should adopt a strategic approach to bulk purchasing. Start by analyzing usage patterns to determine optimal order quantities that minimize waste and storage costs. Engage with suppliers to negotiate pricing based on long-term contracts or recurring orders, which can often yield better rates. Furthermore, consider the total cost of ownership (TCO) rather than just the purchase price; factor in shipping costs, potential tariffs, and the cost of replacing defective products. Establishing a partnership with a reliable supplier can also lead to better terms and the opportunity to test new products at lower risks. Regularly reviewing supplier performance based on quality, delivery times, and responsiveness can help maintain a cost-effective supply chain.

Strategic Material Selection Guide for cup 120ml

When selecting materials for a 120ml cup, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Below, we analyze four common materials used in the manufacturing of 120ml cups, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polypropylene (PP) for 120ml Cups?

Polypropylene (PP) is widely used for disposable cups due to its excellent temperature resistance and lightweight nature. It can withstand temperatures up to 100°C, making it suitable for hot beverages. Additionally, PP exhibits good chemical resistance, which is essential for compatibility with various liquids.

Pros and Cons of Polypropylene (PP)

The primary advantage of PP is its low cost and ease of manufacturing, which allows for high-volume production. However, it is less durable than other materials and may not perform well under extreme conditions, such as high pressure or prolonged exposure to UV light.

Impact on Application

PP is suitable for a variety of beverages, including hot and cold drinks. However, it may not be ideal for long-term storage of acidic beverages, as prolonged contact can degrade the material.

Considerations for International Buyers

Buyers must ensure that the PP used complies with food safety standards such as FDA regulations in the USA or EFSA in Europe. Additionally, understanding local recycling regulations is crucial, as PP is recyclable but not universally accepted in all regions.

How Does Polystyrene (PS) Compare for 120ml Cup Applications?

Polystyrene (PS) is another popular choice for disposable cups, particularly in food service. It offers good clarity and rigidity, making it visually appealing for cold beverages.

Pros and Cons of Polystyrene (PS)

PS cups are generally inexpensive and provide excellent insulation for cold drinks. However, they have a lower temperature tolerance (up to 70°C) and are more prone to cracking under stress, which limits their use for hot beverages.

Impact on Application

PS is primarily suited for cold drinks and is often used in fast-food chains for serving soft drinks or desserts. Its limitations in heat resistance make it unsuitable for hot beverages or prolonged exposure to sunlight.

Considerations for International Buyers

Buyers should be aware of the environmental concerns surrounding PS, as it is not biodegradable and has limited recycling options. Compliance with local regulations regarding single-use plastics is also critical, particularly in regions with stringent environmental laws.

What Are the Advantages of Paperboard for 120ml Cups?

Paperboard cups are an eco-friendly alternative, often lined with a thin layer of polyethylene to provide moisture resistance. They are biodegradable and can be recycled in many regions.

Pros and Cons of Paperboard

The key advantage of paperboard is its sustainability, appealing to environmentally conscious consumers. However, they can be more expensive than plastic options and may require additional processing for moisture resistance.

Impact on Application

Paperboard cups are suitable for both hot and cold beverages, making them versatile for various applications. However, they may not hold up well if exposed to liquids for extended periods without proper lining.

Considerations for International Buyers

Buyers should verify the sourcing of paperboard materials to ensure compliance with sustainability certifications. Understanding local recycling capabilities and consumer preferences for eco-friendly products is also essential.

How Does Stainless Steel Perform in 120ml Cup Applications?

Stainless steel is a durable and reusable option for 120ml cups, known for its strength and resistance to corrosion. It can withstand high temperatures and is suitable for both hot and cold beverages.

Pros and Cons of Stainless Steel

The primary advantage of stainless steel is its durability and longevity, making it a cost-effective choice over time. However, the initial manufacturing cost is higher than that of disposable options, which may deter some buyers.

Impact on Application

Stainless steel cups are ideal for high-end markets or eco-conscious consumers looking for reusable products. They are compatible with a wide range of beverages and maintain temperature effectively.

Considerations for International Buyers

Buyers should ensure compliance with food safety standards and certifications relevant to their markets, such as ASTM or ISO. Additionally, understanding local preferences for reusable products can influence purchasing decisions.

Summary of Material Selection for 120ml Cups

| Material | Typical Use Case for cup 120ml | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Disposable hot/cold beverages | Cost-effective and lightweight | Less durable under extreme conditions | Low |

| Polystyrene (PS) | Cold beverages in food service | Good clarity and insulation | Low temperature tolerance | Low |

| Paperboard | Eco-friendly hot/cold beverages | Biodegradable and recyclable | Higher cost and moisture sensitivity | Medium |

| Stainless Steel | Reusable high-end beverages | Durable and long-lasting | Higher initial cost | High |

This analysis provides B2B buyers with a comprehensive understanding of material options for 120ml cups, enabling informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cup 120ml

What Are the Key Manufacturing Processes for 120ml Cups?

When sourcing 120ml cups for various applications, understanding the manufacturing processes is essential for B2B buyers. The production of these cups typically involves several stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets the required specifications and quality standards.

How Is Material Prepared for 120ml Cup Production?

The first step in the manufacturing process is material preparation. Common materials used for 120ml cups include:

- Plastic (e.g., PP, PS): Polypropylene (PP) and polystyrene (PS) are widely used due to their lightweight and durability. They are also recyclable, which can be an important factor for environmentally-conscious buyers.

- Paper: For eco-friendly options, paper cups coated with a thin layer of polyethylene are preferred. This layer provides moisture resistance while maintaining the cup’s structural integrity.

The materials must undergo a quality check to ensure they meet specific criteria such as thickness, elasticity, and resistance to temperature variations.

What Techniques Are Used in the Forming Stage?

The forming stage is where the actual shape of the cup is created. Several techniques are employed:

- Injection Molding: This method is commonly used for plastic cups. Plastic pellets are heated until molten, then injected into a mold. Once cooled, the cup retains its shape.

- Thermoforming: In this technique, sheets of plastic are heated and then formed over a mold. This is ideal for creating cups with complex shapes.

- Die Cutting: For paper cups, die cutting is used to shape the cup from flat sheets. The edges are then sealed to create a functional product.

Each technique has its advantages, depending on production volume, cost, and desired cup characteristics.

What Happens During the Assembly Process?

After forming, the next step is assembly. This stage involves:

- Sealing and Joining: For paper cups, the bottom is sealed using heat or adhesive to ensure no leakage. For plastic cups, the edges may be trimmed and sealed if necessary.

- Quality Control Checks: During assembly, manufacturers often perform inline quality checks to ensure that the cups are properly formed and sealed.

This step is critical as it directly impacts the cup’s usability and customer satisfaction.

How Is Finishing Handled in 120ml Cup Manufacturing?

The finishing stage includes several processes that add value and enhance the usability of the cups:

- Printing and Branding: Custom printing is often done for branding purposes. This can include logos, labels, or other designs that enhance the product’s marketability.

- Coating: Some cups may undergo additional coating to improve moisture resistance or add a layer of insulation.

- Packaging: Finally, the cups are packaged for shipment. Proper packaging is essential to prevent damage during transportation.

What Are the International Quality Assurance Standards Relevant to 120ml Cups?

Quality assurance is critical in the manufacturing of 120ml cups, especially for international B2B buyers. Several international standards apply, including:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Compliance ensures that the manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: If the cups are intended for use in medical or pharmaceutical applications, adherence to American Petroleum Institute (API) standards may be necessary.

These standards help in ensuring the safety and reliability of the products.

What Are the Key Quality Control Checkpoints in Cup Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process. The main checkpoints include:

- Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected upon arrival. Ensuring that only high-quality materials enter the production line is crucial.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the production parameters and ensure that the cups meet design specifications.

- Final Quality Control (FQC): Before the cups are packaged, a final inspection is performed to assess their overall quality, including checks for leaks, structural integrity, and appearance.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, verifying the quality assurance processes of suppliers is essential. Here are actionable steps:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into their quality management practices and adherence to international standards.

- Request QC Reports: Suppliers should provide detailed reports on their QC processes, including IQC, IPQC, and FQC results.

- Third-Party Inspections: Engaging independent third-party inspection services can add an extra layer of assurance, ensuring that the products meet the required standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions have varying regulations governing product safety and quality. Understanding these can help in selecting compliant suppliers.

- Cultural Differences: Communication styles and business practices may differ across regions, affecting how quality is perceived and assured.

- Supply Chain Considerations: Disruptions in the supply chain can impact quality. Buyers should have contingency plans and maintain open lines of communication with suppliers.

By being informed about the manufacturing processes and quality assurance standards, B2B buyers can make better purchasing decisions, ensuring they source high-quality 120ml cups that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cup 120ml’

In this practical sourcing guide, we aim to provide B2B buyers with a comprehensive checklist to facilitate the procurement of 120ml cups. This guide will help you navigate the complexities of sourcing, ensuring that you make informed decisions that align with your business needs and standards.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the 120ml cups you need. This includes material (e.g., plastic, paper, biodegradable options), design (e.g., with or without lids), and any specific compliance requirements relevant to your industry. Precise specifications will help you communicate your needs effectively and streamline the sourcing process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in manufacturing or distributing 120ml cups. Use online directories, trade shows, and industry networks to compile a list of candidates. Look for suppliers with a proven track record in your target regions (Africa, South America, the Middle East, and Europe), as local knowledge can significantly impact logistics and regulatory compliance.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management or environmental certifications like FSC or compostability standards. Certifications indicate a commitment to quality and sustainability, which are increasingly important to many businesses today. Request documentation to confirm these credentials during your evaluation.

Step 4: Request Samples for Quality Assessment

Before making any commitments, request samples of the 120ml cups from shortlisted suppliers. This step is crucial for assessing the quality, durability, and design of the products. Evaluate the samples against your specifications, and consider conducting tests for performance under various conditions, especially if they will hold hot or cold beverages.

Step 5: Understand Pricing Structures and Terms

Discuss pricing structures and payment terms with potential suppliers. Ensure you understand whether the quoted prices include shipping, taxes, and duties. Inquire about bulk discounts, payment schedules, and any potential penalties for late payments. Transparent pricing will help you budget effectively and avoid unexpected costs later in the procurement process.

Step 6: Assess Supplier Reliability and Reputation

Investigate the reliability and reputation of your shortlisted suppliers. Look for customer reviews, case studies, and testimonials from other businesses that have worked with them. Consider reaching out to industry peers for recommendations. A supplier’s reliability can significantly impact your supply chain, so choose one with a solid reputation for delivering on time and maintaining quality.

Step 7: Establish Clear Communication Channels

Once you have selected a supplier, establish clear communication channels to facilitate ongoing collaboration. Define points of contact, preferred communication methods, and response times. Effective communication is key to addressing any issues that may arise during production or delivery, ensuring a smooth partnership.

By following this step-by-step sourcing guide, B2B buyers can confidently procure 120ml cups that meet their specific needs while fostering strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for cup 120ml Sourcing

What Are the Key Cost Components in Sourcing 120ml Cups?

When sourcing 120ml cups, understanding the cost structure is crucial for international B2B buyers. The main components of the cost include:

-

Materials: The primary materials used for manufacturing 120ml cups can vary significantly. Common materials include plastic (e.g., PET, PP) and biodegradable options. The choice of material influences both cost and environmental impact.

-

Labor: Labor costs are influenced by the region of production. In countries with lower labor costs, such as some regions in Africa or South America, the overall manufacturing cost may be lower. However, labor regulations and skill levels also play a role.

-

Manufacturing Overhead: This includes expenses related to the factory’s operation, such as utilities, maintenance, and administrative costs. Understanding the overhead can help buyers gauge the pricing strategies of suppliers.

-

Tooling: For customized cups, tooling costs can be substantial. This includes the cost of molds and machinery required to produce specific designs or features.

-

Quality Control (QC): Ensuring that products meet quality standards incurs costs, particularly for international shipments where compliance with specific regulations is required.

-

Logistics: Shipping costs can vary greatly depending on the Incoterms used, the distance from the supplier, and the mode of transport. Buyers should evaluate all logistics expenses, including customs duties and potential tariffs.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. Understanding the typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect 120ml Cup Sourcing?

Several factors influence the pricing of 120ml cups, making it essential for buyers to consider them during procurement:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically result in lower unit prices. Many suppliers have minimum order quantities that can affect overall costs.

-

Specifications and Customization: Custom designs, colors, or features can significantly increase costs. Buyers should assess whether customization is necessary or if standard products suffice.

-

Material Quality and Certifications: The quality of materials and any certifications (e.g., FDA approval for food safety) can affect pricing. Higher quality or certified materials often come at a premium.

-

Supplier Factors: Reliability, reputation, and geographical location of suppliers can impact pricing. Suppliers in regions with political instability or economic challenges may charge more to mitigate risks.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) determine who is responsible for shipping costs and insurance. Understanding these terms can help buyers avoid unexpected charges.

What Are the Best Negotiation Strategies for International Buyers?

To effectively negotiate pricing for 120ml cups, consider the following tips:

-

Conduct Market Research: Familiarize yourself with average pricing in the market. This knowledge will strengthen your negotiation position.

-

Leverage Volume Discounts: If you can commit to larger orders, use this leverage to negotiate lower prices or better terms.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term relationships often yield more favorable conditions.

-

Consider Total Cost of Ownership (TCO): Evaluate all costs associated with sourcing, including shipping, storage, and disposal. A lower initial price might not always result in savings when TCO is considered.

-

Be Flexible with Specifications: If possible, consider standard products instead of custom designs. This flexibility can lead to significant cost savings.

What Should Buyers Keep in Mind Regarding Indicative Pricing?

It’s important to note that pricing for 120ml cups can vary widely based on the factors discussed. Prices are often indicative and can fluctuate due to changes in raw material costs, economic conditions, and supply chain disruptions. Buyers should always seek updated quotes from multiple suppliers and consider the total cost implications of their sourcing decisions. By understanding these dynamics, international B2B buyers can make informed purchasing decisions that align with their budget and operational needs.

Alternatives Analysis: Comparing cup 120ml With Other Solutions

When considering the ‘cup 120ml’ for various applications, it is essential to explore alternative solutions that can meet similar needs. Understanding the strengths and weaknesses of these alternatives can help international B2B buyers make informed decisions tailored to their specific requirements. Below, we compare the ‘cup 120ml’ against two viable alternatives: the 250ml cup and biodegradable containers.

| Comparison Aspect | Cup 120ml | 250ml Cup | Biodegradable Container |

|---|---|---|---|

| Performance | Ideal for small servings and precise portions. | Suitable for larger servings, but can lead to waste. | Comparable performance, but may not be as sturdy. |

| Cost | Generally low-cost, ideal for bulk purchases. | Slightly higher cost per unit due to larger size. | Typically more expensive due to eco-friendly materials. |

| Ease of Implementation | Easily integrated into existing workflows. | Requires adjustments in serving sizes and procedures. | May require changes in supplier and logistics. |

| Maintenance | Minimal maintenance; easy cleanup. | Similar ease of maintenance but more waste generated. | Requires proper disposal methods to be effective. |

| Best Use Case | Perfect for sample servings, desserts, and small drinks. | Best for standard beverage servings in cafes and restaurants. | Ideal for eco-conscious businesses looking for sustainable options. |

What Are the Advantages and Disadvantages of Using a 250ml Cup Instead of Cup 120ml?

A stock image related to cup 120ml.

The 250ml cup serves as a larger alternative, which can cater to a broader range of drink sizes. This makes it suitable for cafes and restaurants that prioritize offering larger servings. However, the downside is that it may lead to unnecessary waste if customers do not finish their drinks, which can impact profitability and sustainability efforts.

How Do Biodegradable Containers Compare to Cup 120ml?

Biodegradable containers are becoming increasingly popular due to their eco-friendly attributes. They appeal to environmentally conscious consumers and businesses alike. While they may be more expensive than traditional options like the cup 120ml, they contribute positively to a brand’s sustainability image. Nevertheless, they often require specific disposal methods to ensure they break down properly, which can complicate logistics and waste management processes.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

In choosing between the cup 120ml and its alternatives, B2B buyers should consider their unique operational needs, customer preferences, and sustainability goals. The cup 120ml is ideal for businesses focused on portion control and cost-effectiveness, while the 250ml cup may suit those looking for larger servings but at a potential cost of waste. On the other hand, biodegradable containers appeal to brands emphasizing sustainability but may involve higher costs and disposal challenges. Ultimately, the right choice will align with the company’s values and operational logistics, ensuring both customer satisfaction and business efficiency.

Essential Technical Properties and Trade Terminology for cup 120ml

What Are the Key Technical Properties of a 120ml Cup?

When evaluating the specifications of a 120ml cup, understanding its technical properties is vital for B2B buyers, especially in industries such as food and beverage, hospitality, and retail. Below are critical specifications to consider:

-

Material Grade

– Definition: The type of material used to manufacture the cup, such as plastic (e.g., polypropylene or polystyrene), paper, or glass.

– Importance: Different materials offer varying levels of durability, heat resistance, and recyclability. For example, polypropylene is lightweight and suitable for cold beverages, while paper cups can be biodegradable, appealing to environmentally conscious brands. -

Tolerance

– Definition: The allowable deviation from specified dimensions in the cup’s manufacturing process.

– Importance: Tolerance affects how well the cups fit into dispensers or holders and ensures uniformity in production. A tighter tolerance may lead to higher manufacturing costs but can enhance the product’s overall quality and functionality. -

Capacity

– Definition: The volume that the cup can hold, in this case, 120ml.

– Importance: Knowing the exact capacity is essential for businesses that need to standardize portion sizes, especially in food service or beverage industries. It also impacts shipping and storage considerations. -

Weight

– Definition: The weight of the cup, typically measured in grams.

– Importance: Lighter cups can reduce shipping costs and are often preferred in fast-paced service environments. However, weight must be balanced with durability to ensure the cup does not compromise during use. -

Heat Resistance

– Definition: The ability of the cup material to withstand high temperatures without deforming or melting.

– Importance: For cups intended for hot beverages, heat resistance is critical. Buyers must ensure that the cups will maintain their shape and integrity when filled with hot liquids.

What Are Common Trade Terms Used in the Cup Industry?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some essential terms for international B2B buyers:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or products that are sold under another company’s brand.

– Importance: Understanding OEM relationships can help buyers source customized products that meet specific branding or quality standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. It helps buyers assess the feasibility of purchasing from suppliers and can impact cash flow. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and other details for specific products.

– Importance: An RFQ is a vital tool in the procurement process, enabling buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, ensuring clarity in contracts and reducing disputes.

A stock image related to cup 120ml.

- Lead Time

– Definition: The time taken from placing an order until it is delivered.

– Importance: Understanding lead times is essential for inventory management and planning. It allows buyers to align their stock levels with customer demand and avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding 120ml cups, ultimately optimizing their supply chain and enhancing their product offerings.

Navigating Market Dynamics and Sourcing Trends in the cup 120ml Sector

What Are the Current Market Dynamics and Key Trends in the 120ml Cup Sector?

The global market for 120ml cups is witnessing significant growth, driven by the increasing demand for single-serve packaging across various industries such as food and beverages, pharmaceuticals, and cosmetics. In regions like Africa and South America, the rising trend of on-the-go consumption is pushing manufacturers to innovate in packaging solutions. In contrast, Europe and the Middle East are experiencing a shift towards premium and sustainable packaging options, reflecting changing consumer preferences.

Emerging technologies, such as automation in manufacturing and smart packaging solutions, are reshaping the sourcing landscape. B2B buyers are increasingly leveraging data analytics to optimize their supply chains, ensuring cost-effectiveness and responsiveness to market changes. The integration of e-commerce platforms is also enhancing direct procurement processes, allowing buyers to source products more efficiently. As a result, international buyers must remain agile and informed about these advancements to stay competitive.

Another notable trend is the rise of regional sourcing. Buyers from Africa and South America are increasingly looking to local suppliers to minimize logistics costs and reduce delivery times. This trend is particularly relevant in light of recent disruptions in global supply chains, prompting businesses to rethink their sourcing strategies. As a B2B buyer, understanding these dynamics is crucial for making informed purchasing decisions.

How Is Sustainability Influencing Sourcing Decisions for 120ml Cups?

Sustainability has become a pivotal factor in the sourcing of 120ml cups, particularly for international B2B buyers. The environmental impact of packaging materials is under scrutiny, and businesses are increasingly prioritizing eco-friendly options. This includes the use of biodegradable or recyclable materials, which not only appeal to environmentally conscious consumers but also comply with stringent regulations in regions like Europe.

Ethical sourcing is equally important, with buyers seeking suppliers who adhere to fair labor practices and sustainable production methods. Certifications such as FSC (Forest Stewardship Council) for paper products or ISO 14001 for environmental management systems are becoming essential for suppliers to demonstrate their commitment to sustainability. By prioritizing suppliers with these certifications, B2B buyers can enhance their brand reputation and meet the growing demand for responsible sourcing.

Moreover, the adoption of life cycle assessments (LCA) helps businesses evaluate the environmental impact of their packaging choices. This analytical approach allows buyers to identify areas for improvement and make data-driven decisions that align with their sustainability goals. As a result, integrating sustainability into sourcing strategies is not just a trend but a necessity for long-term business success.

What Is the Evolution of the 120ml Cup Market and Its Importance for B2B Buyers?

The 120ml cup market has evolved significantly over the past few decades. Initially, the focus was primarily on functionality and cost-effectiveness. However, as consumer preferences shifted towards convenience and sustainability, manufacturers began to innovate, introducing a variety of materials and designs that cater to these needs.

In the early 2000s, plastic cups dominated the market due to their affordability and versatility. However, with growing environmental concerns, there has been a marked shift towards alternative materials such as paper and biodegradable plastics. This evolution reflects a broader trend in the packaging industry, where environmental impact is increasingly influencing purchasing decisions.

For B2B buyers, understanding the historical context of the 120ml cup market is essential for making informed decisions. Recognizing how consumer trends and regulatory changes have shaped the industry can provide valuable insights into future sourcing strategies, allowing buyers to stay ahead of the curve in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of cup 120ml

-

How do I ensure the quality of 120ml cups when sourcing internationally?

To ensure the quality of 120ml cups, conduct thorough supplier vetting. Request samples to assess material quality and manufacturing standards. Utilize third-party quality assurance services to inspect products before shipment. Additionally, consider certifications such as ISO or FDA compliance, which indicate adherence to international quality standards. Establish clear quality criteria in your purchase agreement to avoid discrepancies. -

What are the common materials used for 120ml cups, and which is the best for my needs?

120ml cups are commonly made from materials such as plastic, paper, and biodegradable options. The best choice depends on your intended use. For hot beverages, double-walled paper cups offer insulation, while plastic cups are ideal for cold drinks. Biodegradable materials are suitable for environmentally conscious brands. Assess your market demands and sustainability goals when selecting the material. -

What minimum order quantities (MOQ) should I expect when sourcing 120ml cups?

Minimum order quantities (MOQ) for 120ml cups can vary significantly between suppliers. Typically, MOQs range from 1,000 to 10,000 units, depending on the manufacturer’s production capabilities and the type of cup. When negotiating with suppliers, express your needs clearly and inquire about flexibility in MOQs, especially if you’re a small business or testing a new product line. -

What payment terms are standard for international B2B transactions involving 120ml cups?

Standard payment terms for international transactions often include a deposit (usually 30-50%) upfront, with the balance due before shipment. Some suppliers may offer net payment terms, such as 30 or 60 days after delivery. It’s crucial to negotiate terms that protect your interests, possibly using escrow services for larger orders to ensure product quality before full payment is made. -

How can I customize 120ml cups for my brand?

Customizing 120ml cups involves selecting materials, colors, and designs that reflect your brand identity. Most manufacturers offer printing services for logos and graphics, and some allow for shape variations. Start by discussing your requirements with potential suppliers and request samples of previous custom work to ensure they can meet your design specifications. Always confirm lead times for customized orders. -

What logistics considerations should I keep in mind when importing 120ml cups?

When importing 120ml cups, consider logistics factors such as shipping methods, customs duties, and lead times. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Work with a freight forwarder familiar with your destination country to navigate customs regulations and paperwork. Additionally, factor in warehousing needs if you’re ordering large quantities. -

How do I handle potential disputes with suppliers regarding 120ml cups?

To handle disputes effectively, establish clear communication channels with your supplier from the start. Include detailed terms in your contract regarding quality standards, delivery schedules, and payment terms. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, consider mediation or arbitration as outlined in your contract. Keeping thorough documentation can also support your case. -

What are the best practices for sustainable sourcing of 120ml cups?

Sustainable sourcing practices include selecting suppliers that prioritize eco-friendly materials and ethical manufacturing processes. Research suppliers’ sustainability certifications and their commitment to reducing waste and carbon footprints. Incorporate sustainability clauses in your contracts, and consider investing in biodegradable or recyclable cup options. Engage with suppliers who are transparent about their sourcing and production methods to align with your corporate social responsibility goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cup 120ml

In the competitive landscape of international B2B sourcing, the strategic procurement of 120ml cups is pivotal for businesses aiming to enhance their operational efficiency and product offerings. By leveraging a strategic sourcing approach, buyers can ensure not only cost-effectiveness but also quality assurance and supply chain reliability. Engaging with reputable suppliers across diverse regions, including Africa, South America, the Middle East, and Europe, allows for a richer selection of materials and designs that cater to varying market demands.

As we move forward, the emphasis on sustainability and eco-friendly materials will shape the sourcing strategies of businesses. International buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability, as this not only meets growing consumer expectations but also aligns with global environmental standards.

In conclusion, the future of sourcing 120ml cups lies in adaptability and innovation. B2B buyers are encouraged to explore new markets and technological advancements that can streamline procurement processes. By doing so, they can not only enhance their product lines but also position their businesses for long-term success in a rapidly evolving marketplace. Take the next step in your sourcing journey by evaluating your current supply chain strategies and embracing the opportunities presented by global partnerships.