Master Corner Bead: The Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for corner bead

In an increasingly interconnected world, sourcing quality corner bead for construction projects can pose significant challenges for international B2B buyers. Navigating the complexities of different suppliers, materials, and compliance regulations can be daunting, particularly for those operating across diverse markets such as Africa, South America, the Middle East, and Europe. This guide is designed to empower you with the knowledge needed to make informed purchasing decisions in this vital segment of the building materials industry.

The comprehensive scope of this guide covers various types of corner bead, their applications in both residential and commercial projects, and essential supplier vetting strategies. You’ll gain insights into the cost implications of different materials and how to effectively negotiate with suppliers to ensure you receive the best value for your investment. Understanding the nuances of market trends and regional preferences will also equip you to tailor your sourcing strategy to meet local demands.

By leveraging this guide, international B2B buyers can streamline their procurement processes, mitigate risks associated with sourcing, and build lasting relationships with reliable suppliers. Whether you’re looking to enhance your product offerings or ensure compliance with regional construction standards, this resource is your key to navigating the global market for corner bead efficiently and effectively.

Understanding corner bead Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paper-faced Bead | Made with a paper covering, typically lightweight and easy to install. | Residential and light commercial projects | Pros: Cost-effective, easy to finish. Cons: Less durable than metal options. |

| Metal Bead | Constructed from galvanized steel or aluminum, offering high durability. | High-traffic areas, commercial buildings | Pros: Excellent impact resistance, longevity. Cons: Higher cost, heavier weight. |

| PVC Bead | Made from durable PVC material, resistant to moisture and corrosion. | Wet environments, outdoor applications | Pros: Water-resistant, lightweight. Cons: Limited availability in certain regions. |

| Bullnose Bead | Features a rounded edge for a softer appearance, ideal for aesthetic finishes. | Residential interiors, high-end finishes | Pros: Attractive design, less prone to chipping. Cons: More expensive, limited structural strength. |

| L Bead | Provides a clean finish without the need for tape and mud, with a unique “L” shape. | Drywall finishes, seamless joints | Pros: Efficient installation, minimal finishing required. Cons: May require skilled labor for proper application. |

What Are the Characteristics of Paper-faced Bead?

Paper-faced beads are a popular choice for many residential and light commercial projects due to their lightweight nature and ease of installation. They are typically made with a paper covering that can be quickly finished with joint compound. When considering a purchase, buyers should weigh the cost-effectiveness of these beads against their durability, as they may not withstand heavy impacts as well as metal options. For projects with lower traffic and less exposure to wear, paper-faced beads can be an ideal choice.

Why Choose Metal Bead for High-Traffic Areas?

Metal beads, often made from galvanized steel or aluminum, are designed for high durability and longevity, making them suitable for high-traffic areas such as commercial buildings. Their robust construction provides excellent impact resistance, which is crucial in environments where walls are frequently bumped or scratched. Buyers should consider the initial investment, as metal beads tend to be more expensive than their paper counterparts. However, the long-term savings from reduced maintenance and replacement can justify the upfront costs.

How Do PVC Beads Perform in Wet Environments?

PVC beads are an excellent option for wet environments due to their resistance to moisture and corrosion. This makes them particularly suitable for outdoor applications or areas prone to high humidity, such as bathrooms and kitchens. B2B buyers should evaluate the availability of PVC beads in their region, as they may not be as widely stocked as other types. The lightweight nature of PVC also facilitates easier handling and installation, which can be a significant advantage for large-scale projects.

What Are the Aesthetic Benefits of Bullnose Bead?

Bullnose beads are characterized by their rounded edges, offering a softer, more aesthetically pleasing finish compared to traditional corner beads. They are often used in residential interiors and high-end finishes where appearance is a priority. While they do provide an attractive design and are less prone to chipping, buyers should be mindful of their higher price point and potentially limited structural strength. For projects focused on visual appeal, bullnose beads can enhance the overall look of a space.

What Advantages Does L Bead Offer for Seamless Finishes?

L beads are designed to provide a clean finish without the need for additional tape and mud, thanks to their unique “L” shape. This feature allows for seamless joints in drywall installations, making them a favorite among contractors seeking efficiency. While they can save time and labor costs, buyers should consider the necessity of skilled labor for proper application, as incorrect installation can lead to visible imperfections. Overall, L beads are ideal for projects where a polished finish is essential.

Related Video: How to install and finish vinyl corner bead

Key Industrial Applications of corner bead

| Industry/Sector | Specific Application of corner bead | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Finishing drywall corners in residential projects | Enhances durability and aesthetic appeal of interiors | Quality of material, compliance with local building codes, and availability of sizes |

| Commercial Real Estate | Protecting corners in high-traffic areas | Reduces maintenance costs and prolongs the life of finishes | Impact resistance, fire rating, and installation ease |

| Hospitality | Corner bead for hotel lobbies and rooms | Improves guest experience through quality finishes | Design options, color matching, and durability in high-use environments |

| Retail | Corner bead in store displays and fixtures | Creates visually appealing and safe retail environments | Customization options, lead times, and bulk pricing |

| Industrial Facilities | Corner bead in warehouses and factories | Provides safety and reduces damage to structural elements | Compliance with safety regulations and availability of industrial-grade products |

How is Corner Bead Used in Construction & Renovation Projects?

In the construction and renovation sector, corner bead is primarily used to finish drywall corners, providing a sharp, clean edge that enhances both durability and aesthetics. This application is crucial for residential projects where visual appeal is paramount. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality corner bead that meets local building codes is essential. Buyers should consider the material’s resistance to moisture and impact, ensuring longevity in various climates.

What are the Benefits of Corner Bead in Commercial Real Estate?

In commercial real estate, corner bead is vital for protecting corners in high-traffic areas such as hallways and entryways. It minimizes wear and tear, thereby reducing maintenance costs associated with repairs. For buyers in the Middle East and Europe, it is crucial to select corner bead that meets specific impact resistance and fire safety standards. Additionally, ease of installation can significantly affect project timelines and labor costs, making it an important consideration for sourcing.

How Does Corner Bead Enhance Hospitality Environments?

In the hospitality industry, corner bead is used to create polished finishes in hotel lobbies and guest rooms. This application not only improves the visual appeal but also contributes to a positive guest experience, which is essential for customer retention. Buyers from Europe and Australia should focus on design options and color matching capabilities when sourcing corner bead, ensuring that it aligns with the overall aesthetic of the property. Durability is also a key factor, as these spaces experience high levels of foot traffic.

Why is Corner Bead Important for Retail Spaces?

For retail environments, corner bead is utilized in store displays and fixtures to create safe and visually appealing spaces. This application helps in maintaining a professional image while ensuring customer safety. B2B buyers in South America should consider customization options and lead times when sourcing corner bead for retail applications, as these factors can significantly impact store design and layout. Bulk pricing may also provide cost benefits for larger retailers.

How is Corner Bead Used in Industrial Facilities?

In industrial facilities, corner bead serves to protect corners from damage in warehouses and factories, enhancing safety and structural integrity. It is essential for international B2B buyers to ensure that the corner bead complies with relevant safety regulations, particularly in high-stakes environments. Sourcing industrial-grade products that can withstand heavy use and environmental factors is crucial for maintaining operational efficiency and safety in these settings.

3 Common User Pain Points for ‘corner bead’ & Their Solutions

Scenario 1: Difficulty in Achieving Smooth, Even Finishes

The Problem: Many B2B buyers encounter challenges in achieving seamless finishes when installing corner bead, particularly in high-traffic or moisture-prone areas. In regions like Africa and South America, where humidity can fluctuate dramatically, improperly installed corner bead can lead to warping or cracking. This not only affects the aesthetic of the project but can also compromise structural integrity over time, leading to costly repairs and dissatisfied clients.

The Solution: To ensure a smooth and even finish, it is critical to select the appropriate type of corner bead for the specific environment. For humid areas, consider using vinyl corner bead, which is resistant to moisture and less likely to warp. Additionally, proper installation techniques should be adhered to; this includes ensuring that the corner bead is securely fastened to the drywall and using the right type of joint compound. For optimal results, apply a thin coat of joint compound over the corner bead and feather it out onto the wall surface. This method not only provides a seamless look but also strengthens the corner, reducing the likelihood of damage over time. Training installation teams on these techniques can further enhance outcomes.

Scenario 2: Sourcing Quality Corner Bead Materials

The Problem: International buyers often struggle with sourcing high-quality corner bead materials that meet their specific project requirements. In regions such as the Middle East and Europe, the availability of substandard materials can lead to project delays and increased costs. For instance, low-quality metal corner beads may rust or fail to adhere properly, resulting in extensive rework and dissatisfaction from clients.

The Solution: To mitigate the risk of sourcing inferior materials, establish relationships with reputable suppliers that specialize in corner bead products. Conduct thorough research to identify manufacturers with a proven track record of quality. Request samples before making bulk purchases to assess material performance and durability. Additionally, consider leveraging online platforms and industry networks to compare suppliers and read reviews from other B2B buyers. Engaging in transparent discussions about material specifications and certifications can also help ensure that the products meet industry standards and project needs.

Scenario 3: Managing Installation Costs and Labor Efficiency

The Problem: Cost management is a significant concern for B2B buyers, particularly in competitive markets like Europe and South America. The installation of corner bead can sometimes lead to unexpected labor costs if workers are not adequately trained or if the materials do not align with the project specifications. This situation can result in increased timelines and budget overruns, negatively impacting overall project profitability.

The Solution: To streamline installation processes and control costs, invest in comprehensive training programs for your installation teams. This training should cover best practices for handling and installing corner bead, as well as troubleshooting common issues that may arise during the installation. Additionally, consider utilizing prefabricated corner bead systems, which can significantly reduce installation time and labor costs. These systems often come with clear instructions and can be installed with minimal tools, increasing efficiency. By balancing the initial investment in training and quality materials with the potential for reduced labor costs and improved project timelines, B2B buyers can enhance their overall profitability.

Strategic Material Selection Guide for corner bead

When selecting materials for corner bead, it is essential to consider the specific properties and performance characteristics that will best suit the intended application. Below is an analysis of four common materials used for corner bead, focusing on their key properties, advantages and disadvantages, and implications for international B2B buyers.

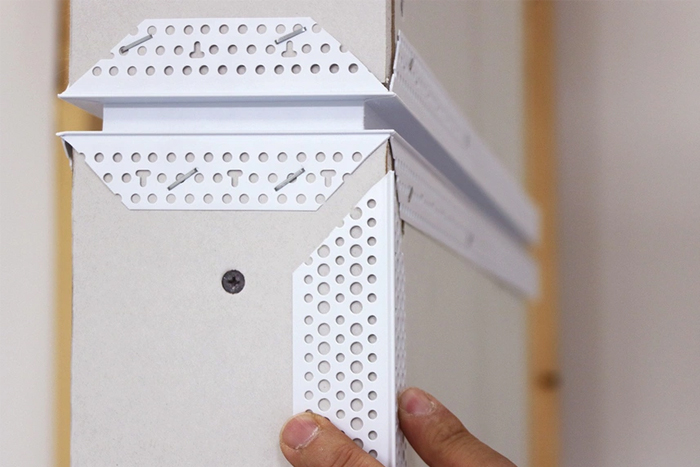

A stock image related to corner bead.

What Are the Key Properties of PVC Corner Bead?

A stock image related to corner bead.

PVC (Polyvinyl Chloride) corner bead is widely used due to its versatility and resistance to moisture. This material is particularly advantageous in environments prone to humidity, making it suitable for regions with high rainfall or in applications such as bathrooms and kitchens.

Pros & Cons:

PVC corner bead offers excellent durability and is resistant to corrosion and impact. It is lightweight, which simplifies installation, but can be more susceptible to UV degradation if exposed to sunlight for extended periods. The cost of PVC is generally moderate, making it a popular choice for many projects.

Impact on Application:

PVC is compatible with various finishing materials, including plaster and drywall, and is suitable for both interior and exterior applications. However, it may require additional treatment for UV exposure in outdoor settings.

Considerations for International Buyers:

Buyers in Africa and South America should ensure compliance with local building codes regarding fire resistance and material safety. In Europe and the Middle East, adherence to standards such as EN and ASTM is crucial for market acceptance.

How Does Metal Corner Bead Compare in Performance?

Metal corner bead, typically made from galvanized steel or aluminum, is known for its strength and durability. It provides excellent protection against impact and is often used in high-traffic areas.

Pros & Cons:

The primary advantage of metal corner bead is its robustness, which can withstand significant wear and tear. However, it is heavier than other materials, which can complicate installation. Additionally, metal is prone to corrosion if not properly treated, especially in humid environments. The cost tends to be higher than PVC but offers longevity.

Impact on Application:

Metal corner bead is ideal for applications where durability is paramount, such as commercial buildings or industrial spaces. Its compatibility with various finishing products makes it a versatile choice.

Considerations for International Buyers:

Buyers should be aware of corrosion resistance standards, particularly in coastal regions or areas with high humidity. Compliance with local standards, such as ASTM and DIN, is essential, especially in Europe.

What Are the Advantages of Paper-Faced Corner Bead?

Paper-faced corner bead combines a metal core with paper facing, providing a balance of durability and ease of installation. This material is particularly popular in residential construction.

Pros & Cons:

The paper facing allows for seamless finishing, making it easy to tape and mud over. It is lightweight and cost-effective, but its durability is less than that of metal corner bead. Paper-faced options are generally more susceptible to moisture damage, which can limit their use in certain environments.

Impact on Application:

This type of corner bead is best suited for interior applications where moisture exposure is minimal. It is often used in residential drywall installations.

Considerations for International Buyers:

Buyers should ensure that the paper used meets local fire safety standards. In regions like Europe and the Middle East, compliance with EN standards is critical for marketability.

What Is the Role of Fiberglass Corner Bead in Modern Construction?

Fiberglass corner bead is gaining popularity due to its resistance to moisture and mold. It is particularly suitable for high-humidity environments, making it an excellent choice for regions with wet climates.

Pros & Cons:

Fiberglass corner bead is lightweight and resistant to corrosion, providing a long-lasting solution. However, it can be more expensive than other options and may require specialized installation techniques.

Impact on Application:

This material is ideal for applications in bathrooms, kitchens, and other moisture-prone areas. Its compatibility with various finishing materials makes it versatile.

Considerations for International Buyers:

Buyers should verify that fiberglass products comply with local health and safety regulations. In Europe, adherence to REACH regulations is important for market acceptance.

Summary Table of Corner Bead Materials

| Material | Typical Use Case for corner bead | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Moisture-prone interiors | Excellent moisture resistance | Susceptible to UV degradation | Medium |

| Metal | High-traffic commercial spaces | Exceptional durability | Heavier and prone to corrosion | High |

| Paper-Faced | Residential drywall installations | Seamless finishing | Less durable, moisture-sensitive | Low |

| Fiberglass | High-humidity environments | Mold and corrosion resistance | Higher cost, specialized installation | High |

This comprehensive analysis provides a strategic overview for international B2B buyers, enabling informed decisions when selecting corner bead materials tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for corner bead

What Are the Key Stages in the Manufacturing Process of Corner Bead?

The manufacturing process of corner bead involves several critical stages designed to ensure durability and quality. Understanding these stages is essential for B2B buyers looking to source reliable products.

-

Material Preparation: The initial stage involves sourcing high-quality raw materials, typically made from metal or PVC. For metal corner beads, galvanization is a common technique to prevent rust and enhance longevity. In contrast, PVC corner beads may require additives to improve flexibility and impact resistance.

-

Forming: This stage includes shaping the prepared materials into the desired corner bead profiles. Techniques such as extrusion for PVC or roll forming for metal are prevalent. In extrusion, raw materials are heated and forced through a die, while roll forming involves passing metal sheets through a series of rollers to create the desired shape.

-

Assembly: In this phase, the formed pieces are cut to length and assembled. This may involve welding metal beads or securing PVC pieces with adhesives. Precision in this stage is crucial, as any misalignment can lead to issues during installation.

-

Finishing: The final manufacturing stage includes surface treatment, such as painting or coating, to enhance appearance and protect against environmental factors. For metal corner beads, powder coating is a popular option, while PVC products might receive UV-resistant treatments.

How Do Quality Control Measures Ensure the Integrity of Corner Bead Products?

Quality assurance is a critical component of the manufacturing process, especially for international B2B buyers who require consistent and reliable products. Here are the primary aspects of quality control (QC) that manufacturers adhere to:

-

International Standards: Compliance with international standards such as ISO 9001 ensures that manufacturers implement systematic processes to enhance product quality. ISO 9001 focuses on quality management systems and requires continuous improvement through regular audits and customer feedback.

-

Industry-Specific Certifications: Depending on the market, manufacturers may also pursue certifications like CE marking in Europe or API standards for products used in specific industries. These certifications often require rigorous testing and adherence to safety protocols.

-

QC Checkpoints: Effective QC involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): This involves monitoring processes and products at various stages of production to catch defects early.

– Final Quality Control (FQC): Finished products undergo comprehensive inspections and testing to verify that they meet all quality criteria before shipment. -

Common Testing Methods: Testing methods can include dimensional checks, tensile strength tests, and corrosion resistance evaluations. These tests help verify that the corner beads can withstand the stresses they will encounter in real-world applications.

What Strategies Can B2B Buyers Use to Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable strategies to verify QC practices:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and QC measures firsthand. This includes reviewing documentation, observing production lines, and checking equipment maintenance records.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC. These documents can give insights into the frequency of defects and the measures taken to rectify them.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can conduct their tests and verifications, ensuring that the products meet the required standards before shipment.

-

Understanding Certification Nuances: Different regions may have specific certification requirements. For instance, while CE marking is crucial for products sold in Europe, other regions may prioritize different certifications. B2B buyers should ensure that suppliers are compliant with the relevant standards for their target markets.

How Do Regional Differences Impact Quality Assurance in Corner Bead Manufacturing?

Quality assurance practices can vary significantly across regions due to differences in regulatory environments, market expectations, and manufacturing capabilities. Understanding these nuances is vital for B2B buyers:

-

Africa: In many African countries, the manufacturing sector is still developing, and not all suppliers may adhere to international standards. Buyers should prioritize suppliers with proven track records and certifications to ensure product reliability.

-

South America: The region is increasingly adopting international quality standards. However, variations exist between countries. Buyers should verify that suppliers comply with local regulations and international norms to avoid quality discrepancies.

-

Middle East: The Middle East has a diverse manufacturing landscape, with some countries adhering to stringent quality standards. Buyers should look for suppliers who have successfully navigated these regulations and can provide documentation to support their claims.

-

Europe: European manufacturers are typically held to high standards, including CE marking. Buyers can leverage this by choosing suppliers with robust quality management systems and a commitment to continuous improvement.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing corner bead products. This knowledge not only helps mitigate risks but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘corner bead’

Introduction: How to Effectively Source Corner Bead for Your Projects

Sourcing corner bead is a critical process for B2B buyers in construction and renovation sectors. This guide provides a step-by-step checklist designed to streamline your procurement process, ensuring you find the right products and suppliers for your needs. Whether you are operating in Africa, South America, the Middle East, or Europe, these actionable insights will help you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to establish clear technical specifications for the corner bead you require. This includes dimensions, material types (such as PVC, metal, or paper), and any specific features like moisture resistance or compatibility with particular wall systems.

- Why it matters: Clearly defined specifications help you communicate your needs effectively and avoid misunderstandings with suppliers.

- What to look for: Ensure your specifications align with local building codes and standards relevant to your region.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for corner bead is essential to make cost-effective decisions. Investigate the pricing models used in your target regions and evaluate how fluctuations in material costs may impact your sourcing strategy.

- Why it matters: Staying informed about market dynamics helps you negotiate better prices and identify reliable suppliers.

- What to look for: Monitor industry reports, supplier catalogs, and trade publications that offer insights into pricing trends.

Step 3: Identify and Evaluate Potential Suppliers

Finding the right suppliers is key to ensuring the quality and reliability of your corner bead procurement. Compile a list of potential suppliers and assess them based on their reputation, experience, and product offerings.

- Why it matters: A thorough evaluation minimizes risks associated with poor-quality products or unreliable delivery.

- What to look for: Request company profiles, product samples, and references from previous clients to gauge supplier reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold the necessary certifications and comply with relevant industry standards. This might include ISO certifications or local building regulations that pertain to corner bead production.

- Why it matters: Compliance with industry standards not only guarantees product quality but also protects you from potential legal issues.

- What to look for: Request documentation that verifies compliance and assess any third-party audits the supplier may have undergone.

Step 5: Request Samples for Quality Assurance

Before finalizing any orders, it’s prudent to request samples of the corner bead you plan to purchase. This allows you to evaluate the quality, durability, and overall suitability of the product for your specific projects.

- Why it matters: Testing samples can prevent costly mistakes and ensure that the final product meets your expectations.

- What to look for: Assess the samples for any defects, finish quality, and compatibility with other materials you plan to use.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, delivery schedules, and return policies. Clear agreements help mitigate misunderstandings later on.

- Why it matters: Effective negotiation can lead to better pricing and more favorable terms, enhancing your overall procurement strategy.

- What to look for: Ensure that all terms are documented in a formal agreement to protect both parties.

A stock image related to corner bead.

Step 7: Establish a Communication Plan

Finally, set up a communication plan to maintain ongoing dialogue with your supplier throughout the procurement process. This should include regular updates on order status, potential delays, and any changes to specifications.

- Why it matters: Open communication fosters a strong supplier relationship and enables quick resolution of any issues that may arise.

- What to look for: Designate a point of contact from both your team and the supplier’s team to streamline communication.

By following these steps, B2B buyers can effectively navigate the sourcing process for corner bead, ensuring they secure quality products that meet their specific project needs.

Comprehensive Cost and Pricing Analysis for corner bead Sourcing

What Are the Key Cost Components in Corner Bead Sourcing?

When sourcing corner bead, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials for corner beads include PVC, metal, and paper-faced options. Prices may vary based on availability and local sourcing capabilities.

-

Labor: Labor costs can fluctuate depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can also affect quality and consistency.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can lower overhead costs, impacting the final price.

-

Tooling: Initial tooling costs for custom designs or unique specifications can be significant. Buyers should consider these costs in their total sourcing budget.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability but may add to the overall cost. Buyers should assess the balance between quality assurance and cost-effectiveness.

-

Logistics: Shipping costs, including freight and customs duties, can vary widely based on the destination and shipping terms. Buyers should factor in these logistics costs when evaluating suppliers.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in your target markets can aid in negotiating better deals.

How Do Price Influencers Affect Corner Bead Costs?

Several factors can influence pricing in the corner bead market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices. Buyers should negotiate favorable MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific dimensions can increase costs. Buyers should clarify their requirements early in discussions to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications can drive up costs but may be necessary for specific applications. Buyers should assess the trade-off between quality and price.

-

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge a premium for their proven track record, while emerging suppliers might offer lower prices to gain market entry.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly affect overall costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears shipping costs and risks, influencing the total price.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Corner Bead?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their sourcing strategy:

-

Negotiate Terms: Always engage in negotiations. Suppliers may have flexibility in pricing or terms based on order size or long-term relationships.

-

Consider Total Cost of Ownership (TCO): TCO includes not just the purchase price but also shipping, handling, and potential disposal costs. Evaluate the long-term implications of your sourcing decisions.

-

Understand Pricing Nuances: Each region may have unique pricing structures influenced by local market conditions, currency fluctuations, and trade policies. Conduct thorough market research to stay informed.

-

Explore Multiple Suppliers: Diversifying your supplier base can lead to better pricing and reduce dependency on a single source. This strategy also allows for comparisons on quality and service.

-

Stay Informed About Market Trends: Keep abreast of industry trends, such as material price fluctuations and technological advancements in manufacturing, to make informed decisions.

Disclaimer on Indicative Prices

Prices for corner bead can vary widely based on the aforementioned factors, and international buyers should seek quotes directly from suppliers for the most accurate pricing. Always consider local market conditions and specific project requirements when evaluating costs.

Alternatives Analysis: Comparing corner bead With Other Solutions

When considering the best solutions for finishing drywall corners, it is essential for B2B buyers to understand the alternatives to traditional corner bead. Corner bead is a popular choice due to its durability and ease of application, but various alternatives may suit specific project needs better. This section examines corner bead in comparison with other viable solutions, offering insights to help buyers make informed decisions.

| Comparison Aspect | Corner Bead | Flexible Corner Bead | Corner Tape |

|---|---|---|---|

| Performance | High durability; withstands impact well | Offers flexibility for irregular surfaces | Good for flat surfaces, less durable |

| Cost | Moderate initial cost; long-term savings due to durability | Slightly higher cost; may save on labor | Low-cost option upfront; may require more labor |

| Ease of Implementation | Straightforward application; requires some skill | Easier to install on uneven surfaces; requires trimming | Simple to apply; needs skilled finishing |

| Maintenance | Minimal maintenance; resistant to damage | Moderate; can be prone to dents | More frequent touch-ups needed |

| Best Use Case | Ideal for standard drywall corners in high-traffic areas | Best for curved or irregular corners | Suitable for low-traffic, aesthetic applications |

What Are the Benefits and Drawbacks of Flexible Corner Bead?

Flexible corner bead is designed to adapt to irregular wall surfaces, making it an attractive alternative for projects where traditional corner bead may not fit. Its primary advantage lies in its ability to accommodate curves and angles without compromising aesthetics. However, while it may save time during installation on uneven surfaces, its slightly higher cost can be a deterrent for budget-conscious projects. Additionally, while it offers good durability, it may not withstand heavy impacts as effectively as standard corner bead.

How Does Corner Tape Compare to Corner Bead?

Corner tape, often made from paper or fiberglass, is another alternative that can be used for finishing drywall corners. Its primary advantage is its low cost, making it accessible for budget-sensitive projects. Corner tape is simple to apply and requires less material than corner bead. However, it generally requires more skilled finishing work to achieve a smooth appearance and is not as durable as corner bead, especially in high-traffic areas. This makes it better suited for aesthetic applications rather than functional durability.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When evaluating solutions for drywall corner finishing, B2B buyers should assess their specific project requirements, including budget, durability, and the nature of the surfaces being worked on. Corner bead remains a strong contender for its balance of performance and cost-effectiveness, particularly in high-traffic environments. For projects with irregular surfaces, flexible corner bead may offer the adaptability needed, albeit at a higher cost. Lastly, for low-budget projects where aesthetics are prioritized over durability, corner tape can be a practical choice. By weighing these factors, buyers can make informed decisions that align with their project goals and financial constraints.

Essential Technical Properties and Trade Terminology for corner bead

What Are the Essential Technical Properties of Corner Bead?

When selecting corner bead for construction projects, understanding its technical properties is crucial for B2B buyers. Here are some key specifications that impact performance, durability, and overall cost-effectiveness:

1. Material Grade: Why Is It Important?

Corner beads are typically made from materials like PVC, metal, or paper-faced gypsum. The material grade directly affects durability and resistance to moisture, impacts on structural integrity, and longevity. For instance, galvanized steel corner beads offer superior strength and resistance to corrosion, making them ideal for high-humidity environments. Buyers should evaluate the material grade to ensure it aligns with their project requirements, particularly in regions prone to extreme weather conditions.

2. Tolerance Levels: How Do They Affect Installation?

Tolerance levels refer to the allowable deviation from specified dimensions. For corner bead, maintaining tight tolerances is essential for ensuring proper installation and alignment. A tolerance of ±0.5 mm is typically acceptable, but this can vary based on specific project needs. Understanding tolerance levels helps buyers avoid costly rework and ensures that the materials will fit seamlessly during installation.

3. Length and Width Specifications: What Should Buyers Consider?

Corner beads come in various lengths and widths to accommodate different wall and ceiling configurations. Standard lengths typically range from 8 to 10 feet, while widths can vary depending on the bead type. Buyers must consider the specific dimensions of their projects to minimize waste and reduce costs. Custom lengths may be available but often come with higher minimum order quantities.

4. Coating and Finish: What Role Does It Play?

The coating and finish on corner beads can significantly influence their performance and aesthetic appeal. Options include powder-coated finishes that provide enhanced durability and resistance to scratches and dents. For projects in high-traffic areas or exposed environments, selecting corner beads with appropriate coatings can lead to lower maintenance costs over time.

5. Weight: How Does It Impact Shipping and Handling?

The weight of corner beads can vary based on material and design. Lighter options, such as PVC, may reduce shipping costs and ease handling during installation. However, heavier materials like metal may offer better durability. Buyers should weigh the trade-offs between weight and performance based on their logistical capabilities and project scope.

What Are the Common Trade Terms Associated with Corner Bead?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer): Why Is It Relevant?

OEM refers to companies that manufacture products that are sold under another company’s brand. When sourcing corner bead, understanding whether you are purchasing from an OEM or a distributor can impact quality and pricing. OEMs typically offer better pricing for bulk orders, which can be advantageous for large-scale projects.

2. MOQ (Minimum Order Quantity): How Does It Affect Purchases?

MOQ is the minimum number of units a supplier is willing to sell. This term is critical for B2B buyers as it can affect inventory management and cash flow. Buyers must assess their project needs to avoid overcommitting to large orders that may not be used.

3. RFQ (Request for Quotation): What Is Its Purpose?

An RFQ is a document that buyers send to suppliers to solicit price bids for specific products or services. For corner bead procurement, issuing an RFQ can help buyers compare prices, quality, and delivery terms from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms): Why Should Buyers Be Aware?

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B transactions, especially for those importing corner bead from different regions. They specify who is responsible for shipping, insurance, and tariffs, thus affecting overall costs and risk management.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions in the corner bead market, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the corner bead Sector

What Are the Current Market Dynamics and Key Trends in the Corner Bead Sector?

The corner bead market is experiencing significant transformation driven by globalization, technological advancements, and shifting consumer preferences. Key trends include the increasing demand for lightweight materials and innovative designs that facilitate easier installation and enhanced durability. International B2B buyers from Africa, South America, the Middle East, and Europe are particularly interested in products that can withstand regional environmental conditions, such as humidity and temperature fluctuations.

Moreover, the rise of digital sourcing platforms has revolutionized how buyers connect with suppliers. E-commerce solutions allow for faster procurement processes, enabling buyers to compare prices and quality from a broader range of manufacturers. This trend is particularly beneficial for emerging markets, where traditional sourcing methods may not be as efficient. Additionally, the incorporation of artificial intelligence in supply chain management is enhancing inventory accuracy and forecasting, allowing B2B buyers to optimize their procurement strategies.

Another significant driver in the corner bead market is the construction industry’s recovery post-pandemic. As infrastructure projects ramp up across various regions, there is a growing need for reliable sourcing partners who can provide quality corner bead solutions that meet international standards. Understanding these market dynamics is crucial for international B2B buyers looking to make informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact Your Corner Bead Procurement?

Sustainability and ethical sourcing are increasingly becoming non-negotiable criteria for B2B buyers in the corner bead sector. The environmental impact of construction materials is under scrutiny, making it essential for buyers to consider the lifecycle of corner bead products. Sustainable sourcing practices not only contribute to environmental conservation but also enhance brand reputation and customer loyalty.

Buyers should prioritize suppliers who adhere to green certifications and utilize eco-friendly materials in their corner bead products. For instance, corner beads made from recycled materials or those certified by organizations like the Forest Stewardship Council (FSC) are gaining traction. These certifications not only signify a commitment to sustainability but also ensure compliance with local and international regulations.

Furthermore, engaging with suppliers who maintain ethical labor practices is vital. Ensuring that workers are treated fairly and that supply chains are transparent can mitigate risks associated with reputational damage. B2B buyers should conduct thorough due diligence when selecting suppliers, including assessing their sustainability practices and commitment to social responsibility.

What Is the Historical Context of Corner Bead and Its Importance in B2B Sourcing?

The corner bead, a vital component in drywall construction, has evolved significantly since its introduction in the early 20th century. Originally designed to protect the corners of drywall installations, corner beads have now become essential for providing a clean and professional finish. The evolution of materials, from metal to plastic and composite options, has opened new avenues for innovation in design and functionality.

This historical context is important for B2B buyers as it highlights the advancements in product performance and the increasing availability of specialized corner bead solutions. Understanding the evolution of corner bead products can inform purchasing decisions and help buyers select the most suitable options for their specific projects, ensuring they meet both aesthetic and structural requirements.

In conclusion, navigating the corner bead sector requires a keen awareness of market dynamics, sustainability considerations, and historical context. By leveraging these insights, international B2B buyers can make strategic sourcing decisions that align with their business goals and contribute positively to the construction industry’s future.

Frequently Asked Questions (FAQs) for B2B Buyers of corner bead

-

How do I choose the right corner bead for my project?

Choosing the right corner bead involves assessing the specific requirements of your project. Consider factors such as the material (metal, vinyl, or paper), the environment (interior or exterior), and the type of finish desired. Ensure the corner bead is compatible with the drywall or plaster system you are using. Additionally, consult with suppliers about local building codes and standards that may affect your choice. Request samples if possible to verify quality and fit. -

What are the most common materials used for corner beads?

The most common materials for corner beads include metal (typically galvanized steel or aluminum), vinyl, and paper-faced varieties. Metal corner beads offer durability and resistance to impact, making them suitable for high-traffic areas. Vinyl is lightweight, rust-proof, and often easier to install, while paper-faced corner beads provide a seamless finish and are commonly used in drywall applications. Evaluate your project’s needs to select the best material. -

What is the minimum order quantity (MOQ) for corner bead?

The minimum order quantity (MOQ) for corner bead can vary widely between suppliers. Typically, it ranges from 500 to 1,000 units, but some manufacturers may accommodate smaller orders for new clients or specific projects. When sourcing from international suppliers, confirm the MOQ in advance to avoid potential delays. Discuss your project requirements to see if bulk purchasing discounts are available, which can help reduce overall costs. -

How can I ensure the quality of corner bead before purchasing?

To ensure the quality of corner bead, consider requesting samples from potential suppliers to assess the material and craftsmanship firsthand. Additionally, review certifications and compliance with international standards, such as ISO or ASTM, which indicate adherence to quality practices. Conducting factory visits or audits, if feasible, can also provide insights into production processes. Lastly, seek testimonials or reviews from other B2B buyers to gauge supplier reliability. -

What payment terms should I negotiate with corner bead suppliers?

When negotiating payment terms with corner bead suppliers, aim for favorable conditions that mitigate risk. Common options include 30% upfront payment with the balance due upon delivery or a letter of credit for larger orders. Consider using escrow services to protect your investment until the product meets agreed specifications. Always clarify currency considerations, especially for international transactions, to avoid unexpected costs. -

How do I handle logistics and shipping for corner bead purchases?

Handling logistics for corner bead purchases involves coordinating with suppliers on shipping options and timelines. Choose a reliable freight forwarder experienced in handling construction materials to ensure safe transport. Discuss shipping terms (Incoterms) to clarify responsibilities for costs and risks. For international shipments, be aware of customs regulations in your country and ensure all necessary documentation is prepared to avoid delays. -

What are the common challenges faced when sourcing corner bead internationally?

Common challenges when sourcing corner bead internationally include language barriers, differing quality standards, and compliance with local regulations. Additionally, fluctuating shipping costs and potential delays can impact project timelines. To mitigate these issues, establish clear communication with suppliers and ensure they understand your specifications. Research the local market conditions and legal requirements in both the supplier’s and your country to ensure a smoother transaction. -

Can I customize corner bead designs for specific projects?

Yes, many manufacturers offer customization options for corner bead designs to meet specific project needs. This may include variations in size, shape, and material to accommodate unique architectural requirements. When seeking customization, provide detailed specifications and consult with the supplier about design feasibility and lead times. Be prepared for potential minimum order quantities that may apply to custom orders, and factor this into your budgeting.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for corner bead

What Are the Key Takeaways for Strategic Sourcing of Corner Bead?

In conclusion, the strategic sourcing of corner bead presents an opportunity for international B2B buyers to enhance their supply chains and optimize project outcomes. By focusing on reliable suppliers and understanding regional variations in product specifications, buyers can mitigate risks associated with quality and availability. Key takeaways include the importance of establishing long-term relationships with manufacturers and distributors, leveraging technology for real-time inventory management, and staying informed about industry trends that may affect pricing and supply.

How Can International Buyers Benefit from Strategic Sourcing?

For B2B buyers from Africa, South America, the Middle East, and Europe, the value of strategic sourcing cannot be overstated. It allows companies to not only save costs but also to ensure compliance with local regulations and standards, ultimately leading to higher customer satisfaction. By implementing a strategic sourcing approach, businesses can better navigate market fluctuations and build resilience against supply chain disruptions.

What Is the Future Outlook for Corner Bead Procurement?

Looking ahead, it is crucial for international buyers to remain proactive in their sourcing strategies. Engage with multiple suppliers to diversify risk and explore innovative materials that may enhance project efficiency. As the construction industry continues to evolve, staying ahead of trends and adapting sourcing strategies will be key to maintaining a competitive edge.

In summary, now is the time to evaluate your corner bead procurement strategies. Consider forming partnerships with trusted suppliers and leverage data-driven insights to make informed decisions. By doing so, you will position your business for success in an increasingly interconnected market.